Abstract

The crystallization and orientation of isotactic polypropylene (iPP) molded by rapid heat cycle molding (RHCM) and conventional injection molding (CIM) were studied. Due to the varying cooling rates and shearing, the molded parts exhibited a multilayered structure (skin, shear and core) across the part thickness, reflecting different degrees of crystallization and lamellae orientation of iPP. The morphology evolution of RHCM products was discussed based on the comparative research of morphology and structure at multiple sites on the RHCM and CIM specimens. Scanning electron microscopy (SEM) and wide angle X-ray diffraction (WAXD) were used to analyze the thickness, crystallinity and lamellae orientation of these three distinct layers. The crystallization and lamellae orientation of iPP correlated strongly with the multilayered structure. In the RHCM process, one side of the mold is equipped with the rapid heat cycle function. The thickness and lamellae orientation next to the heated surface were less than that of the opposite skin layer without heating. Meanwhile, the crystallinity was greater than that of the opposite skin layer.

1 Introduction

Injection molding is the most widely used process for manufacturing plastic parts and accounts for about 32 wt% of all plastics manufacturing (1), (2). There are some novel molding processes to enhance part quality, of which rapid heat cycle molding (RHCM) is a promising molding process that can significantly improve part surface quality with minimum energy consumption and pollution (3).

Earlier reported studies on RHCM focused mainly on controlling the mold temperature distribution and temperature history as well as the relationship between process parameters and macroscopic properties of parts (4), (5), (6), (7). Although it is well known that the morphology determines the macroscopic properties of parts, there are fewer studies on morphologies in the RHCM part.

However, many studies have correlated the relationship between the morphology and part quality in conventional injection molding (CIM) (8), (9), (10), (11), (12), (13), (14), (15), (16), (17). Because isotactic polypropylene (iPP) is a typical crystalline polymer with polymorphism, it is commonly used by many researchers to study the relationship between the molding process, morphology, and part quality in CIM. For example, Kantz et al. (9) investigated the crystalline structure of iPP parts under different molding conditions. They observed a clear multilayered structure in the cross-sectional direction that was composed of three layers: a highly oriented skin layer, a spherulite crystalline layer and a spherulite core layer. Isayev et al. (10), (11) developed the qualitative description of crystallization phenomena by experiment and simulations, and investigated the multilayer microstructure in the injection-molded iPP parts with the developed description. They discussed the “competing mechanisms” of crystallization in terms of the induction time for introducing various microstructure layers are utilized to quantitatively distinguish between the highly oriented skin layer and spherulitic core in the moldings. Zhou and Mallick (12) and Zhang et al. (13) investigated the degree of molecular orientation in the thickness direction and found that it was at a maximum at the skin layer and at a minimum at the core layer. Additionally, the final molecular orientation distribution in the skin layer was highly sensitive to the process conditions.

The highly oriented skin layer was induced by the fountain flow at the melt front during the filling process. However, it was observed that a highly oriented skin layer also appeared under normal shear flow conditions in recent studies (18), (19). It was found that the molecular arrangement in the absence of orientation was randomly coiled, but that it varied sharply under the influence of a flow field. When the melt was influenced by a weak flow field, only a portion of the molecules changed their conformations. However, if the intensity of the flow field surpassed a threshold value over a period of time, the molecular chains would stretch and become oriented. In addition, while crystallization always happens under different flow conditions, a flow field with a higher shear rate will induce a higher degree of crystallinity in the final part (20), (21), (22), (23). Moreover, Cermak et al. (24) investigated the impact of processing conditions on the distribution of α and β crystals in iPP injection molded parts. They confirmed that both crystal forms were insensitive to packing pressure, but that the crystallinity of the products decreased with increasing packing pressure. The crystallization of iPP was significantly relevant to the content of long-chain molecules under lower supercooling and short-time shear (25). The long-chain molecules facilitated crystallization and induced a higher degree of surface orientation. Chen et al. (26) researched the crystallization behavior of polypropylene by polarizing microscope (POM), differential scanning calorimetry (DSC), conventional transmission electron microscopy (TEM), and high resolution transmission electron microscopy (HRTEM). It was found that both molecular weight distribution and isotacticity of polypropylene strongly affect its crystallization characteristics. Zhong et al. (27) found that crystallization conditions had a significant impact on the properties of parts such as the mechanical properties, optical properties, chemical properties and shrinkage rate. Zipper et al. (28) investigated the layered structure in discs with a thickness of 2 mm based on small- and wide-angle X-ray scattering (SAXS and WAXS). The results comprised statements on the preferential orientation and distribution of α- and β-PP in different layers of the cross sections, on crystallite sizes and on the behavior of individual layers in tensile tests. The aforementioned studies extensively analyzed the phenomena and mechanisms of CIM; however, there is a large distinction between the RHCM and CIM processes.

There are also some research on RHCM process. Chen et al. (4), (29) studied the effect of process parameters of RHCM on the mechanical properties and surface quality of plastic parts. The results showed that the RHCM process eliminated the weld marks on the plastic surface and improved the surface quality of plastic parts. Yu et al. (30) researched that the higher mold temperature can improve the filling capacity of the micro-injection molding melt through experiment of ultra-thin plastic parts filled in different mold temperatures. Shen et al. (31) investigated that the mold temperature, melt temperature and other process parameters had an effect on product quality for PP, PA and other materials. Zhang et al. (32) investigated that mold cavity surface temperature affected glossiness, weld line and so on.

Broadly speaking, the recent research of RHCM has mainly focused on heating technologies and process optimization, but the principles and mechanisms of the process have not been well studied, let alone the morphology and structure in RHCM. To study the morphology and structure in RHCM, iPP was employed, and multi-site sampling was performed on an industrial part molded by RHCM and CIM, respectively. Scanning electron microscopy (SEM) and wide angle X-ray diffraction (WAXD) were used to investigate crystallization and lamellae orientation, together with the multi-layered structure at the cross-section of a given point in CIM and RHCM parts. The variations in layer thickness, crystallinity and lamellae orientation of each layer in the multilayered structure between different processes and at different points were comparatively analyzed. Meanwhile, the formation and variation characteristics of the multilayered structure in RHCM were discussed.

2 Experiments

2.1 RHCM part preparation

To study the morphology of CIM and RHCM parts, a semi-crystalline iPP (T30S, Zhenhai branch of Sinopec Corp., Ningbo, China) was used in this study, of which the morphology and crystallinity and its spatial variations could be strongly influenced by the molding process. Performance parameters of this iPP were as follows: melt flow index (MFR) of 2.5 g/10 min, melting point of 167°C, density of 0.91 g/cm3 and an isotactic index greater than 94%.

Electric heating rods were employed to heat one side of the RHCM mold, which was discussed in detail in an earlier study (33). The mold temperature was measured with a K-type thermocouple (Beijing CHN-TOP Machinery Group Co., Ltd., Beijing, China), and the heating temperature was displayed and regulated by an MTS-32II controller (Beijing CHN-TOP Machinery Group Co., Ltd., Beijing, China). Electrical heating rods and cooling tunnels were deployed at the stationary (fixed) mold half, which could be rapidly heated by electric heating before being filled and cooled by circulating water after filling. Meanwhile, the moving mold half only had regular cooling tunnels. The asymmetric molding surface temperature was intended to introduce different degrees of crystallization and lamellae orientation in the RHCM molded iPP.

An RHCM part was produced under the following process conditions: heating mold surface temperature of 120°C, melt temperature of 220°C, injection pressure of 90 MPa, packing pressure of 50 MPa, cooling time of 30 s, and coolant temperature of 25°C. An CIM part was produced under the same condition except the absence of the heating mold surface temperature.

2.2 Specimen preparation

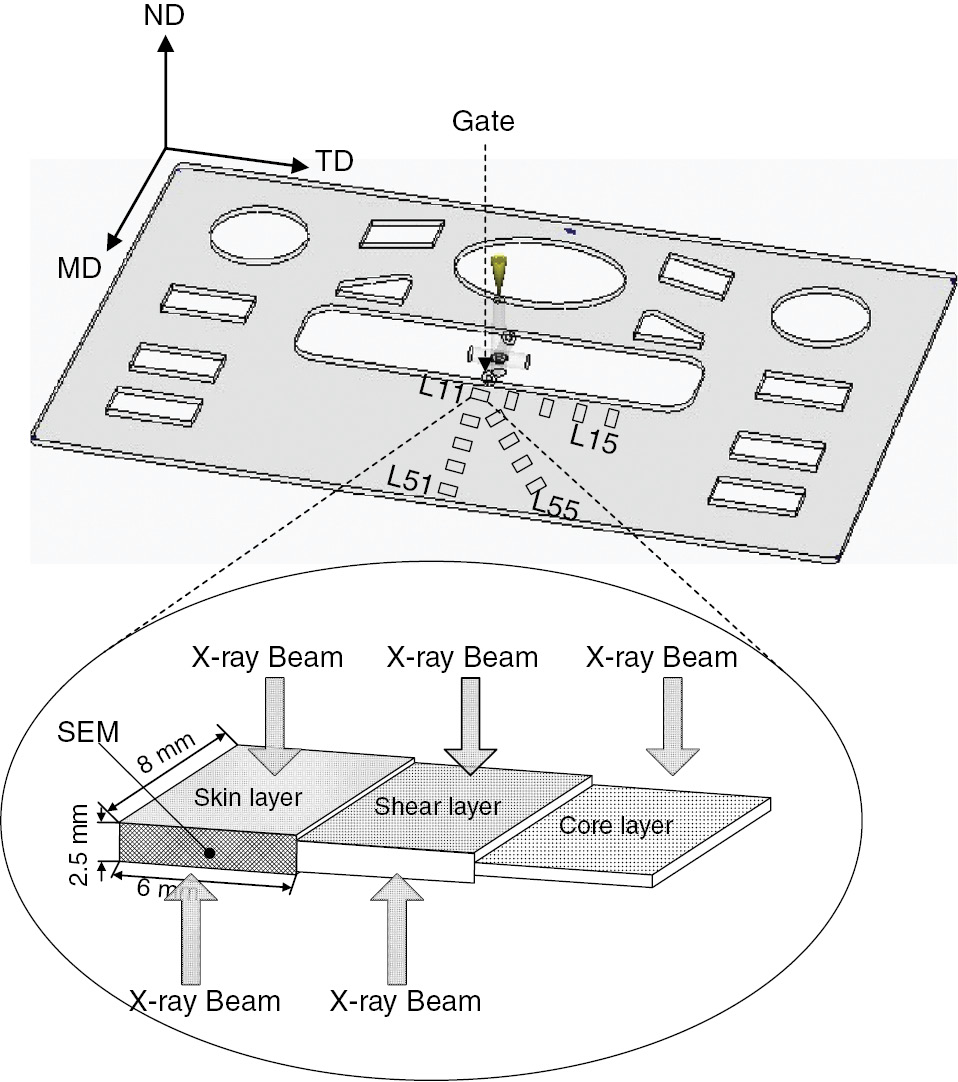

In order to investigate the variation of crystallization and lamellae orientation in the multilayered structure of the RHCM and CIM parts, specimens were sliced as shown in Figure 1 based on the traces of flow front advancements, and were then investigated by SEM and WAXD.

Schematic of part and locations of tested specimens.

2.3 Microstructure investigation

SEM was employed to observe and estimate the multilayered structure and morphology of the cross sections of the samples. The sliced splines were first quenched in liquid nitrogen, dried after 15 h of etching with xylene, and then surface-coated with gold. The splines were then observed with a HITACHIS-4700 field emission scanning electron microscope (Hitachi Limited, Tokyo, Japan) with an acceleration voltage of 15.0 kV.

WAXD was employed to determine the morphology, crystallinity, and orientation variation on the cross section at five sites along the each flow direction (cf. Figure 1). Specimens were polished layer by layer using metallographic sandpaper with particle sizes of 300 #, 600 #, and 1500 # on a grinding and polishing machine. WAXD was carried out on an X′ Pert PRO X-ray diffraction instrument (PANalytical B.V., Almelo, The Netherlands), with an X-ray source of Kα radiation from a Cu target (λ=0.154056 nm), a voltage of 40 kV, and a current of 40 mA. Its diffraction angle 2θ ranged from 10° to 40°.

In this study, the crystallinities of different layers were calculated based on a graphical method, given by (34),

where I110, I300, I040, I130, I111 and I131 are the diffraction intensities corresponding to each crystal phase, while Iα corresponds to the diffraction intensity of the amorphous phase.

The orientation degree f of lamellae was obtained based on the relative intensity ratio of two crystal diffraction peaks in the diffraction pattern. For iPP, the orientation degree f was the ratio of I[040] and I[110] (34). The value of f was used as an index in this paper to quantitatively study the variation of lamellae orientation throughout the multilayered structure.

3 Results and discussion

3.1 Multilayered structure

The multilayered structure was divided into the skin layer, shear layer, and core layer depending on the morphology. In particular, the crystal was highly oriented in the skin layer, there were a large number of fibrous shish-kebab crystal structures in the shear layer, and there were spherulite crystal structures in the core layer.

The multilayered structure on the cross section of the injection molded part reflected the thermal and shear histories of the polymer. The final multilayered structure of the part was determined by the shear stress, temperature and cooling rate of the polymer during the molding process. The thickness difference of the multilayered structures, crystallization and lamellae orientation at different sampling sites or molding and between RHCM and CIM processes also reflected the variations of the temperature and shear gradient during the filling process.

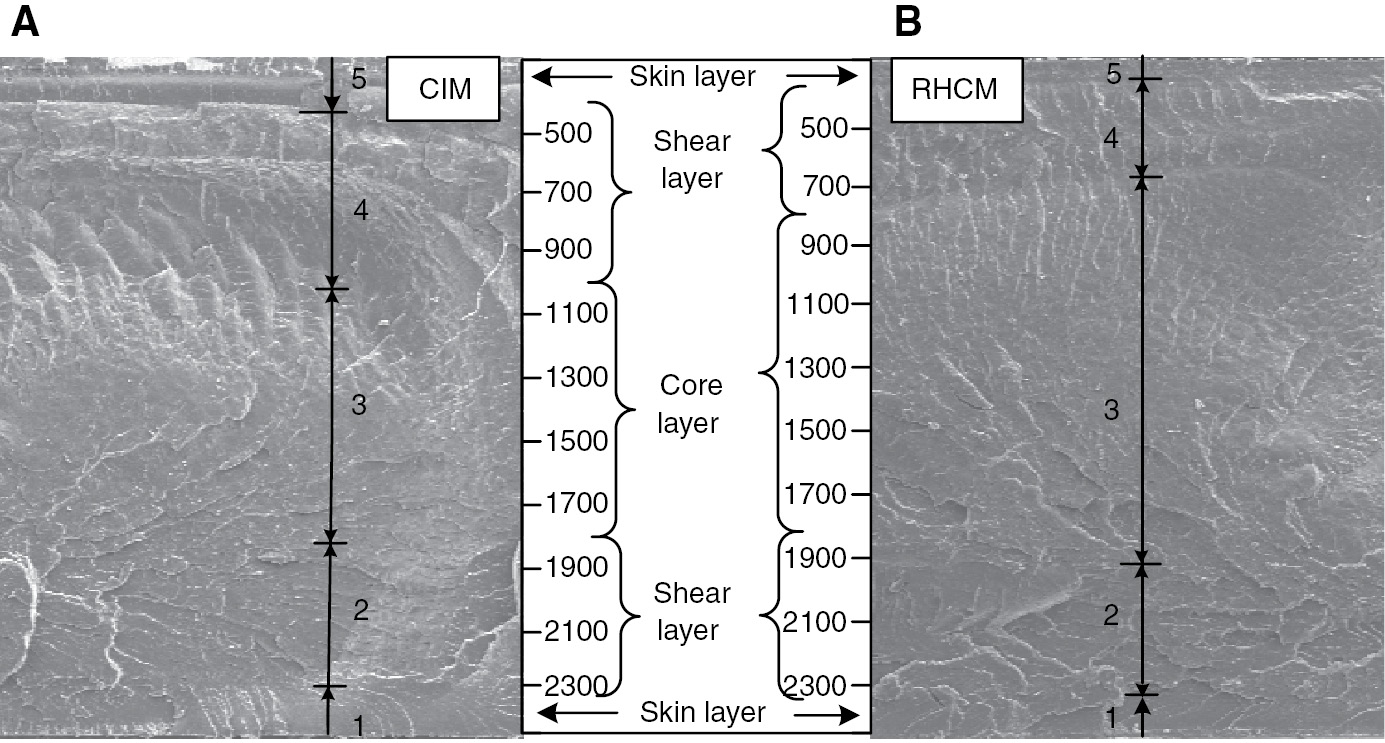

The main difference between RHCM and CIM was the different temperature histories in the mold, which introduced various thermal and shear histories to the polymer. Accordingly, the multilayered structures differed from each other, which could be observed from the SEM pictures of the sampling sites L11 (Figure 2). Note that L11 was the common sampling point on the RHCM and CIM specimens.

Multilayered structure at L11 in parts: (A) CIM, (B) RHCM. The heating surface of the RHCM part is on the bottom side.

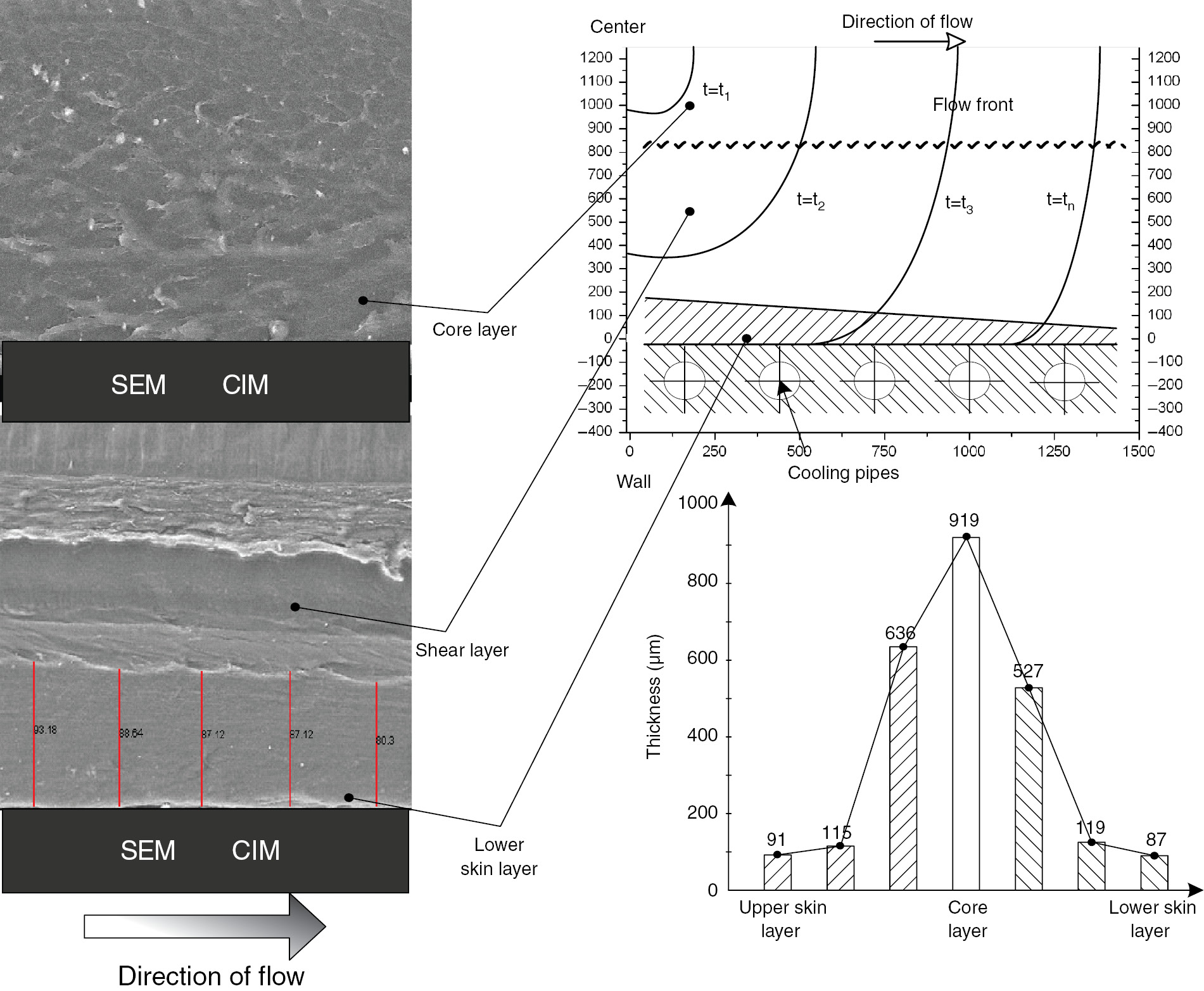

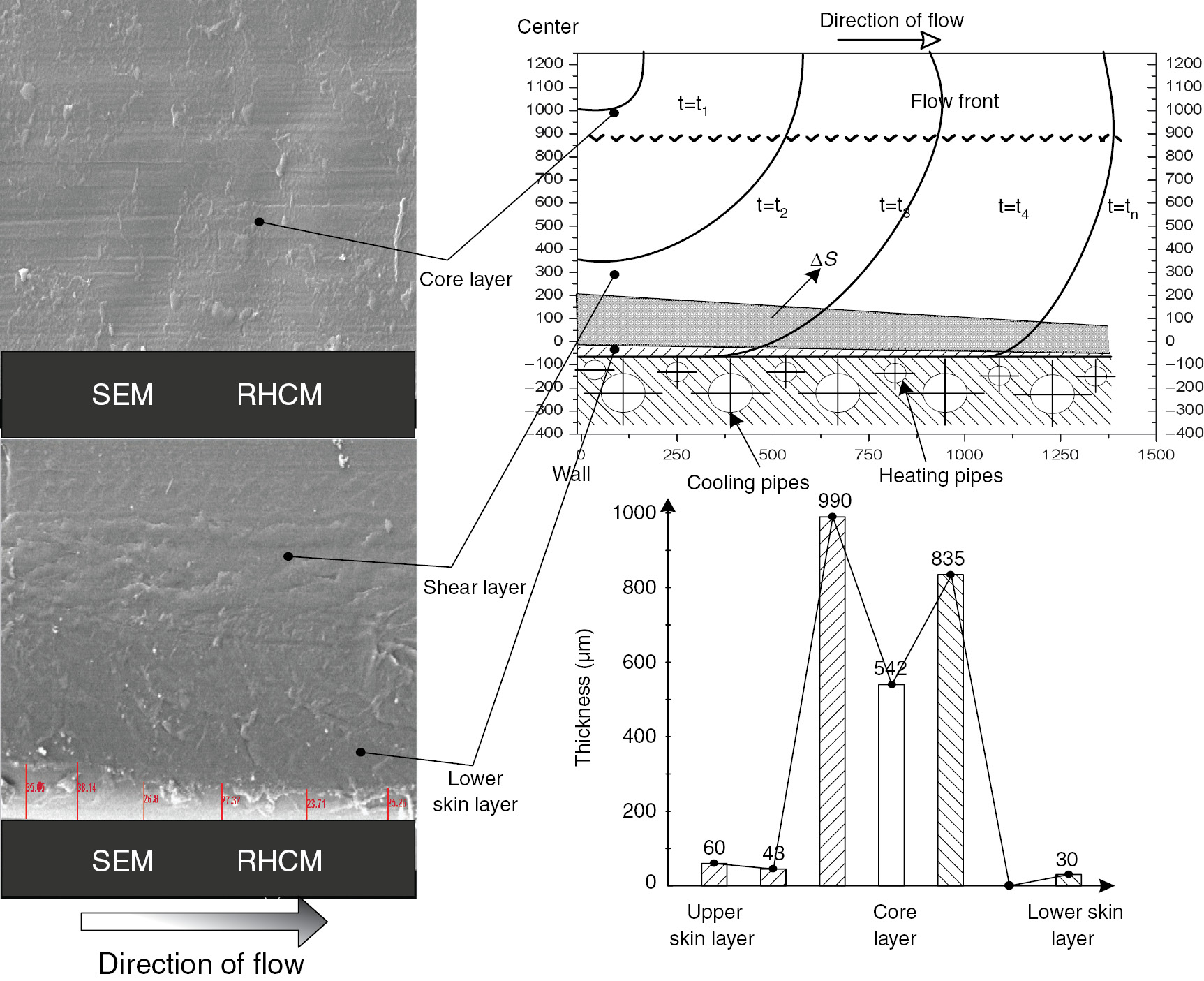

Figure 2A shows the multilayered structure of the CIM part. The thicknesses of the skin layers were almost the same on both sides as expected [34]. However, the multilayered structure of the RHCM part was different from that of the CIM part. The thickness of the skin layer next to the rapidly heated stationary mold half was noticeable smaller than that of the opposite side next to the movable mold half. To more closely examine the skin layer, additional SEM analyses were conducted on the area close to the stationary half of the CIM and RHCM parts and the results are shown in Figures 3 and 4, respectively. It can be seen that the thickness of the skin layer decreased gradually along with the flow length, as shown in Figure 3. The thickness of the RHCM skin layer next to heated stationary half was less than that of CIM, as shown in Figure 4. The difference between them was marked as the region ΔS in Figure 4.

Thickness variation of the multilayered structure next to the stationary half in the CIM part with an average skin layer thickness of 87 μm.

Thickness variation of the multilayered structure next to the stationary half in the RHCM part with an average skin layer thickness of 30 μm.

The different multilayered structures were due to the different temperature gradients and shear variations during the filling stage resulting from the different molding processes employed. During the filling stage, the polymer melt flow was considered to be a creeping laminar (Hele-Shaw) flow. In the flow front area, the melt at the center with higher speed flowed toward the wall, forming a complex “fountain” flow.

In CIM, temperature distributions on the movable and stationary halves were almost the same, and the melt front filled the cavity in a typical “fountain flow” manner, as shown in Figure 3. However, in RHCM, temperatures on the stationary and movable halves differed from each other, which resulted in different temperature gradients between the melt close to both halves, and thus led to asymmetric “fountain flow” behavior in the forefront flow, as shown in Figure 4.

During the filling stage of CIM, the melt on the cavity surface of the flow front was rapidly cooled by the cold mold, and solidified to form a thin frozen layer between the mold surface and the melt, forming the skin layer of the molded part. The more solidification that happened during the ensuing flow thickened the solidified layer with frozen-in molecular elongation and lamellae orientation. The subsequently solidified polymer layer in the molded part constituted the shear layer with a highly oriented structure. During the packing and cooling stage, the packing pressure pushed the remaining polymer melt to continue to flow in order to compensate for the volume shrinkage due to the cooling, solidification, and crystallization. As the rates of cooling, crystallization and solidification of the remaining melt were much slower in the core region, the oriented polymer had time to greatly disorient via relaxation before completely solidifying, which introduced the lower lamellae orientation disappeared in the shear or skin layers. The temporal and spatial changes of flow, shear stress and cooling led to the variation of the morphological distribution from a highly oriented structure in the shear layer to a less-oriented structure in the core layer, as shown in Figure 3.

In RHCM, the mold is heated rapidly before injection and cooled during the cooling stage. Because only the stationary half of the RHCM mold was heated in this study, the melt next to the stationary half flowed under a higher temperature, which introduced a thinner skin layer. The two surfaces of the part were subjected to different temperature and shear fields. The different thermomechanical histories induced the thickness variation of the multilayered structure on the different sides, especially in the regions next to the mold wall, defined as ΔS of the skin layer in Figure 4.

3.2 Crystallization and lamellae orientation of layers at the same location

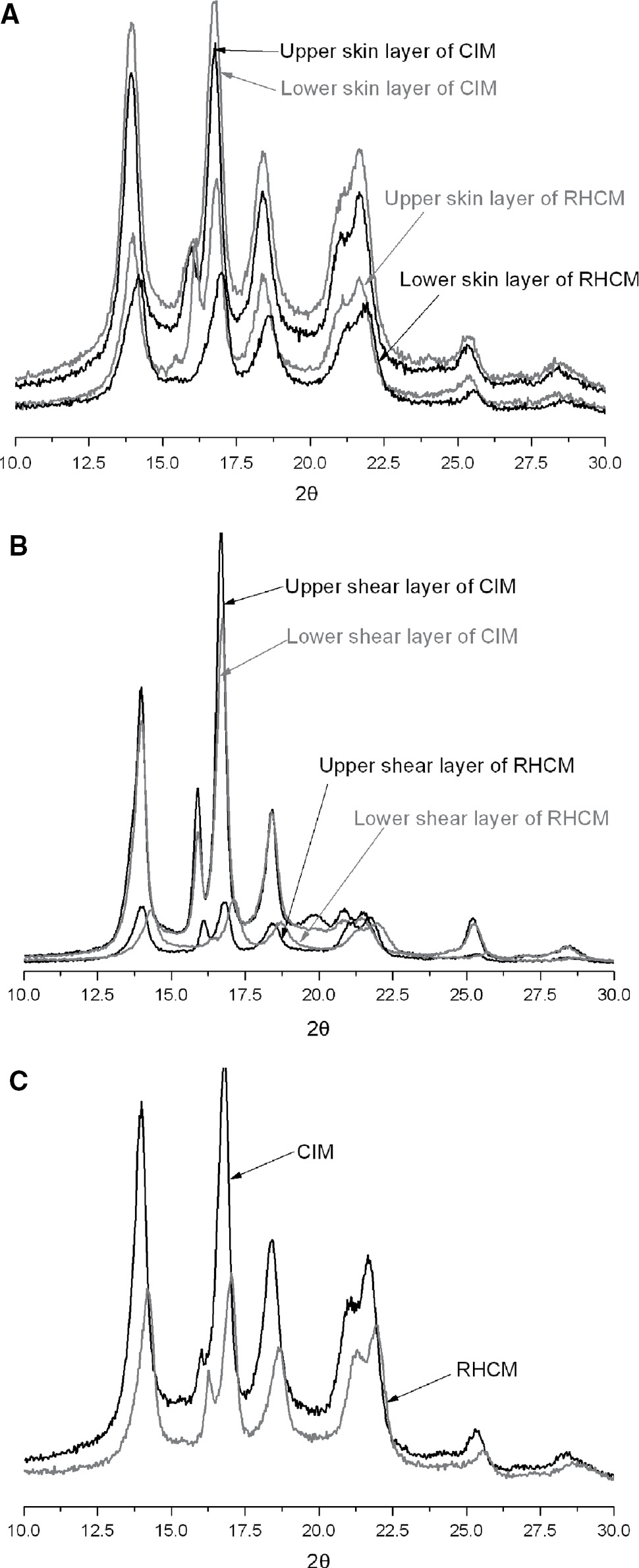

The aforementioned study suggested that the thicknesses of multilayered structures differ between parts molded by RHCM and CIM. The different thicknesses were caused by the variation of temperature and shear fields due to the different mold surface temperatures. The different temperature and shear fields also led to the variations in the crystallization and lamellae orientation at each layer in the multilayered structure. Hence, further investigation was conducted on the crystallization and lamellae orientation of the multilayered structure at the skin layer, shear layer and core layer at the same CIM and RHCM sampling location. WAXD was conducted on different layers of the samples sliced from the CIM and RHCM parts and the resultant X-ray diffraction patterns are shown in Figure 5.

WAXD patterns at different layers of CIM and RHCM parts: (A) skin layer, (B) shear layer, and (C) core layer.

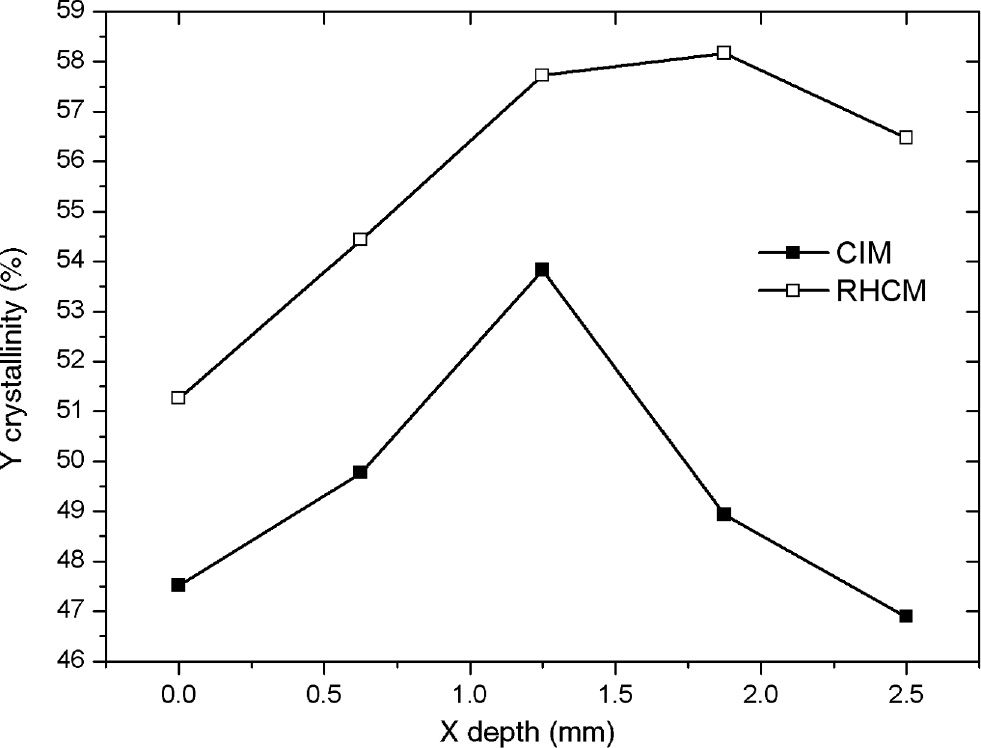

Based on Figure 5, the data of crystallization and lamellae orientation of each layer were obtained through measurements and calculations and were plotted in Figures 6 and 7. According to Figure 6, the crystallinity in all layers of sampling points of the RHCM part was higher than its CIM counterpart, and the variation trend of crystallinity in the thickness direction of the RCHM part differed from that of the CIM part. The crystallinity distribution was centro-symmetric in CIM, but not in RHCM. The variation trend from the skin layer next to the moving half to the core layer of the RHCM part was consistent with that of CIM, but the variation trend from the core layer to the opposite skin layer was very different from that of CIM. The crystallinity of the CIM part increased from the skin layer to the core layer; it was a minimum at the skin layer and increased gradually inward until it reached a maximum at the core.

Crystallinity Wc, x(%) at different depths at sampling points in CIM and RHCM parts.

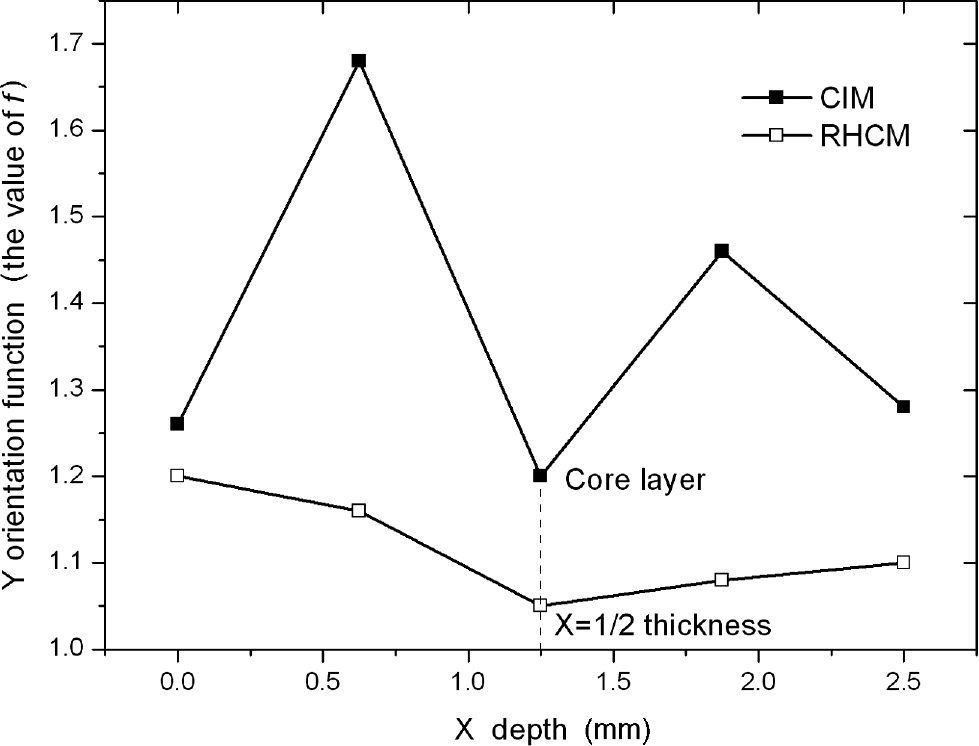

Orientation degree f of different depths at the sampling points of the CIM and RHCM parts.

The crystallinity increased from the skin layer next to the moving half to the core layer continuously in the RHCM part; this trend was similar to that of CIM, as shown in Figure 6. However, the crystallinity was relatively uniform without obvious variation from the skin layer next to the heated stationary half to the core layer in the RHCM part. This relative uniformity was due to the fact that the skin layer next to the stationary half was adjacent to the heated surface. The heated mold surface improved the temperature and fluidity of the melt next to the mold surface, and reduced the gradient of temperature and stress throughout the region from the skin layer next to the stationary half to the core layer. The higher temperature of the polymer melt induced the higher crystallinity, and the lower gradient of temperature and stress of the polymer melt facilitated the more uniform distribution in crystallization.

The degree of lamellae orientation of the sampling points in the thickness direction of CIM and RHCM parts also differed, as shown in Figure 7. In the CIM part, the degree of lamellae orientation was also roughly centro-symmetric, which increased and then decreased from the skin layer to the core layer. The degree of lamellae orientation reached a maximum at the shear layer and reached a minimum at the core layer. For the RHCM part, the degree of lamellae orientation of the different layers varied slightly, and the degree of lamellae orientation of all layers were less than those in the CIM part. The maximum degree of lamellae orientation was at the skin layer next to the moving half, and it decreased slightly to a minimum at the core layer. Then it increased slowly until reaching the skin layer next to the heated stationary half, at which point the degree of lamellae orientation was less than that of the opposite skin layer. The variation of lamellae orientation was attributed to the different flow and temperature histories of the RHCM and CIM molding processes.

In CIM, the polymer melt front was quenched by the cold mold wall during filling and the melt adjacent to the cold mold wall was frozen with a high degree of elongation, which introduced oriented lamellae when the polymer crystallized. But there was not enough time for the polymer to form oriented lamellae because of the low temperature. Therefore, the degree of lamellae orientation was relatively small at the skin layer. The flow behind the forefront was laminar, and the polymer melt next to the frozen layer solidified slowly under high shear conditions during filling, which introduced the high lamellae orientation. The degree of lamellae orientation reached the larger orientation degree of 1.68 at an X depth of 625 μm. Beyond the shear layer and close to the core, the polymer melt did not solidify during the filling stage, and there was enough time to release the shear stress and relax the polymer molecular chains. Thus, the degree of lamellae orientation declined again from the shear layer to the core layer.

In RHCM, the heated stationary half kept the polymer temperature high in the mold cavity. The higher polymer temperature increased the fluidity of the polymer melt and reduced the cooling rate of the polymer during filling, which led to a relatively even distribution of temperature and less shear stress in the polymer. For orientation, temperature and stress were the most important influential factors. The stress mainly affected the formation of the lamellae orientation, while the temperature mainly influenced the relaxation of the lamellae orientation. Thus, there was less lamellae orientation in the RHCM part than in the CIM part.

In summary, the crystallization and lamellae orientation in the RHCM and CIM parts were distinctly different resulting from the different temperatures of the mold surface during molding. The higher mold surface temperature in RHCM introduced different temperature and shear histories of the polymer melt than in CIM, which resulted in different degrees of crystallization and lamellae orientation. In CIM, the orientation degrees of the skin and the shear layer were higher, while the crystallinity of the core layer was the largest. However in RHCM, the lamellae orientation and crystallization showed much less variation throughout the thickness and the various layers.

3.3 Crystallization and orientation of the skin layer at multiple sites

As mentioned previously, the crystallization and lamellae orientation were dependent on the layers in the molded parts. They were influenced greatly by the temperature and shear histories of the polymer caused by the different molding processes. The different temperature and shear histories were not only caused by the molding process, but also related to the location in the mold cavity which mainly depended on the filling direction, flow distance, and local melt front speed.

The results presented previously showed that there were more differences in crystallization and lamellae orientation in the skin layer between the RHCM and CIM parts. A previous study (33) also showed that the thicknesses of the skin layer varied the most in the molded parts. In short, the differences of the microstructure between the RHCM part and CIM part were most obvious in the skin layer. Thus, the crystallization and orientation in the skin layer at multiple sites along three different flow directions of the RHCM part will be presented in this section. The sampling sites and three flow directions are shown in Figure 1.

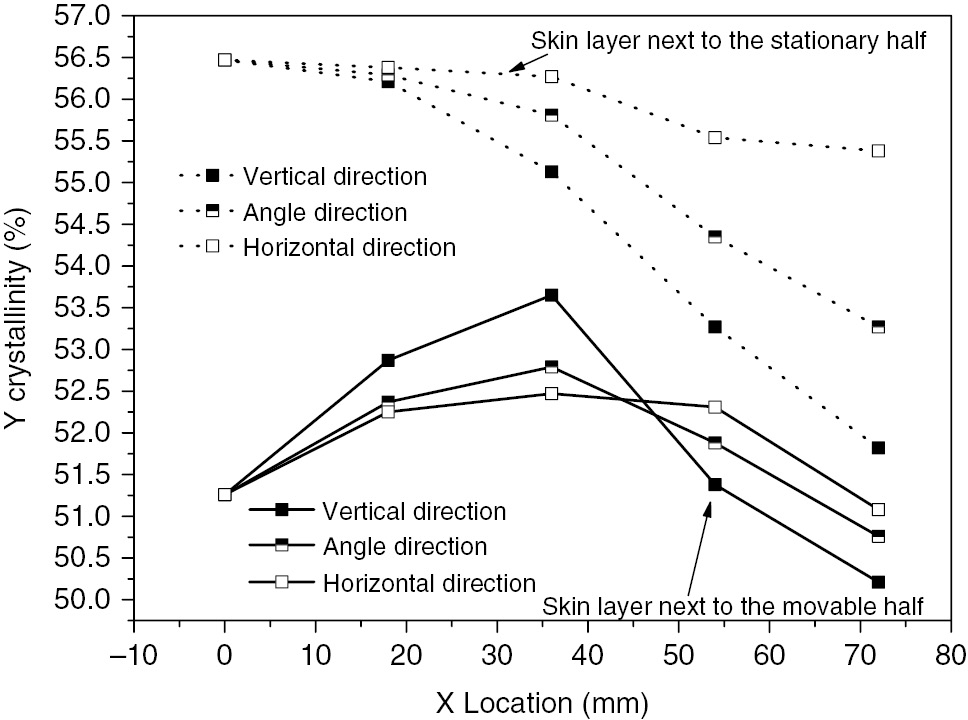

The crystallinity of the skin layers at the multiple sites are shown in Figure 8, where the direction from point L11 to point L55 was defined as the angle direction; the direction from point L11 to L15 was defined as the horizontal direction; and the direction from the point L11 to point L51 was defined as the vertical direction. There were distinguishable differences between both skin layers in these three different flow directions.

Crystallinities at the both skin layers in three flow directions of the RHCM part.

The crystallinity of the skin layer next to the heated stationary half was greater than that of the opposite skin layer, especially next to the gate location. The higher crystallinity was because the skin layer next to the stationary half was heated before filling, and the heated mold surface thinned out the skin layer and improved the fluidity of the melt. Therefore, the temperature field and stress field gradients were reduced throughout the region from the skin layer next to the stationary half to the core layer, which provided favorable temperature and shear conditions for crystallization.

The variations of crystallinity in the corresponding skin layers were mainly consistent in the three directions, but there was an obvious distinction between the variation tendency of the crystallinity in the skin layer next to the heated stationary half and the opposite skin layer. The crystallinity in the skin layer next to the heated stationary half decreased slightly before it dropped greatly at a sampling point 34 mm away from the gate inlet. Meanwhile, the crystallinity in the skin layer next to the moving half increased continuously, reaching a maximum at X=34 mm, and then decreased continually.

The crystallinity was dependent on the combination of crystal nucleation and crystal growth, and was mainly dependent on the shear and thermal histories in the polymer (35). For the polymer next to the gate location, the stronger shear accelerated the crystal nucleation but reduced the crystal growth, while the higher temperature reduced the crystal nucleation but enhanced the crystal growth. For the polymer far from the gate location, the polymer shear and temperature deceased gradually so that the speed of crystal nucleation and growth varied correspondingly.

For the skin layer next to the stationary half, the heated mold surface reduced the temperature gap between the melt and the mold surface and induced a relatively uniform temperature distribution across the polymer. The shear history thus played a more important role in the crystallinity than the temperature. The shear decreased as the flow distance increased because of the increasing melt front area. Correspondingly, the crystal nucleation decreased and the crystallinity diminished along the flow distance.

For the skin layer next to the moving half, the polymers along the flow path went through greater differences because the mold surface was much colder than the polymer melt during filling. Next to the gate location, the flow speed was very high, so the crystal growth was restricted and the influence on the crystallinity of the shear history was greater than that of the temperature history. Hence the crystallinity was not high next to the gate location. For the polymer slightly away from the gate location, the flow speed and temperature decreased and the crystals were easier to grow, although the crystal nucleation rate continued to decrease. Hence the crystallinity reached a maximum at around 34 mm before cooling and the weaker effect of shear took effect. Thus, the crystallinity at a greater distance from the injection location would be lower due to rapid cooling and weaker nucleation.

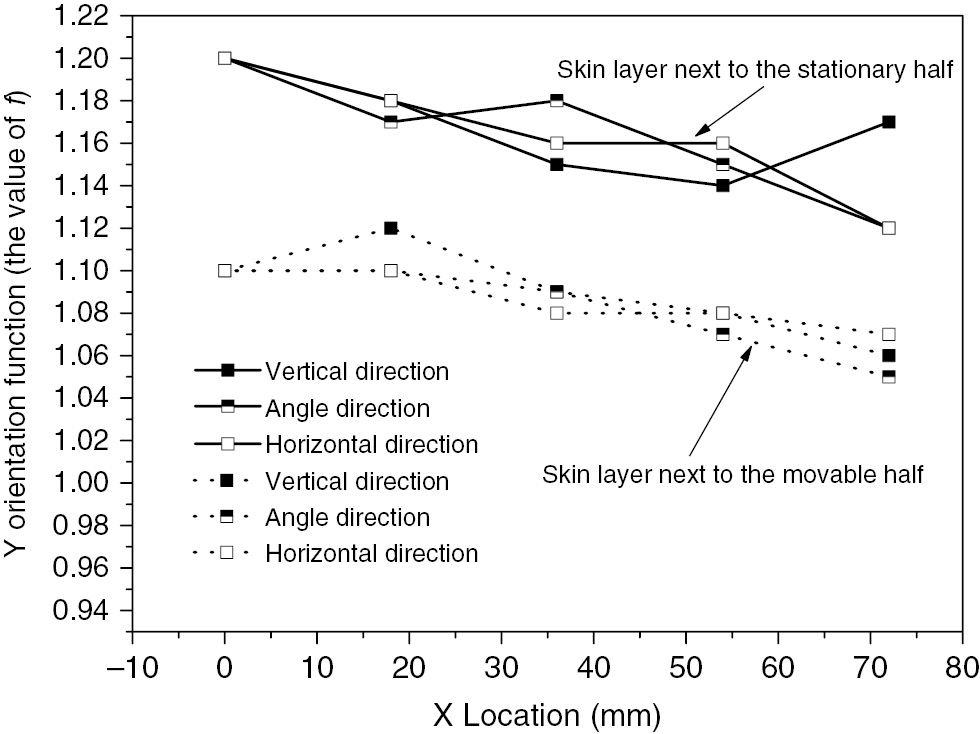

The lamellae orientation of the skin layers in the RHCM part is shown in Figure 9. The lamellae orientation didn’t vary as much as the crystallinity along the flow distance. The degrees of lamellae orientation of the skin layer next to the stationary half varied consistently; their values increasing to a maximum at X=18 mm, and then decreasing continuously thereafter. The degrees of lamellae orientation of the skin layer next to the moving half were higher than that of the opposite skin layer in the three directions and varied from each other, but the overall variation tendency was in accordance, which decreased slightly as the flow distance increased and the shear effect decreased.

Degree of lamellae orientation of skin layer in filling direction of RHCM part.

The skin layer next to the stationary half was adjacent to the heated mold surface, and the lower cooling rate and higher fluidity of the polymer lowered the gradients of the temperature field and the stress field of the polymer from the skin layer next to the stationary half to the core layer. While the skin layer next to the moving half was adjacent to the unheated mold surface, the shear stress of the polymer was always higher. Therefore, the lamellae orientation of the skin layer next to the moving half was higher than that of the opposite skin layer.

4 Conclusions

In this study, crystallization and lamellae orientation in iPP parts molded by RHCM and CIM were investigated using SEM and WAXD at both a single reference point and at multiple sites in three flow directions. The distribution and variation of crystallization and lamellae orientation of each layer in a multilayered structure were quantified. The following results were obtained. (1) The multilayered structure of the CIM part was obviously different from that of the RHCM part in this study (due to asymmetric heating on both sides of the mold halves), and the thickness variation of the skin layer was evident. (2) The crystallization and lamellae orientation of the skin layer, shear layer and core layer in the RHCM and CIM parts were significantly relevant to the distribution of the multilayered structure. The thickness, crystallization and orientation of the skin layer were impacted by the RHCM process. (3) The degree of lamellae orientation of the skin layer next to the heated stationary half in the RHCM part was lower than that of the opposite skin layer, while the crystallinity was higher than that of the opposite skin layer. The degree of lamellae orientation of the skin decreased gradually with an increasing flow distance. Furthermore, the variation of crystallinity was also affected by the flow distance.

Funding source: National Natural Science Foundation of China

Award Identifier / Grant number: 51575491

Award Identifier / Grant number: 51375451

Funding source: Natural Science Foundation of Zhejiang Province

Award Identifier / Grant number: LY15E050015

Funding statement: This project is supported by National Natural Science Foundation of China (Grant No. 51575491 and No. 51375451), Natural Science Foundation of Zhejiang Province (Grant No. LY15E050015), and the Wisconsin Institute for Discovery at the University of Wisconsin-Madison.

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant No. 51575491 and No. 51375451), Natural Science Foundation of Zhejiang Province (Grant No. LY15E050015), and the Wisconsin Institute for Discovery at the University of Wisconsin-Madison.

References

1. Zhou HM. Computer Modeling for Injection Molding: Simulation, Optimization, and Control. Hoboken: Wiley; 2013.10.1002/9781118444887Search in Google Scholar

2. Zhao P, Wang S, Ying J, Fu JZ. Non-destructive measurement of cavity pressure during injection molding process based on ultrasonic technology and gaussian process. Polym Test. 2013;32(8):1436–44.10.1016/j.polymertesting.2013.09.006Search in Google Scholar

3. Yao DG, Chen SC, Kim BH. Rapid thermal cycling of injection molds: an overview on technical approaches and applications. Adv Polym Tech. 2009;27(4):233–55.10.1002/adv.20136Search in Google Scholar

4. Chen SC, Jong WR, Chang JA. Dynamic mold surface temperature control using induction heating and its effects on the surface appearance of weld line. J Appl Polym Sci. 2006;101(2):1174–80.10.1002/app.24070Search in Google Scholar

5. Wang GL, Zhao GQ, Wang XX. Effects of cavity surface temperature on mechanical properties of specimens with and without a weld line in rapid heat cycle molding. Mater Design. 2013;46:457–72.10.1016/j.matdes.2012.10.054Search in Google Scholar

6. Yang D, Zhao P, Zhou HM, Chen L. Computer determination of weld lines in injection molding based on filling simulation with surface model. J Reinf Plast Comp. 2014;33(15):1403–15.10.1177/0731684414535277Search in Google Scholar

7. Wang GL, Zhao GQ, Wang XX. Effects of cavity surface temperature on reinforced plastic part surface appearance in rapid heat cycle moulding. Mater Design. 2013;44:509–20.10.1016/j.matdes.2012.08.039Search in Google Scholar

8. Carrasco F, Gamez-Perez J, Santana O, Maspoch ML. Processing of poly (lactic acid)/organomontmorillonite nanocomposites: microstructure, thermal stability and kinetics of the thermal decomposition. Chem Eng J. 2011;178:451–60.10.1016/j.cej.2011.10.036Search in Google Scholar

9. Kantz M, Newman H, Stigale F. The skin-core morphology and structure-property relationships in injection-molded polypropylene. J Appl Polym Sci. 1972;16(5):1249–60.10.1002/app.1972.070160516Search in Google Scholar

10. Guo X, Isayev AI, Guo L. Crystallinity and microstructure in injection moldings of isotactic polypropylenes. Part 1: a new approach to modeling and model parameters. Polym Eng Sci. 1999;39(10):2096–114.10.1002/pen.11601Search in Google Scholar

11. Guo X, Isayev AI, Demiray M. Crystallinity and microstructure in injection moldings of isotactic polypropylenes. Part II: simulation and experiment. Polym Eng Sci. 1999;39(11):2132–49.10.1002/pen.11603Search in Google Scholar

12. Zhou YX, Mallick PK. Effects of melt temperature and hold pressure on the tensile and fatigue propertied of an injection molded talc-filled polypropylene. Polym Eng Sci. 2005;45(6):755–63.10.1002/pen.20301Search in Google Scholar

13. Zhang J, Zeng T, Zhu J, Lei YW, Shen KZ, Fu Q. Crystal form and orientation of isotactic polypropylene samples prepared by vibration-injection molding. J Appl Polym Sci. 2007;106(3):1456–61.10.1002/app.26554Search in Google Scholar

14. Trotignon J-P, Verdu J. Skin-core structure-fatigue behavior relationships for injection-molded parts of polypropylene. I. Influence of molecular weight and injection conditions on the morphology. J Appl Polym Sci. 1987;34(1):1–18.10.1002/app.1987.070340101Search in Google Scholar

15. Fujiyama M, Wakino T, Kawasaki Y. Structure of skin layer in injection-molded polypropylene. J Appl Polym Sci. 1988;35(1):29–49.10.1002/app.1988.070350104Search in Google Scholar

16. Chen LM, Shen K. Biaxial self-reinforcement of isotactic polypropylene prepared in uniaxial oscillating stress field by injection molding. II. Morphology. J Appl Polym Sci. 2000;78(11):1911–7.10.1002/1097-4628(20001209)78:11<1911::AID-APP90>3.0.CO;2-MSearch in Google Scholar

17. Pantani R, Coccorullo I, Speranza V, Titomanilo G. Modeling of morphology evolution in the injection molding process of thermoplastic polymers. Prog Polym Sci. 2005;30(12):1185–222.10.1016/j.progpolymsci.2005.09.001Search in Google Scholar

18. Viana JC, Cunha AM, Billon N. The thermomechanical environment and the microstructure of an injection moulded polypropylene copolymer. Polymer 2002;43(15):4185–96.10.1016/S0032-3861(02)00253-7Search in Google Scholar

19. Mendoza R, Regnier G, Seiler W, Lebrun J. Spatial distribution of molecular orientation in injection molded ipp: influence of processing conditions. Polymer 2003;44(11):3363–73.10.1016/S0032-3861(03)00253-2Search in Google Scholar

20. Somani RH, Yang L, Hsiao BS, Sun T, Pogodina NV, Lustiger A. Shear-induced molecular orientation and crystallization in isotactic polypropylene: effects of the deformation rate and strain. Macromolecules 2005;38(4):1244–55.10.1021/ma048285dSearch in Google Scholar

21. Kim KH, Isayev AI, Kwon K. Flow-induced crystallization in the injection molding of polymers: A thermodynamic approach. J Appl Polym Sci. 2005;95(3):502–23.10.1002/app.21228Search in Google Scholar

22. Zhang B, Chen JB, Cui J, Zhang H, Ji FF, Zheng GQ, Heck B, Reiter GN, Shen CY. Effect of shear stress on crystallization of isotactic polypropylene from a structured melt. Macromolecules 2012;45(21):8933–7.10.1021/ma3014756Search in Google Scholar

23. Zhou HM, Ying JR, Xie XL, Liu F, Li DQ. Nonisothermal crystallization behavior and kinetics of isotactic polypropylene/ethylene-octene blends. part ii: modeling of crystallization kinetics. Polym Test. 2010;29(7):915–23.10.1016/j.polymertesting.2010.06.004Search in Google Scholar

24. Cermak R, Obadal M, Ponizil P, Polaskova M, Stoklasa K, Lengalova A. Injection-moulded α- and β-polypropylenes: i. structure vs. processing parameters. Eur Polym J. 2005;41(8):1838–45.10.1016/j.eurpolymj.2005.02.020Search in Google Scholar

25. Nogales A, Hsiao B, Somani R, Srinivas S, Tsou A, Balta-Calleja F, Ezquerra T. Shear-induced crystallization of isotactic polypropylene with different molecular weight distributions: in situ small-and wide-angle x-ray scattering studies. Polymer 2001;42(12):5247–56.10.1016/S0032-3861(00)00919-8Search in Google Scholar

26. Chen JF, Yin L, Yang XN, Chen EL. Relating the molecular structure and crystallization behavior of polypropylene. Polym Eng Sci. 2004;44(9):1749–54.10.1002/pen.20176Search in Google Scholar

27. Zhong GJ, Li ZM, Li LB, Mendes E. Crystalline morphology of isotactic polypropylene (ipp) in injection molded poly(ethylene terephthalate)(pet)/ipp microfibrillar blends. Polymer 2007;48(6):1729–40.10.1016/j.polymer.2007.01.056Search in Google Scholar

28. Zipper P, Jánosi A, Wrentschur E, Abuja PM. Small- and wide- angle x-ray scattering investigations of injection-moulded polypropylene. J Appl Crystallogr. 1991;24(5):702–8.10.1107/S0021889891001917Search in Google Scholar

29. Chen SC, Lin YW, Chien RD, Li HM. Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv Polym Tech. 2008;27(4):224–32.10.1002/adv.20133Search in Google Scholar

30. Yu MC, Young WB, Hsu PM. Micro-injection molding with the infrared assisted mold heating system. Mater Sci Eng A-Struct. 2007;460(14):288–95.10.1016/j.msea.2007.02.036Search in Google Scholar

31. Shen YK, Shie YJ, Wu WY. Extension method and numerical simulation of micro-injection molding. Int Commun Heat Mass. 2004;31(6):795–804.10.1016/S0735-1933(04)00066-1Search in Google Scholar

32. Zhang AM, Zhao GQ, Guan YJ, Chen GW. Study on mechanical and flow properties of acrylonitrile-butadiene-styrene/poly (methyl methacrylate)/nano-calcium carbonate composites. Polym Composite. 2010;31(9):1593–602.10.1002/pc.20947Search in Google Scholar

33. Li JQ, Zhen W, Jiang SF, Chai GZ. An experimental study of skin layer in rapid heat cycle molding. Polym-Plast Technol Eng. 2014;53(5):488–96.10.1080/03602559.2013.845210Search in Google Scholar

34. Mo ZS, Zhang HF. Structure and x-ray diffraction of crystalline polymer. Beijing: Science Press; 2003.Search in Google Scholar

35. Yang B, Lin JZ, Xia R, Su LF, Miao JB, Qian JS, Chen P, Liu JW, Deng SQ. Correlation between solidification behavior and melt crystallization kinetics of isotactic polypropylene (ipp) during injection molding. J Macromol Sci B. 2014;53(3):462–73.10.1080/00222348.2013.845060Search in Google Scholar

©2017 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- In this Issue

- Editorial

- Innovations in polymers and composite materials

- Full length articles

- Preparation and properties of chemically reduced graphene oxide/copolymer-polyamide nanocomposites

- Synthesis and properties of well-defined carbazole-containing fluorescent star polymers of different arms

- The effect of high-current pulsed electron beam modification on the surface wetting property of polyamide 6

- Synthesis and application of waterborne polyurethane fluorescent composite

- Medicated structural PVP/PEG composites fabricated using coaxial electrospinning

- Research of the thermal aging mechanism of polycarbonate and polyester film

- Damage indication of 2′, 7′-dichlorofluorescein for epoxy polymer and the effect of water on its damage indicating ability

- Synthesis and characterization of thermosensitive and polarity-sensitive fluorescent PNIPAM-coated gold nanoparticles

- Comparative study of crystallization and lamellae orientation of isotactic polypropylene by rapid heat cycle molding and conventional injection molding

- Determination of deformation of a highly oriented polymer under three-point bending using finite element analysis

- Kinetic studies on the cure reaction of hydroxyl-terminated polybutadiene based polyurethane with variable catalysts by differential scanning calorimetry

- Preparation and swelling properties of poly(acrylic acid-co-acrylamide) composite hydrogels

Articles in the same Issue

- Frontmatter

- In this Issue

- Editorial

- Innovations in polymers and composite materials

- Full length articles

- Preparation and properties of chemically reduced graphene oxide/copolymer-polyamide nanocomposites

- Synthesis and properties of well-defined carbazole-containing fluorescent star polymers of different arms

- The effect of high-current pulsed electron beam modification on the surface wetting property of polyamide 6

- Synthesis and application of waterborne polyurethane fluorescent composite

- Medicated structural PVP/PEG composites fabricated using coaxial electrospinning

- Research of the thermal aging mechanism of polycarbonate and polyester film

- Damage indication of 2′, 7′-dichlorofluorescein for epoxy polymer and the effect of water on its damage indicating ability

- Synthesis and characterization of thermosensitive and polarity-sensitive fluorescent PNIPAM-coated gold nanoparticles

- Comparative study of crystallization and lamellae orientation of isotactic polypropylene by rapid heat cycle molding and conventional injection molding

- Determination of deformation of a highly oriented polymer under three-point bending using finite element analysis

- Kinetic studies on the cure reaction of hydroxyl-terminated polybutadiene based polyurethane with variable catalysts by differential scanning calorimetry

- Preparation and swelling properties of poly(acrylic acid-co-acrylamide) composite hydrogels