Abstract

A ceramic–steel composite structure which consists of Si3N4 ceramic bars and twinning-induced plasticity (TWIP) steel matrix was prepared using lost foam casting method. Microstructural analysis indicated that the ceramic bars and TWIP steel matrix can form favorable and tight interface. A comparison of mechanical properties between the composite structure and TWIP steel matrix was made. Results show that the bending strength increased from 388 to 805 MPa compared with TWIP steel matrix. The influence of annealing heat treatment on the bending strength of this new type of composite structure was also discussed.

Composite structures or materials which combine the advantages of two or more material properties have been used in many areas, such as wear resistance parts, heat resistance parts or special vehicle protections [1,2,3,4]. Metal matrix composites whose reinforcements and matrix are ceramics and metals offer more benefits thanks to higher stiffness, improved strength and better wear resistance compared to the unreinforced metal [5,6,7,8]. Oxides (e.g., ZrO2 and Al2O3), nitrides (e.g., Si3N4 and TiN) and carbides (e.g., TiC and VC) [9,10] ceramics are the common materials proposed to be used as reinforcement in metal based composites. Specifically, nitride ceramics have shown their suitability as reinforcements in steel and iron matrices due to their high hardness, low density, high melting temperature and high corrosion resistance [11].

Recently, some researchers have focused on metal matrix composites on the basis of steel matrix which exhibits special deformation properties. Nowadays, researchers continuously pay attention to the ceramic reinforced steel with the hope to improve the plastic deformation capacity. For example, steels with transformation-induced plasticity (TRIP steels) properties were processed with zirconia acting as particle reinforcements [12,13]. TRIP-steel matrix shows a high ductility and strain hardening capability [14], especially under compressive loading conditions. Particle reinforcements can improve the mechanical properties of steel matrix [15], which leads to a possible application of the materials in crash absorber components [12,16]. Simple changes in the chemical compositions of TRIP steel matrix trigger another important deformation mechanism, namely, mechanical twinning. Also, steels with twinning-induced plasticity (TWIP) effect exhibits excellent strain hardening properties and ductility [17]. Therefore, TWIP steels reinforced by Si3N4 ceramic bars are of interest at present.

It is generally accepted that with the increase in ceramic volume fraction, the wear resistance rises with the decrease in density, but there exists a limit value of reinforcement volume fraction for normal particle reinforced composite. Therefore, several excellent works have carried out research on the combination of monolithic ceramic with metals which can offer more efficient, lightweight and wear resistant structures [18–21]. For example, Sanusi et al. investigated a ceramic–steel composite structure and pointed out that ceramic–steel composite was much more effective in protection performance than medium carbon steel [22]. Ishchenko et al. studied a two-layer metal–ceramic composite which showed a high resistance to the penetration of the steel impactor [23]. Baumgart et al. prepared ceramic particles reinforced TWIP steel with different ceramic range from 0 to 10 vol%, and the results showed that TWIP matrices were much more damage-tolerant [24].

As mentioned above, addition of ceramics often provide a mechanical enhance of steel and many previous work also concentrated on ceramic reinforced steel matrix composites or structures. In fact, it should be noted that most of the reinforcement size in steel composites ranges from nanometers to micrometers in the purpose of ensuring the mechanical or microstructural properties. A few examples have been reported about ceramic bars reinforced TWIP steel composite structures. So, the objective of this study is to investigate the feasibility of processing this new type of TWIP steel matrix composite structure whose reinforcement is silicon nitride ceramic bars. The possibility of further improving the mechanical properties through a simple annealing heat treatment will be discussed here.

1 Experimental procedures

A set of commercially available silicon nitride (Si3N4) ceramic bars with a size of Φ5 mm × 95 mm were chosen as the reinforcements. Lost foam casting method is widely used to fabricate metal matrix composites or other locally reinforced composites because of the low cost and high efficiency. So, lost foam casting is adopted here to fabricate the composite structure. As shown in Figure 1, after polished and cleaned in alcohol, ceramics were inserted into the foam mold pattern which is made of polystyrene with a density of 0.03 g cm−3. Then, the foam mold patterns were coated and dried at 45°C for 24 h. The foam mold patterns were coated and dried for no less than 3 times in order to form a coating which is about 3 mm thick. Then, foam patterns were fixed in sand box whose size is 1 m × 1 m × 2 m. After filling with silica sand of 40–20 mesh size, the sand box is facilitated by a four-point clamping for 5 min at horizontal vibration. A 30 mm × 200 m × 400 m TWIP steel matrix without ceramics were also prepared for the mechanical properties and microstructure analysis.

Schematic picture of composite foam pattern.

The TWIP steel matrix has the composition of Fe–20Mn–0.6C and is prepared by intermediate frequency furnace using medium carbon steel, low carbon ferro-manganese and casting iron as raw materials. First, the medium carbon steel and casting steel were melted and held at 1,600°C for about 5 min. Then, low carbon ferro-manganese was added into the melt and soaked for 10 min during which aluminum deoxidation is used to avoid the burning of manganese alloying element. Finally, the melt is poured into the foam pattern at 1,600°C.

After being solidified, the castings were removed from the sand box. The inner macrostructure assessment was performed through non-destructive computerized tomography (CT) techniques. Annealing process which is shown in Figure 2 was carried out in a box heat treatment furnace based on previous experimental results [25]. The heating rate was 5°C min−1 and the cooling mode was air cooling. Scanning electron microscope (SEM) and optical microscopy (OM) were used to investigate the microstructure of composite structures. The mechanical properties were characterized through three points bending test at a rate of 2 mm min−1 on a MST testing machine. Bending specimens of reinforcement unit with a cross section size of 12 mm × 12 mm were machined from the composite structure. As illustrated in Figure 3, the ceramic bar is located in the center of the bending sample.

Annealing heat treatment process.

Schematic diagram of bending specimens.

2 Results and discussion

Non-destructive CT and SEM results are shown in Figures 4 and 5. Non-destructive CT photo of composite structure in Figure 4(b) reveals that there are no cracks, cavities, inclusions or other types of macroscopic imperfections in the TWIP steel matrix. The ceramics have been fully integrated into TWIP matrix steel. The SEM and Back electron image (BEI) results at the interface are shown in Figure 4(c) and (d) from which a perfect interface between ceramic bar and TWIP steel matrix could be observed. There exists a long crack which should be formed during the specimen preparing process due to uncontrollable factors. Energy dispersive scanning (EDS) results in Figure 5 show that alloying element diffusion phenomena exists at the interface. From the results of Figures 4 and 5, it can be concluded that the ceramic bars and TWIP steel matrix can form a favorable and tight interface.

(a) Photograph of TWIP steel composite structure and (b) non-destructive CT photo of composite structure. (c) SEM microstructure, and (d) BEI of interface between ceramic bar and TWIP steel matrix.

(a) SEM microstructure of interface, (b) Fe and (c) Si alloying elements distribution at interface.

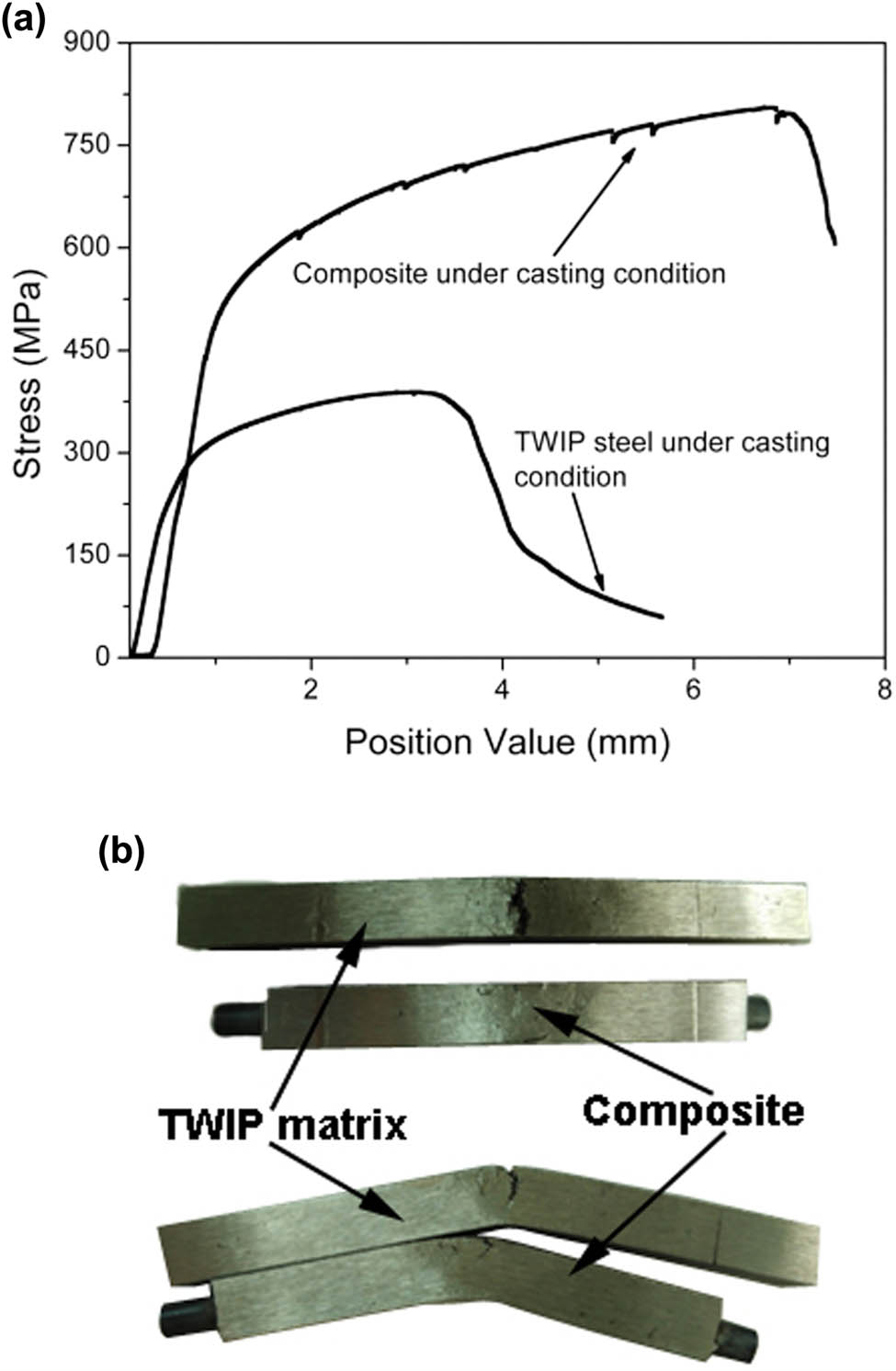

Bending curves and specimens after bending test are shown in Figure 6. As shown in Figure 6(a), an increase in strength and plasticity is demonstrated in the ceramic–steel composite compared with the TWIP steel matrix without ceramic bars. The bending strength of TWIP steel matrix is 388 MPa, while it reaches 805 MPa after combining with ceramics. This can be related to the strengthening effect of ceramic bars. Clamp displacement during bending test, which can be considered as a character of plasticity of TWIP steel matrix, is about 3 mm, while for the composite structure, it is about 6.8 mm. For TWIP steel matrix, after bending test, the specimen fractures completely, while only a short crack is formed in the composite structure even though bearing much more plastic deformation, as shown in Figure 6(b). Both the strength and plasticity of ceramic–steel composite structure are improved notably compared with the TWIP steel matrix under the same conditions.

Bending curves (a) and specimens after bending test (b).

A simple annealing heat treatment whose temperature and holding time are 500°C and 60 min respectively is selected to verify that it is possible to further improve the mechanical properties of this ceramic–steel composite structure. After heat treatment, bending test under the same conditions are used again to characterize the mechanical properties, and the results are shown in Figure 7. From Figure 7, it can be inferred that the bending strength of composite structure increased from 805 to 1,023 MPa while the clamp displacement increased from 6.8 to 9.6 mm after annealing heat treatment.

Bending strength of composite structure before and after heat treatment.

The increase in mechanical properties of ceramic–steel composite structure after annealing heat treatment can be attributed to the mechanical enhancement of TWIP steel matrix [25]. Even though annealing heat treatment has little effect on the ceramic bars, the mechanical properties of TWIP steel matrix are improved significantly. After annealing heat treatment, fine carbide particles were formed on the austenite matrix which has great influence on the mechanical properties of TWIP steels. As shown in Figure 8(a) and (b), the grain size of TWIP steel matrix before and after annealing heat treatment has no significant changes because the annealing temperature was not high enough. But there were precipitate particles to be observed after annealing heat treatment which enhanced the mechanical properties of TWIP steel matrix, as shown in Figure 8(c) and (d).

OM microstructure under casting (a) and annealing (b) conditions. Precipitation distribution under casting (c) and annealing (d) conditions.

The SEM and EDS results of TWIP steel matrix after annealing heat treatment are shown in Figure 9. EDS results indicate that the particles have abundant carbon, manganese and ferro which may be (Fe, Mn)3C precipitations. So the strength of TWIP steel matrix is enhanced after annealing heat treatment because of precipitation strengthening effect. This is consistent with the previous works [26,27]. Usually, the plasticity decreases with the increase in strength, but the plasticity of TWIP steel matrix is improved. This can be attributed to the decrease in stacking-fault energy (SFE) which plays an important role in the mechanical-induced twinning behavior of matrix. Considerable research efforts have been devoted to the influence of SFE on the mechanical properties of TWIP steel. Frommeyer et al. investigated the influence of SFE on the twinning behavior of TWIP steels and found that twinning occurred when the SFE was about 25 mJ m−2 [28]. Han and Hong reported that mechanical twinning occurs when the SFE < 60 mJ m−2 [29]. For the present TWIP steel matrix, the SFE value is about 20–40 mJ m−2. After annealing heat treatment, the value of SFE decreases because of carbide precipitation. So the mechanical-induced twinning behavior could occur more easily [28,29]. The different twinning effects of TWIP steel matrix after tensile under casting and annealing conditions are shown in Figure 10. In Figure 10, it can be seen that more mechanical twins were formed after annealing heat treatment. Both the strength and plasticity of TWIP steel matrix are modified after annealing heat treatment. So the mechanical properties of this ceramic reinforced TWIP composite structure are improved because of the modification of TWIP steel matrix.

SEM microstructure of TWIP steel matrix and EDS analysis results of precipitations.

Twinning morphology of TWIP steel matrix before (a) and after (b) annealing heat treatment.

3 Conclusion

In this study a new type of ceramic bar reinforced TWIP steel composite structure which displayed competitive mechanical properties were investigated. The following conclusions can be made from the aforementioned investigations:

TWIP steel combined with a size of φ 5 mm × 95 mm Si3N4 ceramic bars was successfully prepared through lost foam casting process.

A favorable and tight interface was formed between the ceramic bars and TWIP steel in the composite structure.

The bending strength of composite structure is 805 MPa which is much higher than that of TWIP matrix (only 388 MPa). After annealing at 500°C for 60 min, the bending strength of composite structure increased once more from 805 to 1,023 MPa.

Annealing at 500°C for 60 min is a useful process for the modification of this new type composite structure.

-

Funding information: This study was financially supported by the Key Scientific and Technological Projects in Henan Province (No. 182102210262) and the Fund Project of Henan Institute of Technology, China (KQ1823).

-

Conflict of interest: Authors state no conflict of interest.

References

[1] Kattamis TZ, Suganuma T. Solidification processing and tribological behavior of particulate TiC-Ferrous Matrix composites. Mater Sci & Eng A. 1990;128(2):241–52.10.1016/0921-5093(90)90232-RSearch in Google Scholar

[2] Almangour B, Grzesiak D, Yang JM. In situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J Alloy Compd. 2017;706(6):409–18.10.1016/j.jallcom.2017.01.149Search in Google Scholar

[3] Dong Q, Xing SM, Qiu B. Mixed regulation model of ceramic particles with molten high-chromium iron KmTBCr26. China Foundry. 2019;16(2):65–70.10.1007/s41230-019-8127-5Search in Google Scholar

[4] Degnan CC, Shipway PH. A comparison of the reciprocating sliding wear behaviour of steel based metal matrix composites processed from self-propagating high-temperature synthesized Fe-TiC and Fe-TiB2 master alloys. Wear. 2002;252(9):832–41.10.1016/S0043-1648(02)00051-0Search in Google Scholar

[5] Pai BC, Ramani G, Pillai RM, Satyanarayana KG. Role of magnesium in cast aluminium alloy matrix composites. J Mater Sci. 1995;30(8):1903–11.10.1007/BF00353012Search in Google Scholar

[6] Iwai Y, Hou W, Honda T, Yoneda H. Wear behaviour of high tensile strength aluminium alloys under dry and lubricated conditions. Wear. 1996;196(1):46–53.10.1016/0043-1648(95)06842-2Search in Google Scholar

[7] Kumar SA. In situ synthesis and characterization of TiC-reinforced hadfield manganese austenitic steel matrix composite. Trans Iron Steel Inst Jpn. 2009;49(9):1372–7.10.2355/isijinternational.49.1372Search in Google Scholar

[8] Seupel A, Eckner R, Burgold A, Kuna M, Krüger L. Experimental characterization and damage modeling of a particle reinforced TWIP-steel matrix composite. Mater Sci Eng A. 2016;662(4):342–55.10.1016/j.msea.2016.03.056Search in Google Scholar

[9] Pagounis E, Lindroos VK, Talvitie M. Influence of reinforcement volume fraction and size on the microstructure and abrasion wear resistance of hot Isostatic pressed white iron matrix composites. Metall Mater Trans A. 1996;27(12):4171–81.10.1007/BF02595665Search in Google Scholar

[10] Akhtar F. Ceramic reinforced high modulus steel composites: processing, microstructure and properties. Can Metall Q. 2014;53(3):253–63.10.1179/1879139514Y.0000000135Search in Google Scholar

[11] Wen G, Li SB, Zhang BS, Guo ZX. Reaction synthesis of TiB-TiC composites with enhanced toughness. Acta Materialia. 2001;49(8):1463–70.10.1016/S1359-6454(01)00034-9Search in Google Scholar

[12] Weigelt C, Aneziris CG, Yanina A, Guk S. Ceramic processing for TRIP-Steel/Mg-PSZ composite materials for mechanical applications. Steel Res Int. 2011;82(9):1080–6.10.1002/srin.201100073Search in Google Scholar

[13] Eckner R, Krampf M, Segel C, Krüger L. Strength and fracture behavior of a particle-reinforced transformation-toughened trip steel/ZrO2 composite. Mech Compos Mater. 2016;51(6):707–20.10.1007/s11029-016-9541-zSearch in Google Scholar

[14] Weigelt C, Schmidt G, Aneziris CG, Eckner R, Ehinger D, Krüger L, et al. Compressive and tensile deformation behaviour of TRIP steel-matrix composite materials with reinforcing additions of zirconia and/or aluminium titanate. J Alloy Compd. 2017;695(2):9–20.10.1016/j.jallcom.2016.10.176Search in Google Scholar

[15] Berek H, Aneziris CG, Hasterok M, Biermann H, Wolf S, Krüger L. Investigation of stress induced phase transformation in TRIP-Steel/Mg-PSZ composites using EBSD. Adv Eng Mater. 2011;13(11):1037–41.10.1002/adem.201100014Search in Google Scholar

[16] Weigelt C, Giersberg S, Wenzel C, Aneziris CG. Screening of the interactions between Mg-PSZ and TRIP-steel and its alloys during sintering. Adv Eng Mater. 2010;12(6):486–92.10.1002/adem.200900303Search in Google Scholar

[17] Seupel A, Eckner R, Burgold A, Kuna M, Krüger L. Experimental characterization and damage modeling of a particle reinforced TWIP-steel matrix composite. Mater Sci Eng A. 2016;662:342–55.10.1016/j.msea.2016.03.056Search in Google Scholar

[18] Akella K. Studies for improved damage tolerance of ceramics against ballistic impact using layers. Procedia Eng. 2017;173:244–50.10.1016/j.proeng.2016.12.006Search in Google Scholar

[19] Su Y, Fan H, Zhang Y, Song J, Chen S, Hu L. Fibrous monolithic ceramic with a single alumina phase: Fracture and high-temperature tribological behaviors. J Am Ceram Soc. 2019;102(8):4399–404.10.1111/jace.16420Search in Google Scholar

[20] Almangour B, Grzesiak D, Yang JM. Selective laser melting of TiB2/H13 steel nanocomposites: Influence of hot isostatic pressing post-treatment. J Mater Process Technol. 2017;244:344–53.10.1016/j.jmatprotec.2017.01.019Search in Google Scholar

[21] Islam MRI, Zheng JQ, Batra RC. Ballistic performance of ceramic and ceramic-metal composite plates with JH1, JH2 and JHB material models. Int J Impact Eng. 2020;137(3):103469.1–.27.10.1016/j.ijimpeng.2019.103469Search in Google Scholar

[22] Sanusi O, Oyelaran OA, Badmus JA. Ballistic study of alumina ceramic-steel composite for structural applications. J Ceram Process Res. 2020;21(4):501–7.Search in Google Scholar

[23] Ishchenko AN, Tabachenko AN, Akinshin RN, Afanas’eva SA, Borisenkov IL, Belov NN, et al. Development and investigation of a two-layer metal—ceramic material for protective barriers in conditions of high-speed impact. Technical Phys. 2018;63(7):988–94.10.1134/S1063784218070150Search in Google Scholar

[24] Baumgart C, Ehinger D, Weigelt C, Krüger L, Aneziris CG. Comparative study of TRIP/TWIP assisted high density composite honeycomb structures under compressive load. Compos Struct. 2016;136(2):297–304.10.1016/j.compstruct.2015.09.053Search in Google Scholar

[25] Sun G, Hu S, Gao Y, Chen W. Influence of direct annealing heat treatment on the mechanical properties of as-casting TWIP steels. J Mater Eng Perform. 2017;26(5):1981–5.10.1007/s11665-017-2634-6Search in Google Scholar

[26] Kang S, Jung YS, Jun JH, Lee YK. Effects of recrystallization annealing temperature on carbide precipitation, microstructure, mechanical properties in Fe-18Mn-0.6C-1.5Al TWIP steel. Mater Sci Eng A. 2010;527(3):745–51.10.1016/j.msea.2009.08.048Search in Google Scholar

[27] Curtze S, Kuokkala VT. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Materialia. 2010;58(15):5129–41.10.1016/j.actamat.2010.05.049Search in Google Scholar

[28] Frommeyer G, Brüx U, Neumann P. Supra-ductile and high-strength manganese-TRIP/TWIP steels for high energy absorption purposes. Isij Int. 2003;43(3):438–46.10.2355/isijinternational.43.438Search in Google Scholar

[29] Han YS, Hong SH. The effect of Al on mechanical properties and microstructures of Fe-32Mn-12Cr-xAl-0.4C cryogenic alloys. Mater Sci Eng A. 1997;222(1):76–83.10.1016/S0921-5093(96)10501-3Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete

Articles in the same Issue

- Regular Articles

- Experimental investigations of a novel pressure microfoam preparation device for dust removal

- Influence of hydrothermal aging on the mechanical performance of foam core sandwich panels subjected to low-velocity impact

- Experimental study on surface wrapping strengthening of EPS particles and its concrete performance

- Modification of mechanical properties of Shanghai clayey soil with expanded polystyrene

- A new EPS beads strengthening technology and its influences on axial compressive properties of concrete

- A novel superabsorbent material based on soybean straw: Synthesis and characterization

- Use of line laser scanning thermography for the defect detection and evaluation of composite material

- Research on back analysis of meso-parameters of hydraulic cemented sand and gravel based on Box-Behnken design response surface

- Hot deformation behavior and microstructure of a 0.5 wt% graphene nanoplatelet reinforced aluminum composite

- Analysis of electromagnetic characteristics of the proposed composite four-rail electromagnetic launcher

- Preparation and characterization of a graphene hybridizing polyurethane damping composite

- Effects of layup parameters and interference value on the performance of CFRP–metal interference fit joints

- Vibration and noise reduction of pipelines using shape memory alloy

- Finite element analysis of behavior and ultimate strength of composite column

- Dynamic response of functionally graded plate under harmonic load with variable gradient parameters

- Deformation behavior of rubber composite based on FEA and experimental verification

- Effects of Z-pin on moisture absorption property and damage mode under flexural load for carbon fiber composite

- Design and testing of a smart rubber stave for marine water-lubricated bearings

- Study of carbon nano-modifier of fly ash in cement concrete mixtures of civil engineering

- Analysis of multiple impact tests’ damage to three-dimensional four-directional braided composites

- Theoretical analysis of aluminum honeycomb sandwich panel supported by reinforced concrete wall under low-speed impact load

- Effects of local fiber discontinuity on the fatigue strength parameter at the fiber inclusion corner in fiber-reinforced composites

- Experimental investigation on compressive properties of three-dimensional five-directional braided composites in hygrothermal environment

- Failure process of steel–polypropylene hybrid fiber-reinforced concrete based on numerical simulations

- A simple method for measuring the monofilament diameter of continuous filament yarn with high bending stiffness via synthetic laser imaging

- Span length effect on flexural properties of composite laminate reinforced with a plain weave carbon fiber fabric in a polymer matrix

- Mechanical properties improving and microstructure characterization of inorganic artificial stone binder

- Effect of thermal treatment process on the structure of C/SiO2 composite aerogels

- Mechanical and corrosion resistance analysis of laser cladding layer

- Wear and corrosion mechanisms of Ni–WC coatings modified with different Y2O3 by laser cladding on AISI 4145H steel

- Damage and failure analysis of composite stiffened panels under low-velocity impact and compression after impact with damp-heat aging

- In-situ CT characterization of 2D woven SiCf/SiC composite loading under compression

- Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer

- Study of concrete properties based on crushed stone sand mixture and fiber of fly ash of thermal power plants

- Establishment of wear mechanism distribution diagram of ZTAp-reinforced iron matrix composites

- Calculation method of elastic modulus for carbon fiber-reinforced plastics considering inhomogeneous interphase

- An experimental study on the failure and enhancement mechanism of bolt-strengthening GFRP T-joint subjected to tensile loading

- The viability of cell that encapsulated in calcium alginate hydrogel beads

- Discussion of ceramic bar reinforced TWIP steel composite structure

- A theoretical framework underlying an accelerated testing method and its application to composites under constant strain rates and fatigue loading

- Theoretical analysis of interfacial design and thermal conductivity in graphite flakes/Al composites with various interfacial coatings

- Multiscale heat conduction and fractal oxidation behaviors of needle-punched carbon/carbon composites

- Numerical simulation of composite grid sandwich structure under low-velocity impact

- Wear properties of Al/TiO2 composites fabricated via combined compo-casting and APB process

- Review Articles

- Application of melanin as biological functional material in composite film field

- Review on research progress of cemented sand and gravel dam

- Communication

- Fabrications and microstructure analysis of cobalt-based coatings by an easy-coating and sintering process

- Letter to the Editor

- Investigation on mechanical and conductive behaviors of nano-graphite-based concrete