Abstract

In numerous engineering applications, metal matrix composites strengthened by ceramic particles have played an important role. For this purpose, an aluminum (Al 7075) nanocomposite has been fabricated, and nano-zirconium oxide of particle size 40 nm (0, 0.8, 1.6, and 2.4) wt% reinforced Al 7075 alloy was produced using a stir-casting process. The effect of ZrO2 NPs loading on mechanical properties along with the detailed characterization were demonstrated. The performance of Al with ZrO2 nanocomposite was investigated by Vickers hardness tester, scanning electron microscopy, energy-dispersive X-ray, compression test, Lee’s disc, and Shore D instruments were utilized to determine the hardness, structural morphology, composition of the elements, Young’s modulus, thermal conductivity, and roughness values of the samples, respectively. The hardness (120.3–177) HV, compression strength (624.2–878.6) MPa, yield modulus (38–70) MPa, surface roughness (0.876–0.606) µm, thermal conductivity (2.0–2.39) W/m2 °C improved by increasing the wt% of ZrO2 NP reinforcement particles. The implication of these findings shows that 5 wt% nano-ZrO2-reinforced Al 7075 composites yielded better performance than pure Al 7075 alloy. To sum up, this investigation demonstrated that the ZrO2 reinforcement enhanced the mechanical properties of Al 7075.

1 Introduction

In the last two decades, a lot of attention has been given to composites of base metal due to their remarkable mechanical characteristics, including hardness and strength. Aluminum is considered the most reliable material that can be used to get these superior properties [1,2]. Recently, a ceramic additive to reinforce the metallic matrix has played a significant role in various engineering applications. Its impact appears in the aerospace industries and automotive applications owing to its corrosion resistance, high strength, and low density. These achievements are accomplished by mixing various materials, such as metallic and ceramic alloys [3,4]. Due to its excellent properties [5], aluminum alloy 7075 metal matrix is considered the most promising material used in the aeronautics industry for various applications such as shafts, gears, and aircraft fittings. This aluminum nanocomposite displays a decreased tribological behavior since it is difficult to produce a complete homogeneous microstructure of Al matrix composites [6,7,8]. Powder metallurgy [9,10,11], spray deposition [1,12], squeeze casting [13], mechanical milling [14], and stir casting [4,15–17] are some of the ways that metal matrix composites can be made. Numerous studies have been conducted to study the impact of ceramic nanoparticles (NPs) on the Al matrix to show the tribological and mechanical characteristics. Titanium dioxide (TiO2) (NPs) was added to pure aluminum using powder metallurgy. This revealed an increase in the power of tensile and porosity with increasing TiO2 (NPs) concentration. Similarly, this composite showed excellent anti-wear in contrast to metal matrix alloys [18]. Ravikumar et al. [19] examined the mechanical characteristics and wear behavior of AA7075 reinforced by Al2O3. Abbas and Rasheed reported the mechanical characterization of the Cu:TiO2 nanomaterial [20].

The AA7075 reinforced by Al2O3 was produced using stir casting. The wear resistance and mechanical characteristics of adding Al2O3 particulates have improved significantly. Also, an improvement in mechanical properties has been gained with 25 nm Al2O3 size addition to AA6061 alloy [21]. Al-Zuhairi and Alshalal [22] examined the silicon influence of carbide on the mechanical behavior of the aluminum nanocomposite. The finding showed an enhancement in ultimate compressive strength (UTS), compression test, and the values of hardness [23]. Numerical methods can be utilized to examine the mechanical characteristics of the materials [24–42].

The hardness and wear resistance of Al enhanced with ZrO2 NPs were examined. This alloy was manufactured using the powder metallurgy technique. A pin-on-disc wear test apparatus was utilized for the evaluation. The findings proved that the wear resistance and hardness of reinforced composites were significantly enhanced with increasing ZrO2 NP percentage.

In this investigation, Al 7075 composite materials reinforced with 0.8, 1.6, and 2.4% of ZrO2 NP ratios were synthesized using a stir-casting process. Certain mechanical characteristics of composites, such as structural morphology, hardness, composition of the elements, young modulus, thermal conductivity, and roughness values of the samples, have been examined.

2 Experimental procedure

2.1 Material preparation

Al 7075 was selected as a matrix to synthesize the composite material and the zirconia oxide (ZrO2) NPs as reinforcement. The substance and structure of the Al 7075 ingredient in the weight proportion is shown in Table 1.

Chemical structure of Al 7075 (wt%) [19]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 7075 | 0.4 | 0.5 | 1.2–2.0 | 0.3 | 2.1–2.9 | 0.18–.28 | 5.1–6.1 | 0.2 | Balance |

Al 7075 was reinforced by ZrO2 ceramic NPs by stir casting with a particle size of 40 nm. Different weight percentages of the ZrO2 NPs (0, 0.8, 1.6, and 2.4) wt% were examined to fabricate the Al7075/ZrO2 nanocomposite. Table 2 compares the mechanical and physical characteristics of Al7075 alloy and ZrO2.

Mechanical and physical characteristics of Al 7075 and ZrO2

| Properties | Al 7075 | ZrO2 |

|---|---|---|

| Elastic modulus (GPa) | 70–80 | 94.5 |

| Density (g/cc) | 2.8 | 5.68 |

| Poisson’s ratio | 0.33 | 0.34 |

| Hardness (HB500) | 60 | 5,500 |

| Tensile strength (MPa) | 220 | 5,200 |

| Ultimate tensile strength (MPa) | 572 | 330 |

| Tensile yield strength (MPa) | 503 | 230 |

2.2 Nanocomposite preparation

Figure 1 shows melting the Al 7075 alloy in a gas furnace lined with the isolated material at 750°C for 5 min using a graphite crucible. The temperature was measured using a laser temperature measurement device. Before adding nano-ZrO2 particles, they were covered gently with AL particles to ensure that the particles do not oxidize and prevent them from floating. When the melting process is completed, the slag is removed using aluminum hydrochloride.

Gas furnace.

The structure is homogenized by stirring, and the ZrO2 NP is added to the liquefied ingredient. Mechanical stirring is performed for 3–4 min at a speed of 600 rpm on a stirrer. The molten metal is poured into a cast iron mold to reduce heat leakage, as shown in Figure 2, and then cooled in air.

Casting mold with a cooling system. (a) Aschematic mold, (b) Section A_A in the schematic mold, (c) The section metal mold with cooling tubes and (d) Metal mold assembly.

2.3 Test of compression

Compression test was applied to ascertain the behavior of the Al7075/ZrO2 nanocomposite. The test was conducted at 25°C using the Instron universal testing machine. The sample dimensions that were used for the compression test are 10 and 30 mm in diameter and length, respectively. For more accuracy in the results, each condition was examined three times, and the average value of the three readings was used in the interpretation (compression testing machine, Laryee Technology Co., Ltd., from China).

2.4 Hardness test

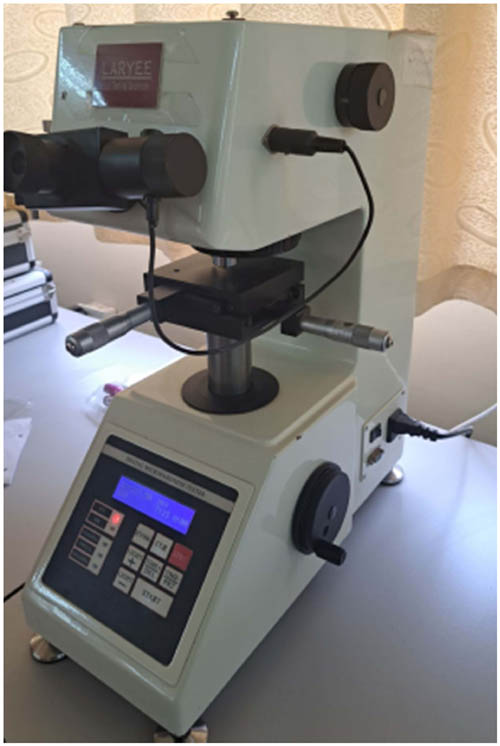

The measurements of all specimens were performed by using the Vickers hardness test with a diamond indenter to determine the hardness of the Al7075/ZrO2 nanocomposite. The accuracy reading was determined by averaging the results of three indentations (HVS-1000 Digital Micro Hardness Tester, Laryee Technology Co., Ltd., from China). The hardness scale HV or HK can be selected on the operation panel. The hardness value tested will be automatically calculated and displayed. Various hardness values can be converted to one another. The hardness error can be corrected by software input to make the hardness more accurate. Test results can be automatically stored, processed, and printed. The HVS-1000 digital display microhardness tester has a manual switch between the head and the objective lens during the test, and the test point positioning is accurate. To determine the ZrO2 NP content on strength, the Vickers microhardness test was performed on the samples using the micro hardness tester (HVS-1000 Digital, Figure 3). The test load (force) was fixed to be (300 gf = 2.942 N) for an indentation time of 0–60 s (5 s as a unit), measuring range = 5–3,000 HV, test microscope magnification = 400× for measuring and 100× for observation, maximum height of specimen = 65 mm, with the diagonal of impression in the range of 40–60 µm. All samples for hardness tests were polished to a surface roughness of around 0.0625 µm. The distance between the tip of the indenter and the plane of the specimen is about 0.4–0.5 mm. The operation system is as follows: press the input buttons measuring on the eyepiece, the LCD screen shows D1 and D2 values, and the system calculates hardness value automatically and shows testing results (HV value) automatically as well. At least five measurements were taken for each sample, the mean value was utilized to compute its hardness.

Micro hardness tester device.

2.5 Scanning electron microscopy (SEM) micrographs

The microstructure of Al-ZrO2 nanocomposites was characterized by high-resolution SEM type (FEI INSPECT S50-BRUKER Company) from the USA.

2.6 Thermal conductivity

Samples were deposited in the device between two temperature sensors, with the thermometer measuring the change in temperature over the course of 1 h.

Using the following equation, the quantity of heat conveyed through the specimen was calculated

where I × V represents the thermal energy, which passed through the heating coil after reaching the equilibrium thermal state; I represents the current (0.25 A); V represents the voltage (6 V); T represents the time (1 h); e represents the temperature amount (thermal energy) passed through a unit area of disc material for each second (W/m2 °C); d s represents the thickness of the sample (mm); d A, d B, and d C indicate the thickness of the disc (A, B, and C), respectively; r indicates the disc’s radius (mm); T A, T B, T C represent temperatures of the disc (A, B, and C), respectively.

From calculated (e), K can be calculated as in the following equation:

where K stands for the coefficient of thermal conductivity for the specimen (W/m2 °C).

2.7 Surface roughness

The surface roughness device (Hand-held Roughness TR200) manufactured by (Time Group Inc. company) was utilized to determine the surface roughness of the samples.

3 Results and discussion

Table 3 reveals the toughness of the Al matrix strengthened with various quantities of ZrO2 NPs. The rigidity of Al-ZrO2 composites increases as the amount of ZrO2 NPs increases, the greatest hardness was 177 HV, which resulted from the sample containing 2.4 wt% of ZrO2 NPs. This figure shows that the hardness value improved after increasing the addition of ZrO2 NPs from 0 to 2.4%; this can be attributed to ZrO2 NPs, which have a high hardness value when compared with Al hardness.

Variation of composite hardness with zirconia concentration

| Samples | D 1 (mm) | D 2 (mm) | Hardness (HV) | Average hardness (HV) |

|---|---|---|---|---|

| Al | 48 | 88 | 120.343 | 120.49 |

| 47.8 | 87.8 | 121.054 | ||

| 82.4 | 53.6 | 120.343 | ||

| 70.2 | 65.8 | 120.343 | ||

| 65.4 | 70.6 | 120.343 | ||

| Al + 0.8% ZrO2 | 45.6 | 87.9 | 124.892 | 124.89 |

| 60.55 | 72.95 | 124.892 | ||

| 61.12 | 72.38 | 124.892 | ||

| 43.56 | 89.94 | 124.892 | ||

| 53.21 | 80.29 | 124.892 | ||

| Al + 1.6% ZrO2 | 60.33 | 64.47 | 142.912 | 142.91 |

| 80.57 | 44.23 | 142.912 | ||

| 35.94 | 88.86 | 142.912 | ||

| 51.24 | 73.56 | 142.912 | ||

| 60.59 | 64.21 | 142.912 | ||

| Al + 2.4% ZrO2 | 67.9 | 44.2 | 177.128 | 177.13 |

| 55.6 | 56.5 | 177.128 | ||

| 44.51 | 67.59 | 177.128 | ||

| 33.88 | 78.22 | 177.128 | ||

| 58.69 | 53.41 | 177.128 |

Table 3 depicts the hardness values of stir-cast Al 7075 composites reinforced with 0.8, 1.6, and 2.4% ZrO2. Owing to an increase in the ratio of ZrO2 reinforcement, Table 3 demonstrates that the hardness value increases progressively. Hard-phase ZrO2 reinforcement particles in the composite structure are primarily responsible for this increase in hardness. Good wetting between the matrix material of the composite, Al 7075, and the ZrO2 reinforcing particulates increases both the mechanical strength and hardness of the structure. The 120 HV hardness of unadulterated Al 7075 alloy without ZrO2 reinforcement increased progressively as the ZrO2 reinforcement ratio increased. The highest hardness value was found to be 177 HV in the composite material with 2.4% ZrO2 reinforcement, which increased the hardness of the Al 7075 alloy by 20%. In addition to increasing the composites’ hardness, the addition of harder reinforcement particles increased the formation of dislocations, which inhibit plastic deformation. The fluidity of the molten matrix, the density of the reinforcing particles, the rate of solidification, and the distribution of the reinforcing particles are the primary factors influencing the hardness of composites. Consequently, it was observed that the hardness values of ZrO2-reinforced composites were significantly higher than those of the unadulterated Al 7075 alloy.

SEM images of stir-casted Al 7075 composites reinforced with 0, 0.8, 1.6, and 2.4% of ZrO2 ratios are given in Figure 3. Energy-dispersive X-ray (EDX) spectra of Al-ZrO2 surfaces were collected at three individual positions on a solo test section. The average values for the three locations are displayed in Table 3. It seems that the ZrO2 substance rises with increasing the ZrO2 NPs except for the specimen with 2.4% ZrO2 amount, which has less concentration. It is attributed to the nonhomogeneous distribution of ZrO2 NPs. Figure 4 depicts the distribution of ZrO2 reinforcement particles in the composite structure using microstructure images. The images suggest that increasing the ZrO2 reinforcement ratio enhanced the reinforcement distribution’s homogeneity.

Micrograph images and EDX for different amounts of ZrO2 (a) 0 wt%, (b) 0.8 wt%, (c) 1.6 wt%, and (d) 2.4 wt% adding to Al 7075.

However, increasing the ZrO2 ratio caused the reinforcement to aggregate. It appears that the displacement of ZrO2 particles during the stir-casting process causes agglomeration in certain regions of the molten Al 7075 matrix. Figure 4, which depicts the microstructure of a composite material reinforced with 2.4% ZrO2, suggests that dissolving the matrix material in the graphite crucible caused the ZrO2 particles to migrate upward.

However, this study, which employed the stir-casting method, revealed that the matrix material and reinforcement were sufficiently wetted, and there was no significant porosity in the composite structure. It is possible that the addition of 0.8% ZrO2 to the molten aluminum during the stir-casting process contributed to hydration. The procedure of preheating the graphite crucible prior to its immersion in the molten metal could have had a positive effect on the absorption. Therefore, it can be concluded that the parameters for the stir-casting procedure used in this study (750°C for the molten metal matrix temperature and 5 min) were suitable. In the production of such particle-reinforced aluminum composites, the construction of a porous composite structure is a significant obstacle. The composite structure’s porosity increases as the number of reinforcing particles increases.

In this investigation, the stir-casting technique appears to have yielded superior matrix-reinforcement compatibility than other production techniques. Figure 4 depicts the interface between the ZrO2 reinforcing element and the Al 7075 matrix material with greater clarity. The images of the microstructure reveal that there is no porous structure between the aluminum matrix (Al 7075) and the ZrO2 reinforcing particle, and that the bond between the two phases is strong. This depicts that this excellent hydration will increase the mechanical strength of the composite material, and that the stir-casting method used to produce composites in this study is fruitful.

Additionally, the surface images reveal that the cavities are irregular, with some being larger or deeper than others. The ZrO2 particles removed from the composite structure by fracture must have been relatively small, as particles with smaller surfaces have weaker adhesion between the matrix and reinforcement interface. Therefore, smaller ZrO2 particles must have created the microscopic voids on the eroded surfaces.

The surface morphology of all four samples is shown as (a) for Al 7075 alloy, (b) for 0.8% ZrO2, (c) for 1.6% ZrO2, and (d) for 2.4% ZrO2. All images presented have specifications of 10 HV, KV, Mag. 3,500, 30 µm, and 11.3 mm WD. It indicates that there is an aggregation of ZrO2 particles as a result of a non-regular allocation of particles in the nanocomposite. This may be attributed to stirring speed or stirring time. EDS analyses indicate that the peaks represent the presence of Al, Zr, and O. This confirms that the composite contains ZrO2 particles. This analysis serves to comprehend the elemental composition of the Al7075/ZrO2 composite sample (Table 4).

Semiquantitative assessment of the EDX spectra of oxygen and chosen constituents of Al-ZrO2 surfaces

| Sample | Al | O | Mg | C | Zr |

|---|---|---|---|---|---|

| Al | 95.0 | 1.94 | 1.67 | 1.33 | 0 |

| Al + 0.8% ZrO2 | 89.42 | 4.27 | 2.29 | 3.43 | 0.59 |

| Al + 1.6% ZrO2 | 94.38 | 1.25 | 1.36 | 2.33 | 0.67 |

| Al + 2.4% ZrO2 | 59.25 | 11.12 | 10.45 | 18.39 | 0.79 |

In casting procedures, nano-ZrO2 NPs typically do not perform a nucleation role. They are utilized as reinforcement particulates to enhance the mechanical properties of the cast material, including grain refinement in solidified materials such as Al 7075.

Nucleation typically refers to the initial formation of solid crystals (nuclei) from a molten state in casting processes. In conventional casting techniques, nucleation occurs naturally as the molten metal solidifies, and the presence of impurities or particular alloying elements can influence the nucleation process. However, adding nano-ZrO2 NPs to the liquid to promote nucleation in casting is not a prevalent practice. In order to refine the particle size in a cast material like Al 7075, other techniques include the following

Grain refiners: In conventional casting, titanium or boron-based grain refiners are added to the molten metal to promote nucleation and control particle development during solidification.

Ultrasonic treatment: During the casting process, ultrasonic treatment can be used to induce nucleation and facilitate the formation of nanoscale granules.

Controlling the chilling rate during solidification can also have an effect on particle size. Typically, faster chilling rates result in finer granules.

Concerning the assessment of grain size variations in Al7075 with nano-ZrO2 NPs added, it would indeed be necessary to conduct experiments to observe the effect of reinforcement. Grain refinement in NPs is expected to occur via the anchoring effect, where nano-ZrO2 NPs act as obstacles to grain growth, resulting in reduced grain diameters.

It is important to note that the specific processing conditions, such as the quantity and size of nano-ZrO2 NPs introduced, the casting technique used, and the overall composition of the alloy, can all affect the final results. In order to determine the actual effects on grain size and other mechanical properties of the Al 7075 alloy with nano-ZrO2 NPs added, experimental testing is required.

I can, however, provide some general information regarding the addition of ZrO2 to composite materials.

In many instances, the performance of composite materials tends to improve as the amount of reinforcing particulates (such as ZrO2 NPs) increases up to a certain threshold. Beyond this threshold, the performance enhancements may begin to diminish, indicating that the gains become less significant with each additional addition of ZrO2 NPs. This is due to factors such as particulate agglomeration, limited matrix adhesion, and other potential material property trade-offs. Cost and practicality: When determining the optimal content of ZrO2 NPs or any other reinforcement, the cost and practicality of the material should also be considered. High concentrations of ZrO2 NPs or other additives may increase the overall cost of the composite material, rendering it uneconomical. Additionally, some processing techniques may have restrictions on the greatest quantity of ZrO2 NPs that can be effectively incorporated. Material compatibility: The addition of an excessive quantity of ZrO2 NPs (or any other reinforcement) may result in compositional imbalances or phase separation, altering the material’s overall properties and potentially decreasing its performance. Experimental validation: In research and development, determining the optimal amount of ZrO2 NPs or any other additive is typically a portion of the inquiry. Researchers conduct a series of experiments with varying concentrations of the reinforcement to determine the optimal concentration at which the material exhibits the desired properties while avoiding potential disadvantages. In conclusion, the decision to add more ZrO2 NPs (or any other additive) to a composite material is determined by the application’s specific objectives, intended properties, and limitations. Typically, researchers evaluate the trade-offs and conduct experimental tests to determine the optimal composite material composition for attaining the desired performance characteristics.

To characterize Al-ZrO2 nanocomposite, a compression test was carried out for all specimens, and the results are shown in Figure 5. The outcomes demonstrate that the yield strength (YS) and maximum strength rise with growing ZrO2 NP concentration. The change in the composite strength also benefits from the improved distribution and stronger packing of the hard metal into the pure aluminum matrix, which contributes to better interfacial characteristics and this agrees with that of previous study [23]. The variation of yield and maximum strength with ZrO2 concentration is shown in Figure 6. By incorporating ZrO2 reinforcement particles, the yield and UTSs have been enhanced. As the quantity of ZrO2 particles increases, the composite’s YS and UTS increase, while elongation (%) decreases. In comparison to the Al7075 matrix material, the Al 7075/2.4ZrO2 composite exhibits greater YS and UTS with less elongation. The difference in thermal expansion coefficient is responsible for the composite material’s enhanced compression strength. During solidification, the difference in the coefficient of thermal expansion between matrix material and reinforcements tends to reduce dislocations surrounding ZrO2 particles. This reinforces the composite under stress conditions.

Stress–strain curve for (a) Al 7075, (b) 0.8% ZrO2, (c) 1.6% ZrO2, and (d) 2.4% ZrO2 nanocomposite.

Young’s modulus yield and maximum strength with ZrO2 particle concentration.

The composite’s compression strength is enhanced as a result of the increase in the wt% of ZrO2 particles due to the close interaction between reinforcements and matrix, which reduces dislocation and increases the composite’s tensile strength.

The uniform distribution of ZrO2 particles with spherical morphology also contributes significantly to the composite’s increased tensile strength. Due to the distinct interface between reinforcements and matrix material, the tensile strength of the composite increases further. The stir-casting technique utilized in the synthesis of composite allows for the homogenous distribution of ZrO2 reinforcement particles and a distinct interface between reinforcements and matrix material. This reduces the initiation of fracture propagation under conditions of high load. The absence of defects in the uniform distributions of ZrO2 particles on YS, UTS, and % elongation of AA7075/ZrO2 particles enhances the YS and UTS of the composite. The refinement of the composite’s particle structure also increases its compressive strength. Overall, the addition of ZrO2 particles increased the composite’s hardness and compression strength, which decreased its elongation.

Table 5 and Figure 7 depict that the thermal analysis is carried out of stir-casted Al 7075 composites reinforced with 0, 0.8, 1.6, and 2.4% ZrO2 to find out the thermal behavior of composite materials. In thermal analysis, the thermal conductivity of samples is found with respect to the composition ratio. The thermal conductivity of Al 7075/0.8ZrO2 composite is higher than other composite materials, in which thermal conductivity will increase by adding zirconium content in composite material. In Al 7075/0.8ZrO2, the zirconium content is 0.8%, so the thermal conductivity of the material gets increased compared with pure Al 7075.

Changes in thermal conductivity of nanocomposite samples due to the addition of ZrO2 (0, 0.8, 1.6, 2.4) wt%

| No | Sample (%) | T A (°C) | T B (°C) | T C (°C) | d s (mm) | e (W/m2 °C) | K (W/m °C) |

|---|---|---|---|---|---|---|---|

| A | Al7075 | 23.5 | 26.5 | 26.5 | 10.78 | 7.077141 | 2.000111 |

| B | 0.8 ZrO2 | 26 | 28.5 | 28.5 | 10.58 | 6.568028 | 2.391294 |

| C | 1.6 ZrO2 | 27 | 30 | 30 | 11.31 | 6.16767 | 2.130673 |

| D | 2.4 ZrO2 | 27.5 | 30.5 | 30.5 | 11.38 | 6.056068 | 2.14799 |

Thermal conductivity of samples after adding ZrO2 (0, 0.8, 1.6, 2.4) wt% nanocomposite samples.

The values of the surface roughness of samples R ave are listed in Table 6, one can see that the sample with the greatest average surface roughness value obtained for the pure sample, and this value decreased by adding ZrO2 NPs.

Surface roughness value of the samples

| Sample (%) | R ave (μm) |

|---|---|

| Al7075 | 0.876 |

| 0.8 ZrO2 | 0.743 |

| 1.6 ZrO2 | 0.765 |

| 2.4 ZrO2 | 0.606 |

Due to the presence of ZrO2 NPs, the surface roughness of an Al7075 alloy can decrease when more ZrO2 is added. These NPs can also improve the material’s mechanical properties and surface polish. Here are some explanations for why this occurs:

Fine grain structure: During the solidification of the Al7075 alloy, ZrO2 NPs serve as nucleation sites, promoting the formation of a fine-grained microstructure. Smaller granules minimize surface irregularities, so fine-grained materials typically have cleaner surfaces than coarse-grained materials. Refinement of grain size: The addition of ZrO2 NPs can refine the grain size of Al7075 alloy, thereby improving its mechanical properties, such as hardness and strength. A material with enhanced mechanical properties is less susceptible to plastic deformation and attrition, which reduces surface roughness. The dispersion of ZrO2 NPs within the matrix of Al7075 alloy can enhance the homogeneity of the material. Homogeneous materials have a tendency to exhibit more uniform surface properties, resulting in a decrease in surface roughness.

Reduced porosity: ZrO2 NPs may act as effective grain refiners and reduce the formation of porosity during solidification. As pores produce cavities and irregularities on a material’s surface, porosity can be a significant factor contributing to increased surface roughness.

Enhanced wear resistance: The presence of ZrO2 NPs can enhance the Al7075 alloy’s wear resistance. Materials with greater resistance to wear are less susceptible to surface damage and abrasion, resulting in surfaces that become smoother over time.

Surface refinement (smoothing) during processing: In some instances, the incorporation of ZrO2 NPs may contribute to processing techniques that further enhance the surface finish of the Al7075 alloy, resulting in reduced surface roughness. Notably, the precise effect of adding ZrO2 to Al7075 can vary depending on the processing parameters, chemical composition, and particle size of the ZrO2 utilized. Therefore, the reduction in surface roughness should be evaluated experimentally in each instance to corroborate the actual results.

4 Conclusion

After evaluating the microstructures and mechanical characteristics of stir-casted Al 7075 composites reinforced with 0, 0.8, 1.6, and 2.4% ZrO2, one can reach the following conclusions:

Al 7075 matrix composites reinforced with 0, 0.8, 1.6, and 2.4% ZrO2 were effectively produced using the stir-casting technique, and the manufacturing parameters were determined.

In the composite structure, ZrO2 reinforcement distribution was only partially homogeneous. Effective condensation between the matrix-reinforcement led to the formation of strong bonds.

The ZrO2 reinforcing elements increased the composite structure’s hardness, compressive strength, and Young’s modulus while decreasing its thermal conductivity and surface roughness.

The photos of the micrographs refer to the consistent allocation of the soft matrix hard reinforcement. The weight ratio selection of ZrO2 NPs was optimistic since the mechanical characteristics of the Al-ZrO2 is better than the pure Al alloy.

The findings of this work suggest that the composite’s mechanical characteristics are enhanced by the strong bonds formed between the matrix and reinforcing phases as a result of excellent hydration.

-

Funding information: The authors have not disclosed any funding.

-

Author contributions: FA, LA, IA – methodology; FA, MR, IA – planned and conducted the tests; FA, LA, IA, MR – data analysis and interpretation; and MR, IA, FA – prepared the manuscript. All authors have read and approved the final manuscript version.

-

Conflict of interest: The authors declare that they have no conflict of interest.

-

Data availability statement: On request, the corresponding author will provide you with the data sets generated during this investigation.

References

[1] Sachit TS, Bongale A, Kumar S, Jadhav P. Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method. J Mech Behav Mater. 2023 Mar;32(1):20220274.10.1515/jmbm-2022-0274Search in Google Scholar

[2] Ashokkumar M, Thirumalaikumarasamy D, Sonar T, Ivanov M, Deepak S, Rajangam P, et al. Effect of post-processing treatments on mechanical performance of cold spray coating–an overview. J Mech Behav Mater. 2023 Feb;32(1):20220271.10.1515/jmbm-2022-0271Search in Google Scholar

[3] Hernández-Martínez SE, Cruz-Rivera JJ, Garay-Reyes CG, Elias-Alfaro CG, Martínez-Sánchez R, Hernández-Rivera JL. Application of ball milling in the synthesis of AA 7075–ZrO2 metal matrix nanocomposite. Powder Technol. 2015 Nov;284:40–6.10.1016/j.powtec.2015.06.030Search in Google Scholar

[4] Sunardi S, Ariawan D, Surojo E, Prabowo AR, Akbar HI, Cao B, et al. Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material. J Mech Behav Mater. 2023 Jan;32(1):20220269.10.1515/jmbm-2022-0269Search in Google Scholar

[5] Banerjee JK, Liang M, Rahamati S. A preliminary comparative experimental study on machining of an Al/SiC composite material and a mild steel. J Mech Behav Mater. 1999 Apr;10(2):101–12.10.1515/JMBM.1999.10.2.101Search in Google Scholar

[6] Pham Van D, Huu PN, Minh ND. Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode. J Mech Behav Mater. 2023 Mar;32(1):20220283.10.1515/jmbm-2022-0283Search in Google Scholar

[7] Abbu M, Al-Attar AA, Abd Alrahman S, Al-Gburi M. The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures. J Mech Behav Mater. 2022 Dec;32(1):20220249.10.1515/jmbm-2022-0249Search in Google Scholar

[8] Elaiyarasan U, Satheeshkumar V, Senthilkumar C. Effect of sintered electrode on microhardness and microstructure in electro discharge deposition of magnesium alloy. J Mech Behav Mater. 2020 Aug;29(1):69–76.10.1515/jmbm-2020-0007Search in Google Scholar

[9] Hadeed M, Humad AM, Al-Gburi M. Utilization of hybrid fibers in different types of concrete and their activity. J Mech Behav Mater. 2023 Feb;32(1):20220262.10.1515/jmbm-2022-0262Search in Google Scholar

[10] Alam MA, Hamdan HY, Azeem M, Hussain PB, bin Salit MS, Khan R, et al. Modelling and optimisation of hardness behaviour of sintered Al/SiC composites using RSM and ANN: A comparative study. J Mater Res Technol. 2020 Nov;9(6):14036–50.10.1016/j.jmrt.2020.09.087Search in Google Scholar

[11] Shwan BJ. Numerical analysis of slopes treated by nano-materials. J Mech Behav Mater. 2023 Jan;32(1):20220227.10.1515/jmbm-2022-0227Search in Google Scholar

[12] Prabhuraj P, Rajakumar S, Lakshminarayanan AK, Balasubramanian V. Evaluating stress corrosion cracking behaviour of high strength AA7075-T651 aluminium alloy. J Mech Behav Mater. 2017 Dec;26(3–4):105–12.10.1515/jmbm-2017-0019Search in Google Scholar

[13] Natrayan L, Kumar MS. An integrated artificial neural network and Taguchi approach to optimize the squeeze cast process parameters of AA6061/Al2O3/SiC/Gr hybrid composites prepared by novel encapsulation feeding technique. Mater Today Commun. 2020 Dec;25:101586.10.1016/j.mtcomm.2020.101586Search in Google Scholar

[14] Ashokkumar M, Thirumalaikumarasamy D, Sonar T, Deepak S, Vignesh P, Anbarasu M. An overview of cold spray coating in additive manufacturing, component repairing and other engineering applications. J Mech Behav Mater. 2022 Jul;31(1):514–34.10.1515/jmbm-2022-0056Search in Google Scholar

[15] Awate PP, Barve SB. Microstructural observation and mechanical properties behavior of Al2O3/Al6061 nanocomposite fabricated by stir casting process. Eng Res Express. 2022 Feb;4(1):015023.10.1088/2631-8695/ac54edSearch in Google Scholar

[16] Jagadeesha CB. FSW between Al alloy and Mg Alloy: the comparative study. J Mech Behav Mater. 2017 Apr;26(1–2):25–42.10.1515/jmbm-2017-0011Search in Google Scholar

[17] Jawad SI, Omar MH. Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar. J Mech Behav Mater. 2022 Dec;32(1):20220265.10.1515/jmbm-2022-0265Search in Google Scholar

[18] Vijayavel P, Balasubramanian V. Effect of tool velocity ratio on tensile properties of friction stir processed aluminum based metal matrix composites. J Mech Behav Mater. 2016 Aug;25(3–4):99–109.10.1515/jmbm-2016-0012Search in Google Scholar

[19] Ravikumar M, Reddappa HN, Suresh R, Reddy MS. Experimental studies of different quenching media on mechanical and wear behavior of Al7075/SiC/Al2O3 hybrid composites. Frat Integrità Strutt. 2021;15(55):20–31.10.3221/IGF-ESIS.55.02Search in Google Scholar

[20] Abbas MM, Rasheed M. Solid state reaction synthesis and characterization of Cu doped TiO2 nanomaterials. J Phys: Conf Ser. 2021;1795:012059.10.1088/1742-6596/1795/1/012059Search in Google Scholar

[21] Mandava RK, Reddy VV, Rao VR, Reddy KS. Wear and frictional behaviour of Al 7075/FA/SiC hybrid MMC’s using response surface methodology. Silicon. 2022 Jul;14(10):5319–31.10.1007/s12633-021-01300-3Search in Google Scholar

[22] Al-Zuhairi HM, Alshalal I. Enhancement of Mechanical Properties of Aluminum Piston Alloy Using Al2O3 Material. 2020 6th International Engineering Conference “Sustainable Technology and Development" (IEC); 2020 Feb 26–27; Erbil, Iraq. IEEE, 2020. p. 196–200.10.1109/IEC49899.2020.9122921Search in Google Scholar

[23] Ali M, Alshalal I, Al Zubaidi FN, Yousif AR. Improvement of corrosion and erosion resistance properties for cast iron. IOP Conf Ser: Mater Sci Eng. 2020;881:012068.10.1088/1757-899X/881/1/012068Search in Google Scholar

[24] Kadri E, Dhahri K, Zaafouri A, Krichen M, Rasheed M, Khirouni K, et al. Ac conductivity and dielectric behavior of a − Si : H/c − Si1−yGey/p − Si thin films synthesized by molecular beam epitaxial method. J Alloy Compd. 2017 May;705:708–13.10.1016/j.jallcom.2017.02.117Search in Google Scholar

[25] Azaza NB, Elleuch S, Rasheed M, Gindre D, Abid S, Barillé R, et al. 3-(p-nitrophenyl) Coumarin derivatives: Synthesis, linear and nonlinear optical properties. Optical Mater. 2019 Oct;96:109328.10.1016/j.optmat.2019.109328Search in Google Scholar

[26] Rasheed M, Mohammed OY, Shihab S, Al-Adili A. A comparative analysis of PV cell mathematical model. J Phys: Conf Ser. 2021;1795:012042.10.1088/1742-6596/1795/1/012042Search in Google Scholar

[27] Kadri E, Messaoudi O, Krichen M, Dhahri K, Rasheed M, Dhahri E, et al. Optical and electrical properties of SiGe/Si solar cell heterostructures: Ellipsometric study. J Alloy Compd. 2017 Oct;721:779–83.10.1016/j.jallcom.2017.06.025Search in Google Scholar

[28] Rasheed M, Mohammed OY, Shihab S, Al-Adili A. Explicit numerical model of solar cells to determine current and voltage. J Phys: Conf Ser. 2021;1795:012043.10.1088/1742-6596/1795/1/012043Search in Google Scholar

[29] Rasheed M, Alabdali O, Hassan HH. Parameters extraction of a single-diode model of photovoltaic cell using false position iterative method. J Phys: Conf Ser. 2021;1879:032113.10.1088/1742-6596/1879/3/032113Search in Google Scholar

[30] Enneffatia M, Rasheed M, Louatia B, Guidaraa K, Shihab S, Barillé R. Investigation of structural, morphology, optical properties and electrical transport conduction of Li0.25Na0.75CdVO4 compound. J Phys: Conf Ser. 2021;1795:012050.10.1088/1742-6596/1795/1/012050Search in Google Scholar

[31] Rasheed M, Shihab S, Mohammed OY, Al-Adili A. Parameters estimation of photovoltaic model using nonlinear algorithms. J Phys: Conf Ser. 2021;1795:012058.10.1088/1742-6596/1795/1/012058Search in Google Scholar

[32] Sarhan MA, Shihab S, Kashem BE, Rasheed M. New exact operational shifted pell matrices and their application in astrophysics. J Phys: Conf Ser. 2021;1879:022122.10.1088/1742-6596/1879/2/022122Search in Google Scholar

[33] Kadri E, Krichen M, Mohammed R, Zouari A, Khirouni K. Electrical transport mechanisms in amorphous silicon/crystalline silicon germanium heterojunction solar cell: impact of passivation layer in conversion efficiency. Opt Quantum Electron. 2016 Dec;48:1–5.10.1007/s11082-016-0812-7Search in Google Scholar

[34] Gharbi S, Dhahri R, Rasheed M, Dhahri E, Barille R, Rguiti M, et al. Effect of Bi substitution on nanostructural, morphologic, and electrical behavior of nanocrystalline La1–xBixNi0.5Ti0.5O3 (x = 0 and x = 0.2) for the electrical devices. Mater Sci Eng B. 2021 Aug;270:115191.10.1016/j.mseb.2021.115191Search in Google Scholar

[35] Rasheed M, Alabdali O, Shihab S. A new technique for solar cell parameters estimation of the single-diode model. J Phys: Conf Ser. 2021;1879:032120.10.1088/1742-6596/1879/3/032120Search in Google Scholar

[36] Jalal R, Shihab S, Alhadi MA, Rasheed M. Spectral numerical algorithm for solving optimal control using Boubaker-Turki operational matrices. J Phys: Conf Ser. 2020;1660:012090.10.1088/1742-6596/1660/1/012090Search in Google Scholar

[37] Rasheed M, Ali AH, Alabdali O, Shihab S, Rashid A, Rashid T, et al. The effectiveness of the finite differences method on physical and medical images based on a heat diffusion equation. J Phys: Conf Ser. 2021;1999:012080.10.1088/1742-6596/1999/1/012080Search in Google Scholar

[38] Alshalal I, Al-Zuhairi HM, Abtan AA, Rasheed M, Asmail MK. Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles. J Mech Behav Mater. 2023 Apr;32(1):20220280.10.1515/jmbm-2022-0280Search in Google Scholar

[39] Rasheed M, Barillé R. Comparison the optical properties for Bi2O3 and NiO ultrathin films deposited on different substrates by DC sputtering technique for transparent electronics. J Alloy Compd. 2017 Dec;728:1186–98.10.1016/j.jallcom.2017.09.084Search in Google Scholar

[40] Jaber AS, Ismael M, Rashid T, Sarhan MA, Rasheed M, Sala IM. Comparesion the electrical parameters of photovoltaic cell using numerical methods. EUREKA: Phys Eng. 2023 Jul 27(4):29–39.10.21303/2461-4262.2023.002770Search in Google Scholar

[41] Shihab S, Rasheed M, Alabdali O, Abdulrahman AA. A novel predictor-corrector Hally technique for determining the parameters for nonlinear solar cell equation. J Phys: Conf Ser. 2021;1879:022120.10.1088/1742-6596/1879/2/022120Search in Google Scholar

[42] Ismael M, Nillsen R, Williams G. Standard deviation of recurrence times for piecewise linear transformations. Asian-Eur J Math. 2017;10(1):1750009.10.1142/S1793557117500097Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil