Abstract

The properties of epoxy asphalt materials and carbon fiber composites are closely related to temperature, so it is important to study the mechanical properties of these two materials when they are used in track at different temperatures. The parallel analysis method is adopted in this study. The carbon fiber composite is regarded as a continuous elastomer, and its stress and strain components are fully expressed in a matrix form in a three-dimensional coordinate system. Finally, 21 elastic constants are selected. At the same time, the mechanical properties of epoxy asphalt materials in viscoelastic and tensile aspects were studied considering the temperature zone expansion factor. The results show that the maximum degradation of carbon fiber composites in tensile strength occurs at low temperature and dry state, and the degradation rate is 30.8%. In terms of compressive strength, the maximum degradation rate of the material is 21.9% under high temperature and wet conditions. The elongation at break of epoxy asphalt materials showed a trend of first increasing and then decreasing. In the whole working temperature zone, it increased from 311.78 to 354.55% and then decreased to 228.89%. The bond elongation first increases and then decreases. Taking 0℃ as the dividing point, the bond elongation increases from 85.7% at − 20℃ to 256.7% at 0℃ in the temperature zone below 0℃, while it decreases from 256.7% at 0℃ to 80.6% in the temperature zone above 0℃. Therefore, the mechanical properties of the two materials have the characteristics of high temperature sensitivity.

1 Introduction

Carbon fiber composite materials often exist in the form of laminates in engineering practice. Laminates can be formed by arranging carbon fiber composite single-layer boards according to appropriate angles and in a specific order. Therefore, changing the layup angle and sequence of a single-layer board has a significant impact on its physical performance. For the idealized model set, lamination method of the laminate is infinite, and its mechanical properties can be understood through experiments on its tensile and shear properties. The specific applications of carbon fiber composites in rail transit are common, such as the research on the optimization of the pavement in the maglev vehicle body and the research on the dynamic performance of flexible rail protection. Epoxy asphalt is a cured product of irreversible three-dimensional interpenetrating network structure formed by preparing and processing epoxy resin, curing agent, and matrix asphalt in a certain proportion. The cured epoxy asphalt has high strength performance, super strong bonding performance, excellent permanent deformation ability, fatigue resistance, and chemical corrosion resistance. At present, the material has been successfully used in steel bridge deck pavement, heavy-duty traffic, long longitudinal slope road surface layer, and so on [1–4]. The specific application of epoxy asphalt in rail transit is common, such as sealing the track with this material and curing the ballast bed. Considering that the existing research on the mechanical properties of carbon fiber composites under different temperature conditions is less, and the mechanical analysis of epoxy asphalt materials cannot be carried out in the extended temperature zone, the research creatively analyzed the mechanical properties of the two materials under different temperature changes through setting temperature experiments and pointed out that the two materials have the characteristics of high temperature sensitivity when they are used in orbit.

Many scholars have made rich research results on the track structure and its stress–strain direction. Bigdeli and other scholars predicted and analyzed the volume fractions of three silicon carbide materials, aiming to apply them to the rail gear industry. The experimental results show that this material can withstand more stress than other composite materials [5]. In order to observe the microscopic properties of orbital materials, the MD Sangid research team proposed a multi-modal technique for material tracking and measurement. Data indicate that the degree of inhomogeneity of material is positively correlated with the degree of deformation [6]. Ma et al. aimed to investigate the wear of railway lining materials under low temperature conditions and carried out performance tests using a high-speed brake tester. The experimental results show that the wear degree of railway lining increases with the decrease in temperature [7]. Zhai et al. designed a multi-functional experimental system for high-speed rail tracks to study the mechanical properties of subgrades. Studies have shown that the system can realize the observation of the strain and deformation of the subgrade structure using multiple types of sensors [8]. In order to study the bad state of track structure, Yi et al. studied the propagation characteristics of the orbital elastic wave by solving the equation. The results show that bad state will bring an increase in resonance frequency [9]. Huang et al. designed a new type of vibration testing machine with the subway line 3 of a city as the research object and studied the pressure of the subway under earthquake. The results show that the rail is in the maximum stress state in the circumferential shear force [10].

Many scholars have carried out diversified research on asphalt materials or carbon fiber materials. Wang et al. aimed to study the translational and rotational behaviors of asphalt mixtures in various field environments. The study showed that under the rolling of pneumatic tires, the relative rotation of particles decreased [11]. Scholars such as Zeng et al. provided a three-level analysis method to ascertain pavement dynamic quantity. Considering that the study pavement belongs to the multi-layer full-depth pavement, the extraction operation of the total core was carried out. The results showed that the calculated value was overtop than the measured value [12]. Mousavi et al.’s research team aims to study the humidity sensitivity of materials, introduced a polarization factor, and defined a shear thinning index. The results showed that waste vegetable oils possess high humidity sensitivity [13]. Bakamal et al. carried out a detailed analysis of carbon fibers and graphene materials using finite element analysis methods and evaluated their microstructures from dimensions such as length, volume, and thickness. The structures have shown that microstructure of materials is closely related to their vibration performance [14]. Su and Dai revealed the bonding ability and failure characteristics of the interface between concrete and cement asphalt mortar through field tests under longitudinal and transverse shear loads and further proposed an interface mechanical model using the bilinear local bond slip law. The results show that the model has a good effect on the material adhesion test [15]. For the sake of studying the static properties of materials, the damage characteristics of carbon fiber materials were obtained through laser experiments. The experimental results show that there is a positive correlation between the perforation time and the laser energy value [16]. For the sake of discussing the stiffness characteristics of carbon fiber materials, four types of stiffness experiments were carried out. The results show that the stiffness response of material is decided by its elastic properties [17].

To sum up, in terms of track structure and its stress–strain direction, scholars have mainly conducted experiments or analysis on the structural parameters of materials such as silicon carbide and concrete, while on asphalt materials or carbon fiber materials, they have mainly focused on the humidity sensitivity of material particles or materials. Or the thinning index was analyzed. However, there are few experiments on changing temperature analysis of track materials, especially the mechanical properties of materials under changing temperature conditions. Therefore, the purpose of this study was to determine the influence of carbon fiber composites and epoxy asphalt materials on track stress and strain, that is, mechanical properties, by analyzing their tensile and shear properties under temperature changes.

2 Influence analysis of on-orbit stress and strain of carbon fiber composite materials and epoxy asphalt materials considering temperature factors

Carbon fiber-reinforced composite materials have unique advantages, such as high specific modulus, high specific strength, and versatility, and have become key materials for structural lightweight design in fields such as aerospace and rail transit. Unlike metal materials, carbon fiber-reinforced composite materials are composed of two materials: carbon fiber and polymer matrix, and belong to anisotropic materials. Their stiffness and failure theory have more complex forms. Therefore, this section mainly explains the constitutive relationship between anisotropic materials based on the theory of elasticity. In addition, different temperatures have different effects on the mechanical properties of epoxy asphalt caulking materials. Only −20 and 23℃ are considered in the engineering performance test, and the epoxy asphalt caulking materials may be damaged at other temperatures. Based on this, it is necessary to analyze the mechanical properties of epoxy asphalt caulking materials at different temperatures, including viscoelasticity, tensile properties, interfacial bonding properties, and compression properties.

2.1 Analysis of the stress–strain relationship of carbon fiber composites

Carbon fiber composite materials are favored in the field of rail transit research because of their lightweight structure. Different from common metal materials, the material has anisotropy. It is made of polymer matrix and carbon fiber dual materials. The advantages of material properties are obvious, and therefore, more complex expressions have been obtained in macroscopic mechanical analysis. For a continuous elastic solid that can still maintain a state of equilibrium when the external load is applied, the stress corresponding to its internal point in a three-dimensional coordinate system

It should be pointed out that, restricted by the law of mutual equality of shear stress,

where

where

where

Schematic diagram of orthotropic materials in a rectangular coordinate system.

Coordinate systems 1, 2, and 3 in Figure 1 refer to the main axis coordinate system of the orthotropic material, wherein the coordinate system is used to indicate the fiber direction; the coordinate system 2 is used to indicate the direction of the vertical fiber; and the coordinate system 3 is used to indicate the thickness direction. The carbon fiber composite material can be regarded as an orthotropic material because it has two or more elastic symmetry axes and symmetry planes at 90°C with each other. And under the decomposition of the main axis coordinate system, the material tension and shear effect are also decomposed, so that the shear stress and shear strain are only related in the own plane, so the elastic constant can be reduced to 9. Combined with engineering practice, carbon fiber composite materials are often used in the form of laminated sheets. At the same time, because the dimensions of the fiber direction and the vertical fiber direction are far larger than the thickness direction, the stress value in this direction can be ignored, so there is

where

where

where

2.2 Analysis of on-orbit stress–strain relationship of epoxy asphalt material

For epoxy asphalt materials, the temperature change will have a great impact on their mechanical properties, but most material performance tests only consider the changes brought by −20 and 23℃ on the mechanical properties of the material and do not expand the effect of going to other temperature regions on the damage of asphalt materials. The study of mechanical properties of materials includes viscoelasticity, stretchability, and interfacial adhesion. In the viscoelastic analysis of epoxy asphalt materials, there are two kinds of tests: static test and dynamic test. The static test tends to investigate the creep and relaxation dimensions of the material, that is, the mechanical test is only carried out under the condition that the stress remains unchanged, but in practical engineering, there are many alternating stresses, so it is more appropriate to use dynamic mechanical tests that consider alternating stresses. The expression of stress–strain hysteresis relationship in dynamic analysis is given by the following formula:

where

where

where

where

Relationship between epoxy asphalt material and binder.

As can be seen from Figure 2, wetting will occur between the bituminous material and the binder. This is because there will be many voids on the surface of the asphalt material, and after the binder is fully combined with it, the latter will penetrate as strongly as the former, forming mechanical interlocking, thereby generating bond strength. As shown in Figure 2,

3 Experimental results of mechanical properties of carbon fiber composites and epoxy asphalt materials based on temperature changes

Carbon fiber composite materials are composed of carbon fiber and resin-based materials, with carbon fiber as the reinforcing phase and resin based as the matrix phase. The reinforcing phase has high strength and stiffness, but is a discontinuous phase that requires a resin matrix to bond the fibers together to form a carbon fiber composite material. During the formation of carbon fiber composite material structures, the resin-based material is heated and pressurized by the forming process and then cooled and solidified to form. The commonly used resin-based material has a glass transition temperature within 300℃. In addition, the mechanical property test of epoxy asphalt caulking material was carried out to explore the changes of mechanical properties of epoxy asphalt caulking material at different temperatures, including changes in viscoelastic properties, tensile properties, interfacial bonding properties, and compression properties. For changes in viscoelastic properties, dynamic mechanical analysis is mainly used to analyze the storage modulus, loss modulus, and phase angle at different temperatures. For the changes in tensile and interfacial bonding properties, the relationship between tensile strength, bonding strength, elongation at break, and bonding elongation at different temperatures is mainly investigated.

3.1 Experimental results of mechanical properties of carbon fiber composites based on temperature changes

The carbon fiber composite material used in the research experiment is composed of EN199 resin matrix in the matrix phase and carbon fiber in the reinforcing phase, and the glass transition temperature of the resin matrix material is 120°C; there is no difference from test piece 1 to test piece 5. The reason for setting 5 is that it reflects repeated tests and avoids the contingency of single test piece experiment. Since the glass transition temperature of general resin-based materials is around 300°C, when the material is in a non-standard environment, especially in high-temperature humid heat and low-temperature dry–cooling conditions, the bearing capacity of the material will be significantly reduced. In this part, the stress–strain state of the material in various environments is monitored experimentally. The high temperature test is realized by UTM51 series electronic universal machine. For the high temperature and humidity test, let the samples stand for more than 24 h in an environment with a relative humidity of 70 ± 3.5℃ and 85 ± 4.5℃ and then use them for the standard test. The low-temperature experiment was realized by magnetic torquing system tension-twisting machine. Figure 3 is a graph showing the results of tensile properties in a high-temperature and wet-state experiment.

Tensile property curve of high-temperature wet test: (a) high-temperature wet tensile force–displacement curve and (b) high-temperature wet tensile stress–strain curve.

From the curve of tensile force and specimen displacement in Figure 3(a), it can be seen that with the increase in tensile force from specimen 1 to specimen 5, the deformation and displacement of specimen itself increase linearly. For example, for specimen 1, the tensile external force corresponding to the linear increasing stage ranges from 0 to 19.8 kN, and the maximum displacement is 2.87 mm. Then, specimen 1 breaks instantaneously, and the curve drops sharply. The curve changes of the rest of the specimens are not different from this; only the displacement point at the maximum tensile force value is different: 2.34 and 25.8 kN − 2.43 mm. From Figure 3(b), it can be seen that the stress–strain relationship in the tensile state presents a linear positive proportional relationship, and the linearly increasing nodes from specimen 1 to specimen 5 are 526.1 MPa – 0.0092 and 575.2 MPa – 0.0094, 575.1 MPa – 0.0089, 576.1 MPa – 0.0095 and 610.3 MPa – 0.0079. Figure 4 is a graph showing the results of shear performance in a high-temperature and wet-state experiment.

Curve of shear performance results of high-temperature wet test: (a) high-temperature wet shear force–displacement curve and (b) high-temperature wet shear stress–strain curve.

From Figure 4(a) and (b), it can be seen that the relationship between shear force and displacement or shear stress–strain relationship of carbon fiber composite specimens in the early high-temperature and humid environment shows a nonlinear increasing relationship. In the relationship between force and displacement, the curve first shows a trend of rapid increase and then slow increase. The inflection point of the speed change from specimen 1 to specimen 5 is about 1.5 mm, and the corresponding maximum shear force is 5.4 kN – 13.9 mm, respectively, 5.6 kN – 13.7 mm, 5.5 kN – 14.1 mm, 5.05 kN – 12 mm, and 5.5 kN – 14.0 mm. In the shear stress–strain relationship, the maximum stress corresponding to displacements of specimen 1 to specimen 5 is 0.0649, 0.0620, 0.0660, 0.0590, and 0.0587 mm. Figure 5 is a graph showing the results of tensile properties in a low-temperature dry-state experiment.

Curve of tensile property results of low-temperature dry test: (a) low-temperature dry tensile force–displacement curve and (b) low-temperature dry tensile stress–strain curve.

It can be seen from Figure 5 that the variation trend of the tensile curve in the dry state at low temperature is similar to that in the wet state at high temperature. The tensile force and displacement and tensile stress–strain show a linear increasing relationship, while the shear force and displacement and shearing stress–strain show a nonlinear increasing relationship. The displacement and strain corresponding to the maximum tensile force of specimen 1 to specimen 5 are 3.78, 3.51, 3.99, 2.90, and 2.72 mm and 0.0080, 0.0081, 0.0072, 0.0068, and 0.0066, respectively. Figure 6 is a graph showing the results of shear performance in a low-temperature dry-state experiment.

Curve of shear performance results of low-temperature dry test: (a) low-temperature dry shear force–displacement curve and (b) low-temperature dry shear stress–strain curve.

It can be seen from Figure 6 that the displacement and strain corresponding to the maximum shear force of specimen 1 to specimen 5 are 9.40, 10.05, 10.10, 9.80, and 10.20 mm, and 0.058, 0.042, 0.051, 0.041, and 0.046, respectively. Table 1 is a comparison table of strength parameters in different environments after calculation.

Comparison table of strength parameters under different environments after calculation

| Strength (MPa) | Standard environment | High-temperature dry state | High-temperature wet state | Low-temperature dry state | Maximum degradation (%) |

|---|---|---|---|---|---|

| Tensile strength | 771.83 | 587.66 | 544.53 | 534.2 | 30.81 |

| Shear modulus | 94.24 | 59.86 | 51.4 | 71.68 | 45.46 |

| Compressive strength | 930.93 | 657.72 | 648.47 | 769.74 | 21.95 |

From Table 1, it can be seen that in terms of tensile strength, the tensile strength parameters, shear modulus size, and compressive strength parameters obtained from standard environmental experiments are 771.83, 94.24, and 830.93, respectively. The strength parameters corresponding to the high-temperature wet state and low-temperature dry state are lower than the standard values, indicating that the material exhibits varying degrees of performance degradation in abnormal environments. Among them, for the tensile strength parameter, the maximum degradation occurs in the low-temperature dry condition, the tensile strength of the material is 534.2 MPa, and the degradation rate is 30.8%. For the shear modulus, the maximum degradation occurs in the high-temperature wet state. Under the state condition, the corresponding value is 51.4 MPa and the degradation rate is 45.5%. In terms of compressive strength, the maximum degradation rate also appeared in the high-temperature and wet state, the corresponding value was 648.47 MPa, and the degradation rate was 21.9%.

3.2 Experimental results of mechanical properties of epoxy asphalt materials based on temperature changes

The research uses dynamic mechanical analysis instruments made in the United States to carry out temperature tests on epoxy asphalt materials, including viscoelasticity tests, tensile performance tests, and interfacial bonding performance tests. Figure 5 is the change curve of material viscoelasticity under each test temperature experiment.

On the basis of change curve in Figure 7, the storage modulus of epoxy asphalt material increases as the temperature decreases from +80°C to −80°C. When the temperature is lower than −50°C, the storage modulus of the material is as high as 2698.79 MPa, and when the temperature is higher than 50℃, the storage modulus of the material can be lower than 0.25 MPa. According to these two nodes, epoxy asphalt materials can be divided into low-temperature glass state, medium-temperature transition state, and high-temperature rubber state. At the same time, in line with loss modulus curve in Figure 5, the highest value of the modulus is 394.69 MPa near the temperature of −42°C. The high loss modulus only occurs in the glass transition process. In this process, high energy loss is achieved because the molecular motion of the material lags behind the stress change level. Therefore, −42°C can be regarded as the glass transition temperature of the epoxy asphalt material. The phase angle curve has two peaks and one peak-to-peak value. The first peak of the phase angle is 0.619 at −16.9°C, followed by a secondary peak of 0.638 at 18.8°C, and the peak-to-peak valley appears at −6.3°C. The phase angle is 0.604. The reason for the double peak phenomenon is that the epoxy bitumen material is a multi-component material, and there is intra-group repulsion between the modified bitumen and the curing agent, which makes the phase appear double peak. At the same time, the temperature zone corresponding to the phase angle tangent value higher than 0.3 is −40 to 67°C, which includes the working temperature range of epoxy asphalt material, that is, between −20 and 60°C. The storage modulus, loss modulus, and phase angle reflect the elastic properties, viscous properties, and viscoelastic ratio of the material, respectively. Therefore, in the working temperature range, even if the material encounters instantaneous shocks such as train starting or parking, it can rely on its elastic properties. Good viscoelasticity buffers the dynamic load, resists the deformation caused by the external force, and returns to the stable state under the fast response. Figure 8 is a graph showing the results of tensile mechanical properties test.

Viscoelastic change curve of materials under various test temperatures.

Curve chart of tensile mechanical property test results: (a) tensile stress–strain curve and (b) tensile strength and elongation at break curve.

On the basis of Figure 8(a), the relationship between tensile stress and strain of epoxy asphalt material is divided into two categories within its working temperature range. The first type is the curve from −20 to 0°C. This type of curve reflects the characteristics of elastic deformation and is divided into two stages of change. The first stage is between 0 and 71% of the strain, which is called the elastic deformation zone. At this time, the tensile stress and strain approximately show a positive proportional linear increase relationship, and the maximum stress value is reached at the strain of 71%, which is 0.62, 0.41, and 0.33 MPa. The strain between 71 and 375% is the second stage, which is called the post-yielding stress softening zone. At this time, the increase of strain will reduce the tensile stress of the material, the material will shrink, and the tensile interface will decrease until the material breaks. The second type is the curve from 0 to 60°C. Compared with the first type of curve, there is no post-yielding stress softening zone. The epoxy asphalt material as a whole exhibits linear elastic characteristics, that is, the curve before and after the temperature increase can keep the same slope, and the stress and strain always show a positive correlation. In line with Figure 8(b), the increase in temperature reduces the tensile strength of the epoxy asphalt material. In the entire working temperature range, the tensile strength value of the material decreases from 0.629 to 0.258 MPa, and the curvature also shows a downward trend. The minimum tensile strength is 0.258 MPa. The elongation at break of the material had a tendency of raising before reducing, increasing from 311.78 to 354.55% in the entire working temperature zone and then decreasing to 228.89%. Figure 9 is a graph showing the results of the interfacial adhesion test.

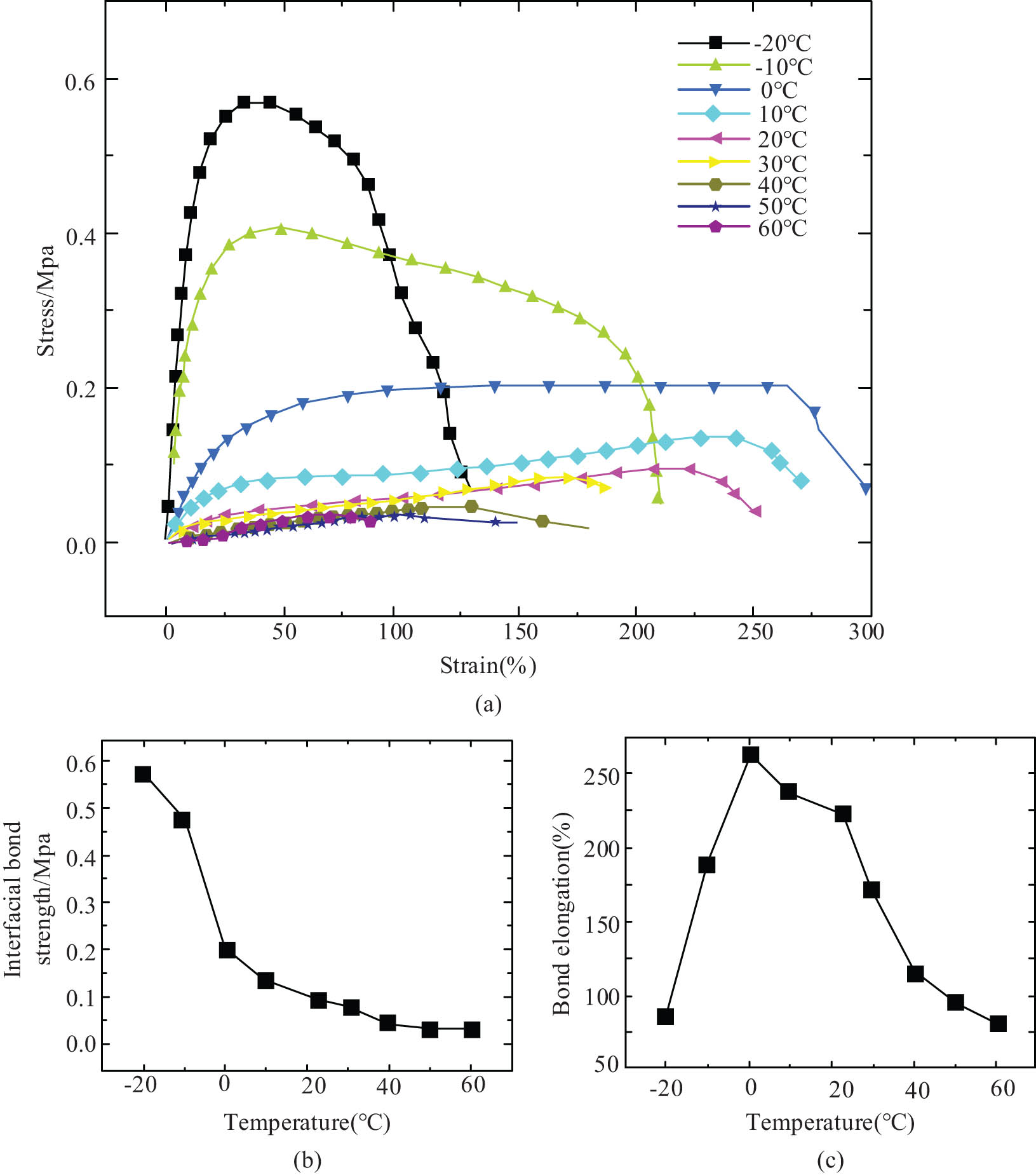

Curve of interface adhesion test results: (a) stress–strain curve of interfacial adhesion, (b) bond strength change curve, and (c) change curve of bond elongation.

The interfacial adhesion mainly occurs between the contact between epoxy asphalt and concrete; especially, the working temperature of the material is higher than the glass transition temperature, so the material will show significant adhesion performance under variable temperature conditions. On the basis of Figure 9(a), when the test temperature is set between −20 and 0°C, the interface bond of the material will be damaged, corresponding to three processes, namely, the rising section where the stress increases linearly with the strain; after reaching the maximum compressive stress of the interface, the stress decreases with the strain and the failure section where the material is gradually and completely separated from the concrete. When the test temperature is set from 0 to 60°C, the failure process of the material will be divided into two stages. The first stage is an approximate linear region where the stress increases with the strain, and the second stage is that the strain further increases but the stress rapidly follows. Destruction segment reduces and eventually separates from the concrete. On the basis of Figure 9(b), the bond strength of epoxy asphalt material decreases continuously with the increase in temperature, and the decreasing speed shows a trend of first fast and then slow. In the whole working temperature area of the material, the bond strength decreases from 0.568 to 0.0331 MPa. Among them, in the temperature zone −20 to 0°C, 0 to 40°C, and 40 to 60°C, the decrease rates of adhesion degree are 65.1, 75, and 26.7%, respectively. On the basis of Figure 9(c), the bond elongation shows a trend of first increase and then decrease, and taking 0°C as the dividing point, in the temperature range below 0°C, the bond elongation increases from −20°C to 85.7% increased to 256.7% at 0°C, while the bond elongation of the material decreased from 256.7% at 0°C to 80.6% in the temperature region above 0°C. Therefore, the results show that epoxy asphalt materials exhibit different mechanical properties before and after the demarcation point at 0°C.

4 Conclusion

The rapid development of high-speed rail has put forward high requirements for the durability of the track structure. In order to adapt to the development of the times, the study starts with the analysis of the mechanical properties of carbon fiber composite materials and epoxy pitch and conducts experiments on tensile properties and shear properties in a variable temperature environment. The results show that the relationship between tensile force and displacement, tensile stress, and strain of carbon fiber composites in the high-temperature and wet-state test shows a linear increase, and the fracture damage occurs after the maximum value occurs. The incremental nodes are 526.1 MPa – 0.0092, 575.2 MPa – 0.0094, 575.1 MPa – 0.0089, 576.1 MPa – 0.0095, and 610.3 MPa – 0.0079, respectively. The shear force, displacement, and shear stress–strain curves show a nonlinear incremental relationship. The maximum stress corresponding to the displacement of specimen 1 to specimen 5 is 0.0649, 0.0620, 0.0660, 0.0590, and 0.0587 mm. The mechanical properties of epoxy asphalt materials include viscoelasticity, tensile properties, and interfacial adhesion. Among them, the highest value of the modulus is 394.69 MPa near the temperature of −42°C, indicating that the material has a certain buffering function in the face of sudden impact. However, the increase in temperature reduces the tensile strength of the epoxy asphalt material, and the tensile strength value of the material decreases from 0.629 to 0.258 MPa in the entire working temperature range. This shows that the mechanical properties of the material are highly sensitive to temperature when it is used in orbit. Although the research has carried out a detailed temperature experimental mechanical analysis of the two materials, the aging problem of the materials has not been explored in detail, especially in the alkaline water environment or freeze–thaw environment, the mechanical analysis still needs further research in the future. This experiment on fiber composite materials only conducted tensile, shear, and compressive mechanical performance tests on standard specimens, without conducting experimental analysis on specific structural components and aging issues under complex working conditions. In addition, due to objective conditions, thermal aging, UV aging, and immersion aging issues have not been considered in the mechanical properties of epoxy asphalt. Therefore, after the expansion of scientific research resources, it is necessary to conduct research on aging issues in the future.

-

Funding information: Author states no funding involved.

-

Conflict of interest: Author states no conflict of interest.

References

[1] Huang T, Zhang D, Huang Y, Fan C, Lin Y, Zhang F. Flexural bearing capacity and failure mechanism of CFRP-aluminum laminate beam with double-channel cross-section. Sci Eng Compos Mater. 2021;28(1):139–52.10.1515/secm-2021-0012Suche in Google Scholar

[2] Abderezak R, Tahar HDD, Benferhat R, Tounsi A. Mechanical behavior of RC cantilever beams strengthened with FRP laminate plate. Adv Comput Des. 2021;6(3):169–90.Suche in Google Scholar

[3] Wang K, Cheng J, Zhu Y, Wang X, Li X. Experimental research on the performance of the thermal-reflective coatings with liquid silicone rubber for pavement applications. E-Polymers. 2021;21(1):453–65.10.1515/epoly-2021-0046Suche in Google Scholar

[4] Morey DA, Marquisee JM, Gifford RC, Fitzgerald MC, Rayo MF. Predicting graceful extensibility of human-machine systems: A new analysis method for evaluating extensibility plots to anticipate distributed system performance. Proc Hum Factors Ergon Soc Annu Meet. 2020;64(1):313–8. 10.1177/1071181320641072Suche in Google Scholar

[5] Bigdeli M, Monfared V. The prediction of stress and strain behaviors in composite gears using FEM. Int J Eng Trans B: Appl. 2021;34(2):554–61.10.5829/ije.2021.34.02b.29Suche in Google Scholar

[6] Sangid MD, Rotella J, Naragani D, Park JS, Kenesei P, Shade PA. A complete grain-level assessment of the stress-strain evolution and associated deformation response in polycrystalline alloys. Acta Mater. 2020;201(3):36–54.10.1016/j.actamat.2020.09.051Suche in Google Scholar

[7] Ma L, Shi H, Ding S, Zhang C, Yuan H, Pan J. Study on temperature field and surface damage characteristics of railway brake disc/pad at low temperatures. Ind Lubr Tribol. 2022;74(5):472–80.10.1108/ILT-11-2021-0440Suche in Google Scholar

[8] Zhai W, Wang K, Chen Z, Zhu S, Cai C, Liu G. Full-scale multi-functional test platform for investigating mechanical performance of track–subgrade systems of high-speed railways. Railw Eng Sci. 2020;28(3):213–31.10.1007/s40534-020-00221-ySuche in Google Scholar

[9] Yi Q, Zhao C, Wang P. Characteristics of defect states in periodic railway track structure. J Low Freq Noise Vib Active Control. 2022;41(1):196–208.10.1177/14613484211038261Suche in Google Scholar

[10] Huang QB, Gao H, Liu N, Ma YJ, Shaking table model test on seismic response of metro tunnel crossing ground fissure site. J Geomech. 2022;24(6):785–94.Suche in Google Scholar

[11] Wang X, Shen S, Huang H. Meso-scale kinematic responses of asphalt mixture in both field and laboratory compaction. Transp Res Rec. 2021;2675(9):1631–42.10.1177/03611981211009222Suche in Google Scholar

[12] Zeng Z, Lee K, Kim YR. Determination of dynamic modulus master curve of damaged asphalt pavements for mechanistic-empirical pavement rehabilitation design. Transp Res Rec: J Transp Res Board. 2021;2675(8):161–74.10.1177/0361198121996708Suche in Google Scholar

[13] Mousavi M, Oldham D, Fini EH. Using fundamental material properties to predict the moisture susceptibility of the asphalt binder: Polarizability and a moisture-induced shear-thinning index. ACS Appl Bio Mater. 2020;3(11):7399–407.10.1021/acsabm.0c00374Suche in Google Scholar PubMed

[14] Bakamal A, Ansari R, Hassanzadeh-Aghdam MK. Bending, free vibration, and buckling responses of chopped carbon fiber/graphene nanoplatelet-reinforced polymer hybrid composite plates: An inclusive microstructural assessment. Proc Inst Mech Eng Part C: J Mech Eng Sci. 2021;235(8):1455–69.10.1177/0954406220942783Suche in Google Scholar

[15] Su M, Dai GL, Peng H. Bond-slip constitutive model of concrete to cement-asphalt mortar interface for slab track structure. Struct Eng Mech. 2020;74(5):589–600.Suche in Google Scholar

[16] Wolfrum J, Eibl S, Oeltjen E, Osterholz J, Wickert M. High-energy laser effects on carbon fiber reinforced polymer composites with a focus on perforation time. J Compos Mater. 2021;55(16):2249–62.10.1177/0021998320988885Suche in Google Scholar

[17] Koloor SSR, Karimzadeh A, Abdullah MR, Petrů M, Yidris N, Sapuan SM, et al. Linear-nonlinear stiffness responses of carbon fiber-reinforced polymer composite materials and structures: A numerical study. Polymers. 2021;13(3):344.10.3390/polym13030344Suche in Google Scholar PubMed PubMed Central

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Investigation of differential shrinkage stresses in a revolution shell structure due to the evolving parameters of concrete

- Multiphysics analysis for fluid–structure interaction of blood biological flow inside three-dimensional artery

- MD-based study on the deformation process of engineered Ni–Al core–shell nanowires: Toward an understanding underlying deformation mechanisms

- Experimental measurement and numerical predictions of thickness variation and transverse stresses in a concrete ring

- Studying the effect of embedded length strength of concrete and diameter of anchor on shear performance between old and new concrete

- Evaluation of static responses for layered composite arches

- Nonlocal state-space strain gradient wave propagation of magneto thermo piezoelectric functionally graded nanobeam

- Numerical study of the FRP-concrete bond behavior under thermal variations

- Parametric study of retrofitted reinforced concrete columns with steel cages and predicting load distribution and compressive stress in columns using machine learning algorithms

- Application of soft computing in estimating primary crack spacing of reinforced concrete structures

- Identification of crack location in metallic biomaterial cantilever beam subjected to moving load base on central difference approximation

- Numerical investigations of two vibrating cylinders in uniform flow using overset mesh

- Performance analysis on the structure of the bracket mounting for hybrid converter kit: Finite-element approach

- A new finite-element procedure for vibration analysis of FGP sandwich plates resting on Kerr foundation

- Strength analysis of marine biaxial warp-knitted glass fabrics as composite laminations for ship material

- Analysis of a thick cylindrical FGM pressure vessel with variable parameters using thermoelasticity

- Structural function analysis of shear walls in sustainable assembled buildings under finite element model

- In-plane nonlinear postbuckling and buckling analysis of Lee’s frame using absolute nodal coordinate formulation

- Optimization of structural parameters and numerical simulation of stress field of composite crucible based on the indirect coupling method

- Numerical study on crushing damage and energy absorption of multi-cell glass fibre-reinforced composite panel: Application to the crash absorber design of tsunami lifeboat

- Stripped and layered fabrication of minimal surface tectonics using parametric algorithms

- A methodological approach for detecting multiple faults in wind turbine blades based on vibration signals and machine learning

- Influence of the selection of different construction materials on the stress–strain state of the track

- A coupled hygro-elastic 3D model for steady-state analysis of functionally graded plates and shells

- Comparative study of shell element formulations as NLFE parameters to forecast structural crashworthiness

- A size-dependent 3D solution of functionally graded shallow nanoshells

- Special Issue: The 2nd Thematic Symposium - Integrity of Mechanical Structure and Material - Part I

- Correlation between lamina directions and the mechanical characteristics of laminated bamboo composite for ship structure

- Reliability-based assessment of ship hull girder ultimate strength

- Finite element method on topology optimization applied to laminate composite of fuselage structure

- Dynamic response of high-speed craft bottom panels subjected to slamming loadings

- Effect of pitting corrosion position to the strength of ship bottom plate in grounding incident

- Antiballistic material, testing, and procedures of curved-layered objects: A systematic review and current milestone

- Thin-walled cylindrical shells in engineering designs and critical infrastructures: A systematic review based on the loading response

- Laminar Rayleigh–Benard convection in a closed square field with meshless radial basis function method

- Determination of cryogenic temperature loads for finite-element model of LNG bunkering ship under LNG release accident

- Roundness and slenderness effects on the dynamic characteristics of spar-type floating offshore wind turbine

Artikel in diesem Heft

- Research Articles

- Investigation of differential shrinkage stresses in a revolution shell structure due to the evolving parameters of concrete

- Multiphysics analysis for fluid–structure interaction of blood biological flow inside three-dimensional artery

- MD-based study on the deformation process of engineered Ni–Al core–shell nanowires: Toward an understanding underlying deformation mechanisms

- Experimental measurement and numerical predictions of thickness variation and transverse stresses in a concrete ring

- Studying the effect of embedded length strength of concrete and diameter of anchor on shear performance between old and new concrete

- Evaluation of static responses for layered composite arches

- Nonlocal state-space strain gradient wave propagation of magneto thermo piezoelectric functionally graded nanobeam

- Numerical study of the FRP-concrete bond behavior under thermal variations

- Parametric study of retrofitted reinforced concrete columns with steel cages and predicting load distribution and compressive stress in columns using machine learning algorithms

- Application of soft computing in estimating primary crack spacing of reinforced concrete structures

- Identification of crack location in metallic biomaterial cantilever beam subjected to moving load base on central difference approximation

- Numerical investigations of two vibrating cylinders in uniform flow using overset mesh

- Performance analysis on the structure of the bracket mounting for hybrid converter kit: Finite-element approach

- A new finite-element procedure for vibration analysis of FGP sandwich plates resting on Kerr foundation

- Strength analysis of marine biaxial warp-knitted glass fabrics as composite laminations for ship material

- Analysis of a thick cylindrical FGM pressure vessel with variable parameters using thermoelasticity

- Structural function analysis of shear walls in sustainable assembled buildings under finite element model

- In-plane nonlinear postbuckling and buckling analysis of Lee’s frame using absolute nodal coordinate formulation

- Optimization of structural parameters and numerical simulation of stress field of composite crucible based on the indirect coupling method

- Numerical study on crushing damage and energy absorption of multi-cell glass fibre-reinforced composite panel: Application to the crash absorber design of tsunami lifeboat

- Stripped and layered fabrication of minimal surface tectonics using parametric algorithms

- A methodological approach for detecting multiple faults in wind turbine blades based on vibration signals and machine learning

- Influence of the selection of different construction materials on the stress–strain state of the track

- A coupled hygro-elastic 3D model for steady-state analysis of functionally graded plates and shells

- Comparative study of shell element formulations as NLFE parameters to forecast structural crashworthiness

- A size-dependent 3D solution of functionally graded shallow nanoshells

- Special Issue: The 2nd Thematic Symposium - Integrity of Mechanical Structure and Material - Part I

- Correlation between lamina directions and the mechanical characteristics of laminated bamboo composite for ship structure

- Reliability-based assessment of ship hull girder ultimate strength

- Finite element method on topology optimization applied to laminate composite of fuselage structure

- Dynamic response of high-speed craft bottom panels subjected to slamming loadings

- Effect of pitting corrosion position to the strength of ship bottom plate in grounding incident

- Antiballistic material, testing, and procedures of curved-layered objects: A systematic review and current milestone

- Thin-walled cylindrical shells in engineering designs and critical infrastructures: A systematic review based on the loading response

- Laminar Rayleigh–Benard convection in a closed square field with meshless radial basis function method

- Determination of cryogenic temperature loads for finite-element model of LNG bunkering ship under LNG release accident

- Roundness and slenderness effects on the dynamic characteristics of spar-type floating offshore wind turbine