Abstract

In recent years, studies focused on Chaîne Opératoire reconstruction of pottery vessels have shown important developments and provided new data related to vessel production and the complexities acquired by prehistoric societies. This research focuses on the pottery vessels discovered at the Mines Prehistóriques de Gavà (Barcelona, Spain), which constitute the earliest evidence of a mining center for variscite during the 4th millennium BC. The main objective of this study is to determine the technological procedures employed in the production of these potteries by identifying the Chaînes Opératoires and establishing their relationship to the site’s context, which is linked to extensive exchanges within the European network. Through a meticulous analysis and comparison of the morpho-typological and technological characteristics of the vessels, we aim to identify different production methods. The findings of this study, along with their reconstruction in techno-stylistic trees, contribute to a deeper understanding and explanation of the variability and technological complexity found in these pottery vessels. This work exposes a novel approach to studying the pottery vessels in Iberian Peninsula by involving the application of archaeometric techniques such as direct macroscopic and microscopic observation traces (using naked eyes; microscopic Dino – Lite), as well as chemical analyses such as petrographically and X-ray diffraction enabling the identification of key mineral components within the clay.

1 Introduction

The study of prehistoric pottery vessel production methods in the Iberian Peninsula has witnessed a significant increase in recent years (Calvo, Bosch, Gómez, & Molist, 2021; Cámara, Clop, García, Pons, & Saña, 2021; Cámara, Clop, García Roselló, & Pons, 2021; Clemente, Mazzuco, Mozota, & Díaz, 2019; Clop & Álvarez, 2009; Díaz, 2019; Díaz et al., 2020; Dorado, 2019). This research demonstrated the significant gap in the existing bibliography regarding the ceramic strategies and production techniques. However, the evidence shows a volume of information about typological, morphological, and decorative analyses. This type of study transforms shreds into direct fossils that contribute to data chronology and the definition of cultural groups (Gibson & Woods, 1990; Orton, Tyers, & Vince, 1993).

Since the beginning of the twentieth century, numerous researchers have emerged, developing a series of approaches that integrate archaeological and ethnographical data within laboratory analysis. These methodologies have allowed a more comprehensive understanding of the technical phenomena involved at different stages of ceramic vessel production (Balfet, 1953; García Rosselló, 2008; Gosselain, 1992, 2002, 2008; Rice, 1981, 1987; Roux, 1990, 2016; Shepard, 1980).

The concept of Chaîne Opératoire in relation to ceramic assemblage has become a frequent presence in contemporary archaeological literature, particularly in the context of Neolithic studies, providing almost unpublished information in many of the archaeological contexts. However, despite the significance of these works, they are often facing challenges regarding their recognition and impact, being undervalued and, in some cases, ignored.

The concept Chaîne Opératoire related to pottery studies is commonly found. It originated in ethnology through field work that observed the diverse fabrication processes of objects and their implication for social and symbological systems. This concept serves as evidence of the cultural and social dimension of the processes and, therefore, the technical aspects (Mauss, 1947).

From this point, a new school of anthropology and archaeology emerged, focused on the study of techniques, with notable contributions from A. Leroi-Gourhan and R. Cresswell, as key researchers.

In 1964, the concept of Chaîne Opératoire was introduced explicitly for the first time in archaeological literature by Leroi-Gourhan (1964, p. 164). It was defined as: “La technique est à la fois geste et outil, organisés en chaîne par une véritable syntaxe qui donne aux séries opératoires à la fois leur fixité et leur souplesse.”

This definition transformed the concept into a fundamental tool needed to describe the gestures and operational processes performed and adopted by different groups. On this basis, Cresswell (1976) developed the concept as: “a series of operations that transforms a raw material into a final product, which will be an object of consumption or tool.” It is Cresswell’s definition that serves as the foundation for the work presented in this article.

Numerous studies have been developed both as methodological proposals (Arnal, 1976; Berg, 2008, 2009; García Rosselló & Calvo, 2013; Manem, 2016) and as practical studies across different chronologies and geographical regions around the world. These include research on the Early Neolithic periods in southern Europe (Gomart et al., 2017); the Chasséen group in northern areas (Colas, 2007); Late Neolithic assemblages in central–western France (Ard, 2014); the valleys of Senegal (Gelbert, 2000, 2003); French Middle Bronze age assemblages (Manem, 2008), contexts in the Ecuadorian Andes (Lara, 2017); and in sites in the Orinoco Valley in Venezuela (Lozada, 2020).

This study is developed from the theoretical and methodological framework of Chaîne Opératoire as described by Roux (1990, 1994, 2003, 2010, 2011, 2013, 2014, 2016, 2019). The selection of this approach for analyzing our pottery set is guided by several factors: 1. the extensive body of work by Roux on different areas (ethnographical, experimental archaeology, and archaeology sets) has established a robust methodology for exploring social aspects through a technological overview; 2. the structured methodology recognized for the different stages of pottery production allows one to understand the different strategies employed by artisans; and 3. this methodology can be adapted to be applied on the pottery set related to its characteristics. Therefore, a lot of bibliography with different strategies on the study of the pottery technology and reconstruction of the Chaîne Opératoire is available (Ard, 2013, 2014; García Rosselló & Calvo, 2013; Gosselain & Livingstone-Smith, 1995; Martineau, 2002; Vuckovic, Filipovic, Stojanovic, & Risch, 2021).

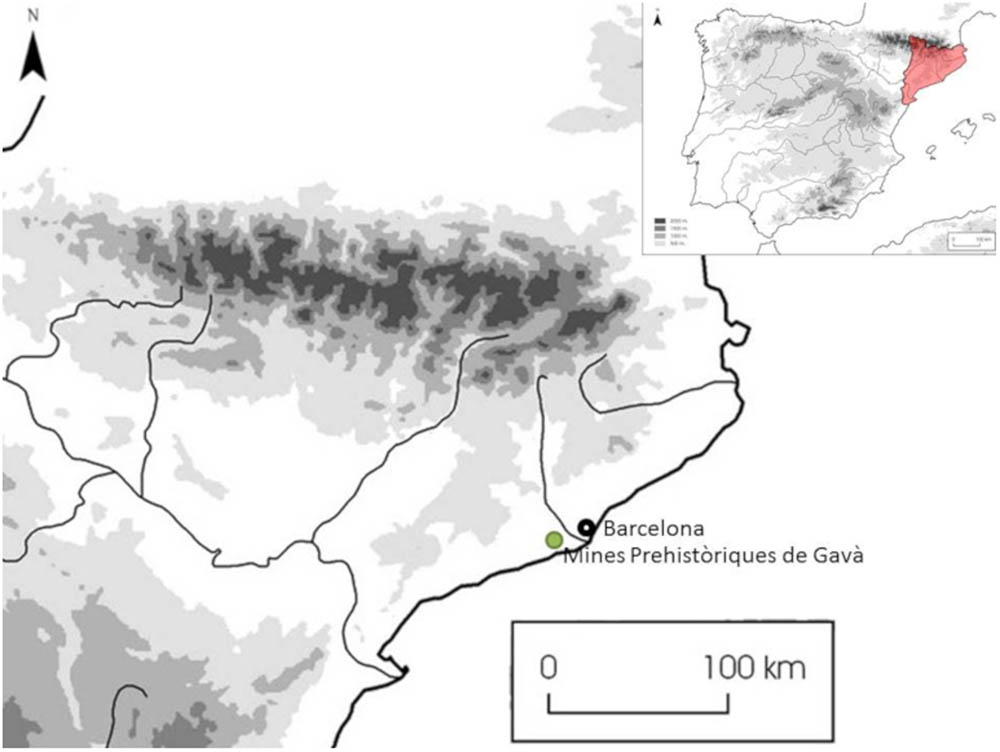

Based on Roux’s approach, the objective of this study focuses on the manufacturing process of part of the ceramic production recovered from the Mines Prehistòriques de Gavà (Barcelona – Spain – Figure 1). This will be achieved through the identification of macro-traces of manufacture, since they provide valuable insights into the technological solutions employed during the time/work investment processes.

Location map of the site Mines Prehistòriques de Gavà (Author: S. Calvo).

The Mines Prehistòriques de Gavà is a well-documented site that has been recognized as a mining center focused on the extraction of variscite. The site has an extensive bibliography available since its discovery in the late 70s of the twentieth centuries. This mineral was transformed into personal ornamentation and distributed throughout the western Mediterranean region (Bosch & Santacana, 2009; Bosch, Gómez, Calvo, & Molist, 2020).

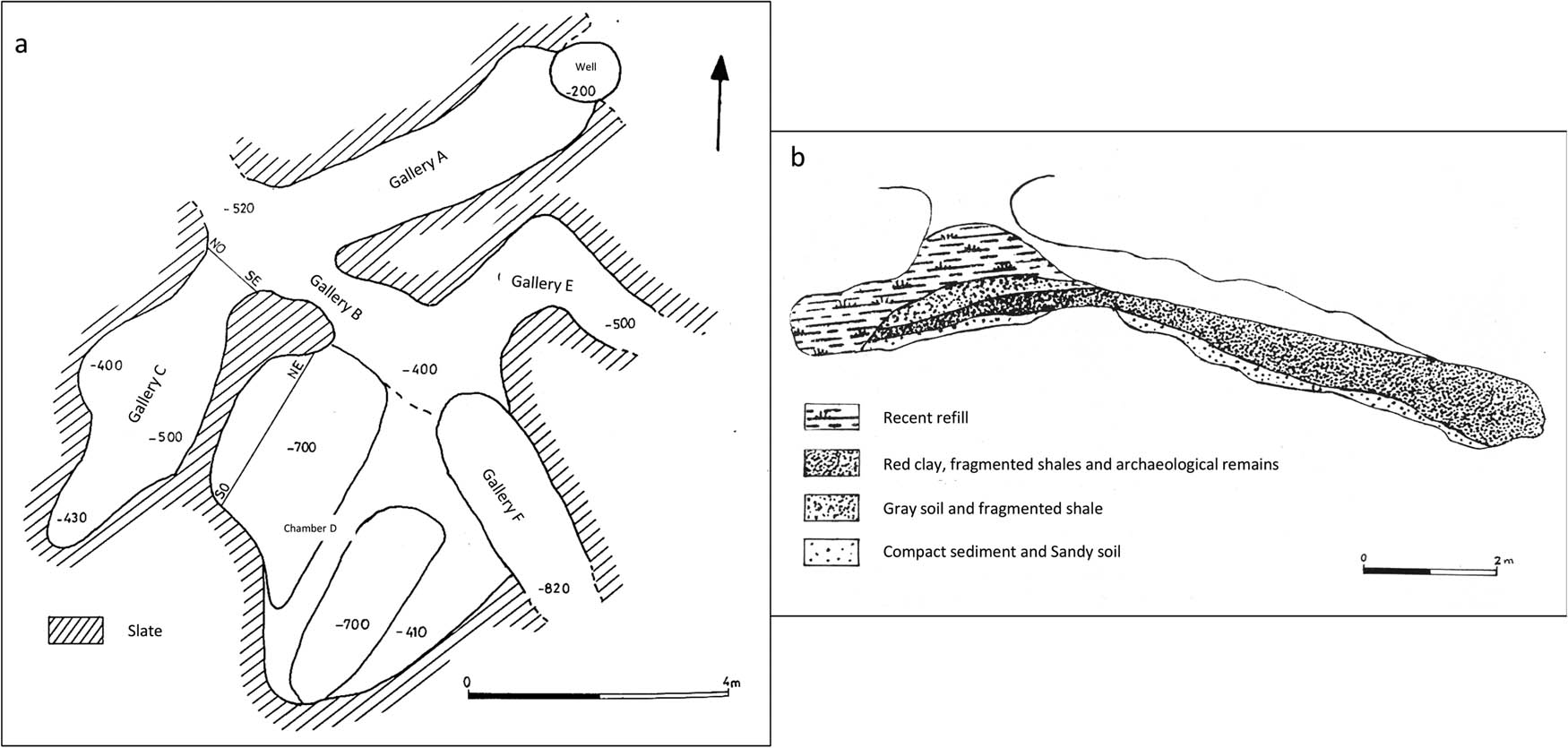

One of the most remarkable aspects of the archaeological complex is the network of mining structures formed by shafts, chambers, and galleries developed at various depths interconnected with each other. Once mineral extraction was completed, each mine was filled with residues of daily life, including fauna and botanical remains, ceramic fragments, lithic industries, bone industries, as well as remnants of mining activities and fragmented slate that allowed the creation of this network (Bosch & Borrell, 2009; Borrell & Bosch, 2012; Gimeno, Fernández, Villalba, Edo, & Blasco, 1996; Villalba, Bañolas, Arenas, & Alonso, 1986). This type of closure has led to a remarkable conservation of archaeological material, particularly ceramic remains, allowing the recovery of complete profiles and, in some cases, more than 50% of the ceramic vessels, which facilitates technological studies (Calvo, 2019).

The radiocarbon dates indicate the intensity of the extraction during the first quarter of the fourth millennium BC and the beginnings of the second quarter (Borrell, Bosch, & Vicente, 2009; Borrell & Orri, 2009; Borrell & Bosch, 2012; Calvo, 2019 – Table 1). During this period, the Catalonia region, where the Mines de Gavà are situated, was inhabited by a population belonging to a culture known as Sepulcres de Fossa. This homogeneous cultural group was associated with the consolidation of the agricultural and breeding practices in Catalonia.

Some radiocarbon dates from the site

| Mine – Level | C14 radio carbon date | Calibration | Material | Code | Reference |

|---|---|---|---|---|---|

| 5/11 | 5160 ± 40 BP | 4046–3806 cal BC (95.4%) | Charcoal | Beta 268.775 | Personal communication – J-Bosch – April 2019 |

| 6 | 5070 ± 100 BP | 4146–3646 cal BC (95.4%) | Charcoal | I-11.786 | Villalba et al., 1986 |

| 16–2 | 5190 ± 40 BP | 4223–3824 cal BC (95.4%) | Charcoal | Beta 268.776 | Bosch, 2010 |

| 16–6 | 5090 ± 40BP | 3969–3794 cal BC (95.4%) | Charcoal | Beta 268.778 | Bosch, 2010 |

| 16–8 | 5160 ± 40 BP | 4046–3806 cal BC (95.4%) | Charcoal | Beta 268.780 | Bosch, 2010 |

| Mina 28 | 4690 ± 100 BP | 3661–3105 cal BC (95.4%) | Charcoal | UBAR-48 | Alonso & Villalba, 1984; Buxó, Català, & Villalba, 1991 |

| 70–1 | 4660 ± 110 BP | 3565–3040 cal BC (95.4%) | Faunal bone | Beta 6491 | Bosch & Estrada, 1994 |

| 70–3 | 5000 ± 60 BP | 3948–3662 cal BC (95.4%) | Charcoal | Beta 72552 | Bosch & Estrada, 1994 |

| 84 | 4880 ± 40 BP | 3765–3538 cal BC (95.4%) | Human bone | Beta 250.405 | Bosch & Borrell, 2009 |

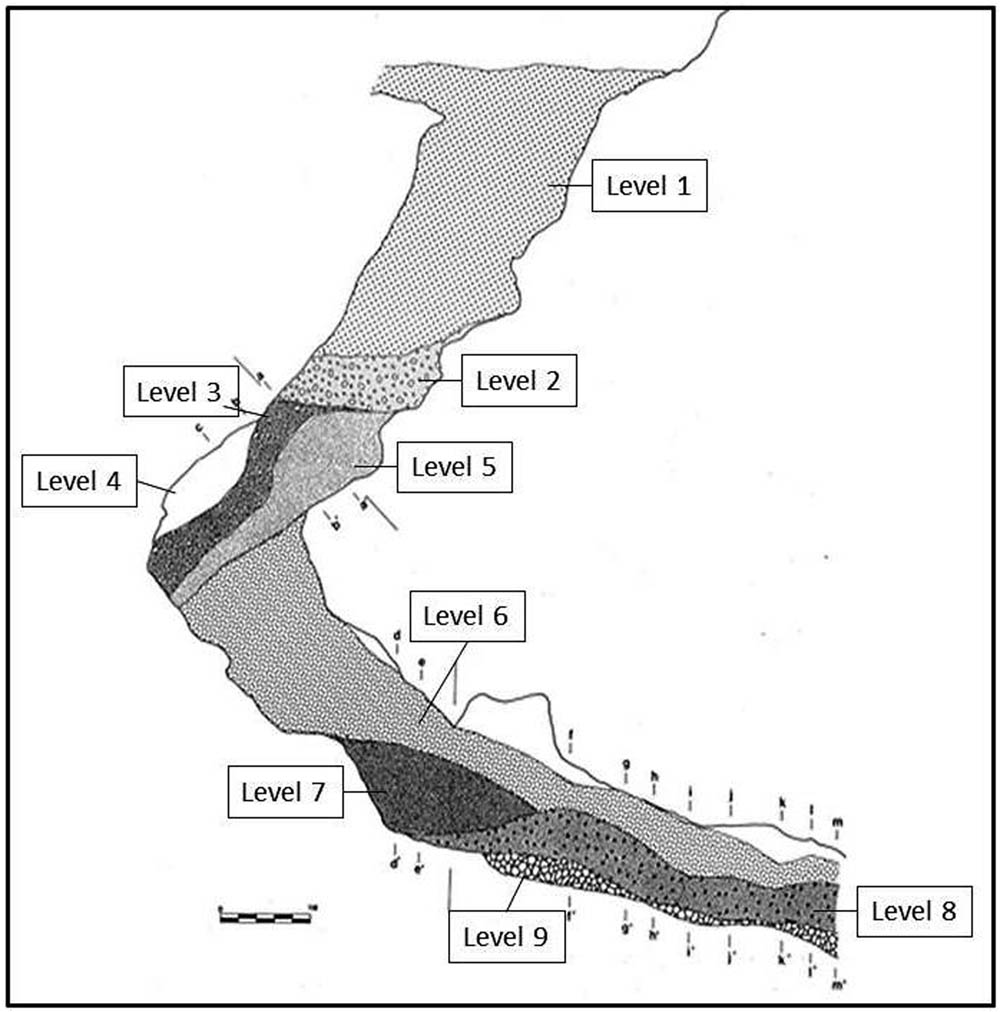

The materials examined in this study originate from two mining structures identified as 5/11 and 16 (Figures 2 and 3). Both structures were selected for analysis among the numerous known mines due to materials recovered in well-defined contexts, with the availability of radiocarbon dating enabling the identification of a chronological framework of the Catalan Middle Neolithic period (Table 1); this period represents a peak in mining exploitation (Bosch & Borrell, 2009; Borrell & Bosch, 2012; Bosch, 2012; Oliva, 2015; Villalba, Bañolas, & Arenas, 1990; Villalba, 2002). The second factor influencing the selection of this site was the excellent preservation of the set of ceramic vessels recovered, something that is not usual in archaeological contexts.

(a) Ground plan mine 11 and (b) section mine 5 (Author: Villalba et al., 1986 modified by: S. Calvo).

Section mine 16 (Author: Bosch, 2010 modified by S. Calvo).

2 Methodology

The methodology applied in this work is based on the identification of macro-traces of manufacture left on the ceramic vessels, using both macroscopic observations (naked eye) and microscopic observations (Dino-Lite digital microscope).

The recognition of these macro-traces allows the reconstruction of the Chaîne Opératoire, which is characterized by a specific sequence of operations comprising three main parts: the base, body, and neck/lip. Each part of the vessel’s manufacture consists of two phases: first roughing out, which involves creating a homogeneous volume without the final geometric shapes, and performing, consisting of the sequence of operations that give the vessel its final geometric shape before finishing and surface treatment operations. Only the vessels produced using the mold technique are documented in a single phase (Roux, 1990, 2016).

Once the reconstruction of the Chaîne Opératoire of the ceramic vessels is achieved, the procedure to follow is to classify the ceramic assemblage using the same process, based on the technical processes and objects. This classification aims to identify the technical traditions present in the ceramic assemblage and, consequently, the social groups associated with them (Roux, 2016).

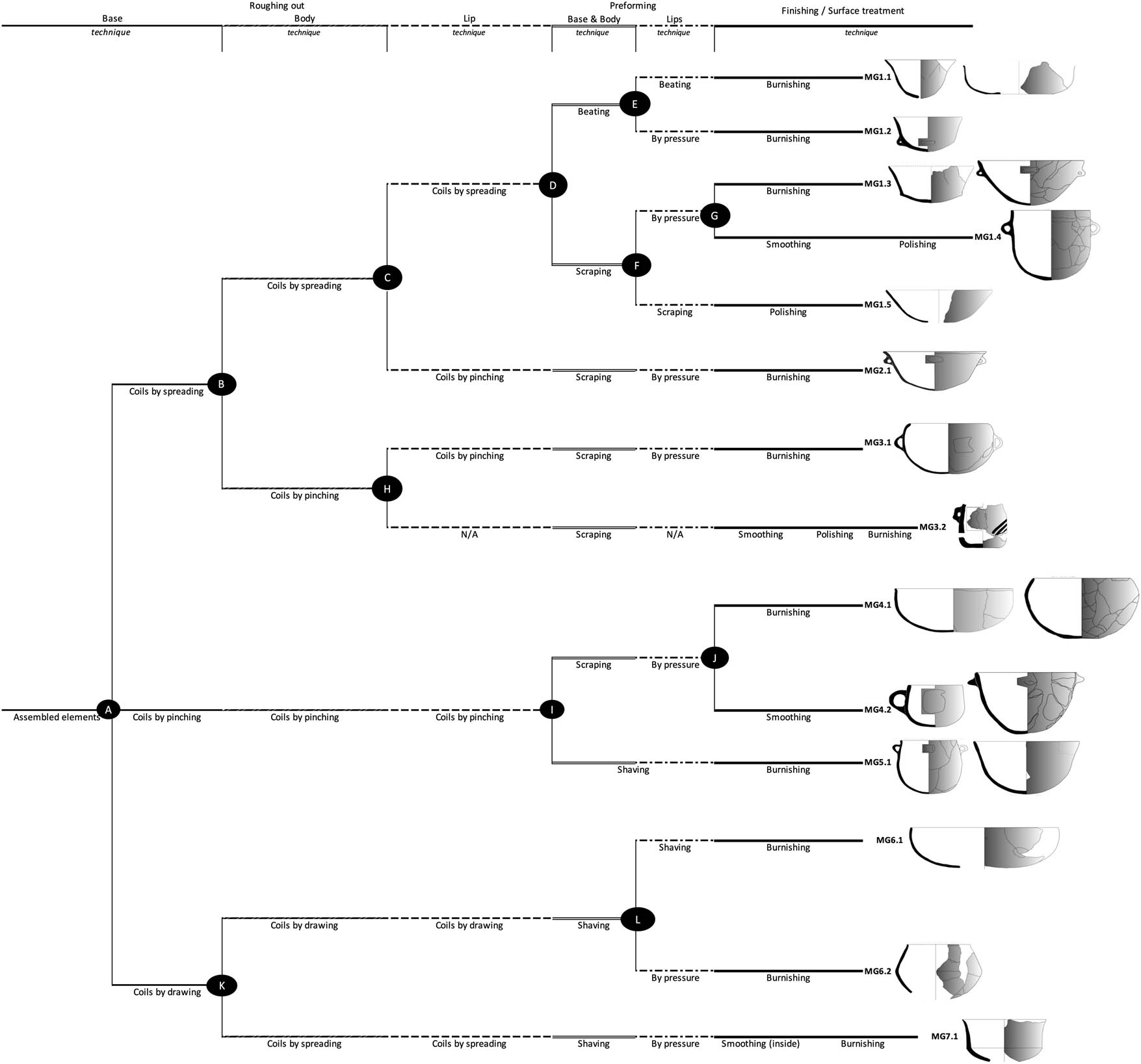

The procedure involves creating hierarchical techno-stylistic trees (of the dendrogram type), obtained through both the technological and typological classifications of the vessels. This approach enables the description of the technical processes and the objects produced offering an understanding of the different traditions comprising the ceramic assemblage. This analysis will be both qualitative and quantitative, allowing us to know the distribution of vessels and their belonging to each branch of the tree.

For the construction of this tree, two principles can be applied: either division or unification. In this study, groups are formed through division, according to the criteria that unifies all the vessels based on the type of clay mass we are working with and the sketching technique employed. As the reconstruction of the Chaîne Opératoire progresses, the groups are further subdivided until they reach a level where they can no longer be divided (such as finishes and surface treatments). This hierarchical tree reveals multiple Chaînes Opératoires rising from its branches, providing an overview of the technical traditions comprising the whole assembly. Through this observation, it is understood that each technical group represents a set of technical operations that make it possible to characterize the elements that distinguish them from another. This interpretation suggests that each technical group along with the specific aspects describing each branch of the tree enables the characterization of certain Chaînes Opératoires (Roux, 2016). The nodes, representing the bifurcation points in the tree’s branches, serve as indicators of the diversity of operational sequences and the artisans’ selection of techniques (Manem, 2008).

In summary, these trees facilitate the description of both the technical steps and the objects produced according to these processes, providing an understanding of the different traditions that build the ceramic assemblage. The obtained results indicate the distribution of vessels among the branches of the tree. Once the techno-stylistic tree is defined, it becomes possible to examine whether the technological variability is linked to functional and social factors, as well as to determine the complexity of the sociological composition (Roux, 2016).

Based on this approach, the vessels (total: 63 vessels) included in this study allow for typological recognition. By incorporating these data, we can gain insights into the production techniques employed within the ceramic assemblage, establish clearer delineation of technical traditions, and assess the significance of each tradition within the pottery set and the mining center context.

3 Results

Through the analysis of technical procedures and objects, the ceramic set is classified to identify the technical traditions and associated social groups. This classification provides a global view of the different traditions, both qualitatively and quantitatively. These traditions are represented through techno-stylistic trees, which help distinguish between functional and social variables (Roux, 2016).

In this study, the initial classification is based on the modeling technique applied to each vessel: assembled elements or clay mass. The results are classified in three different trees: vessels made from clay mass, vessels produced by assembling elements, and vessels created using a combination of both techniques named as mixed techniques (when the vessel was produced with these two types).

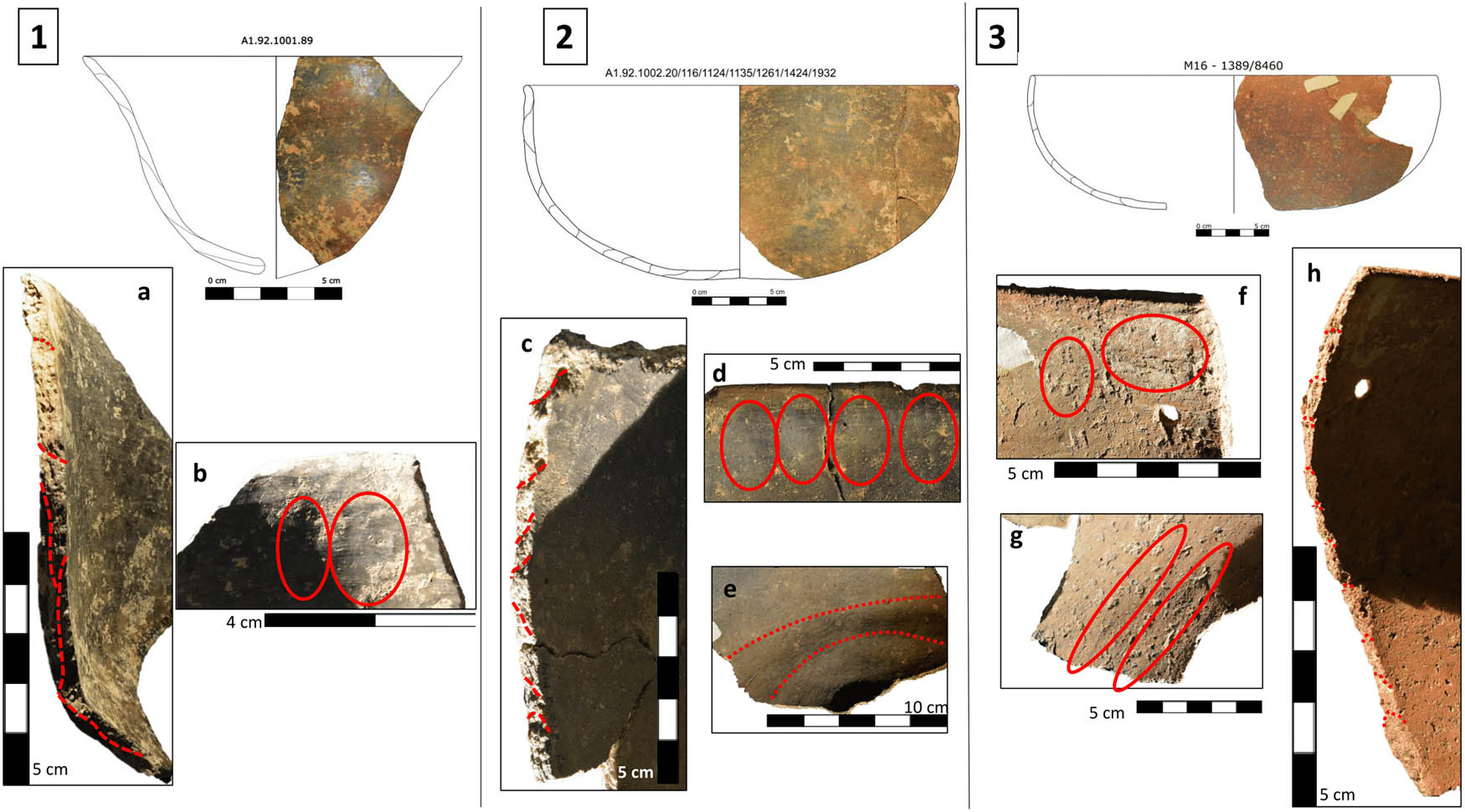

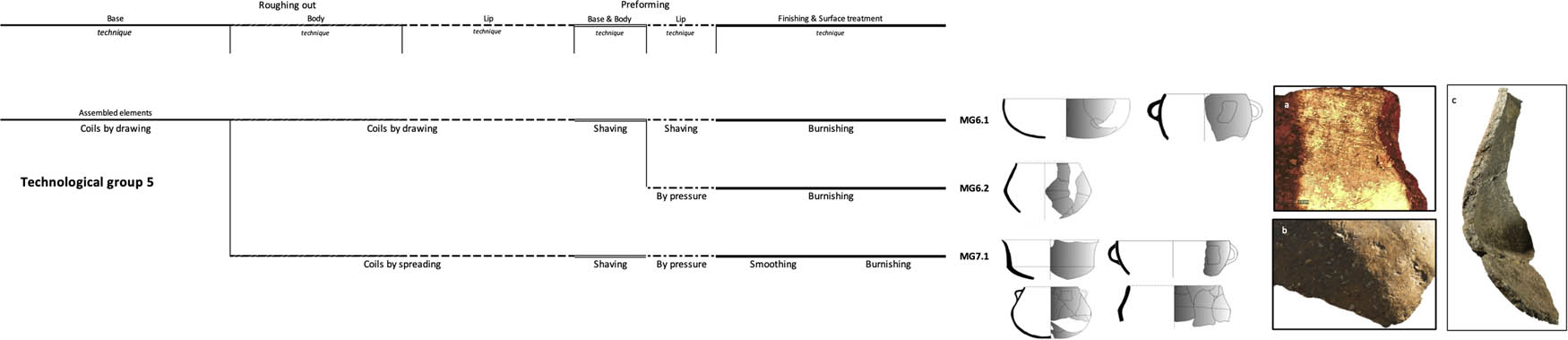

The first tree assembled element vessels (Figure 4) reveal 14 different production methods that originate from 12 different nodes. Each node indicates the diversity of operational sequences and the technique selection applied by the craftsmen (Manem, 2008). Although the coiling technique is consistent across the ramifications, there are variations in the application strategy: spreading in the A/B ramification, pinching in the A/I ramification, and drawing in the A/K ramification (Figure 5). Most cases exhibit a series of fingerprints, continuous over thicknesses and fissures.

Techno-stylistical group from assembled elements potteries (Author: S. Calvo).

Traces of assembled elements potteries: (1a) coils by drawing junction; (1b) fingerprints; (2c) coils by pinching junction; (2d) fingerprints from coils by pinching; (2e) coil organization in spiral; (3f) fingerprints from coils by spreading; (3g) fissure junction; (3g) coils by spreading junction (Author: S. Calvo).

From a border perspective, these Chaînes Opératoires can be differentiated into two main groups based on the vessel’s production methods, represented by the A/B and A/I ramifications. In these two variations, we observe important variability of typologies. The third group is characterized by a lower variability in production methods with techniques adapted to a specific typology. Within each group, the existence of variabilities between each production responds to the vessel’s morphology (first group) and by the functional option (second group).

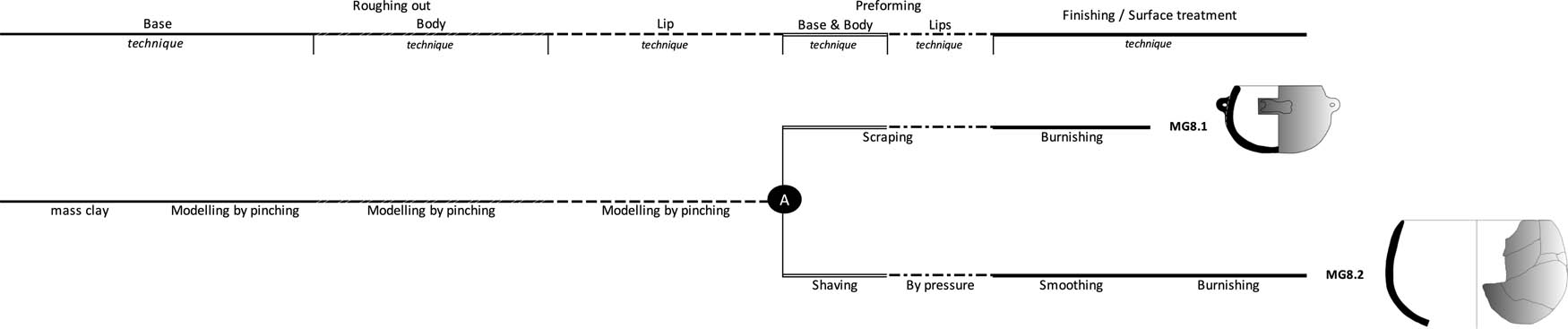

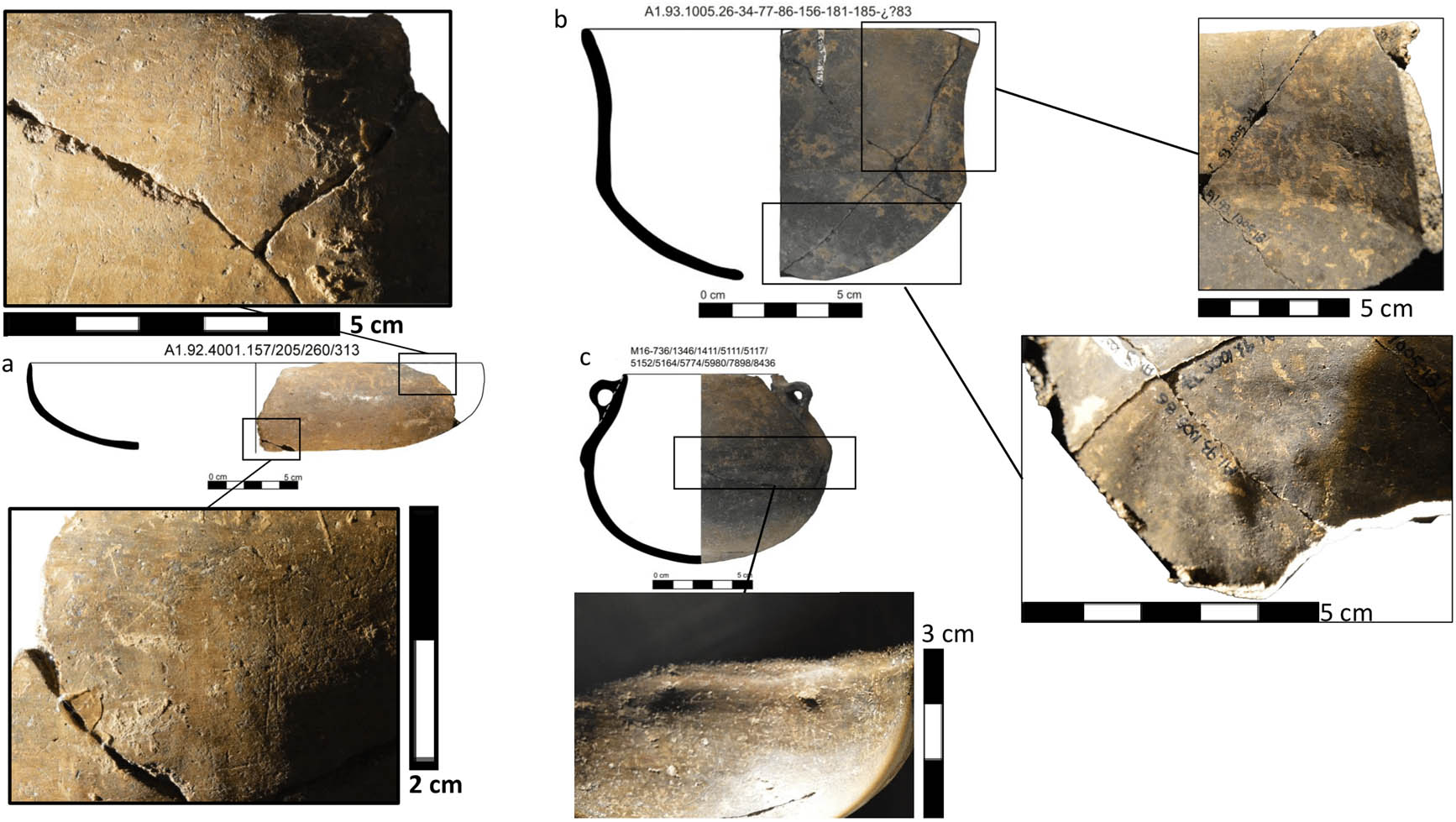

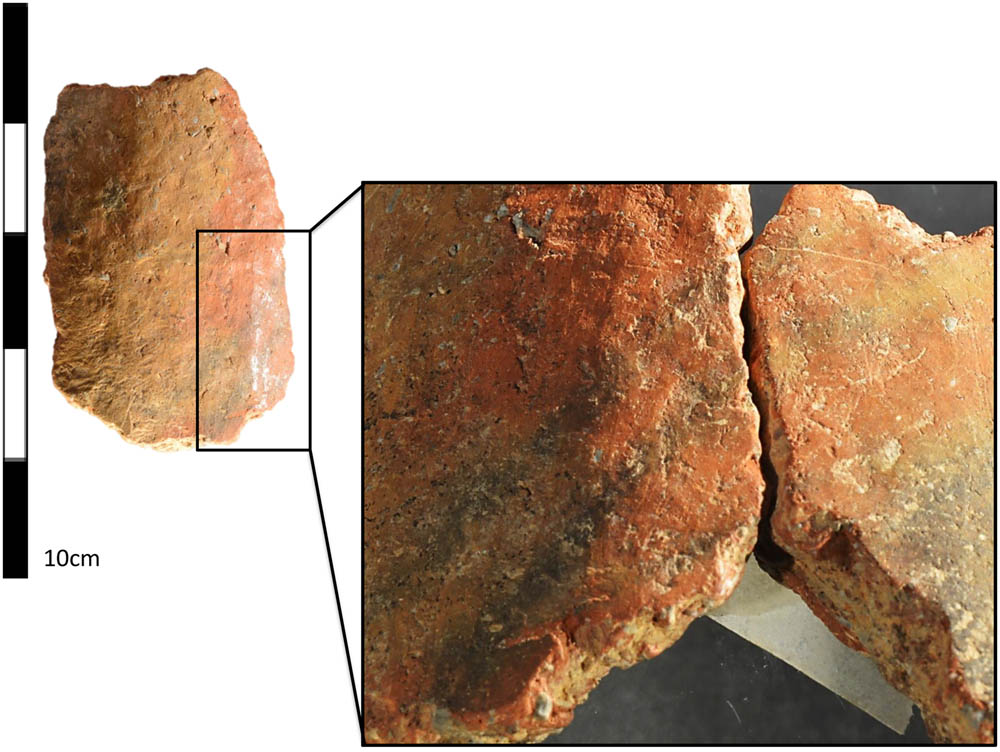

The second tree represents mass clay vessels, which reveals the existence of two ramifications divided by one node (Figure 6). All vessels in this category were produced using pinching as a modeling technique. The node that divides this tree in two Chaînes Opératoires was detected by variations on the performing techniques. The first branch documents the scraping technique, while the second branch involves the production based on shaving techniques (Figure 7). In this case, it is possible to observe a technical difference between vessels. This first case includes small-sized vessels presented with noticeable traces and fingerprints in its fabrication (Figure 8). The second case features medium- to large-sized vessels showcasing a higher level of specialization artisan. The differentiation in techniques is characterized by functional aspects related to a variation in the vessel’s dimensions.

Techno-stylistical group from mass clay potteries (Author: S. Calvo).

Fingerprints by pinching technique from different points of view (Author: S. Calvo).

Fingerprints by pinching technique (Author: S. Calvo).

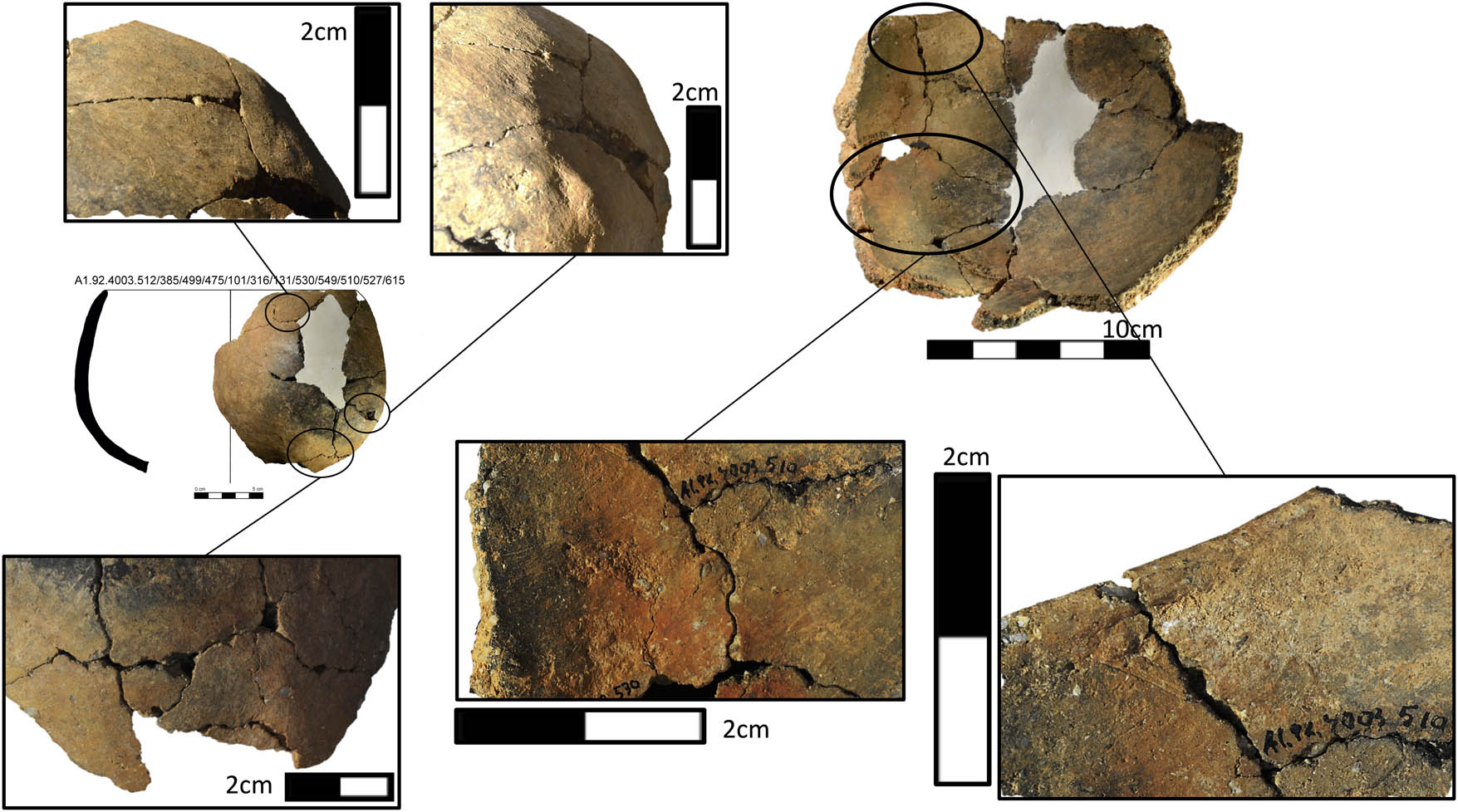

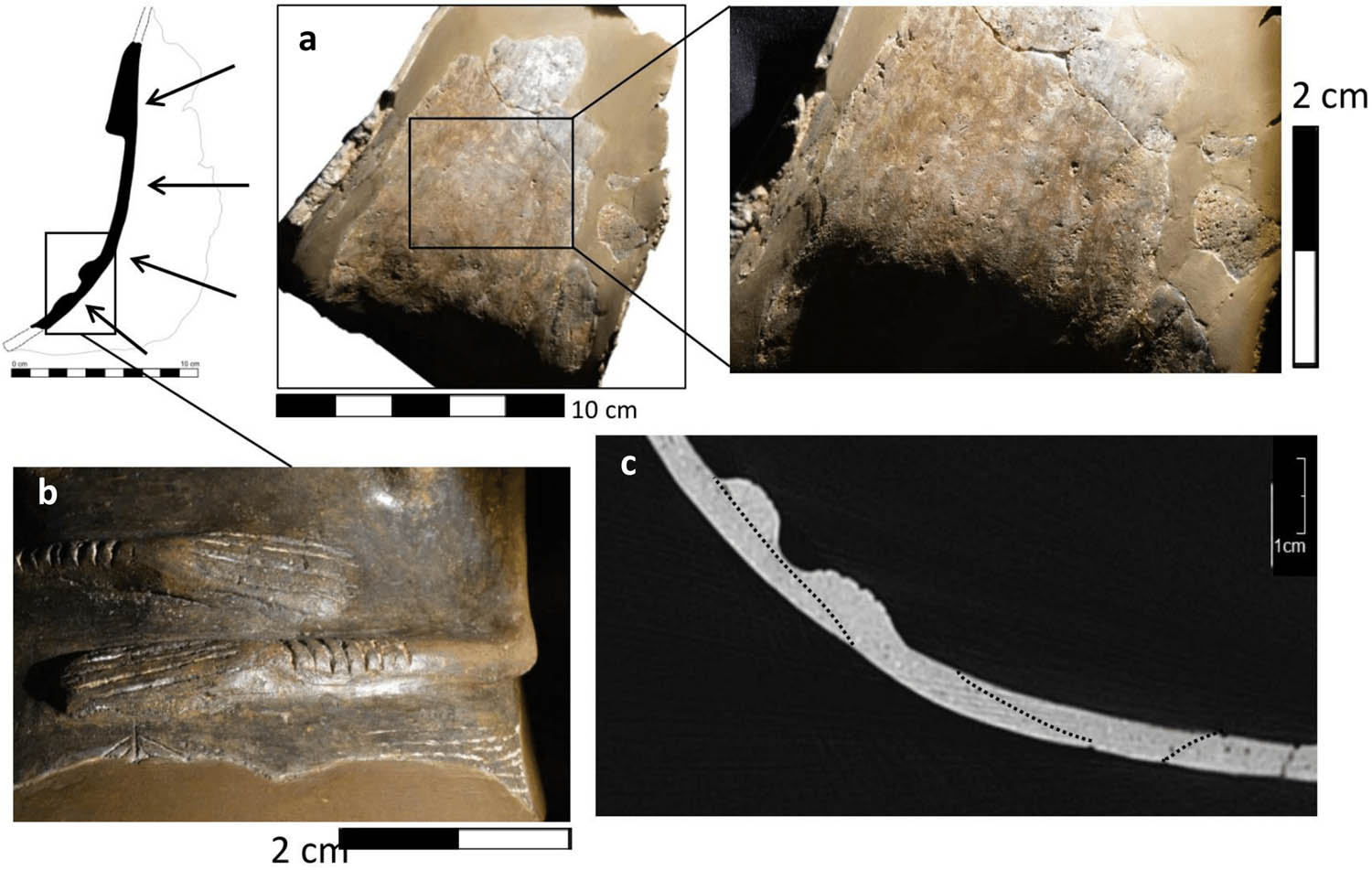

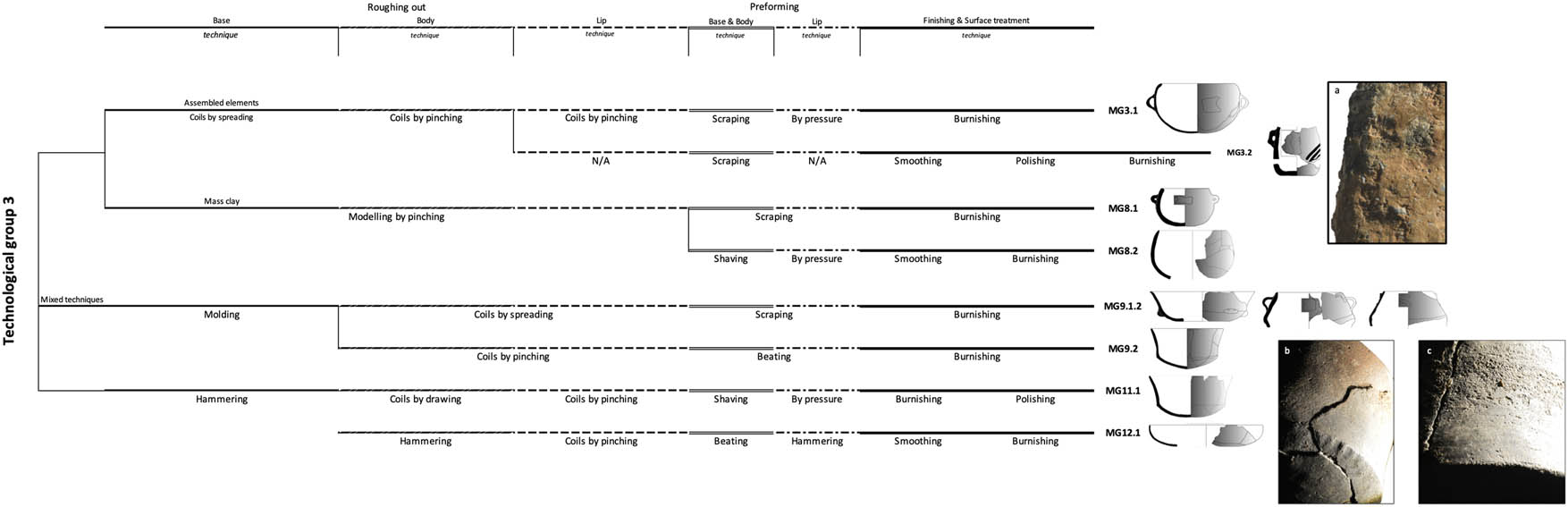

Finally, the third tree representing vessels using mixed clay techniques displays seven different ramifications by four nodes (Figure 9). This tree exhibits a higher level of complexity compared to the other two cases. All ramifications share a common base produced using the modeling technique with clay mass. However, two types of techniques are documented: on the first branch, A/B involves percussion techniques, while in the second branch, the vessel was produced using direct pressure.

Techno-stylistical group from mixed techniques potteries (Author: S. Calvo).

In this case, the first branch is the most interesting. Within this branch, some vessels exhibit a base production using molding techniques (B/C), while other vessels show hammering techniques (B/D). Beyond node “C,” various Chaînes Opératoires emerge, showcasing a wide range of techniques employed during the roughing-out stage, such as coiling technique by spreading, molding technique, and modeling by pinching. Additionally, different performing techniques are documented, including beating, pressure technique for the lip, scraping, and shaving techniques (Figure 10). The major evidence is the presence of a fissure between both techniques along with the presence of fingerprints.

Traces of mixed techniques: (a) flat prints from beating technique; (b) coils junction and flat prints; and (c) junction between coil technique and molding (Author: S. Calvo).

From a broader perspective, these six Chaînes Opératoires can be categorized into three principal groups of technical traditions distinguished by cultural features. In the first group, the morphological characteristics determine the different techniques used for its fabrication. Similarly, in the second group, the morphological characteristics play a crucial role in differentiating the techniques employed.

As an initial observation, it is possible to observe the existence of a great variability on the ways of production. While roughing-out techniques are more prevalent, the variability of techniques increases during performing and finishing techniques. It is acknowledging the artisan’s capacity to find technical solutions within the ceramic set to produce vessels with consolidated typologies specific to their social group.

4 Discussion

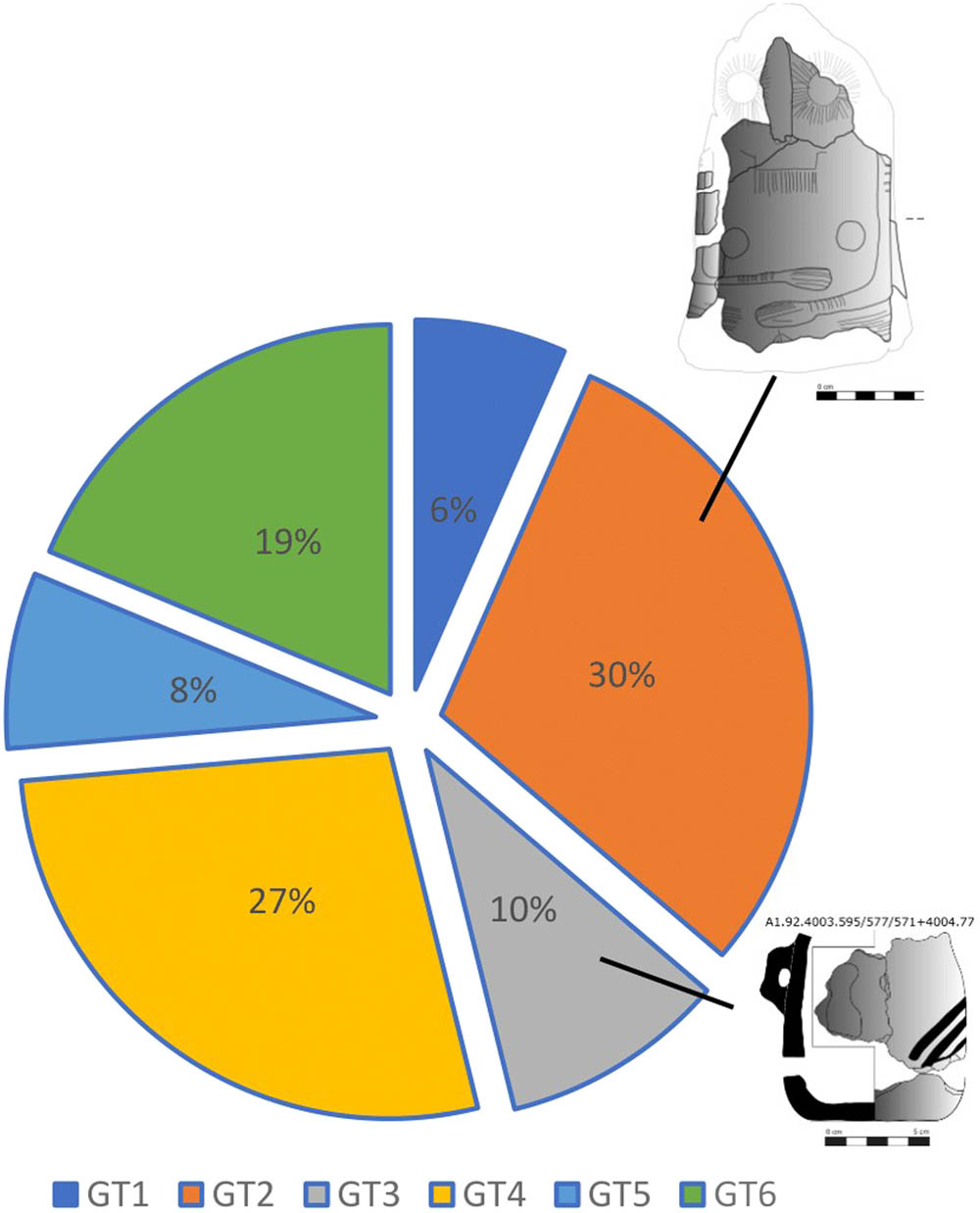

Once the technological analysis has been conducted, a comparative approach is applied to examine the social variations among the three different techno-stylistic groups. This comparison reveals the existence of six technical tradition groups at the site, each characterized by specific techniques and gestures, despite a homogeneous typological set. These six groups are described as follows:

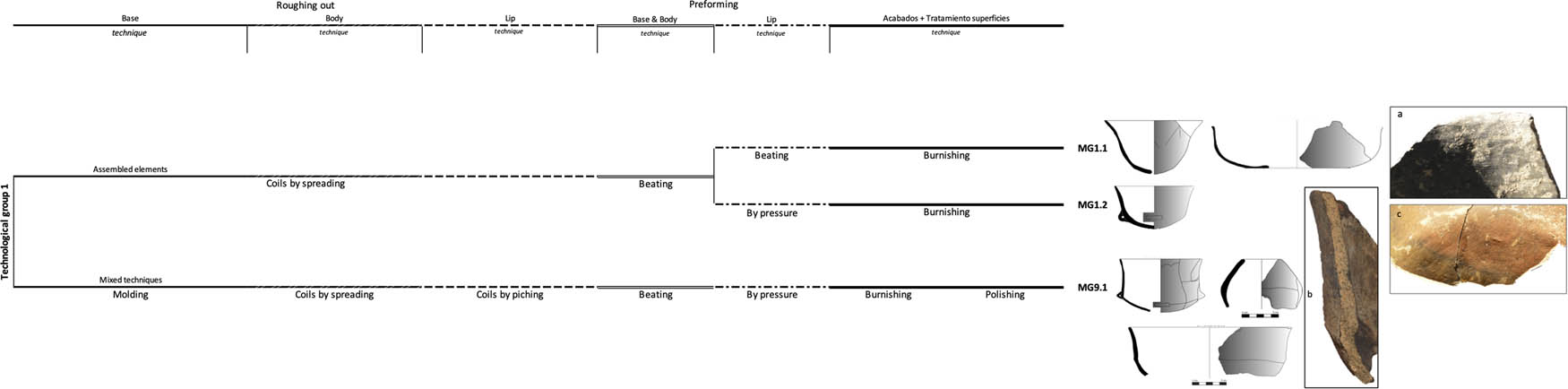

Technological group 1: constituted by six pottery vessels; this group exhibits variations in the roughing-out stage, employing techniques such as coiling by spreading and molding (Figure 11). Some of the vessels are produced using both techniques. Although there are differences in the first stage, the most important characteristic is the use of percussion techniques on the pre-forming stage, as a beating, with occasional modeling by lip pressures. And finally, the use of burnishing as a principal surface treatment. The different manufacturing strategies that are documented in these groups respond to functional aspects of the vessel related to its size and typology: semi-spherical vessels and spherical vessels with medium dimensions and carinated open vessels.

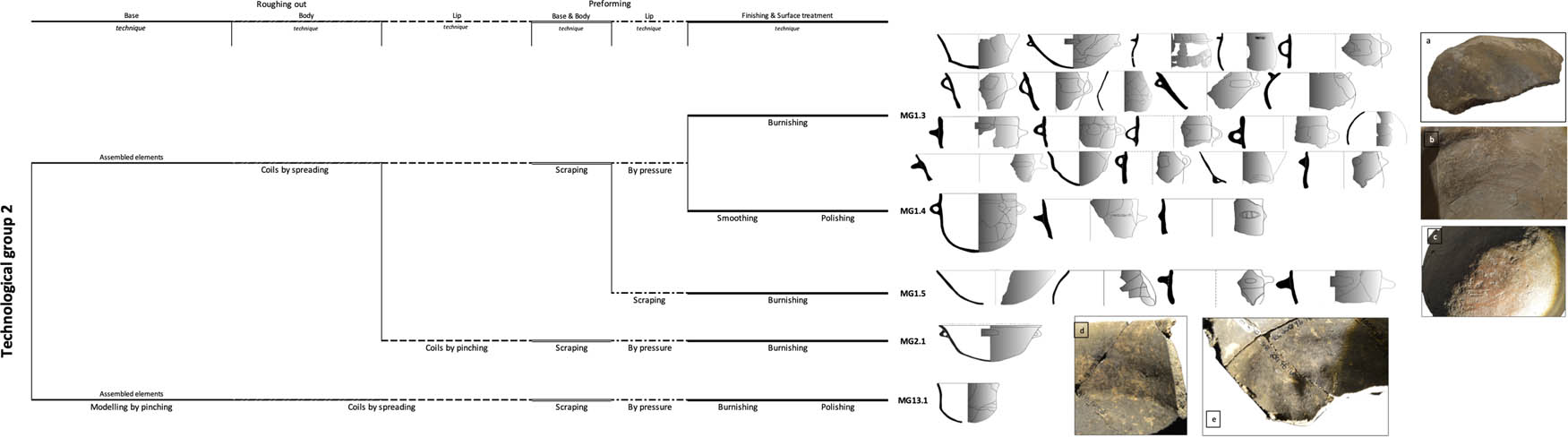

Technological group 2: this group is significant due to the quantity of documented vessels (29 vessels) and the typological variability observed. All vessels within this group were produced using coiling by spreading as a technique on the first stage of its production. In this case, the most important techniques include performing by pressure (scraping technique), and all vessels documented in this group undergo a surface treatment of burnishing (Figure 12). In this group, it is important to mention the presence of the Venus de Gavà (Figure 13). This feminine figure presents the same technical procedure as the vessels of this group, and it is considered part of this technical group (Calvo et al., 2021). The technological variability observed within this group appears to be related to functional aspects, particularly in the manufacturing of the lips and surface treatment. In terms of lip modeling, the choice of a particular technique may depend on whether reinforcement is desired to prevent easy fracturing in that area. This suggests the presence of technical solutions integrated within this specific technical tradition to address potential issues during vessel modeling. Regarding surface treatment, the decision to apply a specific type of treatment seems to be influenced by the vessel’s dimensions, particularly in relation to their volume capacities. Therefore, the technological variabilities in this group respond in the first place to technical solutions developed during the manufacturing process or because of vessel use. Additionally, the dimensions of the desired containers also play a role in shaping the technological variations within this group. The most typological vessels documented in this group are carinated and spherical (both open and closed) with medium dimensions and containers with big dimensions.

Technological group 3: this group is characterized by a low presence of vessels with only ten documented examples. This low variability is documented on typological variation too. However, technological variability is significantly high, offering diverse technical possibilities considering the dimensions of the vessel. Techniques such as hammering, coils by pinching, and coils by spreading are frequently combined. The presence of flat prints, fingerprints, or overthicknesses indicates the use of these techniques. All vessels within this group show burnishing as a surface treatment (Figure 14). Notably, a unique vessel in this group features as a distinctive decoration: two diagonal lines on the base displaying an atypical morphology on the Catalan context (Figure 15). The other vessels associated in this group are spherical and big-dimension vessels, and open and closed carinated vessels with medium dimensions.

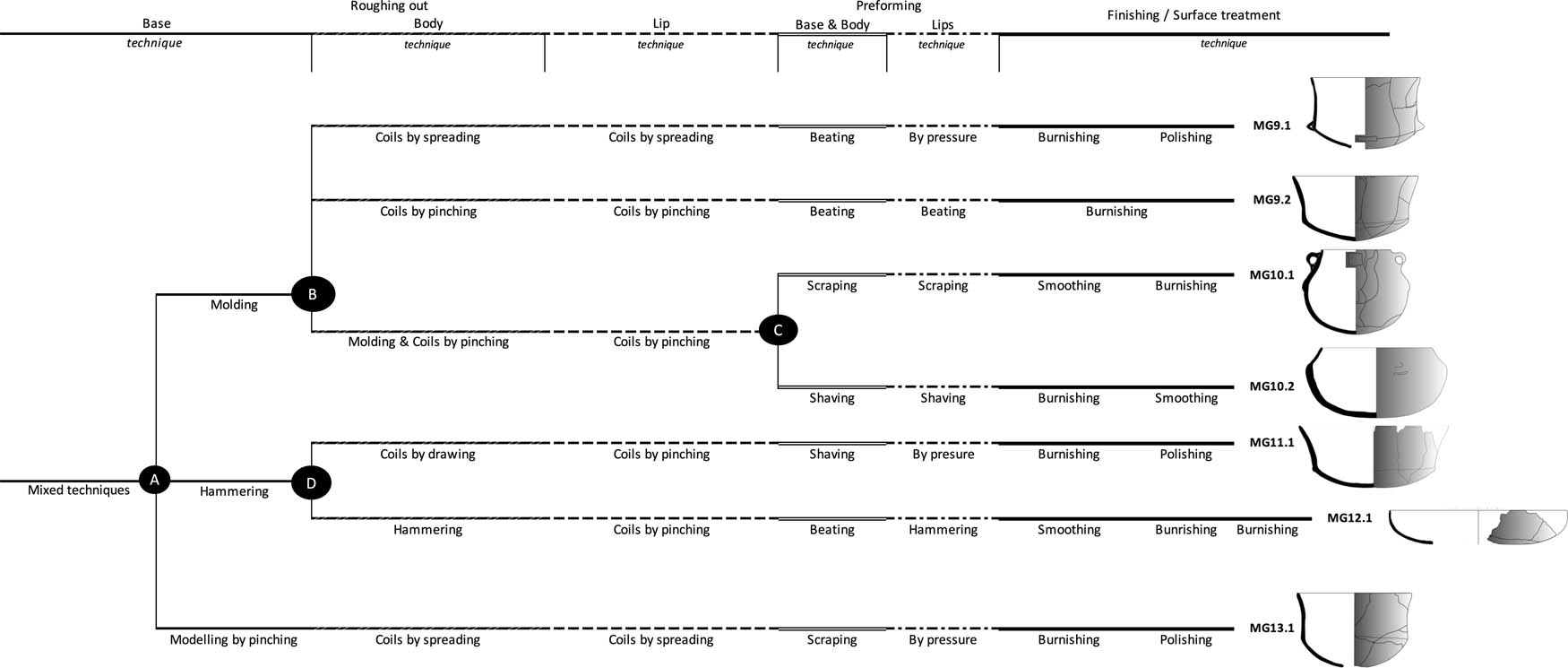

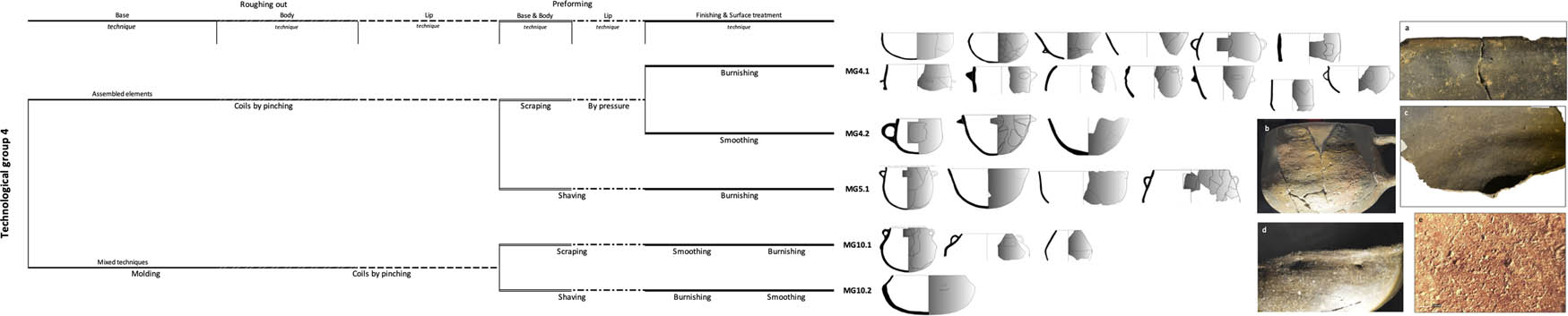

Technological group 4: Like technological group 2, this group has a significant number of potteries produced with this technical tradition (25 vessels). The typological variation within this group is considerable, while the technical gestures employed throughout the Chaîne Opératoire remain consistent in each phase. The documented differences in all procedures have minimal variability and are dependent on the type of the vessel. All of them were fabricated by coils by pinching technique; however, the carinated vessels combined this technique with molding. It can be observed in the presence of the junction fissure (Figure 16). Principally, the technical variants respond to typological factors and, finally, to the size of the vessels. The different typologies documented are spherical open vessel and closed carinated vessels, both in medium dimensions.

Technological group 5: This group consists of only seven containers that can be related between them, resulting in a low typological variability and, consequently, being the least documented group within the set. Consequently, there are few changes observed in the Chaîne Opératoire. All the vessels presented the same techniques throughout the fabrication process with a slight variation on the junction of the coils. Traces such as overthicknesses, fissures, and/or disorganized sections are similar across all vessels (Figure 17). The main differences in the sequence are documented in the modeling of the lips and, as documented in other groups, appear to be related to technical solutions addressing potential issues that may arise during vessel modeling. Finally, the typologies are semi-spherical medium vessels, spherical medium vessels, and carinated open and closed medium vessels.

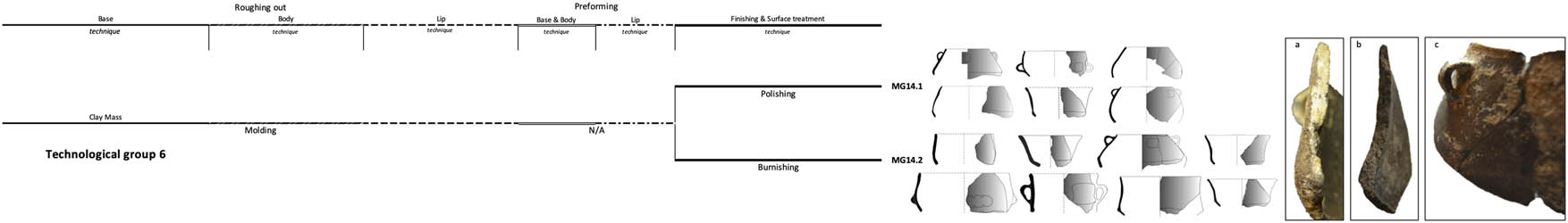

Technological group 6: Finally, this group stands out in the study due to its low variability in both typological and technological characteristics. It exclusively includes open and closed carinated vessels, all of which are manufactured using the molding technique, with slight variations in surface treatments. The most documented feature in this group is thin walls (Figure 18). The variabilities in the sequence of operation are influenced by functional aspects related to the sizes of the vessels.

Technological group 1 (Author: S. Calvo).

Technological group 2 (Author: S. Calvo).

Observed traces on Venus de Gavà ((a) fingerprints, (c) coil junctions, and (b) traces from burnishing) (Author: S. Calvo).

Technological group 3 (Author: S. Calvo).

Atypical vessel with diagonal decoration (Author: S. Calvo).

Technological group 4 (Author: S. Calvo).

Technological group 5 (Author: S. Calvo).

Technological group 6 (Author: S. Calvo).

One common aspect among all these groups is that the different technological strategies employed in vessel production are closely related to dimensions and the type of the vessels. This relation is evident in the variability of the surface treatment.

All groups exhibit a high degree of typological variability. Technological groups 2 and 4 have standing out due to their big volume of vessels compared to the rest of groups. These two groups not only exhibit a large number of vessels but also demonstrate homogeneity within their typological corpus.

In contrast, technological groups defined (1, 3, and 5) feature a small number of vessels per tradition, and the typological variations within these groups are limited. However, technological group 6, characterized by a single sequence of operation but a significant number of vessels in comparison with the other groups, raises the possibility of relating it to the technological groups 2 and 4.

5 Conclusions

This study aimed to approach the analysis of ceramic materials from the Mines Prehistòriques de Gavà in a new perspective, moving beyond the conventional morphological and decorative analyses that have predominated in previous research on the Neolithic period (Muñoz, 1965; Martí, Pou, & Carlús, 1997; Roig & Coll, 2010). The objective was to provide fresh and significant insights into the manufacturing techniques of the ceramic remains within the historical framework of agricultural societies in the northeast peninsular.

This information is particularly valuable considering the archaeological context of historical periods analyzed and characterized by short- and long-distance exchanges. Understanding the various methods of manufacturing can provide us with significant information.

Through the data analysis conducted in this study, and how it is defined in this work, the study focuses in the first half of the fourth millennium (4000–3400 cal ANE) and specifically on mines 5/11 and 16; a great variability in the ways of doing allows us to define six different technological groups that reflect different technical traditions.

An important aspect to highlight within the vessel manufacturing process is the surface treatments employed, particularly the presence of high-quality burnishing. This technique effectively eliminates most of the technical evidence from the performing and finishing stages. Experimental studies have indicated that burnishing requires significant time and effort (Calvo, Bosch, Molist, & Gómez, 2018; Díaz, 2019). The technical gesture applied at a given moment in which the paste in the leather-hard state is optimal to avoid deformations and technical intermittences, while the piece acquires the brightness and good quality that characterizes the archaeological piece.

The results obtained in this study allow us to formulate hypotheses regarding functional and sociological factors represented on the techno-stylistically trees. Following the principles defined by Roux (2016), the evaluation of the grade of complexity enables the interpretation of the sociocultural context and the characteristics of the site.

To address these issues, it was essential to consider the functionality of the site. The archaeological site Mines Prehistòriques de Gavà shows a purely mining character intended for the extraction of the variscite and, later, its transformation into beads to necklace and/or bracelets. Therefore, it is a reason to focus on the characterization of the degree of complexity shown by the ceramic set.

The ceramic forms showed a great heterogeneity of Chaînes Opératoires, which allowed the definition of six technological groups within the same area. A technological group is also understood as representing different approaches to produce archaeological vessels, regardless of the type or functionality of the container. This is associated with the fact that each technological tradition would be, therefore, the representation of different groups. In fact, we propose two main social groups in the Middle Neolithic, represented by technological groups 2 and 4 (57% of total set), which are separated by the number of containers that form part of each group and, by the typological variability of dimensions, covering a wide range of functionalities that respond to the different needs. These two social groups would share the same objectives within the mining activity, such as the extraction of the variscite or the elaboration of corporal ornamentation. Since their exchange, they would also participate in shared spaces, including settlements, agricultural areas, and livestock areas, and they would collaborate in shared waste management areas; grouping one to waste is subsequently occupied as filler mines closed, such as to the case of both the mines 5/11 and 16. We reinforce this idea through the radiocarbon dates (Table 1) that show us the same data for both mines.

The data obtained from the reconstruction of Chaînes Opératoires can be further supported by radio carbonic data recovered in the different sectors of the site (Serra de les Ferreres and Can Tintorer), allowing us to consider a simultaneous activity of the different areas. It is possible with the presence of the two or more groups on the site, as commented by Borrell and Bosch (2009). In fact, the mines studied in this work are situated in the same chronological range (Table 1). The large size of the mine structures indicates the need for a substantial workforce to operate at the same time. Moreover, the practice of refilling the mines with residues suggests the coexistence of multiple groups in the same area, sharing mining goals.

These social groups would not only share domestic spaces or economic goals but also share the manufacturing method for certain ceramic vessels. This hypothesis has technological group 6 as an empirical basis, with open and closed carinated vessels, which present a single sequence of operations, representing 19% of the total set (Figure 19). These vessels manufactured in a concrete way of doing shared by both technical traditions perhaps respond to a common need or related to mining.

Percentages of the different technological group (Author: S. Calvo).

The presence of technological groups 1, 3, and 5, which are documented from a few individuals and, in fact, have a 24% presence throughout the ceramic set, with little typological variability of the defined corpus, gives these ways of doing a minority character in the manufacture of containers within the mining complex. The presence of these groups is related to one of the most important aspects that characterizes the Catalan Middle Neolithic, and well known, such as exchange networks. The Mines Prehistòriques de Gavà are considered as a receptor and distributor of materials that circulated in these exchange networks. It is likely that the existence of these groups is due to the presence of other craft groups less linked to the extraction of variscite but related to obtaining variscite in the form of necklaces and bracelets and the contribution of exogenous elements such as silex bedouliense or obsidian and some typologies as a painted vessel.

It is important to emphasize the fragmentation of ceramic containers. The re-assembly of different fragments has allowed for the study of nearly complete vessels. It is at this point, where it has been able to observe that these fragments do not come from a single stratigraphic level; the great majority of these containers are made up of fragments that come from more than one of the levels and even sometimes, up to three levels.

Acknowledgements

Thanks to Angel Alvarez from the Servei Difracció Raigs X of Universitat Autònoma de Barcelona and to Francisco Bohils Riu from the Servei de Microscòpia of Universitat Autònoma de Barcelona for performing the different chemical analysis. Finally, thanks to the radiation technician staff from the Mutua de Terrassa for the realization of the CT scan. And finally, thanks to Museu de Gavà, Parc Arqueològic de les Mines Prehistòriques de Gavà, and Grup de Recerca Arqueològica al Meditarrani i Pròxim Orient and Seminari d’Arqueologia Prehistòrica del Pròxim Orient.

-

Funding information: This research was funded by grants for the recruitment of pre-doctoral research staff (2015–2019): Ministerio de Ciencia, Innovación y Universidades del Estado Español, GRAMPO (Grup de Recerques Arqueològiques al Mediterrani i Pròxim Orient) – 2014-SGR-1248 y 2017-SGR-1302. Projects: Mines Prehistòriques de Gavà. Espai i temps, dinámica evolutiva i caracterització mineralógica – 437 K117 – 2014/100280, Servei d’Arqueologia de la Generalitat de Catalunya. Rius, assentaments i minería a les valls de l’Ebre, Ter i Gavà – CLT009/18100028, Servei d’Arqueologia de la Generalitat de Catalunya. Del Taurus al Zagros: problemática de los procesos de neolitización en el norte de Mesopotamia – HAR2013 – 43624 – P, Ministerio de Ciencia, Innovación y Universidades del Estado Español. Procesos de transferencia e interacción social en el neolítico del Próximo Oriente: Estudio de los ámbitos del valle del Eufrates y altiplanos del Zagros – HAR2016 – 78416 – P, Ministerio de Ciencia, Innovación y Universidades del Estado Español.

-

Author contributions: Silvia Calvo Peña is a Tutor/Professor – Universidad Nacional de Educación a Distancia (UNED) – Centre de Barcelona/Nou Barris. Silvia Calvo Peña contributed to the design and implementation of the research, to the analysis of the results, and to the writing of the manuscript.

-

Conflict of interest: Author states no conflict of interest.

Appendix Terms Used

Assembled elements: hollow volume made by the union of pieces of clay (Roux, 2019). Mass clay: hollow volume made by a lump of clay (Roux, 2019). Coiling by spreading: consists in placing the coil against the previous one and flattening it by discontinuous pressure (Roux, 2019, p. 55). Coiling by pinching: consists in placing the coil on the edge of the previous one (Roux, 2019, p. 55). Coiling by drawing: consists in stretching one or several large coils (Roux, 2019, p. 55). Modeling by pinching: consists in transforming a spherical or flattened clay mass into a hollow volume with discontinuous point interdigital pressure (Roux, 2019, p. 60). Hammering technique: consists of roughing out a hollow volume from a clay mass by percussion, without using a mold (Roux, 2019, p. 61). Molding technique: consist in roughing-out and preforming recipient by spreading a clay mass onto a convex or concave mold (Roux, 2019, p. 61). Beating technique: consists in beating the outer surface of recipients with a paddle (Roux, 2019, p. 66). Modeling lip by pressure: consists in modeling the lip with continuous pressure to give the final form. Burnishing treatment: corresponds to a friction action on leather-hard to dry clay with a rigid tool and without water (Roux, 2019, p. 96). Scraping technique: consist in shaping the walls by discontinuous pressures by pushing them and profiling them with a rigid tool (Roux, 2019, p. 64). Junction of coils: diagnostic traits observable in the sections of the vessels leave by the union between coils. Fissures: are deep incisions situated at the limit of juxtaposed elements (Roux, 2019, p. 145).

References

Alonso, M., & Villalba, M. J. (1984). Informe sobre les excavacions d’urgència realitzades en el jaciment arqueològic de Can Tintorer, Gavà (Baix Llobregat) – 1982/1983. Unpublished.Suche in Google Scholar

Ard, V. (2013). Ceramic traditions and cultural identities: West-central France during the Late Neolithic II period (c. 3400 – 2900 cal. BC). Oxford Journal of Archaeology, 32(4), 367–389. doi: 10.1111/ojoa.12020.Suche in Google Scholar

Ard, V. (2014). Produire et échanger au Néolithique. Traditions céramiques entre Loire et Gironde au IVè millénaire. Paris: Éditions du Comité de Travaux Historiques et Scientifiques.Suche in Google Scholar

Arnal, G. B. (1976). La céramique néolithique dans le Haut Languedoc: Projet pour une étude systématique. Lodève (Hérault): Centre de recherche archéologique du Haut – Languedoc.Suche in Google Scholar

Balfet, H. (1953). Note sur le façonnage des poteries Préhistoriques. Bulletin de la Société Préhistorique française, 50–4, 211–217. doi: 10.3406/bspf.1953.3031.Suche in Google Scholar

Berg, I. (2008). Looking through pots: Recent advances in ceramic X-Radiography. Journal of Archaeological Sciences, 35, 1177–1188. doi: 10.1016/j.jas.2007.08.006.Suche in Google Scholar

Berg, I. (2009). X-Radiography of Knossian Bronze Age Vessels: Assessing our knowledge of primary forming techniques. Annual of the British School at Athens, 104, 137–173. doi: 10.1017/S0068245400000228.Suche in Google Scholar

Borrell, F., Bosch, J., & Vicente, O. (2009). Datacions per radiocarboni a les mines neolítiques de la Serra de les Ferreres de Gavà. In J. Bosch & F. Borrell (Eds.), Rubricatum. Revista del Museu de Gavà: Intervencions arqueològiques a les Mines de Gavà (Sector Serra de les Ferreres). Anys 1998 – 2009. De la variscita al ferro: Neolític i antiguitat, 4 (pp. 241–246). Gavà: Instituts Municipal de Gestió del Patrimoni Cultural i Natural de Gavà. Ajuntament de Gavà.Suche in Google Scholar

Borrell, F., & Bosch, J. (2009). Conclusions. In J. Bosch & F. Borrell (Eds.), Rubricatum. Revista del Museu de Gavà. Intervencions arqueològiques a les Mines de Gavà (Sector Serra de les Ferreres). Anys 1998 - 2009. De la variscita al ferro: Neolític i antiguitat, 4 (pp. 263–269). Gavà: Institut Municipal de Gestió del Patrimoni Cultural i Natural de Gavà, Ajuntament de Gavà.Suche in Google Scholar

Borrell, F., & Bosch, J. (2012). Las minas de variscita de Gavà (Barcelona) y las redes de circulación en el Neolítico. In M. Borrell, F. Borrell, J. Bosch, X. Clop, & M. Molist (Eds.), Rubricatum. Revista del Museu de Gavà: Xarxes al Neolític. Circulació i itercanvi de matèries, productes i idees a la Mediterrània occidental (VII–III mil·lenni aC), 5 (pp. 315–322). Gavà: Institut Municipal de Gestió del Patrimoni Cultural i Natural. Ajuntament de Gavà.Suche in Google Scholar

Bosch, J., & Estrada, A. (Eds.). (1994). El Neolític Postcardial a les Mines Prehistòriques de Gavà (Baix Llobregat). Rubricatum. Revista del Museu de Gavà, 0. Gavà: Museu de Gavà.Suche in Google Scholar

Borrell, F., & Orri, E. (2009). Excavacions arqueològiques a la Serra de les Ferreres, Mines Prehistòriques de Gavà. In L’Arqueologia a Gavà. Homentage a Alícia Estrada. Col·lecció La Nostra Gent, 5. Associació d’Amics del Museu de Gavà i Institut Municipal de Gestió del Patrimoni cultural i Natural de Gavà – Ajuntament de Gavà, Gavà.Suche in Google Scholar

Bosch, J., & Borrell, F. (Eds.). (2009). Rubricatum. Revista del Museu de Gavà: Intervencions arqueològiques a les Mines de Gavà (Sector Serra de les Ferreres). Anys 1998–2009, 4. Gavà: Institut Municipal de Gestió del Patrimoni Cultura i Natural, Ajuntament de Gavà.Suche in Google Scholar

Bosch, J., & Santacana, J. (2009). Blat, metalls i cabdills. Catalunya del Neolític a la Iberització. Barcelona: Rafael Dalmau.Suche in Google Scholar

Bosch, J. (2010). Representaciones antropomorfas muebles del Neolítico en Cataluña: Primeros ídolos oculados. In C. Cacho, R. Maicas, E. Galán, & J. A. Martos (Eds.), Los ojos que nunca se cierran. Ídolos en las primeras sociedades campesinas (pp. 13–37). Madrid: Museo Arqueológico Nacional. Ministerio de Cultura.Suche in Google Scholar

Bosch, J. (2012). Producir, distribuir y redistribuir. In M. Borrell, F. Borrell, J. Bosch, X. Clop, & M. Molist (Eds.), Actes Congrés Internacional Xarxes al Neolític. Circulació I intercanvi de matèries, productes I idees a la Mediterrània occidental (VII–III mil·lenni aC), Gavà – Bellaterra, 2-4/2/2011. Rubricatum. Revista del Museu de Gavà, 5 (pp. 575–580). Gavà: Ajuntament de Gavà.Suche in Google Scholar

Bosch, J., Gómez, A., Calvo, S., & Molist, M. (2020). Green beads during the Late Prehistory in the northeast Iberian Peninsula: Social dynamics in a production and consumption context. In C. Rodríguez Rellán, B. A. Nelson, & R. Fábregas Valcarce (Eds.), A Taste for Green. A global perspective on ancient jade, turquoise and variscite Exchange (pp. 59–76). United Kingdom: Oxbow Books. doi: 10.2307/j.ctv138ws4v.Suche in Google Scholar

Buxó, R., Català, M., & Villalba, M. J. (1991). Llavors i fruits en un conjunt funerari situat en la galería d’accés a la mina 28 del complex miner de Can Tintorer (Gavà). Cypsela, IX, 65–72. https://www.raco.cat/index.php/Cypsela/article/view/119356/254939.Suche in Google Scholar

Calvo, S. (2019). Aproximación y caracterización de la tecnología de fabricación de los recipientes cerámicos en las Minas Prehistóricas de Gavà (Doctoral dissertation), Departament de Prehistòria, Universitat Autònoma de Barcelona, Bellaterra. doi: 10.13140/RG.2.2.35308.18567.Suche in Google Scholar

Calvo, S., Bosch, J., Molist, M., & Gómez, A. (2018). Aproximación a los tratamientos de superfície de los recipientes cerámicos de las Minas Prehistóricas de Gavà (Barcelona). Bulletí Arqueològic, Època V, 40, 251–256. Real Societat Arqueològica Tarraconense.Suche in Google Scholar

Calvo, S., Bosch, J., Gómez, A., & Molist, M. (2021). Use of imaging and chemical techniques to observe technological features of the Venus of Gavà. Journal of Archaeological Science: Reports, 40, Part B, 103237. doi: 10.1016/j.jasrep.2021.103237.Suche in Google Scholar

Cámara, J., Clop, X., García, J., Pons, E., & Saña, M. (2021). Identifying forming techniques and ways of doing from diachronic perspective: The example of pottery production of La Dou (Northeast Iberian Peninsula) during the Middle Neolithic I and Late Bronze Age. Archeopress, Contribution of Ceramic Technological Approaches to the anthropology and archaeology of pre – and protohistoric societies: Proceedings of the XVIII UISPP World Congress (4–9 June 2018, Paris, France) (pp. 19–35).Suche in Google Scholar

Cámara, J., Clop, X., García Roselló, J., & Pons, E. (2021). Técnicas de modelado de cerámicas y prácticas funerarias durante el Bronce Final: Análisis traceológico de las producciones cerámicas de la necrópolis de incineración del Pi de la Lliure (Ne Península Ibérica). Saguntum, Papeles de Laboratorio de Arqueología de Valencia, K, 9–34. doi: 10.7203/SAGVNTVM.53.20706.Suche in Google Scholar

Clemente, I., Mazzuco, N., Mozota, M., & Díaz, S. (2019). Cerámica prehistórica y el kit instrumental para su producción. Descripción del registro arqueológico de Coro Trasito (Tella-sin, Huesca). Treballs d’Arqueologia, 23, 118–152. doi: 10.5565/rev/tda.100.Suche in Google Scholar

Clop, X., & Álvarez, A. (2009). Estudi de caracterització petrogràfica d’un vas de boca quadrada neolític de la mina 83 de Gavà. In J. Bosch & F. Borrell (Eds.), Intervencions Arqueològiques a les Mines de Gavà (sector Serra de les Ferreres), Anys 1998 – 2009, Rubricatum, Revista del Museu de Gavà, 4 (pp. 85–91). Gavà: Ajuntament de Gavà.Suche in Google Scholar

Colas, C. (2007). Reconstitution des techniques de fabrication des céramiques des constructeurs d’enceinte du Néolithique moyen II en France septentrionale. In O. Agogué, D. Leroy, & C. Verjux (Eds.), Camps, enceintes et structures d’habitat néolithiques en France septentrionale. Actes du 24eme Colloque interrégional sur le Néolithique, Orléans, 19 au 21 novembre 1999, 27eme Supplément à la Revue Archéologique du Centre de la France (pp. 217–228).Suche in Google Scholar

Cresswell, R. (1976). Techniques et culture: Les bases d’un programme de travail. Enquêtes dans les haute et moyenne vallées du fleuve Sénégal (Sénégal). Paris: Éditions de la Maison des sciences de l’homme, Éditions Épistèmes.10.4000/tc.6265Suche in Google Scholar

Díaz, S. (2019). Experimentación aplicada a la cerámica prehistórica hecha a mano: Creación de una colección experimental de referencia para el análisis del tratamiento de superficie. Treballs d’Arqueologia, 23, 203–222. doi: 10.5565/rev/tda.98.Suche in Google Scholar

Díaz, S., Mazzucco, N., Gassiot, E., Clop, X., Clemente, I., & Benavides, A. (2020). Approaching surfaces treatment in prehistoric pottery: Exploring variability in tool traces on pottery surfaces through experimentation. Quaternary International, 569–570, 135–149. doi: 10.1016/j.quaint.2020.06.27.Suche in Google Scholar

Dorado, A. (2019). Caracterización de las producciones cerámicas de Andalucía oriental y el sudeste de la Península Ibérica: Del Bronce tardío al mundo protoibérico (1550/1500 – 500 cal. AC). (Doctoral dissertation). Universidad de Granada, Departamento de Prehistoria y Arqueología, Granada. https://digibug.ugr.es/handle/10481/55777.Suche in Google Scholar

García Rosselló, J. (2008). Etnoarqueología de la producción cerámica: Identidad y territorio en los valles centrales de Chile. Mayurqa, 32, 11–328.Suche in Google Scholar

García Rosselló, J., & Calvo, M. (2013). Making Pots. El modelado de la cerámica y su potencial interpretativo. Oxford: BAR International Series.10.30861/9781407311609Suche in Google Scholar

Gelbert, A. (2000). Etude ethnoarchéologique des phénomènes d’emprunts céramiques: Enquêtes dans les haute et moyenne vallées du fleuve Sénégal (Sénégal). (Doctoral dissertation). Paris 10: Université Paris X – Nanterre. https://www.theses.fr/2000PA100057.Suche in Google Scholar

Gelbert, A. (2003). Traditions céramiques et emprunts techniques dans la vallée du fleuve Sénégal. Paris: Éditions de la Maison des Sciences de l’homme, Éditions Épistèmes.Suche in Google Scholar

Gibson, A., & Woods, A. (1990). Prehistoric pottery for the archaeologist. Leicester: University Press.Suche in Google Scholar

Gimeno, D., Fernández, J. L., Villalba, M. J., Edo, M., & Blasco, A. (1996). Complejo minero de Can Tintorer, Gavà: Geología y técnicas de explotación en el IV milenio. In X. Clop, A. Estrada, J. M. Faura, T. Majó, J. Nadal, & M. Saña (Eds.), Rubricatum. Revista del Museu de Gavà: Actes del I Congrés del Neolític a la Península Ibèrica. Formació i implantació de les comunitat agrícoles. Gavà – Bellaterra, 27, 28 i 29 de Març de 1995, 1 (pp. 259–263). Gavà: Museu de Gavà.Suche in Google Scholar

Gomart, L., Weiner, A., Gabriele, M., Gilles, D., Sorin, S., Anglei, L., … Binder, D. (2017). Spiralled Patchwork in Pottery Manufacture and the Introduction of Farming to Southern Europe. Antiquity, 91(360), 1501–1514. doi: 10.15184/aqy.2017.187.Suche in Google Scholar

Gosselain, O. (1992). Technology and style: Potters and pottery among Bafia of Cameroon. Man, 27, 559–586.10.2307/2803929Suche in Google Scholar

Gosselain, O. (2002). Poteries du Cameroun méridional: Styles techniques et rapports à l’identité. Paris: CNRS Éditions, Collection Monographie du CRA, 26.Suche in Google Scholar

Gosselain, O. (2008). Mother Bella was not a Bella. Inherited and transformed traditions in South-western Niger. In M. Stark, B. Bower, & L. Horne (Eds.), Cultural transmission and Material culture. Breaking down boundaries (pp. 150–177), Tucson: Arizona University Press.10.2307/j.ctv2phprdh.13Suche in Google Scholar

Gosselain, O., & Livingstone-Smith, A. (1995). The Ceramics and Society Project: An Ethnographic and Experimental approach to technological choices. KVHAA Konferenser, 34, 147–160.Suche in Google Scholar

Lara, C. (2017). Aportes del enfoque tecnológico a la arqueología precolombina: Pasado y presente de la alfarería en el valle del río Cuyes y su región (Andes surorientales del Ecuador). Paris monographs in American Archaeology, 47. Archeopress – Acces Archaeology.10.2307/j.ctv1zcm1jkSuche in Google Scholar

Leroi-Gourhan, A. (1964). La geste et la Parole. Technique et Langage. Paris: Albin Michel.Suche in Google Scholar

Lozada, N. (2020). Ancient pots and potters of the Atures Rapids regions: Occupation and interaction processes in pre – colonial Middle Orinoco, Venezuela. (Unpublished doctoral dissertation). University College of London.Suche in Google Scholar

Manem, S. (2008). Étude des fondements technologiques de la culture des Duffaits (âge du Bronze moyen). (Unpublished doctoral dissertation). Université Paris - X, Nanterre.Suche in Google Scholar

Manem, S. (2016) “Modéliser l’évolution des traditions techniques et des filières d’apprentissage selon l’approche phylogénétique (encadré)”. In V. Roux (Ed.), Des céramiques et des hommes. Décoder les assemblages archéologiques (pp. 343–349). Paris: Presses Universitaires de Paris Ouest.Suche in Google Scholar

Martí, M., Pou, R., & Carlús, X. (1997). Excavacions arqueològiques a la Ronda Sud de Granollers, 1994. La necropolis del neolític mitjà i les restes romanes del Camí de Can Grau (La Roca del Vallès, Vallès Oriental). Els jacimens de Cal Jardiner (Granollers, Vallès Oriental). Direcció General del Patrimoni Cultural. Servei d’Arqueologia. Generalitat de Catalunya, Departament de Cultura, Barcelona.Suche in Google Scholar

Martineau, R. (2002). Poterie, techniques et sociétés. Études analytiques et expérimentales à Chalain et Clairvaiux (Jura), entre 3200 et 2900 av. J.-C-. Bulletin de la Société Préhistorique Française, 99(1), 150–153. https://www.persee.fr/doc/bspf_0249-7638_2002_num_99_1_12619.Suche in Google Scholar

Mauss, M. (1947). Manuel d’ethnographie. Paris: Payot.Suche in Google Scholar

Muñoz, A. M. (1965). La cultura neolítica catalana de los “Sepulcros de Fosa”. Barcelona: Instituto de Arqueología y Prehistoria. Universidad de Barcelona. Publicaciones Eventuales, n°9. Barcelona.Suche in Google Scholar

Oliva, M. (2015). Aprofitament i transformació de matèries primeres per a l’elaboració d’ornaments durant la prehistòria recent (5600–3400 cal ANE) al nord – est de la Península Ibèrica (Doctoral dissertation). Universitat Autònoma de Barcelona, Bellaterra. http://hdl.handle.net/10803/325679.Suche in Google Scholar

Orton, C., Tyers, P., & Vince, A. (1993). La cerámica en arqueología. Barcelona: Editorial crítica.Suche in Google Scholar

Rice, P. M. (1981). Evolution of specialized pottery production: Considerations of variability and diversity in a trial model. Current Anthropology, 22, 219–240.10.1086/202661Suche in Google Scholar

Rice, P. M. (1987). Pottery Analysis: A Soucerbook. Chicago: University of Chicago Press.Suche in Google Scholar

Roig, J., & Coll, J. M. (2010). La necropolis del Neolític Mitjà de Can Gambús – 1 (Sabadell, Vallès Oriental): Nova tipologia dels sepulchres de fossa I pràctiques funeràries durante el IV mil·leni calBC a Catalunya. Cypsela, 18, 83–122. Barcelona: Generalitat de Catalunya.Suche in Google Scholar

Roux, V. (1990). The psychological analysis of technical activities: A contribution to the study of craft specialization. Archaeological Review from Cambridge, 9, 142–153.Suche in Google Scholar

Roux, V. (1994). La technique du tournage: Définition et reconnaissance par les macrotraces. In D. Binder & J. Courting (Eds.), Terre cuite et Société. La céramique, document technique, économique, culturel (pp. 51–62). Juan-les-Pins, Éditions APDCA, collection XIVè Rencontres Internationales d’Archéologie et d’Historie d’Antibes.Suche in Google Scholar

Roux, V. (2003). A dynamic systems framework for studying technological change: Application to the emergence of the potter’s wheel in the southern Levant. Journal of Archaeological Method and Theory, 10, 1–30.10.1023/A:1022869912427Suche in Google Scholar

Roux, V. (2010). Lecture anthorpologique des assemblages céramiques. Fondements et mise en oeuvre de l’analyse technologique. Les Nouvelles de l’archéologie, 119, 2–11. doi: 10.4000/nda.957.Suche in Google Scholar

Roux, V. (2011). Anthropological interpretation of ceramic assemblages: Foundations and implementations of technological analysis. In S. Scarcella (Ed.), Archaeological ceramics: A review of current research (pp. 80–88). Oxford: BAR International Series.Suche in Google Scholar

Roux, V. (2013). Spreading of innovative technical traits and cumulative technical evolution: Continuity or discontinuity?. Journal of Archaeological Method and Theory, 20(2), 312–330.10.1007/s10816-012-9153-4Suche in Google Scholar

Roux, V. (2014). Technologie céramique: Une approche anthropologique. Paris: Errance.Suche in Google Scholar

Roux, V. (2016). Des céramiques et des hommes. Décoder les assemblages archéologiques. En collaboration avec Marie – Agnès Courty. Paris: Presses Universitaires de Paris Ouest.10.4000/books.pupo.25317Suche in Google Scholar

Roux, V. (2019). Ceramics and society. A technological approach to archaeological assemblages. Switzerland: Springer.10.1007/978-3-030-03973-8Suche in Google Scholar

Shepard, S. (1980). Ceramics for the archaeologist. Washington: Carnegie Institution of Washington.Suche in Google Scholar

Villalba, M. J. (2002). La gîte de variscite de Can Tintorer: Production, transformation et circulation du mineral ver. In J. Guilaine (Eds.), Matériaux, productions, circulations de Néolitique à l’Age du Bronze (pp. 115–127). Séminaire du Collège de France: Éditions Errance.Suche in Google Scholar

Villalba, M. J., Bañolas, L., & Arenas, J. (1990). Can Tintorer, Gavà (Catalogne). Une exploitation néolithique de phosphates et silicates. In Le silex. De sa genése a l’outil, Vth Flint International Symposium, Bourdeaux, 1987. Cahiers du Quaternaire, 17(1), 275–285. CNRS Paris.Suche in Google Scholar

Villalba, M. J., Bañolas, L., Arenas, J., & Alonso, M. (1986). Les Mines neolítiques de Can Tintorer. Gavà. Excavacions de 1978–1980. Barcelona: Departament de Cultura de la Generalitat de Catalunya.Suche in Google Scholar

Vuckovic, V., Filipovic, V., Stojanovic, B., & Risch, R. (2021). Crafting pottery in Bronze Age Europe: The archaeological background of the CRAFTER project. Paracin: Regional Museum of Paracin.Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- A 2D Geometric Morphometric Assessment of Chrono-Cultural Trends in Osseous Barbed Points of the European Final Palaeolithic and Early Mesolithic

- Wealth Consumption, Sociopolitical Organization, and Change: A Perspective from Burial Analysis on the Middle Bronze Age in the Carpathian Basin

- Everything Has a Role to Play: Reconstruction of Vessel Function From Early Copper Age Graves in the Upper Tisza Region (Eastern Hungary)

- Urban Success and Urban Adaptation Over the Long Run

- Exploring Hypotheses on Early Holocene Caspian Seafaring Through Personal Ornaments: A Study of Changing Styles and Symbols in Western Central Asia

- Victims of Heritage Crimes: Aspects of Legal and Socio-Economic Justice

- On the (Non-)Scalability of Target Media for Evaluating the Performance of Ancient Projectile Weapons

- Small Houses of the Dead: A Model of Collective Funerary Activity in the Chalcolithic Tombs of Southwestern Iberia. La Orden-Seminario Site (Huelva, Spain)

- Bigger Fish to Fry: Evidence (or Lack of) for Fish Consumption in Ancient Syracuse (Sicily)

- Terminal Ballistics of Stone-Tipped Atlatl Darts and Arrows: Results From Exploratory Naturalistic Experiments

- First Archaeological Record of the Torture and Mutilation of Indigenous Mapuche During the “War of Arauco,” Sixteenth Century

- The Story of the Architectural Documentation of Hagia Sophia’s Hypogeum

- Iconographic Trends in Roman Imperial Coinage in the Context of Societal Changes in the Second and Third Centuries CE: A Small-Scale Test of the Affluence Hypothesis

- Circular Economy in the Roman Period and the Early Middle Ages – Methods of Analysis for a Future Agenda

- New Insights Into the Water Management System at Tetzcotzinco, Mexico

- How Linguistic Data Can Inform Archaeological Investigations: An Australian Pilot Study Around Combustion Features

- Leadership in the Emergent Baekje State: State Formation in Central-Western Korea (ca. 200–400 CE)

- Middle Bronze Age Settlement in Czeladź Wielka – The Next Step Toward Determining the Habitation Model, Chronology, and Pottery of the Silesian-Greater Poland Tumulus Culture

- On Class and Elitism in Archaeology

- Archaeology of the Late Local Landscapes of the Hualfín Valley (Catamarca, Argentina): A Political Perspective from Cerro Colorado of La Ciénaga de Abajo

- Review Article

- The State of the Debate: Nuragic Metal Trade in the Bronze Age and Early Iron Age

- A Review of Malta’s Pre-Temple Neolithic Pottery Wares

- Commentary Article

- Paradise Found or Common Sense Lost? Göbekli Tepe’s Last Decade as a Pre-Farming Cult Centre

- Special Issue Published in Cooperation with Meso’2020 – Tenth International Conference on the Mesolithic in Europe, edited by Thomas Perrin, Benjamin Marquebielle, Sylvie Philibert, and Nicolas Valdeyron - Part II

- The Time of the Last Hunters: Chronocultural Aspects of Early Holocene Societies in the Western Mediterranean

- Fishing Nets and String at the Final Mesolithic and Early Neolithic Site of Zamostje 2, Sergiev Posad (Russia)

- Investigating the Early-to-Late Mesolithic Transition in Northeastern Italy: A Multifaceted Regional Perspective

- Socioeconomic, Technological, and Cultural Adaptation of the Mesolithic Population in Central-Eastern Cantabria (Spain) in the Early and Middle Holocene

- From Coastal Sites to Elevated Hinterland Locations in the Mesolithic – Discussing Human–Woodland Interaction in the Oslo Fjord Region, Southeast Norway

- Exploitation of Osseous Materials During the Mesolithic in the Iron Gates

- Motorways of Prehistory? Boats, Rivers and Moving in Mesolithic Ireland

- Environment and Plant Use at La Tourasse (South-West France) at the Late Glacial–Holocene Transition

- Stylistic Study of the Late Mesolithic Industries in Western France: Combined Principal Coordinate Analysis and Use-Wear Analysis

- Mesolithic Occupations During the Boreal Climatic Fluctuations at La Baume de Monthiver (Var, France)

- Pressure Flakers of Late Neolithic Forest Hunter-Gatherer-Fishers of Eastern Europe and Their Remote Counterparts

- The Site Groß Fredenwalde, NE-Germany, and the Early Cemeteries of Northern Europe

- Special Issue on Archaeology of Migration: Moving Beyond Historical Paradigms, edited by Catharine Judson & Hagit Nol

- The Blurry Third Millennium. “Neolithisation” in a Norwegian Context

- Movement or Diaspora? Understanding a Multigenerational Puebloan and Ndee Community on the Central Great Plains

- Human Mobility and the Spread of Innovations – Case Studies from Neolithic Central and Southeast Europe

- The Thule Migration: A Culture in a Hurry?

- The Transformation of Domes in Medieval Chinese Mosques: From Immigrant Muslims to Local Followers

- Landscapes of Movement Along the (Pre)Historical Libyan Sea: Keys for a Socio-Ecological History

- Arab Migration During Early Islam: The Seventh to Eighth Century AD from an Archaeological Perspective

- Special Issue on Ancient Cultural Routes: Past Transportations Infrastructures as a Two-Way Interaction Between Society and Environment, edited by Francesca Fulminante, Francesca Mazzilli & Franziska Engelbogen

- The Impact of Transportation on Pottery Industries in Roman Britain

- The Role of the Road in Settling a Mountainous Region

- An Example of Geographic Network Analysis: The Case Study of the Fortore Valley (Molise and Apulia, Italy)

- Water, Communication, Sight, and the Location of Fortifications on the Strata Diocletiana (Syria) in Late Antiquity

- Transport, Interaction, and Connectivity

- Special Issue on Scales of Interaction in the Bronze and Iron Age Central Mediterranean, edited by Emily Holt & Davide Schirru

- Tracing Mobility Patterns of Buried Species of the Late Iron Age Funerary Staggered Turriform of Son Ferrer (Calvià, Spain)

- Approaching Interaction in Iron Age Sardinia: Multi-Scalar Survey Evidence from the Sinis Archaeological Project and the Progetto S’Urachi

- From the Atlantic to the Mediterranean and Back: Sardinia, Iberia, and the Transfer of Knowledge in Late Bronze Age Networks

- Special Issue on Bricks Under the Scope: Microscopic and Macroscopic Approaches to the Study of Earthen Architecture, edited by Marta Lorenzon, Moritz Kinzel, & Benjamín Cutillas-Victoria

- Earthen Architecture in Nordic Countries: Future Directions

- Earthen Architecture and Craft Practices of Early Iron Age Ramparts: Geoarchaeological Analysis of Villares de la Encarnación, South-Eastern Iberia

- Earthen Architecture in Southern Algeria: An Assessment of Social Values and the Impact of Industrial Building Practices

- Studying the Use of Earth in Early Architecture of Southwest and Central Asia

- Roof Tiles and Bricks of the Etruscan Domus dei Dolia (Vetulonia, Italy): An Archaeological and Archaeometric Study of Construction Materials

- The Building Blocks of Circular Economies: Rethinking Prehistoric Turf Architecture Through Archaeological and Architectural Analysis

- Undecorated Roman-Period Roof Tiles – An Old Material Providing New Results

- Turf Building in Iceland – Past, Present, and Future

- Special Issue on Past Sounds: New Perspectives in the Field of Archaeoacoustics, edited by Margarita Díaz-Andreu & Neemias Santos da Rosa

- Employing Psychoacoustics in Sensory Archaeology: Developments at the Ancient Sanctuary of Zeus on Mount Lykaion

- One, Two, Three! Can Everybody Hear Me? Acoustics of Roman Contiones. Case Studies of the Capitoline Hill and the Temple of Bellona in Rome

- Ringing Tone and Drumming Sages in the Crevice Cave of Pirunkirkko, Koli, Finland

- Music and Storytelling at Rock Art Sites? The Archaeoacoustics of the Urkosh Area (Russian Altai)

- Listening in Sacred Spaces: The Sanctuary of Poseidonia and Selinunte’s Main Urban Sanctuary

- Presenting Archaeoacoustics Results Using Multimedia and VR Technologies

- Special Issue on Reconsidering the Chaîne Opératoire: Towards a Multifaceted Approach to the Archaeology of Techniques, edited by Marie-Elise Porqueddu, Claudia Sciuto & Anaïs Lamesa

- Reconsidering the Chaîne Opératoire: At the Crossroad Between People and Materials

- Materiality of Plaster Vessels: The Problem of Southwest Asian Neolithic White Ware

- The Chaîne Opératoire Approach for Interpreting Personal Ornament Production: Marble Beads in Copper Age Tuscany (Italy)

- Seriality and Individualization: Carving the Fluted Sarcophagi from Hierapolis of Phrygia

- Making Vessels for the Dead: Pottery-Making Practices, Chaîne Opératoire and the Use of Grog (Crushed Sherds) as a Technological and Cultural Choice during Late and Inca Periods in the Northwestern Argentine Region (Southern Andes)

- An Invention Shading Light to the Socio-History of Bonneuil Quarry Basin: The Roadheaders with Rotating Drill Bits

- The Ugly Duckling: Understanding the Making of an Early Copper Age Atypical Ceramic Vessel from the Great Hungarian Plain

- Synopsis of a Treasure. A Transdisciplinary Study of Medieval Gold Workings Biographies

- Identification of Ceramic Traditions on the Prehistoric Mines of Gavà (Barcelona, Spain)

Artikel in diesem Heft

- Regular Articles

- A 2D Geometric Morphometric Assessment of Chrono-Cultural Trends in Osseous Barbed Points of the European Final Palaeolithic and Early Mesolithic

- Wealth Consumption, Sociopolitical Organization, and Change: A Perspective from Burial Analysis on the Middle Bronze Age in the Carpathian Basin

- Everything Has a Role to Play: Reconstruction of Vessel Function From Early Copper Age Graves in the Upper Tisza Region (Eastern Hungary)

- Urban Success and Urban Adaptation Over the Long Run

- Exploring Hypotheses on Early Holocene Caspian Seafaring Through Personal Ornaments: A Study of Changing Styles and Symbols in Western Central Asia

- Victims of Heritage Crimes: Aspects of Legal and Socio-Economic Justice

- On the (Non-)Scalability of Target Media for Evaluating the Performance of Ancient Projectile Weapons

- Small Houses of the Dead: A Model of Collective Funerary Activity in the Chalcolithic Tombs of Southwestern Iberia. La Orden-Seminario Site (Huelva, Spain)

- Bigger Fish to Fry: Evidence (or Lack of) for Fish Consumption in Ancient Syracuse (Sicily)

- Terminal Ballistics of Stone-Tipped Atlatl Darts and Arrows: Results From Exploratory Naturalistic Experiments

- First Archaeological Record of the Torture and Mutilation of Indigenous Mapuche During the “War of Arauco,” Sixteenth Century

- The Story of the Architectural Documentation of Hagia Sophia’s Hypogeum

- Iconographic Trends in Roman Imperial Coinage in the Context of Societal Changes in the Second and Third Centuries CE: A Small-Scale Test of the Affluence Hypothesis

- Circular Economy in the Roman Period and the Early Middle Ages – Methods of Analysis for a Future Agenda

- New Insights Into the Water Management System at Tetzcotzinco, Mexico

- How Linguistic Data Can Inform Archaeological Investigations: An Australian Pilot Study Around Combustion Features

- Leadership in the Emergent Baekje State: State Formation in Central-Western Korea (ca. 200–400 CE)

- Middle Bronze Age Settlement in Czeladź Wielka – The Next Step Toward Determining the Habitation Model, Chronology, and Pottery of the Silesian-Greater Poland Tumulus Culture

- On Class and Elitism in Archaeology

- Archaeology of the Late Local Landscapes of the Hualfín Valley (Catamarca, Argentina): A Political Perspective from Cerro Colorado of La Ciénaga de Abajo

- Review Article

- The State of the Debate: Nuragic Metal Trade in the Bronze Age and Early Iron Age

- A Review of Malta’s Pre-Temple Neolithic Pottery Wares

- Commentary Article

- Paradise Found or Common Sense Lost? Göbekli Tepe’s Last Decade as a Pre-Farming Cult Centre

- Special Issue Published in Cooperation with Meso’2020 – Tenth International Conference on the Mesolithic in Europe, edited by Thomas Perrin, Benjamin Marquebielle, Sylvie Philibert, and Nicolas Valdeyron - Part II

- The Time of the Last Hunters: Chronocultural Aspects of Early Holocene Societies in the Western Mediterranean

- Fishing Nets and String at the Final Mesolithic and Early Neolithic Site of Zamostje 2, Sergiev Posad (Russia)

- Investigating the Early-to-Late Mesolithic Transition in Northeastern Italy: A Multifaceted Regional Perspective

- Socioeconomic, Technological, and Cultural Adaptation of the Mesolithic Population in Central-Eastern Cantabria (Spain) in the Early and Middle Holocene

- From Coastal Sites to Elevated Hinterland Locations in the Mesolithic – Discussing Human–Woodland Interaction in the Oslo Fjord Region, Southeast Norway

- Exploitation of Osseous Materials During the Mesolithic in the Iron Gates

- Motorways of Prehistory? Boats, Rivers and Moving in Mesolithic Ireland

- Environment and Plant Use at La Tourasse (South-West France) at the Late Glacial–Holocene Transition

- Stylistic Study of the Late Mesolithic Industries in Western France: Combined Principal Coordinate Analysis and Use-Wear Analysis

- Mesolithic Occupations During the Boreal Climatic Fluctuations at La Baume de Monthiver (Var, France)

- Pressure Flakers of Late Neolithic Forest Hunter-Gatherer-Fishers of Eastern Europe and Their Remote Counterparts

- The Site Groß Fredenwalde, NE-Germany, and the Early Cemeteries of Northern Europe

- Special Issue on Archaeology of Migration: Moving Beyond Historical Paradigms, edited by Catharine Judson & Hagit Nol

- The Blurry Third Millennium. “Neolithisation” in a Norwegian Context

- Movement or Diaspora? Understanding a Multigenerational Puebloan and Ndee Community on the Central Great Plains

- Human Mobility and the Spread of Innovations – Case Studies from Neolithic Central and Southeast Europe

- The Thule Migration: A Culture in a Hurry?

- The Transformation of Domes in Medieval Chinese Mosques: From Immigrant Muslims to Local Followers

- Landscapes of Movement Along the (Pre)Historical Libyan Sea: Keys for a Socio-Ecological History

- Arab Migration During Early Islam: The Seventh to Eighth Century AD from an Archaeological Perspective

- Special Issue on Ancient Cultural Routes: Past Transportations Infrastructures as a Two-Way Interaction Between Society and Environment, edited by Francesca Fulminante, Francesca Mazzilli & Franziska Engelbogen

- The Impact of Transportation on Pottery Industries in Roman Britain

- The Role of the Road in Settling a Mountainous Region

- An Example of Geographic Network Analysis: The Case Study of the Fortore Valley (Molise and Apulia, Italy)

- Water, Communication, Sight, and the Location of Fortifications on the Strata Diocletiana (Syria) in Late Antiquity

- Transport, Interaction, and Connectivity

- Special Issue on Scales of Interaction in the Bronze and Iron Age Central Mediterranean, edited by Emily Holt & Davide Schirru

- Tracing Mobility Patterns of Buried Species of the Late Iron Age Funerary Staggered Turriform of Son Ferrer (Calvià, Spain)

- Approaching Interaction in Iron Age Sardinia: Multi-Scalar Survey Evidence from the Sinis Archaeological Project and the Progetto S’Urachi

- From the Atlantic to the Mediterranean and Back: Sardinia, Iberia, and the Transfer of Knowledge in Late Bronze Age Networks

- Special Issue on Bricks Under the Scope: Microscopic and Macroscopic Approaches to the Study of Earthen Architecture, edited by Marta Lorenzon, Moritz Kinzel, & Benjamín Cutillas-Victoria

- Earthen Architecture in Nordic Countries: Future Directions

- Earthen Architecture and Craft Practices of Early Iron Age Ramparts: Geoarchaeological Analysis of Villares de la Encarnación, South-Eastern Iberia

- Earthen Architecture in Southern Algeria: An Assessment of Social Values and the Impact of Industrial Building Practices

- Studying the Use of Earth in Early Architecture of Southwest and Central Asia

- Roof Tiles and Bricks of the Etruscan Domus dei Dolia (Vetulonia, Italy): An Archaeological and Archaeometric Study of Construction Materials

- The Building Blocks of Circular Economies: Rethinking Prehistoric Turf Architecture Through Archaeological and Architectural Analysis

- Undecorated Roman-Period Roof Tiles – An Old Material Providing New Results

- Turf Building in Iceland – Past, Present, and Future

- Special Issue on Past Sounds: New Perspectives in the Field of Archaeoacoustics, edited by Margarita Díaz-Andreu & Neemias Santos da Rosa

- Employing Psychoacoustics in Sensory Archaeology: Developments at the Ancient Sanctuary of Zeus on Mount Lykaion

- One, Two, Three! Can Everybody Hear Me? Acoustics of Roman Contiones. Case Studies of the Capitoline Hill and the Temple of Bellona in Rome

- Ringing Tone and Drumming Sages in the Crevice Cave of Pirunkirkko, Koli, Finland

- Music and Storytelling at Rock Art Sites? The Archaeoacoustics of the Urkosh Area (Russian Altai)

- Listening in Sacred Spaces: The Sanctuary of Poseidonia and Selinunte’s Main Urban Sanctuary

- Presenting Archaeoacoustics Results Using Multimedia and VR Technologies

- Special Issue on Reconsidering the Chaîne Opératoire: Towards a Multifaceted Approach to the Archaeology of Techniques, edited by Marie-Elise Porqueddu, Claudia Sciuto & Anaïs Lamesa

- Reconsidering the Chaîne Opératoire: At the Crossroad Between People and Materials

- Materiality of Plaster Vessels: The Problem of Southwest Asian Neolithic White Ware

- The Chaîne Opératoire Approach for Interpreting Personal Ornament Production: Marble Beads in Copper Age Tuscany (Italy)

- Seriality and Individualization: Carving the Fluted Sarcophagi from Hierapolis of Phrygia

- Making Vessels for the Dead: Pottery-Making Practices, Chaîne Opératoire and the Use of Grog (Crushed Sherds) as a Technological and Cultural Choice during Late and Inca Periods in the Northwestern Argentine Region (Southern Andes)

- An Invention Shading Light to the Socio-History of Bonneuil Quarry Basin: The Roadheaders with Rotating Drill Bits

- The Ugly Duckling: Understanding the Making of an Early Copper Age Atypical Ceramic Vessel from the Great Hungarian Plain

- Synopsis of a Treasure. A Transdisciplinary Study of Medieval Gold Workings Biographies

- Identification of Ceramic Traditions on the Prehistoric Mines of Gavà (Barcelona, Spain)