Abstract

The SiC/Al-Mg-Cu-Si-Sn composites with different quantities of SiC particles by volume were fabricated using hot-pressing sintering. The effects of SiC volume fraction on the microstructure, Vickers hardness, and corrosion behavior of the composites were studied using the optical microscope, scanning electron microscope, Vickers hardness test, and corrosion testing. The results show that adding SiC particles shortened the time required to reach the peak-aged state of the composites and increased the hardness. Corrosion potentials of the composites did not vary greatly or show any definite trends in relation to the amounts of the SiC contents.

1 Introduction

SiC-particle-reinforced aluminum matrix composites (AMCs) are considered excellent structural materials suitable for use in the aeronautic-aerospace transportation and automotive industries because of their excellent combination of qualities, specifically their low density, high thermal conductivity, and high specific strength, specific stiffness, and heat resistance [1–4]. The key to improving these properties lies in the structure, chemistry, and the bonding nature of aluminum (Al)-silicon carbide (SiC) interfaces. In this way, improving the combined properties of AMCs, age hardenable aluminum alloys such as those based on Al-Cu [5–7], Al-Mg-Si [8–12], and Al-Zn-Mg-Cu [13, 14] have been used as matrix alloys. Many methods have also been developed to fabricate the SiC-particle-reinforced AMCs, including casting, pressure infiltration, and powder metallurgy (PM). Among all these fabrication techniques, PM is the most attractive because it offers uniform distribution of the reinforcements, fine-grained structures, and easy control of the microstructures [15].

Reports of the effects of aging treatment and SiC content on age-hardening and corrosion behavior have not produced consistent results. Rack reported that age hardening is slower in a 20 vol.% SiCw/Al-Mg-Si composite than in a monolithic alloy [16]. Ahn and Yu found that the precipitation sequence and the characteristics of the precipitates in the Al-Mg-Si-Cu alloy were not considerably affected by the presence of SiC particulate and the volume fraction of SiC particulate [17]. Mohmad thought that the degree of corrosion of T6-treated SiCp/Al-Mg-Si composites in chloride solutions increased with increasing SiCp content [18]. However, the study published by Naya and Hebbar showed that the corrosion inhibition efficiency of T6-treated Al-Mg-Cu-SiC composite was found to be poorer than that of the non-heat-treated composite [19].

The objective of this study was to investigate the age-hardening and corrosion behavior of Al-0.64Mg-0.60Cu-0.2Si-0.15Sn (mass.%) matrix composites with different volume fractions of SiCp and to discuss how the SiC particles affected the age-hardening and corrosion behaviors using hardness measurement, corrosion testing, and microscopy.

2 Materials and methods

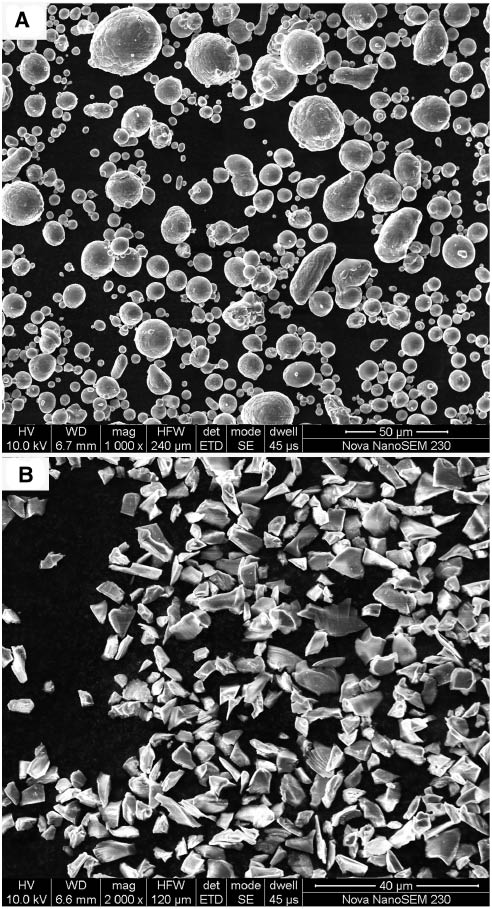

The raw materials included the following: pre-alloying Al-0.64Mg-0.60Cu-0.2Si-0.15Sn powder (Angang Group Aluminium Powder Co., China) and α-SiC particles (99.5%) (Xuzhou Jiechuang New Material Technology Co., China). Figure 1 shows the scanning electron microscope (SEM) images of SiC particles and pre-alloying powders. The pre-alloying powder was composed of almost spherical particles (Figure 1A) with an average size of 10 μm. The SiC particles with the average size of 30 μm are angular and bulky (Figure 1B). The 0 vol.% (sample 1), 5 vol.% (sample 2), 10 vol.% (sample 3), 20 vol.% (sample 4), or 30 vol.% SiC (sample 5) powder was added to Al-0.64Mg-0.60Cu-0.2Si-0.15Sn pre-alloying powders before milling. Mechanical milling was performed for 24 h in a planetary ball milling system (Nanjin Kexi Instrument, Nanjin, China) in alcohol under argon atmosphere using WC-5Co balls with a diameter of 10 mm as the milling bodies. The ball-to-powder weight ratio was 3:1, and the milling speed was 8.5 g. After milling, the pulp was dried in a vacuum oven at 70°C for 12 h. The mixed reactants were granulated and die-pressed to compact discs with 50 mm in diameter and 50 mm in thickness under a load of 300 MPa. Because the liquid phase sintering temperature of Al-Mg-Si alloy was 649°C, the compacts were heated to 600°C with a heating rate of 10°C/min in vacuum [20]. At 600°C, the compacts were sintered for 2 h with an applied load of 25 MPa. After sintering, the samples were cooled to room temperature in the furnace. The samples were treated with solution at 500°C for 2 h, followed by water quenching, and finally aged for different times at 175°C.

SEM graphs of (A) pre-alloying powder and (B) SiC particles.

The hardness of the samples was measured using an HD9-45 optical surface Vickers hardness tester with a load of 100 g (Sh-lianer Testing Equipment, Shanghai, China). For each aging time, an average of five indentations was performed. The microstructural observation of the samples was conducted using an optical microscope (Olympus-bx51m; Olympus America) and a FEI Nano230 SEM (FEI Company, OR, USA).

To determine the effect of SiC particle on the corrosion behavior of Al-Mg-Cu-Si-Sn alloy, the electrochemical experiment was carried out on the CHI660C electrochemical test equipment (CH Instruments Inc., Shanghai, China) at 25°C using the typical three-electrode electrochemical system [21], which consists of a platinum electrode as the counter electrode, a saturated calomel electrode as the reference electrode, and samples as the working electrode with a surface of about 0.5 cm2 exposed to the 3.5% NaCl solution. The polarization test was carried out by sweeping the potential from cathode to anodic direction at a scan rate of 1 mV/s. Each polarization experiment was run after holding the electrode for 1 min at the open circuit potential to allow steady state to be achieved. All the tests were executed in triplicate.

3 Results and discussion

Figure 2 shows the SEM images of the sintered composites. When the SiCp fraction was <5 vol.%, the reinforcement particles were located in the vacant sites between the coarser matrix grains, as shown in Figure 2a. The grain surfaces of sample 3 were almost decorated by the reinforcement particles at 10 vol.% SiC (Figure 2c), although some of the reinforcement particles formed clusters in some limited positions. At higher volume fractions, however, non-uniform arrangement of reinforcement particles and clusters of SiCp were clearly observed (Figure 2d). The clustering became more severe as the SiC particle fraction increased to 30 vol.% (Figure 2e). It is pertinent to point out that the pores formed inside the necklace structure of SiC particles were partly attributable to the removal of the reinforcement particles during sample preparation (Figure 2e).

Microstructure graphs of the samples after hot sintering at 600°C. (a) Sample 1; (b) sample 2; (c) sample 3; (d) sample 4; (e) sample 5.

Figure 3 shows the variation in hardness with aging time at 175°C for different samples. Different behaviors have been observed in the effects of SiC contents on the aging response. In the unreinforced sample 1, the increase in the hardness with aging time was not obvious, and the hardness reached a peak at 63 HV at 10 h. However, the hardness of sample 2 increased remarkably with the aging time, peaking at 92 HV at 10 h. Similarly, in samples 3 and 4, the hardness gradually increased with the aging time up to the peak hardness, with the hardness of 101 HV and 112 HV at 5 h aging, respectively. However, the maximum hardness has no obviously increase (with a value of about 112 HV), when the SiC contents were further increased to 30%. Results have shown that the age-hardening accelerated in that the times required to reach peak hardness were shortened by about 5 h by the presence of reinforcement in the SiC/Al-Mg-Cu-Si-Sn composites.

Aging-hardness curves of the samples aging at 175°C.

Figure 4 shows the transmission electron microscope (TEM) micrographs of samples 1 and 3 observed after aging for 10 h at 175°C. This shows that the volume fraction of precipitate phases in the composite is significantly greater than those of sample 1. Ahn and Yu showed that the diffusion of alloy elements is required in order to produce precipitation during the aging treatment [17]. Many dislocations were introduced by severe deformation at the interface between SiC and Al matrix during hot pressing sintering in the composites. These high-density dislocations offer not only a heterogeneous nucleation site for the precipitation but also a high-diffusivity path for the alloy elements [22]. In this way, the age hardening of the composites was accelerated. Also, sample 3 required less time to reach peak hardness than sample 2 because the number of dislocations increased with increase in the volume fraction of the reinforcements.

TEM graphs of (A) sample 1 and (B) sample 3 after aging for 10 h at 175°C.

Figure 5 shows the potentiodynamic polarization curves for the materials in 3.5% NaCl solution at 25°C. This showed that the different cathodic polarization currents were caused by the different compositions of the samples. The galvanic corrosion current density decreased as the SiC content increased. This finding is inconsistent with published results concerning galvanic corrosion of SiC wafer reinforced by Al-1.0Mg-0.6Si [23]. As the volume fraction of SiC in the composite increased, the dissolution rate of the aluminum matrix decreased. It was therefore concluded that the principal corrosion process for SiCp/Al-Mg-Cu-Si-Sn composites was galvanic coupling of the matrix and reinforcement [18]. Meanwhile, Table 1 shows Ecorr, and Figure 5 shows icorr. It was observed that none of the Ecorr of any of the samples showed more than moderate variation or any definite trends in relation to the amounts of SiC particulate content. However, the icorr in the samples containing SiC was lower than that of sample 1.

Polarization curves of the samples after aging for 10 h at 175°C.

Electrochemical corrosion parameters of composites in 3.5% NaCl solution.

| Sample | Ecorr (V) | icorr (μA.cm-2) |

|---|---|---|

| Sample 1 (Free SiC) | -1.0475 | 901.60 |

| Sample 2 (5 vol.% SiC) | -1.2349 | 330.45 |

| Sample 3 (10 vol.% SiC) | -1.0556 | 108.32 |

| Sample 4 (20 vol.% SiC) | -1.1078 | 325.47 |

| Sample 5 (30 vol.% SiC) | -1.1346 | 261.61 |

The corrosion resistance of SiC/Al-Mg-Cu-Si-Sn composites depends on many factors, such as the SiC contents and size [2, 24], Al-Mg-Cu-Si-Sn alloy composition, Si/Mg molar ratios [4], microstructure, environment, and properties of the Al2O3 film covering the alloy matrix surface in the aggressive solution. The silicon carbide particles are conductive and act as local cathodes for the reduction of oxygen in the composites [2]. The study by Zakaria showed that reducing the SiC particles size and/or increasing the volume fraction of the SiC particulates reduces the corrosion rate of the Al/SiC composites [24]. Meanwhile, Mohmad inferred that the degree of corrosion changed with increasing SiC content in the SiC/Al-Mg-Si composites probably mainly due to galvanic couple [18].

4 Conclusions

The time required to reach peak hardness in the composites with 10–30% SiC was shorter than that of the unreinforced Al-0.64Mg-0.60Cu-0.2Si-0.15Sn alloy. The times required to reach peak hardness were shortened by about 5 h by the presence of reinforcement in the SiC/Al-Mg-Cu-Si-Sn composites. The age hardening was accelerated in most of the samples that contained composites with 20% and 30% SiC. The galvanic corrosion current density decreased as the SiC contents increased, and the dissolution rate of the aluminum matrix decreased.

Acknowledgments

This work is supported by National Natural Science Foundation of China (No. 51301206).

References

[1] Chawla N, Shen YL. Adv. Eng. Mater. 2001, 3, 357–370.10.1002/1527-2648(200106)3:6<357::AID-ADEM357>3.0.CO;2-ISearch in Google Scholar

[2] Díaz-Ballote L, Velva L, Pech-Canul MA, Pech-Canul MI, Wipf DO. J. Electrochem. Soc. 2004, 151, B299–B303.10.1149/1.1737384Search in Google Scholar

[3] Lakshmipathy J, Kulendran B. Sci. Eng. Compos. Mater. 2014, 22, 573–582.10.1515/secm-2013-0268Search in Google Scholar

[4] Pech-Canul MI, Escalera-Lozano R, Pech-Canul MA, Rendón-Angeles JC, López-Cuevas J. Mater. Corros. 2007, 58, 833–840.10.1002/maco.200704067Search in Google Scholar

[5] Gupta M, Lu L, Ang SE. J. Mater. Sci. 1997, 32, 1261–1267.10.1023/A:1018596221106Search in Google Scholar

[6] Lu YX, Lee CS, Meng XM. J. Mater. Sci. Lett. 1999, 18, 533–535.10.1023/A:1006614225269Search in Google Scholar

[7] Sun C, Shen RJ, Song M. J Mater. Eng. Perform. 2012, 21, 373–381.10.1007/s11665-011-9940-1Search in Google Scholar

[8] Escalera-Lozano R, Pech-Canul MA, Pech-Canul MI, Quintana P. Mater. Corros. 2009, 60, 683–689.10.1002/maco.200805164Search in Google Scholar

[9] Escalera-Lozano R, Pech-Canul MI, Pech-Canul MA, Montoya-Dávila M, Uribe-Salas A. Open Corros. J. 2010, 3, 73–79.10.2174/1876503301003010073Search in Google Scholar

[10] Pech-Canul MA, Giridharagopal R, Pech-Canul MI, Coral-Escobar EE. J. Mater. Eng. Perform. 2013, 22, 3922–3932.10.1007/s11665-013-0674-0Search in Google Scholar

[11] Tekmen C, Cocen U. J. Mater. Sci. Lett. 2003, 22, 1247–1249.10.1023/A:1025497816387Search in Google Scholar

[12] Woo KD, Zhang DL. Curr. Appl. Phys. 2004, 4, 175–178.10.1016/j.cap.2003.11.002Search in Google Scholar

[13] El-baradie ZM, El-Shahat OA. J. Mater. Process. Tech. 1998, 79, 1–8.10.1016/S0924-0136(97)00096-4Search in Google Scholar

[14] Sheu CY, Lin SJ. J. Mater. Sci. 1997, 32, 1741–1747.10.1023/A:1018576000575Search in Google Scholar

[15] Tham JM, Da-Costa CE, Velasco F. J. Mater. Process. Tech. 2003, 133, 203–206.10.1016/S0924-0136(02)00234-0Search in Google Scholar

[16] Rack HJ. Proc. 6th. Int. Conf. on Composite Materials, Matthews, FL, Buskell, NCR, Eds., Elsevier Applied Science, 1987, Vol. 2, p 382.Search in Google Scholar

[17] Ahn HK, Yu CH. Metals Mater. Int. 2001, 7, 1–7.10.1007/BF03026930Search in Google Scholar

[18] Mohmad SBS. Adv. Perform. Mater. 1996, 3, 183–204.10.1007/BF00136745Search in Google Scholar

[19] Naya J, Hebbar KR. Trans. Indian Inst. Met. 2008, 61, 221–224.10.1007/s12666-008-0006-5Search in Google Scholar

[20] Asgharzadeh H, Simchi A. Powder Metall. 2009, 52, 28–35.10.1179/174329008X286721Search in Google Scholar

[21] Xiao DH, Geng ZW, Chen L, Wu Z, Diao HY, Song M, Zhou PF. Metall. Mater. Trans. A 2015, 46, 4793–4803.10.1007/s11661-015-3053-7Search in Google Scholar

[22] Hong SK, Tezuka H, Kamio A. J Japan Inst. Light Metal 1993, 43, 328–331.10.2464/jilm.43.328Search in Google Scholar

[23] Hihara LH, Latanium RM. Corrosion, 1992, 48, 546–552.10.5006/1.3315972Search in Google Scholar

[24] Zakaria HM. Ain Shams Eng. J. 2014, 5, 831–838.10.1016/j.asej.2014.03.003Search in Google Scholar

©2017 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Review

- Automated profile preforming for structural components

- Original articles

- Effects of surface grafting of copper nanoparticles on the tensile and bonding properties of flax fibers

- Thermomechanical study of polyethylene porous membrane by coating silicon dioxide nanoparticles

- Crystallization, structural and mechanical properties of PA6/PC/NBR ternary blends: effect of NBR-g-GMA compatibilizer and organoclay

- Aging analysis of high voltage silicone rubber/silica nanocomposites under accelerated weathering conditions

- Investigation of viscoelastic properties and thermal behavior of photocurable epoxy acrylate nanocomposites

- The research of soft matter properties by light scattering material adding drop additive

- Microstructure and corrosion properties of SiC/Al-Mg-Cu-Si-Sn composites

- Tribological properties and microstructures of Al2O3-TiC-TiB2 reinforced composites

- Sustained release of OIC-A006 from PLGA microspheres to induce osteogenesis of composite PLGA/β-TCP scaffolds

- Study the effect of fiber loading and alkali treatment on the mechanical and water absorption properties of wheat straw fiber-reinforced epoxy composites

- Effect of mechanical alloying on the synthesis of Fe-TiC nanocomposite

- A comparative finite element analysis of two types of axial and radial functionally graded dental implants with titanium one around implant-bone interface

- Investigation of the effect of inert inclusions on densification during solid-state sintering of metal matrix composites

- Multiscale thermomechanical modeling of short fiber-reinforced composites

- Effects of the alkaline solution/binder ratio and curing condition on the mechanical properties of alkali-activated fly ash mortars

- Failure analysis and strengthening mechanism of Z-pinned composite T-joints under tensile loading

- Characteristic analysis of carbon nanotube thread embedded into three-dimensional braided composite under bending load

Articles in the same Issue

- Frontmatter

- Review

- Automated profile preforming for structural components

- Original articles

- Effects of surface grafting of copper nanoparticles on the tensile and bonding properties of flax fibers

- Thermomechanical study of polyethylene porous membrane by coating silicon dioxide nanoparticles

- Crystallization, structural and mechanical properties of PA6/PC/NBR ternary blends: effect of NBR-g-GMA compatibilizer and organoclay

- Aging analysis of high voltage silicone rubber/silica nanocomposites under accelerated weathering conditions

- Investigation of viscoelastic properties and thermal behavior of photocurable epoxy acrylate nanocomposites

- The research of soft matter properties by light scattering material adding drop additive

- Microstructure and corrosion properties of SiC/Al-Mg-Cu-Si-Sn composites

- Tribological properties and microstructures of Al2O3-TiC-TiB2 reinforced composites

- Sustained release of OIC-A006 from PLGA microspheres to induce osteogenesis of composite PLGA/β-TCP scaffolds

- Study the effect of fiber loading and alkali treatment on the mechanical and water absorption properties of wheat straw fiber-reinforced epoxy composites

- Effect of mechanical alloying on the synthesis of Fe-TiC nanocomposite

- A comparative finite element analysis of two types of axial and radial functionally graded dental implants with titanium one around implant-bone interface

- Investigation of the effect of inert inclusions on densification during solid-state sintering of metal matrix composites

- Multiscale thermomechanical modeling of short fiber-reinforced composites

- Effects of the alkaline solution/binder ratio and curing condition on the mechanical properties of alkali-activated fly ash mortars

- Failure analysis and strengthening mechanism of Z-pinned composite T-joints under tensile loading

- Characteristic analysis of carbon nanotube thread embedded into three-dimensional braided composite under bending load