Abstract

This article presents results that seriously challenge conventional frameworks regarding the time, course, and cultural context of the introduction of iron and steel in Europe, in turn central metals in the narrative of civilization development. From focusing on 2,000-year-old finds from 42 different sites across the national borders of present-day northernmost Norway, Finland, and Sweden, our study reveals advanced iron and steel production contemporaneous with Roman steel production within the hitherto unthinkable cultural context of hunter-gatherers. By employing archaeometric analyses alongside a lens that considers the Arctic climate and landscape, long-standing inadequate interpretative frameworks are challenged and we manage to shed novel light on the metallurgical practices and skills of the ancient Arctic hunter-gatherers. By examining local conditions, the research specifically reveals adaptation strategies and previously underexplored social and organizational aspects of early ironmaking. The implications of these findings are profound, urging historians and archaeologists to adopt similar methods and perspectives to potentially uncover additional “unthinkable” locations/regions or contexts with advanced and early metalworking.

1 Introduction

This article challenges conventional scholarly views by presenting evidence that hunter-gatherer communities in ancient Arctic Europe (as defined by the Arctic Council, arctic-council.org) had widespread knowledge of advanced and early iron production already more than 2,000 years ago. The material evidence originates from 42 different sites distributed across the national borders of Arctic Sweden, Finland, and Norway. The area covers 375,000 km2, which is equivalent to the combined surface area of the Czech Republic, Slovakia, Austria, Hungary, and the southern part of Germany. This wealth of archaeometallurgical material concerns partly newly identified and partly previously surveyed or excavated (still not previously analyzed) finds of iron and steel production including smithing, where the majority can be related to pre-Roman/Roman Iron Age hunter-gatherer sites (Figure 1).

Analyzed sites in Arctic Europe. Norway: 1. Hemmestad Nedre; 2. Flakstadvåg; 3. Øvreværet; 4. Røsnesvalen; 5. Slettnes; 6. Fjære; 7. Makkholla; 8. Virdnejavre 112; 9. Hellervikjä; 10. Mestersanden. Finland: 11. Kemijärvi, Neitilä; 12. Kajani, Äkälänniemi; 13. Rovaniemi, Riitakanranta; 14. Rovaniemi, Kotijänkä; 15. Mikkeli, Kitulansuo, Ristiina; 16. Lahti, Kilpisaari. Sweden: 17. Vivungi, Jukkasjärvi 723; 18. Sangis, Nederkalix 842; 19. Nåttiholmen, SMA 4006; 20. Revi, SMA 929; 21. Revi, SMA 3319; 22. Revi, SMA 4131; 23. Hoppot, NA 36; 24. Sangis, Nederkalix 730; 25. Sangis, Nederkalix 797; 26. Rappasundet; 27. Revi Saxplats; 28. Sandudden, NA 53; 29. Sandudden, NA 54; 30. Sandudden, Ö Gottjärn, NA 55; 31. Sandudden, NA 80; 32. Sandudden, NA 82;, 33. Sandudden, NA 83; 34. Vallen, Nederluleå 90; 35. Måttsund, Nederluleå 134; 36. S Holmnäs, NA 303; 37. Gottjärnmynnet, NA 69; 38. Snotterholmen, NA 71A; 39. Sandudden, NA 79; 40. Räktjärv, Töre 50; 41. Bergnäsudden, NA 16; 42. Kosjärv, Töre 510; 43. Månsträsk, NA 2145; 44. Notvik, NA 2153; 45. Tellek; 46. Masseviken, NA 357; 47. Nåludden, NA 397; 48. Vivungi, ore survey; 49. Vuolgamjaur, NA 202; 50. Abraur, NA1738; 51. Abraur, Åmynne, NA 36, Apl; 52. Skidträsk, NA 2179; 53. Ö Sguegesuolo, NA 48; 54. Vivungi, experiment.

The historical narrative surrounding the spread of metals, particularly iron and steel, and their importance for the development of civilizations is strongly influenced by conventional frameworks rooted in diffusionist and evolutionary theories (Bebermeier et al., 2016; Buchwald, 2005; Charlton et al., 2010; Childe, 1944; Karlsson & Magnusson, 2015; Pleiner, 2000; Wertime & Muhly, 1980; Zavyalov & Terekhova, 2018). Within these explanatory frameworks, perceived peripheral areas, such as the ancient Arctic, are disadvantaged. Consequently, the emergence of iron technology is traditionally viewed as peripheral to Old World Ferrous metallurgical developments, and full-scale iron production is not believed to have reached the Arctic parts until the seventeenth and eighteenth centuries, primarily through migrating miners from the south (Karlsson & Magnusson, 2015; Norberg, 1958).

The disadvantage concerns not only the ancient Arctic area but also extends to its ancient population. Hence, scholars on a broader European scale often overlook the potential for metal technology in hunter-gatherer societies. Despite the abundance of archaeometallurgical material uncovered in Arctic European hunter-gatherer contexts since the mid-twentieth century, including substantial collections of iron artifacts and remnants from ironworking (such as slag), as well as the discovery of several iron production sites since the 1980s, this material is frequently regarded as an anomaly and consistently disregarded in iron research even today.

This dismissal is further maintained by the selective use of analytical methods, such as archaeometallurgical analyses and radiocarbon dating, and a narrow focus solely on certain morphological artifact types. Hence, the prevailing view is that ancient Arctic European hunter-gatherers primarily obtained metals through long-distance trade with metal-producing agricultural societies in eastern and central Russia, or southern Scandinavia (Bennerhag et al., 2021). As a result, hunter-gatherer communities are often not perceived as sufficiently complex to organize iron production themselves (Alpern, 2005; Bergman, 1995; Dyakonov et al., 2019; Jørgensen, 2011; Koryakova & Epimakhov, 2007). Consequently, the social and material dynamics surrounding ancient Arctic European metallurgy remain poorly understood (Bennerhag et al., 2023).

In this article, we have two primary objectives. First, with a focus on know-how and established process stages in iron technology, we aim to provide a detailed examination of the widespread evidence of iron finds across the national borders of northern Finland, Sweden, and Norway (with a particular focus on previously overlooked metallurgical remains such as slag). Second, we seek to advance our understanding of the local conditions of iron technology and its impact on the ancient Arctic European hunter-gatherer communities by focusing on the social aspects of metallurgical production, the prehistoric landscape of iron production, and the organization that facilitated the entire system. To achieve this, we employ an interdisciplinary approach, including archaeometric methods, involving petrographic and bulk chemical analyses of slag and iron ore, metallographic analyses of iron, ceramic analyses of hearth linings and furnace walls, and radiocarbon dating of metallurgical remains. Through these analyses, we gain valuable insights into the knowledge of the different process steps in the ancient Arctic metallurgical production. However, by combining the metallurgical analyses with landscape and climate perspectives, we get to explore an increased range of potential practices and mechanisms involved in the production, and we can illuminate related human-landscape and climate interactions (Ingold, 1993). It is close at hand to assume that the marked seasonal fluctuations of the Arctic European landscape (the climate 2,000 years ago is similar to what we have today, Jørgensen et al., 2023) with harsh, snowy winters from November to March/April and springs half as short as those in southern Scandinavia, along with short but often sunny summers from June to August, influenced the organization and rhythm of the ancient Arctic metalworking activities.

Overall, by breaking away from conventional theories, employing archaeometric methods, and adopting a landscape/climate lens, we demonstrate a far greater spatiotemporal complexity in how iron technology was organized than previously assumed. This not only allows us to raise new questions about the metallurgical material but also provides us with deeper insights into the significance of iron among ancient Arctic hunter-gatherers, alongside a widened perspective of these societies.

2 To Add Context – The Ironmaking of Pre-Roman Arctic Hunter-Gatherers

To explore the organization and technology of ironworking in ancient Arctic Europe, we must delve into the production process and the various metal-related activities that occurred. Through archaeometric analyses of the material, we can uncover the technical framework, including variations, of the iron produced. This encompasses qualities, necessary knowledge, temperature considerations, raw materials, and the origin of ore. By applying the concept of chaîne opératoire, we further untangle the condensed records of purposeful human activities embedded in the material (Leroi-Gourhan, 1993). Thus, iron technology involves a complex series of processes, with each step revealing manufacturing choices and allowing for variables (Gosselain & Stark, 1998; Lemonnier, 1992).

Already before ironmaking, a series of highly knowledge-dependent choices and activities must be conducted in terms of (1) identifying and collecting viable ores suitable for different products based on factors like iron content, phosphorus content, and manganese content; (2) prospecting and collecting clays with refractory properties and suitable plasticity; (3) acquiring stone building material resistant to heat for construction purposes; (4) building furnaces and forging hearths; (5) roasting iron ores; and (6) producing charcoal, the crucial fuel source. The actual production of iron from iron ores by the direct bloomery process involves a lengthy process, roughly divided into three main stages: (1) the smelting (reduction) of the ores to produce a bloom; (2) the refining of the bloom (primary smithing) to produce a more compacted metal suitable for smithing; and (3) the forging of the end product (secondary smithing). These stages can occur continuously at the smelting site. Alternatively, the iron, either in bloom or bar form, can be transported to iron smithies for further refinement. Interestingly, while conventional assumptions hold that the rough bloom was unsuitable for transportation and needed refining directly at the smelting sites, evidence from the ancient Arctic smelting and smithing sites examined here (see further below) indicates that blooms were transported to the iron smithies for further refinement.

Examining the technical practices across different production stages allows for a more nuanced and sophisticated reconstruction of the behavioral influences of local production than those afforded by the conventional one-sided focus on morphological and stylistic traits within archaeology. In this study, we conduct such a reconstruction of the technical practices and characteristics across a larger region, Arctic Europe. By highlighting the expertise and choices of smelters and smiths, we can facilitate a factual discussion about how the craft in one area relates to that in another, going beyond the assumption of mere imitation.

The taskscape approach (Ingold, 1993) allows us to explore iron-making as an array of interrelated activities and relationships within the context (places and rhythms) of everyday life. By incorporating the temporality of these activities and adopting a cyclical view of time tied to repeating patterns of activities in the landscape, we gain insights into the iron-making process (Hadden et al., 2022). Factors such as the localization of raw materials in the landscape and climate-related seasonal fluctuations play a role in determining where and when tasks could be conducted alongside other livelihood activities. Consequently, implementing iron-making alongside existing rhythms required reorganization to create space for it. Overall, the taskscape approach enriches our understanding of the strategies employed by ancient Arctic iron-making hunter-gatherers.

In line with the taskscape approach, however, without subscribing directly to it, Bergman (1995, p. 194ff) highlights the crucial importance of marked seasonal changes for the ancient Arctic population’s resource supply activities and settlement patterns. She suggests that during the pre-Roman and Roman Iron Ages, settlement patterns followed an annual cycle, where autumn and winter were characterized by aggregation at a base camp settlement in the forested land, while spring and summer saw division into several different camps. Fishing and hunting – particularly for moose, reindeer, and small game – played a decisive role in shaping settlement patterns as the harvest period for animal resources primarily occurred during autumn and early winter due to the spawning season. Moose and reindeer followed specific routes from the mountains down to the forested areas, and animals like marten, fox, and wolverine were easily tracked in the snow. This favorable environment allowed for large catches to be frozen and stored. Bergman suggests that autumn was the time when local groups converged into so-called microbands, comprising about 25–50 people (Kelly, 2013, p. 171), for joint work. In contrast, spring (March to May) posed supply challenges due to depleted stores. Additionally, transport, hunting, and fishing were more difficult in spring because of the light snow (poor bearing capacity) and water on the ice.

Hence, Bergman (1995, p. 194ff) points to the lack of conditions for larger joint settlements from spring-winter to summer. Instead, a division of the microbands into smaller units was the most advantageous form of resource utilization during the summer. She suggests the need to secure fuel (wood), especially for the winter months, while still reducing the risk of overexploitation. This speaks in favor of such division. Bergman (1995) also highlights the influence of seasonal changes on the disposition of activities within the settlement area. For example, during the cold and dark winter, tool maintenance could only be carried out in a heated (and lit) dwelling. However, during the bare ground season, maintenance could occur in optional places all over the settlement area.

Similar to Bergman (1995), Wallerström (1995) also examines the multifaceted nature of resource procurement activities in response to seasonal variations. However, both scholars overlook the significance of ironworking in their analyses. This oversight is a common theme in the limited literature on Arctic hunter-gatherers during the pre-Roman and Roman Iron Ages. Previous studies have predominantly concentrated on subsistence activities such as hunting, fishing, and the gathering of raw materials for stone tools and pottery, neglecting the crucial role of ironworking (Forsberg, 1985; Mulk, 1994).

3 Materials and Methods

The groundbreaking dataset presented in this article is the result of the first-ever extensive implementation of archaeometallurgical analyses on archaeological materials from the Arctic European region. The dataset encompasses a diverse range of materials, including slags, technical ceramics, ores, iron, and artifacts, sourced from as many as 42 different prehistoric sites across Arctic Europe. Among these sites, 31 have undergone detailed analysis, comprising 26 in northern Sweden, 6 in Finland, and 10 in Norway (for an overview, see Table 1 and Figure 1). The identified contexts primarily include iron production sites and multiperiod habitation or dwelling sites. While many lack visible structures, some feature huts and occasional hearth structures (for specifics, see Table 1). Furthermore, samples of fresh ore from 11 different sites (lakes) have been subjected to test roasting, with detailed analysis performed on four of these sites. Overall, the metallurgical findings form part of larger assemblages gathered during archaeological surveys or from well-documented excavations spanning from the early 1940s to recent times. The majority of findings originate from surface collections and occasional excavations associated with large-scale hydropower expansion projects in Arctic Europe during the latter half of the twentieth century, as well as other industrial exploitations such as gas line installations. Some discoveries stem from smaller-scale excavations, typically undertaken in connection with locally funded research initiatives. For a more comprehensive understanding of the sampling and analyses conducted (in addition to the information provided in Section 3), see Supplementary S.1.

Analyzed sites in Arctic Europe

| No. | Country | Site | Site ID | Context | Production step | Material |

|---|---|---|---|---|---|---|

| 1 | Norway | Hemmestad Nedre | — | Smelting | Smelting | Slag, furnace wall |

| 2 | Norway | Flakstadvåg | — | Smelting | Smelting | Slag, furnace wall |

| 3 | Norway | Øvreværet | — | Dwelling | Smelting/primary smithing | Slag with metal inclusions |

| 4 | Norway | Røsnesvalen | 26 980 | Hut | Smelting/smithing | Hearth lining/furnace wall, slag |

| 5 | Norway | Slettnes | — | Hut | Secondary smithing | Slag, iron fragment, iron object |

| 6 | Norway | Fjære | — | Dwelling | Secondary smithing | Slag, hearth lining |

| 7 | Norway | Makkholla | 150 901 | Dwelling | Secondary smithing | Hearth lining, slag |

| 8 | Norway | Virdnejavre 112 | — | Dwelling | Smithing? | Sandstone with slag layer |

| 9 | Norway | Hellervikjä | 46 967 | Hut | — | Fragment of iron object (knife?) |

| 10 | Norway | Mestersanden | 56 557 | Dwelling | — | Iron fragment, bone with iron |

| 11 | Finland | Kemijärvi, Neitilä | 320 010 104 | Dwelling | Smelting | Slag, furnace wall, iron waste |

| 12 | Finland | Kajani, Äkälänniemi | 205 010 002 | Dwelling | Smelting | Slag, furnace wall, iron waste |

| 13 | Finland | Rovaniemi, Riitakanranta | 699 010 474 | Dwelling | Smelting | Slag, furnace wall, iron waste |

| 14 | Finland | Rovaniemi, Kotijänkä | 699 010 469 | Dwelling | Smelting | Slag |

| 15 | Finland | Mikkeli, Kitulansuo, Ristiina | 696 010 026 | Dwelling | Smelting | Slag, lining (slag pit), iron waste |

| 16 | Finland | Lahti, Kilpisaari | 532 010 021 | Dwelling | Smelting | Slag, lining (slag pit) |

| 17 | Sweden | Vivungi, Jukkasjärvi 723 | L1994:8821 | Smelting | Smelting | Ancient ore |

| 18 | Sweden | Sangis, Nederkalix 842 | L1992:9207 | Smelting | Smelting | White metal, clips |

| 19 | Sweden | Nåttiholmen, SMA 4006 | L1995:364 | Dwelling | Smelting and smithing | Slag, lining |

| 20 | Sweden | Revi, SMA 929 | L1995:53 | Dwelling | Smithing | Slag, lining |

| 21 | Sweden | Revi, SMA 3319 | L1996:9978 | Dwelling | Smelting | Slag |

| 22 | Sweden | Revi, SMA 4131 | — | Dwelling | Smithing | Slag, lining |

| 23 | Sweden | Hoppot, NA 36 | L1996:9593 | Dwelling | Smelting/primary smithing | Metallic iron |

| 24 | Sweden | Sangis, Nederkalix 730 | L1992:6497 | Dwelling | Primary/secondary smithing | Slag, lining |

| 25 | Sweden | Sangis, Nederkalix 797 | L1992:8588 | Dwelling | Primary/secondary smithing | Slag, lining, metallic iron |

| 26 | Sweden | Rappasundet | L1996:9944 | Dwelling | Smithing | Slag, lining |

| 27 | Sweden | Revi Saxplats | — | Dwelling | Smithing | Slag, lining |

| 28 | Sweden | Sandudden, NA 53 | L1996:9040 | Dwelling | Smithing | Hearth lining, lining |

| 29 | Sweden | Sandudden, NA 54 | L1996:8099 | Dwelling | Primary/secondary smithing | Slag, lining, metallic iron, stone |

| 30 | Sweden | Sandudden, Ö Gottjärn, NA 55 | L1996:8103 | Dwelling | Smithing | Slag, lining, stone |

| 31 | Sweden | Sandudden, NA 80 | L1996:7942 | Dwelling | Smithing | Slag |

| 32 | Sweden | Sandudden, NA 82 | L1996:8958 | Dwelling | Primary/secondary smithing | Slag, lining, metallic iron |

| 33 | Sweden | Sandudden, NA 83 | L1995:4248 | Dwelling | Smithing | Slag |

| 34 | Sweden | Vallen, Nederluleå 90 | L1992:5168 | Hut | Primary/secondary smithing | Slag, metallic iron, stone |

| 35 | Sweden | Måttsund, Nederluleå 134 | L1992:918 | Dwelling | Smithing | Slag |

| 36 | Sweden | S Holmnäs, NA 303 | L1995:2336 | Dwelling | Smithing? | Lining |

| 37 | Sweden | Gottjärnmynnet, NA 69 | L1996:8638 | Dwelling | Smithing? | Slag, lining |

| 38 | Sweden | Snotterholmen, NA 71A | L1996:8026 | Dwelling | Smithing? | Lining |

| 39 | Sweden | Sandudden, NA 79 | L1996:7938 | Dwelling | Smithing? | Lining, fresh ore |

| 40 | Sweden | Räktjärv, Töre 50 | L1992:3598 | Grave | — | Knife, iron |

| 41 | Sweden | Bergnäsudden, NA 16 | L1996:9129 | Dwelling | ? | Slag (?) |

| 42 | Sweden | Kosjärv, Töre 510 | L1992:5683 | Dwelling | — | Slag(?), metallic iron, needle |

| 43 | Sweden | Månsträsk, NA 2145 | L1995:3887 | — | — | Fresh ore |

| 44 | Sweden | Notvik, NA2153 | L1995:3875 | — | — | Fresh ore |

| 45 | Sweden | Tellek | — | — | — | Fresh ore |

| 46 | Sweden | Masseviken, NA 357 | L1995:3605 | — | — | Fresh ore |

| 47 | Sweden | Nåludden, NA 397 | L1995:2182 | — | — | Fresh ore |

| 48 | Sweden | Vivungi, ore survey | — | — | — | Fresh ore |

| 49 | Sweden | Vuolgamjaur, NA 202 | L1995:2480 | — | — | Fresh ore |

| 50 | Sweden | Abraur, NA1738 | L1995:6070 | — | — | Fresh ore |

| 51 | Sweden | Abraur, Åmynne, NA 36, Apl | — | — | — | Fresh ore |

| 52 | Sweden | Skidträsk, NA 2179 | L1995:6955 | — | — | Fresh ore |

| 53 | Sweden | Ö Sguegesuolo, NA 48 | L1996:9549 | — | — | Fresh ore |

| 54 | Sweden | Vivungi, experiment | — | — | Experimental smelting | Slag, metallic iron |

Prior to our study, only a limited number of analyses had been published on Finnish, Swedish, and Norwegian ironworking materials (Bartolotta et al., 1988, 1990; Buchwald, 2005; Grälls, 1986; Hood & Olsen, 1988; Jørgensen, 2010; Sundquist, 1999). These analyses primarily targeted small iron ore and slag pieces (ranging from 2.5 to 10 cm in size), typically assessing a few key elements crucial for evaluating ore quality. In some instances, bulk chemical analyses were also conducted. As a result, there are few comparable analyses with available reference data. Our interdisciplinary approach and extensive knowledge of iron production and smithing processes have led to significant reinterpretations of previous micrographs and descriptions. However, already at the time of publishing, interpretations of some of the analytical results were questioned (Espelund, 1989). Additionally, in certain cases, residual pieces – though not necessarily the previously analyzed samples – have been re-examined, with new samples selected as close as possible to the original sampling place. These new analyses provide an opportunity to calibrate old analytical results, which often comprised fewer elements, with the comprehensive data generated by our study.

More recently, two iron production sites and one smithing site in Swedish Sangis and Vivungi underwent archaeological investigation and archaeometallurgical analyses conducted by us along with our fellow researchers (Bennerhag et al., 2021). We applied the same methods used in the current study, enabling direct analytical comparison. Consequently, the findings from the Sangis and Vivungi sites serve as a foundational reference framework, with some of the slags, technical ceramics (hearth linings), and ancient ores from these sites also re-examined in the present study. These sites have been under investigation since at least 2006 (Bennerhag et al., 2021).

3.1 Chronology

Previously, radiocarbon dating of charcoal samples from and around construction remains has been carried out at 19 of the 42 studied sites. These sites were primarily iron production sites, although, at the time of the dating, they were generally not yet known as either smelting or smithing sites. The majority of these sites have been attributed to the pre-Roman Iron Age, representing the initial phase of iron technology in Arctic Europe (as detailed in Tables 2–4). In our current study, we have expanded this dataset by conducting new radiocarbon dating on metallurgical remains at three previously undated sites and seven previously dated sites. We achieved this by sampling charcoal trapped in slag and extracting carbon from iron (steel). Prior to radiocarbon dating, wood species analyses were conducted to assess the intrinsic age of the charcoal samples and address potential errors such as the “old wood effect.” Additionally, contamination from fossil carbon was ruled out due to the absence of calcium carbonates in the local geology (Gassman & Schäfer, 2018). This approach allowed us to obtain reliable dating for the actual ironworking and confirm the established chronology (as summarized in Tables 2–4). However, 20 of the analyzed sites remain undated with respect to archaeometric analyses, and the chronology at these sites remains uncertain. The challenge lies in making fine-scale chronological attributions due to the long-term use of these sites. This complexity is particularly pronounced for interior sites, which, owing to land uplift, may contain traces of settlements extending back over 10,000 years. To address this, we have approximated the dating of metallurgical material at these sites through a careful analysis of its contextual relation to typologically dated asbestos-tempered ceramics (Hulthén, 1991; Jørgensen & Olsen, 1988). Consequently, these sites are assigned to a broader Late Bronze Age/pre-Roman – Roman Iron Age phase.

Radiocarbon dating, Finland

| Site | Sample | Context | Material | 14C-age (BP) | Lab id |

|---|---|---|---|---|---|

| Kemijärvi, Neitilä | KM 16145:68 | 1.5 m from furnace | Charcoal in slag | 2074 ± 33 BP | Ua-643441 |

| Kemijärvi, Neitilä | KM 16145:1678 | 1 m from furnace | Carbon from steel | 1968 ± 31 BP | Ua-660621 |

| Kajani, Äkälänniemi | KM 21213:55_1 | Furnace, slagheap | Charcoal in slag | 2195 ± 31 BP | Ua-643431 |

| Kajani, Äkälänniemi | KM 21213:55_2 | Furnace, slagheap | Carbon from steel | 1970 ± 28 BP | Ua-677781 |

| Rovaniemi, Riitakanranta | KM 26172:391 | 3.5 m from furnace | Carbon from steel | 2048 ± 28 BP | Ua-660631 |

| Rovaniemi, Riitakanranta | KM 25374:107:2 | Furnace | Carbon from steel | Undatable1 | |

| Mikkeli, Kitulansuo, Ristiina | KM 28960:1749:2 | Furnace | Carbon from steel | 1722 ± 42 BP | Ua-677791 |

| Mikkeli, Kitulansuo, Ristiina | KM 28960:2224 | Furnace, slagheap | Carbon from steel | Undatable1 | |

| Kajani, Äkälänniemi | — | — | Charcoal | 2220 ± 100 BP | Hel-20982 |

| Kajani, Äkälänniemi | — | — | Charcoal | 2180 ± 90 BP | Hel-21012 |

| Rovaniemi, Riitakanranta | — | Furnace | Charcoal | 2090 ± 100 BP | Hel-29553 |

| Rovaniemi, Riitakanranta | — | Furnace | Charcoal | 1820 ± 110 BP | Hel-29653 |

| Rovaniemi, Kotijänkä | — | — | Charcoal | 1560 ± 90 | Tku-0343 |

| Rovaniemi, Kotijänkä | — | — | Charcoal | 1750 ± 90 | Tku-0353 |

| Rovaniemi, Kotijänkä | — | Furnace | Charcoal | 1880 ± 110 | Hel-31733 |

| Mikkeli, Kitulansuo, Ristiina | — | Furnace | Charcoal | 1530 ± 80 BP | Hel-38374 |

| Lahti, Kilpisaari I | — | In connection to the furnace | Charcoal | AD 550 | Unpublished5 |

Radiocarbon dating, Norway

| Site | Sample | Context | Material | 14C-age (BP) | Lab id |

|---|---|---|---|---|---|

| Hemmestad Nedre | 11225C | Structure I (furnace) | Charcoal (pine) | 2300 ± 30 | Ua-671091 |

| Hemmestad Nedre | 11225B | Furnace II | Charcoal in slag (coniferous tree) | Undatable1 | |

| Slettnes | 9433e | Smithing | Charcoal on iron (deciduous tree/birch?) | 1189 ± 29 | Ua-671081 |

| Øvreværet | 11297:2 | Smelting/primary smithing | Carbon from steel included in slag | 281 ± 26 | Ua-677771 |

| Hemmestad Nedre | — | Furnace I | Charcoal (pine/birch) | 2344 ± 69 | T-147612 |

| Hemmestad Nedre | — | Furnace I, slagheap | Charcoal (pine/birch) | 2360 ± 89 | T-147622 |

| Hemmestad Nedre | — | Furnace II | Charcoal (birch) | 2351 ± 67 | Tua-26622 |

| Hemmestad Nedre | — | Furnace II, below furnace (slag pit?) | Charcoal (pine/birch) | 2255 ± 68 | Tua-26632 |

| Hemmestad Nedre | — | Charcoal kiln | Charcoal (deciduous trees) | 2247 ± 70 | T-147632 |

| Flakstadvåg | — | 1 m outside the furnace | Charcoal (pine) | 1747 ± 37 | T-131262 |

| Flakstadvåg | — | Furnace | Charcoal in slag (pine) | 1793 ± 34 | Wk-206392 |

| Slettnes | — | Tuft F204 | Charcoal | 1160 ± 70 | Beta-522203 |

| Slettnes | — | Tuft F204 | Charcoal | 1250 ± 80 | Beta-522193 |

| Øvreværet | — | Charcoal | 2296 ± 70 | T-42964 | |

| Øvreværet | — | Tilv. 1981/43, F56 | Organic material adhered to ceramics | 2380 ± 55 | TUa-24485 |

| Fjære | — | Ceramics | 2860 ± 110 | T-61516 | |

| Makkholla | — | Felt II, rute 42x, -3y, lag 2 | Reindeer antler | 2280 ± 100 | T-48157 |

| Makkholla | — | Felt III, rute 5x, -1y, lag 3 | Charcoal (birch) | 2400 ± 110 | T-48147 |

| Mestersanden | — | Cultural layer, area 3 | Fishbone | 1650 ± 90 | T-17288 |

| Mestersanden | — | Cultural layer, area 3 | Fishbone | 1700 ± 90 | T-17298 |

| Mestersanden | — | Cultural layer, area 4 | Reindeer antler | 1770 ± 90 | T-27438 |

| Mestersanden | — | — | Ceramics | 2550 ± 100 | T-61476 |

| Mestersanden | — | — | Ceramics | 2170 ± 90 | T-64726 |

| Mestersanden | — | — | Ceramics | 2450 ± 120 | T-64746 |

Radiocarbon dating, Sweden

| Site | Sample | Context | Material | 14C-age (BP) | Lab id |

|---|---|---|---|---|---|

| Sandudden, NA 82 | No 30 | Smithing | Charcoal in slag (pine) | 1747 ± 30 | Ua-696991 |

| Sangis 797 | — | Smithing | Charcoal in slag (pine) | 1676 ± 36 | Ua-697001 |

| Revi | SMA 3319 | Smelting | Charcoal in slag (pine) | 1955 ± 30 | Ua-697011 |

| Sangis 842 | F13:1 | Furnace, slag heap | Charcoal in slag (pine) | 2295 ± 35 | Ua-387062 |

| Sangis 842 | — | Furnace, slag heap | Charcoal (birch) | 2025 ± 30 | Ua-405882 |

| Sangis 842 | F759 | Furnace, slag heap | Carbon extracted from steel (iron waste) | 1994 ± 31 | Ua-577872 |

| Sangis 842 | — | Furnace, slag pit | Charcoal (birch) | 1950 ± 32 | Ua-405892 |

| Sangis 730 | F1112 | Smithing hearth A4 | Charcoal in slag (pine) | 2980 ± 100 | Ua-362932 |

| Sangis 730 | F7045 | Smithing hearth A4 | Carbon extracted from steel (iron waste) | 2186 ± 29 | Ua-595982 |

| Sangis 730 | — | Smithing hearth A4 | Charcoal (pine) | 2125 ± 30 | Ua-333352 |

| Sangis 730 | F925 | Smithing hearth A4 | Carbon extracted from steel (iron waste) | 1981 ± 77 | Ua-595952 |

| Sangis 730 | F2768 | Structure A27 | Pottery | 2740 ± 30 | Poz-239602 |

| Sangis 730 | — | Structure A27 | Burnt bone | 2720 ± 110 | Poz-236112 |

| Sangis 730 | F1784 | Structure A27 | Charcoal (organic residue next to bronze buckle) | 1990 ± 30 | Poz-237332 |

| Sangis 730 | F2771 | Structure A27 | Carbon extracted from steel (unidentified object) | 1966 ± 34 | Ua- 595972 |

| Sangis 730 | F3010 | Structure A27 | Carbon extracted from steel (iron waste) | 1895 ± 30 | Ua-362962 |

| Sangis 730 | — | Structure A29 | Charcoal (crowberry, small twigs) | 1885 ± 30 | Poz-237372 |

| Sangis 730 | — | Structure A29 | Burnt bone | 1850 ± 50 | Poz-236102 |

| Sangis 730 | F3763 | Smithing hearth, A45 | Charcoal in slag (pine) | 2430 ± 75 | Ua-362942 |

| Sangis 730 | — | Smithing hearth A45 | Burnt bone | 2115 ± 35 | Poz-236082 |

| Sangis 730 | F1840 | Smithing hearth A53 | Carbon extracted from steel (iron waste) | 2150 ± 30 | Ua-595962 |

| Sangis 730 | F913 | Smithing hearth A53 | Charcoal in slag (pine) | 1915 ± 35 | Ua-362922 |

| Sangis 730 | F2684 | Single find within site | Carbon extracted from steel (socketed axe) | 2115 ± 30 | Ua-362952 |

| Sangis 730 | F878 | Single find within site | Carbon extracted from steel (knife) | 1831 ± 41 | Ua-595942 |

| Vivungi 723 | — | Furnace 2, slag pit | Charcoal (pine) | 2076 ± 32 | Ua-574882 |

| Vivungi 723 | — | Furnace 2, slag heap | Charcoal (pine, twig/branch) | 1962 ± 31 | Ua-574872 |

| Vivungi 723 | Id 392 | Furnace 2, slag heap | Carbon extracted from steel (iron waste) | 1899 ± 32 | Ua-577882 |

| Vivungi 723 | — | Furnace 2, slag heap | Charcoal (pine) | 1820 ± 32 | Ua-574912 |

| Vivungi 723 | — | Furnace 3, slag heap | Charcoal (pine) | 2124 ± 32 | Ua-574892 |

| Vivungi 723 | — | Furnace 3, slag pit | Charcoal (pine, twig/branch) | 2035 ± 32 | Ua-574902 |

| Vivungi 723 | Id 1759 | Furnace 3, slag heap | Carbon extracted from steel (iron waste) | 1998 ± 31 | Ua-577892 |

| Vivungi 723 | — | Single find within site | Charcoal in slag (birch) | 2097 ± 29 | Ua-512792 |

| Töre 50 | — | Grave | Cremated human bones | 1761 ± 39 | Ua-515693 |

| Nederluleå 90 | Kp 6 | Dwelling site, house | Charcoal | 2000 ± 35 | Ua-368004 |

| Nederluleå 90 | Kp 16 | Dwelling site, house | Organic material adhered to ceramics | 2035 ± 30 | Ua-368014 |

| Nederluleå 90 | Kp 13 | Dwelling site, house | Charcoal | 2060 ± 35 | Ua-368024 |

| Nåttiholmen | 128 | Dwelling site | Organic material adhered to ceramics | 2286 ± 30 | Ua-727025 |

| Nåttiholmen | 131 | Dwelling site | Organic material adhered to ceramics | 2177 ± 30 | Ua-727035 |

| Nåttiholmen | 237 | Dwelling site | Organic material adhered to ceramics | 2413 ± 31 | Ua-727045 |

| Nåttiholmen | 304 | Dwelling site | Organic material adhered to ceramics | 2321 ± 30 | Ua-727055 |

| Nåttiholmen | 308 | Dwelling site | Organic material adhered to ceramics | 2313 ± 30 | Ua-727065 |

| Kosjärv | — | Dwellingsite | Burnt bone | 2280 ± 40 | Ua-331796 |

3.2 Data Collection, Sampling Strategy, and Constraints

A stepwise strategy was employed to collect data related to prehistoric metallurgical material in Arctic Europe. The process began with a comprehensive review of excavation reports, museum collection databases, and published works on various sites. The primary focus was on sites representing the initial phase of iron technology, specifically those dated to the Late Bronze Age, pre-Roman Iron Age, and Roman Iron Age. The initial selection method was primarily based on available radiocarbon dating and the depositional contexts of the finds, which were dated by the associated pottery and so-called “Stone Age finds” (certain asbestos-tempered pottery and lithics). Sites were also selected according to geographical spread (to cover the widest possible area). Additionally, sites were chosen based on their association with Kjelmöy and Risvik ceramics, which, according to previous literature, are linked respectively to hunter-gatherer and agrarian economies (Bennerhag et al., 2023). Subsequently, material studies were conducted at the archival institutions holding the metallurgical material: in Finland at the Finnish Heritage Agency in Helsinki, in Norway at the Arctic University Museum of Norway in Tromsø, and in Sweden at the Silver Museum in Arjeplog and the County Museum of Norrbotten in Luleå. This thorough approach allowed us to refine the chronology.

Our selection process at each institution was guided by a visual (macroscopic) examination of the finds. Specifically, we focused on slag samples, aiming to create a representative collection that encompassed different morphological types. This allowed us to identify various production processes associated with ironworking. The most common type of slag, as observed macroscopically, was included in our selection. Additionally, we deliberately chose samples of slag that deviated in form, texture, and magnetism. The degree of magnetism served as an indicator of the specific type of slag. Moreover, iron fragments lost in the production process or parts of objects/semi-finished objects were especially targeted to establish the different types and qualities of iron used and produced. The most magnetic pieces were selected with the aid of a magnet. In addition to slag and iron fragments, we also considered technical ceramics. Our selection criteria for technical ceramics were based on identifiable shape and macroscopic observations of temperature gradients. By studying these ceramics, we aimed to identify variations in raw materials (such as clay), understand the construction details of furnace shafts and smithing hearths, and explore aspects related to refractivity and firing temperatures. In some instances, the sampling was limited to a few technical ceramic fragments overall recovered from excavation.

In addition, samples were taken from fresh ore found in the vicinity of the Swedish lakes Kakel and Storavan. The purpose was to assess whether these ores were viable for iron production. These ore samples were originally collected during archaeological surveys conducted in the 1970s–1980s due to hydropower expansion in the area. At the time of collection, the approach followed an unrestricted sampling design. This meant that artifacts and anomalous objects were gathered without regard to their cultural or natural affiliation, as well as the historical period they represented (sometimes even misidentified and referred to as slag).

As part of our study, we also surveyed the raw material supplies in the local vicinity of the excavated iron production site in Vivungi, Sweden. Our goal was to gain insights into the availability and quality of both local clay and ore. This work involved close collaboration with local residents, who actively participated in the surveys and shared invaluable knowledge about the local raw material sources they were familiar with from participating in modern taskscapes. Our surveys revealed numerous sources of limonite ore in the local lakes. However, locating high-quality clays proved to be quite challenging. The nearest clay source was more than 15 km away.

Of particular interest for our sampling was the large assemblage from metalworking collected between the 1940s and 1980s in Arctic Sweden, Finland, and Norway. These collections resulted from surveys and excavations of ancient settlements associated with lake regulations and hydropower expansion. While the number of slag fragments found at each site was limited, the aggregated material from all these sites represents an extensive landscape of metalworking. Intriguingly, this material was found at early hunter-gatherer sites, alongside Stone Age artifacts – including lithics, projectile points, and pottery – indicating an early utilization of iron. However, during the time of recovery, these sites posed challenges due to persistent evolutionary ideas. These ideas revolved around the dichotomy between hunter-gatherers and farmers and the dominant chronological model of the Three-Age system, with the assumed evolutionary stages inherent in the progression from the Stone Age – the Bronze Age and the Iron Age. The material context did not align with these evolutionary ideas, and as a result, a general idea of a “delayed Stone Age” (rather than an “Early Iron Age”) was established, which in turn meant that the metallurgical remains were severely neglected, and no methods were employed for the identification of the metallurgical material, such as archaeometric analyses including radiocarbon dating of carbon in steel and charcoal trapped in slag – methods since long established in European iron research.

The preconceived notions regarding the Arctic regions of Scandinavia as a periphery with a relatively late settlement history have significantly influenced interpretations of the metallurgical material associated with lake regulations. Unfortunately, the documentation of this material collection often lacks contextual records. This is particularly pronounced when it comes to slags, which were traditionally regarded as waste material with limited information, meaning that some slag finds were not even collected. Furthermore, misidentifications have significantly impacted our understanding of the material, typically downplaying variation, i.e., almost all the metallurgical material has been unilaterally recorded as slag and, in rare cases, as burnt clay. While a few archaeological features and structures related to metallurgical activities have been identified, there is a notable absence of hammer scales (magnetic flakes detached from metal during smithing) among the collected material, although these should have been part of the material, given the now-identified smithing activities. Unfortunately, several of the sites are now submerged underwater and exposed to erosion due to the construction of dams and hydroelectric power stations. As a result, much of the microscopic evidence of production activity has been irretrievably lost. Unfortunately, these conventional views persist within the material-holding institutions, leading to selection-related restrictions (such as sampling) that were occasionally imposed before we could study the material. Additionally, parts of the collections remain stored in inaccessible find magazines. The institutions were rather uncomprehensive by the fact that slags could provide interesting information if explored more comprehensively, as it (according to the traditional view) was considered waste/mass material.

Overall, our study encompasses material collected over a 70-year period (including our recent excavations) with all that this entails in terms of varying interpretative and methodological perspectives, practical research techniques, and levels of ambition. Despite the serious limitations, we have managed to distinguish both reduction and smithing slag alongside technical ceramics (such as furnace wall and hearth lining), ore, iron waste, and iron fragments across a broad geographical area. These aggregated sites form a rich and extensive landscape of metalworking, allowing us to draw initial but substantial conclusions about the technology and organization involved. Slags and other refuse materials provide more informative insights into the metal craft than merely examining the morphology of the final products. This shift in focus from product to process represents a departure from the traditional approach in North Scandinavian iron research. Consequently, this material offers a valuable synchronic perspective on Early Iron Age metallurgical traditions in the Arctic European area.

3.3 Set of Samples, Methods, and Detailed Analyses

In total, 237 finds were selected for the present study: 65 from Finland, 33 from Norway, and 139 from Sweden (some of which included more than one underlying find item and various material types) (for details, see Supplementary S.5–S.7). Most of these finds consist of reduction or smithing slags (including both primary and secondary smithing) and technical ceramics (furnace walls and hearth linings). Additionally, the collection includes iron waste, fragments of iron objects, fresh and ancient ores, heat-affected stones, stones with slag cover, and red-brown magnetic particles and lumps. Initially, a visual inspection and morphological description were conducted on all the sampled material. This process included a special recording of technical ceramics and a characterization of slag finds based on their degree of magnetism. Subsequently, in collaboration with archaeometric fellow researchers, we selected samples for more detailed analyses.

We employed archaeometric analyses to extract relevant metallurgical information about the metal smelting and smithing material. These analyses also shed light on the technologies used to reconstruct craft practices. Furthermore, we aimed to gain insights into the economic organization, resource acquisition, and the overall social context of metal technology. Understanding the production processes is crucial for establishing the various activities and practices related to iron production at each site. Additionally, it allows us to explore how metalworking was integrated into the organization of society and the overall spatial layout of the crafting landscape (Erb-Satullo, 2022). Variations in resource acquisition and production practices may also indicate different levels of participation among distinct social groups across different communities.

Several analytical methods were employed for the metallurgical finds. Metallographic analyses were conducted on iron waste to establish its quality, determining whether it is ferritic iron, steel, or, for instance, phosphoric iron. Additionally, petrographic and bulk chemical analyses were performed on slag samples. The primary purpose was to define the process stage during which the slag was formed and to determine its composition in terms of major, minor, and trace elements. This allowed for a comparison of slags from various contexts (both within and between sites) and provided insights into the types of ores used. Furthermore, samples of fresh iron ore underwent test-roasting and were subjected to petrographic and chemical analysis. These assessments aimed to evaluate the quality of the local ore and uncover possible prehistoric connections and uses. Additionally, technical ceramics (primarily from furnace walls and hearth linings) were classified and recorded macroscopically. A subset of these ceramics underwent further analysis, including petrographic microscopy and thermal analyses. These investigations helped establish raw material choices and provided insights into construction and curation strategies. Moreover, they shed light on the thermal and mechanical properties of the clays (Supplementary S.1).

Radiocarbon dating has been performed on iron waste and samples of charcoal included in slag. Before dating the charcoal, wood species analyses were conducted to assess the intrinsic age of the sample and identify possible sources of error. The radiocarbon dates consistently fall within the pre-Roman to Roman Iron Age period, except for a sample from Norway that was radiocarbon dated to the Viking Age (AD 800–1050). Tables 2–4 provide a compilation of all radiocarbon dating samples, including previous data from excavated iron production and smithing sites.

4 Results

Although the amount of slag at each site is small compared to the more large-scale production in Europe during later times, and not all find categories are covered at every site, the analyzed material (along with its spatial distribution), considered a group of formally related remains, unambiguously suggests an extensive ironworking landscape in Arctic Europe already during the Early Iron Age. Our sites, encompassing both smithing and smelting activities, are almost exclusively radiocarbon-dated to the pre-Roman and Roman Iron Age. We observe a high degree of conformity across the sites, where all aspects of the technological chaîne opératoire appear to have been established from the very outset of iron production. For more detailed information on the results of archaeometallurgical analyses (presented in Section 4), see Supplementary S.2–S.4 (Grandin, 2019, 2020, 2021; Stilborg, 2020, 2021a,b).

4.1 Iron Smelting

Analytical results confirm the production of iron at 10 previously excavated production sites (Bennerhag et al., 2021; Forsberg, 2012; Jørgensen, 2010), with 16 furnaces spread throughout Arctic Norway, Sweden, and Finland. Radiocarbon dating spans the period from 300 BC to AD 300 (Figure 1, Tables 2–4). These sites include Hemmestad and Flakstadvåg in Norway, Sangis and Vivungi in Sweden, and Riitakanranta, Kotijänki, Kemijärvi, Äkälänniemi, Mikkeli, and Lahti in Finland. Additionally, two smelting sites have been confirmed in the Lake Kakel area in northern Sweden. These sites, known as the Revi site (SMA 3319) and the Nåtti site (without a number), were identified through detailed petrographic and chemical analyses of stearin-like slag. Notably, these sites currently lack any traces of furnace construction. As they belong to the lake-regulation material, they are submerged and further excavations are not possible. The Revi slag has been radiocarbon-dated (using charcoal inclusion in the slag) to the pre-Roman Iron Age (Figure 1 and Table 4).

Interpretations in the literature regarding iron smelting in the Arctic European area have often centered around a dichotomic division of furnace remains into a western and eastern cultural sphere attributed to different smelting technologies and traditions. The argument stems from reconstruction models of the furnaces, which, unfortunately, rely on insufficient knowledge regarding the necessary criteria for the smelting process to function effectively. For instance, the aerodynamic perspective emphasizes the fundamental role of furnace shaft height, as well as the need for adequate room above the slag mass for the bloom to form. In the literature, the eastern furnaces (in our study including the north Swedish and north Finnish sites) are typically associated with a relic and archaic bowl-furnace technology, lacking superstructures (Kotivuori, 2013; Lavento, 1999). These furnaces are often seen as part of a hunter-gatherer economy. In contrast, the western furnaces (in our study including the Norwegian sites) are considered part of a supposedly superior European shaft furnace tradition (Jørgensen, 2010) related to agrarian societies (Pleiner, 2000). However, our findings diverge from this prevailing view. Substantial evidence from clay-built furnace shafts at all our smelting sites suggests a consistent smelting technology across the entire region – from Finland in the east to Norway in the west. Notably, recent years have witnessed discussions questioning the overall validity of the typological division of furnace constructions at a broader European level. Consequently, the tendency to downgrade furnace types for certain groups extends beyond Arctic Europe (Dungworth, 2014; Hjärthner-Holdar et al., 2018; Rondelez, 2017).

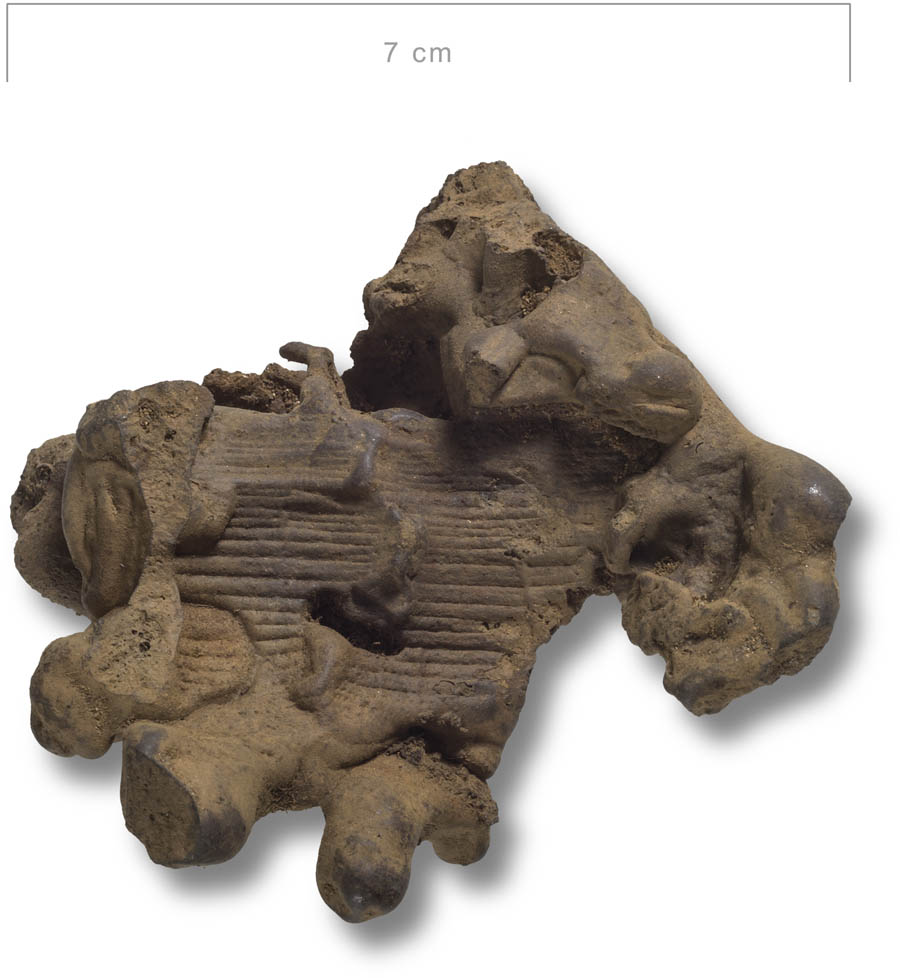

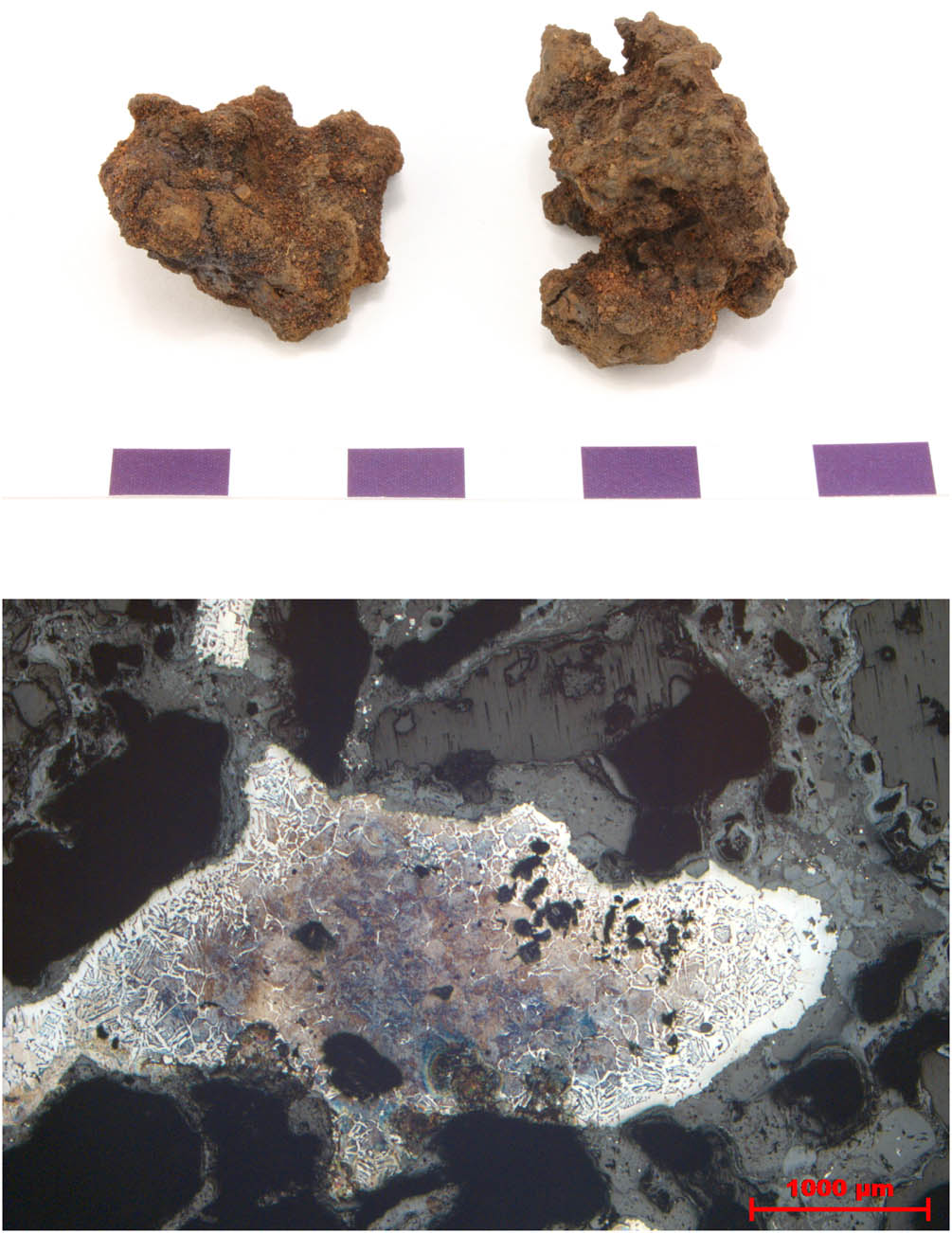

Analyses of process-related parameters at sites with construction remains demonstrate, at odds with literature, that smelting operations took place in small bloomery furnaces (inner diameter of app. 0.3 m) with an upright cylindrical shaft made of clay, and with a rectangular stone framed base and underlying slag pit, in a few cases lined with clay (Figure 2). Analyses further demonstrate that the furnaces were used several times. Roasted limonites in terms of lake and bog ores along with charcoal (as fuel) from pine and birch were used in the smelting process; the charcoal provided the high temperatures and the reducing atmosphere needed for the iron ore to reduce into metallic iron. Air-inlet holes, visible on furnace wall fragments, were identified at all sites with construction remains, indicating that air was supplied using bellows (Figure 3). The bellows were placed at the bottom of the furnace shaft and mounted on the stone frame – the hottest zone of the furnace, where temperatures slightly exceeded 1,250°C. Within this zone, the viscous slag (Figure 4) separated from the solid iron and accumulated at the bottom part of the furnace in the slag pit. Subsequently, the slag was removed through an arch in the stone frame or through the top of the furnace. Since the smelting occurred below the melting temperature of iron, the iron formed in a solid state, creating a spongey mass known as a bloom just below the blowing zone. Remarkably, blooms are rarely found in archaeological material globally. However, at 7 of our 12 smelting sites, small fragments of iron waste (detached parts of blooms showing no signs of additional consolidation or mechanical processing) were discovered around the furnaces (Figure 5). Overall, the ancient Arctic furnace technology aligns with the shaft furnace technology – essentially the same basic technology used in other contemporary and later iron production furnaces (Bennerhag et al., 2021; Hjärthner-Holdar et al., 2018).

Bloomery furnaces at the Vivungi site, northern Sweden. Within one of the furnaces, a circular charcoal feature was discovered, indicating that the inner part of the furnace shaft was round (photograph by Carina Bennerhag © Norrbottens museum).

A wall fragment from one of the furnaces at the Vivungi site, comprising a section of the original clay shaft (with an air inlet hole), and parts of the stone frame (photograph by Staffan Nygren © Norrbottens museum).

Stearin-like reduction slag from the iron production site in Vivungi, featuring well-preserved charcoal imprints (photograph by Staffan Nygren © Norrbottens museum).

Iron waste from the Vivungi site. The etched sample shows a pearlite texture, which demonstrates a high carbon content (photograph and micrograph by E. Ogenhall © The Archaeologists, Swedish National Historical Museums).

4.2 Iron Smithing

Evidence from smithing is more abundant than evidence from iron smelting in the analyzed material. Twenty-seven of the 42 studied sites show indications of smithing, with a significant portion spatially connected to large settlement sites. These sites are spread across a vast geographic area covering northernmost Norway and Sweden (Figure 1 and Table 1). However, regarding Finland, language barriers and lack of time have contributed to the fact that the Finnish smithing material (although smithing finds are abundant also in the Finnish material) has not yet been selected and analyzed.

Physical remains of ancient smithing hearths are rare, and overall, there is limited knowledge in the literature regarding the organization of European iron workshops and roofed forges during the Early Iron Ages (for exceptions, see Berranger & Fluzin, 2014; Dieudonné-Glad, 1997; Englund & Hjärthner-Holdar, 2017). Historically, the focus has been on the exchange and trade of metal objects rather than the organization of metal production. If any physical remains exist, they are generally limited to the spatial distribution of slags, iron waste (bloom pieces), hammering scales (indicating the location of the anvil) (Figure 6), and remnants of the clay lining of slag pits. Against this backdrop, our relatively abundant discoveries of smithing installations in Arctic Europe stand out as remarkable.

Hammering scales produced during smithing, the distribution indicating the location of the anvil (photo © Norrbottens museum).

In our study, we have identified various types of smithing remains, with slag cakes – each corresponding to a single work session – being the most common debris found at smithing sites in both Sweden and Norway. Most of these slag cakes result from object fabrication and consequently exhibit oxidizing conditions (Serneels & Perret, 2003). However, we also find smithing slag cakes displaying reducing conditions, along with separate lumps of metallic iron (either concentrated within slag or as distinct pieces). These findings suggest that bloom consolidation (primary smithing) (Erb-Satullo & Walton, 2017) occurred right at the smithing sites. Interestingly, and contrary to existing literature, this implies iron blooms (rather than semi-finished products like iron bars) served as raw material for smithing. The prevailing organizational model of iron working in Europe (primarily based on materials from the Late Iron Age) is the primary forging of the raw iron was carried out at the smelting site before being distributed to various workshops (for exceptions see, e.g., Bauvais & Fluzin, 2009). The Arctic organizational way of iron working appears to have required the close proximity of smithing and smelting sites, as blooms are unwieldy to transport over long distances. This is supported by three of our 27 studied smithing sites (specifically the Swedish Revi, Nåtti, and Sangis sites), where the distance between smithing and smelting ranges from 10–500 m. Additionally, the proximity between smelting and smithing offered logistical advantages, especially regarding the use of charcoal, essential for both processes, since there is a great risk for charcoal to shatter while transported.

At two of our excavated sites, Sangis and Vallen, remarkable evidence of hearth installations – characterized by oval features containing charcoal – has been uncovered (Figure 7). What makes this discovery even more significant is that one of these hearths was found within the remains of a hut. Consequently, the pre-Roman Vallen site now stands as the oldest known remains from a roofed forge in all of Scandinavia. Before this, the oldest known iron workshop with a roof (dating to the Roman Iron Age) was located in southern Sweden, approximately 1,000 km south of Vallen (Englund & Hjärthner-Holdar, 2017). In the broader context of Arctic Europe, only a limited number of metallurgical contexts with evidence of forging installations have been previously excavated, primarily from later periods (around AD 400 and beyond) (Jørgensen, 2012). Interestingly, workshops are not even mentioned in the literature concerning Arctic Europe during earlier periods. Finds of smithing slag are often interpreted simply as evidence for tool maintenance (Sundquist, 1999). However, our research underscores the critical role of controlled lighting for ancient Arctic blacksmiths. This lighting allowed them to observe color changes in iron – an essential aspect for understanding the metal’s temperature and behavior during heating. Consequently, it strongly suggests that forging took place under a roof, shielding the process from direct sunlight and rain, as well as the harsh Arctic winters. This concept likely applies to smelting as well, where the smelter requires optimal conditions to monitor the process (Stepanov et al., 2022). Unfortunately, several of our sites are now submerged underwater due to dam construction, making it challenging to further substantiate these hypotheses regarding our sites.

Smithing hearth structure in cross section, recovered at the Sangis site, northern Sweden (photo © Norrbottens museum).

Additionally, finished metal artifacts have been unearthed at various Swedish and Norwegian smithing sites. Among these artifacts, knives constitute the majority of finds. Notably, two knives and an axe from Sangis – whose chemical composition indicates they were made from local ores – have been analyzed and radiocarbon-dated. These artifacts span the period from 200 BC to AD 100. Given the context, it is likely that the yet-to-be-dated knives also originate from this same time frame.

4.3 Raw Materials

The knowledge and availability of raw materials significantly influence the technological choices and chaîne opératoire of the ironworking process. This impact is particularly pronounced for pyrotechnical ceramics (furnace walls and hearth linings). The functionality of these ceramics is significantly constrained by the thermo-mechanical properties of the clay, including plasticity and refractoriness (i.e., performance at extremely high temperatures). Selecting and supplying clay that can endure high temperatures while remaining sufficiently plastic for constructing a maintainable shaft is a crucial but often overlooked aspect of iron manufacturing (Martinón-Torres & Rehren, 2014; Stilborg, 2023). Constructions used to smelt iron ores – often built wholly or partly of clay – must withstand temperatures of up to 1,200–1,300°C for extended periods. Most natural clays in Scandinavia possess adequate refractivity for bloomery process temperatures. However, there are exceptions. Calciferous clays and clays with large iron oxide concentrations or iron-rich rock fragments may lead to instability and, in the worst-case scenario, collapsing furnace walls. To enhance refractivity, tempering the clay with non-plastic, often silicate-rich materials (such as quartz), can be beneficial.

Procurement analyses reveal a complex raw material composition at many of our sites, with deliberate selections of clays possessing special characteristics. Notably, the Finnish Neitilä, Äkkälänniemi, and Riitakanranta smelting sites exhibit close similarities to the Swedish Sangis and Vivungi melting sites. At these locations, smelters employed medium to very coarse-grained clays for constructing furnace shafts. Although these clays had a high volume of sand (predominantly quartz, enhancing thermal properties), they were somewhat limited in plasticity. However, to gain a deeper understanding of the choice of clay, we require additional information about the types of clay available in the areas surrounding these sites. This would help determine whether clay choices were primarily influenced by a shared craft tradition or driven by geological factors. Interestingly, our analyses indicate that curation strategies were adapted to address the insufficient plastic qualities of the clay. Instead of rebuilding the furnaces, cracks were repeatedly repaired, and layers of clay were applied between runs. After each repair, the furnaces continued to be used for additional smelting cycles. This practice underscores widespread knowledge of handling this specific type of clay. Furthermore, the sintering interval of these clays exhibits deformation and melting between 1,150 and 1,250°C, indicating narrow temperature windows for carrying out metallurgical processes. Consequently, ancient smelters skillfully balanced working temperatures on the very edge of the furnace’s thermal capability. Interestingly, nearly all analyzed smithing sites with refractory remains in terms of hearth linings – including most Swedish sites and approximately half of the Norwegian smithing sites – also employed the same coarse-grained clays as those used for the furnaces. These clays were well-suited for high-temperature operations.

Analyses reveal alternative choices of clay at the Swedish Vivungi and the Finnish Neitilä sites. These sites show the use of finer-grained clay with higher plasticity (while maintaining refractivity). This choice indicates a different curation strategy, where the furnace shaft was torn apart and re-built after only a few smelts. While the direct reason might have been that the furnace builders found a larger or closer clay bed with better plasticity, the fact that they could readily shift to a different curation strategy further testifies to their solid knowledge of the raw material.

At the Hemmestad and Flakstadvåg sites in Norway, as well as the Lahti site in southern Finland, clays with clearly low-refractory qualities were used. These included calciferous clay and clay stone, both unsuitable for high temperatures (a conclusion further supported by slag analyses indicating oxygen leakage into the furnaces caused by cracks). Interestingly, despite the repeated use of furnaces at the Hemmestad and Flakstadvåg sites, there are no signs of repairing the troublesome cracks that appeared in the furnace walls. The utilization of clays with low-refractory qualities, coupled with the lack of curation strategies at these sites, suggests a partly different technological system compared to the north Swedish and Finnish smelting sites. In an upcoming article, we intend to explore whether this divergence could be interpreted as a result of partly different knowledge acquisition.

The availability of viable ores was another essential component of smelting technology. Ancient ores are rarely found during excavations of iron production sites, and this study is no exception, with the Vivungi site being the sole outlier (Bennerhag et al., 2021). However, bulk chemical analysis of slag recovered from various iron smelting sites provides valuable information about the type of ancient iron ore used in the furnaces. These analyses exclusively show the use of limonite ores, which are generally abundant in the Arctic European geography (Aschan, 1906), across all 12 smelting sites. We infer that these ores are primarily lake ores. Consequently, all 12 sites are strategically located near lakes or watercourses, ensuring a steady supply of lake ores. This offers an advantage over bog ores, which can be depleted, as lake ores naturally renew every 25–50 years (Naumann, 1922). Additionally, we conducted further sampling and analysis of fresh ores (often mistaken for slag) collected during the lake regulation surveys in northern Sweden. Some of these fresh ores were found to be viable as iron ores, with a high iron oxide content exceeding 70% and the presence of manganese (2–4% MnO). Furthermore, the chemical composition of the ore collected from the lake adjacent to the Vivungi site correlates with bloomery slags from that same site, confirming that ancient smelters indeed sourced their ores from the lake.

Slag analyses further imply that ancient smelters employed ores with varying elemental compositions, which significantly impacted the quality of the manufactured iron. Specifically, the Finnish sites of Neitilä, Äkälänniemi, Riitakanranta, and Mikkeli utilized phosphorus ores (containing up to 1.7% P2O5), while the Swedish sites of Sangis and Vivungi, along with the Finnish sites mentioned earlier, used manganese-containing ores (ranging from 0.4 to 5 wt% MnO). The presence of phosphorus in the ores contributes to the production of ductile iron, albeit with some hardness. On the other hand, manganese enables the direct production of steel within the bloomery furnace (see, e.g., Bennerhag et al., 2021; Crew et al., 2011; Hjärthner-Holdar et al., 2018). This results in a harder product that has the potential for various heat treatments, further enhancing its material properties. Notably, this practice was not unique to our analyzed sites but was also widespread elsewhere in Europe during that period (Hjärthner-Holdar et al., 2018).

4.4 Iron Alloys

We gain valuable insight into what was achievable in the furnaces from the small fragments of iron waste – detached parts of blooms measuring 10–40 mm – that were recovered at seven of the ten smelting sites with construction remains. At two of these seven sites (both located in northern Sweden), over 1 kg of iron waste was discovered. However, at the other three smelting sites – the Finnish Lahti and the Norwegian Hemmestad and Flakstadvåg sites – no metallic iron debris was found. This absence of iron waste may be attributed to problems observed during the reduction process.

At all seven smelting sites with iron waste, metallographic analyses demonstrate a highly similar pattern in terms of high levels of carbon (more than 0.8% C). Consequently, this study establishes the presence of high-quality steel as a key iron alloy. At six sites (Swedish Sangis and Vivungi, Finnish Neitilä, Äkälänniemi, Riitakanranta, and Mikkeli), this can be attributed to the use of manganese-containing ores (evidenced through chemical analyses of slag), indicating deliberate steel production directly in the bloomery furnace. Even cast iron (with more than 2% C), typically associated with blast furnace production (but also claimed to be an inevitable by-product of high-carbon steel production in bloomery furnaces, Crew et al., 2011), is revealed in a few lumps at the Swedish (Vivungi) and Finnish (Riitakanranta and Mikkeli) sites. The iron waste discovered at 6 of the 16 confirmed Swedish smithing sites (Sangis R730 and R797, Sandudden NA 54 and NA 82, Hoppot NA 36, and Vallen R 90) (Table 1), most likely originating from primary smithing, provides additional evidence of steel as a desired product. Furthermore, the presence of phosphoric iron observed at two Finnish smelting sites (Riitakanranta and Mikkeli) suggests a demand for hard and ductile metals. This is further confirmed by the chemical analyses of slag at these sites, as well as at two other Finnish sites (Neitilä and Äkälänniemi), which reveal the use of ores with a phosphorus content. The production of phosphoric iron in the Arctic European region is also indicated through the recovery of an iron knife at the Swedish Sangis smithing site, combining both phosphoric iron and steel.

4.5 Fabrication and Composition of Artifacts

Another crucial aspect of the technological system lies in how the smelted iron was shaped into desired products. Our analytical results reveal that the most typical fabrication techniques employed were on par with the cutting-edge technology of Europe during that era, both in terms of expertise and specialization. At the Sangis smithing site, artifact analyses demonstrate welding techniques that combined different steel and iron qualities (including both phosphorus and soft ferritic iron) into multilayered tools. These tools were further enhanced through various heat treatments, such as quenching and tempering. The analyzed objects – primarily knives and an axe – consistently featured the hardest steel along the edges, emphasizing the desire for tough and durable cutting tools. The fabrication techniques and iron alloys used were carefully tailored to specific tool types. Additionally, one of the analyzed knives provides evidence of an intent for visual and stylistic effects, achieved through lamination techniques that combine different layers of steel and phosphoric iron (Figure 8).

Knife composed of multiple layers of phosphoric iron and low-carbon steel, resembling pattern welding techniques commonly used in the Late Iron Age, found at the Sangis smithing site in northern Sweden (photograph by Staffan Nygren © Norrbottens museum).

In literature, the welding and laminating procedures observed in ancient Arctic Europe are widely regarded as the most challenging operations undertaken by ancient European smiths (Gilmour, 2017). The difficulty arises from the fact that the different iron alloys to be joined often have distinct optimal smithing temperatures (Güder et al., 2017), resulting in narrow temperature windows for successful attachment. Consequently, the ancient blacksmith’s ability to determine these temperatures using their senses – such as assessing the color of the glowing metal – becomes crucial. Previous literature suggests that these methods were attempted in Europe (particularly its central regions) as early as 500 BC. However, they did not gain widespread adoption until Roman times, eventually reaching the northern European continent during the Middle Ages (but never really to its Arctic parts) (Pleiner, 2006). Remarkably, the present study reveals that over 2,000 years ago, advanced smithing techniques were already established in Arctic Europe. These techniques persisted for 400–500 years, as documented at the Swedish Sangis site and in the Kakel and Storavan areas.

4.6 Similarities in Style and Technological Choice

A comparison between our studied sites reveals striking similarities in style and technological choices between the north Swedish and Finnish smelting sites, as well as between the north Norwegian and Swedish smithing sites (Finnish smithing material has not yet been selected and analyzed). Consequently, analyses demonstrate conformity in technological features, including the use of raw materials (clay and ore), curation strategies, and finished products (raw metal and artifacts). Moreover, there are only minor chronological differences between the sites. This “standardization,” which pertains to the mastery of excellent smelting and smithing operations identified at each workshop, strongly indicates a well-established and recognizable technology (possibly including a technological network) across a large geographical area in Arctic Europe.

Overall, our data allow us to reconstruct, for the Early Iron Age (200–50 BC), a departure from existing literature (Pleiner, 2000) by revealing the deliberate production of steel directly in the bloomery furnace. Steel can be traced through all stages of the metallurgical process, strongly indicating a widespread demand for steel as a product. The identification of phosphoric iron at some sites also suggests a demand for other alloys. The predominant use of coarse-grained clays and the repair technology observed at the north Swedish and Finnish smelting sites further point to conformity in technological tradition. While repairs themselves are not necessarily distinctive elements of a specific craft tradition, the fact that furnace shafts with necessary repairs could be reused underscores an established technological practice. A more significant and potentially defining detail lies in the apparent focus on repairing the area around the air-inlet hole(s). Interestingly, coarse-grained clays were also employed by ancient Arctic smiths, as evidenced by the remnants of hearth linings at both Swedish and Norwegian smithing sites. This observation suggests a knowledge base that may have differed from that of the smelters in the Norwegian region, who utilized much finer clays and adopted different curation strategies.

While our results reveal a shared, complex technological system across a large geographical area in Arctic Europe, it does not exclude individual or local differences in technical choices. Morphological characteristics point to certain variations in the construction of smithing hearths at both local and regional scales. For instance, there are differences in the placement of the clay lining: the north Norwegian sites feature wholly lined hearths, while the Swedish sites exhibit both wholly lined and upper-lined hearths. Additionally, the varying sizes and underlying contact materials (sandy subsoil or charcoal bed) for the slag cakes found at the Swedish smithing sites indicate diverse solutions for hearth constructions. These variations are further evident in the dimensions of the hearth lining remnants.

4.7 Landscape Structuring and Organization

The apparent conformity not only pertains to technological features but also extends to the spatial distribution of iron production and smithing operations. When mapped out, distinct clusters emerge around larger lakes and water bodies within forested landscapes (Figure 9). These clusters are closely related to primary resources – namely, ore and wood required for fuel. The spatial organization of smelting and smithing processes is particularly distinctive in Arctic Europe. In fact, the entire metal production cycle often unfolded within the same local context. By clustering different process stages spatially, ancient communities could effectively manage the complete metal production cycle – from ore selection to the manufacturing of finished objects. This sophisticated system relied on an extensive knowledge base held by the relatively small-scale Arctic hunting-gatherer communities, comprising 25–50 people (Kelly, 2013). Similar clustered organizational patterns are also suggested in Siberian iron workshops during the Iron Age (first to third centuries AD) (Vodyasov et al., 2021), as well as in Mongolia, northern Germany, and Denmark during pre-Roman times (Brosseder et al., 2023; Brumlich, 2020; Winther Olesen et al., 2020).

Excavation at the Vivungi site. The spatial clustering of iron production around larger lake systems indicates a strategic location near the primary resources of ore, fuel, and building material (photograph by Staffan Nygren © Norrbottens museum).

The water bodies further typically contained (and still do) an abundance of fish, and we have found large amounts of faunal remains from freshwater fish at the sites where we had access to material context (Sangis and Vivungi). Overall, this points toward coordination of iron production and good supply/utilization of fish. All the Swedish and the Norwegian smithing sites are further spatially connected to large known settlement places, and as a rule also to other craft activities, such as lithic technology, pottery, horn/bone, and skin/fur-craft. Hence, ironworking seems integrated with the existing material technologies and organizationally incorporated with other residential activities (Binford, 1979). Regarding the lithic tradition, we see no signs of a broader technological change at the time of the inception of iron but rather a continuity well before and after. In addition to dismantling the Three-Age system, this indicates that iron was integrated and incorporated seamlessly into the social and economic organization of the Arctic hunter-gatherers.

5 Discussion

In this article, we establish a widespread and uniform distribution of advanced ironworking among hunter-gatherer communities across the Arctic European region. This discovery covers approximately 375,000 km2, encompassing the northernmost parts of present-day Norway, Finland, and Sweden. The striking uniformity in terms of a complete and highly specialized technology observed across the 42(!) known sites seems to have spread rapidly indicated by contemporary radiocarbon dating and maintained (largely unchanged) for a period of at least 500 years, from 300 BC to AD 200. Hence, the implications of these findings are profound and challenge conventional thinking about the diffusion of technological advancements. The fact that hunter-gatherers in the Arctic were involved in advanced iron production as early as the Romans and that this knowledge diffused quickly across such a large region forces us to reevaluate the typical understanding of societal development. Rather than focusing on the traditional center-periphery model, which emphasizes power dynamics and linear social progression, we must explore alternative interpretations and pave the way for a more nuanced understanding of technological transmission/adoption and societal dynamics.

Below, and through a combined chaîne opératoire and taskscape/landscape/climate approach, we will discuss how the task of iron production influenced the everyday lives of the ancient Arctic hunter-gatherers. We will approach this discussion as if they were a unified group, although it is important to remember that, of course, they consisted of several local groups with local variations. These variations are also evident in the material evidence.

The strong seasonality, including significant climatic variations and related environmental constraints, created fundamental challenges for the people living in ancient Arctic Europe. Survival alone required a combination of skills and extensive planning. While activities related to hunting, fishing, and gathering are often emphasized (Bergman, 1995), there is also reason to highlight tasks related to other aspects, such as the preparation of clothing and housing suitable for the Arctic climate. Now, even metallurgical activities play a role. The climatic variations and environmental constraints significantly impacted the timing and organization of different taskscapes within the hunter-gatherer communities. Balancing these diverse tasks required complex coordination of activities and landscape use. Basic prerequisites for these groups to engage in iron production included access to primary resources like ore, clay, and wood, as well as the ability to participate in activities beyond mere food collection. By strategically locating iron production in forested areas and near productive fishing lakes, which also tended to contain abundant lake ore, all basic prerequisites appear to have been met at a majority of the studied sites.