Abstract

This study was aimed to develop a quick detection method to test aldehydes and ketones in textiles in order to control the quality of automotive textiles in the development process from fabric production to end-use in vehicles. In this study, a pretreatment of samples was applied to simulate the actual environment of textiles used in vehicles. Collected volatiles were reacted with 2,4-dinitrophenylhydrazine and then eluted with acetonitrile tetrahydrofuran. The eluent was analyzed with high-performance liquid chromatography. Findings showed more than 90% volatiles could be detected in the established method; the lowest determination limit was 0.0297 mg/mL; and the lowest quantification limit was 0.0991 mg/mL, which meant sensitivity and capability of the method were high. Regression coefficients of linear models between volatile concentrations and chromatographic peak characteristics were >0.995, indicating that the method could effectively and efficiently determine the contents of volatiles in automotive textiles.

1 Introduction

In the market of automobiles, textiles have become important parts to provide sufficient comfort and decoration, but volatile organic compounds (VOCs) that are often contained in automotive textiles have certain toxicity and could gradually evaporate to the air in vehicles. Aldehydes and ketones are the main VOCs in automotive textiles. These compounds are very harmful to human health and influence the sustainability of vehicles. Lots of testing standards are related to automotive VOC determination, but few research were carried out to detect volatile contents of textiles in vehicles. To improve the in-vehicle air quality, it is highly necessary to test VOC evaporated from automotive textiles in time [1,2]. Detection of VOC should be conducted in the entire production process of automotive textiles from fabric manufacturing to finishing to end products. Therefore, this study simulated the actual environment of textile using in vehicles and explored the high-performance liquid chromatography (HPLC) to determine the contents of aldehydes and ketones. The findings of this research enable highly effective and efficient determination of main toxic compounds volatilized from automotive textiles to control textile quality in the development process and to reduce air pollution in vehicles.

1.1 Testing standards of VOC

Current studies have shown that formaldehyde, benzaldehyde, and the other aldehydes and ketones are the main harmful volatile compounds in cars [3]. When some researchers analyzed VOC in vehicles, they found that the contents of formaldehyde and other aldehydes and ketones were higher than other compounds [4,5,6]. Thus, in this study, aldehydes and ketones are the main VOC detected in automotive textiles.

The literature reviews of testing standards present that the German Automobile Industry Association has proposed several testing standards for volatile substances in-vehicle parts. According to “Determination of Organic Emissions From Non-Metallic Materials in Vehicle Interiors” VDA 277-1995, volatile compounds under a static condition can be measured by the headspace method. “Thermo-Desorption Analysis of Organic Emissions for the Characterization of Non-Metallic Automobile Interior Materials” VDA 278-2002 specifies that volatile and semi-volatile substances can be determined by thermal desorption analysis under dynamic conditions. Tests for the entire vehicle part need to be done in a sealed compartment. In addition, Japan and Russia have proclaimed related testing standards to test organic volatiles in cars [7]. In China, the State Environmental Protection Administration has declared “Evaluating Guidelines for Air Quality in Passenger Vehicles” GB/T 27630-2011, which limits the contents of formaldehyde, acetaldehyde, and acrolein separately less than 0.10, 0.05, and 0.5 mg/m3 in vehicles [8].

Current testing standards of VOC focus on quantitative analysis of each compound in the car, rather than on general qualitative analysis. In addition, in the current testing methods, the air quality is measured in whole vehicles, and it is very difficult to supervise volatile substances in different vehicle parts before assembling, so that contents of VOC released from each part cannot be detected in time. To provide good air quality in vehicles, each in-vehicle part or interior materials including automotive textiles should be detected and meet standard requirements. Generally, there is a lack of specialized testing standards for detecting VOC in automotive textiles, so this study was aimed to establish an effective and reliable testing method to detect mainly aldehydes and ketones in automotive textiles before the car assembling.

1.2 Testing methods of aldehydes and ketones

Methods for volatile substances collection and analysis include detection module, headspace method, thermal analysis method, and sampling bag method [9,10]. The detection module method is commonly used to test VOC in the whole vehicle, and it is not suitable for interior textiles. The cost and testing conditions of this method are very high, and it is often applied by motor corporations or third-party testing organizations. The headspace method is easy to implement and the cost is relatively low. In this method, the entire quantity of organic volatile substances in vehicles is tested, but each substance cannot be analyzed. The thermal analysis method is only used to detect benzene and hydrocarbons. The sampling bag is the most common method used in Japanese car corporations. Tested samples are put into a sealed bag. This method is very convenient to operate and is friendly to small sample sizes. In comparison, the sampling bag is the most feasible method to collect aldehydes and ketones in automotive textiles.

Detection methods of aldehydes and ketones include gas chromatography and liquid chromatography [11,12,13]. When the contents of aldehydes and ketones in the air are less, the sensitivity and accuracy of instruments need to be high enough. In addition, compounds such as formaldehyde and acetone do not have UV-responsible groups to be detected in the UV detection method. Aldehydes and ketones could react with 2,4-dinitrophenylhydrazine (DNPH) in a strong acid condition, and the derivatives have high sensitivity in liquid chromatography [14]. According to “Determination of Formaldehyde in Ambient Air Using Adsorbent Cartridge Followed by High Performance Liquid Chromatography (HPLC)” EPA-TO-11, liquid chromatography is commonly used to detect aldehydes and ketones organic volatiles in the air. Therefore, this study selected HPLC to test aldehydes and ketones in automotive textiles.

2 Experimental design

2.1 Simulation of the inner environment in vehicles

The inner environment of vehicles is relatively complex. When windows and doors were closed for a certain time, in addition to aldehydes and ketones, lots of nitrogen exit inside the vehicle, and harmful volatile matters are hard to spread out [15]. Referring to standards “Interior Air of Road Vehicles—Part 2: Screening Method for the Determination of the Emissions of Volatile Organic Compounds from Vehicle Interior Parts and Materials—Bag Method” CNS15676-2-2013 and “Determination of Volatile Organic Compounds and Carbonyl Compounds in Cabin of Vehicles” HJ/T400-2007, the study designed sealed bags with insert materials such as polyvinylidene fluoride to isolate outside air and to avoid reaction with organic compounds in bags. Then the sealed bags were filled with pure and dry nitrogen to simulate the enclosed inner environment of vehicles.

When the vehicle is exposed to the sun for a long time, the inner temperature increases rapidly which can accelerate the volatilization of aldehydes and ketones in a short time [16]. In this study, treated samples were placed in an oven to simulate the condition of the sun exposure. Two aldehyde reagents and two ketone reagents were used to simulate VOC evaporated from automotive textiles.

2.2 Testing method

The sampling bag method was selected to collect VOCs in textiles. In the experiment, woven fabric samples were added with a certain amount of standard aldehyde and ketone solutions and quickly put into sealed bags. Five liters of highly pure nitrogen as an insert gas were used to fill 10 L sealed bags. To accelerate the volatile of aldehydes and ketones, sealed bags with treated samples were placed in an oven at 65°C for 2 h ± 5 min.

After cooling the bags, adsorption tubes filled with DNPH were used to adsorb aldehyde and ketone volatiles in bags. Organic volatiles can react with DNPH to form a stable hydrazine derivative in acidic conditions. Then adsorption tubes were eluted with acetonitrile tetrahydrofuran. The collected 5 mL eluent was analyzed by the HPLC method to determine the contents of each aldehyde and ketone volatiles. The testing conditions of HPLC are shown in Table 1.

Testing conditions of HPLC

| Items | Parameters |

|---|---|

| Chromatographic column | Agilent C18 (250 mm × 4.6 mm × 5 μm) |

| Injecting volume | 25 μL |

| Mobile phase | 45% pure water 55% acetonitrile tetrahydrofuran |

| Flow rate | 1 mL/min |

| Column temperature | 25°C |

| Detection wavelength of DAD | 360 nm |

| Spectral scanning range | 190–400 nm |

2.3 Material and solutions

In this study, to validate the efficiency and effectiveness of the pretreatment and the HPLC method, linear regression models of concentrations and chromatographic peaks were developed. Four aldehyde/ketone–DNPH solutions including formaldehyde, hexanal, butanone, and cyclohexanone were applied to investigate the effects of concentrations on liquid chromatography. Nine concentration levels of each standard aldehyde/ketone–DNPH solution were 15μ, 7.5μ, 3.75μ, 1.875μ, 0.9375μ, 0.4688μ, 0.2344μ, 0.0586μ, and 0.0293 μg/mL, respectively. With the lowest concentration (0.0293 μg/mL), 10 samples were treated with each mixed solution, yielding 40 samples. According to the results of liquid chromatography, limit of detection (LOD) and limit of quantitation (LOQ) in the HPLC method were identified.

Fabric samples were woven with polyester, and their size was 10 cm × 10 cm. Four types of aldehyde and ketone solutions added to woven fabrics were formaldehyde, hexanal, butanone, and cyclohexanone. Of note, 0.05 g pure solutions were mixed with acetonitrile solutions in 50 mL volumetric flask and made into 1000 μg/mL with standard aldehyde and ketone solutions. For each monomer solution, 100 μL was added to fabric samples for pretreatment and detected contents in HPLC were compared with the added amount.

3 Results and discussions

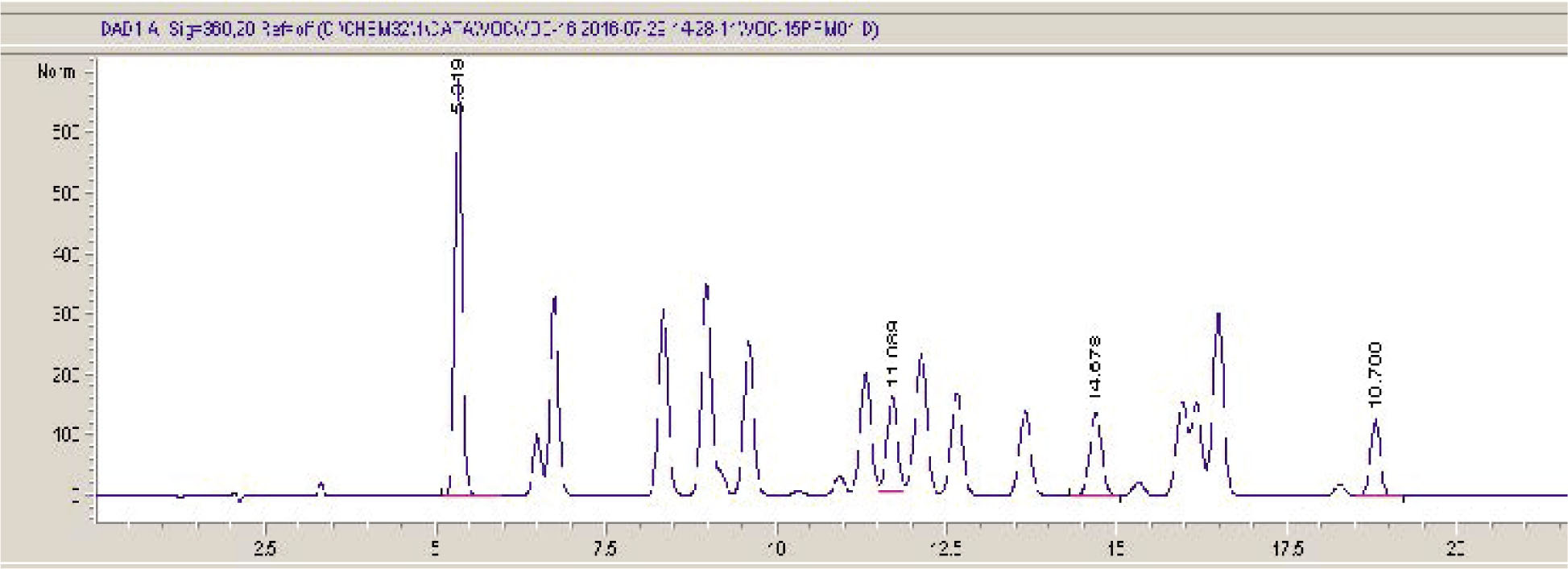

Clear chromatograms in Figure 1 indicated that each VOC could be separated in the method of liquid chromatography with the designed parameter setting. The retention time of formaldehyde, hexanal, butanone, and cyclohexanone could be obtained and is shown in Table 2.

The retention time of aldehyde and ketone volatiles

| Name | Retention time (min) |

|---|---|

| Formaldehyde | 5.319 |

| Hexanal | 18.780 |

| Butanone | 11.689 |

| Cyclohexanone | 14.678 |

High-performance liquid chromatograms.

3.1 Efficiency and effectiveness of the method

3.1.1 Linear analysis

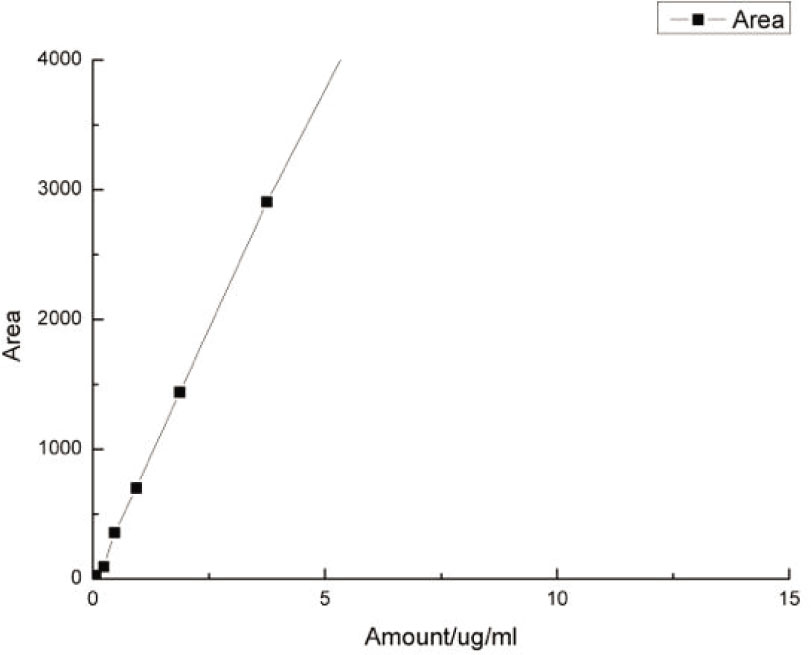

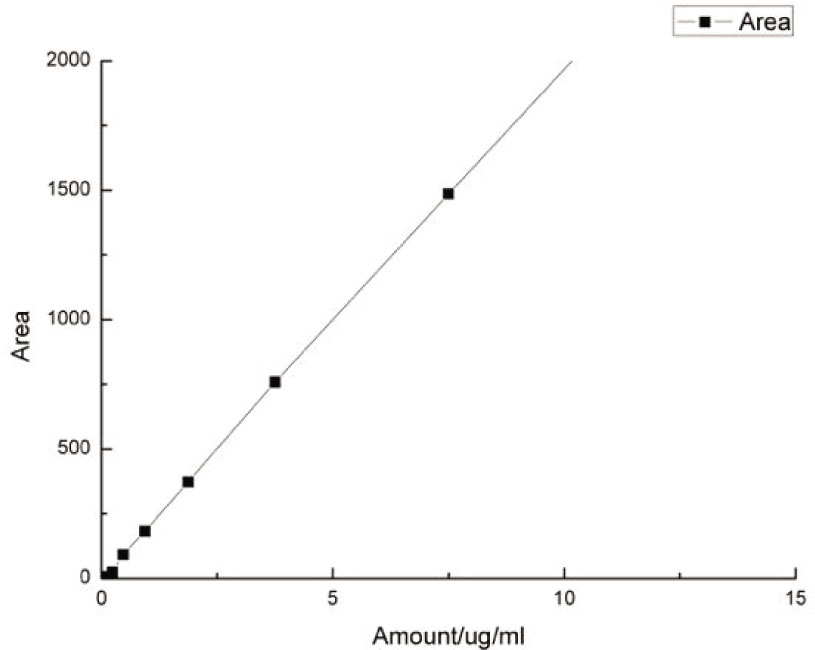

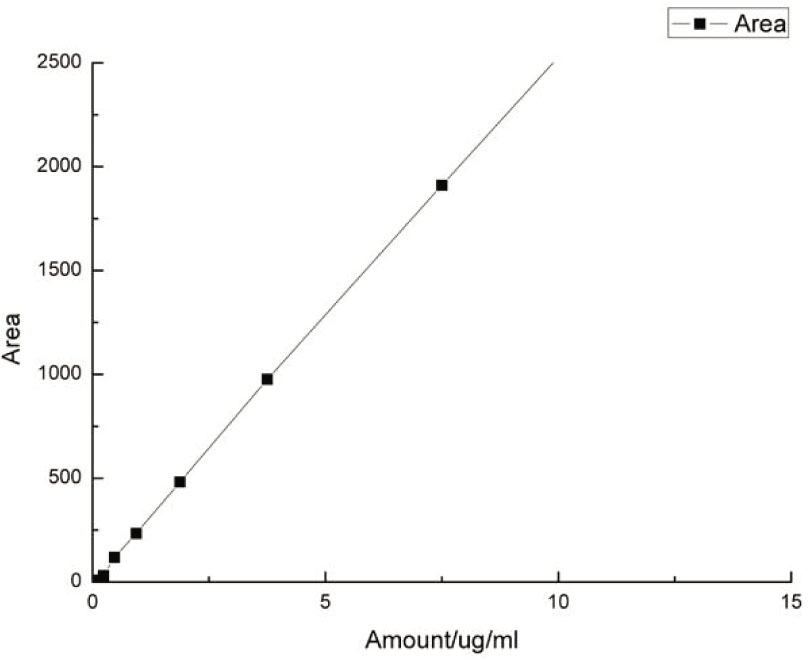

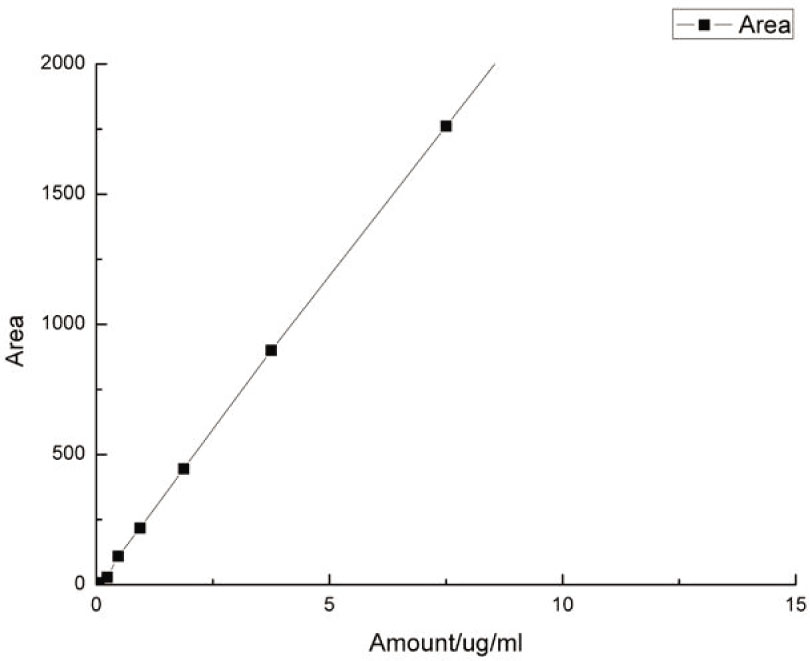

To estimate the efficiency of HPLC in determining volatiles of automotive textiles, linear analysis had been done to compare characteristic peak in chromatogram with the concentration of volatiles. High correlation means the method could effectively and efficiently determine the contents of the volatiles [17].

Testing results presented that the peak area for each volatile was raised with increasing concentrations. To verify the correlation between peak area and concentration, a linear model was established in the least square method as shown in the following equation:

where Ai means the peak area of aldehyde and ketone compounds in standard solutions and i = 4, representing formaldehyde, hexanal, butanone, and cyclohexanone; Ki is the slope of the linear model; Cj means the concentration of aldehyde and ketone compounds in standard solutions, and its unit is mg/mL, j = 9; and bi is the intercept of the linear model.

Linear models for formaldehyde, hexanal, butanone, and cyclohexanone are separately illustrated in Figures 2–5.

Linear regression of formaldehyde.

Linear regression of hexanal.

Linear regression of butanone.

Linear regression of cyclohexanone.

Regression coefficients of each model are listed in Table 3, and they are >0.995, indicating that four standard curves have very high linear correlations. Therefore, the peak area in chromatogram could be used to represent the contents of aldehyde and ketone compounds in tested samples, and the method provides an efficient and effective way of determining VOC of automotive textiles.

The linear model of four VOCs in automotive textiles

| Name | Linear model | Regression coefficients (R2) |

|---|---|---|

| Formaldehyde | y = 746.39 × −4.82 | =0.999 |

| Hexanal | y = 196.2 × −0.23 | =1.000 |

| Butanone | y = 252.01 × +0.79 | =1.000 |

| Cyclohexanone | y = 232.9 × −0.07 | =1.000 |

3.1.2 LOD and LOQ

LOD means the lowest concentration of VOC that could be detected on a test instrument, and LOQ means the lowest quantity that could be detected [18]. The values of LOD and LOQ represent the sensitivity and capability of a test method [19]. In this study, the four aldehyde/ketone–DNPH solutions with a 0.0293 μg/mL concentration were detected to identify their LOD and LOQ. Ten fabric samples were treated with each solution, and their chromatographic peak areas were collected. LOD and LOQ were calculated by the following equations:

where X̅ represents average value of 10 chromatographic peak areas; S is standard error; and C is equal to 0.0293 mg/mL.

In this study, LOD and LOQ of formaldehyde, butanone, cyclohexanone, and hexanal were obtained. According to the results in Table 4, LOD and LOQ are relatively low, which means the pretreatment method and HPLC method could detect VOC even with low concentration.

LOD and LOQ of main VOC

| Volatile | X̅ | S | LOD (μg/mL) | LOQ (μg/mL) |

|---|---|---|---|---|

| Formaldehyde | 15.32 | 6.07 | 0.0348 | 0.1160 |

| Butanone | 4.94 | 1.97 | 0.0351 | 0.1169 |

| Cyclohexanone | 12.01 | 23.03 | 0.1685 | 0.5618 |

| Hexanal | 4.07 | 1.38 | 0.0297 | 0.0991 |

3.2 Accuracy and precision of the method

Differences between the added quantity of aldehyde and ketone volatiles and the detected contents of those volatiles in HPLC could validate the accuracy of the method to determine VOC in automotive textiles. Lower differences prove less loss of VOC in the process of testing and declare that the results in HPLC can accurately present the contents of VOC in textiles. Usually, the ratio of detected contents and added quantity should be above 50% [20]. Precision was proved by the relative standard error (RSD) as shown in the following equation:

where n equals sample repeats; Xi represents detected content of volatiles in each sample; and X̅ represents average of detected contents.

In the experiment, 100 μL standard formaldehyde, hexanal, butanone, and cyclohexanone solutions were, respectively, added to blank woven fabrics. For each treatment, six samples were pretreated and detected contents of each volatile were collected.

In Table 5, differences between the added amount and detected contents are very low. Of note, 94.48% formaldehyde, 93.23% hexanal, 98.61% butanone, and 91.12% cyclohexanone could be detected. Findings reveal that HPLC is an easy and repeatable method that can accurately and precisely determine the contents of VOC in automotive textiles.

Comparison between added and detected contents

| Volatiles | Additive amount (μg/m2) | Detected content (μg/m2) | RSD | Ratio (%) |

|---|---|---|---|---|

| Formaldehyde | 17.92 | 16.93 | 0.051 | 94.48 |

| Hexanal | 24.38 | 22.73 | 0.051 | 93.23 |

| Butanone | 19.44 | 19.17 | 0.032 | 98.61 |

| Cyclohexanone | 23.32 | 21.25 | 0.042 | 91.12 |

4 Conclusions

Textiles are important parts of vehicles as interior decoration. Many chemical additives have to be added in automotive textiles to improve durability and colorfastness and to enhance properties such as wrinkle-free, flame retardant, and others. But these additives would increase the probability of VOC in textiles which affect customers’ health and reduce the sustainability of textile products definitely. At present, no specific testing standard of VOC in automotive textiles was issued. Therefore, in this study, a quick pretreatment was applied to simulate the inner environment in vehicles, and HPLC was used to analyze the collected eluent. Results of chromatographic peak area, LOD, and LOQ indicated that the pretreatment of test samples and HPLC could effectively and efficiently determine the contents of aldehydes and ketones in fabrics.

Findings in this study provide a useful method to test aldehyde and ketone volatiles in automotive textiles, as well as other in-vehicle products. In comparison with current VOC testing methods, this new detection method is more appropriate to test aldehyde and ketone volatiles in interior materials. This simple and quick method can be used in the entire development process of automotive textiles to detect harmful volatiles in time in order to avoid VOC of textiles after vehicle assembling. The results of the research will provide a theoretical foundation for establishing testing standards of VOC in automotive textiles and benefit promoting sustainable production of automotive textiles and reducing VOC in the whole vehicles. Due to limited time and resources, this study explored only four typical aldehyde and ketone compounds, and other volatiles were not discussed in this paper but could be investigated in future research.

Acknowledgment

This research was funded by the National Natural Science Foundation of China, grant number 71704021. The research was funded by Shanghai Technical Standards Project (Grant No. 18DZ2205900).

References

[1] Zhu, Y., Wang Z. Q. (2014). The source of pollutants and the measures to improve the air quality inside the vehicle. Automobile Technology & Material, 10(1), 69–72.Search in Google Scholar

[2] Weng, M. R. (2016). Insides vehicle air pollution detection method and control. Journal of Agricultural Mechanization Research, 10(1), 211–214.Search in Google Scholar

[3] Fu, T. Q., Lu, H. Y., Zhang, Z. R., Shi, G. B. (2010). A research on the detection of air pollutant components in the passenger compartment of vehicle. Automotive Engineering, 32(2), 1098–1101.Search in Google Scholar

[4] Fedoruk, M. J., Kerger, B. D. (2003). Measurement of volatile organic compounds inside automobiles. Journal Exposure Analysis Environmental Epidemiology, 13(1), 1–41.10.1038/sj.jea.7500250Search in Google Scholar

[5] Chien, Y. C. (2007). Variations in amounts and potential sources of volatile organic chemicals in new cars. Science of the Total Environment, 382(2), 228–239.10.1016/j.scitotenv.2007.04.022Search in Google Scholar

[6] Som, D., Dutta, C., Chatterjee, A., Mallick, D., Jana, T. K., et al. (2007). Studies on commuters’ exposure to BTEX in passenger cars in Kolkata, India. Science of the Total Environment, 372(2), 42–43.10.1016/j.scitotenv.2006.09.025Search in Google Scholar

[7] Stephen, K., Brown, M. C. (2000). Volatile Organic Compounds (VOCs) in New Car Interiors. 15th International Clean Air & Environment Conference. Sydney: CASANZ, 464–468.Search in Google Scholar

[8] Liu, L. Y., Yuan, B., Jin, Y. (2013). Determination of 13 aldehydes and ketones by ultra performance liquid chromatography with vehiclebonyl column. Environmental Chemistry, 32(4), 715–716.Search in Google Scholar

[9] Meng, N., Yuan, A., Yuan, H. (2017). Detection and evaluation of organic volatile substances in automotive interior materials. Textile Testing and Standard, 3(04):5–7.Search in Google Scholar

[10] Krzysztof B, Joanna F, Damian L, Anna, G. K. (2014). In-vehicle VOCs composition of unconditioned, newly produced cars. Journal of Environmental Sciences, 26(5), 1052–1061.10.1016/S1001-0742(13)60459-3Search in Google Scholar

[11] Wang, L. Huang, J. L., Liu, D. D. (2012). Sampling method for VOC content analysis of automotive interior parts and materials. Automobile Technology & Material, 12(3), 12–17.Search in Google Scholar

[12] Zhou, Z. J., Liu, Y. X., Zeng, J. N., et al. (2005). Simultaneous determination of 13 aldehyde and ketone of organic pollutants in the air by high performance liquid chromatography. Journal of Environment and Health, 22(4), 297–299.Search in Google Scholar

[13] Yu, Y. B., Tan, P. G., Liu Z., Jiang, H., Zhang, W. (2000). HPLC determination of 11 aldehydes and ketones in ambient air with a ternary mobile-phase gradient program. Journal of Instrumental Analysis, 16(1), 73–77.Search in Google Scholar

[14] An, C. X., Liu, J. W., Wand L., et al. (2010). Determination of vehiclebonyl compounds in water by reversed-phase high performance liquid chromatography. Chinese Journal of Analysis Laboratory, 30(1), 371–374.Search in Google Scholar

[15] You, K. W., Ge, Y. S. (2006). In-vehicle air pollution and its testing technology. Automotive Engineering, 28(5), 495–498.Search in Google Scholar

[16] Marion, J., Fedoruk, A., Brent, D. K. (2003). Measurement of volatile organic compound inside automobiles. Journal of Exposure Analysis and Environmental Epidemiology, 13(2), 31–41.10.1038/sj.jea.7500250Search in Google Scholar

[17] Han, L. (2015). Characterization and comprehensive evaluation for volatile organic compounds (VOC) of auto interior materials based on the analytic hierarchy process. Master Thesis, Donghua University, Shanghai, China.Search in Google Scholar

[18] Tian, Q. B. (2007). Discussion on detection limit and lower limit of Analytical Chemistry. Chemical Analysis and Meterage, 16(3), 72–73.Search in Google Scholar

[19] Zeng, C. P. (2014). Establishment and application of pentaflu or ophenyl hydrazine derivatization-thermal desorption-gas chromatography/mass spectrometry for determination of airborne carbonyl compounds. Master Thesis, Shanghai University, Shanghai, China.Search in Google Scholar

[20] Fu, Y. (2012). Detection method of interior TVOC and modification. Master Thesis, Qingdao University, Qingdao, China.Search in Google Scholar

[21] Grabbs, J. S., Corsi, R. L., Torres, V. M. (2000). Volatile organic compounds in new automobiles: screening assessment. Journal of Environmental Engineering, 126(10), 974–977.10.1061/(ASCE)0733-9372(2000)126:10(974)Search in Google Scholar

© 2021 Yanxue Ma et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Defect Detection of Printed Fabric Based on RGBAAM and Image Pyramid

- Hydrophilization of Polyester Textiles by Nonthermal Plasma

- Prediction of Sewing Thread Consumption for Over-Edge Stitches Class 500 Using Geometrical and Multi-Linear Regression Models

- Experimental Investigation of the Properties of Laminated Nonwovens Used for Packaging of Powders in Mineral Warmers

- An Approach to Estimate Dye Concentration of Domestic Washing Machine Wastewater

- Moisture and Thermal Transport Properties of Different Polyester Warp-Knitted Spacer Fabric for Protective Application

- Quick Detection of Aldehydes and Ketones in Automotive Textiles

- Identification of Miao Embroidery in Southeast Guizhou Province of China Based on Convolution Neural Network

- Effect of Temperature on the Structure and Filtration Performance of Polypropylene Melt-Blown Nonwovens

- Analysis of Mechanical Properties of Unidirectional Flax Roving and Sateen Weave Woven Fabric-Reinforced Composites

- Development of Mask Design Knowledge Base Based on Sensory Evaluation and Fuzzy Logic

- Preparation of Polypyrrole/Silver Conductive Polyester Fabric by UV Exposure

- A New Approach for Thermal Resistance Prediction of Different Composition Plain Socks in Wet State (Part 2)

- Analyzing Thermophysiological Comfort and Moisture Management Behavior of Cotton Denim Fabrics

- Comparison of the Effects of the Cationization of Raw, Bio- and Alkali-Scoured Cotton Knitted Fabric with Different Surface Charge Density

Articles in the same Issue

- Defect Detection of Printed Fabric Based on RGBAAM and Image Pyramid

- Hydrophilization of Polyester Textiles by Nonthermal Plasma

- Prediction of Sewing Thread Consumption for Over-Edge Stitches Class 500 Using Geometrical and Multi-Linear Regression Models

- Experimental Investigation of the Properties of Laminated Nonwovens Used for Packaging of Powders in Mineral Warmers

- An Approach to Estimate Dye Concentration of Domestic Washing Machine Wastewater

- Moisture and Thermal Transport Properties of Different Polyester Warp-Knitted Spacer Fabric for Protective Application

- Quick Detection of Aldehydes and Ketones in Automotive Textiles

- Identification of Miao Embroidery in Southeast Guizhou Province of China Based on Convolution Neural Network

- Effect of Temperature on the Structure and Filtration Performance of Polypropylene Melt-Blown Nonwovens

- Analysis of Mechanical Properties of Unidirectional Flax Roving and Sateen Weave Woven Fabric-Reinforced Composites

- Development of Mask Design Knowledge Base Based on Sensory Evaluation and Fuzzy Logic

- Preparation of Polypyrrole/Silver Conductive Polyester Fabric by UV Exposure

- A New Approach for Thermal Resistance Prediction of Different Composition Plain Socks in Wet State (Part 2)

- Analyzing Thermophysiological Comfort and Moisture Management Behavior of Cotton Denim Fabrics

- Comparison of the Effects of the Cationization of Raw, Bio- and Alkali-Scoured Cotton Knitted Fabric with Different Surface Charge Density