Abstract

Greenhouse farming is considered as one of the most scientific approaches in agriculture, which are suitable for all climatic conditions, especially in Middle East, North America, and Europe. Sustainable greenhouses are innovative farming facilities for healthy vegetables and fruits in a controlled, conditioned indoor space. This article presents a literature review on the upgradation of a conventional to a sustainable greenhouse using modern engineering concept. This includes maintaining fully controlled indoor conditions such as temperature, relative humidity, and air velocity for specific agronomical parameters. The influence and improvements in upgradation of various heating, ventilation, and air-conditioning (HVAC) with the associated control systems and covering materials to reduce the energy consumption have been reviewed. Financial viability of conventional as well as upgraded greenhouses is highlighted. In Middle East climatic conditions, the major challenge is to control the optimal range of temperature (18–21°C), relative humidity (55 to 75%), and air velocity (0–1.3 m/s). It is found that the upgraded HVAC systems with climate control modules can increase the crop yield by 30%. Scientifically selected polycarbonate sheet covering materials are also found to increase the crop yield by up to 15% more than the conventional commercial greenhouses.

1 Introduction

Open-field agriculture has a lot of constraints in maintaining consistent crop production, such as unfavourable topographical and environmental conditions like fluctuating temperature, humidity, etc. They typically provide secure environments for better growth of plants in the present controlled environment conditions with optimum temperature, humidity, ventilation, air velocity, and soil moisture content. Greenhouse farming started the revolution of mechanized farming automation with automatic climate as well as fertigation mechanisms (Baptista et al. 2000). Gerasimov and Lyzlova (2014) propose the implementation of a controller system based on these parameters to enable farmers to monitor their greenhouses online. The primary objective associated with this review is to summarize the various studies carried out in the field of mechanized greenhouse farming to develop a cost-effective sustainable commercial greenhouse using evaporative cooling technology in conjunction with automatic climate control and different covering material upgradations with a focus on Middle East climatic conditions. In the Middle East, half of the year the cultivation is not feasible to normal climate due to the high temperature. Major objective of this study is to optimize energy utilization to improve the crop yield throughout the year.

To maintain the in-house temperature ranging 24–26°C during summer months and to maintain the in-house temperature not less than 18°C during winter months.

To maintain the in-house humidity between 55 and 75% with an effective heating, ventilation, and air-conditioning (HVAC) system.

To provide sensors/probes to measure and log readings of temperature, humidity, CO2 levels and daylight for 24 h/365 days and integrate the field devices to a climate control system (CMS) to manage all the cooling, heating, and humidifying systems to achieve ideal weather inside the greenhouse according to the “growth stages.”

The upgraded greenhouse should be economically viable with a reduction in energy costs.

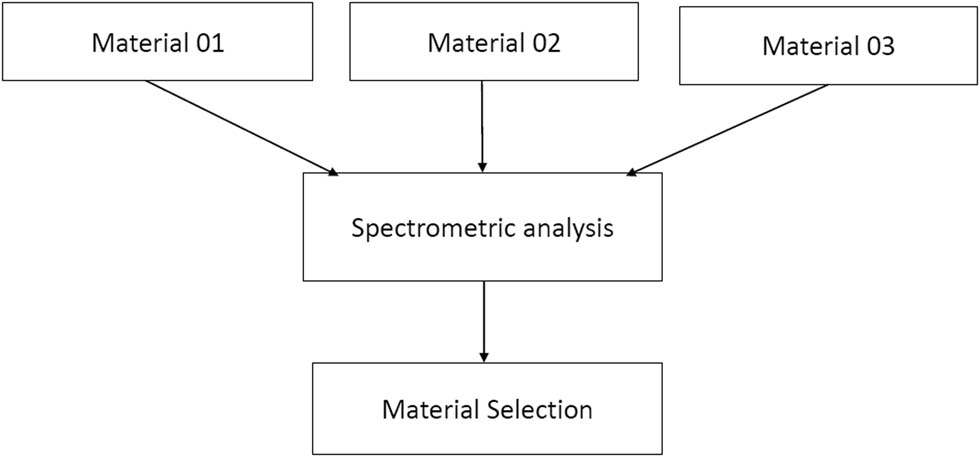

The above-mentioned objectives can be achieved with upgradation on the existing greenhouse. Upgradation of commercial greenhouse into a sustainable platform can be achieved in four stages, namely, (i) major factors related to HVAC systems, (ii) associated factors influencing the HVAC systems and related controls, (iii) effect on control system upgradation, and (iv) optimization. The sustainable greenhouse has been given much more priority than the commercial form of agriculture through leading upgradation in HVAC system and related controls. Sustainable platform of greenhouse activities is helpful in reducing the need for precious natural resources like land and water and at the same time with a high yield of crops per unit area and enhanced productivity as compared to an open-field grown crops. A flow chart for the upgradation of the current greenhouse is shown in Figure 1.

Flow chart of the commercial greenhouse upgradation plan.

1.1 Conventional greenhouse HVAC systems

Existing greenhouse systems, i.e., conventional greenhouse systems, are considered as experiencing high heat loss rates due to the high energy demands of the materials used to construct the greenhouse envelopes. As Ganguly and Ghosh (2011) explained, greenhouses that have cooling and ventilation systems need constant supply of electricity. The use of fan-driven cooling pad system is basically made to take away the heat generated by the supplying components as the pad and fan systems which consist of basic exhaustive fans at one end of the greenhouse and a circulating water pump with cooling pad at the other end. In order to maintain the constant temperature level in the greenhouses all the vents' opening and closing are being interfaced with automatic climate control module to trigger the same as per the requirement. Thus, this driven cooling pad system is helpful in removing energy from the air, which lowers the temperature of the air introduced into the controlled farming indoor space (Baptista et al. 2010). The cooling process was highly inefficient as it seemed to be not achieving its maximum productivity and also leading to a high amount of wastage of resources and failing to make the best use of limited time and resources. This high level of inefficiency is seen in the process of recirculation as it has been observed that the conditioned closed space in the conventional greenhouse is done without the use of air grills on the top or sides, which reduces its efficiency and leads to a poor and inefficient process that require much more time and resources. In many mechanical systems, the use of axial fans with metal blades reduces their efficiency of operation. Deployment of a large workforce to maintain and regulate the indoor variables like temperature, relative humidity etc., is also forms a vital factor gar is giving significant affect in the value of net realization which is mainly caused by range recurring of a cooling pad along with the recirculation system maintenance. Figures 2 and 3 represent the 3D and sectional views of a conventional greenhouse.

3D view of the exterior of the conventional greenhouse ventilation.

Sectional view of the conventional greenhouse ventilation.

In the recent years, a large number of researchers have dwelt on the control of factors affecting the indoor conditions of the greenhouses. Researchers investigated the efficiency of using specifically designed HVAC systems (Bot 1983) as well as the use of wet pads (Coelho et al. 2005) and spray cooling (Bot 1989a). Natural ventilation is taken as the most fundamental and vital technique that facilities education in the usage of energy while making buildings. This phenomenon is based on the fact that the rage of cooling power and capacity of an ambient air could be easily harnessed to increase theoverall level of indoor thermal comforts which is a vital factor to be analyzed while designing the air conditioning systems. In order to take advantage of either deriving force or combining both, the building need to be designed in a proper way (Beven and Binley 1992). Further, being an old technology, the natural ventilation still serves and leads to enhanced experience of recent resurgence of better meeting the interest mainly in Europe where a large number of major research initiatives are conducted to evaluate this vital concept of natural ventilation.

1.2 Sustainable greenhouse

Greenhouse structures enhance developing situations of vegetable, fruits, and decorative vegetation. Commercial greenhouses protect flora from unfavourable atmospheric dealers and, collectively with appropriate gadget, impact, and in the end modify the crop micro-climate, consequently increasing the marketplace accessibility of products, enhancing their high satisfactory, and permitting high yield. Thus, the consistent global growth within the region protected by means of greenhouses has led to enhanced need for growing sustainable blanketed horticulture. Sustainable greenhouse horticulture may be achieved via means of various cultivation techniques good enough to control gadgets and also by progressive substances aimed at lessening the agro-chemical substances, electricity use, and water intake.

2 Effect of upgradation of HVAC systems

Sustainable greenhouse horticulture is mainly associated with the use of various cultivation techniques along with some better management and use of adequate upgraded equipment along with innovative materials. The basic aim of sustainable greenhouse is to reduce the agro-chemicals, other energy use, and water consumption along with reduction in waste generation to move toward a more sustainable and vital greenhouse which leads to enhancement in production with optimum use of resources. It has been analysed that the upgradation of heating ventilation and use of air-conditioning systems, which are associated with control systems, lead to a more adequate and upgraded form of tools and techniques to build and structure a more efficient and better sustainable greenhouse (Boaventura Cunha 2003).

2.1 Greenhouse ventilation

For the successful growth of crops in agricultural greenhouses, there is a need to control and maintain the temperature and humidity at optimum levels. These optimum conditions are required for the successful survival and yield of the crops. Settles (2000) analysed a basic greenhouse model to identify the controlled parameters such as temperature, relative humidity, and air velocity for plant growth in early days. The control parameters mainly consist of the factors that can be controlled or managed as per the need. With respect to the current greenhouse ventilation, the various controllable factors comprise temperature, relative humidity, and air velocity for plant growth, which are taken into full control and can be managed as per the need and requirement.

In a common way, the structure used as a ventilation vent that forms a part of the greenhouse would have a much significant impact on the level of the ventilation of the greenhouse. Greenhouse structure, design, and geometry are modelled to withstand the adversity of external factors such as the wind, rain, snow, etc. Along with the protection from environmental factors, internal factors which includes the dead and live loads for the entire greenhouse also shall be designed in an efficient way to maximize the optimal solar radiation for the crop growth. The structural components of the greenhouse and their geometry seem to directly affect or associate with the solar radiation transmission (Bot 1989b). The geometry of the greenhouse designs is basically reflected in terms of the ratio of the expected length and width, which is assumed to be 30 m and were around 10, 10, and 8, respectively, to maintain the proper geometry and design of greenhouse. Various studies have been carried out to understand the effect of the vent structure and orientation in commercial greenhouses (Albright et al. 2001). Generally, on the basis of greenhouse design and construction, the ventilation system comprises side, roof, and a combination of two in greenhouses.

Commercial greenhouses that utilize conventional air-conditioning systems are not as effective as in terms of cooling; and with humidity controls, they ought to be operating at half of their microclimate control potential. The concept of the microclimate is mainly defined as a fundamental factor which is based on the temperature, humidity, and speed of moving air. Thus, the microclimate control potential system is mainly designed for having a climate control of a sustainable greenhouse for increasing or lowering the temperature and relative humidity. The use of natural ventilation is made but the forced ventilation is not taken into account as the number of additional equipment and tools required for forced ventilation results in increased cost of greenhouse. Thus, to maintain the cost efficiency and to ensure a greenhouse with a normal use of technique, only natural ventilation is implicated and forced ventilation is not used (Coelho et al. 2005).

2.1.1 Natural ventilation

Natural ventilation is the best suitable mode of ventilation for commercial greenhouses, if the external weather conditions are moderate in nature. Several models have been developed for natural ventilation systems, which were verified using analytical methods as well as computational fluid dynamics (CFD) technique. Kittas et al. (2005) developed a naturally ventilated greenhouse model, which was verified using experiments in Mediterranean climate conditions (De Zwart 1996). Natural ventilation is the best suitable mode of ventilation for commercial greenhouses, if the external weather conditions are moderate in nature. Thus, CFD is predicted according to the mode and is verified from the experimental data but not all are verified with experimental data as it could be a complex and time-consuming process. Therefore, implication and utilization of CFD models attempt more effective analysis of problems and facts through simulating the interaction among various forms of liquids and gases where the surfaces are defined by boundary conditions (De Zwart 1997).

On the other hand, the analytical model basically represents a set of mathematical models and other statistical tools and techniques to have a close form of solution to support enhanced decision making and conclusion. The analytical model makes and applies the use of equation to describe the changes that are taking place in a system and can be expressed as a mathematical form of analytic function (Dincer and Cengel 2001). Hornero-Méndez et al. (2002) studied the greenhouse ventilation variance using 2D lattice. The various variables on which the indoor climatic conditions depend comprise humidity, temperature, and sterility; all these environmental conditions are maintained at constant by a greenhouse. Further the expected temperature kept under the indoor climatic conditions and air velocity ranges from 80 to 85°F (Effat et al. 2015). The American society of Agricultural Engineers recommend a ventilation rate of 0.04 m3 s−1. The results discussed are obtained from the analysis of proper temperature (ranges from 80 to 85°F) and relative humidity for better growth and enhanced productivity of crops. In another study conducted by Baeza et al. (2009), ventilation rates between 0.36 and 1.65 kg s−1 for a greenhouse produced the maximum yield. Many of the studies about ventilation variance was validated using CFD techniques in order to compare the results with natural ventilation (El Ghoumari et al. 2005).

2.1.2 Fan-induced ventilation

A fan-induced ventilation system that makes use of mounted fans, blowers, motors, etc., for one or more zones is vital to achieve better control over management and inside conditions. Greenhouse ventilation forms a most important and crucial part of any sustainable or other form of greenhouse, which involves removing air from inside the greenhouse and replacing it with outside air. Further, an evaporative cooler which is also commonly known as swamp cooler, swamp box, desert cooler, and wet air cooler is basically a device that is used to cool air through the evaporation of water. Further studies were carried out for developing a simple model of fan-ventilated greenhouse with fan pad evaporative cooling system. This gained wide acceptability in the past due to reduced quantum of investment and improved yield. Kittas et al. 2005 developed a successful mathematical model to determine the cooling potential of a fan pad evaporative cooling system. Temperature and humidity gradient models were determined for a commercial greenhouse and the variance in temperature inside and outside the greenhouse was fixed at 5–10°C. This work was provided by Kittas et al. (2005) who had also improved the model by including the shading factors (Haefner 2005).

Reviewed articles, approaches, and parameters studied

| Author | Innovations with the aspects studied | |

|---|---|---|

| Settles (2000) | Air flow systems | Air flow visualization in a greenhouse |

| Ishii et al. (2016) | Natural ventilation | Proposed the use of mild pump heating to enhance cooling in greenhouses in mild climates |

| He et al. (2015) | Greenhouse vents | Proposed the use of vent openings to regulate greenhouse microclimates |

| Bartzanas et al. (2004) | Greenhouse ventilation | Proposed a model vent arrangement to enhance windward ventilation |

| Wei et al. (2015) | Experimental evaluation | Proposed the use of removable back walls in greenhouse ventilations |

| Zhou et al. (2018) | Dehumidification | Proposed the use of outdoor heated air through a heat release system |

| Joudi and Hasan (2013) | Solar-assisted desiccant system | Utilized a solar-assisted desiccant system to implement cooling and heating in greenhouses |

Having proper ventilation is important and vital for greenhouse because when the water gets evaporated, heat energy is lost from the air, reducing its temperature and, thus, proper mounted fans, blowers, motors, etc., are needed to maintain proper flow of air and ensure an effective ventilation system (Hameed and Sorensen 2010). Table 1 presents an analysis of the literature sources that inform the review process.

Reviewed articles, approaches, and parameters studied

| Author | Approach | Aspects of study |

|---|---|---|

| Wang and Liang (2006) | Solar greenhouses | Explored the current status of solar technology use in modern greenhouses |

| Li et al. (2016) | Regulation of greenhouse microclimates | Identified the influential factors behind the use of solar technology in modern greenhouses |

| Haeussermann et al. (2007) | Fogging systems | Analysed the evaporation characteristics of fogging systems |

| Erens and Dreyer (1988) | Evaporative cooling | Investigated about a numeric or quantitative form of procedure in order to evaluate the performance level of evaporative and condensers in any geometry as well as flow arrangements |

| Alahmer (2016) | Direct evaporative cooling system | Conducted a thermal analysis of the cooling system to enhance its dehumidification capacity |

| Mizushina et al. (1968) | Evaporative cooling system | An empirical correlations is provided between the mass and heat transfer which are taken as coefficients corresponding to the three different tube diameters which are considered at a constant temperature of water (Mohammadi et al. 2018) |

| Kreid et al. (1978) | Evaporative cooling system | Investigated on finned evaporative coolers and condensers |

On the basis of the above-stated table regarding the various innovation with respect to better ventilation and air flow in a greenhouse, it has been found that Settles (2000) provides a better innovation related with the airflow systems which emphasizes and focuses on the air flow visualization in a greenhouse. Further, the greenhouse vents basically comprise a vent opening which is utilized to regulate and control microclimate inside a greenhouse. Besides this, Zanas et al. (2004) also facilitate an understanding about the greenhouse ventilation which enhances windward ventilation by making use of a better model based on vent arrangement. At last, it has been found out that a novel approach for ventilation is provided by the Katsoulas et al. (2006) who proposed a vent opening innovation in order to improve the ventilation inside greenhouse by making use of fog evaporative cooling system. However, based on the previous studies, the vent opening time and orientations were not studied; upgradation with a proper number, orientation, and opening time of the vents can improve the microclimate inside the greenhouse through a proper effect on the relative humidity to maintain a proper temperature and ventilation inside the greenhouse. Therefore, implementation of sensor-interfaced air vents on top of the greenhouse structure can utilize the natural ventilation to control the temperature and relative humidity, remotely with the help of climate control stations.

2.2 Greenhouse cooling using evaporative systems

Various researchers have explored the utilization of evaporative systems in temperature management of greenhouses. An evaporative system mainly comprises an intake chamber along with various filter(s) with supply fan which acts as a heat exchanger in order to maintain the proper cooling and temperature inside a greenhouse. The use of exhaust fan, water sprays, recirculating water pump, and water sump are made to have a proper and efficient evaporative cooling systems which are mainly characterized by low energy use compared with a refrigeration cooling system. A typical evaporative cooling system components and the flow of operations have been shown in Figures 4 and 5. Joudi and Hasan (2013) studied the effectiveness of using absorption-type evaporative coolers in Baghdad. Besides this, it has also been observed that the use of evaporative cooler is also vital to ensure effective cooling along with air-condition as it has been understood that evaporative coolers are utilized to perform both functions. Thus, making efficient utilization of evaporative coolers is better and suitable while covering HVAC as it performs both the important and crucial functions of cooling and conditioning the air (Linker et al. 2011).

Box-type evaporative cooling system.

Working principle of an evaporative cooler.

The annual total amount of coal required for maintaining and running an HVAC system basically ranged from 160.34 to 466.78 t/ha, while the total cost of the system is between 37,412 and 108,916 $/ha. Apart from this, the total annual fixed cost on the basis of the cost per hectare was taken to be between 10,325 and 14,328 $/year whereas the total variable cost fluctuates and varies from 20.1 to 30.9 $/ha. Further, the total cost which was calculated as the total annual and hourly costs per hectare ranged from 65,891.5 to 151,220.6 $/year and from 23.8 to 34.2 $/ha, respectively (López-Cruz et al. 2012a). The upgradation, therefore, aims at minimizing this cost by using efficient evaporative coolers, where the cooling load itself is reduced by using a covering material appropriate for Middle East’s climatic condition. Figure 6 shows the structure of such an upgraded greenhouse.

Single span greenhouse with individual box-type evaporative coolers and ventilation fans (V-flow fans) – sectional view and 3D view.

An in-depth analysis of these factors are discussed as a part of qualitative analysis while concentrating and focusing on further evaluation of these factors to be used in the commercial greenhouse (López-Cruz et al. 2012b). Existing technologies implement the evaporative cooling technique to manage temperatures. One such technology system that reduces air temperature without altering the air moisture content is the indirect evaporative cooling system. In such systems, the process air stream does not make a direct connect with the cooling fluid stream although there is sensible heat transfer between them leading to the cooling of one stream. Thus, an analysis can be made that the indirect evaporative cooling system has an efficiency of 60–70% as compared with the direct evaporative coolers, as it costs nearly about one-half and also makes use of only about one-quarter of energy compared other cooling systems; thus, it is more efficient than other systems (López-Cruz et al. 2014). Thus, here the discussion about the thickness and width of cooling pad structure is made, based on that a requirement to select the proper packing material has been identified in order to meet the desired water flow (Luo et al. 2005). The improved technology using Maisotsenko cycle (M-cycle) can provide a better result in energy-friendly evaporative cooling operation. This cycle is mainly taken as an indirect evaporative cooling–based cycle that makes utilization of a much smarter geometrical configuration for leading and ensuring better air distribution. The energy source of this type of cooler is water in place of electricity; thus, the usage of M-cycle-based coolers ensures a more significant way for energy saving as it leads to more than 80% saving in terms of average consumption of electricity (Mashonjowa et al. 2013a).

The M-cycle in greenhouse is used as an air-conditioning technology that offers better opportunities for energy conservation and reduction of greenhouse gas emissions, thus leading to better growth of crop. Kreid et al. (1978) had investigated the finned evaporative coolers along with the range of other condensers (Mashonjowa et al. 2013b). The above discussions have been summarized in Table 2.

To sum up, based on the research available on upgradation of commercial greenhouses, evaporative cooling systems are suitable for high-temperature and low relative humidity ambient conditions. Because of such climatic conditions in the Middle East, we have used custom-designed box-type evaporative coolers for better performance in terms of yield management in commercial greenhouses. Effective results from the evaporative coolers require the cooling pads to be saturated at all times. The discharge between the fans and cooling pads also has to be negotiated effectively employing proper motor controls. This can be achieved with box-type individual evaporative cooling configurations, making this more energy saving, simple, environment friendly, and cost-effective air-conditioning strategy.

2.3 Greenhouse heating

Different greenhouse heating systems have been adopted in the past, such as direct air heaters, central pipe surface heating systems, geothermal heating, etc. Ghosal and Towar developed a greenhouse model with geothermal energy suitable for freezing temperature conditions. In this study, the authors realize a remarkable temperature rise of 14–23°C while it was freezing outside the greenhouse. Carlini et al. (2010), through their experimental study conducted in Viterbo, Italy, proved the feasibility of geothermal plant through a TRNSYS simulation and verified the results, thereby confirming the efficacy of using geothermal solutions. Table 3 summarizes the list of reviewed papers, with their major findings and conclusions.

Reviewed articles, approaches, and parameters studied

| Author | Approach | Aspects of study |

|---|---|---|

| Burdick (2011) | Load calculations | Issued a strategy guideline for heating and cooling as well as the performance of load calculations |

| Navas et al. (1998) | Evaporative cooling | Proposed the use of geothermal energy to implement the cooling mechanism in greenhouses |

| Carlini et al. (2010) | Geothermal energy utilization | Developed a simulation model for exploiting geothermal energy |

Various options for greenhouse heating have been mentioned in the literature. One of the major drawbacks in many of the upgradation practices were the level of CO2 emission. Qerimi et al. (2020) carried out a solar thermal energy model for the upgradation of urban areas to avoid CO2 emission mainly from buildings and other sources. Upgradation using solar thermal energy system similar to other buildings in urban areas to reduce the CO2 emission is an innovative option where the controlled farming can convert into more sustainable way. In our upgraded greenhouse, HVAC control systems are capable of controlling the CO2 level without any additional CO2 generators which is a significant contribution towards sustainability.

3 Associated factors for greenhouse HVAC system upgradation

To have a comprehensive upgradation of the HVAC and control systems by regulating the controlled variables with respect to the disturbances such as temperature and relative humidity, parameters such as greenhouse structure, orientation of the greenhouse, and the irrigation system management have to be studied. They are described individually in the following sections (Van Straten 2008).

3.1 Greenhouse covering materials

The covering material for the greenhouse, which is integral to its design structure, is chosen based on the effective control of yield management. This is similar to the shading system associated with the structure. A study was conducted in United Arab Emirates to interpret the results from different combinations of covering materials which include Solexx twin-wall covering, poly film plastic greenhouse covering, single-walled polycarbonate, and twin-walled polycarbonate. Structures have been tested using two different combinations of polycarbonate covering materials with the conventional covering material using polyethylene (Udink ten Cate 1984). The experiments concluded that multilayer polycarbonate combinations of covering materials are providing a higher yield of up to 20% compared to the conventional polyethylene sheet. A vital parameter of greenhouse cultivation is light. Nageib et al. (2012) experimented with various shading options in cucumber farming, which is taken as the most high-yield vegetable during the course of greenhouse methodology. In the commercial greenhouses, cucumbers are grown, which tend to have lower percentages of defective growth and higher commercial yield than the ones which are grown in the open field. Abu-Zahra and Ateyyat (2016) chose shading materials with proper optical properties based on the photosynthetically active radiation of the crop.

3.1.1 Shading

In conventional upgradation, the shading of greenhouses was quite common, which is achieved by various methods such as whitening the covering materials by wrapping with external shading cloths mounting plastic nets of variable covers, movable refractive screens, and spraying the covering material with aqueous sprays. Shading using whitening is inexpensive and one of the most efficient methods in preventing the heat load in deep summer in the early days. However, this can be damaged easily over time. Shading reduces the average transmittance due to direct solar radiations. In arid climatic conditions, shading can reduce the consumption of irrigation water. Shading could be either internal or external and this can affect/control the microclimate inside the greenhouse positively on many occasions. However, shading has a major disadvantage as internal/external shadings on covering materials can obstruct the incident solar radiations required for photosynthetic activities (Trigui 2000).

3.1.2 Radiation filters for covering materials

Regions of hot and sunny climate poses a major challenge in developing a covering material which can sustain the climatic conditions. In arid climatic regions major properties to be considered while designing the covering material are cooling effect, high mechanical properties, and durability with less maintenance. This technique is known as liquid radiation filters (LRFs). The advantages of the usage of LRFs have been verified using simulations, although complexity and high investment costs are the significant disadvantages of this system. In order to avoid the difficulties in implementation and maintenance of LRF, various researchers tested the near-infrared (NIR) reflecting film covers (Tap et al. 1996). This is considered as an improved arrangement. LRFs in polycarbonate sheet panels can reduce the temperature inside the greenhouse by 6–8°C (Kittas et al. 2005). Various combinations of fluid roof covers and NIR reflecting film coatings have also been tested in the past.

3.1.3 Covering material upgradation

Behera et al. (2016), in their study, reviewed the properties of polyethylene sheets used for greenhouses and covering material upgradations. From this study, the major inference is that a polycarbonate sheet with two layers of 2 mm each in operation provides better result than a single layer of same thickness. Real-time cultivations were carried out for one complete cycle of cucumber growth in those three different greenhouses. Real-time cultivation results emphasized that the crops harvested from the polycarbonate sheet-mounted greenhouse yielded more with good quality, and this has also been verified by spectrometric analysis by making use of filed devises like the temperature sensors and PAR meters (Tap 2000).

Test setup was in three different greenhouses with polyethylene as material 01 while the other two comprise polycarbonate of different thicknesses 2 mm and 4 mm as materials 02 and 03, respectively (Stanghellini and de Jong 1995). A general methodology of covering material selection has been shown in Figure 7. Hochmuth (1993), in his study, outlined the various properties of polyethylene sheets and their correlation to the agronomical gradients which are defined as different parameters for the plant growth. Teitel (2007) observed the effect of thickness of the covering materials on plant growth and concluded that polycarbonate sheets produce the best results in terms of temperature control and crop yield.

Flow chart of the covering material selection methodology.

Figures 8 and 9 show the experimental setup comprising greenhouses with polyethylene and polycarbonate as the covering materials (Wang and Liang 2006). The first greenhouse has a polyethylene covering while the second one has a polycarbonate covering of 4 mm thickness. The double-film-covered setup works well with heat storage–release systems; the covering materials coated both sides with thermal absorbent coatings that can manage the heat generated from the underground thermal systems and this has been verified in the study conducted by Wang and Liang (2006).

Polyethylene sheet covering material.

Polycarbonate covering material.

Hochmuth (1993) successfully carried out the spectrometric analysis of various combinations of the available shading options and recorded the optimal combinations. Results of a spectrometric analysis using the licor-LI190 R sensors are summarized in Table 4.

| Material | Range | Wavelength (nm) | Transmittance (%) | Reflectance (%) | Absorptance (%) | |

|---|---|---|---|---|---|---|

| Total | Direct | |||||

| 2 mm double-wall polyethylene sheet | PAR | 400–700 | 90 | 66 | 13.4 | 7.2 |

| 2 mm polycarbonate sheet | PAR | 400–700 | 63 | 41 | 23.4 | 14.2 |

| 4 mm double-wall polycarbonate sheet | PAR | 400–700 | 27.2 | 11.8 | 56.1 | 17.2 |

Abdel-Ghany et al. (2015) studied the effect of the overall shading on indoor plant growth and analysed the U-value characteristics (the thermal transmittance of a material or an assembly is expressed as a U value). Nelson (1998) analysed the shade curtain components with detailed upgradation plans suitable for plant growth while Radojević et al. (2014) emphasized the effect of energy balance in HVAC systems upon shading upgrades. Rumsey recorded a detailed study about the high-density polycarbonate shade screens and the advantages of the same in terms of energy efficiency as well as the crop protection from the sunlight (Speetjens 2008). Sanford (2011) indicated how shade curtains are useful in reducing heating and cooling costs. Since the curtain thicknesses range from 0.5 mm to 3 mm, which can be controlled using a manual arrangement of roller or sensor for automated climate control. Curtain influences the incoming transmission of light and heat retention within greenhouse, and both these factors highly influence the total energy usage of greenhouse (Figures 10 and 11).

Micrograph of the upgraded covering material with HDPE-reinforced energy curtains.

Greenhouse using HDPE fibre-reinforced shade curtains.

With the use of curtains, the total energy costs related to commercial greenhouse might decline by 25–40%. Apart from this, proper use of climate screens assists in optimizing the overall climate in greenhouse that will lessen the cost as well as the intensity of activities associated with crop management including spraying, watering, and pruning (Sethi and Sharma 2007a). A summary list of the reviewed articles along with their major findings and innovations is detailed in Table 5.

Reviewed articles, approaches, and parameters studied

| Author | Approach | Aspects of study |

|---|---|---|

| Nageib et al. (2012) | Shading | Declared the importance of crop shading in the growth of apricots |

| Abu-Zahra and Ateyyat (2016) | Shading methods | Analysed how shading techniques affect the survival of cucumbers |

| Abdel-Ghany et al. (2015) | Shading properties and plant characteristics | Researched about the correlation with the photosynthetic active region and the shade properties |

| Taleb (2014) | Passive cooling | Recommended the use of passive cooling to reduce energy consumption |

| Nageib et al. (2012) | Shading | Declared the importance of crop shading in the growth of apricots |

| Sanford (2011) | Shade curtains | Studied greenhouse structure and materials and identified the benefits that curtains present to heating and cooling cost reductions |

| Teitel (2007) | Covering materials | Analysed suitable materials for greenhouse covering and explored the best combination for the polycarbonate sheet |

Based on the available literature on upgradation of covering materials, the major challenge was the selection of covering materials and its thickness. However, based on the methodology shown in Figure 7, a polycarbonate sheet of 2 mm thickness provides good yield in the Middle East climatic conditions with a reasonable capital investment. Moreover, a specially designed shade curtain supplements the covering materials efficiently. The transparent energy screen and traditional shade curtains are meant for the retention of energy and enable increased level of light transmission. Proper installation of curtains and screens are important for maximizing cost saving. This also improves the yield by up to 20% and maintains the temperature, ensuring proper growth of crops.

3.2 Greenhouse direction or orientation

An all-year greenhouse model has been developed; and in 24° E–W direction, the results were successful. Thermal modelling of the successful model has been carried out in the previous studies by researchers and proved the abovementioned recommendations (Panwar et al. 2012). Selection of optimal shape of the greenhouse in conjunction with the orientation may provide an improved result in the arid climatic conditions especially in Middle East regions (El-Maghlany 2015). E–W direction with arch-shaped combination can provide a good crop yield (Sengar et al. 2013). Greenhouse location selection is crop-specific and based on the required temperature requirement of the crops.

3.3 Greenhouse irrigation systems

Irrigation is defined as the artificial application of water to soil by different systems of pumps, tubes, and sprays. Different types of irrigation systems uniformly supply water to the whole field. The water for irrigation comes from the ground through surface water, wells or springs, reservoirs, lakes, rivers, and other sources. Some common irrigation system types include surface irrigation in which the water is distributed across and over the land through gravity and no mechanical pump is included (Sethi and Sharma 2007b). Localized irrigation is another type of irrigation in which the water is distributed through piped network under low pressure and applied on each plant. Apart from this, sprinkler irrigation is also one of the types in which water is distributed through overhead high-pressure guns or sprinkler from a central location in the field. In addition to these types of irrigation, other types include drip irrigation, centre pivot irrigation, lateral move irrigation, manual irrigation, and sub-irrigation.

4 Effect of upgradation of greenhouse using CMS

The greenhouses must render controlled environment for the production of plant with sufficient humidity, temperature, and sunlight. Greenhouses require exposure to maximum light, specifically in the morning hours. The greenhouse quality has everything to do with control technology use in the greenhouse. The facilities designed and outfitted proper efficient systems of HVAC which will develop better environment to assist in continuous production of connoisseur grade products. Evaporative cooling was used to upgrade the HVAC in greenhouse and for climate control. The system involves cooling pad made of porous material with water that flowing through it, keeping it saturated on the end wall of greenhouse; and at opposite end wall is a large extraction fan which develops negative pressure in the structure, full exterior air by cooling pad, moves it along the length of facility as well as at the back of the other end. When warm air from outside passes through the cooling pad and the water evaporates, the air temperature and the greenhouse climate drop (Zaragoza et al. 2007).

Kim et al. (2006) created a wireless sensor network irrigation system capable of collecting soil and weather information from sensors and then conveying it via a Bluetooth antenna to a base station. The programmable logic controller (PLC) processed feedback information from the base system to vary water irrigation in order to maintain the desired moisture level (Wallach et al. 2014). Crop water stress index (CWSI) helps a farmer to determine the best level of soil moisture to support optimum plant growth, crop production, and crop yield based on the estimated evaporation of moisture from the soil. The crop variety determines the calibration curves which involves the soil moisture content against the crop water index (it is agronomical). Indeed, temperature and soil moisture are the main factors of CWSI (Vadiee and Martin 2013a, b).

A model which can integrate environmental sensors, drip irrigation system, PLC, and wireless devices to construct an intelligent wireless irrigation system (WIS) for use in greenhouses can control the indoor parameters in a systematic and most beneficial manner, resulting in maximum crop yield (Vadiee and Martin 2012).

4.1 Climate control module

Climate control module with a microcontroller in the sensing unit was tested in the field to evaluate their data transmission with PLCs in the beginning. A scientifically designed control system in a commercial greenhouse is becoming a necessity for high crop yield by controlling the field requirements of the crops with minimal human interference (Udink ten Cate 1985). Irrigation and the crop transpiration rates are controlled using the respective sensors mounted at various locations of the greenhouses and aided in accurate measurement monitoring necessary to trigger corrective measures in greenhouses (van Ooteghem 2005, 2007, 2010). Temperature and relative humidity sensors can log the variance between the set value for the crop and this can improve the crop quality as well as avoid typical phenomena like tip burn for the crops due to the sudden fluctuations in temperatures. Figure 12 illustrates a typical climate control module schematic in a commercial greenhouse.

Climate control setup (Subin et al. 2020).

Implementation of a nonlinear multivariable transfer function control system model of a greenhouse using thermodynamic laws in conjunction with the variables directly affecting temperature and relative humidity can maintain the greenhouse indoor conditions in an optimal manner. Mamdani model-based fuzzy proportional integral derivative (PID) has been developed (Subin et al. 2020) to compare the performance and productivity level of a PID and proportional integral (PI) in order to accomplish a smooth and better controllable action. A typical control system schematic using fuzzy logic controllers for commercial greenhouses is shown in Figure 13. A concise list of the reviewed articles and their major findings and conclusions are shown in Table 6.

Schematic for an upgraded greenhouse using fuzzy logic controllers (Subin et al. 2020).

Reviewed papers and their findings

| Author | Approach | Aspects of study |

|---|---|---|

| Olenewa (2014) | Wireless communication in agricultural systems | Present findings on the efficacy of using Bluetooth devices to communicate through piconets |

| Kim et al. (2006) | Water irrigation | PLC processed feedback information from the base system to vary water irrigation in order to achieve the desired moisture level |

| Adeyemi et al. (2017) | Drip irrigation | Explained why drip irrigation is the most preferred – because of the ability to conserve water |

| Roy and Ophori (2014) | CWSI estimation | Concluded that it is important to determine CWSI for the management of irrigation |

| Akkuzu et al. (2010) | CWSI | Calculated and determined water use efficiency CWSI to recommend irrigation applications |

| Subin et al. (2020) | Micro climate | Mamdani model-based fuzzy PID to control the greenhouse microclimate variables (temperature and relative humidity) |

CWSI = crop water stress index; PLC = programmable logic controller; PID = proportional integral derivative.

Bluetooth technology has been used to control the indoor agriculture ambient conditions in our upgraded greenhouse. Based on the previous studies conducted, upgradation in control system using PID and PLCs maintained the required indoor ambient conditions. By implementing a Mamdani model-based fuzzy PID controller, the yield improved by up to 20% with properly selected HVAC systems. Further enhancement is possible using artificial intelligence and neural network systems which is beyond the scope of this study.

5 Dynamic modelling of greenhouse climate optimization

The dynamic modelling for the greenhouse climate optimization comprises of the optimization of uncertain control variables and associated optimal setting parameter estimation for analysis for an improved greenhouse model in terms of yield and energy management. The main structural feature of this model is described using the system state approach. It comprises a physical process with many dynamic equations having sufficient emphasis on the greenhouse climate (Saltelli et al. 2000). Apart from this, the type and form of equation are based on either the concept of differential equation or the transfer function, which are also important during the evaluation of dynamic model. Besides, almost all the models had seemed to be calibrated and evaluated through a measured firm of data collected from the system; thus it ensures and leads to the lack of all possible uncertainties and also ensures sensitivity analysis for better development and creation of greenhouse model. A concise summary of the articles reviewed is listed in Table 7.

Reviewed articles, approaches, and parameters studied

| Model/author | States | Inputs | Type | Calibration | Evaluation | UA | SA | Greenhouse type |

|---|---|---|---|---|---|---|---|---|

| Takakura (1971) | 8/10/12 | To, RHo, Ro, Wo | ODEs | Yes | Yes | No | No | Polyethylene GH |

| Bot (1983, 2005) | 9 | To, RHo, Ro, Wo | ODEs | Yes | Yes | No | No | Glasshouses |

| Solar-2 (Joudi and Farhan 2015) | 8 | Ro, To, RHo, Wo | ODEs | Yes | Yes | No | No | Polyethylene GH |

| CSG (Pieters et al. 2013a, b) | 7 | To, Ro, Wo, | ODEs | Yes | Yes | No | No | Polyethylene GH |

| Watergy (Speetjens et al. 2009, 2010) | 10 | Ro, To, Rho, Wo | ODEs | Yes | Yes | No | Preliminary | Polyethylene GH |

| Closed-GH (Vadiee and Martin 2013a) | 4 | Ro, Airin, Heating | ODEs | Yes | Yes | No | No | Glasshouses |

| Taki et al. (2018) | 6 | Ro, RHo, To | ODEs | Yes | Yes | No | No | Glasshouses |

| Reyes-Rosas (2017) | 6 | Ro, To, RHo, Tsd, Wo | ODEs | Yes | Yes | No | No | Polyethylene GH |

| Tap et al. (1996) | 5 | Heating, CO2 inj., window opening | ODEs | Yes | Yes | No | Local SA | Glasshouses |

| Trigui et al. (2001) | 3 | Heating, window opening, humidification | ODEs | Yes | Yes | No | Preliminary | Glasshouses |

| Pohlheim and Heiβner (1996, 1997, 1999) | 4 | Heating, ventilation, CO2 inj., vapor_inj. | ODEs | Yes | Yes | No | No | Glasshouses |

| Van Beveren et al. (2015) | 2/3 | Heating, cooling, specific ventilation, CO2 inj. | ODEs | Yes | Yes | No | No | Glasshouses |

| Coelho et al. (2005) | 1 | Heating, window opening | ARX | Yes | Yes | No | No | Polyethylene GH |

| Blasco et al. (2007) | 3 | Window opening, fogging, heating | ODEs | Yes | Yes | No | No | Polyethylene GH |

| De Jong and Stanghellini (1995) | 1 | Crop transpiration, humidity | ODE | Yes | Yes | No | No | Glasshouses |

| Sethi and Sharma (2007b) | 1/3 | Heating, cooling | ODEs | Yes | Yes | No | No | Polyethylene GH |

| Rasheed et al. (2015) | 3/4 | Building energy | BES | Yes | Yes | No | No | Polymethylmethacrylate covering |

| Shen et al. (2018) | 2/3 | Building energy | BES | Yes | Yes | Yes | Yes | Polycarbonate GH |

UA = uncertainty analysis; SA = sensitivity analysis; RH = outside relative temperature; R = global solar radiation; W = wind velocity; Tsky = sky temperature; CO2 = carbon dioxide outside the greenhouse; Tsd = depth soil layer temperature; ODEs = ordinary differential equations; ARX = autoregressive with external inputs; BES = building energy system modelling; GH = Greenhouse.

6 Energy and economic analysis of greenhouse farming

While comparing the cost of open-field farming and greenhouse farming in a stable climatic conditions, it is understood that the yield is high in open-field farming; and the actual cost–benefit ratio has been demonstrated in certain countries (Ozkan et al. 2007); however, the open-field farming has limitations of cultivating the crops in all weather conditions. Therefore, while comparing the net yield in all the cycles in a year, commercial farming will be economical, especially in arid climatic geographical regions like Middle East. Based on the literature, in a standard commercial greenhouse, the annual total coal requirement for maintaining and running an HVAC system basically ranged from 160.34 to 466.78 t/ha in addition to the total cost of the system, which is between 37,412 and 108,916 $/ha. Apart from this, the total annual fixed cost on the basis of the cost per hectare ranged between 10,325 and 14,328 $/year, whereas the total variable cost also fluctuates and varies from 20.1 to 30.9 $/h. Further, the total cost which was calculated as the total annual and hourly costs per hectare was 65,891.5–151,220.6 $/year and 23.8–34.2 $/h, respectively (López-Cruz et al. 2012a). However, for an electrically powered HVAC system in a controlled greenhouse, on average 15.12 GJ/h is required to operate the greenhouse per day. In order to forecast the greenhouse yield, the management decision support system is one of the important tools that can be used in agricultural prototypes while doing upgradations (Fenu and Malloci 2019). Upgradation using solar-powered greenhouse can further decrease the energy cost and can keep the commercial greenhouse farming more sustainable. Based on the total power requirements, solar photovoltaic modules need to be selected based on the area available to mount and accordingly the battery design needs to be evaluated (Nazir et al. 2019) (Figure 14).

Greenhouse energy analysis pie chart showing the relative costs of various heads.

Comparisons of energy portfolios of the conventional and upgraded greenhouse are listed in Table 8 with operational expenditure reduction in the upgraded greenhouse. We observed an overall reduction of 30% in the operational recurring cost in the HVAC head with evaporative cooler equipped with upgraded covering material and 5% in the irrigation head due to the irrigation control system implementation in the climate control module, and around 10% in the associated labour component for the farm monitoring due to the installation of climate control module. A bar diagram representing both the scenarios with reduction in energy expenditure has been shown in Figure 15.

Energy portfolio reduction comparison (before and after upgradation)

| Cost head | HVAC | Irrigation | Monitoring and supervision labour | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Scenario | Conventional | Upgraded | % reduction | Conventional | Upgraded | % reduction | Conventional | Upgraded | % reduction |

| % | 31 | 21.60 | 30 | 25 | 23 | 5.38 | 23 | 21 | 10.43 |

Energy expenditure comparison before and after upgradation on major heads.

This energy reduction resulted in an increase of more than 45% in the sales realization. In Middle East climatic conditions, the net half-yearly realization per hectare for the conventional greenhouse was AED 267,748.00 with HVAC energy operational expense of AED 159,888.00; however, in the upgraded sustainable greenhouse the net realization has been increased to AED 385,461.00 with HVAC energy operational expense reduced to AED 50,561.84 which is almost 50% less than the existing greenhouse consumption. Correspondingly the associated labour and irrigation components also reduced. The major cost reduction factor in the upgradation was the replacement of the conventional HVAC system with box-type evaporative coolers and running the same with half the numbers in full-load condition is enough to maintain the indoor conditions in the upgraded greenhouse with box-type evaporative cooler of 7 numbers, each with polycarbonate sheet roofing equipped with a remote monitoring CMS, which can remarkably reduce the energy operational expenditure; and the total energy spend in a day has been reduced from 15.12 to 10.24 GJ.

7 Conclusion

Conventional greenhouse systems endure challenges related to losses due to their energy efficiency especially in hot climatic regions such as the Middle East. Various conventional ventilation systems are aimed at improving the performance of such greenhouses including the use of axial fans and cooling pads – without roof ventilation. However, the best combination that ensures free air circulation is roof ventilation along with the usage of axial fans and cooling pads. Combined design with roof ventilation and automatic air vent systems can improve the performance of the greenhouses in terms of energy conservation and high yield of the crops. The HVAC systems which is older than 10 years can be replaced with products that are energy star certified. A feedback loop was linked with a system of linear sprinklers that is mainly controlled with the help of a PLC. Scientifically selected covering materials can influence greenhouse indoor cultivation in a very high level of efficiency, and this can increase the yield up to 20% than conventional practices. Different combinations of polycarbonate sheets with varying thickness in the range of 2–4 mm improved the greenhouse yield. Spectrometric analysis of combinations of covering materials provided continuous developments in the various combinations of the covering materials. However, the covering materials manufactured by adding some additives such as natural reinforced high-density polyethylene-reinforced fibre provided a better result while using the same on top of polycarbonate sheets. Upgraded greenhouse facilitated a constant temperature between 18 and 25°C, relative humidity (55–75%), and air velocity (0–1.3 m/s) for the optimal plant growth. Selection of covering materials can be verified with the help of comparison of micrographs of the improved specimens with the original ones before the implementation of the materials in the real scenario. On the other hand, upgradation of conventional commercial greenhouses to the soil-less irrigation system is quite challenging requiring high initial investment. However, combining the various upgradations of HVAC and control systems of commercial greenhouses can manage this challenge, which need to be studied further.

Abbreviations

- ARX

-

autoregressive with external inputs

- BES

-

building energy system modelling

- CFD

-

computational fluid dynamics

- CMS

-

climate control system

- CWSI

-

crop water stress index

- GH

-

greenhouse

- HVAC

-

heating, ventilation, and air-conditioning

- HDPE

-

high-density polyethylene

- LRF

-

liquid radiation filter

- ODE

-

ordinary differential equation

- PAR

-

photosynthetically active radiation

- PID

-

proportional integral derivative

- PLC

-

programmable logic controller

- RH

-

outside relative temperature

- SA

-

sensitivity analysis

- UA

-

uncertainty analysis

- WIS

-

wireless irrigation system

Acknowledgments

I would sincerely like to thank Dr. Ram Karthikeyan (Professor) and Dr. Snhanshu Chowdhury (Assistant Professor) of the Department of Mechanical Engineering at BITS Pilani Dubai Campus for their guidance and support that was instrumental in the presentation of this review paper.

-

Funding information: The authors state no funding involved.

-

Author contributions: Mr. M. C. Subin comprehended the data collection from the previous studies conducted in the field of commercial greenhouse in order to structure the review paper. Dr. S. Chowdhury formulated the review article structure and the future upgradation views for optimization studies and the associated future improvements in commercial greenhouses. Dr R. Karthikeyan oversaw the entire activities and technical structure of the review paper.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Data sharing is not applicable to this article as no datasets were generated or analysed during the current study.

References

[1] Abdel-Ghany AM, Picuno P, Al-Helal I, Alsadon A, Ibrahim A, Shady M. Radiometric characterization, solar and thermal radiation in a greenhouse as affected by shading configuration in an arid climate. Energies. 2015;8:13928–37.10.3390/en81212404Search in Google Scholar

[2] Abu-Zahra TR, Ateyyat MA. Effect of various shading methods on cucumber (Cucumis sativus L.) growth and yield production. Int J Environ Sustain. 2016;5:10–7.10.24102/ijes.v5i1.659Search in Google Scholar

[3] Adeyemi O, Grove IP, Norton T. Advanced monitoring and management systems for improving in precision irrigation. Sustainability. 2017;9(353):1–29. 10.3390/su9030353.Search in Google Scholar

[4] Akkuzu E, Çamoğlu G, Kaya Ü. Diurnal variation of canopy temperature differences and leaf water potential of field-grown olive (Olea europaea L. cv. Memecik) trees. Philipp Agric Sci. 2010;93(4):399–405.Search in Google Scholar

[5] Albright LD, Gates RS, Arvanitis KG, Drysdale AE. Environmental control for plants on Earth and in space. IEEE Control Syst Mag. 2001;21:28–47.10.1109/37.954518Search in Google Scholar

[6] Alahmer A. Thermal analysis of a direct evaporative cooling system enhancement with desiccant dehumidification for vehicular air conditioning. Appl Therm Eng. 2016;98:1273–85. 10.1016/j.applthermaleng.2015.12.059.Search in Google Scholar

[7] Baeza E, Pérez-Parra J, Montero J, Bailey B, López J, Gázquez J. Analysis of the role of sidewall vents on buoyancy-driven natural ventilation in parral-type greenhouses with and without insect screens using computational fluid dynamics. Biosyst Eng. 2009;104:86–96. 10.1016/j.biosystemseng.2009.04.008.Search in Google Scholar

[8] Baptista FJ, Bailey BJ, Meneses JF, Navas LM. Greenhouses climate modelling. Tests, adaptation and validation of a dynamic climate model. Span J Agric Res. 2010;8(2):285–98. 10.5424/sjar/2010082-1629.Search in Google Scholar

[9] Baptista FJ, Bailey BJ, Navas LM, Meneses JF. Validation of a dynamic greenhouse climatic model in Portugal. Acta Hortic. 2000;534:163–70. 10.17660/ActaHortic.2000.534.18.Search in Google Scholar

[10] Bartzanas T, Boulard T, Kittas C. Effect of vent arrangement on windward ventilation of a tunnel greenhouse. Biosyst Eng. 2004;88:479–90.10.1016/j.biosystemseng.2003.10.006Search in Google Scholar

[11] Behera DB, Pattnaik DR, Das MM, Jena MJ. An experimental study on strength characteristics of shade nets for construction of low cost shade houses in a tropical climate. Int J Appl Pure Sci Agric. 2016;2:47–54.Search in Google Scholar

[12] Beven K, Binley A. The future of distributed models: model calibration and uncertainty prediction. Hydrol Process. 1992;6:279–98. 10.1002/hyp.3360060305.Search in Google Scholar

[13] Blasco X, Martínez M, Herrero JM, Ramos C, Sanchis J. Model-based predictive control of greenhouse climate for reducing energy and water consumption. Comput Electron Agric. 2007;55:49–70. 10.1016/j.compag.2006.12.001.Search in Google Scholar

[14] Boaventura Cunha J. Greenhouse climate models. An overview. EFITA 2003 conference, July 5–9, Debrecen, Hungary; 2003.Search in Google Scholar

[15] Bot GPA. Greenhouse climate: from physical processes to a dynamic model. Ph.D. thesis. Wageningen, the Netherlands: Wageningen Agricultural University; 1983.Search in Google Scholar

[16] Bot GPA. Greenhouse simulation models. Acta Hortic. 1989a;245:315–25. 10.17660/ActaHortic.1989.245.42.Search in Google Scholar

[17] Bot GPA. A validated physical model of greenhouse climate. Acta Hortic. 1989b;245:389–96. 10.17660/ActaHortic.1989.245.52.Search in Google Scholar

[18] Bot GPA, Van de Braak N, Challa H, Hemming S, Rieswijk Th, Van Straten G, et al. The solar greenhouse: state of the art in energy savings and sustainable energy supply. Acta Hortic. 2005;691:501–8. 10.17660/ActaHortic.2005.691.59.Search in Google Scholar

[19] Burdick A. Strategy guideline: accurate heating and cooling load calculations. Oak Ridge, TN: US Department of Energy; 2011.10.2172/1018100Search in Google Scholar

[20] Carlini M, Monarca D, Honorati T, Castellucci S. A simulation model for the exploitation of geothermal energy for a greenhouse in the Viterbo Province. International conference Ragusa SHWA2010, Ragusa, Italy; 2010.10.1155/2010/842380Search in Google Scholar

[21] Coelho JP, de Moura Oliveira PB, Boaventura Cunha J. Greenhouse air temperature predictive control using the particle swarm optimisation algorithm. Comp Electron Agric. 2005;49:330–44. 10.1016/j.compag.2005.08.003.Search in Google Scholar

[22] De Jong T, Stanghellini C. A model of greenhouse humidity suitable for control of crop processes. Acta Hortic. 1996;406:125–31. 10.17660/ActaHortic.1996.406.12.Search in Google Scholar

[23] De Zwart HF. Analyzing energy-saving options in greenhouse cultivation using a simulation model. Ph.D. thesis. Wageningen, the Netherlands: IMAG-DLO, Wageningen Agricultural University; 1996.Search in Google Scholar

[24] De Zwart HF. A simulation model to estimate prospectives of energy saving measures in horticulture. Acta Hortic. 1997;443:119–27. 10.17660/ActaHortic.1997.443.15.Search in Google Scholar

[25] Dincer I, Cengel YA. Energy, entropy, and exergy concepts and their roles in thermal engineering. Entropy. 2001;3:116–49. 10.3390/e3030116.Search in Google Scholar

[26] Effat MB, Shafey HM, Nassib AM. Solar greenhouses can be promising candidate for CO2 capture and utilization: mathematical modeling. Int J Energy Env Eng. 2015;6:295–308. 10.1007/s40095-015-0175-z.Search in Google Scholar

[27] El Ghoumari MY, Tantau HJ, Serrano J. Non-linear constrained MPC: real-time implementation of greenhouse air temperature control. Comp Electron Agric. 2005;49:345–56. 10.1016/j.compag.2005.08.005.Search in Google Scholar

[28] Erens J, Dreyer A. An improved procedure for calculating the performance of evaporative closed circuit coolers. The 25th National heat transfer conference. Vol. 84; 1988. p.140–5.Search in Google Scholar

[29] Fenu G, Malloci FM. Decision support systems: main developments & future trends an agricultural prototype DSS LANDS for monitoring the main crop productions in Sardinia. EmC-ICDSST 2019 proceedings – online version euro mini international conference on decision support system technology, Madeira, Portugal, 27–29 May; 2019.Search in Google Scholar

[30] Ganguly A, Ghosh S. A review of ventilation and cooling technologies in agricultural greenhouse application. Iran J Energy Environ. 2011;2:32–46.Search in Google Scholar

[31] Gerasimov DN, Lyzlova MV. Adaptive control of microclimate in greenhouses. J Comput Syst Sci Int. 2014;53:896–907.10.1134/S1064230714050074Search in Google Scholar

[32] Haefner JW. Modeling biological systems. principles and applications. New York: Springer Science + Business Media Inc.; 2005.10.1007/b106568Search in Google Scholar

[33] Hameed IA, Sorensen CG. A more energy efficient controller for the greenhouses climate control system. Appl Eng Agric. 2010;26(3):491–8. 10.13031/2013.29947.Search in Google Scholar

[34] Haeussermann A, Hartung E, Jungbluth T, Vranken E, Aerts J-M, Berckmans D. Cooling effects and evaporation characteristics of fogging systems in an experimental piggery. Biosyst Eng. 2007;97:395–405. 10.1016/j.biosystemseng.2007.03.019.Search in Google Scholar

[35] He K-S, Chen D-Y, Sun L-J, Liu Z-L, Huang Z-Y. The effect of vent openings on the microclimate inside multi-span greenhouses during summer and winter seasons. Eng Appl Comput Fluid Mech. 2015;9(1):399–410. 10.1080/19942060.2015.1061553.Search in Google Scholar

[36] Hochmuth GJ. Production of Florida greenhouse vegetables in rockwool: greenhouse design and crop management. Gainesville, FL: Florida Cooperative Extension Service; 1993.Search in Google Scholar

[37] Hornero-Méndez D, Costa-García J, Mínguez-Mosquera M. Characterization of carotenoid high-producing capsicum annuum cultivars selected for paprika production. J Agric Food Chem. 2002;50:5711–6. 10.1021/jf0256236.Search in Google Scholar PubMed

[38] Ishii M, Sase S, Moriyama H, Okushima L, Ikeguchi A, Hayashi M, et al. Controlled environment agriculture for effective plant production systems in a semiarid greenhouse. Jpn Agric Res Q. 2016;50(2):101–13. 10.6090/jarq.50.101.Search in Google Scholar

[39] Joudi PD, Hasan MM. Cooling and heating in a greenhouse in Baghdad by a solar assisted desiccant system. J Eng. 2013;8:933–51.Search in Google Scholar

[40] Joudi KA, Farhan AA. A dynamic model and experimental study for the internal air and soil temperatures in an innovative greenhouse. Energy Convers Manag. 2015;91:76–82. 10.1016/j.enconman.2014.11.052.Search in Google Scholar

[41] Katsoulas N, Bartzanas T, Boulard T, Mermier M, Kittas C. Effect of vent openings and insect screens on greenhouse ventilation. Biosyst Eng. 2006;93:427–36.10.1016/j.biosystemseng.2005.01.001Search in Google Scholar

[42] Kim Y, Evans R, Iversen W, Pierce R, Chavez J. Software design for wireless in-field sensor-based irrigation management. St Joseph, MI: ASABE; 2006.Search in Google Scholar

[43] Kittas C, Karamanis M, Katsoulas N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005;37:807–12.10.1016/j.enbuild.2004.10.009Search in Google Scholar

[44] Kreid D, Johnson B, Faletti D. Approximate analysis of heat transfer from the surface of a wet finned heat exchanger. ASME Paper; 1978.Search in Google Scholar

[45] Li T, Yu-Qi Z, Yi Z, Rui-Feng C, Qi-Chang Y. Light distribution in Chinese solar greenhouse and its effect on plant growth. Int J Horticultural Sci Technol. 2016;3(2):99–111. 10.22059/ijhst.2017.61273.Search in Google Scholar

[46] Linker R, Kacira M, Arbel A. Robust climate control of a greenhouse equipped with variable-speed fans and a variable-pressure fogging system. Biosyst Eng. 2011;110:153–67. 10.1016/j.biosystemseng.2011.07.010.Search in Google Scholar

[47] López-Cruz IL, Fitz-Rodríguez E, Torres-Monsivais JC, Trejo-Zúñiga EC, Ruíz-García A, Ramírez-Arias A. Control strategies of greenhouse climate for vegetables production. In: Guevara-González R, Torres-Pacheco I. Biosystems engineering: biofactories and food production in the century XXI. Switzerland: Springer International Publishing; 2014. p. 401–21.10.1007/978-3-319-03880-3_14Search in Google Scholar

[48] López-Cruz IL, Rojano-Aguilar A, Salazar-Moreno R, Ruiz-García A. Global sensitivity analysis of greenhouse crop models. Acta Hortic. 2012a;952:103–9. 10.17660/ActaHortic.2012.952.11.Search in Google Scholar

[49] López-Cruz IL, Rojano-Aguilar A, Salazar-Moreno R, Ruiz-García A, Goddard J. A comparison of local and global sensitivity analyses for greenhouse crop models. Acta Hortic. 2012b;957:267–73. 10.17660/ActaHortic.2012.957.30.Search in Google Scholar

[50] Luo W, De Zwart HF, Dai J, Wang X, Stanghellini C, Bu C. Simulation of greenhouse management in the subtropics, part 1: model validation and scenario study for the winter season. Biosyst Eng. 2005;90(3):307–18. 10.1016/j.biosystemseng.2004.11.008.Search in Google Scholar

[51] Mashonjowa E, Ronsse F, Milford JR, Pieters JG. Modeling the thermal performance of a naturally ventilated greenhouse in Zimbabwe using a dynamic greenhouse climate model. Sol Energy. 2013a;91:381–93. 10.1016/j.solener.2012.09.010.Search in Google Scholar

[52] Mashonjowa E, Ronsse F, Mubvuma M, Milford JR, Pieters JG. Estimation of leaf wetness duration for greenhouse roses using a dynamic greenhouse climate model in Zimbabwe. Comp Electron Agric. 2013b;95:70–81. 10.1016/j.compag.2013.04.007.Search in Google Scholar

[53] Mohammadi B, Ranjbar SF, Ajabshirchi Y. Application of dynamic model to predict some inside environment variables in a semi-solar greenhouse. Inf Proc Agric. 2018;5:279–88. 10.1016/j.inpa.2018.01.001.Search in Google Scholar

[54] Mizushina T, Ito R, Miyashita H. Characteristics and methods of thermal design of evaporative cooler. Int Chem Eng. 1968;8(3):532–8.10.1252/kakoronbunshu1953.32.55Search in Google Scholar

[55] Nageib MM, Malaka AS, Salwa AK, Mansour AE, Nagwa SZ. Effect of shading at different dormancy periods on Kanino apricot productivity. J Appl Sci Res. 2012;8:4290–5.Search in Google Scholar

[56] Navas LM, de la Plaza S, García JL, Durán JM, Retamal N. Formulation and sensitivity analysis of a dynamic model of the greenhouse climate validation for a mild Mediterranean climate. Acta Hortic. 1998;456:305–12. 10.17660/ActaHortic.1998.456.36.Search in Google Scholar

[57] Navas LM, de la Plaza S, Garcia JL, Duran JM, Retamal N, Luna L, et al. Formulation and sensitivity analysis of a dynamic model of the greenhouse climate validation for a mild Mediterranean climate. Acta Horticulturae. 1998;452:305–12.10.17660/ActaHortic.1998.456.36Search in Google Scholar

[58] Nazir CP. Solar energy for traction of high speed rail transportation: a techno-economic analysis. Civ Eng J. 2019;5(7):1566–76. 10.28991/cej-2019-03091353.Search in Google Scholar

[59] Nelson PV. Greenhouse operation and management. 5th edn. Upper Saddle River, NJ: Prentice Hall; 1998.Search in Google Scholar

[60] Olenewa J. Guide to wireless communication. Boston, MA: Cengage Learning; 2014.Search in Google Scholar

[61] Ozkan B, Fert C, Karadeniz C. Energy and cost analysis for greenhouse and open-field grape production. Energy. 2007;32:1500–4. 10.1016/j.energy.2006.09.010.Search in Google Scholar

[62] Panwar NL, Kaushik SC, Kothari S. A review on energy and exergy analysis on solar drying systems. Renew Sust Energ Rev. 2012;16:2812–9. 10.1016/j.rser.2012.02.053.Search in Google Scholar

[63] Pohlheim H, Heiβner A. MENDEL’96 – 2nd International conference on genetic algorithms (Brno, Czech Republic); 1996. p. 112–9.Search in Google Scholar

[64] Pohlheim H, Heiβner A. Optimal control of greenhouse climate using a short time climate model and evolutionary algorithms. ISHSIFAC, 3rd workshop on “Mathematical and control applications in agriculture and horticulture”; 1997. p. 113–8.10.1016/S1474-6670(17)41255-9Search in Google Scholar

[65] Pohlheim H, Heiβner A. Optimal control of greenhouse climate using real-world weather data and evolutionary algorithms. In: Banzhaf W, ed., Proceedings of the genetic and evolutionary computation conference GECCO’99. San Francisco, CA: Morgan Kaufmann; 1999. p. 1672–7.Search in Google Scholar

[66] Qerimi D, Dimitrieska C, Vasilevska S, Rrecaj A. Modelling of the solar thermal energy use in urban areas. Civ Eng J. 2020;6(7):1349–67. 10.28991/cej-2020-03091553.Search in Google Scholar

[67] van Ooteghem RJC. Optimal control design for a solar greenhouse. IFAC Proc. 2010;43(26):304–9. 10.3182/20101206-3-JP-3009.00054.Search in Google Scholar

[68] Radojevic N, Kostadinovic D, Vlajkovic H, Veg E. Microclimate control in greenhouses. FME Trans. 2014;42:167–71.10.5937/fmet1402167RSearch in Google Scholar

[69] Rasheed A, Lee J, Lee H. A review of greenhouse energy management by using building energy simulation. Protected Horticulture Plant Fact. 2015;24:317–25. 10.12791/KSBEC.2015.24.4.317.Search in Google Scholar

[70] Reyes-Rosas A, Molina-Aiz FD, Valera DL, López A, Khamkure S. Development of a single energy balance model for prediction of temperatures inside a naturally ventilated greenhouse with polypropylene soil mulch. Comp Electron Agric. 2017;142:9–28. 10.1016/j.compag.2017.08.020.Search in Google Scholar

[71] Roy S, Ophori D. Estimation of crop water stress index in almond orchards using thermal aerial imagery. J Spat Hydrol. 2014;12(1):1–14.Search in Google Scholar

[72] Saltelli A, Chan K, Scott M, eds., Sensitivity analysis. New York: John Wiley & Sons, Ltd; 2000.Search in Google Scholar

[73] Sanford S. Using curtains to reduce greenhouse heating and cooling costs. Energy Effic Greenhouses; 2011. p. 1–8.Search in Google Scholar

[74] Sengar S, Patil S, Chendake A. Economic feasibility of briquetted fuel. Glob J Reserach Eng. 2013;13:21–6.Search in Google Scholar

[75] Sethi VP, Sharma SK. Greenhouse heating and cooling using aquifer water. Energy. 2007a;32:1414–21. 10.1016/j.energy.2006.10.022.Search in Google Scholar

[76] Sethi VP, Sharma SK. Experimental and economic study of a greenhouse thermal control system using aquifer water. Energy Convers Manag. 2007b;48:306–19. 10.1016/j.enconman.2006.04.003.Search in Google Scholar

[77] Settles GS. Airflow visualization in a model greenhouse. 15th International congress for plastics in agriculture, Hershey, PA; 2000.Search in Google Scholar

[78] Speetjens SL. Towards model based adaptive control for the Watergy greenhouse. Design and implementation. Ph.D. thesis. Wageningen, the Netherlands: Wageningen University; 2008. p. 198.Search in Google Scholar

[79] Speetjens SL, Stigter JD, Van Straten G. Towards an adaptive model for greenhouse control. Comp Electron Agric. 2009;67:1–8. 10.1016/j.compag.2009.01.012.Search in Google Scholar

[80] Speetjens SL, Stigter JD, Van Straten G. Physics-based model for a water-saving greenhouse. Biosyst Eng. 2010;105:149–59. 10.1016/j.biosystemseng.2009.06.026.Search in Google Scholar

[81] Stanghellini C, De Jong T. A model of humidity and its applications in a greenhouse. Agric Meteorol. 1995;76:129–48. 10.1016/0168-1923(95)02220-R.Search in Google Scholar

[82] Subin MC, Abhilasha S, Kalaichelvi V, Karthikeyan R, Periasamy C. Design and robustness analysis of intelligent controllers for commercial greenhouse. Mech Sci. 2020;11:299–316. 10.5194/ms-11-299-2020.Search in Google Scholar

[83] Subin MC, Lourence JS, Karthikeyan R, Periasamy C. Analysis of materials used for greenhouse roof covering – structure using CFD. IOP Conf Ser Mater Sci Eng. 2018;346:1–14.10.1088/1757-899X/346/1/012068Search in Google Scholar

[84] Takakura T, Jordan KA, Boyd LL. Dynamic simulation of plant growth and environment in the greenhouse. Trans ASABE. 1971;14(5):964–71. 10.13031/2013.38432.Search in Google Scholar

[85] Taki M, Ajabshirchi Y, Ranjbar SF, Rohani A, Matloobi M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf Proc Agric. 2016;3:157–74. 10.1016/j.inpa.2016.06.002.Search in Google Scholar

[86] Taki M, Rohani A, Rahmati-Joneidabad M. Solar thermal simulation and applications in greenhouse. Inf Proc Agric. 2018;5:83–113. 10.1016/j.inpa.2017.10.003.Search in Google Scholar

[87] Taleb HM. Using passive cooling strategies to improve thermal performance and reduce energy consumption of residential buildings in UAE buildings. Front Agric Res. 2014;2:154–65.10.1016/j.foar.2014.01.002Search in Google Scholar

[88] Tap RF. Economics-based optimal control of greenhouse tomato crop production. Ph.D. thesis. Wageningen, the Netherlands: Wageningen University; 2000.Search in Google Scholar

[89] Tap RF, Van Willigenburg LG, Van Straten G. Experimental results of receding horizon optimal control of greenhouse climate. Acta Hortic. 1996;406:229–38. 10.17660/ActaHortic.1996.406.23.Search in Google Scholar

[90] Teitel M. The effect of screened openings on greenhouse microclimate. Agric For Meterol. 2007;143:159–75.10.1016/j.agrformet.2007.01.005Search in Google Scholar

[91] Trigui M. Strategy for the optimal climate control of greenhouse tomatoes. Ph.D. thesis. Montreal, Canada: McGill University; 2000.Search in Google Scholar

[92] Trigui M, Barrington S, Gauthier L. A strategy for greenhouse climate control, part I: model development. J Agri Eng Res. 2001;78(4):407–13. 10.1006/jaer.2000.0647.Search in Google Scholar

[93] Udink ten Cate AJ, van de Vooren J. Modelling of greenhouse temperatures using time-series analysis techniques. IFAC Proceedings Volumes. 1984;17(2):2033–8. 10.1016/S1474-6670(17)61275-8.Search in Google Scholar

[94] Udink ten Cate AJ. Modelling and simulation in greenhouse climate control. Acta Hortic. 1985;174:461–7. 10.17660/ActaHortic.1985.174.61.Search in Google Scholar

[95] Vadiee A, Martin V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew Sust Energ Rev. 2012;16:5087–100. 10.1016/j.rser.2012.04.022.Search in Google Scholar

[96] Vadiee A, Martin V. Energy analysis and thermoeconomic assessment of the closed greenhouse: the largest commercial solar building. Appl Energy. 2013a;102:1256–66. 10.1016/j.apenergy.2012.06.051.Search in Google Scholar

[97] Vadiee A, Martin V. Thermal energy storage strategies for effective closed greenhouse design. Appl Energy. 2013b;109:337–43. 10.1016/j.apenergy.2012.12.065.Search in Google Scholar