Abstract

Fiberglass-reinforced plastics (FRP) composite materials for ships that are widely used are marine-grade unsaturated polyester resin matrix and combimat fiber, a combination of marine-grade chopped strand mat (CSM) and woven roving (WR) fibers. Although less popular than marine CSM–WR, marine biaxial warp-knitted glass fabrics have the potential to be applied as fiber laminates for ship hull materials. A comparative study of tensile and bending strength between marine CSM–WR composite and marine CSM–biaxial composite had been conducted. All composites met the criteria of the Indonesian Classification Bureau. Specifically, the CSM–biaxial had higher tensile and flexural strength with fewer laminations than the CSM–WR. Laminate type II had the highest average normalized tensile and flexural strength, 186.1 and 319.2 MPa. A layer of biaxial fiberglass had a very significant effect on tensile and flexural strength. Besides its strength, fewer type II laminations can speed up the production process of FRP ship hulls. Furthermore, the CSM–biaxial composite had relatively high normalized flexural strength compared to other references. However, the normalized tensile strength achieved in this study was at an intermediate level compared to other references.

1 Introduction

Archipelagic countries need small vessels of various types, such as patrol boats [1], fishing boats [2], and small inter-island passenger boats [3]. Ships for this function generally use fiberglass-reinforced plastics (FRP) materials because FRP materials have easy manufacturing techniques, flexible geometries and shapes, fairly good material durability, corrosion resistance, and a high strength-to-weight ratio [4]. Furthermore, this lightweight FRP material has an impact on high payload, which is expected to be able to transport more goods in one trip, resulting in cost savings for ship owners and lower pollution, which supports the international maritime organization target of reducing greenhouse gas emissions by 50% in 2050 [5,6]. Compared to ships made of aluminum which are also light, FRP shipyards do not require significant investments, the technology is simple, the construction is lightweight, and it does not require high qualifications of the worker.

The most widely used FRP composite materials for ships are the matrix in the form of marine-graded unsaturated polyester resin (UPR) and combimat fiber which is a combination of marine-grade chopped strand mat (CSM) fibers and marine-grade woven roving (WR) [7]. Although less popular than conventional fibers (CSM–WR), biaxial warp-knitted glass fabrics have the potential to be applied as fibers for ship hull composite materials due to their high modulus of elasticity and good delamination resistance. FRP with biaxial fiber warp-knitted glass fabrics has high strength, stiffness, and yarn utilization efficiency [8].

Biaxial warp-knitted glass fabrics have good structural integrity, flexible design, high tear resistance, and improved through-the-thickness strength [9]. Biaxial warp-knitted glass fabric composite has been fabricated by the vacuum-assisted resin transfer molding method. FRP biaxial composite showed higher tensile and flexural strength than FRP quadriaxial composite [10]. Furthermore, composite materials with warp-knitted fabric were reported to have higher tensile strength and tensile modulus compared to weft fabric-reinforced composite due to their interlocking of the yarns from the consecutive yarn [11]. FRP biaxial composite has been studied on the effect of stitch and biaxial yarn types on tensile, bending, and impact properties [12].

The tensile and flexural behavior of composites with multiaxial fibers has been studied. Biaxial fiber, included in the multiaxial fiber group, has superior strength due to straight fiber bundles [13]. Bending and impact properties of biaxial composite FRP have been investigated, where better mechanical properties can be achieved by using aramid stitch yarn with a combination of glass warp and glass weft yarns [14]. Biaxial fiberglass composite has been tested for tensile and flexural. Composites with multiwalled carbon nanotubes showed a 3% increase in tensile strength and 65% flexural strength compared to composites without multiwalled carbon nanotubes [15]. An experimental study of the tensile and flexural properties of the biaxial warp-knitted fiberglass composite has been carried out. The study shows that the stacking configuration of fabric layers affects the performance of tensile and flexural properties [16]. The failure mechanism and deformation behavior of the biaxial warp-knitted flexible composite have been investigated. The tensile failure has two failure modes: fiber fracture and tensile-shearing mixed failure [17]. Gao et al. have studied the tensile and flexural behavior of various types of multiaxial warp-knitted fiberglass composites [18]. Still, the mechanical properties of composites with multiaxial fibers and conventional fibers (CSM and WR) have not been studied in a comparative study.

Most studies on biaxial composites are developed for general applications, even though applications on ships must meet specific class/standard criteria. Fojtl et al. performed a flexural test on a biaxial glass fabric composite for front-end cab application [19]. Biaxial fiberglass-reinforced vinyl ester composites have been subjected to tensile and flexural tests for application in marine environments, but the lamination arrangement, acceptance of certain ship structure standards, and marine-grade materials used have not been very clearly stated [20], making it difficult for FRP shipyards to reproduce ship based on this research. Bonded reinforcement elements for the application of yacht decks have been studied but have not used biaxial glass fabric [21]. Composites for marine applications have been investigated, but the fibers used are CSM, WR, and unidirectional fiberglass [7].

From the various studies on the biaxial composite, strength studies of the matrix in the form of marine-grade UPR combined with biaxial marine fiber for ship applications are still limited. However, composites with biaxial fibers have very interesting potential to be applied as ship materials. In addition, not much literature discusses comparative studies of strength between marine-grade FRP composites with biaxial fibers and marine-grade FRP composites with CSM and WR fibers. For Indonesia, ship FRP materials must meet the tensile and flexural strength criteria set by the Indonesian Classification Bureau to ensure the strength and safety of ships [22].

Therefore, comparative studies of tensile and bending strength between marine-grade CSM–WR composites and marine-grade biaxial composites need to be carried out. Tensile and bending strength must meet the criteria of the Indonesian Classification Bureau so that a material composition can be applied to shipyards in Indonesia. An experimental study was conducted to determine the effect of UPR type, laminate arrangement, and fiber orientation on normalized tensile and flexural strength. A comprehensive review of normalized tensile and flexural strength from various references is also compared with the tensile and flexural strength achieved in this study.

2 Materials and methods

This experimental study aims to compare the tensile and bending strength between marine-grade CSM–WR composites and marine-grade biaxial composites. Section 2 provides an explanation of the materials used in specimen preparation and the methods employed for the uniaxial tensile and three-point flexure tests to address the research objective mentioned above.

2.1 Material development

In this study, FRP composites were developed for ship hulls using marine-grade UPR. UPR has good mechanical properties, low in weight, non-corrosive, and less costly than epoxy resin [23], making it very suitable for FRP ship hull applications. The matrix has been formed from different marine-grade UPR brands, namely Yukalac 157 BQTN-EX (UPR brand A), which was supplied by PT. Justus Sakti Raya, Indonesia, and Everpol 324 AR-1 (UPR brand B) purchased from PT. Arindo Pacific Chemicals, Indonesia. Both brands are commonly used in FRP shipyards in Indonesia and have been approved by the Indonesian Classification Bureau (BKI) with material characteristics, as shown in Table 1. UPR A and B have similar specific gravity, tensile and flexural strength, but the viscosity is different, UPR A is 450–500 cps, and UPR B is 540 cps. Methyl ethyl ketone peroxide as a curing agent was obtained from PT. Kawaguchi Kimia Indonesia. Methyl ethyl ketone peroxide was added 5% by weight of the resin to help initiate the hardening process and control the pot life, gel time, and curing time in the fiber lamination process.

Material characteristics of marine-grade UPR brands A and B

| Properties | Marine-grade UPR brand A | Marine-grade UPR brand B |

|---|---|---|

| Specific gravity (g/cm3) | 1.1 ± 0.02 | 1.1–1.2 |

| Tensile strength (MPa) | 54 | 55 |

| Flexural strength (MPa) | 92 | 95 |

| Viscosity (cps) | 450–500 | 540 |

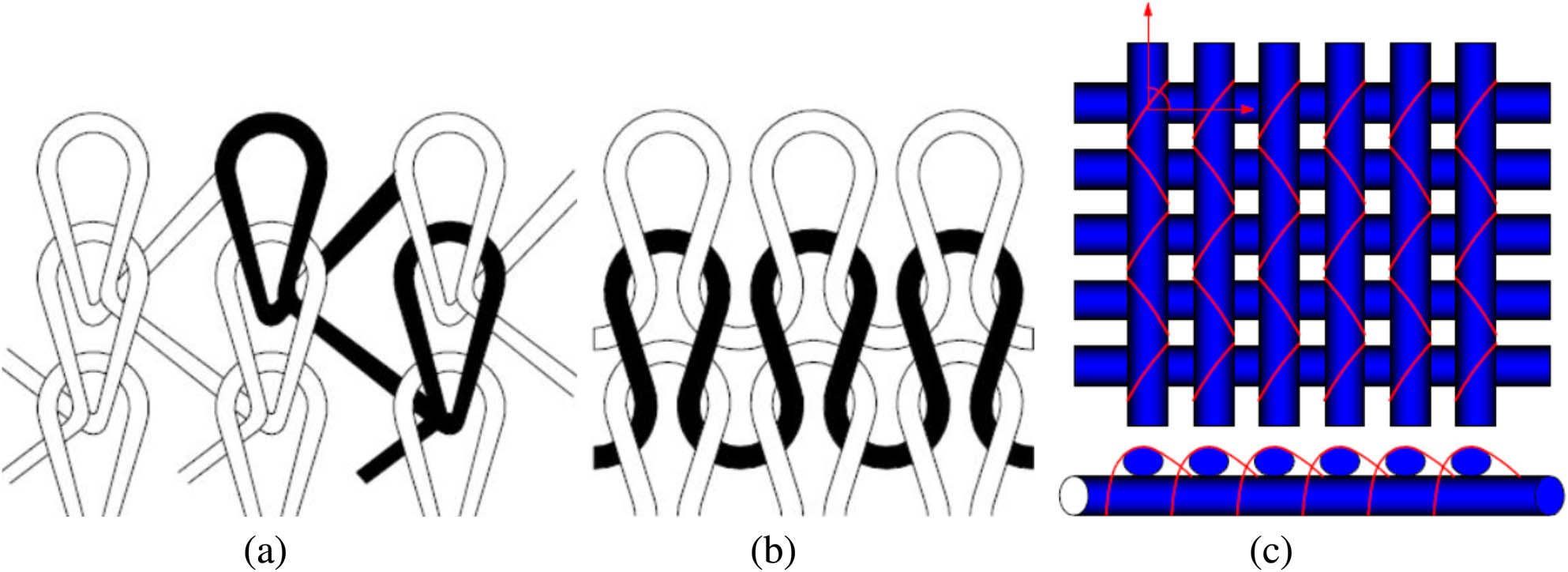

The types of fiberglass used in this study were Chopped Strand Mat 300 g/m2 (CSM 300), Chopped Strand Mat 450 g/m2 (CSM 450), Woven Roving 600 g/m2 (WR 600), Woven Roving 800 g/m2 (WR 800), biaxial warp-knitted fabrics 800 g/m2 (Biaxial 800), double biaxial warp-knitted fabrics 800 g/m2 (DB 800), and double biaxial warp-knitted fabrics 800 g/m2 (DB 800/M225E). CSM and WR fiberglass fibers are supplied from PT. Justus Sakti Raya, Indonesia, while the Biaxial 800, DB 800, and DB 800/M225E fiberglass fibers were purchased from PT. Triaxis Composites, Indonesia. The Indonesian Classification Bureau (BKI) has approved all types of fiberglass fibers above. Warp- and weft-knitted structures [11], including stitch yarn on a biaxial warp-knitted fabric [24], are illustrated in Figure 1.

(a) Warp-knitted structures, (b) weft-knitted structures, and (c) biaxial warp-knitted fabric.

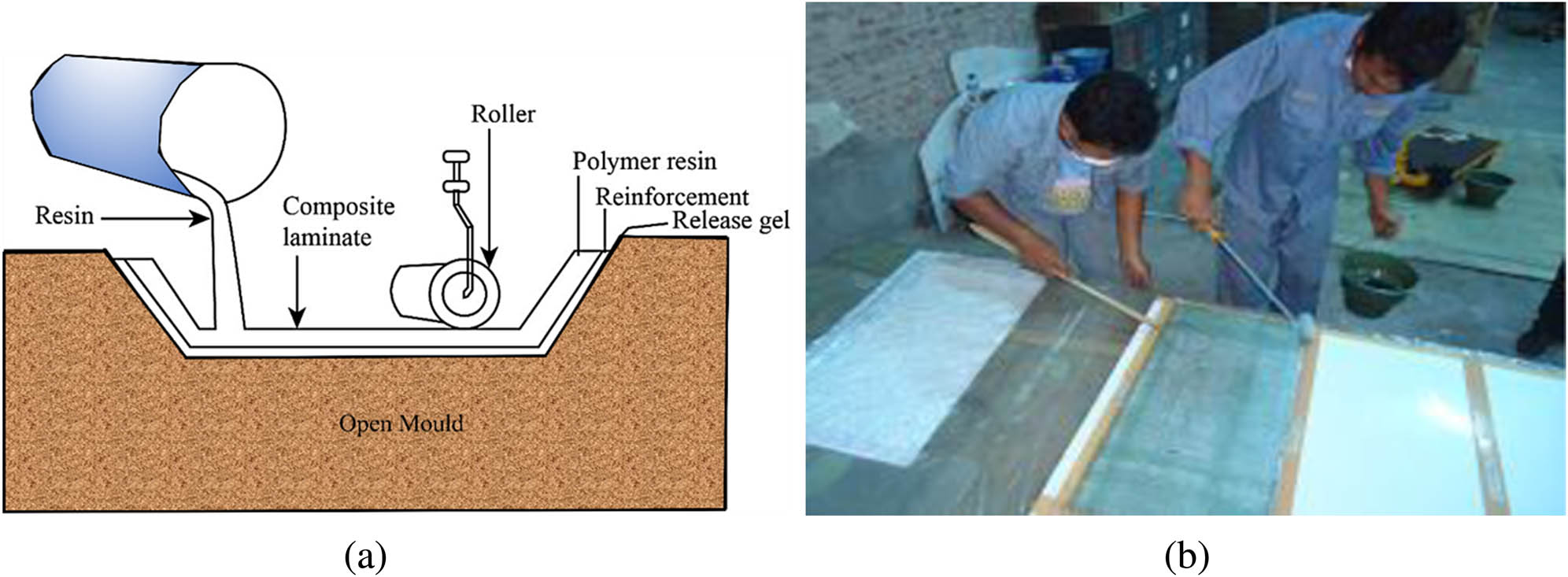

The 35 cm × 70 cm specimen sheet was designed using the hand lay-up technique and cured at room temperature, as illustrated in Figure 2(a), with a laminated arrangement as shown in Table 2. Specimen I was a laminated arrangement according to Indonesian yard practices, while specimens II, III, and IV were developmental lamination arrangements for ship hulls with biaxial wrap-knitted fabric fibers. The combination of CSM/WR and biaxial laminates was also applied to yacht shipbuilding [21]. A hand roller was used to press the resin onto the fiberglass and to remove air bubbles. The hand lay-up technique was applied in several studies [12,25] (Figure 2(b)). In contrast, the hand lay-up technique was often used in FRP shipyards, including yacht shipbuilding [21] and fishing boats [7].

(a) Schematic of hand lay-up technique and (b) specimen sheet fabrication process.

Lamination arrangement

| Stacking sequences | Lamination arrangement | |||||||

|---|---|---|---|---|---|---|---|---|

| Resin A | Resin B | |||||||

| IA | IIA | IIIA | IVA | IB | IIB | IIIB | IVB | |

| Layer 1 | CSM 300 | CSM 300 | CSM 300 | CSM 300 | CSM 300 | CSM 300 | CSM 300 | CSM 300 |

| Layer 2 | CSM 450 | CSM 450 | CSM 450 | CSM 300 | CSM 450 | CSM 450 | CSM 450 | CSM 300 |

| Layer 3 | WR 600 | Biaxial 800 | DB 800/M225E | DB 800 | WR 600 | Biaxial 800 | DB 800/M225E | DB 800 |

| Layer 4 | CSM 450 | CSM 450 | DB 800/M225E | DB 800 | CSM 450 | CSM 450 | DB 800/M225E | DB 800 |

| Layer 5 | WR 800 | Biaxial 800 | DB 800/M225E | CSM 450 | WR 800 | Biaxial 800 | DB 800/M225E | CSM 450 |

| Layer 6 | CSM 450 | CSM 450 | DB 800/M225E | DB 800 | CSM 450 | CSM 450 | DB 800/M225E | DB 800 |

| Layer 7 | WR 800 | Biaxial 800 | CSM 300 | CSM 450 | WR 800 | Biaxial 800 | CSM 300 | CSM 450 |

| Layer 8 | CSM 450 | CSM 450 | CSM 450 | CSM 450 | ||||

| Layer 9 | WR 800 | Biaxial 800 | WR 800 | Biaxial 800 | ||||

| Layer 10 | CSM 450 | CSM 300 | CSM 450 | CSM 300 | ||||

| Layer 11 | WR 600 | WR 600 | ||||||

| Layer 12 | CSM 450 | CSM 450 | ||||||

The fiber volume fraction was calculated using formula 1 [12,26] with a fiberglass density of 2.56 g/cm3 [18]. Thus, there were four lamination arrangements, namely I, II, III, and IV, with resins A and B and fiber orientation 0° (specimen code 0) and 90° (specimen code 90)

where

The specimen sheet was cut according to the tensile test specimen’s and flexure test’s size and adjusted to the orientation of the fibers 0° and 90°. The cutting method was also carried out in previous studies [10,16,17] with the same type of material as this study, namely biaxial warp-knitted composite. These specimen variations were designed to determine the effect of resin type, fiberglass type configuration, number of layers/laminations, and fiber orientation on FRP composite ships’ tensile and flexural strength.

2.2 Experimental method

This study investigated the strength of FRP ship materials through a uniaxial tensile and three-point flexure test using a calibrated Universal Testing Machine (RME 100 Schenck Trebel) in a certified laboratory (KAN No. 077-IDN and KNAPP No. PL 007-INA, P68-01 a). A uniaxial tensile test was carried out referring to ISO 527-3 with a crosshead speed of 5 mm/min [27]. Figure 3 shows the tensile test specimen type 3, which had dimensions of overall length (L3) 250 mm, width (b1) 25 mm, and thickness (h) 8 mm, with a total of five specimens for each type. The reported data from the uniaxial tensile test data represented an average value of five specimens for each type with standard errors. The tensile loading can be seen in Figure 4, where the strain was measured using a strain gauge sensor, as was done in the study of Demircan et al. [12].

![Figure 3

Dimensions of the uniaxial tensile test specimen [27].](/document/doi/10.1515/cls-2022-0209/asset/graphic/j_cls-2022-0209_fig_003.jpg)

Dimensions of the uniaxial tensile test specimen [27].

Uniaxial tensile loading using UTM.

Meanwhile, the three-point flexure test refers to ISO 14125 with a strain rate of 0.01 (i.e., 1% per minute) [28]. The flexure test results were based on the average values of six specimen measurements for each type with standard errors. The specimen and scheme of three-point flexure referred to Class II for plastics reinforced with mats, continuous matting, and fabrics with specimen length (l) 80 mm, outer span (L) 66 mm, width (b) 15 mm, thickness (h) 4 mm, the radius of central loading (R1) 5 mm, and radius of supports members (R2) 5 mm, as shown in Figure 5. Normalized strength was calculated using formula (2) [18,29] so that the tensile and flexural strength had a value comparable to the same fiber volume fraction, namely 30%. Formula (2) was also used to analyze other studies’ tensile and flexural strength to compare it to this study

where E normal (30%) (MPa) is the normalized strength at 30% volume fraction, E(V f) is the tensile/flexural strength (MPa), and V f is the volume fraction (%).

![Figure 5

(a) Flexural test schematic [28] and (b) flexural loading using UTM.](/document/doi/10.1515/cls-2022-0209/asset/graphic/j_cls-2022-0209_fig_005.jpg)

(a) Flexural test schematic [28] and (b) flexural loading using UTM.

3 Results and discussion

This section describes the results and discussion regarding the influence of UPR type, laminate arrangement, and fiber orientation on normalized tensile and flexural strength. A thorough analysis compares the normalized tensile and flexural strength obtained in this study with the results obtained from various references.

3.1 Tensile properties

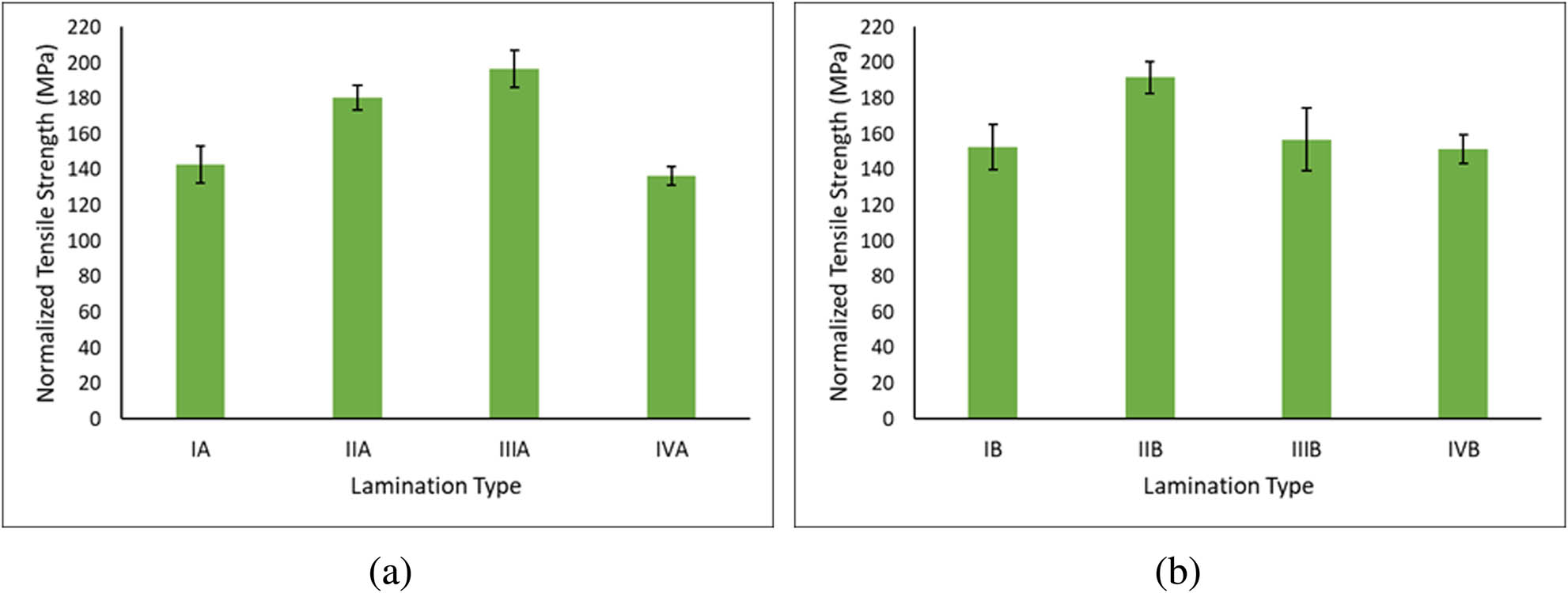

The results of the tensile test with standard errors on resins A and B are shown in Figure 6. All variations of the specimens showed adjacent volume fractions, which were between 27.06 and 31.89%. In other references, the difference in volume fraction variation of 10% indicates that the higher the volume fraction, the higher the tensile strength [30,31,32]. Figure 6 and Table 3 show something similar; the higher the fiber volume fraction, the higher the tensile strength of the same resin type. However, this trend did not apply to laminates IIA and IIB, which had pretty high tensile strength, even with a fiber volume fraction of 27.06%. The volume fraction of 29.69% in CSM–biaxial resin A had an average tensile strength of 135.2 MPa. The increase in the volume fraction of 0.76–30.45% increased the tensile strength to 145.1 MPa. A slight increase in volume fraction also impacted the tensile strength of CSM–biaxial resin B, where a rise of 0.39% increased the tensile strength from 148.9 to 152.3 MPa. So, the FRP with the CSM–biaxial fiber combination in this study, especially the lamination types I, III, and IV, had a tensile strength that was sensitive enough to be affected by volume fraction, which did not occur in vinyl ester resin/biaxial weft-knitted fiberglass materials using hand lay-up specimen fabrication method [12] and polyester resin/CSM-continuous fiberglass material using the injection molding fabrication method [33].

Effect of volume fraction on tensile strength: (a) Resin A and (b) Resin B.

Effect of volume fraction on tensile strength

| Lamination type | IA | IIA | IIIA | IVA |

|---|---|---|---|---|

| Average tensile strength (MPa) | 145.1 | 162.8 | 199.7 | 135.2 |

| Fiberglass volume fraction (%) | 30.45 | 27.06 | 30.48 | 29.69 |

| Lamination type | IB | IIB | IIIB | IVB |

|---|---|---|---|---|

| Average tensile strength (MPa) | 152.3 | 173.9 | 166.8 | 148.9 |

| Fiberglass volume fraction (%) | 29.92 | 27.22 | 31.89 | 29.53 |

In contrast, all specimens in this study met the minimum tensile strength criteria of 121.23 MPa as required by the Indonesian Classification Bureau [22], so the hand lay-up technique, material type, and laminate I–IV arrangement types in this study can be applied to FRP shipyard. The hand lay-up technique is the most applicable FRP shipbuilding technique for shipyards in Indonesia. Even yacht manufacturing in Italy still uses hand lay-up and not standardized procedures [21].

Normalized strength at a 30% volume fraction was used so that tensile strength had a comparative value to several tensile strengths between variations in this study and other studies, as can be seen in Figure 7 and Table 4. The average tensile strength of resin A was 160.7 MPa, while resin B of 160.5 MPa. Meanwhile, after normalization using formula (2), the average normalized tensile strength of all resin A specimens was 164.1 MPa, and resin B was 163.1 MPa, so that differences in resin brands did not affect the tensile strength. FRP yards could choose brand A or B based on price or ease of purchase for parts of the ship that were subject to frequent tensile loads.

Normalized tensile strength: (a) Resin A and (b) Resin B.

Normalized tensile strength

| Lamination type | Tensile strength (MPa) | Standard error (MPa) | Fiberglass volume Fraction (%) | Normalized tensile strength (MPa) | Standard error (MPa) |

|---|---|---|---|---|---|

| IA0° | 132 | ±3.96 | 30.45 | 130.03 | ±3.90 |

| IIA0° | 165.2 | ±4.29 | 27.06 | 183.17 | ±4.76 |

| IIIA0° | 197.4 | ±6.90 | 30.48 | 194.29 | ±6.79 |

| IVA0° | 124.8 | ±4.08 | 29.69 | 126.10 | ±4.12 |

| IA90° | 158.2 | ±17.36 | 30.45 | 155.84 | ±17.10 |

| IIA90° | 160.4 | ±8.46 | 27.06 | 177.85 | ±9.38 |

| IIIA90° | 202 | ±14.50 | 30.48 | 198.81 | ±14.27 |

| IVA90° | 145.6 | ±6.07 | 29.69 | 147.12 | ±6.13 |

| IB0° | 123.8 | ±8.04 | 29.92 | 124.14 | ±8.06 |

| IIB0° | 165.6 | ±7.91 | 27.22 | 182.50 | ±8.72 |

| IIIB0° | 157.2 | ±22.02 | 31.89 | 147.89 | ±20.71 |

| IVB0° | 141.8 | ±10.08 | 29.53 | 144.08 | ±10.24 |

| IB90° | 180.8 | ±6.66 | 29.92 | 181.30 | ±6.68 |

| IIB90° | 182.2 | ±15.67 | 27.22 | 200.80 | ±17.27 |

| IIIB90° | 176.4 | ±3.20 | 31.89 | 165.96 | ±3.01 |

| IVB90° | 156 | ±7.86 | 29.53 | 158.51 | ±7.99 |

More specifically, specimens of the IIA and IIB laminate types had the highest tensile strength on average, 186.1 MPa. Specimens IIIA and IIIB had an average tensile strength of 176.7 MPa, specimens IA and IB had 147.8 MPa, and specimens IVA and IVB had 144 MPa. Specimens II and III, a combination of CSM and biaxial fiber laminations, had higher tensile strength, although the number of laminations was less than specimen I (CSM and WR fibers). Even specimen III (CSM–biaxial), which consisted of 7 layers, had a 19.5% higher tensile strength than specimen I (CSM–WR), which consisted of 12 layers. Specimen IV (CSM–biaxial) also consisted of seven layers and had almost the same tensile strength as specimen I (CSM–WR). Thus, the CSM–biaxial lamination type had better tensile strength than CSM–WR.

Biaxial warp-knitted fabric fiberglass had a significant effect on tensile properties. The average tensile strength of specimens II and III was better than that of specimen IV because specimens II and III had four layers of biaxial fiberglass. In comparison, specimen IV consisted of three layers of biaxial fiberglass. The CSM–biaxial fiber combination can speed up the production process of FRP ship materials because to get the same volume fraction, a smaller number of laminations is required compared to the CSM–WR fiber combination, which so far has been more frequently used by FRP shipyards, especially Indonesia. Thus, the CSM–biaxial fiber combination has the potential to be further applied to FRP vessels because it can accelerate production and has high tensile strength.

This result confirmed other studies that biaxial warp-knitted fabric fiberglass has high strength and stiffness [8], low production cost, and high production and efficiency [9]. These fibers have superior strength due to straight fiber bundles and have been widely applied in various applications [13]. However, these fibers have yet to be widely used to produce FRP vessels, especially in Indonesia.

Furthermore, the combined lamination arrangement, commonly called rovimat/combimat [7] as in Table 2, has been used in other references, namely the CSM–biaxial combination [21,25] and the CSM–WR combination [7]. Several CSM layers in this study and other studies [7,21,25] have a function to increase the resin content [7]. So that, this rovimat/combimat technique is widely applied to the marine industry, such as pleasure boats and fishing boats [7]. It was proven in this study that the specimens with relatively low resin content, specimens IVA and IVB, had not as good a tensile strength performance as specimens IIA, IIIA, IIB, and IIIB. This result showed that the biaxial warp-knitted fabric fiber should be combined with CSM fiber layers to increase the resin content and improve tensile properties.

In addition, Table 4 shows that specimens with 90° fiber orientation had greater tensile strength than 0° fiber orientation, both for resin A and B resin specimens. Specimens with 0° fiber orientation had an average tensile strength of 154 MPa, while fiber orientation 90° of 173.3 MPa. Stitch yarn provides more support for tensile loads in specimens with a fiber orientation of 90° than 0°, where the effect of stitch yarn is shown in the study of Zhao et al. [17]. Fibers with a fiber orientation of 90° in the outer layers of the laminate are in the direction of loading so that fibers in that direction will bear the tensile load and increase the load-carrying capacity of the composite. Warp fibers in that direction are also distributed more evenly [16].

For various FRP composite studies, normalized tensile strength was also used as a comparative value. The average normalized tensile strength of CSM–biaxial resin A (laminations II, III, and IV) is 171.2 MPa, while CSM–biaxial resin B is 166.6 MPa, as can be seen in Table 5. In Table 5, the CSM–biaxial composite in this study had better normalized tensile strength compared to several other studies, which were also made using the hand lay-up technique [30,32,34]. Compared to other studies using a matrix in the form of polyester resin, the CSM–biaxial composite in this study was still better [31,32,35]. Furthermore, the composites in this study had higher normalized tensile strength than other reference composites using more advanced fabrication techniques, such as spray forming [31] and contact molding [35]. However, the composites in this study were not better than those of previous studies [7,12,18,29,36–38], so that the CSM–biaxial composite can be classified as having normalized tensile strength at an intermediate level.

Normalized tensile strength comparison of various references

| Reference | Fabrication | Material | Tensile strength (MPa) | Fiberglass volume fraction (%) | Normalized tensile strength (MPa) |

|---|---|---|---|---|---|

| [7] | Hand lay up | Polyester resin/CSM and WR mat | 100 | 16 | 187.5 |

| Polyester resin/CSM and Unidirectional fiberglass | 156 | 23 | 203.5 | ||

| [12] | Hand lay up | Vinyl ester resin/biaxial weft-knitted fiberglass | 321 | 40 | 240.8 |

| 317 | 41.5 | 229.2 | |||

| [18] | Vacuum-assisted resin transfer molding | Epoxy/quadriaxial warp-knitted fabric fiberglass | 391.72 | 51.6 | 227.9 |

| 387.69 | 50.8 | 229.0 | |||

| 330.12 | 50.6 | 195.9 | |||

| 316.97 | 50.6 | 188.1 | |||

| Epoxy/biaxial warp-knitted fabric fiberglass | 342.8 | 56.6 | 181.7 | ||

| 280.09 | 55.8 | 150.6 | |||

| 515.51 | 48.4 | 319.7 | |||

| 495.72 | 48.6 | 306.3 | |||

| [29] | Vacuum-assisted resin transfer molding | Epoxy/E-glass fiber mats | 589.7 | 40 | 442.3 |

| [30] | Hand lay up | Epoxy resin/natural and glass fiber | 40 | 18 | 66.7 |

| 46 | 24 | 57.5 | |||

| 50 | 30 | 50.0 | |||

| 62 | 36 | 51.7 | |||

| 72 | 42 | 51.4 | |||

| [31] | Spray forming | Polyester/random fiberglass | 90.39 | 30 | 90.4 |

| 101.27 | 30 | 101.3 | |||

| 87.68 | 30 | 87.7 | |||

| 90.44 | 30 | 90.4 | |||

| 92.44 | 30 | 92.4 | |||

| 115.39 | 40 | 86.5 | |||

| 121.88 | 40 | 91.4 | |||

| 116.65 | 40 | 87.5 | |||

| 126.23 | 40 | 94.7 | |||

| 118.44 | 40 | 88.8 | |||

| 132.12 | 50 | 79.3 | |||

| 143.45 | 50 | 86.1 | |||

| 140.11 | 50 | 84.1 | |||

| 136.57 | 50 | 81.9 | |||

| 145.67 | 50 | 87.4 | |||

| [32] | Hand lay-up | UPR/transversely aligned fiberglass | 10.36 | 10 | 31.1 |

| 9.78 | 20 | 14.7 | |||

| 8.06 | 30 | 8.1 | |||

| 7.41 | 40 | 5.6 | |||

| 7.26 | 50 | 4.4 | |||

| UPR/unidirectional discontinuous fiberglass | 42.57 | 10 | 127.7 | ||

| 52.52 | 20 | 78.8 | |||

| 63.83 | 30 | 63.8 | |||

| 70.91 | 40 | 53.2 | |||

| 65.68 | 50 | 39.4 | |||

| UPR/short fiberglass (random) | 43.96 | 10 | 131.9 | ||

| 49.74 | 20 | 74.6 | |||

| 53.9 | 30 | 53.9 | |||

| 57.57 | 40 | 43.2 | |||

| 55.78 | 50 | 33.5 | |||

| UPR/woven fiberglass | 52.15 | 10 | 156.5 | ||

| 73.12 | 20 | 109.7 | |||

| 99.17 | 30 | 99.2 | |||

| 118.61 | 40 | 89.0 | |||

| 109.83 | 50 | 65.9 | |||

| [34] | Hand lay up | Epoxy/woven E-glass mat | 17.59 | 10 | 52.8 |

| [35] | Contact molding | UPR/woven E-fiberglass | 120 | 40 | 90.0 |

| [36] | Hand lay up | UPR/woven E-glass fabric | 65 | 11 | 177.3 |

| [37] | Resin Transfer Molding | Polyester resin/woven E-glass | 382 | 41.5 | 276.1 |

| 472 | 41.5 | 341.2 | |||

| 499 | 41.5 | 360.7 | |||

| 374 | 36.5 | 307.4 | |||

| 379 | 36.5 | 311.5 | |||

| 308 | 28.5 | 324.2 | |||

| 344 | 28.5 | 362.1 | |||

| 347 | 28.5 | 365.3 | |||

| [38] | Compression molded | Polyester resin/Glass fiber roving | 288 | 20 | 432.0 |

3.2 Flexural properties

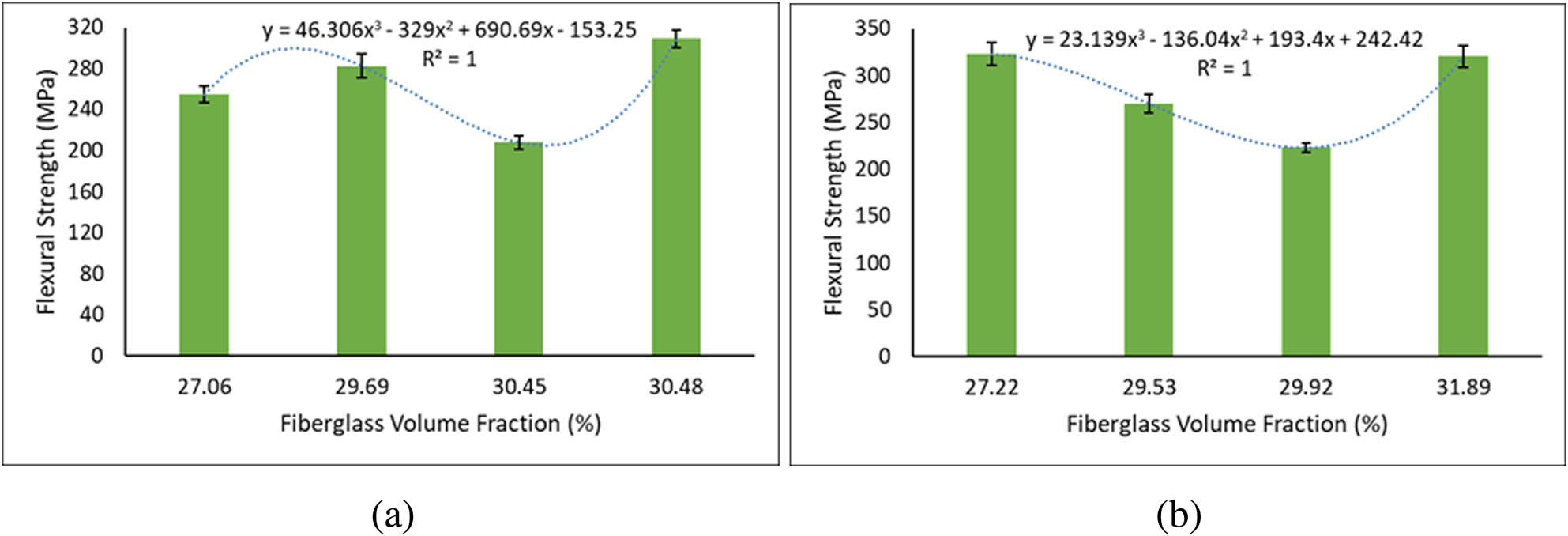

Flexural strength with standard errors on resins A and B is shown in Table 6 and Figure 8. Figure 8 shows flexural strength was not correlated with variations in volume fraction with adjacent ranges. In general, the higher the volume fraction, the higher the flexural strength if the difference in fractional volume variation is around 10%, as in the previous studies [30,32,39]. The discrepancy in the correlation between the variation in the volume fraction range below 2.3% was also confirmed in other studies using better fabrication methods, namely the injection molding technique [33] and a hot-press machine [15]. Few references have examined the effect of flexural strength on FRP ships with low volume fraction range variations due to the difficulty of controlling fiber volume fraction over the overall volume. In addition, experimental variability has an influence that cannot be ignored [16], especially at low-volume fraction variations.

Effect of volume fraction on flexural strength

| Lamination type | IA | IIA | IIIA | IVA |

|---|---|---|---|---|

| Average flexural strength (MPa) | 208.08 | 254.75 | 309.08 | 282.58 |

| Fiberglass volume fraction (%) | 30.45 | 27.06 | 30.48 | 29.69 |

| Lamination type | IB | IIB | IIIB | IVB |

|---|---|---|---|---|

| Average flexural strength (MPa) | 223.00 | 322.92 | 320.25 | 270.17 |

| Fiberglass volume fraction (%) | 29.92 | 27.22 | 31.89 | 29.53 |

Effect of volume fraction on flexural strength: (a) Resin A and (b) Resin B.

Hence, to get better flexural strength, the fiber volume fraction should be increased by at least 10%. However, all variations in this study fully met the minimum flexural strength criteria of 116.15 MPa as required by the Indonesian Classification Bureau [22]. So the hand lay-up technique, material type, and laminate I–IV arrangement types in this study can be applied to the FRP shipyard. Even the lowest flexural strength obtained at the IA0o variation of 200.3 MPa is 72% above the minimum criteria.

Normalized flexural strength analysis was carried out to obtain comparative values between variations in this study and other studies, as shown in Table 7. After normalized flexural strength analysis, specimens using B resin showed a higher average normalized flexural strength of 288.8 MPa than resin A specimens, with an average normalized flexural strength of 269.3 MPa. Alternatively, in other words, resin B has 7.2% higher flexural strength compared to resin A. Thus, the flexural properties analysis shows that resin B was more recommended for FRP ship materials to have higher flexural strength.

Normalized flexural strength

| Lamination type | Flexural strength (MPa) | Standard error (MPa) | Fiberglass volume fraction (%) | Normalized flexural strength (MPa) | Standard error (MPa) |

|---|---|---|---|---|---|

| IA0° | 200.33 | ±5.72 | 30.45 | 197.34 | ±5.63 |

| IIA0° | 227.17 | ±6.77 | 27.06 | 251.88 | ±7.51 |

| III A0° | 303.67 | ±10.56 | 30.48 | 298.88 | ±10.39 |

| IVA0° | 247.67 | ±8.77 | 29.69 | 250.25 | ±8.86 |

| IA90° | 215.83 | ±8.02 | 30.45 | 212.61 | ±7.90 |

| IIA90° | 282.33 | ±9.88 | 27.06 | 313.05 | ±10.96 |

| IIIA90° | 314.50 | ±6.80 | 30.48 | 309.54 | ±6.69 |

| IVA90° | 317.50 | ±15.26 | 29.69 | 320.81 | ±15.42 |

| IB0° | 207.00 | ±4.27 | 29.92 | 207.58 | ±4.28 |

| IIB0° | 322.33 | ±13.32 | 27.22 | 355.24 | ±14.68 |

| IIIB0° | 395.67 | ±18.36 | 31.89 | 372.24 | ±17.28 |

| IVB0° | 225.17 | ±11.08 | 29.53 | 228.78 | ±11.25 |

| IB90° | 239.00 | ±5.56 | 29.92 | 239.66 | ±5.57 |

| IIB90° | 323.50 | ±10.46 | 27.22 | 356.52 | ±11.53 |

| IIIB90° | 244.83 | ±4.17 | 31.89 | 230.34 | ±3.92 |

| IVB90° | 315.17 | ±9.08 | 29.53 | 320.23 | ±9.22 |

Furthermore, flexural properties analysis further proved that the CSM–biaxial fiber combination was better than CSM–WR. Specimen I, a CSM–WR combination, had an average flexural strength of 214.3 MPa, while all CSM–biaxial specimens had a higher average flexural strength. The CSM–biaxial lamination type (specimens II, III, and IV) indicated that the greater the number of laminations, the higher the flexural strength. Specimen II (10 layers) had the highest average flexural strength of 319.2 MPa, followed by specimens III and IV (7 layers), which were 302.7 and 280 MPa, respectively.

Specimen IV, which only had seven layers, has 31% higher flexural strength than specimen I, which had 12 layers. Even the flexural strength of specimen III, which also consisted of 7 layers, was 41% higher than that of specimen I. Thus, the flexural strength of CSM–biaxial was much higher than that of CSM–WR, even though CSM–WR (specimen I) had more lamination. In addition, type IV biaxial composites had flexural strength, which was not as good as type II and III biaxial composites because specimen IV had low resin content due to a minimal CSM layer. In type II and III laminations, a layer of CSM was applied between the biaxial fiber layers to increase the resin content [7]. Thus, marine composites with biaxial fibers should be combined with CSM fibers to increase the resin content and result in better flexural properties.

In this study, flexural strength was more influenced by lamination quality. The biaxial warp layer of knitted fabric fiberglass significantly affected the flexural properties, which also happened to affect the tensile properties. Biaxial warp-knitted fabric fiberglass contributed significantly to flexural strength because this layer had high strength, high yarn utilization, high orientation, and stable size. It has high resistance to delamination [8], where delamination is often a reducing factor for flexural properties. The effect of through-layer binding from a knitted tricot provides excellent delamination resistance compared to conventional laminated fibers [9]. Fewer layers with better tensile and flexural properties allow CSM–biaxial fiber (lamination types II, III, and IV) to be applied in the FRP shipping industry. These advantages provide lower production time and labor costs. Not surprisingly, composites reinforced with biaxial warp-knitted fabric fiberglass are reported to have low production costs and high production efficiency [9].

Furthermore, the average flexural strength in the 90° fiber orientation was higher than the 0° fiber orientation for both resins A and B. Specimens with 90° fiber orientation had an average flexural strength of 287.8 MPa. In comparison, 0° fiber orientation was 270.3 MPa. The flexural strength of 90° is higher than 0° because, in the orientation of 90°, the biaxial fiber has stitch yarns that better support the increase in bending strength [10,14].

In Figure 9, the CSM–biaxial resin A composite (laminations II, III, and IV) had an average normalized flexural strength of 290.7 MPa. CSM–biaxial resin B had an average normalized flexural strength of 310.5 MPa. This value indicated that the flexural strength was relatively high compared to other references, as summarized in Table 8. Compared to other references that also use specimen fabrication techniques in hand lay-up, the composites in this study have higher normalized flexural strength [12,14,30,32]. This study also had better normalized flexural strength than [32,33,39], which used a polyester matrix. Even the CSM–biaxial composite (made by hand lay-up technique) had higher normalized flexural strength compared to composites fabricated using more advanced techniques, such as vacuum-assisted resin transfer molding [10], contact molding [39], and injection molding [33].

Normalized flexural strength: (a) Resin A and (b) Resin B.

Comparison of normalized flexural strength from various references

| Reference | Fabrication | Material | Flexural strength (MPa) | Fiberglass volume fraction (%) | Normalized flexural strength (MPa) |

|---|---|---|---|---|---|

| [7] | Hand lay up | Polyester resin/CSM and WR mat | 182 | 16 | 341.25 |

| Polyester resin/CSM and Unidirectional fiberglass | 191.4 | 23 | 249.65 | ||

| [10] | Vacuum-assisted resin transfer molding | Epoxy/biaxial warp-knitted glass fabric composite | 430.85 | 56.68 | 228.04 |

| Epoxy/quadriaxial warp-knitted glass fabric composite | 194.67 | 50.8 | 114.96 | ||

| [12] | Hand lay up | Vinyl ester resin/biaxial weft-knitted fiberglass | 365 | 41.5 | 263.86 |

| [14] | Hand lay up | Vinyl ester resin/biaxial weft-knitted fiberglass | 385 | 41.5 | 278.31 |

| 369 | 41.5 | 266.75 | |||

| [18] | Vacuum-assisted resin transfer molding | Epoxy/quadriaxial warp-knitted fabric fiberglass | 585.99 | 51.57 | 340.89 |

| 494.22 | 50.79 | 291.92 | |||

| 564.71 | 50.55 | 335.14 | |||

| 499.71 | 50.55 | 296.56 | |||

| Epoxy/biaxial warp-knitted fabric fiberglass | 1022.63 | 56.6 | 542.03 | ||

| 192.31 | 55.81 | 103.37 | |||

| 911.2 | 48.37 | 565.14 | |||

| 812.46 | 48.55 | 502.04 | |||

| [29] | Vacuum-assisted resin transfer molding | Epoxy/E-glass fiber mats | 522.7 | 40 | 392.03 |

| [30] | Hand lay up | Epoxy resin/natural and glass fiber | 125 | 18 | 208.33 |

| 149 | 24 | 186.25 | |||

| 187 | 30 | 187.00 | |||

| 207 | 36 | 172.50 | |||

| 236 | 42 | 168.57 | |||

| [32] | Hand lay-up | UPR/transversely aligned fiberglass | 10.93 | 10 | 32.79 |

| 11.69 | 20 | 17.54 | |||

| 12.36 | 30 | 12.36 | |||

| 12.92 | 40 | 9.69 | |||

| 12.48 | 50 | 7.49 | |||

| UPR/unidirectional discontinuous fiberglass | 81.93 | 10 | 245.79 | ||

| 85.72 | 20 | 128.58 | |||

| 90.06 | 30 | 90.06 | |||

| 92.31 | 40 | 69.23 | |||

| 90.59 | 50 | 54.35 | |||

| UPR/short fiberglass (random) | 66.76 | 10 | 200.28 | ||

| 74.88 | 20 | 112.32 | |||

| 80.94 | 30 | 80.94 | |||

| 86.77 | 40 | 65.08 | |||

| 83.59 | 50 | 50.15 | |||

| UPR/woven fiberglass | 85.22 | 10 | 255.66 | ||

| 122.34 | 20 | 183.51 | |||

| 165.56 | 30 | 165.56 | |||

| 177.53 | 40 | 133.15 | |||

| 158.25 | 50 | 94.95 | |||

| [33] | Injection molding | UPR/chopped fiberglass and continuous fiberglass | 131.78 | 21 | 188.26 |

| [38] | Compression molded | Polyester resin/glass fiber roving | 118.87 | 18.7 | 190.70 |

| 106.65 | 19.8 | 161.59 | |||

| [39] | Contact molding | UPR/woven E-fiberglass | 74 | 30 | 74.00 |

| 81 | 45 | 54.00 |

In the future, the mechanical properties of the CSM–biaxial composite obtained in this study can be applied to FRP ship structure models to determine stress and structural deformation using the finite-element method, as shown in previous studies [40,41]. Structural dynamic analysis of the CSM–biaxial composite is also interesting to be developed in the future both experimentally [42] and numerically [43,44,45,46]. Furthermore, structural analysis of sandwich materials with core materials in the form of CSM–biaxial composite or CSM–WR needs to be studied, as in previous studies [47,48].

4 Conclusion

FRP ship composites were subjected to uniaxial tensile and three-point flexural tests to determine the effect of fractional volume with adjacent variation ranges, resin type, laminate arrangement type, and fiber orientation on tensile and flexural properties. Based on the tensile and flexural tests, all laminate types, resin types, and fiber orientations met the criteria of the Indonesian Classification Bureau. So, in general, the hand lay-up technique, type of material, and arrangement of laminates I–IV in this study can be applied as FRP ship materials.

Volume fraction (with adjacent range) affects tensile and flexural strength differently. In general, the tensile strength correlates well with the volume fraction increase. However, flexural strength did not correlate with variations in volume fraction within the adjacent range. Therefore, the fiber volume fraction should be increased by at least 10% to get better flexural strength.

The proposed CSM–biaxial or type II, III, and IV laminations had higher tensile and flexural strength with fewer laminations than CSM–WR (type I laminations), so the CSM–biaxial composite has the potential to be applied to ship hulls. FRP. Type II laminates had the highest tensile and flexural strength, followed by type III laminates. Type II laminates had normalized tensile and flexural strength averages 186.1 and 319.2 MPa, respectively. While the average normalized tensile and flexural strength of type III laminates was 176.7 and 302.7 MPa, respectively. Apart from its strength, fewer type II and III laminations can speed up the production process of FRP ship hulls. The presence of biaxial warp-knitted fabric fiberglass had a very significant effect on tensile and flexural strength.

On the other hand, resin brands A and B meet the classification criteria of the Indonesian Classification Bureau. Resins A and B had relatively the same tensile strength, but resin B had slightly better flexural strength, so resin B is recommended for application in FRP shipyards. In addition, for all types of resin and laminate type, the composite with the 90° fiber orientation had more excellent tensile and flexural strength than the 0° fiber orientation, which was influenced by the stitch yarn, outer layers of the laminate in the direction of loading, and distribution warp fibers. Furthermore, the CSM–biaxial composite had relatively high normalized flexural strength compared to other references. However, the normalized tensile strength achieved in this study was at an intermediate level compared to other references.

Acknowledgments

This research was funded by LPDP (Indonesia Endowment Funds for Education) through the Riset dan Inovasi untuk Indonesia Maju (RIIM) batch 3 program, managed by BRIN (National Research and Innovation Agency) under contract numbers B-839/II.7.5/FR.06/5/2023 and B-1066/III.3/FR.06/5/2023. The second author (Abdi Ismail) is a postdoctoral fellow under BRIN with contract number 151/II/HK/2022 dated September 1, 2022.

-

Author contributions: Buana Ma’ruf and Abdi Ismail contributed equally as the main contributor of this article. All authors have accepted responsibility for the entire content of this manuscript and approved the final article.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Rizal N. Resistance test of fast patrol ships in the islands of Indonesia. J Ocean Mech Aerosp Sci Eng. 2018;58(1):6–11.Search in Google Scholar

[2] Klara S, Mahmuddin F, Muas M. Analysis of loading change effect to boat velocity on a 2.5 GT fishing FRP boat with a field test. SPECTA J Technol. 2018;2(1):5–10.10.35718/specta.v2i1.89Search in Google Scholar

[3] Yusuf I, Yani A, Baba MS. Approaches method to solve ships routing problem with an application to the Indonesian national shipping company. Proceedings of the 2011 International Conference on Applied, Numerical and Computational Mathematics; 2011 Sep 15–17; Barcelona, Spain. ACM, 2011. p. 57–62.Search in Google Scholar

[4] Jayaram S, Sivaprasad K, Nandakumar CG. Recycling of FRP Boats. Int J Adv Res Eng Technol. 2018;9(3):244–52.Search in Google Scholar

[5] Juradoa A, Garciaa C, Sancheza E, Beltran P. FIBRESHIP project: Engineering, production and life cycle management for the complete construction of large length fibre-based ships. Proceedings of 8th Transport Research Arena TRA 2020; 2020 Apr 27–30; Helsinki, Finland. TRA, 2020.Search in Google Scholar

[6] Dominic M, Nandakumar CG. Environmental impact of non metallic hull ships. 2012 International Conference on Green Technologies (ICGT); 2012 Dec 18–20; Trivandrum, India. IEEE, 2013. p. 307–12.10.1109/ICGT.2012.6477991Search in Google Scholar

[7] Anbusagar NRR, Giridharan PK, Rakesh S, Balaj BP, Kathiresh VK. Analysis of fiber reinforced polymer composite material using experimental and CLT approach. Front Automob Mech Engineering-2010; 2010 Nov 25–27; Chennai, India. IEEE, 2011. p. 4–7.10.1109/FAME.2010.5714789Search in Google Scholar

[8] Gao X, Tao N, Chen S, Wang L, Wu W. Tensile-tensile fatigue behavior of multi-axial warp-knitted reinforced composite. Fibres Text East Europe. 2018;26(1(127)):73–80. 10.5604/01.3001.0010.7800.Search in Google Scholar

[9] Pan Z, Wu Z, Xiong J. Localized temperature rise as a novel indication in damage and failure behavior of biaxial non-crimp fabric reinforced polymer composite subjected to impulsive compression. Aerosp Sci Technol. 2020;103:105885. 10.1016/j.ast.2020.105885.Search in Google Scholar

[10] Xu H, Liu C, Yang J, Gao X. Preparation and bending properties of curved structure composite reinforced with multi-axial warp-knitted glass fabric. Acta Mater Compositae Sin. 2022;40(8):4512–21. 10.13801/j.cnki.fhclxb.20221104.001.Search in Google Scholar

[11] Temesgen AG, Sahu O. Comparative study on the mechanical properties of weft knitted and warpfabric reinforced composites. J Mod Mater. 2022;9(1):21–5. 10.21467/jmm.9.1.21-25.Search in Google Scholar

[12] Demircan O, Kosui T, Ashibe S, Nakai A. Effect of stitch and biaxial yarn types on tensile, bending, and impact properties of biaxial weft-knitted composites. Adv Compos Mater. 2014;23(3):239–60. 10.1080/09243046.2013.851062.Search in Google Scholar

[13] Chen J, Gao X, Zhao K, Wu W. Research on influence of matrix component on the mechanical behavior of multiaxial warp-knitted composites. Fibers Polym. 2022;23:3126–37.10.1007/s12221-022-0298-9Search in Google Scholar

[14] Demircan Ö, Torun AR, Kosui T, Nakai A, Hamada H. Design and manufacturing - bending and impact properties of biaxial weft knitted composites. Proceedings of ASME 2011 International Mechanical Engineering Congress and Exposition; 2011 Nov 11–17; Denver (CO), USA. ASME, 2011. p. 223–31.10.1115/IMECE2011-64964Search in Google Scholar

[15] Demircan O, Al-darkazali A, İnanç İ, Eskizeybek V. Investigation of the effect of CNTs on the mechanical properties of LPET/glass fiber thermoplastic composites. J Thermoplast Compos Mater. 2020;33(12):1652–73. 10.1177/0892705719833105.Search in Google Scholar

[16] Demircan O, Yilmaz C, Kocaman ES, Yildiz M. An experimental study on tensile and bending properties of biaxial warp knitted textile composites. Adv Compos Mater. 2020;29:73–88. 10.1080/09243046.2019.1639016.Search in Google Scholar

[17] Zhao Z, Yan B, Hu D, Ma P. Experimental investigation on mechanical properties of biaxial warp-knitted flexible composite. Fibers Polym. 2021;22:3135–43. 10.1007/s12221-021-0447-6.Search in Google Scholar

[18] Gao X, Li D, Wu W, Chen S. Experimental investigation of the tensile and bending behavior of multi-axial warp-knitted fabric composites. Text Res J. 2018;88(3):333–44. 10.1177/0040517516679155.Search in Google Scholar

[19] Fojtl L, Rusnáková S, Žaludek M, Rusnák V. Experimental characterization of multiaxial glass laminates for front end cab. Appl Mech Mater. 2015;752-753:291–4.10.4028/www.scientific.net/AMM.752-753.291Search in Google Scholar

[20] Spasova D, Argirov Y, Mechkarova T, Atanasov N. Investigation of the suitability of fiber reinforced polymer matrix composites for facilities operating in marine environment. IOP Conf Ser Mater Sci Eng. 2021;1037(1):012029.10.1088/1757-899X/1037/1/012029Search in Google Scholar

[21] Di Bella G, Galtieri G, Borsellino C. Three-point flexural properties of bonded reinforcement elements for pleasure craft decks. Appl Compos Mater. 2018;25:21–34. 10.1007/s10443-017-9605-9.Search in Google Scholar

[22] Biro Klasifikasi Indonesia. Rules for fibreglass reinforced plastic ships, rules for classification and construction. Jakarta, Indonesia: Biro Klasifikasi Indonesia; 2006.Search in Google Scholar

[23] Naqvi SZ, Ramkumar J, Kar KK. Fly ash/glass fiber/carbon fiber-reinforced thermoset composites. Handbook of Fly Ash. Oxford, UK: Butterworth-Heinemann; 2022. p. 373–400. 10.1016/B978-0-12-817686-3.00023-2.Search in Google Scholar

[24] Ma P, Gao Z. A review on the impact tension behaviors of textile structural composites. J Ind Text. 2015;44(4):572–604. 10.1177/1528083713503001.Search in Google Scholar

[25] Spasova D, Argiro Y, Mechkarova T. Comparative analysis of the mechanical properties of polymer matrix composites reinforced with fiberglass fabric. TEM J. 2021;10(4):1745–50. 10.18421/TEM104-35.Search in Google Scholar

[26] Rios CR, Ogin SL, Lekakou C, Leong KH. A study of damage development in a weft-knitted fabric reinforcement composite. Part 1: experiment using model sandwich laminates. Compos Part A Appl Sci Manuf. 2007;38:1773–93.10.1016/j.compositesa.2006.02.027Search in Google Scholar

[27] ISO 527-3. plastics — determination of tensile properties — part 3: test conditions for films and sheets. Geneva, Switzerland: ISO Committee; 2018.Search in Google Scholar

[28] ISO 14125. Fibre-reinforced plastic composites – determination of flexural properties. Geneva, Switzerland: ISO Committee; 1998.Search in Google Scholar

[29] Mohamed M, Selim MM, Ning H, Pillay S. Effect of fiber prestressing on mechanical properties of glass fiber epoxy composites manufactured by vacuum-assisted resin transfer molding. J Reinf Plast Compos. 2020;39:21–30. 10.1177/0731684419868841.Search in Google Scholar

[30] Reddy MI, Kumar MA, Raju CRB. Tensile and flexural properties of jute, pineapple leaf and glass fiber reinforced polymer matrix hybrid composites. Mater Today Proc. 2018;5(1):458–62. 10.1016/j.matpr.2017.11.105.Search in Google Scholar

[31] Spanu P, Abaza BF. Tensile strength prediction of fiberglass polymer composites using artificial neural network model. Mater Plastice. 2022;59(2):111–8.10.37358/MP.22.2.5590Search in Google Scholar

[32] Jariwala H, Jain P, Maisuriya V. Experimental and statistical analysis of strength of glass fiber reinforced polymer composite for different fiber architecture. Polym Compos. 2021;42:1407–19. 10.1002/pc.25911.Search in Google Scholar

[33] Khoun L, Chaudhuri RI, Hubert P. Effect of low-profile additives on thermo-mechanical properties of glass fiber-reinforced unsaturated polyester composites. J Reinf Plast Compos. 2011;30(9):815–23. 10.1177/0731684411412643.Search in Google Scholar

[34] Al-Dulaimy AMA, Al-hassany MOA, Shakir SW. The effect of unidirectional pre-load on tensile characteristics of E-glass fiber and epoxy composite. Mater Today Proc. 2021;42(5):2510–5. 10.1016/j.matpr.2020.12.571.Search in Google Scholar

[35] Belaid S, Chabira SF, Balland P, Sebaa M, Belhouideg S. Thermal aging effect on the mechanical properties of polyester fiberglass composites. J Mater Environ Sci. 2015;6(10):2795–803.Search in Google Scholar

[36] Mostafa NH, Ismarrubie ZN, Sapuan SM, Sultan MTH. Effect of fabric biaxial prestress on the fatigue of woven E-glass/polyester composites. Mater Des. 2016;92:579–89. 10.1016/j.matdes.2015.12.109.Search in Google Scholar

[37] Santa JF, Vanegas-Jaramillo JD, Patiño ID. Mechanical characterization of composites manufactured by RTM process: effect of fiber content, strain rate and orientation. Lat Am J Solids Struct. 2016;13(2):344–64. 10.1590/1679-78252252.Search in Google Scholar

[38] de Oliveira FH, Helfer AL, Amico SC. Mechanical behavior of unidirectional curaua fiber and glass fiber composites. Macromol Symposia. 2012;319(1):83–92. 10.1002/masy.201100202.Search in Google Scholar

[39] Mahmoud M, Elnaby A. Experimental investigation of the relief time for fiberglass/epoxy composites with volume fraction 30% and 40%. Port-Said Eng Res J. 2020;24(1):141–7. 10.21608/pserj.2019.15934.1007.Search in Google Scholar

[40] Ismail A, Zubaydi A, Piscesa B, Tuswan T, Ariesta RC. Study of sandwich panel application on side hull of crude oil tanker. J Appl Eng Sci. 2021;19(4):1090–8.10.5937/jaes0-30373Search in Google Scholar

[41] Tuswan T, Zubaydi A, Piscesa B, Ismail A, Ariesta RC, Ilham MF, et al. Influence of application of sandwich panel on static and dynamic behaviour of ferry ro-ro ramp door. J Appl Eng Sci. 2021;19(1):208–16.10.5937/jaes0-27708Search in Google Scholar

[42] Ariesta RC, Zubaydi A, Ismail A, Tuswan T. Damage evaluation of sandwich material on side plate hull using experimental modal analysis. Mater Today Proc. 2021;47:2310–4.10.1016/j.matpr.2021.04.293Search in Google Scholar

[43] Tuswan T, Zubaydi A, Piscesa B, Ismail A, Ariesta RC, Prabowo AR. A numerical evaluation on nonlinear dynamic response of sandwich plates with partially rectangular skin/core debonding. Curved Layer Struct. 2022;9:25–39.10.1515/cls-2022-0003Search in Google Scholar

[44] Ismail A, Zubaydi A, Piscesa B, Ariesta RC, Tuswan T. Vibration-based damage identification for ship sandwich plate using finite element method. Open Eng. 2020;10(1):744–52.10.1515/eng-2020-0086Search in Google Scholar

[45] Tuswan T, Zubaydi, Piscesa B, Ismail A, Ilham MF. Free vibration analysis of interfacial debonded sandwich of ferry ro-ro’s stern ramp door. Procedia Struct Integr. 2020;27:22–9.10.1016/j.prostr.2020.07.004Search in Google Scholar

[46] Ariesta RC, Tuswan T, Zubaydi A, Ismail A. Identification of damage size effect of natural frequency on sandwich material using free vibration analysis. Nase More. 2022;69(1):1–8.10.17818/NM/2022/1.1Search in Google Scholar

[47] Tuswan T, Sari EN, Ismail A, Prabowo AR. Experimental evaluation on palm oil and sesame oil-based resin properties as core sandwich material for lightweight ship structure. Int J Eng Trans C. 2022;35(9):1690–8.10.5829/IJE.2022.35.09C.03Search in Google Scholar

[48] Ismail A, Zubaydi A, Piscesa B, Tuswan T. A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship-plate system. J Mech Behav Mater. 2023;32(1):20220288.10.1515/jmbm-2022-0288Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Investigation of differential shrinkage stresses in a revolution shell structure due to the evolving parameters of concrete

- Multiphysics analysis for fluid–structure interaction of blood biological flow inside three-dimensional artery

- MD-based study on the deformation process of engineered Ni–Al core–shell nanowires: Toward an understanding underlying deformation mechanisms

- Experimental measurement and numerical predictions of thickness variation and transverse stresses in a concrete ring

- Studying the effect of embedded length strength of concrete and diameter of anchor on shear performance between old and new concrete

- Evaluation of static responses for layered composite arches

- Nonlocal state-space strain gradient wave propagation of magneto thermo piezoelectric functionally graded nanobeam

- Numerical study of the FRP-concrete bond behavior under thermal variations

- Parametric study of retrofitted reinforced concrete columns with steel cages and predicting load distribution and compressive stress in columns using machine learning algorithms

- Application of soft computing in estimating primary crack spacing of reinforced concrete structures

- Identification of crack location in metallic biomaterial cantilever beam subjected to moving load base on central difference approximation

- Numerical investigations of two vibrating cylinders in uniform flow using overset mesh

- Performance analysis on the structure of the bracket mounting for hybrid converter kit: Finite-element approach

- A new finite-element procedure for vibration analysis of FGP sandwich plates resting on Kerr foundation

- Strength analysis of marine biaxial warp-knitted glass fabrics as composite laminations for ship material

- Analysis of a thick cylindrical FGM pressure vessel with variable parameters using thermoelasticity

- Structural function analysis of shear walls in sustainable assembled buildings under finite element model

- In-plane nonlinear postbuckling and buckling analysis of Lee’s frame using absolute nodal coordinate formulation

- Optimization of structural parameters and numerical simulation of stress field of composite crucible based on the indirect coupling method

- Numerical study on crushing damage and energy absorption of multi-cell glass fibre-reinforced composite panel: Application to the crash absorber design of tsunami lifeboat

- Stripped and layered fabrication of minimal surface tectonics using parametric algorithms

- A methodological approach for detecting multiple faults in wind turbine blades based on vibration signals and machine learning

- Influence of the selection of different construction materials on the stress–strain state of the track

- A coupled hygro-elastic 3D model for steady-state analysis of functionally graded plates and shells

- Comparative study of shell element formulations as NLFE parameters to forecast structural crashworthiness

- A size-dependent 3D solution of functionally graded shallow nanoshells

- Special Issue: The 2nd Thematic Symposium - Integrity of Mechanical Structure and Material - Part I

- Correlation between lamina directions and the mechanical characteristics of laminated bamboo composite for ship structure

- Reliability-based assessment of ship hull girder ultimate strength

- Finite element method on topology optimization applied to laminate composite of fuselage structure

- Dynamic response of high-speed craft bottom panels subjected to slamming loadings

- Effect of pitting corrosion position to the strength of ship bottom plate in grounding incident

- Antiballistic material, testing, and procedures of curved-layered objects: A systematic review and current milestone

- Thin-walled cylindrical shells in engineering designs and critical infrastructures: A systematic review based on the loading response

- Laminar Rayleigh–Benard convection in a closed square field with meshless radial basis function method

- Determination of cryogenic temperature loads for finite-element model of LNG bunkering ship under LNG release accident

- Roundness and slenderness effects on the dynamic characteristics of spar-type floating offshore wind turbine

Articles in the same Issue

- Research Articles

- Investigation of differential shrinkage stresses in a revolution shell structure due to the evolving parameters of concrete

- Multiphysics analysis for fluid–structure interaction of blood biological flow inside three-dimensional artery

- MD-based study on the deformation process of engineered Ni–Al core–shell nanowires: Toward an understanding underlying deformation mechanisms

- Experimental measurement and numerical predictions of thickness variation and transverse stresses in a concrete ring

- Studying the effect of embedded length strength of concrete and diameter of anchor on shear performance between old and new concrete

- Evaluation of static responses for layered composite arches

- Nonlocal state-space strain gradient wave propagation of magneto thermo piezoelectric functionally graded nanobeam

- Numerical study of the FRP-concrete bond behavior under thermal variations

- Parametric study of retrofitted reinforced concrete columns with steel cages and predicting load distribution and compressive stress in columns using machine learning algorithms

- Application of soft computing in estimating primary crack spacing of reinforced concrete structures

- Identification of crack location in metallic biomaterial cantilever beam subjected to moving load base on central difference approximation

- Numerical investigations of two vibrating cylinders in uniform flow using overset mesh

- Performance analysis on the structure of the bracket mounting for hybrid converter kit: Finite-element approach

- A new finite-element procedure for vibration analysis of FGP sandwich plates resting on Kerr foundation

- Strength analysis of marine biaxial warp-knitted glass fabrics as composite laminations for ship material

- Analysis of a thick cylindrical FGM pressure vessel with variable parameters using thermoelasticity

- Structural function analysis of shear walls in sustainable assembled buildings under finite element model

- In-plane nonlinear postbuckling and buckling analysis of Lee’s frame using absolute nodal coordinate formulation

- Optimization of structural parameters and numerical simulation of stress field of composite crucible based on the indirect coupling method

- Numerical study on crushing damage and energy absorption of multi-cell glass fibre-reinforced composite panel: Application to the crash absorber design of tsunami lifeboat

- Stripped and layered fabrication of minimal surface tectonics using parametric algorithms

- A methodological approach for detecting multiple faults in wind turbine blades based on vibration signals and machine learning

- Influence of the selection of different construction materials on the stress–strain state of the track

- A coupled hygro-elastic 3D model for steady-state analysis of functionally graded plates and shells

- Comparative study of shell element formulations as NLFE parameters to forecast structural crashworthiness

- A size-dependent 3D solution of functionally graded shallow nanoshells

- Special Issue: The 2nd Thematic Symposium - Integrity of Mechanical Structure and Material - Part I

- Correlation between lamina directions and the mechanical characteristics of laminated bamboo composite for ship structure

- Reliability-based assessment of ship hull girder ultimate strength

- Finite element method on topology optimization applied to laminate composite of fuselage structure

- Dynamic response of high-speed craft bottom panels subjected to slamming loadings

- Effect of pitting corrosion position to the strength of ship bottom plate in grounding incident

- Antiballistic material, testing, and procedures of curved-layered objects: A systematic review and current milestone

- Thin-walled cylindrical shells in engineering designs and critical infrastructures: A systematic review based on the loading response

- Laminar Rayleigh–Benard convection in a closed square field with meshless radial basis function method

- Determination of cryogenic temperature loads for finite-element model of LNG bunkering ship under LNG release accident

- Roundness and slenderness effects on the dynamic characteristics of spar-type floating offshore wind turbine