Abstract

This article aims to study the simulation and design of automobile automatic clutch under mechatronics. A new control strategy for the automatic clutch of the electromagnetic transmission is proposed. The clutch mechanism model, clutch drive model, clutch system model, and internal combustion engine model are constructed. The fuzzy logic control performance of the automatic clutch was verified in different operating modes, including starting on flat roads and mountain roads. The method provides a reasonable reference for the design of an automatic clutch of electromagnetic continuously variable transmission.

1 Introduction

Clutch failure affects the quality of cars and damages the image of enterprises [1]. Clutch faults can be divided into the following types: start shaking, slipping, heavy pedal, and abnormal sound. The aforementioned faults are caused by the complicated clutch combination process, incomplete separation, and difficult control [2]. The traffic jam caused by the increasing number of cars year by year is obvious, and this also put forward higher requirements for driver’s control technology. Therefore, good control technology plays an important role in the reliability of the clutch [3]. According to the statistics, the clutch is used 8–10 times per kilometer while driving in a busy city. The frequent shift not only brings physical consumption to the driver but also brings mental burden, leading to safety risks. Therefore, it is very important to require a clutch with simple and convenient operation, low cost, and excellent performance [4]. With the rapid development of continuously variable transmission (CVT), the control method has made great progress from early mechanical control and mechanical hydraulic control to widely used electro-hydraulic control. The CVT has the unique advantage of being able to change the speed ratio simultaneously without interrupting the torque transmission. Currently, a new type of electromechanical control electromagnetic coupling continuously variable transmission (EM-CVT) is proposed, which relies on disc spring pressure to ensure the clamping force of pulley [5]. The motion of the pulley can be controlled by the speed control system, which mainly includes the motor, reduction gear, actuator, sensor, and electronic control unit (ECU). Because there is no hydraulic system, the efficiency of the new CVT can be improved by more than 10% compared to electro-hydraulic control. Therefore, EM-CVT is likely to be the development direction of the next-generation of CVT [6], as shown in Figure 1.

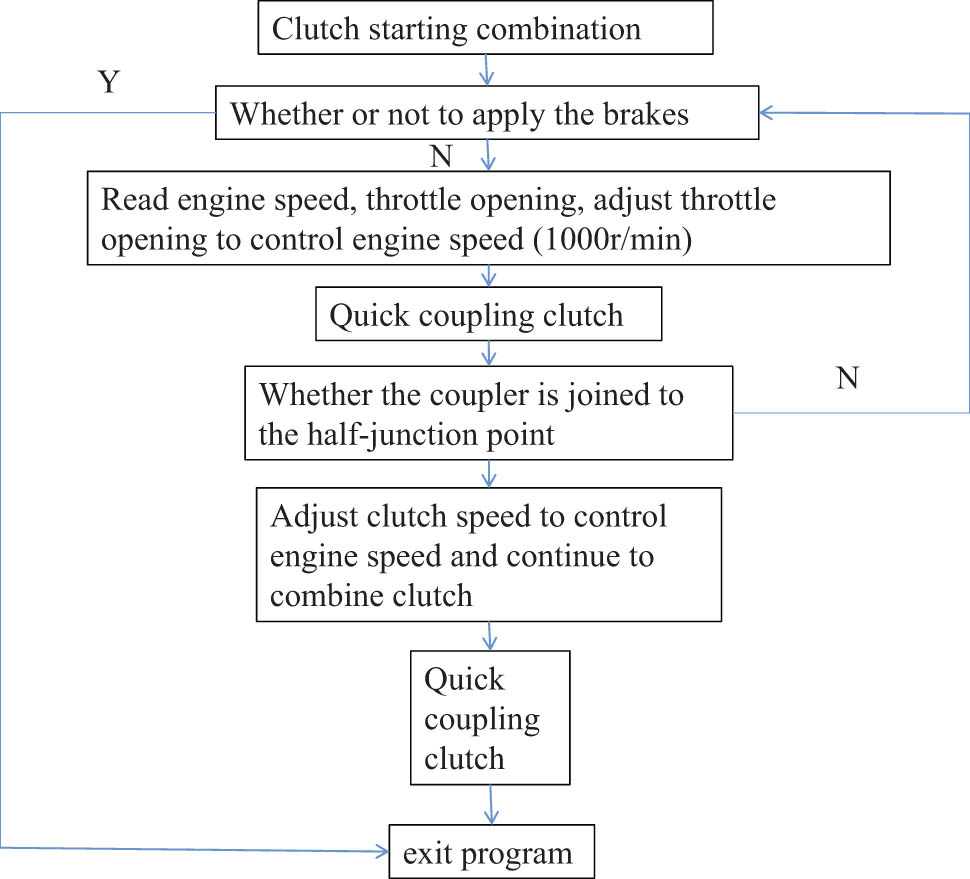

Vehicle starting current variable clutch control.

The failure diagnosis function needs to be added to the software system, so that the driver can quickly diagnose the system faults for emergency handling. The slope function helps to accommodate vehicles on mountain or hilly areas. This system performance needs to be further improved.

2 Literature review

To obtain the pulleys’ clamping force, a disc spring is used. In short, the control of clamping force can be ignored. Therefore, EM-CVT has only two control purposes as follows: (1) automatic clutch control for vehicle start and (2) control problems of EM-CVT speed control system. The new CVT expands the application range of automatic clutch and provides the large-scale application capability of automatic clutch [7].

Ompusunggu et al. used the movement of the viscosity change of the emulated reality liquid between the parallel plates to transfer power, keeping the two plates always in a slip state, and designed the Oga clutch, providing a new product with advanced technology for the realization of energy-saving fan speed regulation [8]. Kashiri et al. based on the Bingham model puts forward the theoretical design of the disc-type electrorheological clutch; puts forward the following requirements for the basic structure of the electrorheological clutch, including the clutch insulation, high pressure, sealing, and the specific selection method of plate structure spacing; and carries out the specific structural design. It has laid an important foundation for the structural research of electrorheological clutch in the future [9].

To improve driving comfort when the engine starts, Dong et al. have developed a multiphase sliding coordination control strategy to achieve sliding coordination between the disconnected clutch and the shift clutch. A detailed kinetic model of the entire power system, including the engine, p2-hybrid automatic transmission (AMT), dual-mass flywheel, electromagnetic motor, and drive resistance, was established to support the formulation of the control strategy and analyze the transient behavior of the engine start process. Joint simulation platform and control strategy were based on Simulink software. Trials were performed on plug-in hybrid electric vehicles. Simulation and experimental results show that the transmission system vibration can be effectively reduced by the slip coordination between the clutch and the shift clutch [10].

The connection control of the mechanical AMT clutch is related to the comfort, safety, and service life of the vehicle. A two-layer structure control strategy based on AMT clutch autoactuators targeting clutch engagement speed was proposed by Wang et al. The robustness of the proposed control algorithm was verified by the Joint Simulation platform (TruckSim, MATLAB/Simulink). Experimental results show that the double-layer control strategy initiation significantly improves the vehicle performance during ramp initiation [11].

A mechanism-oriented control strategy to cut off the negative damping introduction process caused by the Stribeck effect was proposed by Yuan et al. From the experimental analysis, the characteristic frequency of starting jitter is mainly concentrated around 8.25 Hz, consistent with the first-order inherent frequency of the driveline. The 13 degree of freedom powertrain branch model is established and compared with the time–frequency domain experiment results to verify the effectiveness and accuracy of the branching model reflecting the starting jitter characteristics. The mechanism of the initiating damping is profoundly revealed by the introduction of negative damping and the source of the characteristic frequencies. The positive feedback closed loop caused by the negative gradient characteristics of the Stribeck effect is the decisive factor that increases the speed fluctuation of the clutch slave plate, which is the manifestation of the negative damping. The core idea of the mechanism-oriented control strategy is to cut off the positive feedback closed loop by fine-tuning the release bearing position. Simulation and experimental results show that the proposed system shows good shake vibration suppression performance [12].

Dual-speed or multispeed AMT can significantly improve the overall handling performance of electric vehicles in terms of shift quality and energy efficiency. An automatic two-speed clutch-free electric vehicle transmission (2AT) and a motor control shift mechanism were fully designed by Liu et al. First, a new dual-speed clutch AMT using the motor control shift mechanism is designed to realize the shift action and synchronization of the driving motor and speed control; the coordinated control strategy of different shift motors are described in detail to realize fast and smooth shift and to optimize the torque trajectory with the minimum principle. Simulation and experimental results verify the correctness of the designed 2AT shift mechanism design and shift control algorithm in terms of shift response and stationarity [1].

Byun et al. aim to develop a simplified gear drive mechanism to replace manual gear transmission and make the car driver shift simple. The main goal is to automate the gear train so that the technology can be used by competent people as well as people with different capabilities to achieve low fuel consumption, leading to low carbon emissions and hence more efficient vehicles. The technique includes a proximity sensor that calculates the rotational speed of the wheel and inputs input information into the microcontroller that shifts gears by activating the corresponding clutch to change the speed of the vehicle without any manual operation [13].

To realize the lightweight of plastic replacing steel, the plastic clutch pump is studied and developed. The clutch pump body connected between the upper and lower pump bodies by friction welding process shall meet the technical requirements of withstanding 14 MPa pressure and high durability. The welding type for the end surface of the upper and lower pump bodies is proposed by Agarwal et al. The structure of the clutch pump body (upper and lower pump) is determined by the static analysis of the pump body and welding joints. According to the established welding process, the clutch pump body pressure is greater than 15 MPa, the number of high-temperature durability cycles reaches 7.210 times, and the number of room temperature durability cycles reaches 7.310 times. The results show that the structural design of the clutch pump body meets the design requirements [14].

Auto parts are subject to large power and vibration under working conditions, and they require a detailed system analysis to work properly. The clutch is one of the important components of the automobile power transmission system, with torque transfer, control, and vibration reduction characteristics. Metal helical springs are widely preferred within the clutch disc due to their durable mechanical properties to combat dynamic variables in cars. Genc et al. studied a clutch system consisting of metal spring dampers and rubber spring dampers, while observing its mechanical behavior during use. To study the dynamic characteristics of the hybrid damper in the clutch system, the torsional endurance was simulated with the functional bench test. The results show that the hybrid damper has good durability within the shock absorber torque drop range acceptable to the test vehicle test results. These results also suggest that, for midsized vehicles, the hybrid damper is an optional target vehicle comfort level [15].

To improve the shift characteristics of the AMT, the hydraulic line of the clutch must be controlled and optimized. A model-based automatic calibration method of AT clutch hydraulic pressure was proposed by Lee et al. The automatic calibration method proposed in this study aims to develop a process that automatically performs the basic adjustment of the clutch control parameters by experts currently in the transmission development stage. The calibration method consists of a simulation model, a vehicle simulation analysis algorithm, and an automatic calibration algorithm based on the optimization process, together with an iterative simulation and analysis. Simulation results show that the proposed method can successfully and effectively complete the base map drawing of the clutch hydraulic lines [16].

This article focuses on the development of electronic control strategy for an automatic clutch. Simulation results verify the rationality and feasibility of the control system. This method can be used as an important component of the overall control strategy of EM-CVT.

3 Automatic clutch system

Electronically controlled automatic clutches control motors, clutch control mechanisms, controllers, and various sensors [17,18]. The automatic charging system is structured as a worm gear reducer that reduces the motor speed and a lasso shift that rotates the clutch shift fork around a fixed fulcrum, driving the clutch sleeve to move [19,20,21]. When the motor reverses, the lasso moves to the right, and the big end of the diaphragm spring acting on the spring moves the release bearing to the left while pressing the drive disc against the flywheel [22]. The controller needs to collect the following information: internal combustion engine throttle speed, internal combustion engine speed, speed (or continuous variable transmission output shaft speed), brake pedal signal, and automatic clutch worm output angle signal [23,24]. Since most of the signal can be obtained from the vehicle controller unit, the angular displacement sensor that feeds its output angle signal to the system is installed in the worm reducer. The function of the angle signal is to control the motor trip and ensure the combined speed of the driven disk [25,26].

3.1 Mathematical model of control system

Assume that the displacement of the big end of the clutch is x, and the antidrag torque is generated by the moving rod through the lasso of the worm reduction gear. Due to the role of self-locking worm, the torque cannot transfer the motor, and the motor overcomes the static torque to drive worm and worm rotation, so that the length of the lasso changes. The change is equal to the rotation radius of the worm rotation angle [27,28].

If the control mechanism of elastic deformation is ignored, the movement of clutch disc x′ is expressed as follows:

where

The DC motor is selected as the power supply of the control mechanism, with a rated power of 120 W, a rated voltage of 12 V, and a rated speed of 3,000 rpm. In this article, the dynamic equation is combined with the DC motor and the voltage balance equation to establish a mathematical model of the motor:

where U is the armature voltage of the DC motor, e = C

e

n

d is the back electric torque of the DC motor, C

e is the voltage constant of the dc motor, R is the dc armature resistance,

3.2 Control strategy of automatic clutch system

The clutch engagement process is divided into four stages (some literature divided into three stages): During the period when the drive plate is connected to the flywheel, the clutch is in idle operation (0∼Δ); When the transmission torque of the clutch overcomes the resistance torque and the clutch driven plate starts to rotate, the clutch is in the ready engagement stage (Δ∼t 1); When the clutch driven plate is in the sliding friction state, the clutch is in the sliding stage (t 1∼t 2); When the speed of clutch driven plate (ω c) Less than flywheel speed of internal composite engine (ω e) When the clutch is fully engaged (t 2), the flywheel and driven plate rotate synchronously.

When the vehicle starts, the electronic control automatic clutch engagement is carried out as follows: the CVT shifts from neutral or parking to reverse with or without the braking signal. The Dc motor starts to spin, and the drive worm and worm gear start to spin. According to the feedback signal from the angular displacement sensor, the clutch releases the lasso until the electronically controlled automatic control clutch reaches the semi-connected position. It will prevent vehicles from skidding at the start of the ramp. Then, according to the throttle opening, the clutch will determine the driver’s intent and confirm operating conditions. In the idling operation of electronic control automatic clutch, the armature voltage age of the DC motor is the maximum value that can maximize idling operation time (δ), which can not only accelerate into the joint preparation stage but also ensure that the engaging performance of electronic control automatic clutch is not affected [25,26]. Therefore, during idle operation, the armature voltage of the DC motor maintains the rated voltage value (12 V). The drive disk is in a semi-federated transition state after an idle run. If the driver does not release the brake pedal, the DC motor’s pressure voltage is zero, the motor stops spinning, and the electronically controlled automatic clutch remains half-connected [26,30]. For electronically controlled automatic clutch engagement in the preparation and friction stages, fuzzy language is used in this article to describe the relationship between input and output as follows.

Internal combustion engine throttle opening α: (small, small, medium, and large), internal combustion engine flywheel; electronically controlled automatic clutch drive disk Δn: (large, medium and small), DC electric armature voltage U: (small, medium, and large). The fuzzy control module of the electronic control automatic clutch is constructed by using the fuzzy logic control toolbox of simulation ink. The subordinate functions and control rules are selected according to the experimental errors, which can be adjusted and modified according to the simulation and experimental results. To ensure that the engagement speed of the electronically controlled automatic clutch varies with the engagement degree, the voltage of the DC motor is decided by the opening angle (α) of the internal combustion engine throttle and the speed difference (Δn) between Uis flywheel and pole plate. The speed difference (Δn) is used to correct the voltage (U) of the motor according to the control strategy. As shown in Table 1.

DC armature voltage fuzzy control rules

| Speed, difference, voltage, throttle, opening, degree | Tiny | Small | Medium | Large |

| Large | Small | Medium | Large | Large |

| Medium | Tiny | Small | Medium | Medium |

| Small | Tiny | Tiny | Small | Small |

3.3 PID control theory

PID control theory has become one of the widely used control technologies in industrial process control after more than half a century of development. Its main advantages are simple structure, good stability, and easy to implement. The basic principle of PID control is to use proportion, differential, and integral control algorithm to reasonably calculate the system error generated by the controlled object and realize the control of the whole system. The control parameters of the PID controller are as follows:

Proportion (P) control link: When there is a deviation in the system, the link adjusts the system deviation according to a certain proportion to reduce the error [31,32]. The larger the proportional coefficient is, the shorter the response time and the smaller the steady-state error of the system are. However, if the scale coefficient is too large, the system overshoot will be too large and the system robustness will be reduced.

Differential (D) control link: Reflect the change rate of system dynamic deviation in real time to ensure the good dynamic performance of the system. The larger the differential coefficient, the smaller the overshoot of the whole system. However, if the differential coefficient is too large, the stability of the whole system will be reduced.

Integral (D control link: The steady-state error of the system can be eliminated. The larger the integral coefficient, the more obvious the integral effect, and the smaller the steady-state error of the system [12], the shorter the system response time. However, if the integral coefficient is too large, the system stability will be reduced.

Fuzzy control is based on human experience and is mainly applied to those controlled objects, which are difficult to establish an accurate mathematical model. If the specific practical experience of this experienced personnel is described and expressed in fuzzy language, it will be a qualitative and imprecise control rule “creation,” which has the following advantages:

Fuzzy control is a kind of nonlinear intelligent control method, which belongs to nonlinear control and has a wide range of applications.

There is no need to establish an accurate mathematical model for the controlled object. When a complex object cannot be modeled, people can also design a fuzzy controller by summarizing the experience of the controlled object.

The system has good robustness. The parameters in the fuzzy controller are easy to adjust and are not easily affected by the changes of the controlled object. The system shows strong robustness.

The clutch system model is discussed, and the torque transfer relationship during clutch bonding and separation is given. The performance indexes of the bonding process – shock degree and sliding work – are analyzed. This article discusses the control strategy of the starting process and the shift process, determines the clutch engagement amount and the engagement speed, and lays the theoretical foundation for the software design of the whole control system.

4 Simulation experiment analysis

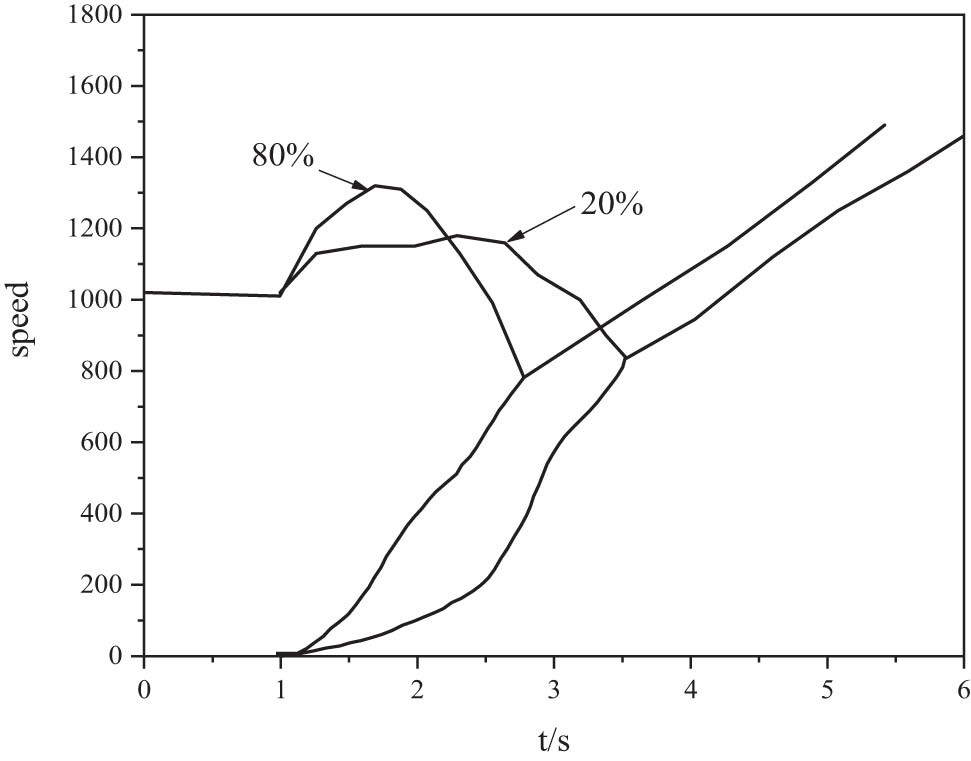

Driver operation: at 0. 5 s, CVT hangs on the forward gear, releases the hand brake (or releases the brake pedal), and opens the throttle to the pre-set target for 1 s. Figure 2 shows the simulation results of 20% and 80% throttle opening degree. This figure shows that when the throttle opening degree is small and the electronic control automatic clutch meshing time is long, the control effect of the electronic control automatic clutch meets the control requirements; otherwise, the bonding time is less than 2 s [33,34]. In the figure, the clutch position is clearly divided into three stages, reflecting the control law. At the position of reaching the initial engagement point, the transmission input shaft speed increases slowly from 0, and the speed also increases, realizing a slow start, reducing the starting impact, and ride comfort.

Simulation results of different throttle positions under flat road starting conditions.

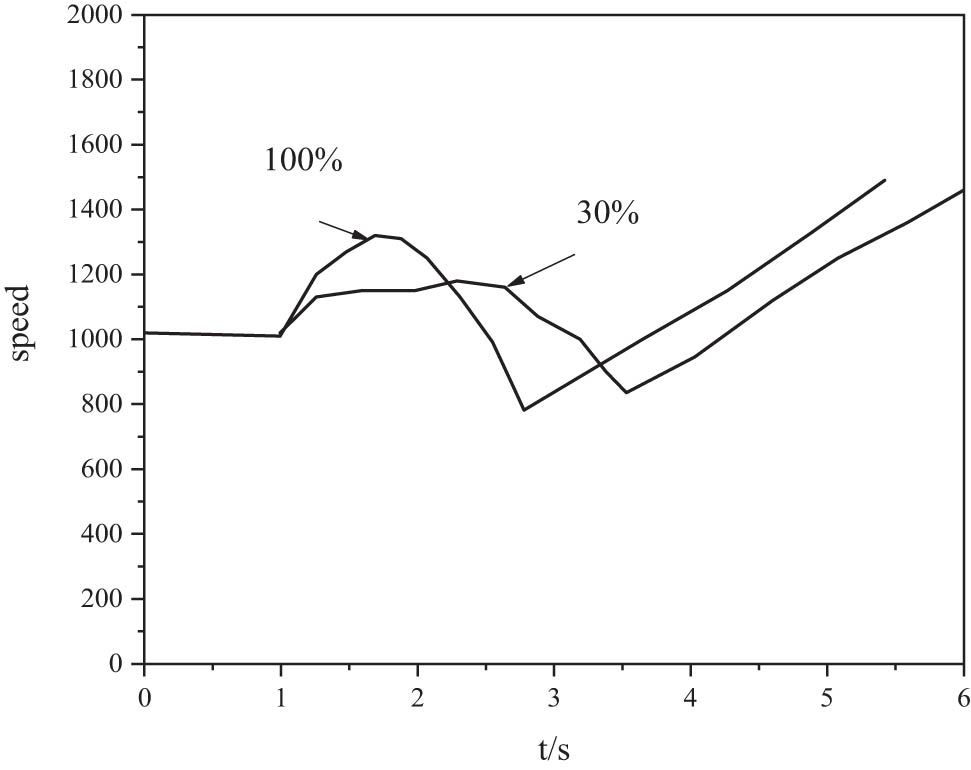

The starting point was selected for the larger starting condition, and the feasibility of the simulated electronic control automatic clutch control strategy was verified based on the starting condition of 10% slope. In contrast to ground start, mountain start should ensure that the vehicle does not slip. In the driver method of operation: the CVT is suspended from the forward gear at 0. At 1 s, the hand brake (or the brake pedal) is released. By comparing 20% with 80% throttle opening and referring to the starting condition of 20% throttle position, the internal combustion engine will keep low speed for a long time, and the state limit may cause the internal combustion engine to shut down. In this situation, the driver usually lowers the throttle position. At the same time, in the case of ramp start, if the throttle opening degree is small, the electronic control of the automatic clutch engagement time will be greater than 2.6 s, which will lead to a great friction work and make a greater wear. However, the combination of flywheel and driven disk produces little mechanical impact. Compared with the simulation results of the two starting conditions, the electronic control automatic clutch control strategy developed in this article can still meet the use of the vehicle in mountain starting conditions, although the vehicle start time lags behind, to ensure that there is no sliding when starting.

To study the response of electronically controlled automatic clutch under the condition of emergency start, two conditions were set up for simulation comparison, as shown in Figure 3. One is to go from 0 to 100% in a very short period of time. The second type is normal starting conditions where the driver increases the throttle reinforcement level from 0 to 30%. As can be seen from the figure, under the condition of emergency start, the engagement time of the electronically controlled automatic clutch is about 2 s, and it is also found that the vehicle has a large acceleration during emergency start.

Simulation of emergency and normal startup conditions.

The simulation results are shown in Table 2, and the impact degree is within the reasonable range of ride comfort requirements. Only near the semi-joint point and the synchronous instantaneous, impact of the main and driven parts of the clutch is very large, which is mainly caused by the sudden change of the clutch transmission torque at these two moments. The greater the throttle opening and the faster the change, the shorter the clutch combination time, the greater the impact, and the greater the electric field intensity. This shows that the fuzzy adaptive PID control strategy proposed in this article can ensure the ride comfort and speed requirements of the vehicle starting process under various working conditions.

The degree of impact is in the comfort

| Binding time | Maximum impact | Maximum electric field strength | |

|---|---|---|---|

| Reptile start | 1.99 | 5.03 | 2,797 |

| Start normally | 1.92 | 5.06 | 2,925 |

| Get started quickly | 1.78 | 8.94 | 3,070 |

The simulation results of the three working conditions are shown in the following table, and the impact degree is within the reasonable range of ride comfort requirements. When the half joint near the main transmission part of the clutch synchronizes instantaneously, the impact is very large, which is mainly caused by the sudden change of the transmission torque of the clutch at this moment. The greater the throttle opening degree and the faster the change, the shorter the binding time of the clutch, the greater the impact degree, and the greater the electric field strength. This shows that the fuzzy adaptive P industry D control strategy proposed in this article can ensure the ride comfort and speed requirements of the vehicle starting process under various working conditions (Table 3).

Comparison of simulation results of clutch combination process under three working conditions

| Combined with the time | Maximum impact | Maximum electric field strength | |

|---|---|---|---|

| Crawl start | 1.78 | 4.97 | 2,806 |

| Normal start | 1.69 | 4.99 | 2,799 |

| Quick start | 1.81 | 9.01 | 3,100 |

5 Conclusions

In this article, the control strategy of electronically controlled automatic clutch is put forward. According to the basic control strategy, the automatic clutch engagement speed (DC armature voltage) controlled by electronic control can match the change of driving disk position (speed difference) and driver’s intention control (throttle opening), fuzzy logic control rules are proposed, and the simulation model of electronic control automatic clutch is built by SIMU-link. The rationality and feasibility of the proposed control strategy of electronic control automatic clutch are verified by combining the conditions of ordinary smooth road starting, mountain starting, and emergency starting. The hardware design of ECU is completed, using 80C196 as the microprocessor, according to the system function and control requirements, making full use of single-chip microcomputer resources, and establishing the functional circuit modules. After this has become a power supply circuit, speed detection circuit, gear detection circuit, LCD drive circuit, and motor H bridge drive circuit design, these constitute the clutch control system hardware platform. This article provides the more reliable theoretical basis and design reference for the design of automatic clutch. This article focuses on the development of electric control automatic clutch control strategy. Simulation results verify the rationality and feasibility of the proposed control system. The proposed method can be used as an important component of the overall control strategy of EM-CVt.

-

Funding information: This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

-

Conflict of interest: Authors state no conflict of interest.

-

Informed consent: Informed consent was obtained from all individuals included in this study.

-

Data availability statement: The datasets and stimuli of this study are available upon reasonable request from the corresponding author.

References

[1] Liu Y, Xie J, Qin D, Zhang Y, Zhang Y. Design, control and validation of two-speed clutch-less automatic transmission for electric vehicle. IEEE/ASME Trans Mechatron. 2021;99:1.10.1109/TMECH.2021.3057098Search in Google Scholar

[2] Li L, Wang X, Qi X, Li X, Cao D, Zhu Z. Automatic clutch control based on estimation of resistance torque for amt. IEEE/ASME Trans Mechatron. 2016;21(6):2682–93.10.1109/TMECH.2016.2517088Search in Google Scholar

[3] Zhang T, Huang H. Design and control of a series elastic actuator with clutch for hip exoskeleton for precise assistive magnitude and timing control and improved mechanical safety. IEEE/ASME Trans Mechatron. 2019;24(5):2215–26.10.1109/TMECH.2019.2932312Search in Google Scholar

[4] Zeghloul S, Laribi MA, Gazeau JP. Design and simulation of robot manipulator position control system based on adaptive fuzzy PID controller. Mech Mach Sci Robot Mechatron. 2016;37:243–50. 10.1007/978-3-319-22368-1. (Chapter 24).Search in Google Scholar

[5] Huang C, Wang X, Li L, Chen X. Multi-structure radial basis function neural networks based extended model predictive control: Application to clutch control. IEEE/ASME Trans Mechatron. 2019;24(6):2519–30.10.1109/TMECH.2019.2949001Search in Google Scholar

[6] Oh JJ, Kim J, Choi SB. Design of self-energizing clutch actuator for dual-clutch transmission. IEEE/ASME Trans Mechatron. 2016;21(2):795–805.10.1109/TMECH.2015.2474855Search in Google Scholar

[7] Temporelli R, Boisvert M, Micheau P. Accurate clutch slip controllers during vehicle steady and acceleration states. IEEE/ASME Trans Mechatron. 2018;23(5):2078–89.10.1109/TMECH.2018.2867281Search in Google Scholar

[8] Ompusunggu AP, Papy JM, Vandenplas S. Kalman-filtering-based prognostics for automatic transmission clutches. IEEE/ASME Trans Mechatron. 2016;21(1):419–30.10.1109/TMECH.2015.2440331Search in Google Scholar

[9] Kashiri N, Laffranchi M, Caldwell DG, Tsagarakis NG. Dynamics and control of an anthropomorphic compliant arm equipped with friction clutches. IEEE/ASME Trans Mechatron. 2016;21(2):694–707.10.1109/TMECH.2015.2497200Search in Google Scholar

[10] Dong P, Wu S, Guo W, Xu X, Liu Y. Coordinated clutch slip control for the engine start of vehicles with p2-hybrid automatic transmissions. Mech Mach Theory. 2020;153(3):103899.10.1016/j.mechmachtheory.2020.103899Search in Google Scholar

[11] Wang H, Wang B, Pi D, Wang E, Wang X. Two-layer structure control of an automatic mechanical transmission clutch during hill start for heavy-duty vehicles. IEEE Access. 2020;8:49617–28.10.1109/ACCESS.2020.2979901Search in Google Scholar

[12] Yuan R, Wu G, Shao C, Su S. Mechanism-oriented control for suppressing start-up judder of vehicle with automatic dry clutch: experiment and simulation analysis. Proc Inst Mech Eng Part D J Automob Eng. 2020;235(2–3):095440702094947.10.1177/0954407020949479Search in Google Scholar

[13] Byun J, Lim W, Park J, Park SC, Kim K. Dynamic load analysis of the lock-up clutch damper spring of automatic transmission. Trans Korean Soc Automot Eng. 2020;28(10):711–9.10.7467/KSAE.2020.28.10.711Search in Google Scholar

[14] Agarwal A, Chauhan P, Sharma S. An elementary electromagnetic automatic gear transmission in automobiles. Int J Adv Res Eng Technol. 2020;7(4):1–7.Search in Google Scholar

[15] Genc MO, Kaya N, Konak S, Imer C. Experimental investigation of the hybrid damper clutch system under dynamic conditions of an automobile powertrain. J Mech Sci Technol. 2021;5(2):44–50.10.26701/ems.751149Search in Google Scholar

[16] Lee H, Gu B, Cha SW, Lim W. Model based automated calibration for shift control of automatic transmission. Int J Automot Technol. 2021;22(2):269–80.10.1007/s12239-021-0026-2Search in Google Scholar

[17] Rogkas N, Vakouftsis C, Vasileiou G, Manopoulos C, Spitas V. Nondimensional characterization of the operational envelope of a wet friction clutch. Computation. 2020;8(1):21.10.3390/computation8010021Search in Google Scholar

[18] Li J, Zhang Y, Wang X, Gu J, Tao L. Influence upon temperature field distribution with straight grooves parameters of clutch friction disk. Proc Inst Mech Eng Part D J Automob Eng. 2020;234(9):095440702091340.10.1177/0954407020913408Search in Google Scholar

[19] Li G, Grges D. Optimal integrated energy management and shift control in parallel hybrid electric vehicles with dual-clutch transmission. Proc Inst Mech Eng Part D J Automob Eng. 2020;234(2–3):599–609.10.1177/0954407019857419Search in Google Scholar

[20] Wang Y, Chen G, Jiang Y. A novel evaluation method for vehicle and traffic performance of different decision control of automatic lane change based on miniature model. Proc Inst Mech Eng Part D J Automob Eng. 2020;234(4):095440702091957.10.1177/0954407020919578Search in Google Scholar

[21] Dong P, Wang Y, Zhao S, Gao Z, Zhang P. Design and experimental study of novel multi-stage gearbox. Proc Inst Mech Eng Part D J Automob Eng. 2020;235(1):095440702094582.10.1177/0954407020945823Search in Google Scholar

[22] Pozzato G, Strada SC, Tanelli M, Savaresi SM, Dambach G. Mems-enabled retrofitting of automobile wheel balancer for automatic unbalance detection. IEEE/ASME Trans Mechatron. 2020;26(2):830–40.10.1109/TMECH.2020.3004372Search in Google Scholar

[23] Seo Y, Hong S, Jung D, Chung N. A study on the performance restoration of torque converters for passenger car 6-speed automatic transmissions with remanufacturing process technology. Int J Automot Technol. 2020;21(4):1061–70.10.1007/s12239-020-0100-1Search in Google Scholar

[24] Rao KS, Srinatha S. Development of a working prototype model of a pollution free automobile. Test Eng Manag. 2020;83:6911–5.Search in Google Scholar

[25] Guo J, Wang J, Luo Y, Li K. Takagi-sugeno fuzzy-based robust h∞ integrated lane-keeping and direct yaw moment controller of unmanned electric vehicles. IEEE/ASME Trans Mechatron. 2020;26(4):2151–62.10.1109/TMECH.2020.3032998Search in Google Scholar

[26] Shiotsu I, Tani H, Kimura M, Nozawa Y, Honda A, Tabuchi M, et al. Development of high efficiency dog clutch with one-way mechanism for stepped automatic transmissions. Int J Automot Eng. 2019;10(2):156–61.10.20485/jsaeijae.10.2_156Search in Google Scholar

[27] Kou B, Huo P, Hou X. Research on the influence of external parameters of fan-type nozzle on water jet performance. Shock Vib. 2020;2020(s1):1–16.10.1155/2020/4386259Search in Google Scholar

[28] Zhang Z, Zou L, Hai Q. Analysis of factors affecting vibration during wet clutch engagement. IEEE Access. 2021;9:34298–306.10.1109/ACCESS.2021.3061009Search in Google Scholar

[29] Martini DD, Facchinetti T. Fault detection of electromechanical actuators via automatic generation of a fuzzy index. IEEE/ASME Trans Mechatron. 2020;25(5):2197–207.10.1109/TMECH.2020.3011005Search in Google Scholar

[30] Sutisna NA, Firmansyah RA. Design of automatic stamping machine for date and dash code marking using pneumatic system and plc controller. J Mech Eng Mechatron. 2019;3(1):40.10.33021/jmem.v3i1.536Search in Google Scholar

[31] Shevchenko DV, Kudryavtsev MA, Orlova AM, Ponomare V SA, Savushkina YV. Numerical modeling of the dynamics of the clutch couplers. Vestn Railw Res Inst. 2019;78(3):155–61.10.21780/2223-9731-2019-78-3-155-161Search in Google Scholar

[32] Ren X, Li C, Ma X, Chen F, Wang H, Sharma A, et al. Design of multi-information fusion based intelligent electrical fire detection system for green buildings. Sustainability. 2021;13(6):3405.10.3390/su13063405Search in Google Scholar

[33] Liu Z, Wu J, Wang L, Zhang B. Control parameters design based on dynamic characteristics of a hybrid robot with parallelogram structures. IEEE/ASME Trans Mechatron. 2020;26(2):1140–50.10.1109/TMECH.2020.3019424Search in Google Scholar

[34] Huang P, Shan W, Xu W, Tan W, Zhang Z. Motion compensation method of an imaging radar based on unmanned automobile. J Eng. 2019;2019(19):6170–4.10.1049/joe.2019.0214Search in Google Scholar

© 2022 Chao Chen et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Construction of 3D model of knee joint motion based on MRI image registration

- Evaluation of several initialization methods on arithmetic optimization algorithm performance

- Application of visual elements in product paper packaging design: An example of the “squirrel” pattern

- Deep learning approach to text analysis for human emotion detection from big data

- Cognitive prediction of obstacle's movement for reinforcement learning pedestrian interacting model

- The application of neural network algorithm and embedded system in computer distance teach system

- Machine translation of English speech: Comparison of multiple algorithms

- Automatic control of computer application data processing system based on artificial intelligence

- A secure framework for IoT-based smart climate agriculture system: Toward blockchain and edge computing

- Application of mining algorithm in personalized Internet marketing strategy in massive data environment

- On the correction of errors in English grammar by deep learning

- Research on intelligent interactive music information based on visualization technology

- Extractive summarization of Malayalam documents using latent Dirichlet allocation: An experience

- Conception and realization of an IoT-enabled deep CNN decision support system for automated arrhythmia classification

- Masking and noise reduction processing of music signals in reverberant music

- Cat swarm optimization algorithm based on the information interaction of subgroup and the top-N learning strategy

- State feedback based on grey wolf optimizer controller for two-wheeled self-balancing robot

- Research on an English translation method based on an improved transformer model

- Short-term prediction of parking availability in an open parking lot

- PUC: parallel mining of high-utility itemsets with load balancing on spark

- Image retrieval based on weighted nearest neighbor tag prediction

- A comparative study of different neural networks in predicting gross domestic product

- A study of an intelligent algorithm combining semantic environments for the translation of complex English sentences

- IoT-enabled edge computing model for smart irrigation system

- A study on automatic correction of English grammar errors based on deep learning

- A novel fingerprint recognition method based on a Siamese neural network

- A hidden Markov optimization model for processing and recognition of English speech feature signals

- Crime reporting and police controlling: Mobile and web-based approach for information-sharing in Iraq

- Convex optimization for additive noise reduction in quantitative complex object wave retrieval using compressive off-axis digital holographic imaging

- CRNet: Context feature and refined network for multi-person pose estimation

- Improving the efficiency of intrusion detection in information systems

- Research on reform and breakthrough of news, film, and television media based on artificial intelligence

- An optimized solution to the course scheduling problem in universities under an improved genetic algorithm

- An adaptive RNN algorithm to detect shilling attacks for online products in hybrid recommender system

- Computing the inverse of cardinal direction relations between regions

- Human-centered artificial intelligence-based ice hockey sports classification system with web 4.0

- Construction of an IoT customer operation analysis system based on big data analysis and human-centered artificial intelligence for web 4.0

- An improved Jaya optimization algorithm with ring topology and population size reduction

- Review Articles

- A review on voice pathology: Taxonomy, diagnosis, medical procedures and detection techniques, open challenges, limitations, and recommendations for future directions

- An extensive review of state-of-the-art transfer learning techniques used in medical imaging: Open issues and challenges

- Special Issue: Explainable Artificial Intelligence and Intelligent Systems in Analysis For Complex Problems and Systems

- Tree-based machine learning algorithms in the Internet of Things environment for multivariate flood status prediction

- Evaluating OADM network simulation and an overview based metropolitan application

- Radiography image analysis using cat swarm optimized deep belief networks

- Comparative analysis of blockchain technology to support digital transformation in ports and shipping

- IoT network security using autoencoder deep neural network and channel access algorithm

- Large-scale timetabling problems with adaptive tabu search

- Eurasian oystercatcher optimiser: New meta-heuristic algorithm

- Trip generation modeling for a selected sector in Baghdad city using the artificial neural network

- Trainable watershed-based model for cornea endothelial cell segmentation

- Hessenberg factorization and firework algorithms for optimized data hiding in digital images

- The application of an artificial neural network for 2D coordinate transformation

- A novel method to find the best path in SDN using firefly algorithm

- Systematic review for lung cancer detection and lung nodule classification: Taxonomy, challenges, and recommendation future works

- Special Issue on International Conference on Computing Communication & Informatics

- Edge detail enhancement algorithm for high-dynamic range images

- Suitability evaluation method of urban and rural spatial planning based on artificial intelligence

- Writing assistant scoring system for English second language learners based on machine learning

- Dynamic evaluation of college English writing ability based on AI technology

- Image denoising algorithm of social network based on multifeature fusion

- Automatic recognition method of installation errors of metallurgical machinery parts based on neural network

- An FCM clustering algorithm based on the identification of accounting statement whitewashing behavior in universities

- Emotional information transmission of color in image oil painting

- College music teaching and ideological and political education integration mode based on deep learning

- Behavior feature extraction method of college students’ social network in sports field based on clustering algorithm

- Evaluation model of multimedia-aided teaching effect of physical education course based on random forest algorithm

- Venture financing risk assessment and risk control algorithm for small and medium-sized enterprises in the era of big data

- Interactive 3D reconstruction method of fuzzy static images in social media

- The impact of public health emergency governance based on artificial intelligence

- Optimal loading method of multi type railway flatcars based on improved genetic algorithm

- Special Issue: Evolution of Smart Cities and Societies using Emerging Technologies

- Data mining applications in university information management system development

- Implementation of network information security monitoring system based on adaptive deep detection

- Face recognition algorithm based on stack denoising and self-encoding LBP

- Research on data mining method of network security situation awareness based on cloud computing

- Topology optimization of computer communication network based on improved genetic algorithm

- Implementation of the Spark technique in a matrix distributed computing algorithm

- Construction of a financial default risk prediction model based on the LightGBM algorithm

- Application of embedded Linux in the design of Internet of Things gateway

- Research on computer static software defect detection system based on big data technology

- Study on data mining method of network security situation perception based on cloud computing

- Modeling and PID control of quadrotor UAV based on machine learning

- Simulation design of automobile automatic clutch based on mechatronics

- Research on the application of search algorithm in computer communication network

- Special Issue: Artificial Intelligence based Techniques and Applications for Intelligent IoT Systems

- Personalized recommendation system based on social tags in the era of Internet of Things

- Supervision method of indoor construction engineering quality acceptance based on cloud computing

- Intelligent terminal security technology of power grid sensing layer based upon information entropy data mining

- Deep learning technology of Internet of Things Blockchain in distribution network faults

- Optimization of shared bike paths considering faulty vehicle recovery during dispatch

- The application of graphic language in animation visual guidance system under intelligent environment

- Iot-based power detection equipment management and control system

- Estimation and application of matrix eigenvalues based on deep neural network

- Brand image innovation design based on the era of 5G internet of things

- Special Issue: Cognitive Cyber-Physical System with Artificial Intelligence for Healthcare 4.0.

- Auxiliary diagnosis study of integrated electronic medical record text and CT images

- A hybrid particle swarm optimization with multi-objective clustering for dermatologic diseases diagnosis

- An efficient recurrent neural network with ensemble classifier-based weighted model for disease prediction

- Design of metaheuristic rough set-based feature selection and rule-based medical data classification model on MapReduce framework

Articles in the same Issue

- Research Articles

- Construction of 3D model of knee joint motion based on MRI image registration

- Evaluation of several initialization methods on arithmetic optimization algorithm performance

- Application of visual elements in product paper packaging design: An example of the “squirrel” pattern

- Deep learning approach to text analysis for human emotion detection from big data

- Cognitive prediction of obstacle's movement for reinforcement learning pedestrian interacting model

- The application of neural network algorithm and embedded system in computer distance teach system

- Machine translation of English speech: Comparison of multiple algorithms

- Automatic control of computer application data processing system based on artificial intelligence

- A secure framework for IoT-based smart climate agriculture system: Toward blockchain and edge computing

- Application of mining algorithm in personalized Internet marketing strategy in massive data environment

- On the correction of errors in English grammar by deep learning

- Research on intelligent interactive music information based on visualization technology

- Extractive summarization of Malayalam documents using latent Dirichlet allocation: An experience

- Conception and realization of an IoT-enabled deep CNN decision support system for automated arrhythmia classification

- Masking and noise reduction processing of music signals in reverberant music

- Cat swarm optimization algorithm based on the information interaction of subgroup and the top-N learning strategy

- State feedback based on grey wolf optimizer controller for two-wheeled self-balancing robot

- Research on an English translation method based on an improved transformer model

- Short-term prediction of parking availability in an open parking lot

- PUC: parallel mining of high-utility itemsets with load balancing on spark

- Image retrieval based on weighted nearest neighbor tag prediction

- A comparative study of different neural networks in predicting gross domestic product

- A study of an intelligent algorithm combining semantic environments for the translation of complex English sentences

- IoT-enabled edge computing model for smart irrigation system

- A study on automatic correction of English grammar errors based on deep learning

- A novel fingerprint recognition method based on a Siamese neural network

- A hidden Markov optimization model for processing and recognition of English speech feature signals

- Crime reporting and police controlling: Mobile and web-based approach for information-sharing in Iraq

- Convex optimization for additive noise reduction in quantitative complex object wave retrieval using compressive off-axis digital holographic imaging

- CRNet: Context feature and refined network for multi-person pose estimation

- Improving the efficiency of intrusion detection in information systems

- Research on reform and breakthrough of news, film, and television media based on artificial intelligence

- An optimized solution to the course scheduling problem in universities under an improved genetic algorithm

- An adaptive RNN algorithm to detect shilling attacks for online products in hybrid recommender system

- Computing the inverse of cardinal direction relations between regions

- Human-centered artificial intelligence-based ice hockey sports classification system with web 4.0

- Construction of an IoT customer operation analysis system based on big data analysis and human-centered artificial intelligence for web 4.0

- An improved Jaya optimization algorithm with ring topology and population size reduction

- Review Articles

- A review on voice pathology: Taxonomy, diagnosis, medical procedures and detection techniques, open challenges, limitations, and recommendations for future directions

- An extensive review of state-of-the-art transfer learning techniques used in medical imaging: Open issues and challenges

- Special Issue: Explainable Artificial Intelligence and Intelligent Systems in Analysis For Complex Problems and Systems

- Tree-based machine learning algorithms in the Internet of Things environment for multivariate flood status prediction

- Evaluating OADM network simulation and an overview based metropolitan application

- Radiography image analysis using cat swarm optimized deep belief networks

- Comparative analysis of blockchain technology to support digital transformation in ports and shipping

- IoT network security using autoencoder deep neural network and channel access algorithm

- Large-scale timetabling problems with adaptive tabu search

- Eurasian oystercatcher optimiser: New meta-heuristic algorithm

- Trip generation modeling for a selected sector in Baghdad city using the artificial neural network

- Trainable watershed-based model for cornea endothelial cell segmentation

- Hessenberg factorization and firework algorithms for optimized data hiding in digital images

- The application of an artificial neural network for 2D coordinate transformation

- A novel method to find the best path in SDN using firefly algorithm

- Systematic review for lung cancer detection and lung nodule classification: Taxonomy, challenges, and recommendation future works

- Special Issue on International Conference on Computing Communication & Informatics

- Edge detail enhancement algorithm for high-dynamic range images

- Suitability evaluation method of urban and rural spatial planning based on artificial intelligence

- Writing assistant scoring system for English second language learners based on machine learning

- Dynamic evaluation of college English writing ability based on AI technology

- Image denoising algorithm of social network based on multifeature fusion

- Automatic recognition method of installation errors of metallurgical machinery parts based on neural network

- An FCM clustering algorithm based on the identification of accounting statement whitewashing behavior in universities

- Emotional information transmission of color in image oil painting

- College music teaching and ideological and political education integration mode based on deep learning

- Behavior feature extraction method of college students’ social network in sports field based on clustering algorithm

- Evaluation model of multimedia-aided teaching effect of physical education course based on random forest algorithm

- Venture financing risk assessment and risk control algorithm for small and medium-sized enterprises in the era of big data

- Interactive 3D reconstruction method of fuzzy static images in social media

- The impact of public health emergency governance based on artificial intelligence

- Optimal loading method of multi type railway flatcars based on improved genetic algorithm

- Special Issue: Evolution of Smart Cities and Societies using Emerging Technologies

- Data mining applications in university information management system development

- Implementation of network information security monitoring system based on adaptive deep detection

- Face recognition algorithm based on stack denoising and self-encoding LBP

- Research on data mining method of network security situation awareness based on cloud computing

- Topology optimization of computer communication network based on improved genetic algorithm

- Implementation of the Spark technique in a matrix distributed computing algorithm

- Construction of a financial default risk prediction model based on the LightGBM algorithm

- Application of embedded Linux in the design of Internet of Things gateway

- Research on computer static software defect detection system based on big data technology

- Study on data mining method of network security situation perception based on cloud computing

- Modeling and PID control of quadrotor UAV based on machine learning

- Simulation design of automobile automatic clutch based on mechatronics

- Research on the application of search algorithm in computer communication network

- Special Issue: Artificial Intelligence based Techniques and Applications for Intelligent IoT Systems

- Personalized recommendation system based on social tags in the era of Internet of Things

- Supervision method of indoor construction engineering quality acceptance based on cloud computing

- Intelligent terminal security technology of power grid sensing layer based upon information entropy data mining

- Deep learning technology of Internet of Things Blockchain in distribution network faults

- Optimization of shared bike paths considering faulty vehicle recovery during dispatch

- The application of graphic language in animation visual guidance system under intelligent environment

- Iot-based power detection equipment management and control system

- Estimation and application of matrix eigenvalues based on deep neural network

- Brand image innovation design based on the era of 5G internet of things

- Special Issue: Cognitive Cyber-Physical System with Artificial Intelligence for Healthcare 4.0.

- Auxiliary diagnosis study of integrated electronic medical record text and CT images

- A hybrid particle swarm optimization with multi-objective clustering for dermatologic diseases diagnosis

- An efficient recurrent neural network with ensemble classifier-based weighted model for disease prediction

- Design of metaheuristic rough set-based feature selection and rule-based medical data classification model on MapReduce framework