Abstract

Due to their excellent thermal conductivity, lightweight, and ease of processing, aluminum alloys are the material of choice for piston manufacture in internal combustion engines. Nanoparticles (NPs) of alumina (Al2O3) with a size of 25 nm were incorporated into an aluminum piston alloy to examine the effect of the NP addition on wear resistance and fatigue behavior. The stir casting method has been utilized to manufacture experimental samples of the composite material by altering the particle weight ratio of aluminum to the matrix alloy to 2, 4, and 6 wt%. The surface morphology of the samples has been examined using an electronic scanning microscope. The results of the wear and fatigue tests indicate that the addition of Al2O3 to the composite enhanced its fatigue resistance and wear strength, with the exception of 6 wt% weight ratio. The best improvement in wear resistance and fatigue strength occurs at 4 wt% Al2O3 particles, which are 12.13 and 67.5%, respectively, more significant than the pure metal and other composites. The mechanical properties of the alloy samples have been enhanced by adding Al2O3 NPs of 25 nm size into the piston’s aluminum matrix alloy. Stir casting was employed to produce the needed composites by incorporating Al2O3 NPs at varied weight percentage ratios of 0, 2, 4, and 6 wt% into the master alloy. Before the composite alloy reached 6 wt%, including Al2O3 NPs, the alloy’s hardness and tensile strength improved, according to the experiment results.

1 Introduction

The purpose of the piston is to transfer the force generated in the power stroke by the extension gas via a connecting rod and the crankshaft of the machine cylinders [1]. Because of this function, the piston is exposed to fatigue and wear while producing power. Wohler was the first researcher to define the concept of “fatigue” to explain material degeneracy. The failure is proportional to the number of cycles of applied load and the fatigue damage is one type of brittle fracture under cyclic loading [2,3]. Most engine combustion (IC) pistons are made of Al2O3 alloys. The piston temperature must be above 66% at around 600°C [4,5]. In the mechanical characteristics of the piston material, the aluminum column alloys play an active part in various intermetallic phases, including Cu3Al, and Mg2Si morphology and their distribution. Therefore, the abovementioned material was subjected to different thermal aging treatments [6]. A research study briefly addresses the fatigue conduct of additive manufacturing (AM) with various problems influencing the actions. In contrast with conventional production processes, AM strategies have several advantages. Besides the opportunity to render components that are always difficult with complicated geometries, it ensures the economical and efficient production of parts in small numbers. Because of these factors, AM processes in different sectors have become more common, especially for aerospace, biomedical, and, more lately, automobile applications [7]. In an experimental procedure, four kinds of heat treatments carried out in four investigations assessed the fatigue performance of steel CK45. The study showed that the fatigue life of oil quenching has better lives and exhaustion than other cases [8]. A comparative study of the casting of aluminum alloys by Al–Si–Cu showed the fatigue effect of air and vacuum. The study’s principal findings showed that vacuum fatigue lives are longer than in air [9]. In aluminum 2024, alloy strengthened in the presence of silicon carbide and artificial aging at 170°C have been proven to increase the strength of fatigue [10]. The mechanical properties of 2024 aluminum alloy composites with Al2O3 particulate additive have been studied for the effect of cryogenic temperature. Surely, cryogenic therapy enhanced fatigue, hardness, and grain size [11]. The gray cast iron was added with micro-chromium material as a weight ratio. Enhanced micro-toughness and wear resistance of the Al2O3/TiO2 nanoalloys dispersed hyperesthetic A390 from laboratory tests [12]. The influence of SiO2 insertion of various nanoparticle (NP) concentrations increases the base matrix’s hardness [13]. To analyze the changes in the composite’s hardness, a compo-casting method was developed to manufacture A356 micro- and nano-sized Al2O3 regenerated composites. The results showed that the hardness increased with increased particle weight fraction and decreased particle size [14,15]. It is concluded from the results of a comparison study between sand-cast Mg–10Gd–3Y–0.5Zr magnesium alloy with sand-cast plus T6 heat-treated magnesium alloy that the fatigue strength can be improved from 95 to 120 MPa when magnesium alloy increases by 26% after T6 heat treatment [16].

Most published articles are based on literature context data on improving the composite matrix’s mechanical and tribological characteristics, including tensile strength and hardness. Nevertheless, none investigate the addition of Al2O3 NPs on fatigue strength and piston materials’ wear resistance [17]. Detonation happens when the compression ratio is higher than the fuel’s octane rating, which is problematic. One of the principal outcomes is a break or fracture on the piston head, as depicted in Figure 1. This analysis has been provided to reduce the impact of the damage. To improve the mechanical characteristics of the piston materials produced by aluminum alloy EN AB-47100 AlSi12Cu1(Fe), Al2O3 NPs were selected as one of the ceramic additions. Based on information from the literature, the obtained alloy had three distinct weight percentage ratios of Al2O3 NPs of 25 m size added using the stir casting process at a given time and speed. Experimental research was carried out to determine how adding of NPs affected the mechanical characteristics of the piston’s composite components. Abbas and Rasheed measured the mechanical properties of the Cu-doped TiO2 NPs [18]. For other applications in this field, mathematical models have been used [19–39].

Prepared samples with dimensions have been utilized.

This research concerns the microstructure and mechanical characteristics of the Al2O3-reinforced addition to a row of aluminum alloy matrix. It is extended mainly on the processing, through the use of a stir casting technique of metal nanocomposites and explores the impact on the fatigue, hardness, tensile, and wear of the modern facilities of the 25 nm Al2O3 NPs of size reinforced. The fracture piston issue that affects USA Chrysler Jeep vehicles undergoing maintenance when low gasoline octane number is utilized is what inspired the author to propose this work. The objective of the present work is to add Al2O3 NPs with 25 nm grain size to the aluminum piston alloy to investigate the effect of NPs on the mehanical behavior of the Al alloy piston.

2 Method and experiment

2.1 Scanning electron microscope (SEM) test

Microstructure characterization of samples was taken out using a high-resolution scanning electron microscopy (FEI INSPECT S50-BRUKER Company) from the USA with a high voltage of 5 kV and magnification of 50k×),

2.2 Fatigue test

Schenck company from Germany has been used to compute the number of cycle to failure (RPM) for the fatigue sample. The material was examined based on ASTM-E1251 for standardization and quality control (COSQC) to get the chemical configuration of the actual piston materials. The formulation of the base alloy is from fragment pistons with the trademark USA Chrysler Jeep. The initial compound configuration of the master ingredient is based on [17]. A hole furnace at 800°C temperature melts the scrap pistons in the container. The liquefied fusion was poured in iron molding warmed at a temperature of 400°C to confirm good quality fabrication. The production of the pure alloy is designed to round with (80 mm × 10 mm) diameter column. The specimen sizes are based on ASTM (E8/E8M-09) in mm; the machine used for the fatigue test is shown in Figure 2.

Fatigue mechine test with specimen has been used.

2.3 Wear test

Wear resistance is a terminology mainly employed to explain the wear-resistance properties of a substance. The part of the wear test has been done in the Material Department in the strength of materials lab/University of Technology, Baghdad, Iraq. Four samples were prepared to be tested in the wear device. Mass loss measurement is a function of the wear measurement. A tube-shaped specimen of 10 mm in diameter and 30 mm in length is filled alongside a flat rotational disc such that a circular wear pathway is defined by the machine rotating by an electrical motor. The device can measure material wear and friction under pure sliding conditions. The first step is to measure the weight of each sample before doing the test with a sensitive measuring device reading up to five digits, as in the figure. The wear device is manufactured locally in the material department lab. The speed used for the test was 950 rpm, and the force (load) used for the test was 25 N. When doing the test, the disc and the sample were cleaned clearly to gain the minimum error measurement. Calibration to the device was taken each time before operating the machine to keep the arm device’s linearity in the correct position. The experiment was repeated four times for the four samples. The time selected for the experiment is fixed at 10 min. The slip distance between the disc’s center diameter and the sample’s center was 65 mm.

2.4 Hardness test

The specimens’ measurements were performed using the Vickers hardness (HV) test method with a diamond indenter to determine the hardness of the samples. Three indentations were taken, and their average was calculated to achieve an accurate reading. HVS-1000 Digital Micro Hardness Tester (Laryee Technology Co., Ltd) from China was used.

2.5 Tensile strength

Tensile strength was determined using the compression testing machine from Laryee Technology Co., Ltd, China.

3 Results and discussion

3.1 SEM images

Figure 3 illustrates the surface morphology of samples with 0, 2, 4, and 6 wt% ratio addition of Al2O3 NPs for the pistons matrix alloy. All depicted images are with the specification of HV 5 kV, Mag. 50k×, and SEM images at 200 nm particle size. It indicates the aggregation of Al2O3 particles to the shape of the non-regular allocation causing non-homogeneity of the composite. This may be due to parameters such as stirring speed and stirring time.

SEM images of aluminum alloy with Al2O3 NPs ratio at 200 nm (Mag. 60k×): (a) 0 wt%, (b) 2 wt%, (c) 4 wt%, and (d) 6 wt%.

3.2 Fatigue test

The obtained result of the fatigue test is recorded in Table 1 and Figure 4. In general, the fatigue life (number of cycle to failure) increases as the ratio of Al2O3 particles increases. The best result is obtained when the NPs are 4 wt% weight of Al2O3 nm. The maximum value of RPM is 271,000 rpm. The increase in rpm life is about 67.5% compared to the received alloy. However, at 6 wt% of Al2O3 NPs the RPM (number of cycle to failure) decreased due to the poor NP distribution in the aluminum matrix.

Fatigue RPM of samples without and with Al2O3 NPs ratio

| Fatigue values (RPM) | |

|---|---|

| 0% Al2O3 | 88,000 |

| 2% Al2O3 | 98,000 |

| 4% Al2O3 | 271,000 |

| 6% Al2O3 | 141,000 |

Fatigue test of Al alloy samples with Al2O3 particles ratio 0, 2, 4, and 6 wt%.

3.3 Wear test

The results of the wear test for each experiment are listed in Table 2. The weight for samples was taken before and after wear testing, and the difference in the weight was obtained. The weight difference before and after the test indicates the weight loss in (g) units as a function of wear. Figures 5 and 6 show that the machine for wear testing has been used, and the weight lost materials decrease as the Al2O3 particles’ weight ratio increases up to 4 wt% by 20.3% from the received one. However, at a 6 wt% particle ratio, the weight loss increased. The increase in the weight is due to the increase in the generated heat in the friction processing, besides the non-homogenous distribution of the NP additive in the matrix.

Samples’ weight values before and after using the wear testing

| Particles ratio (%) | Weight (g) | Time (min) | |||

|---|---|---|---|---|---|

| Before | After | Weight difference | |||

| 0 | 6.2428 | 6.2374 | 0.0054 | 10 | |

| 2 | 6.2374 | 6.232 | 0.0054 | 10 | |

| 4 | 6.4032 | 6.3989 | 0.0043 | 10 | |

| 6 | 6.405 | 6.3986 | 0.0064 | 10 | |

Sample is under the wear testing.

Weight loss values of the samples using wear testing.

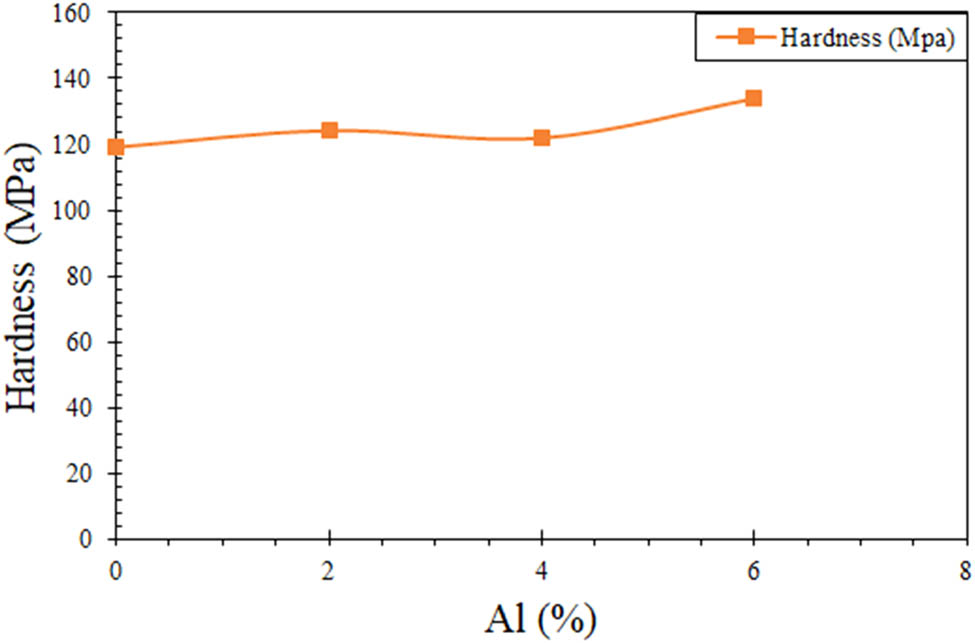

3.4 Hardness test

HV testing was done to see how the primary alloy would be affected by the Al2O3 particle extension. Each sample was subjected to an average of three measurements. The measurements of particle hardness concerning their extension are shown in Figure 7. The graph shows that the hardness typically rises as the ratio of nano-Al2O3 particle weight increases since Al2O3 is a complex ceramic particle combined with a soft aluminum matrix. Nevertheless, compared to the hardness with 2 wt% Al2O3 NPs, the hardness with 4 wt% Al2O3 NPs is lower. This reduction is a result of the matrix alloy’s non-homogeneous particle distribution. The dispersion of particles in the specimen test altered the measurement readings of the Vickers testing.

Hardness values of the samples.

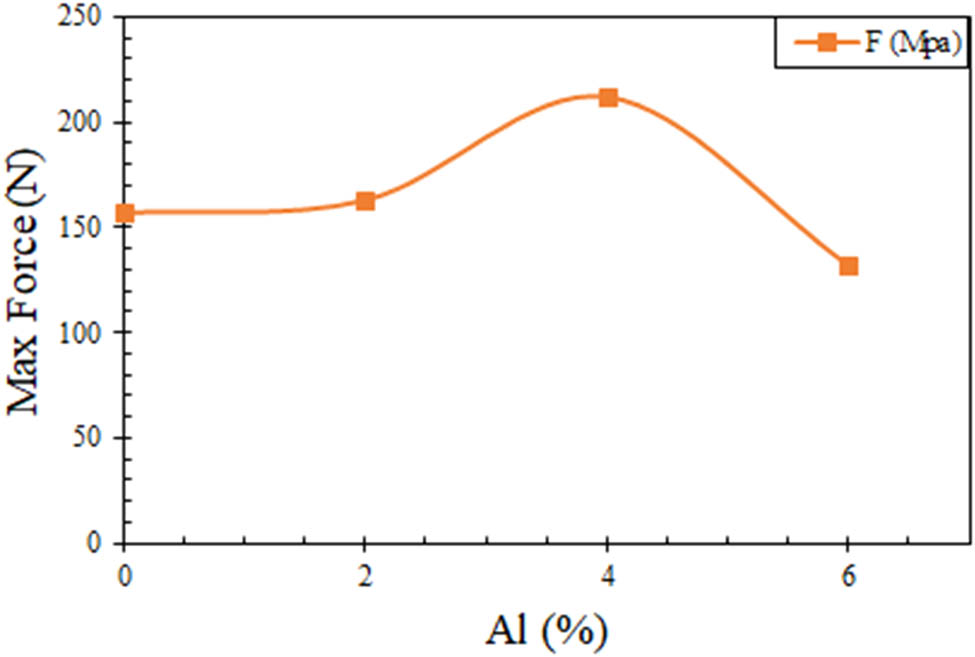

3.5 Tensile strength

The primary alloys’ and composites’ tensile strength values are shown in Figure 8 as a function of the number of Al2O3 NPs added. As shown in this figure, composite materials with less than 6 wt% Al2O3 particles have greater tensile strength than the base alloy. In contrast, those with 0 and 6 wt% Al2O3 particles have lower tensile strength than the base alloy. Furthermore, this figure demonstrates that the maximum tensile stress was 212 MPa of the composite containing 4% Al2O3 is 35% higher than that of the matrix alloy. The tensile strength falls as the percentage, including ceramic particles, increases with 4 wt% Al2O3 particles. The matrix of the alloy’s non-uniformly distributed particle structure is the reason for the loss in tensile strength; this makes the composite more porous. Porosity is the leading cause of poor adhesion at the ceramic–matrix contact.

Tensile strength (maximum force) values of the samples.

4 Conclusion

The matrix aluminum-established NPs in nano-compounds are effectively supplied by the stir casting method and are assessed. The fatigue power of the iron matrix is related to the nano-particle enhancement percentage. The nanocomposite metal matrix containing scrap piston materials plus Al2O3 of 4 wt% has a wear resistance of 12.13% higher than the building metal and other composites. The strengthening, grain allocation, and grain size of NPs are responsible for the nanocomposite’s high-level and enhanced fatigue performance. The impact of strengthening on fatigue lifetime (the number of cycles to failure) increases with the increase in the weight percentage of reinforcement. The hardness value of the samples indicates that it increases after adding the Al2O3 NPs.

In general, it is concluded that adding Al2O3 particles in a predetermined quantity improves the mechanical qualities. Except for the composite with 6 wt% Al2O3 NPs, all experimentally tested composite materials exhibit better excellent tensile strength values than the received aluminum alloy. Because of an increase in porosity caused by the inclusion of Al2O3 NPs over 4 wt%, the tensile strength drops. As the weight percentage of Al2O3 NPs is added, the hardness rises. If we achieve excellent NP dispersion in the matrix alloy, the range of mechanical characteristics improvement may be expanded. The time spent stirring the composite materials in the experimental task and the speed at which the stir motor rotates determine the distribution control.

-

Funding information: The study was performed without financial support.

-

Author contributions: I.A. and H.M.I.A.: methodology; A.A.A., M.K.A., and M.R.: designed and performed the experiments; I.A., H.M.I.A., and M.R.: analyzed and interpreted the data; and I.A., M.R., and H.M.I.A.: prepared the manuscript. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors declare that they have no conflict of interest in relation to this research, whether financial, personal, authorship, or otherwise that could affect the research and its results presented in this article.

References

[1] Kumar M. A survey on electro hydrostatic actuator: architecture and way ahead. Mater Today Proc. 2021;45(1):6057–63.10.1016/j.matpr.2020.10.049Search in Google Scholar

[2] Gaurav A, Singh KK. Fatigue behavior of FRP composites and CNT‐embedded FRP composites: a review. Polym Compos. 2018;39(6):1785–808.10.1002/pc.24177Search in Google Scholar

[3] Qian G, Lei WS. A statistical model of fatigue failure incorporating effects of specimen size and load amplitude on fatigue life. Philos Mag. 2019;99(17):2089–125.10.1080/14786435.2019.1609707Search in Google Scholar

[4] Fei C, Lei T, Qian Z, Shu Z. Piston thermal analysis of heavy commercial vehicle diesel engine using lanthanum zirconate thermal-barrier coating. Energies. 2022;15(12):4225.10.3390/en15124225Search in Google Scholar

[5] Yao Z, Hu K, Li R. Enhanced high-temperature thermal fatigue property of aluminum alloy piston with Nano PYSZ thermal barrier coatings. J Alloy Compd. 2019;790:466–79.10.1016/j.jallcom.2019.03.177Search in Google Scholar

[6] Farokhpour M, Parast MS, Azadi M. Evaluation of hardness and microstructural features in piston aluminum–silicon alloys after different ageing heat treatments. Results Mater. 2022;16:100323.10.1016/j.rinma.2022.100323Search in Google Scholar

[7] Fatemi A, Molaei R, Simsiriwong J, Sanaei N, Pegues J, Torries B, et al. Fatigue behaviour of additive manufactured materials: an overview of some recent experimental studies on Ti–6Al–4V considering various processing and loading direction effects. Fatigue Fract Eng Mater Struct. 2019;42(5):991–1009.10.1111/ffe.13000Search in Google Scholar

[8] Al-Zuhairi HM, Hamza AK, Mahdi BS, Al-Alkawi HJ. Effect of heat treatment on toughness and fatigue behavior strength of steel CK45. IOP Conf Ser Mater Sci Eng. 2020;881(1):012069.10.1088/1757-899X/881/1/012069Search in Google Scholar

[9] Abdulhadi HA, Aqida SN, Ishak M, Mohammed GR. Thermal fatigue of die-casting dies: an overview. The 3rd International Conference on Mechanical Engineering Research (ICMER 2015); 2015 Aug 18–19; Kuantan, Pahang, Malaysia.Search in Google Scholar

[10] Gong B, Zhang Z, Duan Q, Qu Z, Hou J, Zhang Z. Effects of aging state on fatigue properties of 6A01 aluminum alloy. Fatigue Fract Eng Mater Struct. 2022;45(6):1751–62.10.1111/ffe.13697Search in Google Scholar

[11] Alzaidy B, Abod BM. Fatigue life prediction of AA6063-T6 under erosion condition. In Materials Science Forum. Vol. 1021. Trans Tech Publications Ltd; 2021. p. 87–96. http://doi.org/10.4028/www.scientific.net/msf.1021.87.10.4028/www.scientific.net/MSF.1021.87Search in Google Scholar

[12] El-Mahallawi IS, Shash AY, Amer AE. Nanoreinforced cast Al–Si alloys with Al2O3, TiO2 and ZrO2 nanoparticles. Metals. 2015;5(2):802–21.10.3390/met5020802Search in Google Scholar

[13] Selvaraj SK, Ramesh R, Narendhra TM, Agarwal IN, Chadha U, Paramasivam V, et al. New developments in carbon-based nanomaterials for automotive brake pad applications and future challenges. J Nanomater. 2021;2021:1–24.10.1155/2021/6787435Search in Google Scholar

[14] Suroso I. The analysis chemical composition, microstructure, and hardness disk brake of Cessna Caravan. AIP Conf Proc. 2022;2391(1):070008.10.1063/5.0073763Search in Google Scholar

[15] Ali M, Alshalal I, Al Zubaidi FN, Yousif AR. Improvement of corrosion and erosion resistance properties for cast iron. IOP Conf Ser Mater Sci Eng. 2020;881(1):012068.10.1088/1757-899X/881/1/012068Search in Google Scholar

[16] Wang Q, Xiao L, Liu W, Zhang H, Cui W, Li Z, et al. Effect of heat treatment on tensile properties, impact toughness and plane-strain fracture toughness of sand-cast Mg–6Gd–3Y–0.5Zr magnesium alloy. Mater Sci Eng A. 2017;705:402–10.10.1016/j.msea.2017.08.100Search in Google Scholar

[17] Al-Zuhairi HM, Alshalal I. Enhancement of mechanical properties of aluminum piston alloy using Al2O3 material. 2020 6th International Engineering Conference Sustainable Technology and Development (IEC); 2020 Feb 26–27; Erbil, Iraq. IEEE, 2020. p. 196–200.10.1109/IEC49899.2020.9122921Search in Google Scholar

[18] Abbas MM, Rasheed M. Solid state reaction synthesis and characterization of Cu doped TiO2 nanomaterials. J Phys Conf Ser. 2021;1795:012059.10.1088/1742-6596/1795/1/012059Search in Google Scholar

[19] Jalal R, Shihab S, Alhadi MA, Rasheed M. Spectral numerical algorithm for solving optimal control using Boubaker-Turki operational matrices. J Phys Conf Ser. 2020;1660:012090.10.1088/1742-6596/1660/1/012090Search in Google Scholar

[20] Rasheed M, Shihab S, Mohammed OY, Al-Adili A. Parameters estimation of photovoltaic model using nonlinear algorithms. J Phys Conf Ser. 2021;1795:012058.10.1088/1742-6596/1795/1/012058Search in Google Scholar

[21] Enneffatia M, Rasheed M, Louatia B, Guidaraa K, Shihab S, Barillé R. Investigation of structural, morphology, optical properties and electrical transport conduction of Li0.25Na0.75CdVO4 compound. J Phys Conf Ser. 2021;1795:012050.10.1088/1742-6596/1795/1/012050Search in Google Scholar

[22] Rasheed M, Mohammed OY, Shihab S, Al-Adili A. Explicit numerical model of solar cells to determine current and voltage. J Phys Conf Ser. 2021;1795:012043.10.1088/1742-6596/1795/1/012043Search in Google Scholar

[23] Rasheed M, Mohammed OY, Shihab S, Al-Adili A. A comparative analysis of PV cell mathematical model. J Phys Conf Ser. 2021;1795:012042.10.1088/1742-6596/1795/1/012042Search in Google Scholar

[24] Rasheed M, Shihab S, Sabah OW. An investigation of the structural, electrical and optical properties of graphene-oxide thin films using different solvents. J Phys Conf Ser. 2021;1795:012052.10.1088/1742-6596/1795/1/012052Search in Google Scholar

[25] Rasheed M, Alabdali O, Shihab S. A new technique for solar cell parameters estimation of the single-diode model. J Phys Conf Ser. 2021:1879(3):032120.10.1088/1742-6596/1879/3/032120Search in Google Scholar

[26] Rasheed M, Alabdali O, Hassan HH. Parameters extraction of a single-diode model of photovoltaic cell using false position iterative method. J Phys Conf Ser. 2021;1879(3):032113.10.1088/1742-6596/1879/3/032113Search in Google Scholar

[27] Sarhan MA, Shihab S, Kashem BE, Rasheed M. New exact operational shifted pell matrices and their application in astrophysics. J Phys Conf Ser. 2021;1879(2):022122.10.1088/1742-6596/1879/2/022122Search in Google Scholar

[28] Rasheed M, Al-Darraji MN, Shihab S, Rashid A, Rashid T. The numerical calculations of single-diode solar cell modeling parameters. J Phys Conf Ser. 2021;1963(1):012058.10.1088/1742-6596/1963/1/012058Search in Google Scholar

[29] Rasheed M, Al-Darraji MN, Shihab S, Rashid A, Rashid T. Solar PV modelling and parameter extraction using iterative algorithms. J Phys Conf Ser. 2021;1963(1):012059.10.1088/1742-6596/1963/1/012059Search in Google Scholar

[30] Rasheed M, Shihab S, Alabdali O, Rashid A, Rashid T. Finding roots of nonlinear equation for optoelectronic device. J Phys Conf Ser. 2021;1999(1):012077.10.1088/1742-6596/1999/1/012077Search in Google Scholar

[31] Rasheed M, Alabdali O, Shihab S, Rashid A, Rashid T. On the solution of nonlinear equation for photovoltaic cell using new iterative algorithms. J Phys Conf Ser. 2021;1999:012078.10.1088/1742-6596/1999/1/012078Search in Google Scholar

[32] Alabdali O, Shihab S, Rasheed M, Rashid T. Orthogonal Boubaker-Turki polynomials algorithm for problems arising in engineering. AIP Conf Proc. 2022;2386:050019.10.1063/5.0066860Search in Google Scholar

[33] Gharbi S, Dhahri R, Rasheed M, Dhahri E, Barille R, Rguiti M, et al. Effect of Bi substitution on nanostructural, morphologic, and electrical behavior of nanocrystalline La1−xBixNi0.5Ti0.5O3 (x = 0 and x = 0.2) for the electrical devices. Mater Sci Eng B. 2021;270:115191.10.1016/j.mseb.2021.115191Search in Google Scholar

[34] Kadri E, Messaoudi O, Krichen M, Dhahri K, Rasheed M, Dhahri E, et al. Optical and electrical properties of SiGe/Si solar cell heterostructures: ellipsometric study. J Alloy Compd. 2017;721:779–83.10.1016/j.jallcom.2017.06.025Search in Google Scholar

[35] Azaza NB, Elleuch S, Rasheed M, Gindre D, Abid S, Barillé R, et al. 3-(p-Nitrophenyl) Coumarin derivatives: synthesis, linear and nonlinear optical properties. Opt Mater. 2019;96:109328.10.1016/j.optmat.2019.109328Search in Google Scholar

[36] Kadri E, Dhahri K, Zaafouri A, Krichen M, Rasheed M, Khirouni K, et al. AC conductivity and dielectric behavior of a− Si: H/c− Si1−yGey/p− Si thin films synthesized by molecular beam epitaxial method. J Alloy Compd. 2017;705:708–13.10.1016/j.jallcom.2017.02.117Search in Google Scholar

[37] Kadri E, Krichen M, Mohammed R, Zouari A, Khirouni K. Electrical transport mechanisms in amorphous silicon/crystalline silicon germanium heterojunction solar cell: impact of passivation layer in conversion efficiency. Opt Quantum Electron. 2016;48:1–5.10.1007/s11082-016-0812-7Search in Google Scholar

[38] Enneffati M, Rasheed M, Louati B, Guidara K, Barillé R. Morphology, UV–visible and ellipsometric studies of sodium lithium orthovanadate. Opt Quantum Electron. 2019;51:1–9.10.1007/s11082-019-2015-5Search in Google Scholar

[39] Abdulrahman AA, Rasheed M, Shihab S. The analytic of image processing smoothing spaces using wavelet. J Phys Conf Ser. 2021;1879(2):022118.10.1088/1742-6596/1879/2/022118Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil

Articles in the same Issue

- Research Articles

- The mechanical properties of lightweight (volcanic pumice) concrete containing fibers with exposure to high temperatures

- Experimental investigation on the influence of partially stabilised nano-ZrO2 on the properties of prepared clay-based refractory mortar

- Investigation of cycloaliphatic amine-cured bisphenol-A epoxy resin under quenching treatment and the effect on its carbon fiber composite lamination strength

- Influence on compressive and tensile strength properties of fiber-reinforced concrete using polypropylene, jute, and coir fiber

- Estimation of uniaxial compressive and indirect tensile strengths of intact rock from Schmidt hammer rebound number

- Effect of calcined diatomaceous earth, polypropylene fiber, and glass fiber on the mechanical properties of ultra-high-performance fiber-reinforced concrete

- Analysis of the tensile and bending strengths of the joints of “Gigantochloa apus” bamboo composite laminated boards with epoxy resin matrix

- Performance analysis of subgrade in asphaltic rail track design and Indonesia’s existing ballasted track

- Utilization of hybrid fibers in different types of concrete and their activity

- Validated three-dimensional finite element modeling for static behavior of RC tapered columns

- Mechanical properties and durability of ultra-high-performance concrete with calcined diatomaceous earth as cement replacement

- Characterization of rutting resistance of warm-modified asphalt mixtures tested in a dynamic shear rheometer

- Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints

- Wear performance analysis of B4C and graphene particles reinforced Al–Cu alloy based composites using Taguchi method

- Connective and magnetic effects in a curved wavy channel with nanoparticles under different waveforms

- Development of AHP-embedded Deng’s hybrid MCDM model in micro-EDM using carbon-coated electrode

- Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles

- Evaluation of mechanical properties of fiber-reinforced syntactic foam thermoset composites: A robust artificial intelligence modeling approach for improved accuracy with little datasets

- Assessment of the beam configuration effects on designed beam–column connection structures using FE methodology based on experimental benchmarking

- Influence of graphene coating in electrical discharge machining with an aluminum electrode

- A novel fiberglass-reinforced polyurethane elastomer as the core sandwich material of the ship–plate system

- Seismic monitoring of strength in stabilized foundations by P-wave reflection and downhole geophysical logging for drill borehole core

- Blood flow analysis in narrow channel with activation energy and nonlinear thermal radiation

- Investigation of machining characterization of solar material on WEDM process through response surface methodology

- High-temperature oxidation and hot corrosion behavior of the Inconel 738LC coating with and without Al2O3-CNTs

- Influence of flexoelectric effect on the bending rigidity of a Timoshenko graphene-reinforced nanorod

- An analysis of longitudinal residual stresses in EN AW-5083 alloy strips as a function of cold-rolling process parameters

- Assessment of the OTEC cold water pipe design under bending loading: A benchmarking and parametric study using finite element approach

- A theoretical study of mechanical source in a hygrothermoelastic medium with an overlying non-viscous fluid

- An atomistic study on the strain rate and temperature dependences of the plastic deformation Cu–Au core–shell nanowires: On the role of dislocations

- Effect of lightweight expanded clay aggregate as partial replacement of coarse aggregate on the mechanical properties of fire-exposed concrete

- Utilization of nanoparticles and waste materials in cement mortars

- Investigation of the ability of steel plate shear walls against designed cyclic loadings: Benchmarking and parametric study

- Effect of truck and train loading on permanent deformation and fatigue cracking behavior of asphalt concrete in flexible pavement highway and asphaltic overlayment track

- The impact of zirconia nanoparticles on the mechanical characteristics of 7075 aluminum alloy

- Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool

- Low-temperature relaxation of various samarium phosphate glasses

- Disposal of demolished waste as partial fine aggregate replacement in roller-compacted concrete

- Review Articles

- Assessment of eggshell-based material as a green-composite filler: Project milestones and future potential as an engineering material

- Effect of post-processing treatments on mechanical performance of cold spray coating – an overview

- Internal curing of ultra-high-performance concrete: A comprehensive overview

- Special Issue: Sustainability and Development in Civil Engineering - Part II

- Behavior of circular skirted footing on gypseous soil subjected to water infiltration

- Numerical analysis of slopes treated by nano-materials

- Soil–water characteristic curve of unsaturated collapsible soils

- A new sand raining technique to reconstitute large sand specimens

- Groundwater flow modeling and hydraulic assessment of Al-Ruhbah region, Iraq

- Proposing an inflatable rubber dam on the Tidal Shatt Al-Arab River, Southern Iraq

- Sustainable high-strength lightweight concrete with pumice stone and sugar molasses

- Transient response and performance of prestressed concrete deep T-beams with large web openings under impact loading

- Shear transfer strength estimation of concrete elements using generalized artificial neural network models

- Simulation and assessment of water supply network for specified districts at Najaf Governorate

- Comparison between cement and chemically improved sandy soil by column models using low-pressure injection laboratory setup

- Alteration of physicochemical properties of tap water passing through different intensities of magnetic field

- Numerical analysis of reinforced concrete beams subjected to impact loads

- The peristaltic flow for Carreau fluid through an elastic channel

- Efficiency of CFRP torsional strengthening technique for L-shaped spandrel reinforced concrete beams

- Numerical modeling of connected piled raft foundation under seismic loading in layered soils

- Predicting the performance of retaining structure under seismic loads by PLAXIS software

- Effect of surcharge load location on the behavior of cantilever retaining wall

- Shear strength behavior of organic soils treated with fly ash and fly ash-based geopolymer

- Dynamic response of a two-story steel structure subjected to earthquake excitation by using deterministic and nondeterministic approaches

- Nonlinear-finite-element analysis of reactive powder concrete columns subjected to eccentric compressive load

- An experimental study of the effect of lateral static load on cyclic response of pile group in sandy soil