Abstract

Deformation of AZ61-F magnesium alloys with 1 wt % of Al2O3 phase was tested at different temperatures and different strain rates. It was shown that at temperatures 473–523 K and the highest strain rate applied from 1×10–2 s–1 to 1×10–4 s–1, a significant ductility growth was observed. The grain size of 0.6–0.8 μm was reached by severe plastic deformations by means of equal channel angular pressing (ECAP). Secondary Mg17Al12 and Al2O3 phases were identified. Maximum strain was gained at temperature of 473 K and strain rate of 1×10–4 s–1.

Introduction

Superplasticity in polycrystalline materials is facilitated by dynamic modifications in the microstructure. Retrieval of the superplastic microstructure at elevated temperatures rests on the ability to maintain dynamic recovery. The strain rate is defined by Mukherjee equation:

where D is the diffusion coefficient, T is the temperature, d is the grain size, p is the grain size exponent (2–3), and m is the stress exponent (0.4–0.7).

The primary deformation mechanism in superplastic materials is a grain boundary sliding with stress accommodation by diffusion or dislocation movement. According to eq. (1), the finer grains, the higher strain rate to obtain superplasticity at a given stress. Grains size smaller than 10 μm, and equiaxed grains with large angle boundaries are essential. Superplasticity is maintained if the dynamic growth of grains is minimized. However, superplasticity can be limited by cavitation on the grain boundaries, [1]. In Ref. [2], the main features of the high strain rate superplasticity are described:

superplasticity depends on the parameters of the microstructure – both matrix and secondary phase grain size,

temperature suitable for superplasticity is dependent on the matrix material,

thermo-mechanical treatment can significantly influence superplasticity.

Intensive R&D produced a variety of superplastic alloys and after thermo-mechanical treatment, superplastic behaviour was reported in many conventional alloys, too. Research was focused first on Al, Ti and Mg base alloys. Superplasticity in Al base alloys is reported in Refs [3–8].

Magnesium alloys are gaining more recognition as the lightest structural materials for lightweight applications, due to their low density and high stiffness-to-weight ratio. Even so, Mg alloys have not been used for critical performance applications because of their inferior mechanical properties, compared to other engineering materials. Nevertheless, there are some practical limitations on the use of magnesium alloys in industrial applications because these alloys are inherently brittle due to their hexagonal crystal structure and the consequent limited number of active slip systems. An important current requirement is therefore to develop procedures having the potential for improving the ductilities of Mg-based alloys. It is now well established that the processing of fcc metals through the use of equal-channel angular pressing leads to ultrafine grain sizes that are typically within the submicrometer range [9] and, if these small grain sizes are reasonably stable at elevated temperatures. It is possible to achieve superplastic ductilities with elongations to failure of >1,000 % [10, 11]. However, it is more difficult to successfully apply ECAP processing to Mg-based alloys. Miyahara et al. [12] experiments were conducted on a commercial AZ61 magnesium alloy to evaluate the potential for achieving an ultrafine grain size and superplastic ductility through the use of the EX-ECAP two step processing procedure of extrusion plus equal-channel angular pressing. The results show that EX-ECAP gives excellent grain refinement with grain sizes of ~ 0.6 and ~ 1.3 μm after pressing at 473 and 523 K, respectively. The alloy processed by EX-ECAP exhibits exceptional superplastic properties including a maximum elongation of 1,000 % after pressing through four passes when testing at 473 K with an initial strain rate of 3.3×10–4 s–1.

Hence, many researchers attempt to fabricate Mg-based metal matrix composites by different methods in order to obtain light-weight materials with excellent mechanical properties [13–16]. Magnesium-based nanocomposite (AZ91-D Al2O3) was studied in Ref. [17, 18], where the effect of nano-alumina particles and heat treatment on microstructure, mechanical properties and failure mechanism were investigated.

The aim of this paper is to analyse kinetics of superplastic behaviour of AZ61-F-Al2O3 magnesium system with 1 wt % of Al2O3 phase.

Materials and methods

The matrix used in this work is magnesium alloy AZ61-F made by Metaltech Industrial Co, LTD, Taiwan, chemical composition is shown in Table 1.

Chemical composition of AZ61-F.

| Elements | Al | Mn | Zn | Si | Fe | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| wt % | 5.95 | 0.26 | 0.64 | 0.009 | 0.005 | 0.0008 | 0.0007 | Balance |

Particles Al2O3 with the weight fraction of 1 % are used as the reinforcement phase. The commercially available Al2O3 powder with a particle diameter about 20 nm with the purity of ≥99.8 % is added into AZ61-F to form Mg-based metal-matrix composites.

The melt-stirring technique was used to fabricate the present Mg composites. The AZ61-F and Al2O3 particles were initially placed inside a graphite crucible and heated to 673 K in a resistance-heated furnace, then a stirring vane functioned; meanwhile, CO2 and SF6 gushed from gas tank into the crucible to mixture the melt. CO2 and SF6 also can prevent the melt from oxidation. The crucible was continuously heated up to 973 K, and then the molten alloy was stirred with a vane operated at 350 rev/min for 3 min. Finally, the composite melt was poured into a metallic mould.

The Mg composite containing 1 wt % of Al2O3 was prepared for further mechanical testing. ECAP was carried out in a die with the die angle of Φ=120°. The deformation temperature was set at 573 ± 10 K. During deformation, the plunger speed was about 1.0 mm/s. After each extrusion pass, the billet was quenched into water. The billets were rotated counterclockwise around the exit extrusion axis by 90° between each pass, the so-called Bc route, and each bar was ECAPed by 4 passes. From these alloys specimens (Ø3 and 30 mm long) were prepared for tensile testing.

Results and discussion

Microstructure parameters of the system, namely the matrix grain size, mean size of the dispersed particles and their average distance before and after ECAP were evaluated.

Microstructure of the starting material (before ECAP) was heterogeneous with grain size of 25–30 μm.

The grains sizes of material after ECAP were observed by TEM, Figure 1. In comparison with the grain size of starting experimental material, the grain sizes after ECAP decreased on the values of cca 0.7 μm. The mean size was estimated by measurement of 50–100 grains which had good contrast. Results are in a good agreement with [12]. Fine Al2O3 particles observed by TEM were distributed randomly as well as in clusters, Figure 1. Al2O3 particles sized of cca 20 nm and their clusters are localized on the grain boundaries and in the grains.

TEM micrographs of grains sizes and distribution of Al2O3 particles, material after ECAP.

Transmission electron microscopy and selective electron diffraction showed the presence of spherical Mg17Al12 phase; the mean particles size was 0.5 μm, Figure 2. These results are in a good agreement with [19, 20]. This phase has a body centred cubic crystal structure with the lattice parameter a=10.569 Å. Mg17Al12 particles were distributed preferentially on the high angle grain boundaries and inhibit the grains growth.

TEM micrographs and diffractogram of Mg17Al12 phase, material after ECAP.

Analyses of the deformation behaviour were performed by tensile deformation at temperatures 473 and 523 K and strain rates of 10–2–1×10–4 s–1, Figure 3. It was found that experimental material had maximal superplasticity at temperature of 473 K and strain rate of 1×10–4 s–1, Figure 3(a), what is in an agreement with [20, 21] for the commercial alloy AZ61Mg. A probable mechanism of superplasticity is the high angle grain boundary sliding. Strength properties decrease with higher test temperature as expected, Figure 3(b). Dependences of nominal stress versus strain at different strain rates are identical in the both plots.

Nominal stress vs. true strain at 473 K (a) and 523 K (b) for samples with 1 % of Al2O3 phase pressed through four passes.

Figure 4 shows the specimens tested at the slower rates pull out to a point. It is a proof of macroscopic necking within gauge lengths. It is well established that this behaviour represents a true superplastic condition.

Test specimens of AZ61-F with 1 % of Al2O3 phase after deformation by different strain rates at 473 K.

Flow stress (ε=0.1) plotted against the initial strain rate is shown in Figure 5. Considerable differences for temperature 473 K and 523 K were observed. Values of the flow stress increased linearly and equidistant with increasing strain rates. Higher values of equidistant dependence of flow stress on strain rate are for lower test temperature (473 K).

Flow stress (ε=0.1) plotted against the initial strain rate.

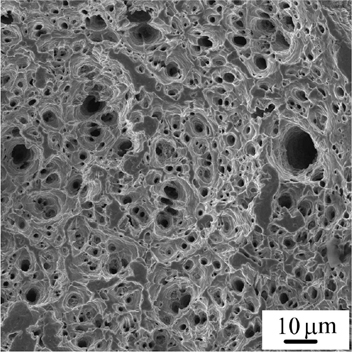

A fracture surface at optimal temperature of 473 K and strain rate of 1×10–4 s–1 is shown in Figure 6. The fracture is a transcrystalline ductile with dimples of two size categories. Larger dimples (10 μm) were created on Mg17Al12 particles, smaller ones on dispersed Al2O3 particles (ca 0.7 μm). According to Gurland–Plateau theory the ductile fracture had three stages: initiation, growth and coalescence of cavities. Cracks were created on the particle–matrix interphases and presumably in the triple junctions of the grains of the matrix [22].

Fracture at temperature of 473 K and strain rate of 1×10–4 s–1.

Conclusions

Based on the extensive experimental studies of kinetics of superplastic deformation of AZ61 Mg-Al2O3 composites the following results were obtained:

The mean grain size of the experimental material with 1 wt % of Al2O3 after ECAP by 4 passes was 0.6–0.8 μm. Mg17Al12 and Al2O3 particles of secondary phases were identified by TEM.

The max value of superplasticity cca 180 % was reached at the temperature of 473 K and strain rate of 1×10–4 s–1. A probable mechanism of superplasticity is the high angle grain boundary sliding.

At maximum values of superplasticity the fracture was transcrystalline ductile with dimples of two size categories (10 μm and 0.7 μm) initiated by the particles of secondary phases (Mg17Al12 and Al2O3).

Funding statement: The work was supported by the Slovak National Grant Agency under the Project VEGA 2/0118/14.

References

[1] [1] R.S. Mishra and A.K. Mukherjee, Mater. Sci. Eng. A, 234–A236 (1997) 1023.10.1016/S0921-5093(97)00321-3Search in Google Scholar

[2] [2] R.S. Mishra, T.R. Bieler and A.K. Mukherjee, Scr. Metall., 26 (1992) 1605.10.1016/0956-716X(92)90264-FSearch in Google Scholar

[3] [3] K. Higashi, Mater. Sci. Eng. A, 166 (1993) 109.10.1016/0921-5093(93)90315-6Search in Google Scholar

[4] [4] I. Jin and T.R. Bieler, J Mater. Sci., 28 (1993) 2413.10.1007/BF01151673Search in Google Scholar

[5] [5] T.G. Nieh, J. Wadsworth and T. Imai, Scr. Metall., 26 (1992) 703.10.1016/0956-716X(92)90423-CSearch in Google Scholar

[6] [6] K. Higashi, T. Okada, T. Mukai and S. Tanimura, Scr. Metall., 26 (1992) 1605.10.1016/0956-716X(92)90170-JSearch in Google Scholar

[7] [7] F. Li, W.T. Roberts and P.S. Bate, Acta Mater., 44(1) (1996) 217.10.1016/1359-6454(95)00141-8Search in Google Scholar

[8] [8] A. Urena, J.M. Gomez de Salazar, J. Qiunones and J.J. Martin, Scr. Mater., 34(4) (1996) 617.10.1016/1359-6462(95)00551-XSearch in Google Scholar

[9] [9] Y. Iwahashi, Z. Horita, M. Nemoto and T.G. Langdon, Acta Mater., 46 (1998) 3317–3331.10.1016/S1359-6454(97)00494-1Search in Google Scholar

[10] [10] C. Xu, M. Furukawa, Z. Horita and T.G. Langdon, Acta Mater., 53 (2005) 749–758.10.1016/j.actamat.2004.10.026Search in Google Scholar

[11] [11] M. Kawasaki and T.G. Langdon, Acta Mater., 53 (2005) 5353–5364.10.1016/j.actamat.2005.08.012Search in Google Scholar

[12] [12] Y. Miyahara, Z. Horita and T.G. Langdon, Mater. Sci. Eng. A, 420 (2006) 240–244.10.1016/j.msea.2006.01.043Search in Google Scholar

[13] [13] G. Cao, H. Choi, J. Oportus, H. Konishi and X. Li, Mater. Sci. Eng. A, 494 (2008) 127.10.1016/j.msea.2008.04.070Search in Google Scholar

[14] [14] S. Ugandhar, M. Gupta and S.K. Sinha, Compos. Struct., 72 (2006) 206.10.1016/j.compstruct.2004.11.010Search in Google Scholar

[15] [15] S.F. Hassan and M. Gupta, J Alloys Compd., 419 (2006) 84.10.1016/j.jallcom.2005.10.005Search in Google Scholar

[16] [16] S.F. Hassan and M. Gupta, Mater. Sci. Eng. A, 392 (2005) 163.10.1016/j.msea.2004.09.047Search in Google Scholar

[17] [17] M. Shanti, K.S. Tun, R.S. Pandey and M. Gupta, Kovove Mater., 49 (2011) 197.10.4149/km_2011_3_197Search in Google Scholar

[18] [18] P.-C. Lin, S.-J. Huang and P.-S. Hong, Acta Metall. Slovaca, 16 (2010) 237.Search in Google Scholar

[19] [19] A. El-Morsy, A. Ismail and M. Waly, Mater. Sci. Eng. A, 486 (2008) 528.10.1016/j.msea.2007.09.044Search in Google Scholar

[20] [20] K. Matsubara, Y. Miyahara, Z. Horita and T.G. Langdon, Metall. Mater. Trans. A, 35A (2004) 1735–1744.10.1007/s11661-004-0082-zSearch in Google Scholar

[21] [21] Y. Miyahara, K. Matsubara, Z. Horita and T.G. Langdon, Metall. Mater. Trans. A, 36A (2005) 1705–1711.10.1007/s11661-005-0034-2Search in Google Scholar

[22] [22] M. Besterci, J.K. Sulleiova and T. Kvačkaj, Kovove Mater., 46 (2008) 309–311.Search in Google Scholar

©2017 by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Research Articles

- Kinetics and Tribological Characterization of Pack-Borided AISI 1025 Steel

- A Comparative Study of Hot Deformation Behaviors for Sand Casting and Centrifugal Casting Q235B Flange Blanks

- Effects of Annealing Temperature on the Microstructure and Mechanical Properties of Electrodeposited Ni-Fe Alloy Foils

- Thermochemical Approach for Screening of Alternative Metal Oxides as a Flame Retardant of Modacrylic Fiber

- Hot Corrosion Behavior of Stainless Steel with Al-Si/Al-Si-Cr Coating

- Calculation of the Combined Heat Transfer Coefficient of Hot-face on Cast Iron Cooling Stave Based on Thermal Test

- The Corrosion Behavior of Stainless Steel 316L in Novel Quaternary Eutectic Molten Salt System

- Corrosion of Nickel-Based Alloys in Ultra-High Temperature Heat Transfer Fluid

- Superplastic Behaviour of AZ61-F Magnesium Composite Materials

- Effects of Laser Shock Processing on Fatigue Performance of Ti-17 Titanium Alloy

- Effect of the Platinum Electroplated Layer Thickness on the Coatings’ Microstructure

- Structural and Microstructural Study on the Arc-Plasma Synthesized (APS) FeAl2O4–MgAl2O4 Transitional Refractory Compound

- Retraction

- Retraction of: Mechanical and Electrochemical Characterization of Super-Solidus Sintered Austenitic Stainless Steel (316L)

Articles in the same Issue

- Frontmatter

- Research Articles

- Kinetics and Tribological Characterization of Pack-Borided AISI 1025 Steel

- A Comparative Study of Hot Deformation Behaviors for Sand Casting and Centrifugal Casting Q235B Flange Blanks

- Effects of Annealing Temperature on the Microstructure and Mechanical Properties of Electrodeposited Ni-Fe Alloy Foils

- Thermochemical Approach for Screening of Alternative Metal Oxides as a Flame Retardant of Modacrylic Fiber

- Hot Corrosion Behavior of Stainless Steel with Al-Si/Al-Si-Cr Coating

- Calculation of the Combined Heat Transfer Coefficient of Hot-face on Cast Iron Cooling Stave Based on Thermal Test

- The Corrosion Behavior of Stainless Steel 316L in Novel Quaternary Eutectic Molten Salt System

- Corrosion of Nickel-Based Alloys in Ultra-High Temperature Heat Transfer Fluid

- Superplastic Behaviour of AZ61-F Magnesium Composite Materials

- Effects of Laser Shock Processing on Fatigue Performance of Ti-17 Titanium Alloy

- Effect of the Platinum Electroplated Layer Thickness on the Coatings’ Microstructure

- Structural and Microstructural Study on the Arc-Plasma Synthesized (APS) FeAl2O4–MgAl2O4 Transitional Refractory Compound

- Retraction

- Retraction of: Mechanical and Electrochemical Characterization of Super-Solidus Sintered Austenitic Stainless Steel (316L)