Abstract

The conventional method for testing the performance of reconfigurable sensory electronics of industry 4.0 relies on the direct measurement methods. This approach gives higher accuracy but at the price of extremely high testing cost and does not utilize the new degrees of freedom for measurement methods enabled by industry 4.0. In order to reduce the test cost and use available resources more efficiently, a primary approach, called indirect measurements or alternative testing has been proposed using a non-intrusive sensor. Its basic principle consists in using the indirect measurements, in order to estimate the sensory electronics performance parameters without measuring directly. The non-intrusive property of the proposed method offers better performance of the sensing electronics and virtually applicable to any sensing electronics. Efficiency is evaluated in terms of model accuracy by using six different classical metrics. It uses an indirect current-feedback instrumentation amplifier (InAmp) as a test vehicle to evaluate the performance parameters of the circuit. The device is implemented using CMOS 0.35 μm technology. The achieved maximum value of average expected error metrics is 0.24, and the lowest value of correlation performance metrics is 0.91, which represent an excellent efficiency of InAmp performance predictor.

Zusammenfassung

Die konventionelle Methode zur Prüfung der Leistungsfähigkeit rekonfigurierbarer sensorischer Elektronik der Industrie 4.0 beruht auf der Methode der direkten Messung. Dieser Ansatz bietet eine höhere Genauigkeit, aber zum Preis extrem hoher Testkosten und nutzt nicht die neuen Freiheitsgrade für Messmethoden, die durch Industrie 4.0 ermöglicht werden. Um die Testkosten zu senken und die modernen Ressourcen effizienter zu nutzen, wurde ein primärer Ansatz vorgeschlagen, der als indirekte Messungen oder alternative Tests unter Verwendung eines rückwirkungsfreien Sensors bezeichnet wird. Sein Grundprinzip besteht darin, die indirekten Messungen zu verwenden, um die Leistungsparameter der Sensorelektronik abzuschätzen, ohne direkt zu messen. Die rückwirkungsfreie Eigenschaft der vorgeschlagenen Methode bietet eine bessere Leistungsfähigkeit der Sensorelektronik und ist praktisch auf jede Sensorelektronik anwendbar. Die Effizienz wird im Hinblick auf die Modellgenauigkeit unter Verwendung von sechs verschiedenen klassischen Metriken bewertet. Sie verwendet einen Instrumentenverstärker mit indirekter Stromgegenkopplung als Testfahrzeug zur Bewertung der Leistungsparameter des Geräts. Der Baustein ist in CMOS 0,35 μm-Technologie entworfen. Der erreichte Maximalwert der Metriken für durchschnittlich erwartete Fehler liegt bei 0,24 und der niedrigste Wert der Korrelationsleistungs-Metriken bei 0,91, eine ausgezeichnete Effizienz des InAmp-Prädiktors darstellt.

1 Introduction and Survey

Recently, Artificial Intelligence (AI) and Machine Learning (ML) have achieved research attention in computer vision, robotics, natural language processing and biomedical applications. The fusion of ML and AI with emerging technologies, such as cyber-physical systems, industrial internet of things, cloud computing and big data analytics is enabling the most profound change in the industrialarea [7] known as industry 4.0 [10]. In IoTs devices and industry 4.0 environment, smart sensors play a fundamental role in data generation [7, 13]. This data accuracy is essential for fruitful estimation of system performance by AI or ML models. But unfortunately, the decay of the quality of the measurement sensory electronics system is observed [12, 14]. To overcome the process variations and aging effects, usually, analog readout circuits are overdesigned that occupy larger space and consume more power. However, AI in smart sensing electronics (SSE) will have the self-x (self-calibration, self-optimize, self-healing, etc.) properties [11]. The AI enables online calibration or in suit calibration methods to calibrate SSE even after the fabrication [6]. One of the well-known calibration methods includes designing an analog IC with controllable calibration knobs (CK) and performance evaluation set-up [12]. With the introduction of controllable calibration knobs, SSE can recalibrate themselves to compensate for severe PVT and aging effects variations, which relax the larger area and power consumption constraints[12]. Our institute is also working in parallel on the controllable calibration knobs issue for SSE [2].

The primary objective of this research is to figure out the low-cost performance measurement methods for SSE. There are two categories of the performance measurement set-up, depending on the evaluation criterion of the target characteristics. The first category uses an on-chip direct measurement method to verify target characteristics [12]. This method offers more precision and accuracy but increases the area and designing complexity [4]. The second category utilizes the indirect measurements (IMs) method based on the statistics that give a simultaneous prediction of multiple performance parameters from simple test stimuli [3, 4, 16, 18, 19]. Reference [19] applied a multitone signal to the operational amplifier and analyzed a time-domain transient signal for indirect predictions of characteristics such as slew rate, gain, bandwidth, phase margin and input range. To improve the prediction accuracy, an alternative test flow based on two defect filters concept is presented in [18]. A similar approach is illustrated in [16], in which an envelope detector is utilized to predict the performance parameters of ICs in a single test step. However, in the case of SSE, this pyramid of IMs would not be feasible due to limited resources constraints.

Among them, a non-intrusive IMs method is being shortlisted due to its simplicity and low-cost measurement set up as compared to other indirect IMs [3, 4]. The non-intrusive property implies that the sensor is electrically disconnected from the sensor electronics. Such low-cost sensors provide an image of operating conditions. As characteristics of analog circuits are highly correlated with operating conditions, the target characteristics can easily be predicted using a statistical model from other characteristics of non-intrusive sensors, measured in a cost-effective way [4, 12]. However, [4] only discussed the measurement methods for process variation, which reduces the accuracy of prediction in case of voltage and temperature variations [12]. Therefore, an extension of the non-intrusive sensor is required to completely capture the process, voltage and temperature variations for SSE in order to meet the demands of SSE for industry 4.0.

2 Proposed Methodology

2.1 Non-Intrusive Sensor

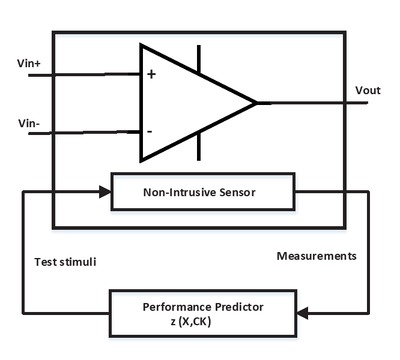

As already mentioned in the literature review, the proposed method uses an enhancement of non-intrusive IMs approach for SSE. The block diagram of the proposed low-cost indirect methodology is shown in figure 1, which uses a sinusoidal signal (1 kHz) as a test stimulus. The non-intrusive sensor is a combination of a current mirror stage, first-order low pass filter, and voltage divider. Figure 2 shows the schematic diagram of the non-intrusive sensor.

Block diagram of the proposed IMs method by using the non-intrusive sensor for SSE.

Detailed schematic diagram of the non-intrusive sensor. (a) Current mirror stage. (b) Voltage divider stage. (c) Firstorder low pass filter.

Firstly, the current mirror stage, as demonstrated in figure 2(a) acquires the variations of biasing current and voltage. The underlying architecture of InAmp also contains passive-resistive components for the gain adjustment, so secondly, the voltage divider stage as can be seen in figure 2(b) is being used to gather the variations of resistive elements of InAmp. Lastly, the first-order low pass filter consists of the passive poly capacitor, as illustrated in figure 2(c) to amass the deviation of compensation capacitors of InAmp. On the other hand, the introduction of a passive resistor element inside the first-order low pass filter stage is not feasible because either it requires a higher passive resistor value or higher frequencies for test stimuli (in GHz range). Therefore, a pseudoresistor constructed by the MOS-diode connected transistors concept [17] is used in the low-pass filter stage to satisfy the substantial resistors requirement. The first two non-intrusive sensors elements (the current mirror and the voltage divider) already used in the literature [3, 4] for performance estimation enhances, however, the accuracy of the prediction significantly by using the first-order low-pass filter. Usually, this circuit is avoided in the literature due to the higher value of the passive resistor or test stimuli. Thanks to the pseudoresistor concept, these requirements are significantly reduced.

2.2 Regression Model

The performances Y of the device under test are related to the PVT variations PV Tr and calibration knobs CK with a function f that can be defined as

It is impossible to measure the PVT variations, so we usually rely on the onset of measurements X that are related by PVT variations with a function g

By combining equation 1 and 2

The function z is unknown, and it is impossible to derive it analytically [4]. For this purpose, an artificial neural network (ANN) is being used for the regression task to approximate this function.

For training purpose, we generated N number of training samples by using Monte Carlo Simulation inside Cadence Virtuoso. Latin hypercube sampling (LHS) is being used in the Monte Carlo Simulation to cover the maximum process parameter space variations. In each sample, we have Y performances and X measurements for nominal CK setting. Therefore, the pairs [(Xn, CK), Yn] are being used to learn the regression model where n = 1, 2, . . . N. ANN is mainly inspired by biological neural networks. Such systems can learn to accomplish tasks by only considering training examples, normally without being programmed with task-oriented rules. Implementation of ANN is being performed in Tensorflow 2.0 and Keras functional API. The parameters of ANN are as follows

Learning rate = 0.01.

The number of hidden layers = 4.

Hidden layers activation function = Rectified Linear Unit (ReLU).

Output layers activation function = Linear activation function.

Optimizer = Adam optimizer.

Loss function = Mean squared error.

The number of epochs = 300.

Batch size = 50.

Validation dataset = 20%.

Dropout probability = 0.5.

3 Results and Discussions

3.1 Indirect Current Feedback Instrumentation Amplifier

A wide swing indirect current-feedback instrumentation amplifier (InAmp), which is one of the fundamental parts of measurement sensory electronics used as a test vehicle [8], and its performance parameters are being predicted using the non-intrusive IMs sensor. The InAmp is designedin the CMOS 0.35 μm technology provided by Austriamicrosystems (AMS). All simulations are carried out in Cadence in the ADEXL environment by Spectre simulator. The complete schematics diagram of InAmp is shown in figure 3.

The complete schematics diagram of fully-differential InAmp.

The InAmp is based on differential-difference amplifier (DDA) [2]. The transconductors at the input and output stage convert the respective voltages to corresponding current levels. The difference between the two currents is amplified by the next amplifying stages. The amplify stages convert their current difference to a voltage signal. They are employed to drive both the feedback network and the output load. The InAmp circuit includes power-down scheme transistors as well that lower the power almost to zero during the standby phase, this is particularly essential for the circuit powered by a battery. The five main performance parameters (gain, bandwidth, phase, slew rate+ and slew rate-) of the InAmp are considered for estimation by using low-cost non-intrusive sensors measurements. The nominal values of performance parameters in a typical simulation along with deviations in the performance parameters due to PVT variations are listed in Table 1. The nominal values of slew rate+ and slew rate- as well as the variations, are almost identical, that show the perfect symmetry of the InAmp for slew rate. The more details and transistors sizing information can be found in our institution’s former research work [2]. Due to the non-intrusive property of the proposed sensor, it is virtually applicable for the performance prediction of any analog integrated circuit.

InAMP nominal performance parameters and deviations due to PVT variations.

| Performance Parameter | Nominal | Maximum | Minimum |

|---|---|---|---|

| Gain (dB) | 106.10 | 134.30 | 83.21 |

| Bandwidth (MHz) | 42.80 | 61.72 | 28.85 |

| Phase Margin (◦) | 69.72 | 80.51 | 58.18 |

| Slew Rate+ | 83.90 | 90.48 | 68.60 |

| Slew Rate- | 83.90 | 90.48 | 68.60 |

3.2 IMs Performance Evaluation

The key of the proposed IMs methodology relay to the accurate derivation of the relationship presented in equation (3). Let yij and ŷij represent the ground truths and predicted values of the i-th performance of the j-th instance respectively, i = 1, . . . , 5, j = 1, . . . , N. In order to evaluate the performance, the following error metrics are being used:

– Root mean square error (RMSE) is one of the most commonly used performance metrics for regression tasks. It demonstrates the average expected error defined as

– Mean Absolute Error (MAS) is a linear score, that implies all individuals are weighted equally. It represents the absolute difference between the true and predicted values defined as

– Pearson’s correlation shows the linear correlation between the predicted and true values defines as

where

– R-squared error is another widely used performance evolution metric for the regression problems. It shows how close the data are to the predicted regression model also known as the coefficient of determination defined as

where yij is mean of the data.

– Adjusted-R squared is a modification of r-squared, that adjusts for the number of predictors in the model (p) to the number of observation points (N)

– A Figure of merit proposed in [5] compares the expected average error with respect to the data variability defined as

Generally, the performance of the regression model is accurate when the expected error is smaller, and the prediction error is less or at least equivalent to the measurement repeatability error of direct measurements. In this experiment, 80% instantiations of Monte Carlo simulation are randomly chosen for the training phase, while remaining

20% are selected for testing the performance of ANN. For PVT variations [1], the source voltage is varied between 3.0 V to 3.6 V with a step size of 300 mV, the temperature variation span is −40◦C to +85◦C with a step size of 5◦C, while for process variations different devices model has been selected provided by the foundry process design kit. The convergence curve of ANN is shown in figure 4.

Error convergence curve of the ANN with respect to epochs for validation and test loss.

The accuracy of prediction is summarized in Table 2. RMSE,MSE and FoM measure the average expectation error of the prediction model, so smaller the value, and better is the performance of prediction. On the other end p, R2 and R̄2 measure the correlation between predicted and true values, so the value closer to 1 (100 in case of p) is considered as a satisfactory performance of the predictor. From Table 2, we can observe that the highest value of average expected error metrics is 0.24 (in the case of RMSE), which is much lower than 1. Similarly, in the case of correlation performance metrics, the lowest value is 0.91, that represents a very good correlation between the true and predicted value of InAmp performance. If we ignore the first-order low pass filter, the performance of predictor reduced drastically from 0.91 to 0.79. Figure 5 shows the accuracy of the performance predictor graphically by using the scatter plot where values are normalized between 0 and 1. As illustrated in figure 5, the performance of the predictor model by using the proposed non-intrusive sensor lies on the 45-degree lines with considerably negligible deviations. In contrast, the efficiency of the non-intrusive sensor without proposed modifications is degraded considerably for complex circuits such as InAmp under several PVT variations.

Scatter plot of performance predicted values versus true values by using the ANN.

Efficiency of trained ANN to different error metrics.

| Performances | RMSE | MAS | p | R2 | R̄2 | FoM |

|---|---|---|---|---|---|---|

| Gain (dB) | 0.03 | 0.02 | 96.72 | 0.98 | 0.96 | 0.075 |

| Bandwidth (MHz) | 0.17 | 94.13 | 0.93 | 0.92 | 0.92 | 0.031 |

| Phase Margin (◦) | 0.09 | 0.06 | 95.33 | 0.96 | 0.93 | 0.018 |

| Slew Rate+ | 0.24 | 0.19 | 93.02 | 0.94 | 0.91 | 0.019 |

| Slew Rate- | 0.24 | 0.19 | 93.02 | 0.94 | 0.91 | 0.019 |

4 Conclusions

The main contribution of this paper is to present the lowcost IMs method in the presence of voltage, temperature and process variations for reconfigurable SSE. The proposed non-intrusive IMs method is a combination of the current mirror, voltage divider and first-order low pass filter. Although the efficiency of the proposed non-intrusive sensor is being evaluated to estimate the performance parameters of the reconfigurable InAmp readout circuit, it is virtually applicable to any analog circuit. Moreover, due to non-intrusive property, it does not degrade the performance of the main circuitry. Finally, the performance of the suggested non-intrusive sensor is being assessed by using six various classical performance evaluation metrics. The prediction error can be modelled easily as an input uncertainty for robust optimization of analog integrated circuits as proposed recently in [20] for efficient optimization of SSE. However, imperfect observer (sensor or ADC) performance degradation problem is also a major concern for SSE [9, 20]. The proposed regression model will be modified accordingly in the near future for efficient handling of this issue [15]. As far as intrinsic evolution is a concern, there is also ongoing research activity on the extension of USIX (universal and Self-X integrated sensor interface) chip [8] to build a hardware platform for SSE [2] where the proposed approach will be applied for indirect performance measurements of USIX chip.

References

[1] "In chip monitoring, telemetry and analytics", 2020 (accessed June 27, 2020). URL https://www.moortec.comSearch in Google Scholar

[2] S. Alraho and A. König. Wide input range, fully-differential indirect current feedback instrumentation amplifier for self- x sensory systems/symmetrischer instrumentierungsverstärker mit indirekter stromgegenkopplung und hoher eingangsignalspanne für integrierte sensorsysteme mit self-x-eigenschaften. tm-Technisches Messen, 86(s1):62–66, 2019.10.1515/teme-2019-0054Search in Google Scholar

[3] M. Andraud, H.-G. Stratigopoulos, and E. Simeu. One-shot calibration of rf circuits based on non-intrusive sensors. In IEEE Design Automation Conference (DAC). IEEE, 2014.10.1109/DAC.2014.6881337Search in Google Scholar

[4] M. Andraud, H.-G. Stratigopoulos, and E. Simeu. Oneshot non-intrusive calibration against process variations for analog/rf circuits. IEEE TCAS I: Regular Papers, 63(11): 2022–2035, 2016.10.1109/TCSI.2016.2598184Search in Google Scholar

[5] M. J. Barragán, R. Fiorelli, G. Leger, A. Rueda, and J. L. Huertas. Alternate test of lnas through ensemble learning of on-chip digital envelope signatures. Journal of Electronic Testing, 27(3):277–288, 2011.10.1007/s10836-010-5193-4Search in Google Scholar

[6] F. Delaine, B. Lebental, and H. Rivano. In situ calibration algorithms for environmental sensor networks: A review. IEEE Sensors Journal, 19(15):5968–5978, 2019.10.1109/JSEN.2019.2910317Search in Google Scholar

[7] A. Diez-Olivan, J. Del Ser, D. Galar, and B. Sierra. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards industry 4.0. Information Fusion, 50: 92–111, 2019.10.1016/j.inffus.2018.10.005Search in Google Scholar

[8] R. Freier. Ein universelles und dynamisch rekonfigurierbares interface fur eingebettete und intelligente multi-sensorsysteme mit self-x eigenschaften. 2015.Search in Google Scholar

[9] M. A. Johar, R. Freier, and A. Koenig. Adding self-x capabilities to amr sensors as a first step towards dependable embedded systems. In 2011 Proceedings of the Ninth International Workshop on Intelligent Solutions in Embedded Systems, pages 41–46. IEEE, 2011.Search in Google Scholar

[10] H. Kagermann, J. Helbig, A. Hellinger, and W. Wahlster. Recommendations for implementing the strategic initiative INDUSTRIE 4.0: Securing the future of German manufacturing industry; final report of the Industrie 4.0 Working Group. Forschungsunion, 2013.10.3390/sci4030026Search in Google Scholar

[11] J. Lee, H. Davari, J. Singh, and V. Pandhare. Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manufacturing letters, 18:20–23, 2018.10.1016/j.mfglet.2018.09.002Search in Google Scholar

[12] S. Lee, C. Shi, J. Wang, A. Sanabria, H. Osman, J. Hu, and E. Sánchez-Sinencio. A built-in self-test andin situanalog circuit optimization platform. IEEE TCAS I: Regular Papers, 65(10):3445–3458, 2018.10.1109/TCSI.2018.2805641Search in Google Scholar

[13] Y.-B. Lin, Y.-W. Lin, J.-Y. Lin, and H.-N. Hung. Sensortalk: An iot device failure detection and calibration mechanism for smart farming. Sensors, 19(21):4788, 2019.10.3390/s19214788Search in Google Scholar PubMed PubMed Central

[14] Y.-B. Lin, Y.-W. Lin, J.-Y. Lin, and H.-N. Hung. Sensortalk: An iot device failure detection and calibration mechanism for smart farming. Sensors, 19(21):4788, 2019.10.3390/s19214788Search in Google Scholar

[15] A. Maas, Q. V. Le, T. M. O’neil, O. Vinyals, P. Nguyen, and A. Y. Ng. Recurrent neural networks for noise reduction in robust asr. 2012.10.21437/Interspeech.2012-6Search in Google Scholar

[16] V. Natarajan, S. Sen, A. Banerjee, A. Chatterjee, G. Srinivasan, and F. Taenzler. Analog signature-driven postmanufacture multidimensional tuning of rf systems. IEEE Design & Test of Computers, 27(6):6–17, 2010.10.1109/MDT.2010.123Search in Google Scholar

[17] W. Rong, J. H. Huijsing, and K. A. Makinwa. Precision instrumentation amplifiers and read-out ICs. 2006.Search in Google Scholar

[18] H.-G. Stratigopoulos and S. Mir. Adaptive alternate analog test. IEEE Design & Test of Computers, 29(4):71–79, 2012.10.1109/MDT.2012.2205480Search in Google Scholar

[19] P. N. Variyam, S. Cherubal, and A. Chatterjee. Prediction of analog performance parameters using fast transient testing. IIEEE TCAD, 21(3):349–361, 2002.10.1109/43.986428Search in Google Scholar

[20] Q. Zaman and A. König. Self-x integrated sensor circuits immune to measurement noise in the presence of input perturbation by using robust optimization/integrierte sensorelektronik mit self-x-eigenschaften und verbesserter immunität gegenüber rauscheinflüssen bei der messung und störung der eingangsgrößen durch ein robustes optimierungsverfahren. tm-Technisches Messen, 86(s1):107–111, 2019.10.1515/teme-2019-0053Search in Google Scholar

© 2020 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Editorial

- XXXIV. Messtechnisches Symposium

- Beiträge

- Detektion der Auflagestege von Flachbett-Laserschneidmaschinen mittels Nahinfrarot-Beleuchtung

- Lichtfeld-Tiefenschätzung für die Vermessung teilspiegelnder Oberflächen

- Ganzheitliche Kalibrierung von Gewinden auf Basis eines dreidimensionalen Ansatzes

- Analyse von 3D-CT-Aufnahmen von Spänen zur Extrahierung der Segmentspanbildungsfrequenz

- Resolution enhancement through nearfield-assistance in interference microscopy

- Fertigung polymerer optischer Phasenplatten zur Erzeugung von Ringmoden mittels direkter Laserlithografie

- Direct-imaging DOEs for high-NA multi-spot confocal microscopy

- Methoden zur Minimierung des Rauscheinflusses durch Hitzeflimmern bei einem heterodynen Laser-Doppler-Vibrometer

- Inverse piezoelectric material parameter characterization using a single disc-shaped specimen

- Klassifikation von Grübchenschäden an Zahnrädern mittels Vibrationsmessungen

- Incorporation of phase information for improved time-dependent instrument recognition

- Akustische Zeitumkehrfokussierung in Wasser mittels FPGA-basierter Plattform

- De-Embedding-Ansatz zur Messung nichtidealer Kapazitäten mit kommerziellen Kapazitätssensoren

- Low-cost Indirect Measurement Methods for Self-x Integrated Sensory Electronics for Industry 4.0

- Reconfigurable Wide Input Range, Fully-Differential Indirect Current-Feedback Instrumentation Amplifier with Digital Offset Calibration for Self-X Measurement Systems

- A Compact Four Transistor CMOS-Design of a Floating Memristor for Adaptive Spiking Neural Networks and Corresponding Self-X Sensor Electronics to Industry 4.0

- Monte-Carlo-Methode zur Verringerung von Messfehlern bei der Materialparameterbestimmung mit Hohlraumresonatoren

- Bestimmung des Anregungsspektrums für kontaktlose breitbandige Messungen der Übertragungsfunktion mit Plasmaanregung und Laser-Doppler-Vibrometrie

- Self-sufficient vibration sensor for high voltage lines

- Flexibler organischer elektrochemischer Transistor als Biosensor für Organ-on-a-Chip

- Erkennung und Kompensation von Vergiftung durch Siloxane auf Halbleitergassensoren im temperaturzyklischen Betrieb

Articles in the same Issue

- Frontmatter

- Editorial

- XXXIV. Messtechnisches Symposium

- Beiträge

- Detektion der Auflagestege von Flachbett-Laserschneidmaschinen mittels Nahinfrarot-Beleuchtung

- Lichtfeld-Tiefenschätzung für die Vermessung teilspiegelnder Oberflächen

- Ganzheitliche Kalibrierung von Gewinden auf Basis eines dreidimensionalen Ansatzes

- Analyse von 3D-CT-Aufnahmen von Spänen zur Extrahierung der Segmentspanbildungsfrequenz

- Resolution enhancement through nearfield-assistance in interference microscopy

- Fertigung polymerer optischer Phasenplatten zur Erzeugung von Ringmoden mittels direkter Laserlithografie

- Direct-imaging DOEs for high-NA multi-spot confocal microscopy

- Methoden zur Minimierung des Rauscheinflusses durch Hitzeflimmern bei einem heterodynen Laser-Doppler-Vibrometer

- Inverse piezoelectric material parameter characterization using a single disc-shaped specimen

- Klassifikation von Grübchenschäden an Zahnrädern mittels Vibrationsmessungen

- Incorporation of phase information for improved time-dependent instrument recognition

- Akustische Zeitumkehrfokussierung in Wasser mittels FPGA-basierter Plattform

- De-Embedding-Ansatz zur Messung nichtidealer Kapazitäten mit kommerziellen Kapazitätssensoren

- Low-cost Indirect Measurement Methods for Self-x Integrated Sensory Electronics for Industry 4.0

- Reconfigurable Wide Input Range, Fully-Differential Indirect Current-Feedback Instrumentation Amplifier with Digital Offset Calibration for Self-X Measurement Systems

- A Compact Four Transistor CMOS-Design of a Floating Memristor for Adaptive Spiking Neural Networks and Corresponding Self-X Sensor Electronics to Industry 4.0

- Monte-Carlo-Methode zur Verringerung von Messfehlern bei der Materialparameterbestimmung mit Hohlraumresonatoren

- Bestimmung des Anregungsspektrums für kontaktlose breitbandige Messungen der Übertragungsfunktion mit Plasmaanregung und Laser-Doppler-Vibrometrie

- Self-sufficient vibration sensor for high voltage lines

- Flexibler organischer elektrochemischer Transistor als Biosensor für Organ-on-a-Chip

- Erkennung und Kompensation von Vergiftung durch Siloxane auf Halbleitergassensoren im temperaturzyklischen Betrieb