Abstract

In this study conductive composites of low-density polyethylene (LDPE)/ethylene-vinyl acetate (EVA) filled with carbon black (CB) and carbon fiber (CF) were prepared by melt-mixing method. The morphological, rheological, and electrical properties of CB filled composites were compared with CF filled composites by digital multimeter, scanning electron microscope, rotational rheometer, etc. The composites filled with different fillers have same percolation threshold but the EVA concentration has different effect on the two systems. For CB filled composites the increase in EVA concentration decreased resistivity first and reached lowest point when the LDPE:EVA ratio was 70:30; then the resistivity increased, but for CF filled composites the resistivity continued to decrease. The differences were caused by the diverse morphological and filler distribution of two different composite systems. The rheological behaviors of two types of composites also had significant difference; the value of complex viscosity of CB filled composites was about two orders of magnitude more than CF filled composites in low frequency region. It was because CB particles was nano-scale and had large surface area, so it had great influence on the value of complex viscosity of composites.

1 Introduction

Conductive polymer composites can be prepared by adding conductive fillers such as carbon black (CB), carbon nanotube, graphite, carbon fiber (CF), and metal powders [1], [2], [3] into polymer matrix. They impart the advantages of being light weight, easy to process like the polymers and good electrical conductivity to the composites. Through controlling the content of conductive fillers the resistivity of composites can be adjusted but the filler content should exceed the percolation to show electrical conductivity [4]. Now the conductive polymer composites are mainly used in various applications in the electronic, chemical, space, and energy industries [5], [6], [7]. CB is the most common conductive filler known for its low resistivity and low price. CB filled composites can achieve permanent conductivity and have good stability. Phase structure of polymer blend system is an important factor to affect electrical properties of composites. In blend system, if CB particles distribute in one of the phases, the content of CB and continuous state of CB affect the electrical property. If CB distributes in the interface of two phases, continuous degree of two phase interface is an important factor in influencing the electrical properties of the composites. If CB percolates at one matrix or at the interface of two matrices, the whole system will conduct electricity. Selective dispersion of CB also has effect on the electrical property [8]. CB tends to disperse in polar polymer phase. So if different matrices have huge differences on polar, CB disperses in strong polar matrices. If the polar difference between matrices is small, CB disperses in the interface of different matrices. Contrast to CB the advantage of the chopped CF lies in large length-diameter ratio and high modulus [9], so that it can work as conductive filler and reinforcing filler simultaneously [10]. But the most serious problem restricting the CF as a universal conductivity filler is its high-cost, so it is important to get high conductivity materials with low filler loading.

Most of previous researches focused on the influence of matrix component, filler characteristics, filler pretreatment on composites conductive property, and positive temperature coefficient [11], [12], [13], [14], [15]. However except conductive property, the rheological property also has great influence on processing and application of composites. The rheological property will experience great change along with the change of fillers and matrices [16].

In this study, the conductive and rheological properties of low-density polyethylene (LDPE)/ethylene vinyl acetate (EVA)/CB and LDPE/EVA/CF composites have been investigated and compared systemically. The EVA contents have different effects on CF and CB filled composites. For CB filled composites, along with the increasing EVA concentration the resistivity of composites decreased first and reached the lowest when the LDPE:EVA ratio is 70:30; then the resistivity increased with the increasing EVA concentration. But for CF filled composites the resistivity of composites monotonously decreased with increasing EVA concentration. Moreover the EVA phase also changed the microstructure of composites and caused the viscosity of composites to increase, with the rheological properties changed.

2 Materials and methods

2.1 Materials

The matrix polymer used in this study were LDPE and EVA. LDPE (LA-0710, Qatar Petroleum Chemical Co., Ltd, Doha, Qatar) was a commercial grade polymer with a melt flow index of 7 g/10 min and density of 0.918 g/cm3 and Tm of 108°C. EVA (770, E. I. du Pont de Nemours and Company, Wilmington, DE, USA) was also a commercial copolymer with a melt flow index value of 0.8 g/10 min and density of 0.93 g/cm3, and Tm of 96°C and a vinyl acetate content of 9.5%. The CB was acetylene black [average size, 24 nm; di-b-butyl-phthalate value, 260 cm3/100 g; Brunauer-Emmett-Teller value. 63 m2/g, Tianjin LiHuaJin Chemical Industry corporation; Tianjing, China]. The CF was pan-based carbon fiber (average length, 5 mm; average diameter, 7 um; Nanjing WeiDa Composite Material Corporation; Nanjing, China).

2.2 Preparation of conducting composites

All the materials were air-oven-dried before use. Composites were prepared by melt processing in internal mixer (ShangHai KCCK, type XSS-300) at temperature of 180°C and rotation speed of 60 r/min for 30 min. CB and CF contents (in wt%) are listed in Tables 1 and 2.

Carbon black content (in wt%) of the composite.

| LDPE/EVA | CB | LDPE/EVA | CB | LDPE/EVA | CB | LDPE/EVA | CB | LDPE/EVA | CB | LDPE/EVA | CB |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 100/0 | 0 | 90/10 | 0 | 80/20 | 0 | 70/30 | 0 | 60/40 | 0 | 50/50 | 0 |

| 100/0 | 3 | 90/10 | 3 | 80/20 | 3 | 70/30 | 3 | 60/40 | 3 | 50/50 | 3 |

| 100/0 | 6 | 90/10 | 6 | 80/20 | 6 | 70/30 | 6 | 60/40 | 6 | 50/50 | 6 |

| 100/0 | 9 | 90/10 | 9 | 80/20 | 9 | 70/30 | 9 | 60/40 | 9 | 50/50 | 9 |

| 100/0 | 12 | 90/10 | 12 | 80/20 | 12 | 70/30 | 12 | 60/40 | 12 | 50/50 | 12 |

| 100/0 | 15 | 90/10 | 15 | 80/20 | 15 | 70/30 | 15 | 60/40 | 15 | 50/50 | 15 |

| 100/0 | 18 | 90/10 | 18 | 80/20 | 18 | 70/30 | 18 | 60/40 | 18 | 50/50 | 18 |

| 100/0 | 21 | 90/10 | 21 | 80/20 | 21 | 70/30 | 21 | 60/40 | 21 | 50/50 | 21 |

| 100/0 | 24 | 90/10 | 24 | 80/20 | 24 | 70/30 | 24 | 60/40 | 24 | 50/50 | 24 |

| 100/0 | 27 | 90/10 | 27 | 80/20 | 27 | 70/30 | 27 | 60/40 | 27 | 50/50 | 27 |

Carbon filler content (in wt%) of the composite.

| LDPE/EVA | CF | LDPE/EVA | CF | LDPE/EVA | CF | LDPE/EVA | CF | LDPE/EVA | CF | LDPE/EVA | CF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 100/0 | 0 | 90/10 | 0 | 80/20 | 0 | 70/30 | 0 | 60/40 | 0 | 50/50 | 0 |

| 100/0 | 3 | 90/10 | 3 | 80/20 | 3 | 70/30 | 3 | 60/40 | 3 | 50/50 | 3 |

| 100/0 | 6 | 90/10 | 6 | 80/20 | 6 | 70/30 | 6 | 60/40 | 6 | 50/50 | 6 |

| 100/0 | 9 | 90/10 | 9 | 80/20 | 9 | 70/30 | 9 | 60/40 | 9 | 50/50 | 9 |

| 100/0 | 12 | 90/10 | 12 | 80/20 | 12 | 70/30 | 12 | 60/40 | 12 | 50/50 | 12 |

| 100/0 | 15 | 90/10 | 15 | 80/20 | 15 | 70/30 | 15 | 60/40 | 15 | 50/50 | 15 |

2.3 Electrical properties

Some 15 mm×15 mm×2 mm shape specimens were compression molded under 10 Mpa force at 180°C for 5 min using platen press and cooled. The resistance was tested with the digital multimeter (VC9808+, Shenzhen Victory Electronic Technology Corporation; Shenzhen, China) when it was lower than 108 and the resistivity was calculated by the following equation:

where R is the resistance of the sample (Ω); S is the cross-sectional area of the sample which is vertical to current direction (cm2); and L is the length of the sample which is parallel to current direction (cm). When the resistance exceeds 108, the high-resistance meter (ZC36, Shanghai Precision Scientific Instrument Corporation; Shanghai, China) was used, and the resistivity was calculated by the following equation:

where R is the resistance of the sample (Ω); S is the effective area of measuring electrode (19.2 cm2); and d is the thickness of the sample (cm).

2.4 Morphology

The microstructure of composites was analyzed using scanning electron microscope (SEM) (JSM-6510, JEOL). All samples are immersed in liquid nitrogen for 15 min and fractured and then gold-sputtered before observation.

2.5 Thermal properties

Different scanning calorimetry (DSC) measurement was performed by AQ20 (USA TA Instruments). The sample was first heated to 180°C at a rate of 10°C/min and held for 5 min at 180°C for elimination of the thermal history; then cooled down to 40°C at a rate of 10°C/min. Finally it was heated up to 180°C at a rate of 10°C/min for collection of the data.

2.6 Rheological measurements

Dynamic rheological behavior was measured by rotational rheometer (MCR302, Anton Paar GmbH) in oscillatory shear at 1% strain in the parallel plate with 25 mm. The sweep frequency is from 0.1 to 100 rad/s, and the temperature is 180°C.

3 Results and discussion

3.1 Conductivity

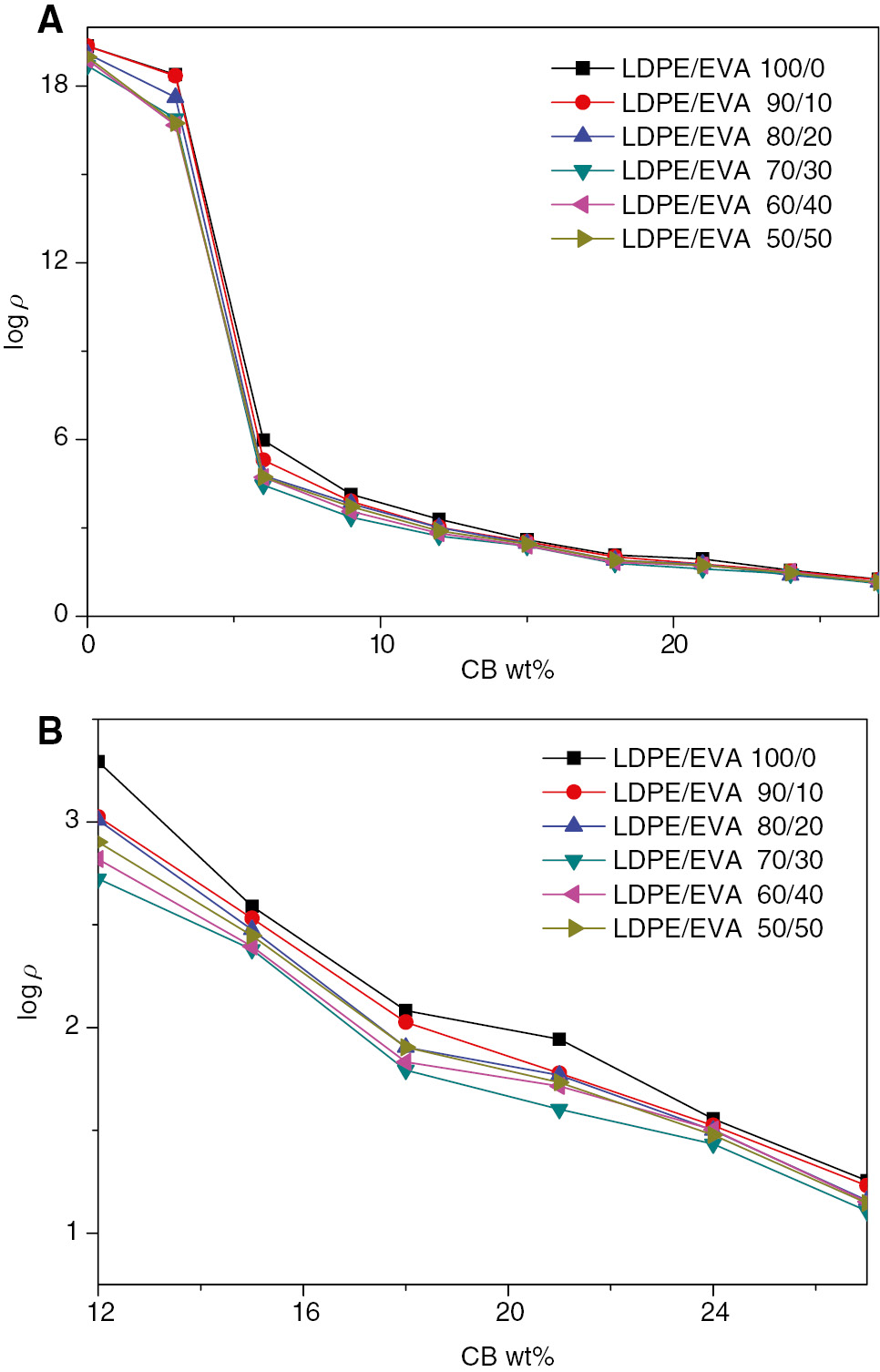

Figure 1A gives the dependence of resistivity on CB content for different proportions of LDPE and EVA from 100/0 to 50/50. When the content of CB exceeds 9% the difference of resistivity between composites is subtle. So Figure 2A gives the dependence of resistivity on CB content between 12% and 27% for different proportion of LDPE and EVA from 100/0 to 50/50. It can be seen that with increasing EVA, the resistivity of composites decreased first and reached the lowest point at a proportion of LDPE/EVA being 70/30. Then along with the increase in EVA, the resistivity began to rise.

The composites resistivity with different EVA contents: (A) Composites resistivity vs. CB content; (B) Composites resistivity vs. CB content from 12% to 27%.

SEM micrographs of the LDPE/EVA/CB containing 15 wt% CB with different LDPE/EVA mass ratios: (A) LDPE/EVA=100/0; (B) LDPE/EVA=80/20; (C) LDPE/EVA=60/40.

There are three causes attributed to this phenomenon. First the addition of EVA changed the CB particles distribution in matrix, which led to some CB particles transfer from LDPE phase to interface of LDPE phase and EVA phase. Because if the polarity of matrix is not having big difference, CB prefers to locate in the interface or one phase near the interface [17]. It is beneficial to uniformly disperse CB. Figure 2 is the SEM picture of LDPE/EVA/CB composites. Contrast (A) and (B), it could be found that CB particles transferred from LDPE phase to the interface of LDPE phase and EVA phase.

Second the increase in EVA content changes the microstructure of the composites. In Figure 2B, LDPE and EVA form net-like structure when the LDPE:EVA ratio is 70:30. In Figure 2C when the ratio increases to 60:40, LDPE and EVA form co-continuous phase, contrast to net-like structure the co-continuous phase structure is not conductive to CB disperse.

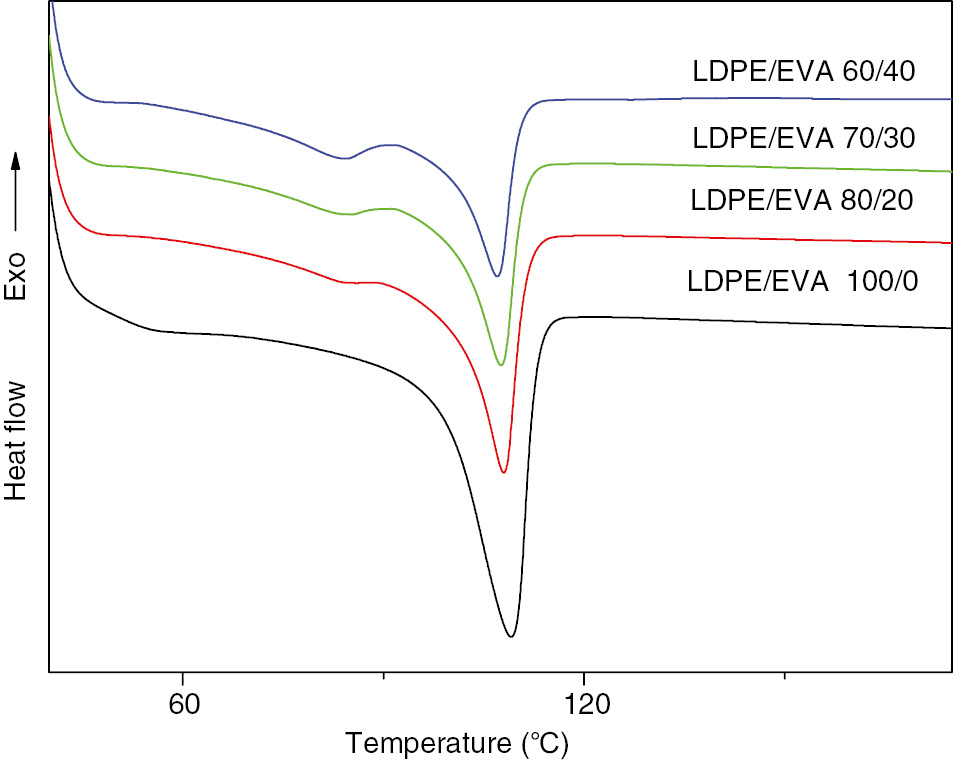

Third some CB particles transfer to the interface, but rest of the CB particles still are present in LDPE amorphous region. From Figure 3, the DSC curves of LDPE/EVA/CB composites with the same CB content but different EVA content, it can be seen that the melting enthalpy of LDPE experienced great decline with the increasing percentage of EVA. So EVA inhibits the crystallization behavior of LDPE, this result is similar to Xu et al.’s [18]; it means the amorphous phase of LDPE is increased, which is equal to dilute CB concentration. The resistivity of composites will increase. The synergistic effect of these three factors causes this phenomenon.

The DSC curves of LDPE/EVA/CB composites.

Figure 4 shows the dependence of resistivity on CF content for different proportions of LDPE and EVA from 100/0 to 50/50. Along with the rise of EVA content, the resistivity of composites drop monotonously. Before explaining this phenomenon, it is shown in Figure 5 that the SEM pictures of composites, the EVA wrap in the surface of CF improve the compatibility of CF and matrix. So EVA works as a compatilizer, and the composites’ resistivity decreases with an increase in EVA content.

Resistivity of composites with different ratios of LDPE to EVA vs. CF content.

SEM micrographs of the LDPE/EVA/CF containing 15 wt% CF with different LDPE/EVA mass ratios: (A) LDPE/EVA=100/0; (B) LDPE/EVA=80/20; (C) LDPE/EVA.

Figure 6 is the contrast of LDPE/EVA/CB and LDPE/EVA/CF composites in electrical properties. When the filler content exceeds the percolation threshold, the resistivity of the samples with CF is much lower than the samples with CB. This is because the chopped CF has large length-diameter ratio, which is beneficial in forming conductive network.

Contrast of LDPE/EVA/CB and LDPE/EVA/CF composites resistivity with different ratios of LDPE to EVA.

(A) LDPE/EVA 100/0, (B) LDPE/EVA 80/20, (C) LDPE/EVA 60/40, (D)LDPE/EVA 50/50.

3.2 Rheological properties

Figure 7 gives the dynamic rheological curves of LDPE/CB and LDPE/CF composites. In Figure 7A, the curve of complex viscosity η* vs. sweep frequency ω, all composites’ η* increased along with the increase in filled concentration. It is because the friction between matrix and filler increased and the chain movement of matrix is restricted. For LDPE/CF composite at low frequency region the complex viscosity was not sensitive to sweep frequency, but along with the increase in sweep frequency the composites exhibited a very strong shear thinning effect, the result is concur with that of Zhang et al.’s [19]. For LDPE/CB composites when the CB reaches 12 wt%, the composites have shear thinning effect in low frequency region; it illustrates dense filler network has formed inside the materials. Figure 6B,C exhibits the function of storage modulus and loss modulus at 180°C. At low frequency the molecular chains of matrices are relaxed and exhibit polymer-like terminal behavior, but at CB loading higher than 12 wt%, the terminal behavior disappears, and the storage modulus and loss modulus of composites are not sensitive with sweep frequency. This phenomenon demonstrates the existence of solid-like structure. But CF filled composites do not have this change, so the CF particle has not effectively restrained the polymer relaxation like CB particle. For LDPE/CF composites, the increase in CF contents improves the complex viscosity of composites because the CF formed net-like structure in matrix. Figure 8 is the residue of composites with different CF contents, all composites experienced 600°C heated for 30 min in muffle furnace. From Figure 8 the increase in CF contents enhanced the density of net-like structure. So the complex viscosity of composites increased with the rise in CF contents. In low frequency region the loss modulus is much higher than storage modulus, the composites exhibit liquid-like property; in high frequency region the value of storage modulus and loss modulus is similar so the composites exhibit semisolid property. In low frequency region when CF contents exceed 6 wt%, the rising rates of complex viscosity, storage modulus, loss modulus are obviously higher, so 6 wt% is also the rheological percolation, and it also shows the change of microstructure for LDPE/CF composites.

Dynamic rheological curves of LDPE/CB and LDPE/CF composite with different filler content.

(A) Complex viscosity vs. sweep frequency; (B) Storage modulus vs. sweep frequency; (C) Loss modulus vs. sweep frequency.

Residues of LDPE/EVA composites

(A) LDPE+3% CF; (B) LDPE+6% CF; (C) LDPE+12% CF.

Figure 9A shows the complex viscosity of LDPE/EVA/CB composites increased with the increase of EVA loading. It is caused by the change of microstructure of composites and the change of CB distribution for the added EVA phase. From previous SEM picture (Figure 2), the microstructure of composites transformed from network structure to co-continuous phase structure, and some CB aggregates transferred from interface of LDPE and EVA phase to EVA phase, these changes also caused the complex viscosity of composite to increase. The storage modulus and loss modulus of composites also increased with the increase of EVA concentration. It also proves the previous view that the microstructure of composites changed. The complex viscosity, storage modulus, loss modulus of composites slightly increased in the low frequency region with the increase of EVA phase, but in high frequency region the gap of storage modulus and loss modulus with different EVA concentration composites gradually disappears, so EVA does not affect the CF distribution in matrix. The increase of complex viscosity is because EVA can work as compatilizer, the surface of CF has little oxygenous groups, it has good compatibility with EVA resin which has carboxyl. So the compatibility between CF and matrix improved, the complex viscosity also increased.

Dynamic rheological curves of LDPE/EVA/CB and LDPE/EVA/CF composites.

(A) Complex viscosity vs. angular frequency; (B) Storage modulus vs. angular frequency; (C) Loss modulus vs. angular frequency.

In order to study the rheological properties of composites more deeply, we chose some samples to take static rheological behavior test and get the curves of apparent viscosity vs. shear rate as shown in Figure 10. Because of the limitations of rotational rheometer, when the shear rate is high the value is not accurate, so we chose the value of log γ range from −1 to 1.5, use origin 8.0 to linear fitting calculate the non-Newtonian index (n) and zero shear viscosity (η0), the value is listed in Table 3.

Apparent viscosity as a function of shear rate for composites filled with CB and CF.

Non-Newtonian index and zero shear viscosity of composites.

| Matrix | Filler | Non-Newtonian index | Zero shear viscosity |

|---|---|---|---|

| LDPE | 0.76 | 3.26 | |

| LDPE | 15 wt% CB | 0.47 | 3.84 |

| LDPE | 15 wt% CF | 0.4 | 3.37 |

| LDPE/EVA(70/30) | 15 wt% CB | 0.72 | 3.91 |

| LDPE/EVA(70/30) | 15 wt% CF | 0.64 | 3.46 |

From Table 3, it could be found that the n values of both CF filled and CB filled composites are lower than one, exhibit shear thinning and pseudoplastic fluid behavior. The non-Newtonian index of CB filled composites is lower than CF filled composites with the same ingredients; it mean CB filled composites deviated much from Newton fluid. So the CB particles restrain the matrix movement more deeply than CF, and the conductive network of CB filled composites are also large than CF filled composites. This conclusion is correct with the previous one. Besides though contrast the value of zero shear viscosity we can get the similar result that the viscosity of CB filled system is higher than CF filled, and the EVA will increase the viscosity of both types of composites.

4 Conclusion

CF filled composites had better electrical conductivity, and their resistivity is much lower than CB filled composites for the same filler loading.

The increase of EVA content decreased resistivity of LDPE/EVA/CB composites and reached lowest point when the LDPE:EVA ratio was 70:30, but the resistivity of LDPE/EVA/CF composites decreased monotonously with the increase of EVA contents.

EVA phase changed the CB distribution to changed properties of CB filled composites but for CF filled composites EVA worked as a compatibilizer to some extent.

In this study, electrical properties, morphological and rheological properties of CB and CF filled LDPE/EVA composites were investigated. Electrical test indicated that CF filled composites had better electrical conductivity, and their resistivity is much lower than CB filled composites for the same filler loading. EVA could decrease resistivity of both types of composites. Microstructural characterization of samples showed that EVA changed the CB distribution to change properties of CB filled composites but for CF filled composites EVA worked as the compatibilizer to some extent. Rheological measurement pointed out that CB had large effect on viscoelastic property of composites than CF, for CB particles own large surface area and nano size. The static rheological test indicated CB filled composite had stronger pseudo-plasticity than CF filled, and the EVA increased the value of Newtonian index and zero shear viscosity. Comparing CF and CB filled composites, the CF filled composites had excellent electrical and processing properties. Addition of EVA was beneficial to improve the electrical properties of composites.

Funding: A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

References

[1] Salinier A, Dagreou S, Leonardi F, Navascués N. Compos. Struct. 2013, 102, 81–89.10.1016/j.compstruct.2013.02.025Search in Google Scholar

[2] Pang H, Xu L, Yan D-X, Li ZM. Progr. Polym. Sci. 2014, 39, 1908–1933.10.1016/j.progpolymsci.2014.07.007Search in Google Scholar

[3] Shen L, Lou ZD, Qian YJ. J. Polym. Sci. Pt B-Polym. Phys. 2007, 45, 3078–3083.10.1002/polb.21307Search in Google Scholar

[4] Pour SAH, Pourabbas B, Hosseini MS. Mater. Chem. Phys. 2014, 143, 830–837.10.1016/j.matchemphys.2013.10.021Search in Google Scholar

[5] Tang H, Liu ZY, Piao JH, Chen XF, Lou YX, Li SH. J. Appl. Polym. Sci. 1994, 51, 1159–1164.10.1002/app.1994.070510701Search in Google Scholar

[6] Thongruang W, Balik CM, Spontak RJ. J. Polym. Sci. Pt B-Polym. Phys. 2002, 40, 1013–1025.10.1002/polb.10157Search in Google Scholar

[7] Hou YH, Zhang MQ, Rong MZ. J. Polym. Sci. Pt B-Polym. Phys. 2003, 41, 127–134.10.1002/polb.10357Search in Google Scholar

[8] Feng JY, Chan CM. Polym. Eng. Sci. 1998, 38, 1649–1657.10.1002/pen.10335Search in Google Scholar

[9] Xu GZ, Cen Y, Ye XJ, Li JT. China Plast. 2008, 07, 27–31.Search in Google Scholar

[10] Jeon EB, Ahn S, Lee IG, Koh HI, Park J, Kim HS. Compos. Struct. 2015, 134, 27–35.10.1016/j.compstruct.2015.08.082Search in Google Scholar

[11] Bao Y, Xu L, Pang H, Yan DX, Chen C, Zhang WQ, Tang JH, Li ZM. J. Mater. Sci. 2013, 48, 4892–4898.10.1007/s10853-013-7269-xSearch in Google Scholar

[12] Zhao SL, Dou Q, Ma CY, Kong L, Li Q. China Plast. Ind. 1998, 06, 27–29.Search in Google Scholar

[13] Yu G, Zhang MQ, Zeng HM, Hou YH, Zhang HB. J. Appl. Polym. Sci. 1999, 73, 489–494.10.1002/(SICI)1097-4628(19990725)73:4<489::AID-APP4>3.0.CO;2-ASearch in Google Scholar

[14] He XJ, Wang LJ, Liu ZH, Chen XF. Chem. J. Chin. Univ-Chin. 2001, 22, 163–165.Search in Google Scholar

[15] Sumita M, Sakata K, Hayakawa Y, Asai S, Miyasaka K, Tanemura M. Colloid Polym. Sci. 1992, 270, 134–139.10.1007/BF00652179Search in Google Scholar

[16] Kasgoz A, Akin D, Durmus A. Compos. Pt B-Eng. 2014, 62, 1113–1120.10.1016/j.compositesb.2014.02.017Search in Google Scholar

[17] Mao C, Chen SJ, Xu HY, Guo W,Wu C. Plast. Sci. Technol. 2012, 03, 51–55.10.1007/s11431-012-4975-6Search in Google Scholar

[18] Xu XQ, Li JQ, Zhang SN, Yu WL. Mater. Sci. Technol. 2003, 03, 297–300.Search in Google Scholar

[19] Zhang QH, Xiong H, Yan WX, Chen D, Zhu M. Polym. Eng. Sci. 2008, 48, 2090–2097.10.1002/pen.21079Search in Google Scholar

©2018 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Review

- Research review of diversified reinforcement on aluminum metal matrix composites: fabrication processes and mechanical characterization

- Original articles

- On the mechanisms of modal damping in FRP/honeycomb sandwich panels

- Innovative experimental and finite element assessments of the performance of CFRP-retrofitted RC beams under fatigue loading

- Mixed-mode I/III fracture toughness of polymer matrix composites toughened with waste particles

- A novel analytical curved beam model for predicting elastic properties of 3D eight-harness satin weave composites

- Microwave absorption and mechanical properties of double-layer cement-based composites containing different replacement levels of fly ash

- Electrical and rheological properties of carbon black and carbon fiber filled low-density polyethylene/ethylene vinyl acetate composites

- Effect of neutron irradiation on neat epoxy resin stability in shielding applications

- Study on the relation between microstructural change and compressive creep stress of a PBX substitute material

- Chemical synthesis and densification of a novel Ag/Cr2O3-AgCrO2 nanocomposite powder

- Reinforcing polypropylene with calcium carbonate of different morphologies and polymorphs

- Fabrication, mechanical, thermal, and electrical characterization of epoxy/silica composites for high-voltage insulation

- Synergy of cashew nut shell filler on tribological behaviors of natural-fiber-reinforced epoxy composite

- Fabrication and Failure Prediction of Carbon-alum solid composite electrolyte based humidity sensor using ANN

- Investigation of three-body wear of dental materials under different chewing cycles

- Structural and physico-mechanical characterization of closed-cell aluminum foams with different zinc additions

- Mechanical performance of polyester pin-reinforced foam filled honeycomb sandwich panels

- Effect of chemical treatment on thermal properties of hair fiber-based reinforcement of HF/HDPE composites

- Indium doping in sol-gel synthesis of In-Sm co-doped xIn-0.05%Sm-TiO2 composite photocatalyst

- Effect of the meso-structure on the strain concentration of carbon-carbon composites with drilling hole

Articles in the same Issue

- Frontmatter

- Review

- Research review of diversified reinforcement on aluminum metal matrix composites: fabrication processes and mechanical characterization

- Original articles

- On the mechanisms of modal damping in FRP/honeycomb sandwich panels

- Innovative experimental and finite element assessments of the performance of CFRP-retrofitted RC beams under fatigue loading

- Mixed-mode I/III fracture toughness of polymer matrix composites toughened with waste particles

- A novel analytical curved beam model for predicting elastic properties of 3D eight-harness satin weave composites

- Microwave absorption and mechanical properties of double-layer cement-based composites containing different replacement levels of fly ash

- Electrical and rheological properties of carbon black and carbon fiber filled low-density polyethylene/ethylene vinyl acetate composites

- Effect of neutron irradiation on neat epoxy resin stability in shielding applications

- Study on the relation between microstructural change and compressive creep stress of a PBX substitute material

- Chemical synthesis and densification of a novel Ag/Cr2O3-AgCrO2 nanocomposite powder

- Reinforcing polypropylene with calcium carbonate of different morphologies and polymorphs

- Fabrication, mechanical, thermal, and electrical characterization of epoxy/silica composites for high-voltage insulation

- Synergy of cashew nut shell filler on tribological behaviors of natural-fiber-reinforced epoxy composite

- Fabrication and Failure Prediction of Carbon-alum solid composite electrolyte based humidity sensor using ANN

- Investigation of three-body wear of dental materials under different chewing cycles

- Structural and physico-mechanical characterization of closed-cell aluminum foams with different zinc additions

- Mechanical performance of polyester pin-reinforced foam filled honeycomb sandwich panels

- Effect of chemical treatment on thermal properties of hair fiber-based reinforcement of HF/HDPE composites

- Indium doping in sol-gel synthesis of In-Sm co-doped xIn-0.05%Sm-TiO2 composite photocatalyst

- Effect of the meso-structure on the strain concentration of carbon-carbon composites with drilling hole