Abstract

Graphene has become an emerging and promising option in the field of protection coating for anti-corrosion due to its specific properties in chemical inertia and physical impermeability. It can be applied to metal protection coating in forms of either atomically thin films or composite materials, known, respectively, as pure chemical vapour deposition (CVD) graphene coatings and graphene composite coatings (GCCs). Nonetheless, various structure defects, synthesis imperfections and graphene’s positive potential to metals would make graphene-based protective coatings tend to exhibit corrosion promotion by arousing micro-galvanic corrosion, largely undermining its anti-corrosion efficiency. Based on this, many optimization strategies and methods have been conceived and applied to the graphene-based protection coatings in these two aspects for improving its anti-corrosion efficiency. For example, a good dispersion and orderly arrangement of graphene derivatives in the GCCs can largely optimize its anti-corrosion performance. Here, this paper separately reviews detailed optimization strategies, corresponding mechanisms and key factors for the use of representative graphene-based materials in these two aspects, with the aim of providing comprehensive knowledge and a roadmap of developing cheap, powerful and effective barrier technologies. Finally, perspectives on opportunities and challenges in improving the barrier coating efficiency of graphene-based materials are discussed.

1 Introduction

Most metals and alloys are subjected to spontaneous corrosion initiated by water and oxygen in the atmosphere due to their thermodynamic instability. The rate at which corrosion occurs depends on multi factors such as the type of metal, the chemical environment, temperature, mechanical forces and so forth. According to a survey (Chang et al. 2012), the corrosion of metals has caused significant financial and material damage, and almost a quarter of the world’s annual steel production is damaged by corrosion. In addition to steel, several other materials, including polymers and ceramics, are not immune to corrosion (Landolt 2007). Corrosion would degrade the good properties typical of the surfaces of some reactive metals commonly used in the industry. So, corrosion resistance is decisive factor in the longevity of metal materials. It becomes imperative that adequate defensive measures are taken to effectively control the rate of corrosion so that the metals can achieve their full effectiveness throughout their lifetime.

The protective coating is commonly used as a barrier to isolate the underlying metal from the outside environment, thus reducing the risk of corrosion to the metal, which is an effective and economical method of corrosion protection. Various protective coatings including inert metals (Pushpavanam et al. 1981), organic polymers (Stratmann et al. 1994), conductive polymers (Redondo and Breslin 2007), silanes (Zhu and van Ooij 2004), oxide layers (Mittal et al. 2009) and even thiol-based monolayers (Lusk and Jennings 2001) have been applied as metal protection coatings. Among them, the ability of forming a barrier between the metal and the outside environment is the key to the corrosion resistance of these coatings, and any flaking or cracking of the coating will affect its corrosion resistance (Sai Pavan and Ramanan 2016). In addition, there are a number of factors that would limit their anti-corrosion efficiency. For example, many protective coatings would change the electrical, thermal and optical properties of the substrate material due to their non-negligible thickness. Therefore, the ideal anti-corrosion surface barrier coating should be lightweight, thin, impermeable, chemically inert and abrasion resistant. Therefore, developing thin protective materials with minimal impact on the substrate material is highly demanded (Prasai et al. 2012).

1.1 Barrier properties of graphene

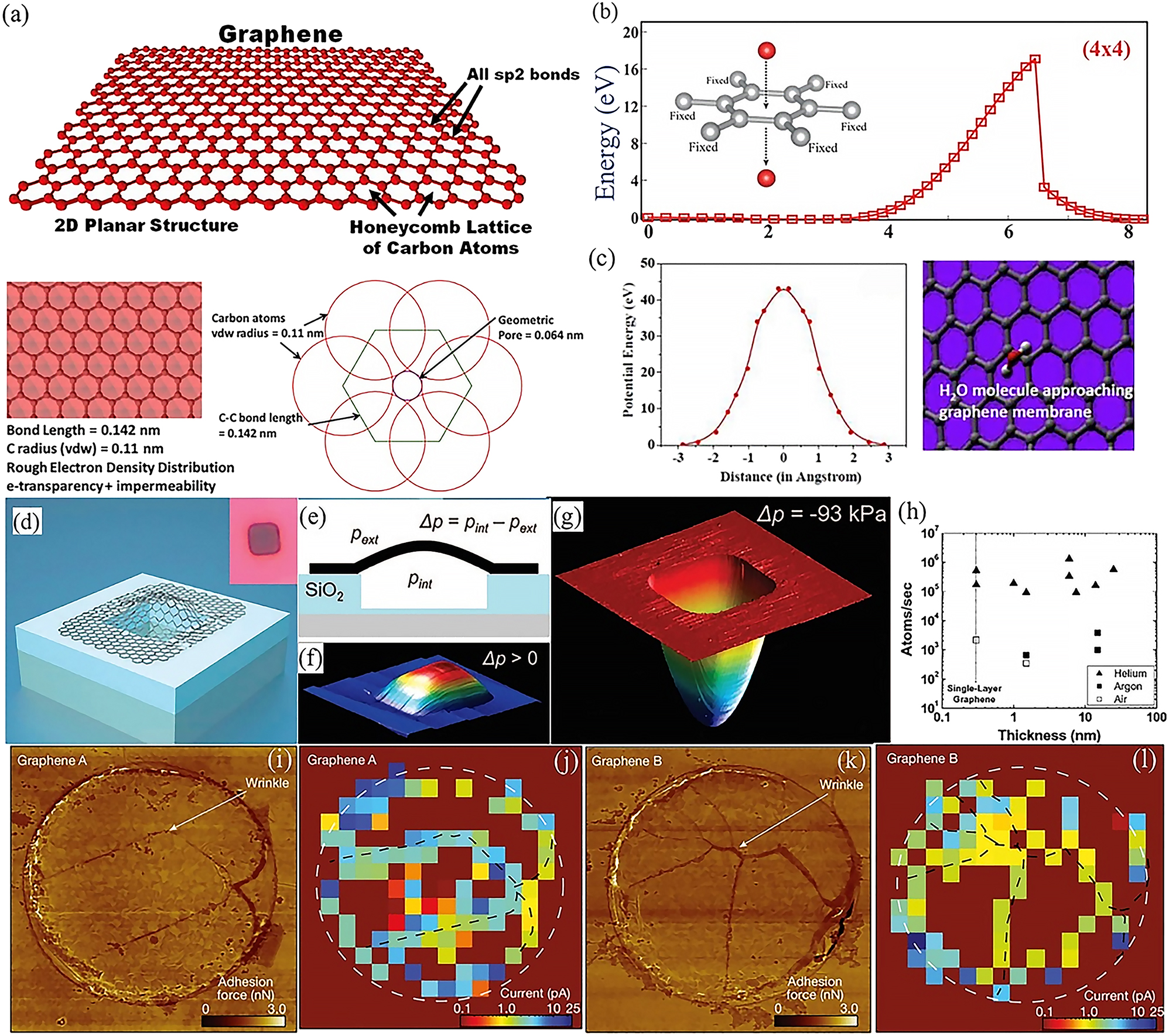

Graphene is assembled by arrangement of sp 2-hybridized carbon atoms, showing uniquely potential in corrosion protection because it can protect metals without altering their inherent properties in a way that is not possible with three-dimensional protective coatings, polymers or oxides. It has been demonstrated that graphene is the thinnest material and that a single layer of graphene can keep an atomic distance between a metal surface and its external environment (Geim and Novoselov 2007; Novoselov et al. 2005). In addition, graphene possesses many distinguished advantages in terms of mechanical toughness, physical impermeability, chemical inertness and optical transparency, which allow graphene to be taken for granted as the most promising alternative for the protective coating. Figure 1a shows graphene’s structure with a very dense grid of hexagonal carbon atoms, and this remarkable two-dimensional physical structure shows exceptional resistance to gases, liquids, salts and acids (Berry 2013). The graphene lattice has a hexagonal pore size of 0.246 nm and a C–C bond length of 0.14 nm (Gass et al. 2008). Taking into account the van der Waals radius of the carbon atom, the pore size of the graphene lattice is reduced to 0.064 nm, through which even an atom as small as helium cannot pass (Bunch et al. 2008). In addition, graphene possesses a delocalized dense electron cloud of π-conjugated carbon networks (Sreeprasad and Berry 2013), which not only blocks voids within the aromatic rings but also provides a repulsive field to reactive atoms or molecules, allowing physical isolation between the metal surface and the environment. The energetics and energy barriers involved in the transfer of oxygen atom and H2O molecule from one side of graphene to the other were calculated in a bare graphene super cell (Figure 1b–c) (Seethamraju et al. 2016; Topsakal et al. 2012). If an oxygen atom traverses a fixed vertical path along the hole in the centre of the graphene hexagonal lattice from the top to the bottom of the graphene, a barrier of 16.34 eV needs to be overcome. This prevents the oxygen atom from passing through. For the H2O molecule, Figure 1c plots the potential energy barrier as a function of distance for water molecules passing through the hexagonal centre of a graphene film. Density functional theory (DFT) calculations show that the energy barrier encountered by a single water molecule passing through a graphene layer with 170 carbon atoms is 42.8 eV. Such a high energy barrier effectively limits the penetration of water molecules. All of the above simulations and calculations show that the resistance of graphene to permeation is attributed to the high potential energy barrier encountered in penetrating the film. This excellent resistance to permeation also has been proved experimentally through a graphene-sealed microchamber (Figure 1d). By applying a pressure difference (∆P = P int−P ext) across the graphene membrane in this way (Figure 1e), the mass transport of graphene can be measured at either ∆P > 0 (Figure 1f) or ∆P < 0 cases (Figure 1g). Figure 1h shows the results of experiments performed when the thickness of the graphene film varies and when different gases are present in the micro-chamber. As seen, helium leaks two orders of magnitude faster than air and argon. However, this leakage rate is not related to the thickness of the graphene films, indicating that the gas leakage is relatively stable and may be caused by the micro-chamber sealed interface between graphene and silica, instead of graphene film itself. This leads to the conclusion that the graphene film is a perfect barrier for gas permeability. However, it has recently been shown that the nanoscale non-flatness of two-dimensional membranes greatly facilitates proton transport (Wahab et al. 2023). The spatial distribution of proton currents visualized by scanning electrochemical cell microscopy (SECCM) reveals significant inhomogeneities correlated with nanoscale wrinkles and other features where strain is accumulated. From Figure 1i–l, it can be seen that the positions of the wrinkles in the graphene devices correlate with some of the most conductive regions in the SECCM maps. Other regions of high proton conductivity appear around the apertures’ rims. Even though, the graphene film is likely to be the ‘thinnest known anti-corrosion coating’ (Ambrosi and Pumera 2015; Prasai et al. 2012).

The structrue and barrier properties of graphene. (a) Graphene lattice structure: sp 2 hybridized carbon atoms arranged in a two-dimensional honeycomb lattice. Bottom: molecular structure with a rough electron density distribution (Berry 2013). Reprinted with permission from Elsevier. (b) Energy barrier for an oxygen atom to pass from the top to the bottom of a suspended graphene (Topsakal et al. 2012). Reprinted with permission from American Physical Society. (c) Simulations to determine the potential energy barrier required to cross a graphene membrane: potential energy barrier versus distance for H2O molecules crossing a monolayer of graphene (left); snapshots of DFT simulations when calculating the potential energy barrier for H2O molecules crossing a graphene membrane (right) (Seethamraju et al. 2016). Reprinted with permission from American Chemistry Society. (d) Schematic diagram of graphene sealed microchamber. Inset: optical image of a single atomic layer of graphene drumhead on silica at 440 nm. The dimensions of the microchamber are 4.75 µm × 4.75 µm × 380 nm. (e) Schematic side view of a graphene-sealed microchamber. (f) Tapping mode atomic force microscopy (AFM) image of a 9 nm thick multi-layer graphene drumhead with ∆P > 0. The square microchamber has dimensions of 4.75 µm × 4.75 µm. The upward offset of the film centre is z = 90 nm. (g) AFM image of the graphene sealed microchamber of Figure 1d with ∆P = −93 kPa across it. (h) Gas leakage rate versus thickness of graphene film for helium (▲), argon (■) and air (□) (Bunch et al. 2008). Reprinted with permission from American Chemical Society. (i, k) AFM force maps of graphene for the proton transport detection. (j, l) SECCM maps for two graphene devices. The white dashed circles mark the rim of the 2-μm diameter apertures in SiN x (Wahab et al. 2023). Reprinted with permission from Nature.

1.2 Graphene-based anti-corrosion coatings and their optimization

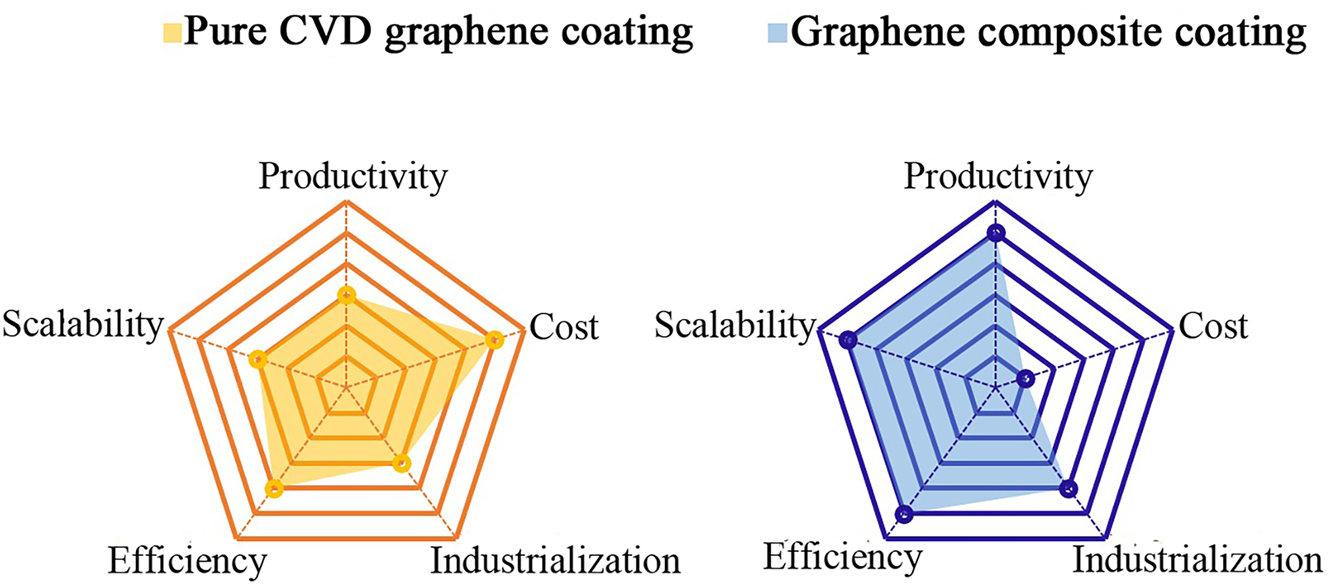

Despite these exceptional highlights of features, the application of graphene as a corrosion barrier coating is not as simple as it seems (Camilli et al. 2019). Firstly, the corrosion resistance of graphene coating highly depends on whether it can prevent the vertical penetration of oxidative species. In principle, as discussed above, continuous and perfect graphene layer would isolate metal surface from any oxidative species. It is thus critical to make prefect graphene coating with high quality and deposit it onto metal surface somehow in a compatible way. Secondly, the negative polarity of graphene to metals would induce galvanic corrosion of metals over time (Schriver et al. 2013; Zhou et al. 2013), which is the notably named corrosion-promotion activity of graphene (Dong et al. 2014; Keil et al. 2010; Lee and Berman 2018). Based on these points, as well as the experimental facts that graphene-based protective coatings are not as effective as we anticipate, numerous efforts have been devoted to improve its protective efficiency for anti-corrosion of metals in recent years. In short, research on graphene-based barrier coating for anti-corrosion applications is currently divided into two types of strategy, that is, using pure graphene anti-corrosive barrier coating (which is usually correlated with the CVD production process) and using GCC (which incorporates graphene into the matrix of a polymer coating). In a sense, GCC is an extended application of pure graphene coating, which gets the research of graphene-based coating started in the field of metal coatings. Therefore, GCC has more advantages in the perspective of mass production in a low-coast manner than pure graphene coating on metals. The differences in the comparison between them are listed in Figure 2. Whether it is pure CVD graphene coating or GCC, great progresses have been achieved among them on optimization strategies for improving their anti-corrosive efficiency of metals by numerous excellent studies. Although a few reviews on various graphene production, anti-corrosion mechanisms and its typical applications for metal protection (Chen et al. 2011; Dlubak et al. 2012; Krishnamurthy et al. 2013; Mohanty et al. 2011), the systematic introduction and summary for the optimization strategies of efficient graphene-based coatings based on their anti-corrosion issues is still lacking in the literatures.

Comparison between pure CVD graphene coating and GCC from the perspective of anti-corrosion efficiency, the industrialization, the production cost, the productivity and the scalability of coating. (a) Pure CVD graphene coating. (b) GCC.

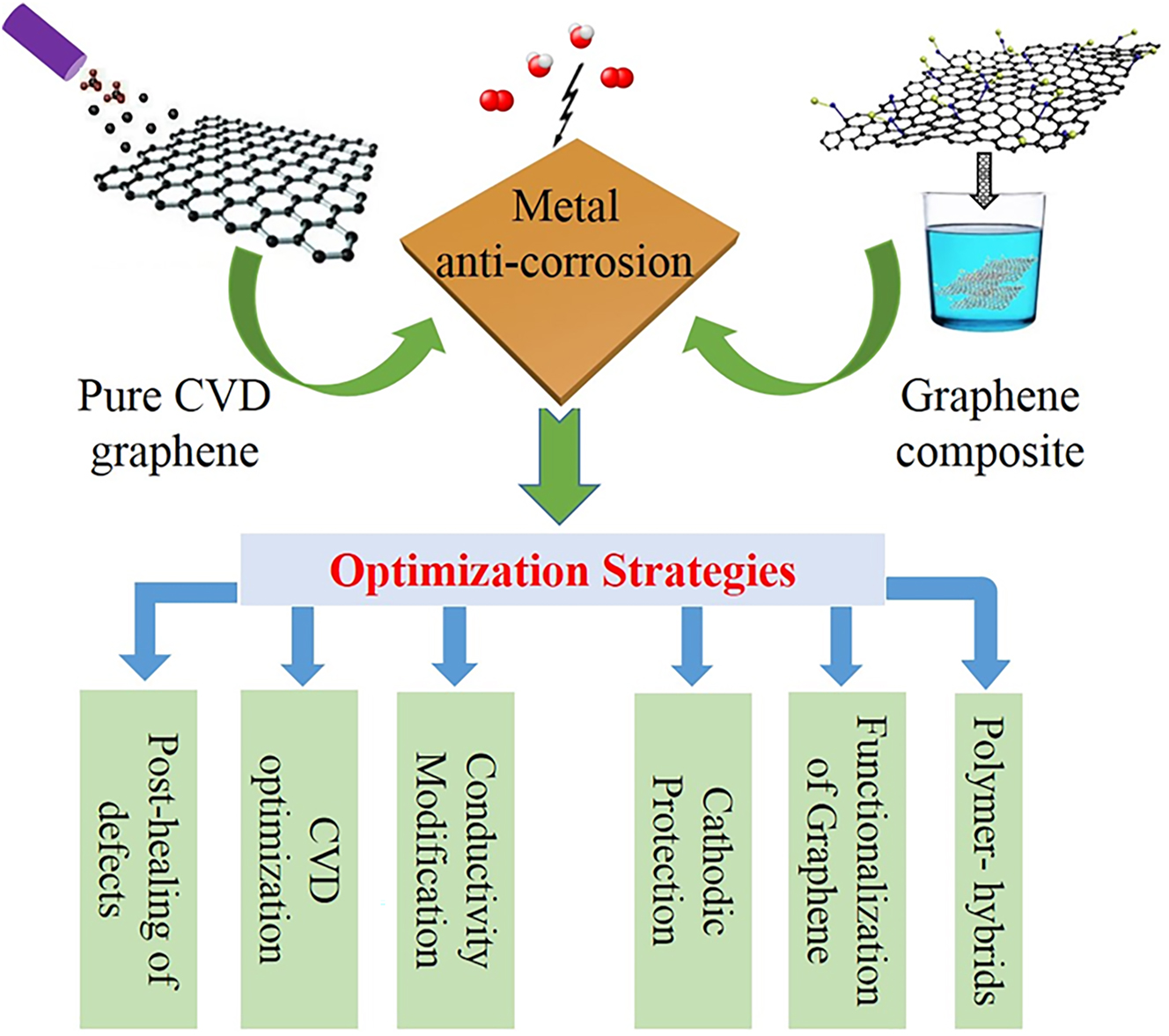

Herein, we carefully review various optimization strategies involving preparation methods, as well as the corresponding optimization mechanisms for graphene-based anti-corrosion barrier coatings in both cases of pure CVD graphene coatings and GCCs (Figure 3). As seen from Figure 3, for the pure CVD graphene coating, optimization strategies including post-healing of defects, CVD optimization and conductivity modification are proposed based on the analysis of the issues that a pure graphene coating cannot effectively provide the long-term protection of metals. For graphene composites coating, optimization strategies involving functionalization of graphene, polymer-hybrids and cathodic protection are included. Many detailed factors, features and drawbacks are analysed between each other to disclose the influence in anti-corrosion properties of graphene-based coatings. Finally, we provide an outlook for the opportunities and challenges in improving the corrosion barrier of graphene-based coatings, aiming to seek a roadmap for developing cheap, powerful and effective graphene-based corrosion barrier technologies.

Representative optimization strategies for graphene-based protection coatings in the cases of pure CVD graphene coatings and graphene composites coatings.

2 Pure CVD graphene coatings and the optimization strategies

As discussed above, pure graphene films, which are normally prepared by CVD method for the large-scale coverage, stand out from the crowds of protective coatings due to their two main advantages of impermeability and chemical stability and are expected to be a favourable material for a wide range of research areas from biology to electronics. As a protective barrier, CVD graphene grown on metal substrates blocks mass transfer between the environment and the metal, thus protecting it from corrosive degradation. Moreover, the experiment demonstrates that graphene as a passivation layer can retard microbially induced electrochemical corrosion (MIC) of metals (Krishnamurthy et al. 2013). In addition, it can provide protection for unstable surfaces in fields as diverse as spintronics (Dlubak et al. 2012) and biology (Mohanty et al. 2011). However, with the development of CVD graphene, there are conflicting opinions about the protective properties of CVD graphene films. Researchers have found that in short-term protection, graphene films do provide protection for the underlying metals from corrosion. However, once the timeline is extended, the graphene conversely promotes the corrosion of the protected metals due to a galvanic corrosion effect. Further, various graphene-related causes of corrosion and the corresponding inhibition strategies have been revealed. As an important part of the graphene-based coatings, the CVD graphene grown on metals for corrosion barrier coating have aroused a wide research interest in developing graphene protective coatings.

2.1 CVD graphene for short-term and long-term anti-corrosion

The representative studies that aroused a wide interest in developing CVD graphene as a metal protective coating can date back to 2011. Chen et al. pioneered the ability of CVD-grown graphene films for protecting the surface of the growth metal substrates (Cu or Cu/Ni alloys) from air oxidation, both in air at high-temperature and hydrogen peroxide solutions (Chen et al. 2011). The basic principle for such a protection is that the presence of graphene films can isolate the metal surfaces from external oxidative species. Indeed, they observed that graphene provided nearly perfect protection for metal substrates in aggressive environments, such as high-temperature annealing and oxidizing liquid solutions. By exposure to H2O2 solution, the half graphene-coated coin retained its original metallic colour in contrast to the seriously oxidative colour in the other uncoated half. This experiment clearly demonstrated how graphene can be used as a passivation layer to protect metal substrates. In addition, Prasai et al. (Prasai et al. 2012) further confirmed that through growing graphene films on Cu surface and then mechanically transferring it onto bare Ni or Cu surface with different layers was another effective method for increasing the corrosion resistance of Ni or Cu. Electrochemical corrosion test results show that copper sheets coated with transferred CVD graphene have a corrosion rate that is seven times slower than that of bare copper. Moreover, with the increase of transferred graphene layers, the corrosion rate of Ni with thicker CVD graphene would have lower corrosion rate. Overall, these examples show that pure CVD graphene films can protect the underlying metals from corrosion in the short term whether in high-temperature air or aggressive solutions, thanks to their impermeability and chemical stability.

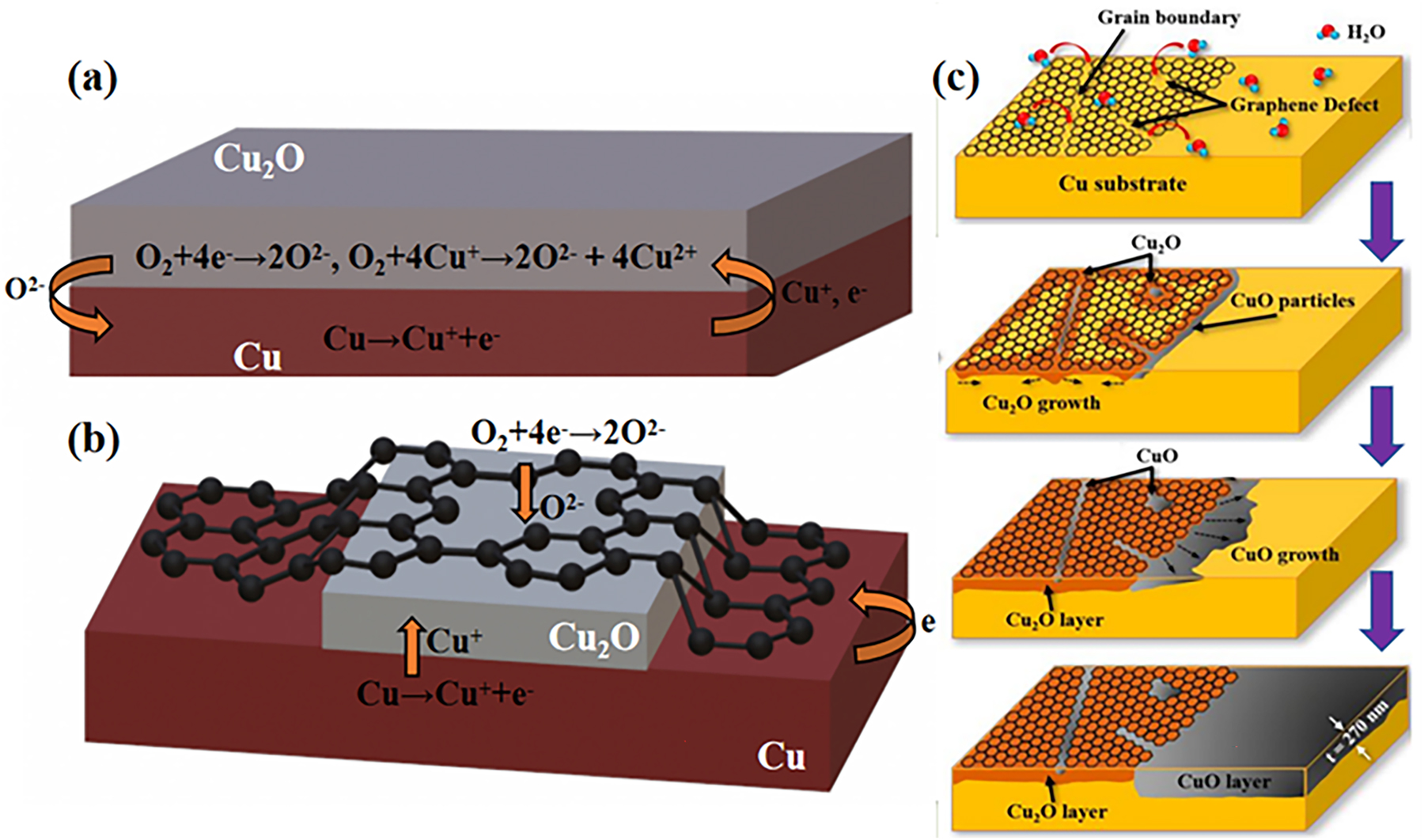

Indeed, it is impressive that the CVD graphene coating prevents corrosive substances from coming into direct contact with the metal surface, protecting the metal surface from corrosion in the short term. But over time, however, it promotes the corrosion of the protected metal surfaces due to galvanic corrosion effect. The long-term protective performance of the graphene coating was investigated by placing bare copper and graphene-covered copper samples at an ambient temperature of 25 °C for ∼2 years and inspecting them optically at regular intervals. The results show that the Cu substrate with graphene was already heavier oxidized than bare Cu substrate and the oxidation phase detected was mainly cuprous oxide. It was then concluded that the conductivity of graphene is responsible for such a promotion of corrosion. It would favour the corrosion by creating a galvanic circuit between graphene and the underlying metal (Schriver et al. 2013). Figure 4a and b shows a schematic representation of the graphene promotion mechanism of galvanic corrosion (Zhou et al. 2013). In the absence of a graphene, copper oxidation occurs at the interface between Cu and Cu2O. In particular, electron migrates through the Cu2O film to the interface between Cu2O and air and reacts with oxygen to produce O2−, which, on the other hand, diffuses into the Cu2O lattice and further combines with Cu+ to form Cu2O. In contrast, in the presence of a graphene coating, free electrons generated at the Cu/Cu2O interface can quickly migrate to the Cu2O/graphene/air interface through the transport of graphene for oxygen reduction, while oxygen can also diffuse through defects and cracks in the graphene layer to the surface of Cu2O. Although the oxidation of copper is not spatially homogeneous, electrons can rapidly migrate to graphene and accelerate corrosion as long as electrical contact between copper and graphene in maintained (Figure 4b). Based on this mechanism, CVD graphene’s anti-corrosion action has been controversial for nearly a decade, with many studies suggesting that graphene accelerates the corrosion of copper. Recently, Lee et al. (Lee et al. 2020) have shown that the CVD grown graphene–Cu2O hybrid structure, which forms after a long period as normal, significantly slows down the oxidation of copper in the longer term, as compared to bare copper (Figure 4c). They observed that over a longer time scale, the CVD graphene–Cu2O hybrid structure became a protective layer against corrosion. At the same time, the unprotected copper area was observed heavily oxidized with CuO, with a far deeper depth compared to the corrosion beneath the graphene shield. Even though, graphene does trigger galvanic corrosion, especially preferential initialling at some defects.

Schematic representation of the corrosion-promoting mechanism of graphene. (a) Electrochemical oxidation of copper in the absence of graphene and (b) the presence of graphene coverage. (c) Schematic diagram of CVD graphene–Cu2O hybrid layer as a protective layer for copper in the long term (Lee et al. 2020). Reprinted with permission from American Chemistry Society.

2.2 Corrosion originators of pure CVD graphene coating

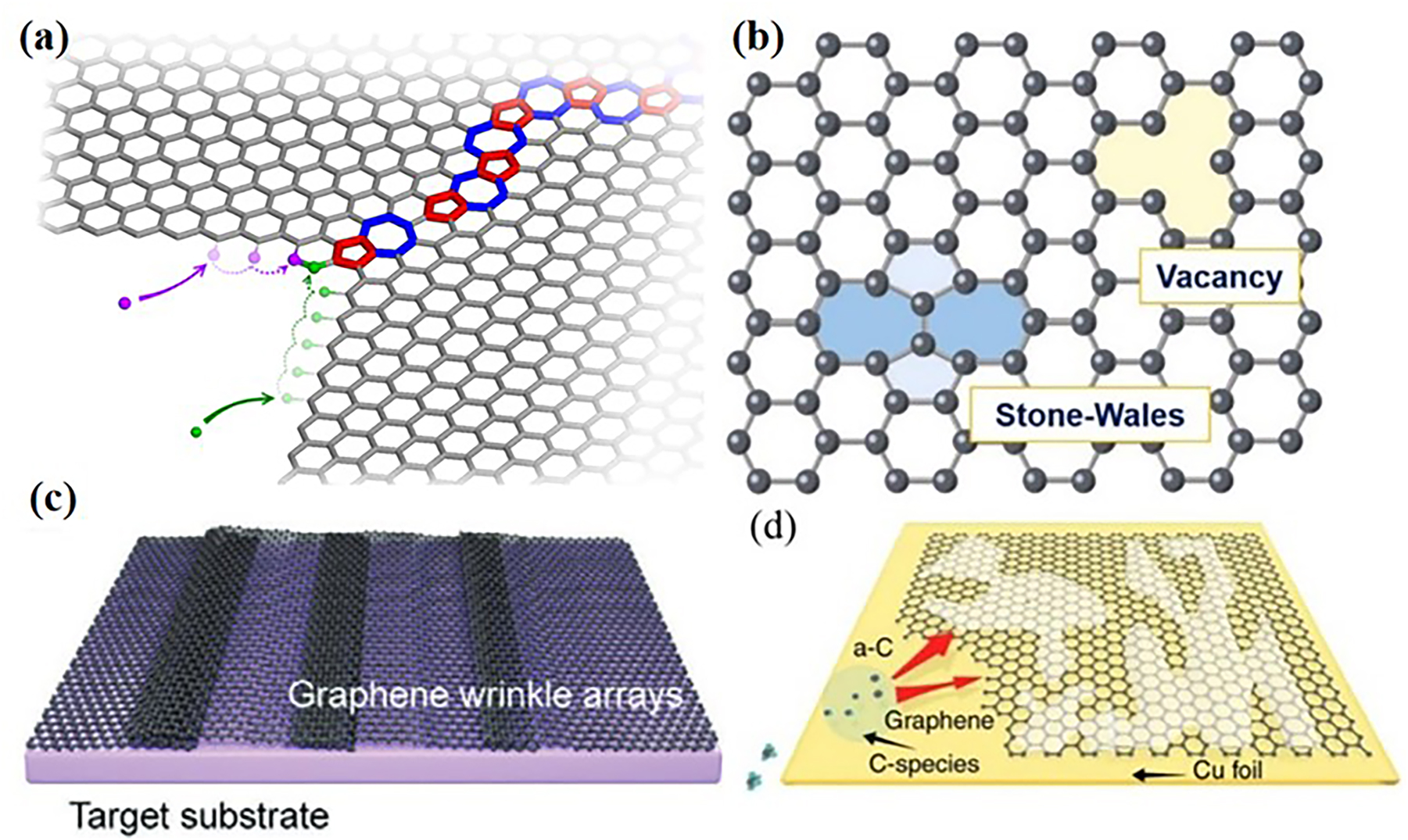

In principle, continuous and perfect graphene with tight coupling to the metal substrate would block the diffusion of oxygen and water molecules between the interfaces, thus preventing the initialization of galvanic corrosion (Yoon et al. 2012). However, CVD graphene films are always subject to various defects such as grain boundaries (Bets et al. 2021), vacancies, S–W defects and cracks (Zhang et al. 2021), sometimes accompanied by folds, wrinkles (Song et al. 2022) and surface contamination (Lin et al. 2019), as seen in Figure 5a–d. These structural defects and/or growth imperfections would eventually facilitate the mass transport of oxidative elements as a pathway in the long term (Luo et al. 2016, 2020; Yuan et al. 2020a). At the same time, the presence of conductive graphene promotes the continuation of electrochemical reactions in the system through delivering electrons (Cui et al. 2019). On this basis, these sites of structural defects and/or growth imperfections as the corrosion originators will further cause more cracks of graphene due to the mechanical stresses of the formed oxides layer and thus opening up new corrosion paths. Singh Raman et al. have shown that if a graphene coating does not provide proper coverage on a metal surface, it can lead to poor corrosion resistance due to the highly cathodic nature of graphene and that the content of defects is the main cause why graphene coatings have varying degrees of corrosion resistance (Singh Raman et al. 2012). Prasai et al. also experimentally confirmed that corrosion starts in the cracks of the graphene film (Prasai et al. 2012). Hsieh et al. suggest that especially the grain boundaries of graphene are responsible for its incomplete passivation (Hsieh et al. 2014). Other types of defects in the graphene coating can also provide a path for corrosion molecules to penetrate and even trap chlorine atoms, undermining the protection of the graphene film to the substrate (Lee and Berman 2018).

Corrosion originators of CVD graphene coating. (a) Graphene grain boundaries (Bets et al. 2021). Reprinted with permission from American Chemistry Society. (b) Vacancies and S–W defects (Zhang et al. 2021). Reprinted with permission from Elsevier. (c) Graphene wrinkle arrays (Song et al. 2022). Reprinted with permission from Wiley Online Library. (d) Surface contamination (Lin et al. 2019). Reprinted with permission from Nature.

Therefore, in order to improve the anti-corrosion efficiency of CVD graphene, extensive efforts have been investigated to inhibit the galvanic corrosion related with various corrosion originators. Many optimization strategies that can enhance the barrier resistance of CVD graphene coatings, as well as their inhibition mechanism related with galvanic corrosion are revealed. It includes post-healing of defects, doping modification of graphene and improving the graphene growth quality by reducing various defects correlated with CVD processes et al., which are demonstrated as follow.

2.3 Post-healing of defects strategies for pure CVD graphene coating

During the CVD growth or post-growth processing of graphene, structural defects like vacancy, disorder and dislocation defects are normally introduced. Besides of this, due to the randomly distributed graphene grains in CVD process, conventional graphene film is a polycrystalline structure composed of many grain boundaries. Here, the galvanic corrosion of the metal beneath would originate. For this issue, several optimization measures by post-healing of defects have been taken to repair the structure of CVD graphene and obtain high quality graphene coatings that provide effective long-term protection of the substrate material.

2.3.1 Atomic layer deposition for defects healing

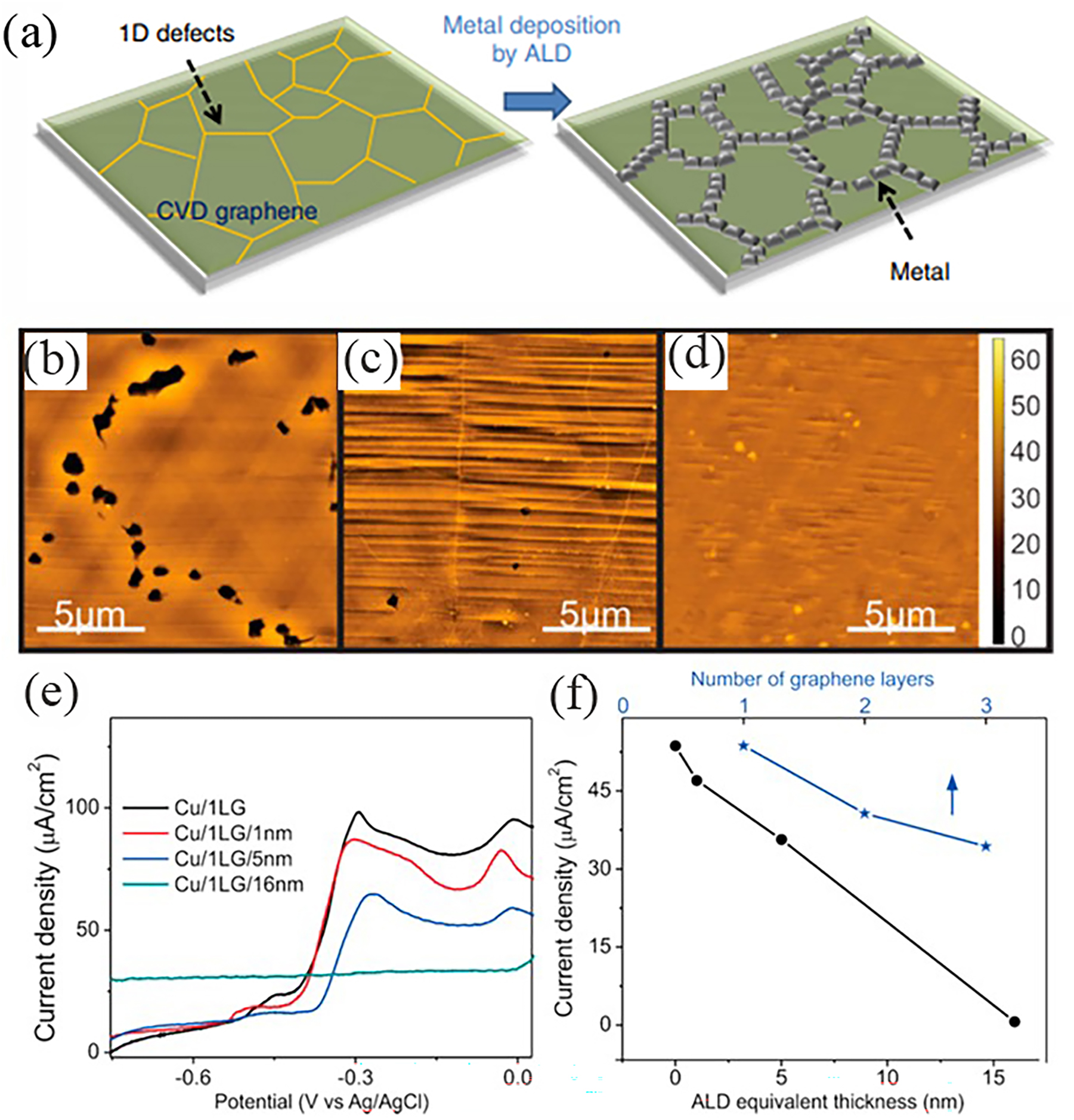

Post-healing for various defects is the most direct method that could improve the anti-corrosion efficiency of CVD graphene. Kim et al. selectively deposited metal nanoparticles (Pt) on linear defects in CVD graphene by atomic layer deposition (ALD) (Kim et al. 2014), as schematically seen in Figure 6a. The metal nanoparticles are selectively deposited on the one-dimensional defect sites of the graphene, particularly at the grain boundaries. From this point, a graphene–metal hybrid structure was obtained by deposition of metal nanoparticles, which just repair defective sites of the graphene. Experimentally, both scanning electron microscopy (SEM) and transmission electron microscopy (TEM) have demonstrated that the deposition sites of most metal particles are highly compatible with the linear defects of graphene. So, such an ALD technique enables the repairment of the local graphene defects and the enhancement of its corrosion barrier as a protective coating.

ALD healing of graphene defects for optimizing anti-corrosion properties. (a) Schematic diagram of the selective growth of platinum on one-dimensional defects in CVD graphene, where various linear defects such as grain boundaries, cracks and folded structures are present. By using atomic layer deposition, metals can be selectively deposited on one-dimensional defect sites in graphene. A graphene–metal hybrid structure can be obtained by this process (Kim et al. 2014). Reprinted with permission from Nature. (b–d) Representative AFM height images of etched graphene: (b) none, (c) ALD film with 5 nm and (d) ALD film with 16 nm. (e) CV spectra of Cu/graphene/ALD samples with different ALD thicknesses. (f) CuO peak currents of Cu/graphene/ALD samples with different ALD thicknesses and comparison with peak currents of Cu/graphene samples with 1–3 layers of graphene (Hsieh et al. 2014). Reprinted with permission from American Chemistry Society.

For example, it has been shown that due to the sensitivity of ALD to dangling bonds, atomic layers of alumina (Al2O3) can preferentially be deposited at lattice defects in graphene, producing separate clusters rather than continuous films on graphene. Moreover, the basic properties of graphene are not much deteriorated by passivation of ALD (Wang et al. 2008, Mazza et al. 2022). By doing this, the anti-corrosion efficiency can be improved accordingly as the thickness of the ALD alumina film increases (Hsieh et al. 2014). Figure 6b–d shows representative AFM height images of etched graphene with and without an ALD deposited film after corrosion. It can be observed that the density of etched pits on the graphene surface decreases as the ALD film thickness increases. Cyclo-voltammetry (CV) plots (Figure 6e) on the Cu/graphene/ALD film system with different ALD thicknesses also show that the corrosion current of the whole system shows a significant decrease as the ALD deposited film increases. Figure 6f shows the variation of current density for the Cu/graphene/ALD film system with different ALD thicknesses, showing that the passivation of the surface of the sample after 50 ALD cycles is better than that of the sample covered with a triple graphene film. In addition, the corrosion rate of the sample after 160 ALD cycles (corresponding to a 16 nm equivalent film thickness) is 1.6 × 10−15 m/s, a reduction of 99 and 87 %, compared to bare copper and the single layer graphene coating, respectively. Electrochemical impedance spectroscopy (EIS) also shows that the pore resistance associated with this healed graphene coating increases by a factor of 65 after 160 ALD cycles. These values are comparable to even the best copper corrosion inhibitors. Overall, inhibiting the passage of corrosive agents through post-ALD healing of structural defects in graphene improves the performance of graphene as a corrosion barrier and opens up the possibility for CVD graphene-based passivation layer applications.

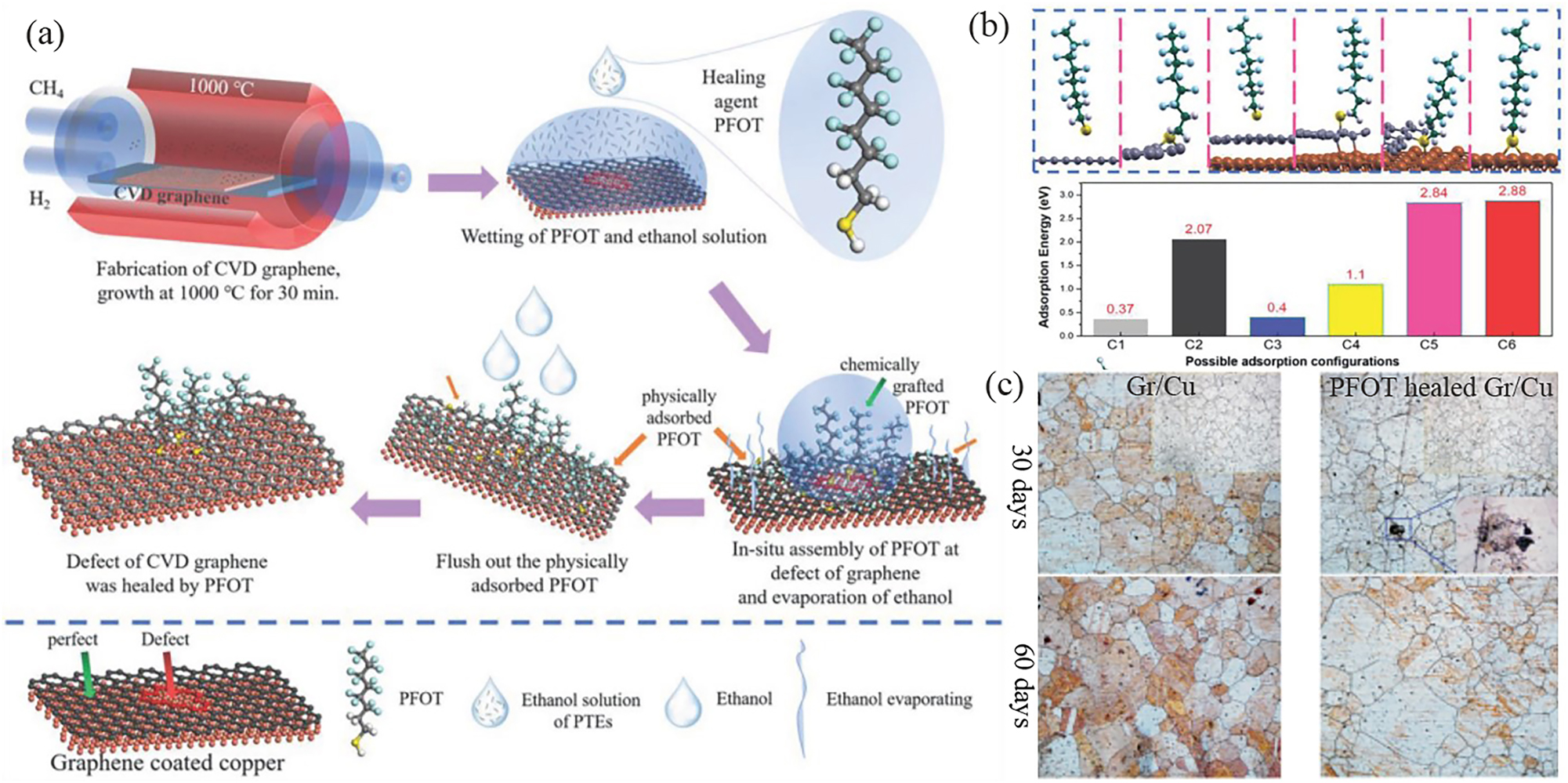

2.3.2 Polymer self-assembly for defects healing

In addition to ALD metal nanoparticles/oxide, polymers can also be used to accurately repair defects of graphene thus improving its barrier resistance property. Wu et al. reported the self-assembly of a hydrophobic perfluorooctyltriethoxysilane (PTES) film, a healing agent selectively chemically grafting onto a copper substrate exposed to a graphene defect site, can repair the defect without sacrificing the electronic properties of the graphene (Wu et al. 2019a). The reaction mechanism for polymer repair is driven by the in situ formation of polysiloxanes, followed by a polymerization reaction (Lee et al. 2016) in which defective sites on graphene are covered by chemical grafting between copper and PTES. Further to improving the healing efficiency, they also proposed a rapid treatment method capable of accurately healing different types and sizes of structural defects on CVD graphene within 15 min by self-assembling hydrophobic 1H,1H,2H,2H-perfluorooctanethiol (PFOT) molecules into the defect sites (Wu et al. 2021b) (Figure 7a). PFOT molecules can accurately graft onto the Cu substrate at the defect sites through Cu–S bonding and the hydrophobic groups of CF3−CF2− can minimize the wetting of corrosive solutions, both of which result in the enhanced anti-corrosion action of graphene coating on Cu substrate. The bonding mechanism and self-assembly behaviour of PFOT molecules was further explained in detail by DFT calculations. Figure 7b shows the six possible adsorption conformations (C1–C6) of PFOT molecules. For C1 and C3, the PFOT molecules are physically adsorbed on the surface of the pristine graphene with a large adsorption distance and low adsorption energy (ΔE ads) (0.37–0.4 eV). The low ΔE ads values for these pristine sites ensure that the physisorbed PFOT molecules can be easily removed by the ethanol rising as shown by in situ self-assembly process in Figure 7a. The higher ΔE ads values in C5 and C6 indicate that the healed PFOT molecules are capable of strong chemical bonding to any part of the copper substrate exposed to the graphene defect region. The relatively low ΔE ads in the C4 conformation can capture PFOT molecules to the defect edge of the graphene and allow C4 to continue to transition to the more stable C5 and C6 states. It is only when the exposed copper substrate is completely filled with PFOT molecules that the C atoms at the edges of the defects begin to be saturated with PFOT molecules. The conformation C4–C6, which enables complete passivation of structural defects, provides a good barrier to the intrusion of corrosion factors. On this basis, galvanic corrosion in the system is significantly suppressed. Figure 7c shows optical images of graphene-coated copper with and without PFOT healing exposed to ambient conditions for 30 and 60 days. After 60 days, as expected, galvanic corrosion (Wu et al. 2016) occurred between the untreated graphene coating and copper, and the copper substrate in the defected area was severely corroded. In the defected areas of the healed graphene, the accumulation of hydrophobic PFOT molecules successfully prevents the wetting of the surface by corrosive media, and some corrosive media such as H2O and O2 are unable to penetrate the graphene coating. Indeed, this potential healing method can significantly improve the corrosion resistance of graphene without affecting its structural and electronic properties.

Polymer self-assembly healing of graphene defects for optimizing anti-corrosion properties. (a) Fast healing strategies of the defects in CVD graphene coating. (b) The adsorption configurations (C1–C6), energies (ΔE ads) of PFOT molecule on pristine/defective graphene coating, where both free-standing and Cu-supported graphene are compared to reveal the effect of Cu substrate. (c) The optical images of pristine graphene-coated Cu and PFOT-healed graphene-coated Cu surface after the exposure to ambient condition of 20–25 °C with a relative humidity at 50–60 % for 30 (upper panels) and 60 (lower panels) days (Wu et al. 2021b). Reprinted with permission from Wiley Library.

2.4 CVD growth optimization strategies

The above-mentioned post-healing strategies are based on the remediation way, which is carried out after the graphene has been grown, depending on the type of defects. Considering that the long-term barrier resistance of graphene is highly correlated with its growth quality, the CVD synthesis history is of significant importance. How to grow graphene films directly from the beginning with good corrosion barrier resistance or even defects-free is also one of the challenges that researchers are concerned about. Various factors such as layers number, initial nucleation, the interface alignment between graphene and the underlying metal surface are revealed to be critical for the inhibition of galvanic corrosion of CVD graphene–metal system and improving its anti-corrosion efficiency.

2.4.1 Multi-layer strategy

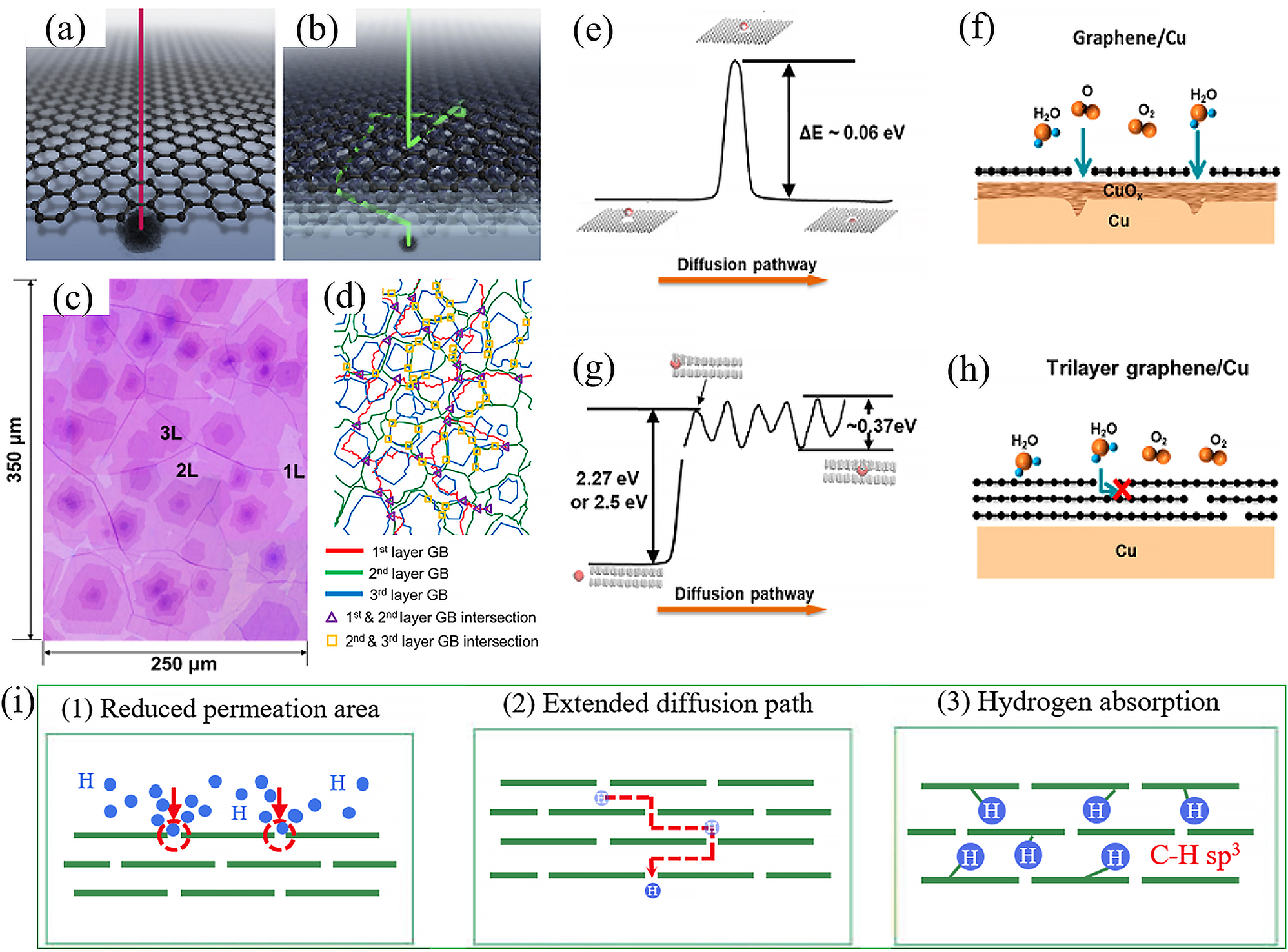

Firstly, the preparation of multi-layer graphene films opens a new door to improving the corrosion barrier resistance of CVD graphene. And the basic idea is that structural defects in adjacent graphene layer do not overlap with each other, eventually forming a spatial resistance that effectively prevents the penetration of corrosive media. Figure 8a-b schematically shows the spatial diffusion paths of the corrosion agents in the cases of mono-layer and multi-layer graphene films (Stoot et al. 2015). Comparing to single layer systems, corrosion agents face far more obstacles in passing through multi-layer graphene films. H2O and O2 molecules need to find lattice defects on the film surface to penetrate to the next layer, crossing multiple complex tortuous paths between layers and finally reaching the metal surface. Based on this optimization mechanism, it was confirmed that CVD grown multi-layer graphene would provide a superior long-term corrosion protection for stainless steel relevant as bipolar plates in polymer electrolyte fuel cells (Yu et al. 2016). In addition, Zhao et al. recently grew polycrystalline few-layer graphene (FLG) films on copper to investigate its long-term corrosion protection (Zhao et al. 2021). They compared copper covered with single and few-layer graphene films for 6 years ambient oxidation, showing a clear superiority of the FLG with respect to the single-layer graphene (SLG). Spatial structure configuration of the FLG (Figure 8c–d) was then verified through an isotope-labelled CVD process, demonstrating the similar spatial barrier resistance with complex diffusion paths. Figure 8e–h further shows the results of an atomic-scale simulation of corrosion molecules passing through defects in graphene to corrode the base metal for different cases. As seen in Figure 8e, the energy required for water molecules to pass through the defects (two-adjacent-carbon-atoms vacancy) in the SLG is approximately 0.06 eV and that a small increase in ambient temperature can assist the diffusion of water molecules to corrode the underlying metal (Figure 8f). However, molecular dynamics (MD) and DFT calculations revealed that the energy required for water molecules to diffuse into the van der Waals gap between the bilayer graphene films is as high as 2.5 eV from MD and 2.27 eV from DFT (Figure 8g). Further theoretical calculations revealed that energy of approximately 0.37 eV is required to move water molecules between the FLG layers, which is 14 times greater than the room temperature thermal activation energy and, therefore, unlikely to lead to the penetration of corrosion molecules as shown in Figure 8h. In short, the high diffusion energy barriers between graphene layers, combined with grain boundary misalignment, make polycrystalline FLG films a promising material for protective coatings in the field of metal corrosion protection. Specially, with such advantages from a multi-layered graphene coating, it can also effectively mitigate hydrogen embrittlement of the protected pipe steel through a strong dangling bonds adsorption effect on hydrogen atoms. Which can produce hydrogen traps to capture hydrogen atoms, enhancing the internal barrier effects (Shi et al. 2022) (see Figure 8i).

Anti-corrosion optimization mechanisms of multi-layer graphene. (a, b) Schematic diagrams of the diffusion paths of single-layer (a) and multi-layer (b) graphene. In the case of multi-layer films, the diffusion paths for oxygen and water molecules are longer (Stoot et al. 2015). Reprinted with permission from Elsevier. (c) Optical image of a large area of FLG film on a SiO2/Si substrate and (d) corresponding GB lines, with the intersection of the different layers marked in the diagram. (e) Schematic diagram of water molecules diffusing through the defective SLG and the calculated energy barrier. (f) Schematic showing the easy diffusion of reactive species such as oxygen and water molecules through the SLG and oxidized copper surface. (g) Schematic and calculated energy barrier for the diffusion of water molecules through the defective BLG. (h) Schematic showing the difficulty of diffusion of oxygen and water molecules through polycrystalline trilayer graphene and into contact with the underlying copper surface, even though the trilayer graphene contains multiple GB defects (Zhao et al. 2021). Reprinted with permission from American Chemical Society. (i) Internal hydrogen resistance mechanism of the MLG coating (Shi et al. 2022). Reprinted with permission from Elsevier.

Zhang et al. investigated the oxidation behaviour of graphene-coated copper in atomic oxygen (AO) environment, both theoretically and experimentally (Zhang et al. 2018). The experimental results show that the multi-layer graphene coating has better resistance to oxidation than the single-layer graphene coating after AO irradiation. In multi-layer graphene coatings, the diffusion of oxygen atoms in the vertical direction is largely inhibited due to the misalignment of defect positions and the formation of steric hindrances. The interlayer potential limits the diffusion of oxygen atoms in the horizontal direction, so that the oxidation process proceeds very slowly in multi-layer graphene systems. Sanjid et al. found through electrochemical characterization that the multi-layer graphene films were able to circumvent their defects and provide a complete covering surface, significantly improving the corrosion resistance of the alloy (Sanjid et al. 2019). Prasai et al. found experimentally that the mechanical transfer of multi-layer graphene films onto a target substrate was able to significantly reduce the corrosion rate of the metal (Prasai et al. 2012).

2.4.2 Interface engineering strategy

The coupling of the interaction between a graphene coating and the underlying metal is also critical in determining the barrier action for corrosion protection. The strong interaction between graphene and the substrate prevents the lateral diffusion of corrosive species at the interface, thereby inhibiting the oxidation of the metal substrate. Researchers have, therefore, been looking for ways to enhance the interaction between graphene and the substrate. Weatherup et al. grew continuous monolayer graphene films on the surface of various polycrystalline transition metal catalysts such as nickel, cobalt and platinum by a CVD process and studied their oxidation at room temperature when exposed to humid air at different time durations (Weatherup et al. 2015). The results showed that single-layer graphene films grown by the CVD process can protect polycrystalline nickel surfaces from oxidation for more than 18 months, due to the strong coupling between graphene and nickel. Graphene grown on copper or platinum substrates would have relatively poor interactions and tend to decouple from the substrates, thereby facilitating the diffusion and invasion of corrosive species at the interface. On the other side, graphene grown on nickel, cobalt and iron substrates would interact strongly, showing much better corrosion barrier resistance. The strong CVD graphene–metal interactions/coupling can prevent the lateral diffusion of aggressive species along with the graphene–substrate interface. These apparent differences in the long-term passivation ability of graphene grown on different metals are highly dependent on the alignment and lattice match between graphene and the substrate. This effective suppression of surface oxidation is critical for many applications such as ferromagnetic spin jets (Martin et al. 2014, 2015), non-precious plasmonic materials (Kravets et al. 2014), etc., which are very sensitive to even minor surface oxidation.

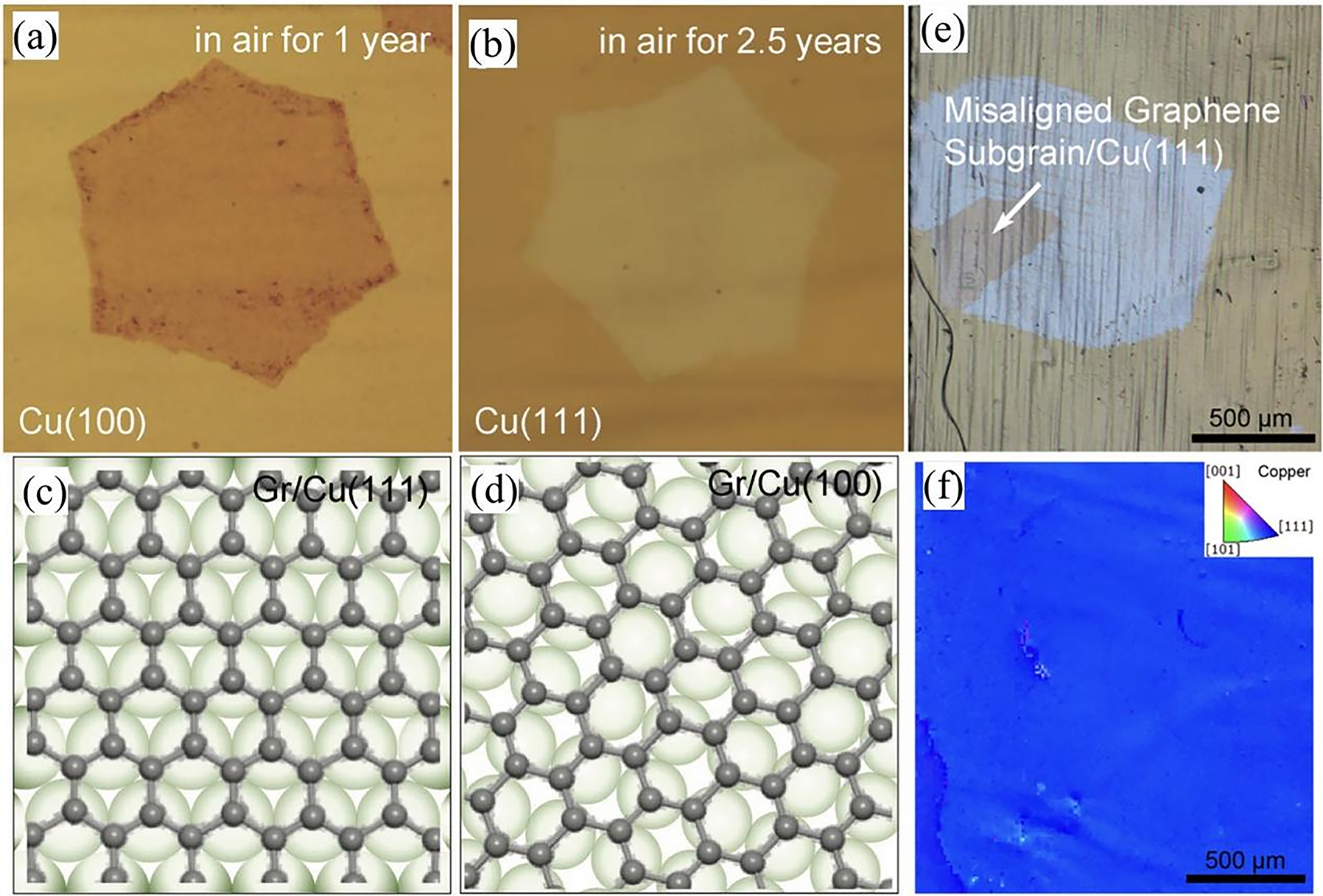

In addition to exploring the interactions with graphene from the perspective of the type of substrate, it is also important to seek how to engineer the interface of CVD graphene on metal substrate (e.g. Cu), which don’t always have strong coupling/interactions with CVD grown graphene. It was pointed out that the lattice alignment and mismatch between CVD graphene and the Cu growth surface play significant role in determining the coupling strength of the interface, then defining their corrosion barrier resistance (Xu et al. 2018). The typical experiment is the Cu facet-dependent anti-corrosion of CVD graphene coating. As shown in Figure 9a–b, the CVD grown single-crystal graphene grain on Cu(111) and Cu(100) surfaces shows disparate oxidation of the Cu surface under graphene in the long-term exposure to the ambient environment. It can be seen that after 1 year in air, Cu surface under graphene was heavily oxidized in the case of CVD graphene–Cu(100) interface (Figure 9a). In contrast, CVD graphene grown on Cu(111) can well protect then underlying Cu surface from oxidation for as long as 2.5 years (Figure 9b). It was revealed that only 4 % of the graphene and Cu(111) surfaces are lattice mismatched so that graphene can be epitaxially grown on its surface to form a commensurate system (Figure 9c). On the other hand, in the graphene–Cu(100) system, a small relative rotation is always observed, demonstrating that the graphene lattice is not perfectly aligned with the lattice orientation of Cu(100) facet (Figure 9d). In addition, Luo et al. systematically investigated the relationship between the crystal structure of CVD-grown graphene and that of the copper substrate and its effect on the oxidation of the substrate metal (Luo et al. 2019). The experimental results demonstrate that the oxidation of copper covered with graphene is highly dependent on the lattice arrangement and crystal orientation of copper and graphene. Figure 9e shows optical images of graphene bi-crystalline domains on Cu substrates with different degrees of oxidation. The corresponding electron backscatter diffraction (EBSD) characterization (Figure 9f) shows that the graphene domains are covered by a homogeneous Cu(111) surface, which implies that the crystal orientation of the graphene bi-crystal and the coupling between graphene and Cu(111) lead to different oxidation levels of the substrate. Recently, Zhao et al. reported a Janus-doped bilayer graphene coating, which provides protection for Cu substrates for more than 5 years at room temperature and 1,000 h at 200 °C (Zhao et al. 2023). This excellent anti-corrosion is attributed to the fact that the heavily doped bottom layer forms a strong interaction with Cu limiting the interfacial diffusion, while the nearly charge neutral top layer behaves inertly to alleviate the galvanic coupling corrosion. All of the above reveals that the anti-corrosive behaviour of the passivation surface is closely related to the differences in interfacial coupling in the graphene–Cu system, which is crucial for the development of efficient anti-corrosive technologies and materials and offers new prospect and opportunities for graphene to achieve ultra-high passivation of metals through precise interface engineering strategy.

Interface coupling of CVD graphene growth and its anti-corrosion properties. (a) Optical image of graphene-coated copper (100) after 1 year of oxidation under ambient conditions. (b) Optical image of graphene-coated copper (111) after 2.5 years of oxidation under ambient conditions. (c) Schematic representation of the graphene lattice on Cu(111). (d) Schematic representation of the graphene lattice on Cu(100). Carbon atoms cannot be matched to Cu. The grey (green) spheres indicate the carbon (Cu) atoms in (c) and (d) (Xu et al. 2018). Reprinted with permission from Wiley Online Library. (e) Optical image and (f) corresponding EBSD orientation map of a graphene bi-crystal domain on a single Cu facet with different degrees of oxidation (Luo et al. 2019). Reprinted with permission from American Chemical Society.

Besides, wrinkles and contamination, which greatly impair the corrosion barrier properties of graphene coating, are inevitably associated with interfacial coupling of graphene–Cu system. For example, wrinkles on the graphene surface can lead to local decoupling and then reduce the interfacial strength of the overall coupled graphene–Cu system. Similarly, contamination can lead to a decrease in graphene’s quality. Therefore, the production of flat and clean graphene shows attractive prospects for optimization of large-area highly tight interface of graphene–Cu system, which is important for suppressing the initialization of galvanic corrosion originated from interfacial coupling. Some CVD growth methods have been exploited for the growth of wrinkles- and contamination-free graphene layer (Choi et al. 2015; Lee et al. 2014; Mun et al. 2014). Especially, as shown in Figure 10, it shows several optimization growth techniques for large-scale production of wrinkles- and contamination-free graphene on Cu substrate.

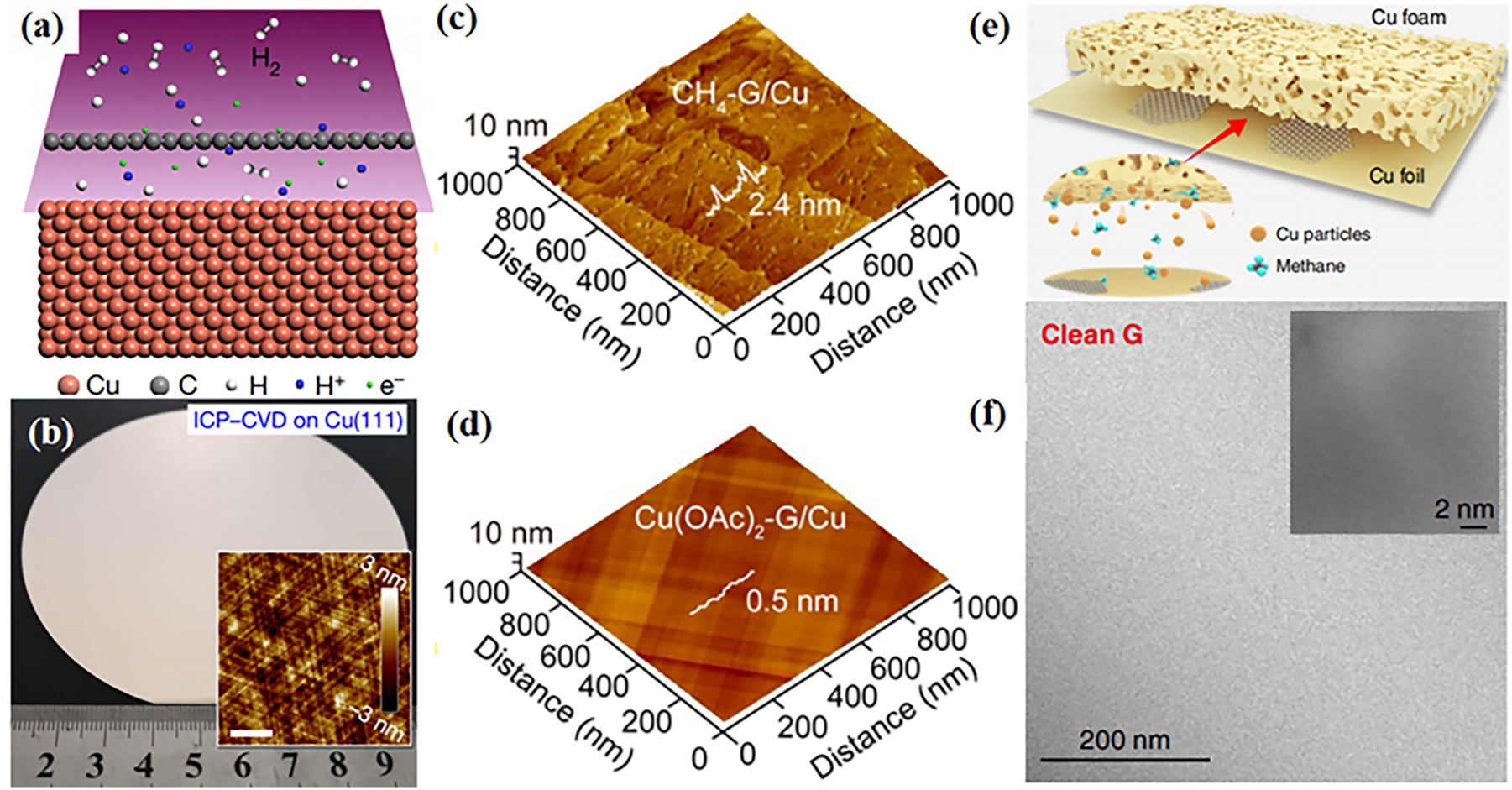

Synthesis and characterization of ultra-flat and ultra-clean graphene. (a) Illustration of protons penetrating through the as-grown graphene film during ICP treatment. (b) Photo of 4-inch graphene film grown on Cu(111). Inset, typical AFM image (Yuan et al. 2020b). Reprinted with permission from Nature. (c, d) AFM of clean graphene by CH4 (c) and Cu(OAc)2 (d) (Jia et al. 2019). Reprinted with permission from American Chemical Society. (e) Schematics of the experimental design. (f) TEM image of the super-clean graphene membrane. Inset: HRTEM image of the graphene lattice (Lin et al. 2019). Reprinted with permission from Nature.

Firstly, Figure 10a and b shows that wrinkle-free, ultra-flat graphene films could be grown on Cu film using proton-assisted CVD method. A proton penetration as well as recombinant hydrogen method effectively reduces the wrinkles formed in graphene during the conventional CVD process (Yuan et al. 2020b). In addition, Wang et al. investigated the wrinkling process of graphene films grown on single-crystal Cu–Ni foils using ethylene as a precursor (Wang et al. 2021). By limiting the initial growth temperature to between 1,000 and 1,030 k, it is possible to grow high-quality, wrinkle-free single-crystal monolayer graphene films that possess highly uniform transport properties, as for the contamination-free production of graphene.

Jia et al. successfully prepared ultraclean graphene by using a novel carbon source (Jia et al. 2019). Compared with methane, using Cu(OAc)2 as the carbon source increases the participation of copper in the reaction and promotes the timely decomposition of carbon clusters, achieving a clean graphene surface. Figure 10c and d shows AFM images of graphene grown with CH4 and Cu(OAc)2 as carbon sources. The surface of graphene grown with Cu(OAc)2 as the carbon source is visibly clean and almost free of impurities. Similarly, Lin et al. used alternately stacked copper foils and copper foam substrates to provide more copper catalysts, greatly inhibiting the formation of amorphous carbon (Lin et al. 2019). Copper foam is a porous structure that grows graphene with a very clean surface (Figure 10e and f). At the same time, the growth rate of graphene on the copper foam is lower than that on the copper foil, ensuring a continuous supply of copper during the growth process. These CVD growth strategies can produce highly tight interface of graphene–Cu system, largely improving their anti-corrosion protection for the underneath Cu substrates.

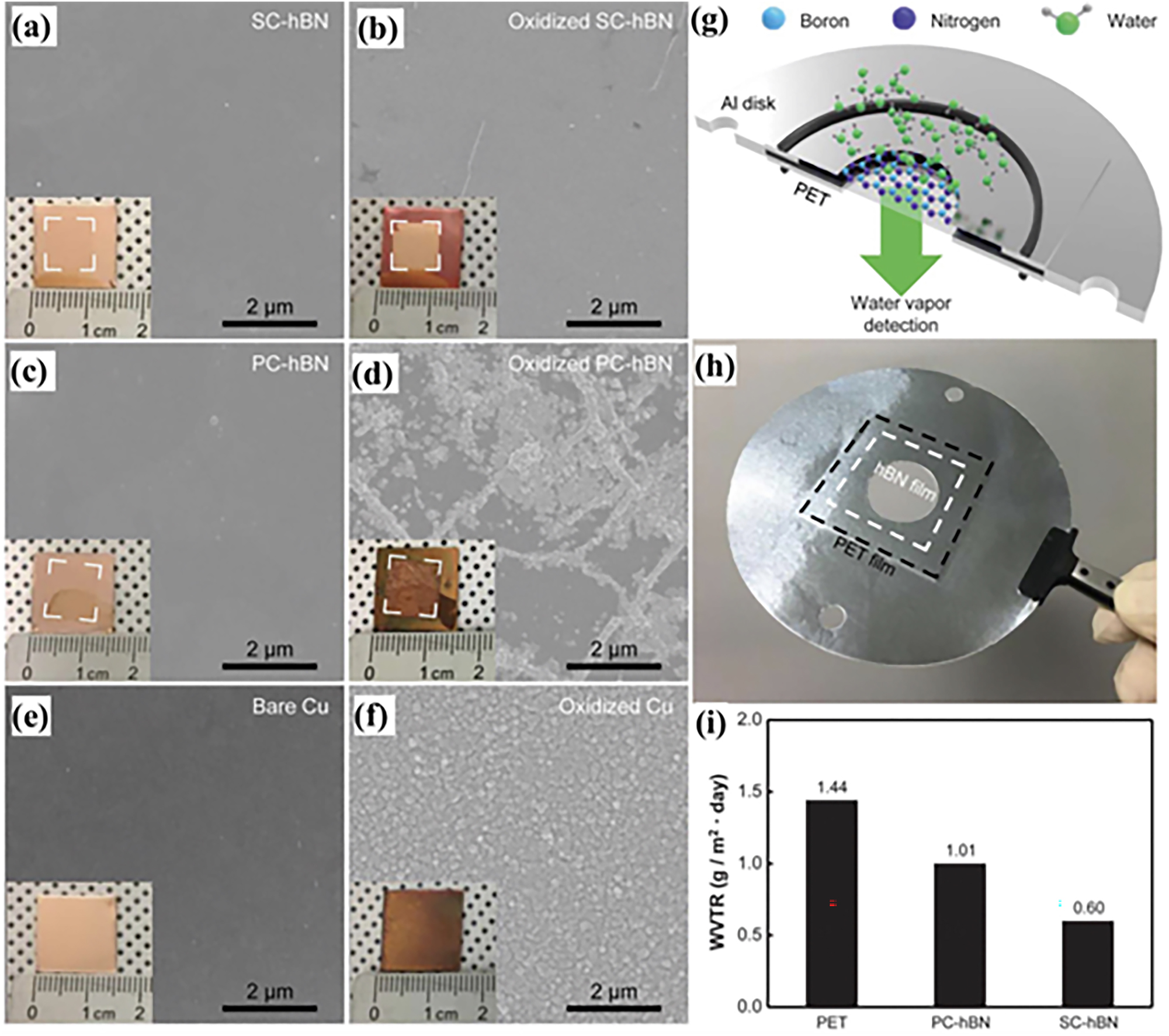

2.5 Graphene conductivity modification strategy

As we know, the semi-metal conductivity of graphene is one of the key elements responsible for the galvanic corrosion of graphene coating in the long-term protection for metals. Thus, modifying graphene’s properties by reducing its conductivity is a strategy for improving its corrosion protection efficiency. Typically, hexagonal boron nitride (h-BN), known as ‘white graphene’ with graphene-like lattice structure (Dean et al. 2010), excellent thermal conductivity (Golberg et al. 2010), high impermeability (Cai et al. 2015; Husain et al. 2013; Liu et al. 2013; Yi et al. 2014) and air stability (Chen et al. 2004; Li et al. 2014), has been considered to offer better corrosion protection than graphene mainly due to its insulating properties, which prevent the occurring of electrochemical reactions in the long term (Galbiati et al. 2017). Shen et al. prepared h-BN coatings by CVD, which exhibited corrosion resistance far beyond of pure graphene after exposure to air for up to 160 days (Shen et al. 2016). Lee et al. reported a method of synthesizing wafer-scale single-crystalline hBN(SC-hBN) monolayer films by CVD (Lee et al. 2018). Such wafer-scale SC-hBN film can serve as a protective layer against metal oxidation and a gas-diffusion barrier for water vapour transport. The Cu surface covered by SC-hBN film is not clearly changed after the oxidation test at 300 ℃ in air, whereas both polycrystalline hBN (PC-hBN)-covered and bare Cu surfaces are severely oxidized (Figure 11a, c, e and 11b, d, f). Water vapour transmission rate (WVTR) measurements of the hBN films (Figure 11g–i) showed that the SC-hBN monolayer films outperformed the PC-hBN monolayer films by about a factor of two, obtaining WVTR values comparable to those of single-layer polycrystalline graphene films. Such wafer-scale SC-hBN films do not have any grain boundaries, thus forming a water vapour barrier and complete protection against Cu oxidation. Structural defects and/or growth imperfections in the CVD graphene and hBN allow unprotected areas of copper to react with oxygen and produce copper oxides, and the corrosion reaction could have been inhibited as the oxides grow. However, the high electrical conductivity of graphene provides a new pathway for electron transport, transporting electrons to the oxygen atoms and allowing the corrosion area to expand in both horizontal and vertical directions, as we have shown above. In contrast, due to the insulating properties of hBN, electron transport is effectively inhibited in the horizontal direction, and then the circuit of the electrochemical reaction is cut off, finally resulting in a slower corrosion rate. Therefore, the conductivity reduction manipulation of graphene down to that of hBN has been a viable strategy to their anti-corrosion protection for metals (Jiang et al. 2017; Khan et al. 2017; Li and Chen 2016).

Anti-corrosion properties of h-BN. (a–f) SEM images of SC-hBN-, PC-hBN-covered and bare Cu foils before (a, c and e) and after (b, d and f) oxidation in air at 300 °C for 1 h. (g, h) Schematic and photograph for the WVTR. (i) WVTR values of PET, PC-hBN and SC-hBN samples (Lee et al. 2018). Reprinted with permission from Science.

2.5.1 Boron or/and nitrogen doped graphene for anti-corrosion

The most common strategy for reducing the conductivity of graphene is including doping atoms into the atomic lattice of graphene. Numerous studies have found that doping graphene with heteroatoms (such as boron, nitrogen, phosphorus and oxygen) can alter the electrochemical properties of graphene by modulating its local electron density and improving its capacitive performance (Bonanni et al. 2012; Lv and Terrones 2012; Poh et al. 2013; Wu et al. 2012; Yang et al. 2011b). The doping of boron atoms into the atomic lattice of graphene is a very attractive corrosion protection strategy, as their atomic sizes are very close to each other, thus avoiding the formation of structural defects (Banhart et al. 2011). Indeed, the stability between boron-doped graphene and copper interfaces was investigated (Boukhvalov et al. 2018), showing that boron-doped graphene coatings can provide high-strength corrosion protection for copper substrates.

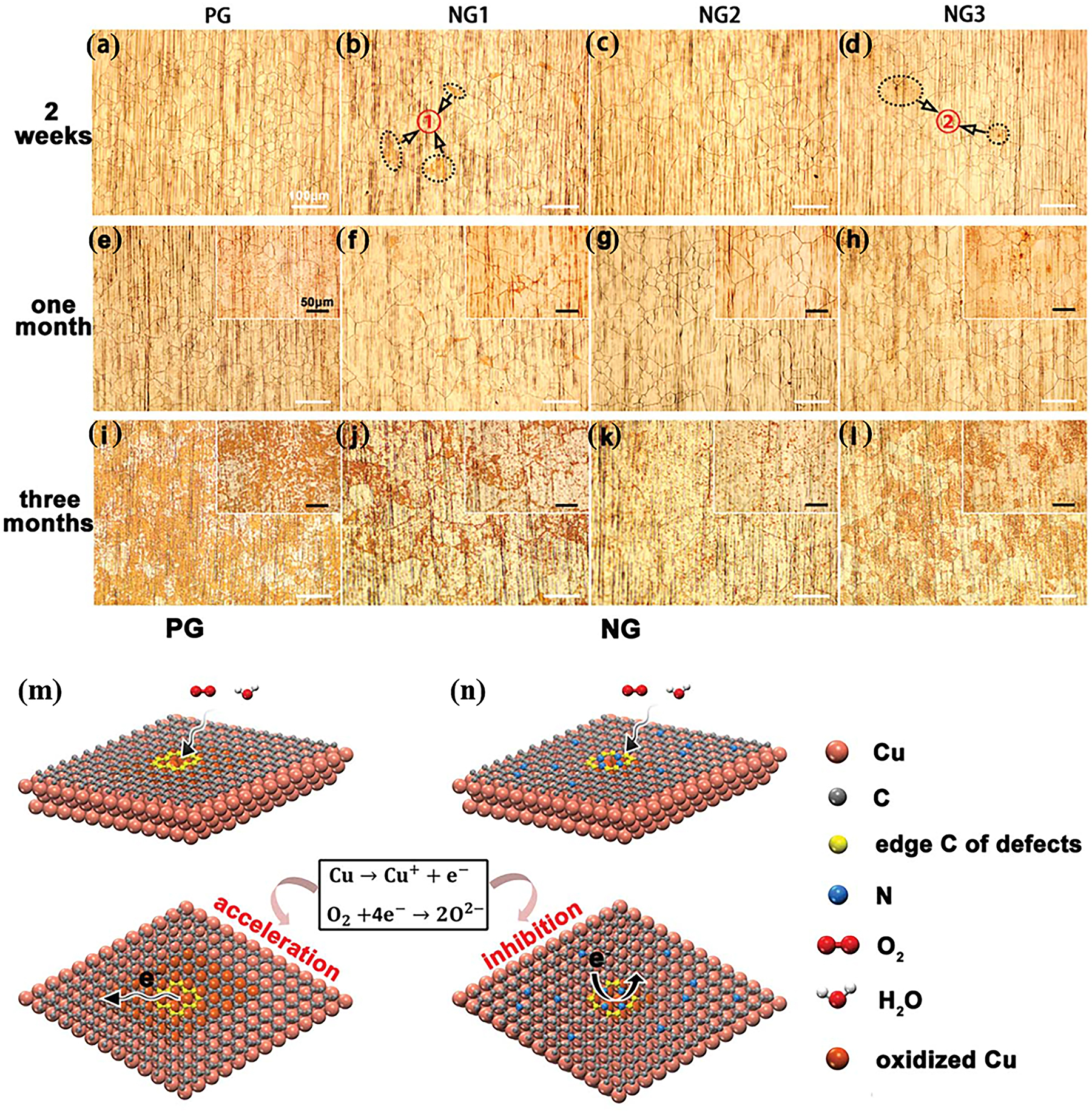

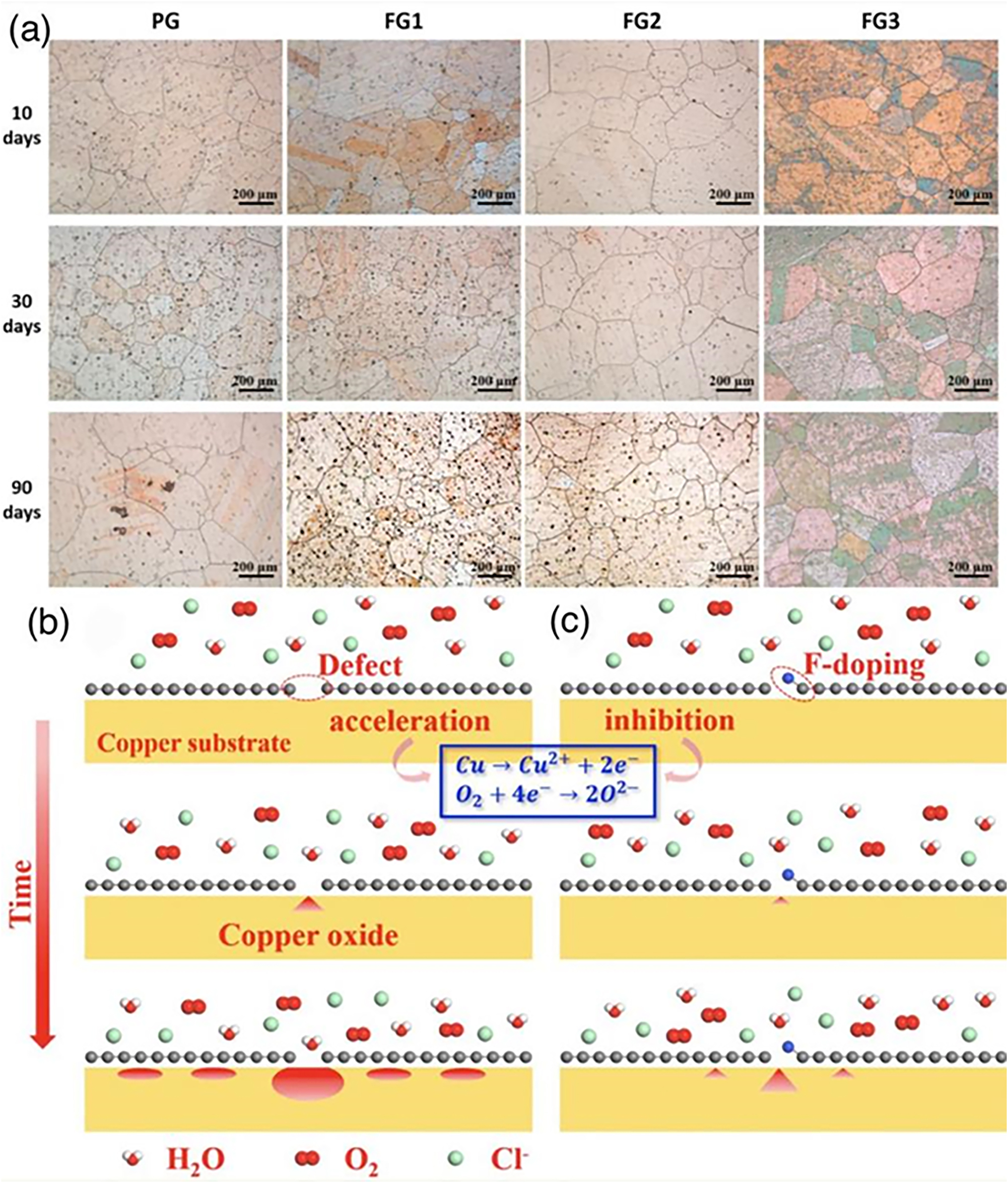

In recent years, researchers have also paid much attention to nitrogen-doped graphene (NG) (Han et al. 2021; Li et al. 2017; Kong et al. 2014; Wang et al. 2010), as nitrogen atoms have similar atomic radii to carbon atoms and are more electronegative than carbon atoms (Cervantes-Sodi et al. 2008; Xie et al. 2015; Yang et al. 2012), which make N-doped graphene considerably less conductive compared to pristine graphene (PG) (Guo et al. 2010; Jin et al. 2011; Liu et al. 2011; Wei et al. 2009). Therefore, the preparation of high-quality NG sheets with desirable chemical properties is key to future corrosion protection applications. Ren al et. used NH3 and CH4 as the source of nitrogen and carbon, respectively, and synthesized NG flakes with different concentrations (increased as NG1, NG2 and NG3) by CVD (Ren et al. 2018). As the environmental oxidation experiment shows in Figure 12a–i, NG could provide better corrosion protection than PG over larger period of time. On the other hand, it is worth considering that excessive atomic doping inevitably introduces additional defects in the graphene lattice, which would conversely increase the physical corrosion on such defects. As a result, proper nitrogen doping (for instance, NG2) enables the film to have good quality and corrosion protection properties as demonstrated in the longer-term corrosion protection (Figure 12k). In general, nitrogen-doped graphene can provide longer corrosion protection than pure graphene. As shown in Figure 12m, during long-term exposure at room temperature, corrosion starts at defects in the PG film and accelerates under the subsequent galvanic corrosion effect (Cubides et al. 2016; Jalili et al. 2015), resulting in a horizontal corrosion reaction gradually. On the other side, nitrogen doping and topological defects reduce the electrical conductivity of graphene, thereby inhibiting corrosion of the copper substrate (Figure 12n) by reducing the transport of electrons. In addition, the good catalysis ability to the absorbed oxygen atoms on NG surface, specifically catalysing the bonding of adsorbed O into O2 to release from NG surface and avoiding the damage of NG film, is another factor that makes the better oxidation resistance of NG than PG (Ren et al. 2019).

Optical micrographs of PG- and NG-coated copper foils exposed to air for (a–d) 2 weeks, (e–h) 1 month and (i–l) 3 months, respectively; scale bars are 100 mm. Areas 1 and 2 marked with ellipses in (b) and (d) are dark yellow areas of corrosion. The insets in (e–l) show corresponding enlarged optical images of PG- and NG-coated copper foils exposed to air for 1 and 3 months; scale bars are 50 mm. (m) Schematic illustration of the corrosion mechanism of (m) PG- and (n) NG-coated copper foils (Ren et al. 2018). Reprinted with permission from Royal Society of Chemistry.

In addition to the single heteroatom doping of graphene, the co-doping of boron and nitrogen can be another way to reducing the conductivity of graphene and promoting its anti-corrosion behaviour. This new material, termed hexagonal boron-carbon nitrogen (BCN), is composed of alternating boron, carbon and nitrogen atoms in a two-dimensional honeycomb lattice. However, the nanostructures of BCN are diverse due to the different bonding forms such as C–N bonds, B–N bonds and B–C bonds (Lei et al. 2011). Different bonding structures can have a profound effect on the properties and chemical activity of BCN materials, so the magnetic, optical and electrochemical properties of BCN materials can be further tuned by adjusting the elemental composition of the boron–carbon–nitrogen triad (Wang et al. 2017). Similarly, their anti-corrosion properties also largely depend on the elemental composition of BCN. The corrosion behaviour of B x C y N z films in acidic, neutral and alkaline solutions was investigated by measuring the dissolution rates using an ellipsometer (Byon et al. 2004). The dissolution rate of the B x C y N z films varied with the pH of the solution, specifically NaOH > NaCl > HCl. At the same time, the effect of different compositions on the dissolution rate of the films gradually increases as the carbon content decreases. This means that the doping of B/N in graphene with the composition of the film closer to that of BN would have better corrosion resistance. In fact, this strategy by using BCN films through doping of B/N in graphene for the corrosion protection has been already reported elsewhere (ArunKumar et al. 2017, 2018, Duan et al. 2022).

2.5.2 Fluorinated graphene film for anti-corrosion

As another case of doping graphene for anti-corrosion purposes, it is worth mentioning fluorinated graphene (FG), which exhibits good physical barrier properties, excellent electrical insulation and thermal stability with low surface energy (Ci et al. 2019; Gong et al. 2018; Lazar et al. 2015). Wu et al. performed vapour phase fluorination of graphene at different temperature (FG1 – room temperature, FG2 – 100 °C, FG3 – 200 °C) and measured their anti-corrosion effects comparing with PG (Wu et al. 2021c). Figure 13a shows optical micrographs of these four samples exposed to ambient conditions for 10, 30 and 90 days. As shown, with the air exposure time increased from 10 to 90 days, FG2 (100 °C) demonstrates the best anti-corrosion effects for copper substrate due to the appropriate fluorination temperature (100 °C), which lead to fluorinated graphene with more intact structure and, therefore, more resistant to the attach from corrosive species. In contrast, FG3 (200 °C) has a poor anti-corrosion resistance. This is because the relative high temperature (200 °C) disrupted the structural integrity of the graphene film. On this basis, the corrosion species could easily reach the copper substrate through the disrupted structure and initiate corrosion. However, the anti-corrosion barrier of FG1 (room temperature) doesn’t show much differences from that of PG mainly due to the low fluorination degree of graphene. Based on these experimental results, Figure 13b–c shows a schematic diagram of the corrosion protection mechanisms of the PG and FG coatings on copper. In the case of PG, the unavoidable defects provide a direct channel for the corrosion molecules to diffuse between the film and the substrate. In addition, the high electrical conductivity of graphene accelerates the local electrochemical corrosion at the graphene–copper interface (Figure 13b). Compared to PG, FG presents good corrosion resistance, especially in the case of FG2. The fluorine atoms bond with the carbon atoms at the edges of the vacancy defects, which greatly increase the physical barrier between corrosion species and the copper substrate. Moreover, the fluorination treatment reduces the electrical conductivity of graphene, effectively inhibiting electrochemical corrosion (Figure 13c). The FG coating is, therefore, able to provide long-term effective corrosion protection for the copper substrate, and even for some special applications such as triboelectric nanogenerators (Jiang et al. 2021).

Fluorinated graphene for optimizing anti-corrosion properties. (a) Optical micrographs of PG- and FG-coated copper exposed to air for different times. (b) Schematic diagram of the corrosion protection mechanism of PG and (c) FG (Wu et al. 2021c). Reprinted with permission from Elsevier.

In all, the anti-corrosion effects of CVD graphene coatings are influenced by both the various defects of graphene itself and its intrinsic semimetal conductivity, wherein defects including structural defects and growth defects are mainly related with the CVD preparation processes on metal surfaces, while the semimetal conductivity of graphene would cause micro-galvanic corrosion in the long-term protection of metals. Therefore, controlling the quality of CVD graphene on metals is of great importance for the anti-corrosion action related with physical barrier. It can be optimized through controllable growth of graphene on metals, including multi-layer growth of graphene, interface engineering and even wrinkles/grain boundaries-free graphene (Chen et al. 2013; Wang et al. 2021). Meanwhile, post-healing approach exhibits high flexibility and compatibility to prepare large area CVD graphene coatings for metal anti-corrosion. On the other hand, conductivity modification of graphene can reduce the conductivity of graphene through doping graphene with heteroatoms, then preventing the micro-galvanic corrosion to some extent in the long term. With such a strategy, the doping process is also highly correlated with CVD processes. Thus, improving the quality and productivity of CVD graphene techniques on protective metals is still the key point for their anti-corrosion application as a metal coating. The representative works reporting the optimization strategies for anti-corrosion properties of CVD graphene coatings are summarized in Table 1 based on their mechanisms, with the main advantages extracted.

Comparison between the three anti-corrosion strategies of pure CVD graphene coatings.

| Strategies | Mechanism | Advantages | References | |

|---|---|---|---|---|

| Defects-healing | Selective deposition/chemical grafting of metal particles/polymers onto linear defects in CVD graphene, thereby repairing defective sites in graphene | Visualization of defect locations and extrapolation of notch sizes allows precise healing of defects without introducing additional defects; the binding of metal particles/polymers to defects does not spread to other regions of the graphene and does not affect the electronic properties of the original graphene |

Kim et al. (2014)

Hsieh et al. (2014) Wu et al. (2021b) |

|

| CVD growth | Multi-layer optimization | Structural defects in adjacent graphene layer do not overlap with each other, thus forming a tortuous path for corrosive species penetration of corrosive media | Provides years of protection for the substrate metal without altering the properties of the substrate |

Stoot et al. (2015)

Zhao et al. (2021) Shi et al. (2022) |

| Interface engineering | The strong interaction between graphene and the substrate metal prevents the lateral diffusion of corrosive species in interface, thereby inhibiting the oxidation of the metal substrate |

Xu et al. (2018)

Luo et al. (2019) Yuan et al. (2020b) Zhao et al. (2023) |

||

| Heteroatomic modification | The introduction of foreign atoms into the graphene lattice can significantly reduce the electrical conductivity of graphene, thus reducing electrochemical corrosion at the graphene–metal interface | Heteroatomic doping can modify the electrochemical properties of graphene by adjusting its local electron density and improving its capacitive properties. Foreign atoms (e.g. boron, nitrogen, fluorine) have similar atomic radii to carbon atoms, thus avoiding the formation of structural defects. The modified graphene after doping has a lattice structure similar to that of pure graphene, as well as good physical barrier properties, excellent electrical insulation and thermal stability |

Lee et al. (2018)

Ren et al. (2018) Wu et al. (2021c) |

|

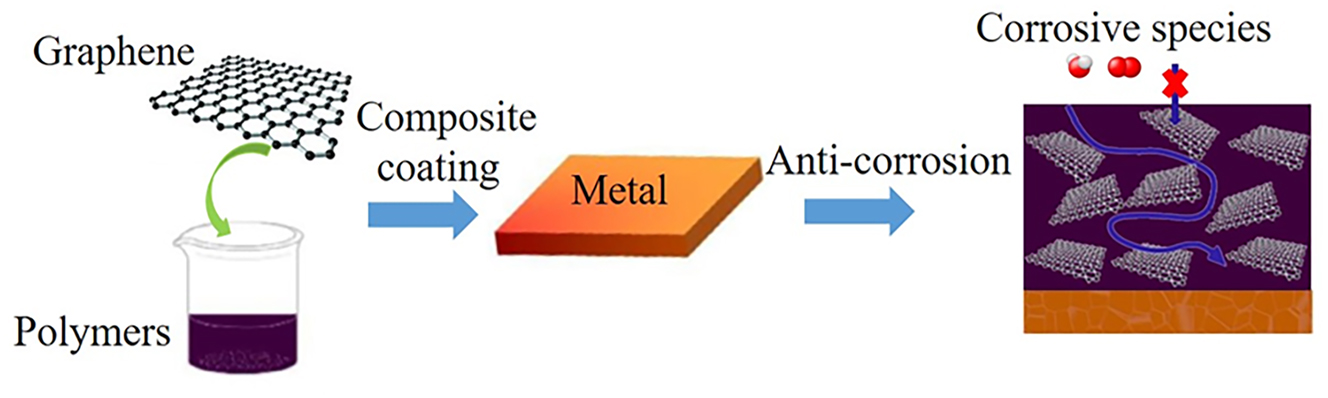

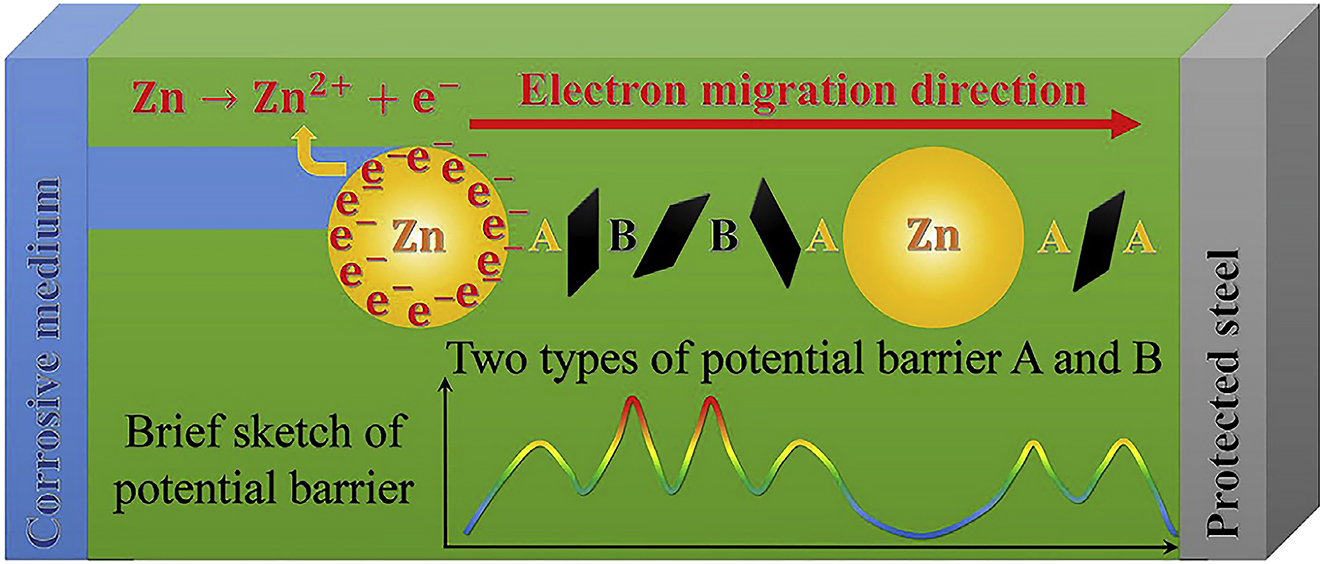

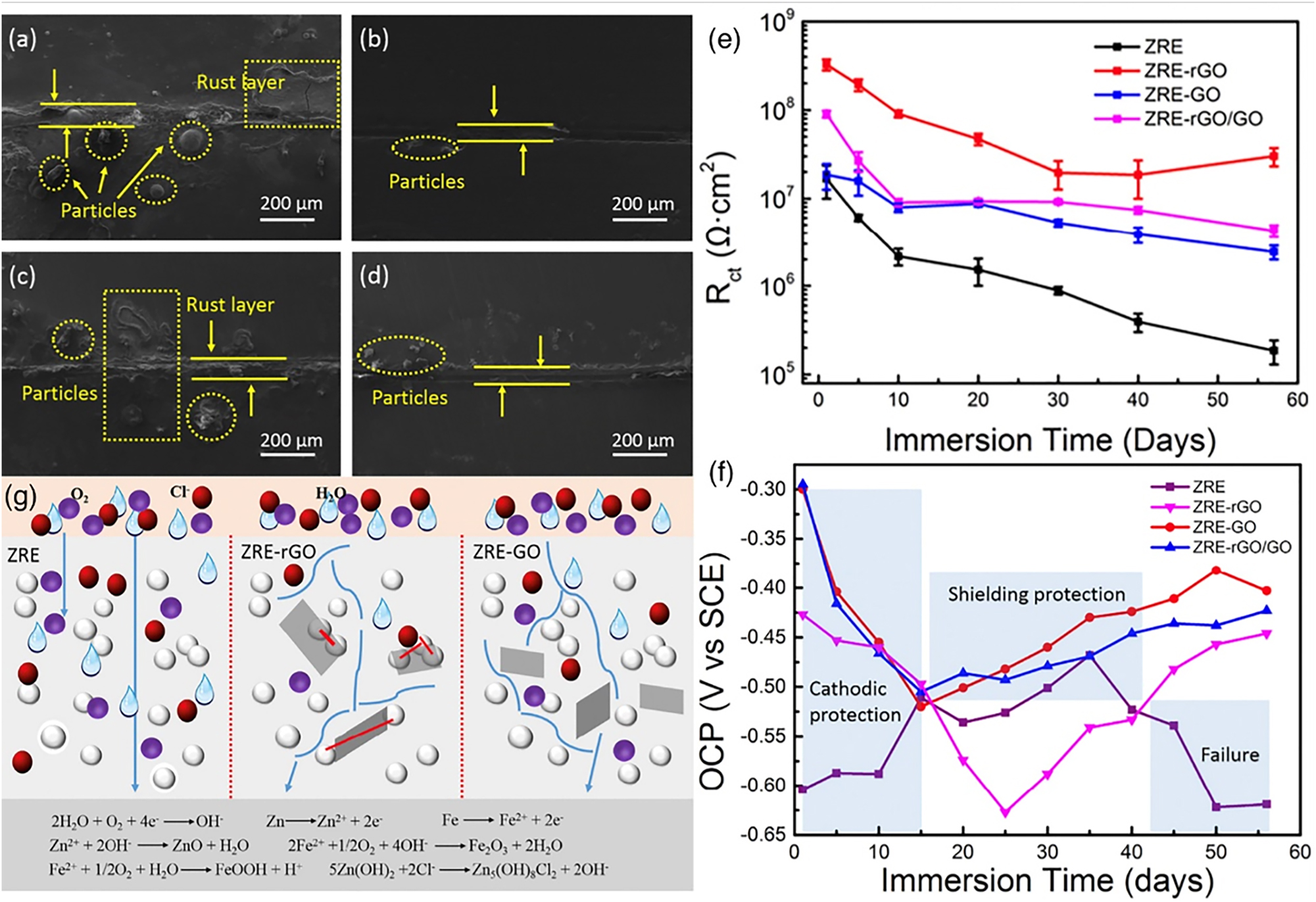

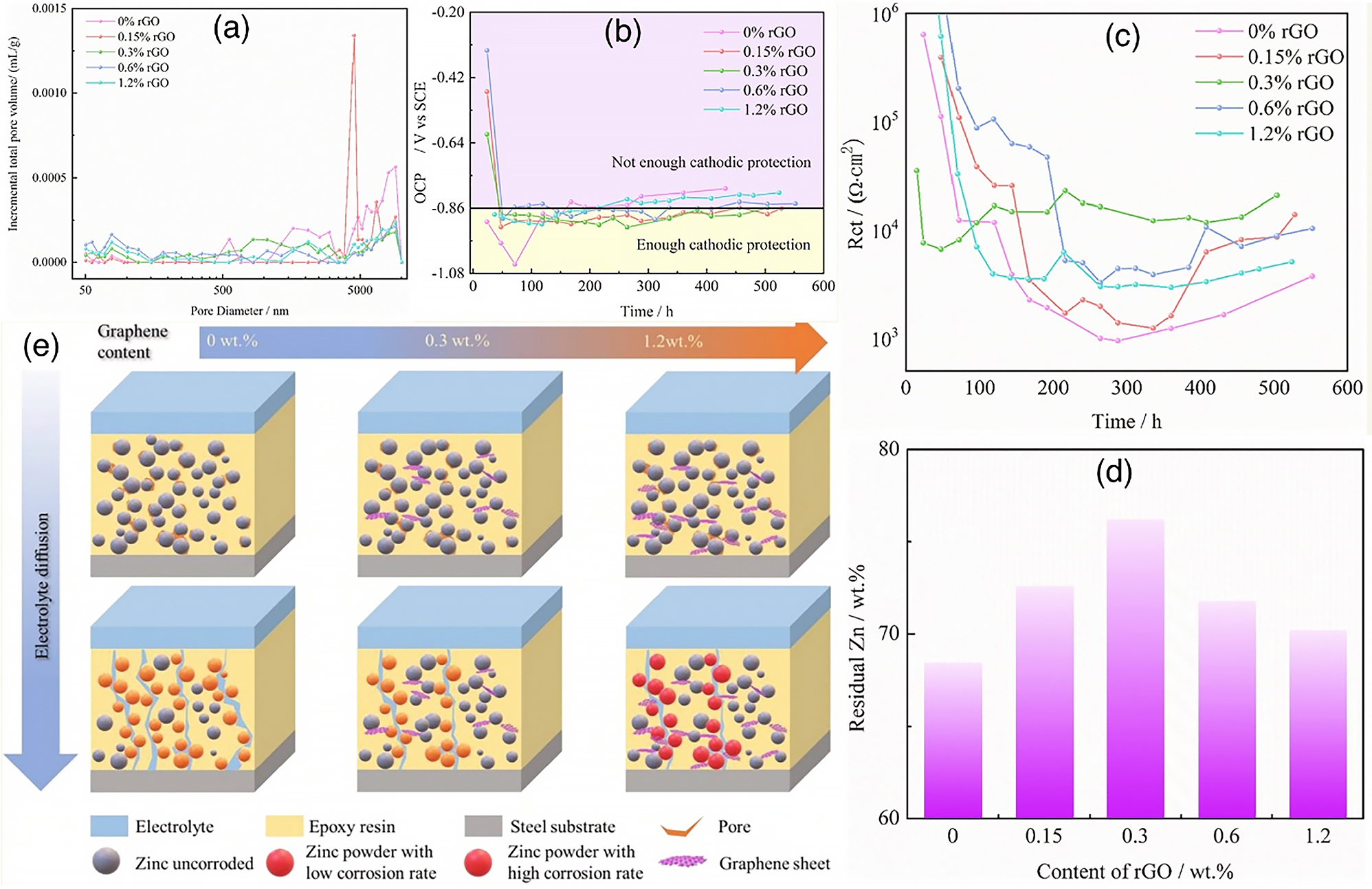

3 Graphene composite coatings and the optimization strategies

CVD graphene coatings have many excellent properties and show a unique advantage in the corrosion protection of metals, but there are many limitations when it comes to industrial applications (Hui et al. 2014; Lanza et al. 2013; Wu et al. 2019b; Zhang et al. 2014a,b). Indeed, the process is difficult to scale up and industrialize under current technological conditions, and the cost of preparation is relatively high. On the other hand, graphene composites show great potential in the field of corrosion protection (Assad et al. 2023; Ding et al. 2023; Jena and Philip 2022; Qi et al. 2015; Qureshi et al. 2022). By physically or chemically mixing graphene or its derivative in forms of nanosheets with polymer matrices such as polyethylene (PE), poly(vinyl alcohol) (PVA), polystyrene (PS), polyacrylonitrile (PAN), etc., different kinds of GCCs are obtained (Yoo et al. 2014). GCCs combine the strong adhesion properties of graphene with the film-forming properties of the coating substrate, greatly improving the overall performance of the final coating. The preparation and application roadmap of GCC is shown in Figure 14. Covering metals with such composite coatings can effectively resist the intrusion of corrosion agents and provide long-term corrosion protection for metal substrates. In addition, compared to pure polymers, GCCs have additional properties, such as electrical conductivity, which could be useful in particular applications, thermal conductivity, thermal stability and mechanical properties (reinforcement action of graphene), showing great promise as multifunctional protective coatings (Das and Harimkar 2014; Kim et al. 2019; Shi and Zhu 2020; Wang et al. 2015; Yang et al. 2019).

Conceptual illustration of graphene composite anti-corrosive coatings on metal.

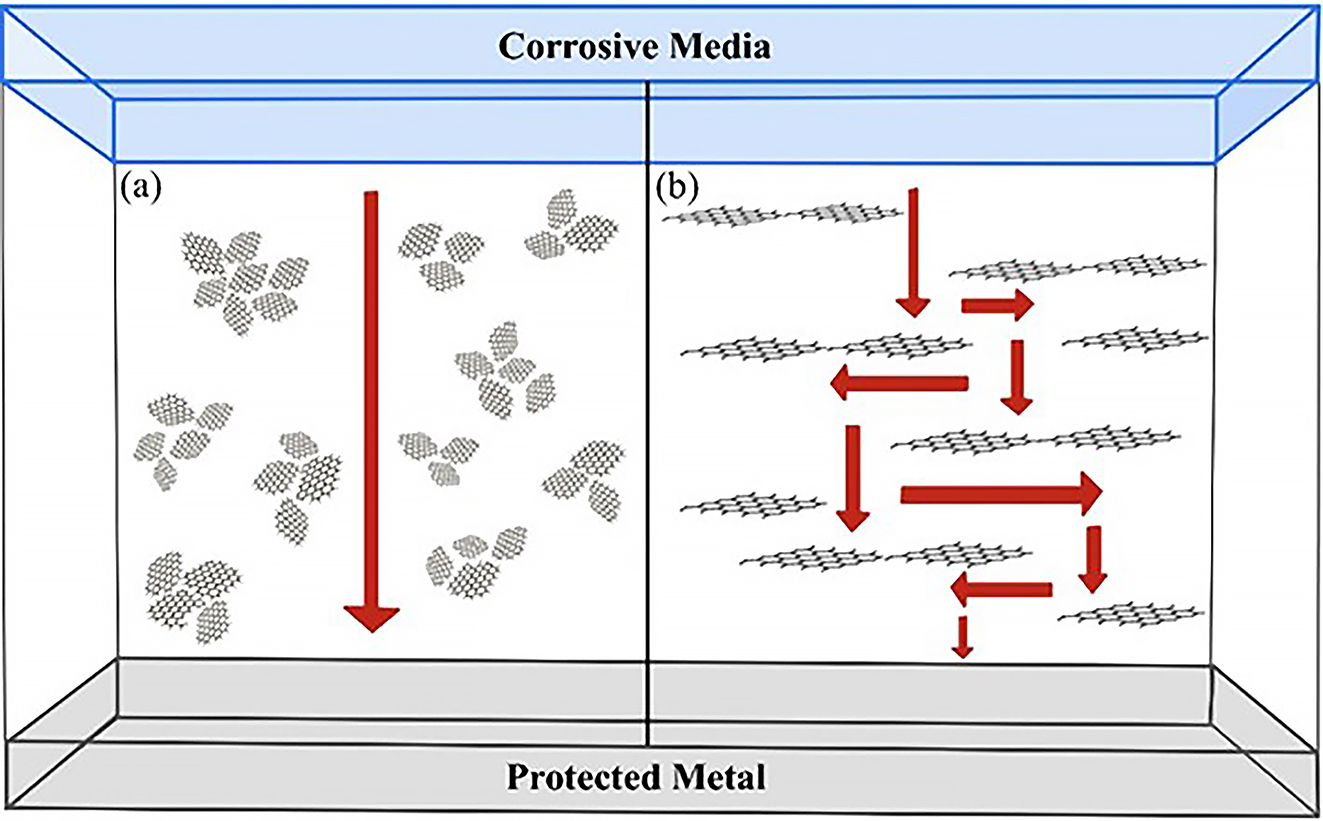

The corrosion protection mechanism of GCCs lies in their ‘labyrinth effect’. In the case of pure polymer coatings, once the corrosive medium penetrates the interface and reaches the metal substrate, corrosion reaction occurs almost unimpeded. The special physical structure of graphene makes it more resistant to penetration. Randomly dispersed in the coating matrix, graphene nanosheets hinder the penetration of corrosive agents by extending their diffusion path (Figure 15). As a result, a good dispersion of graphene derivatives in the coating is crucial for its shielding protection. Only when the graphene nanosheets are uniformly dispersed and stable in the coating can the composite coating achieve higher barrier properties (Papageorgiou et al. 2017; Pierleoni et al. 2016; Sekhavat Pour and Ghaemy 2016; Tan and Thomas 2016). The pure graphene surface has a high aspect ratio, van der Waals interactions and no functional groups, so it can easily agglomerate in aqueous solutions or organic matter, and this low dispersion severely reduces the anti-corrosion properties of the GCC. Therefore, improving the dispersion of graphene in the coating matrix is essential to improve the corrosion protection properties of the composite coating (Wang et al. 2019). In addition, graphene can play a key role in improving the toughness and elasticity of the coating, thus reducing the penetration of corrosion species by effectively hindering the expansion of cracks or tears in the coating.

The corrosion protection mechanism of GCCs. (a) A poorly dispersed coating has a short permeation path. (b) Well-dispersed graphene prolongs the permeation path of the corrosive materials.

The preparation method and film-forming process of GCCs are based on the traditional coating preparation process and show good operability and controllability in industrial synthesis and application. It is believed that GCCs will become a main force in the production of new anti-corrosion coating materials (Chai et al. 2022; Cui et al. 2017; Huang et al. 2020, 2023; Rajabi et al. 2014). This section lists several optimization strategies for GCCs. By exploiting the impermeability and manipulating the electrical conductivity of graphene, the anti-corrosion performance of GCCs can be significantly improved.

3.1 Strategy of functionalization of graphene and its derivatives

It is well known that the dispersion of graphene in a polymer matrix can be significantly improved by graphene functionalization. Depending on the type of chemical bonding between graphene and other materials, functionalization can be classified as covalent and non-covalent functionalization. Covalent functionalization is the strong binding of small molecules, polymer chains or nanoparticles onto graphene (Liu et al. 2018a; Ma et al. 2020; Parhizkar et al. 2018; Wu et al. 2021a; Zhao et al. 2022; Zhang et al. 2022, 2023), while the non-covalent functionalization of graphene occurs through weaker interactions, such as hydrogen bonds, and π-π bonds and electrostatic interactions (Cui et al. 2018; Ding et al. 2018a; Liu et al. 2015; Qiu et al. 2018; Yuan et al. 2023; Zheng et al. 2021). Covalent functionalization is beneficial in maintaining the mechanical properties and chemical stability of graphene. Silane coupling agents are one of the most common chemical modifiers. After functionalization, the surface or edge of the graphene is grafted with a long polymer chain, which improves the compatibility of the graphene in the coating matrix. Parhizkar et al. used 3-(triethoxysilyl) propyl isocyanate (TEPI, IGO nano-fillers) and 3-aminopropyltriethoxysilane (APTES, AGO nano-fillers) for the covalent functionalization of GO, the resulting IGO and AGO were able to be stably dispersed in silane solutions. The experimental results show that the corrosion resistance and adhesion properties of the epoxy coating are significantly improved due to the better compatibility of IGO and AGO with the silane matrix and the formation of covalent bonds with the top epoxy coating (Parhizkar et al. 2018).

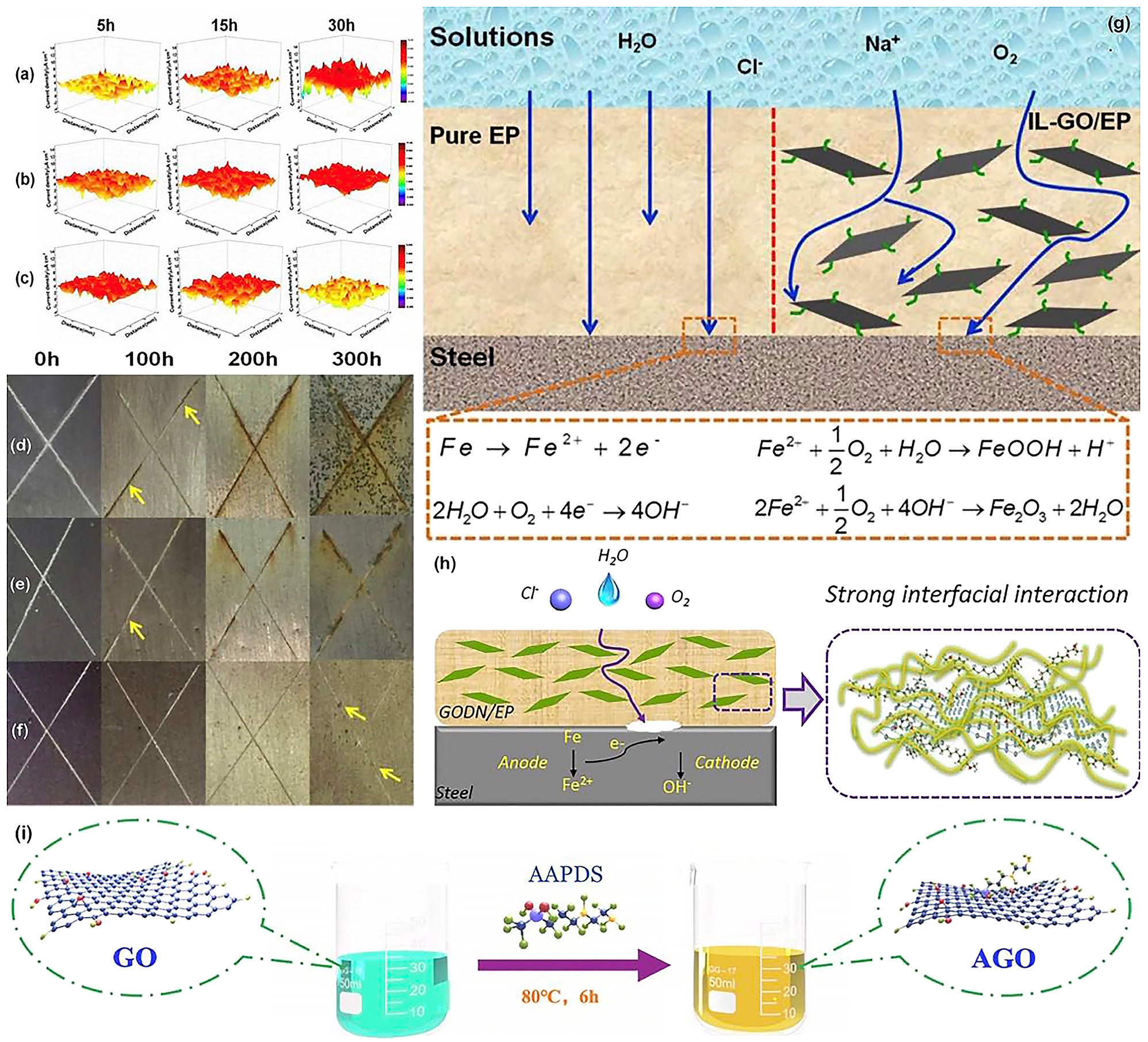

Liu et al. successfully prepared ionic liquid-graphene oxide (IL-GO) hybrid nanomaterials by covalently grafting imidazole ionic liquids onto the surface of graphene oxide nanosheets (Liu et al. 2018a). Scanning vibrating electrode technique (SVET) results show in the case of the IL-GO/epoxy composite coating a decreased trend in current density relative to the pure epoxy and rGO 0.5 % coating, exhibiting the lowest current density values after 30 h of immersion (Figure 16a–c). This effectively demonstrates that the IL-GO mixture performs its protective function by impeding the penetration of corrosive media and inhibiting anodic dissolution. The corrosion protection properties of the composite coating were further verified by salt spray testing, and Figure 16d–f shows digital photographs of the samples at various times. After 100 h of exposure, red rust stains appeared on the surface of both the pure epoxy and the rGO epoxy composite coating, with rust accumulating at the scratches and gradually spreading across the surface as the exposure time increased. However, the IL-GO composite coating showed no visible signs of corrosion even after 300 h of exposure, as the well-dispersed graphene nanosheets effectively hindered the penetration of the corrosive medium and, in addition, the ionic liquid prevented the oxidation of the steel in the scratches. The micro-pores and cracks that form during coating formation and applications are the channels through which the corrosive medium penetrates the coating and initiates the corrosion reaction of the metal. Figure 16g shows a schematic diagram of the protection mechanism of pure epoxy and IL-GO composite coating. The pure epoxy resin coating has an inferior barrier effect and corrosion products can reach the metal surface and initiate corrosion in a short period of time. As for the IL-GO hybrid epoxy composite coating, the well-dispersed graphene nanoflakes impede the straightforward penetration of corrosive media and the covalently grafted imidazole ionic liquid imparts corrosion inhibition to the hybrid material, allowing the composite coating to exhibit significant corrosion resistance. Besides, Wu et al. synthesized a novel bio-based cardanol epoxy–modified graphene oxide (GODN) nanomaterial through the rapid phase transfer process and applied it to epoxy coatings, then explored the anti-corrosion performance of the GODN/EP composite coating (Wu et al. 2021a). DN chains were successfully attached to the surface of GO without damaging the sp2 structure of graphene. In addition, DN also promoted the formation of chemical bonds between GO and EP resin and improved the interface interaction between GO and EP resin. EIS results showed that the addition of GODN had significantly enhanced the anti-corrosion performance of the coating. The schematic diagram of corrosion protection mechanism of the GODN/EP composite coating is shown in Figure 16h. Based on such covalent functionalization of graphene, Zhao et al. recently prepared an EP/GF/A-GO composite coating with a dual physical barrier by incorporating 3-(2-aminoethylamino) propyldimethoxymethylsilane–modified graphene oxide (A-GO) and glass fibre (GF) into an epoxy matrix. Figure 16i shows a schematic diagram of the preparation of the covalently modified A-GO. The modified GO has better compatibility with the epoxy resin, which enhances the crosslink density of the composite coating and reduces defects of coating. In addition, the amine terminal groups of AAPDS can react with the epoxy groups of the epoxy resin and these significantly enhance the barrier performance of the composite coating. The EIS results show that the EP/GF/A-GO composite coating has the highest impedance modulus of the different coatings. After 45 days of immersion, the value was still above 3.9 × 107 Ω cm2 (Zhao et al. 2022).

Covalent functionalization of GO for optimizing anti-corrosion properties. (a) SVET maps of the current density for steel electrodes coated with pure epoxy, (b) rGO0.5 % and (c) IL-GO0.5 % coatings immersed in 3.5 wt% NaCl solution. (d) Digital images of the salt spray tested steel substrates covered with pure epoxy, (e) rGO0.5 % and (f) IL-GO0.5 % coatings. (g) Illustration of protective mechanism for pure epoxy and IL-GO hybrids coatings (Liu et al. 2018a). Reprinted with permission from Royal Society of Chemistry. (h) Schematic diagram of corrosion protection mechanism of GODN/EP coatings in 3.5 wt% NaCl solution (Wu et al. 2021a). Reprinted with permission from Elsevier. (i) Schematic illustration for preparation of A-GO (Zhao et al. 2022). Reprinted with permission from Elsevier.

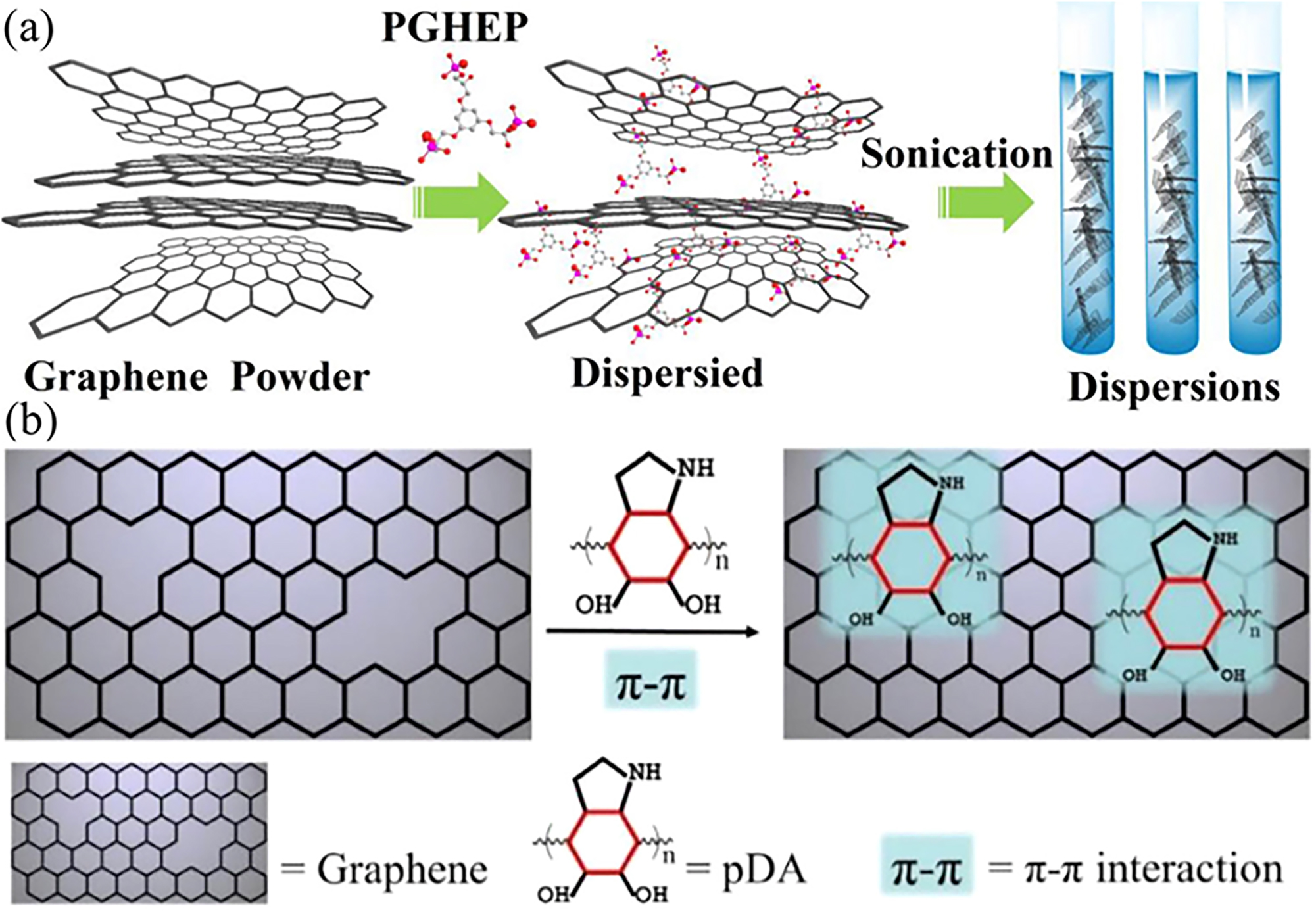

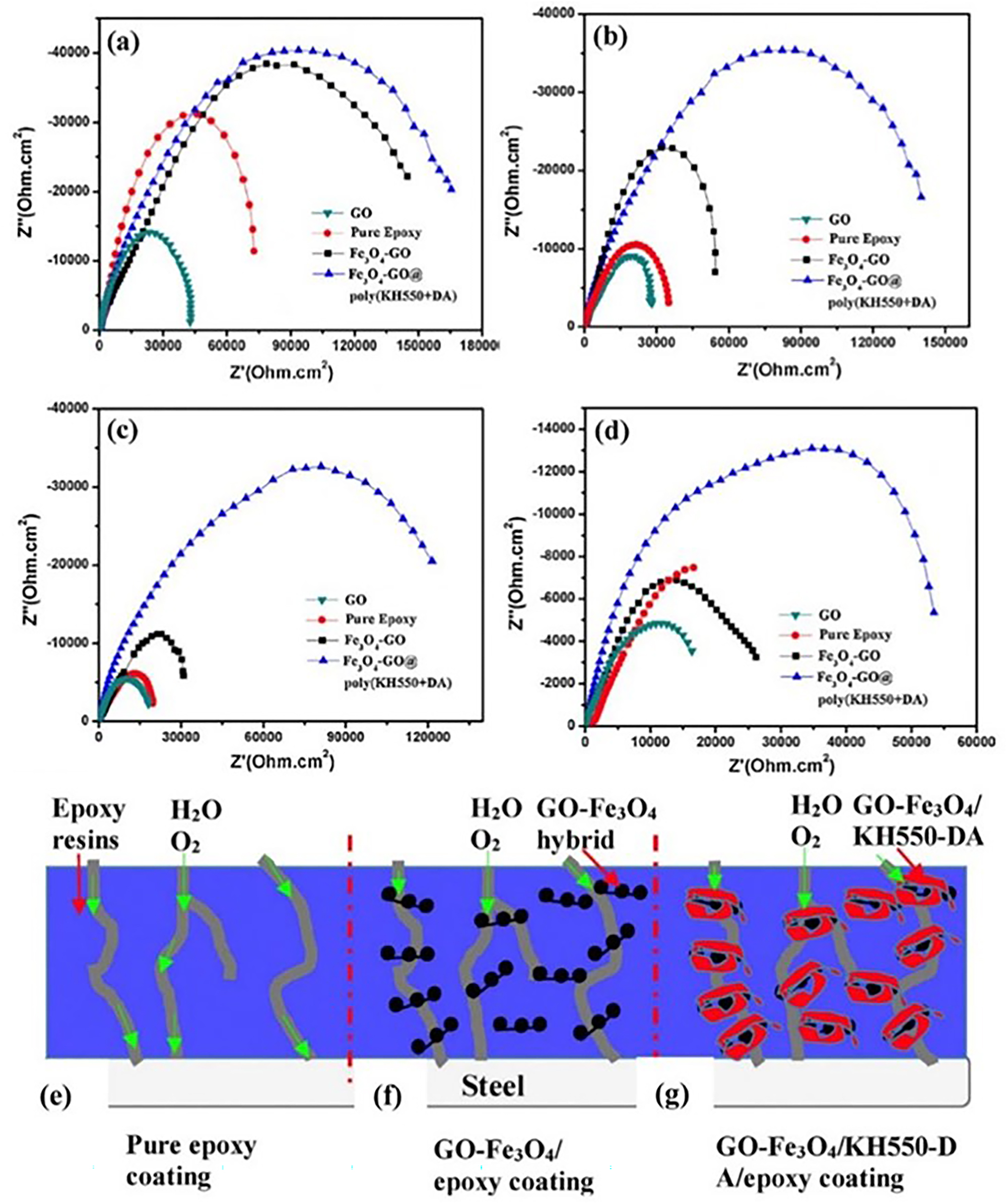

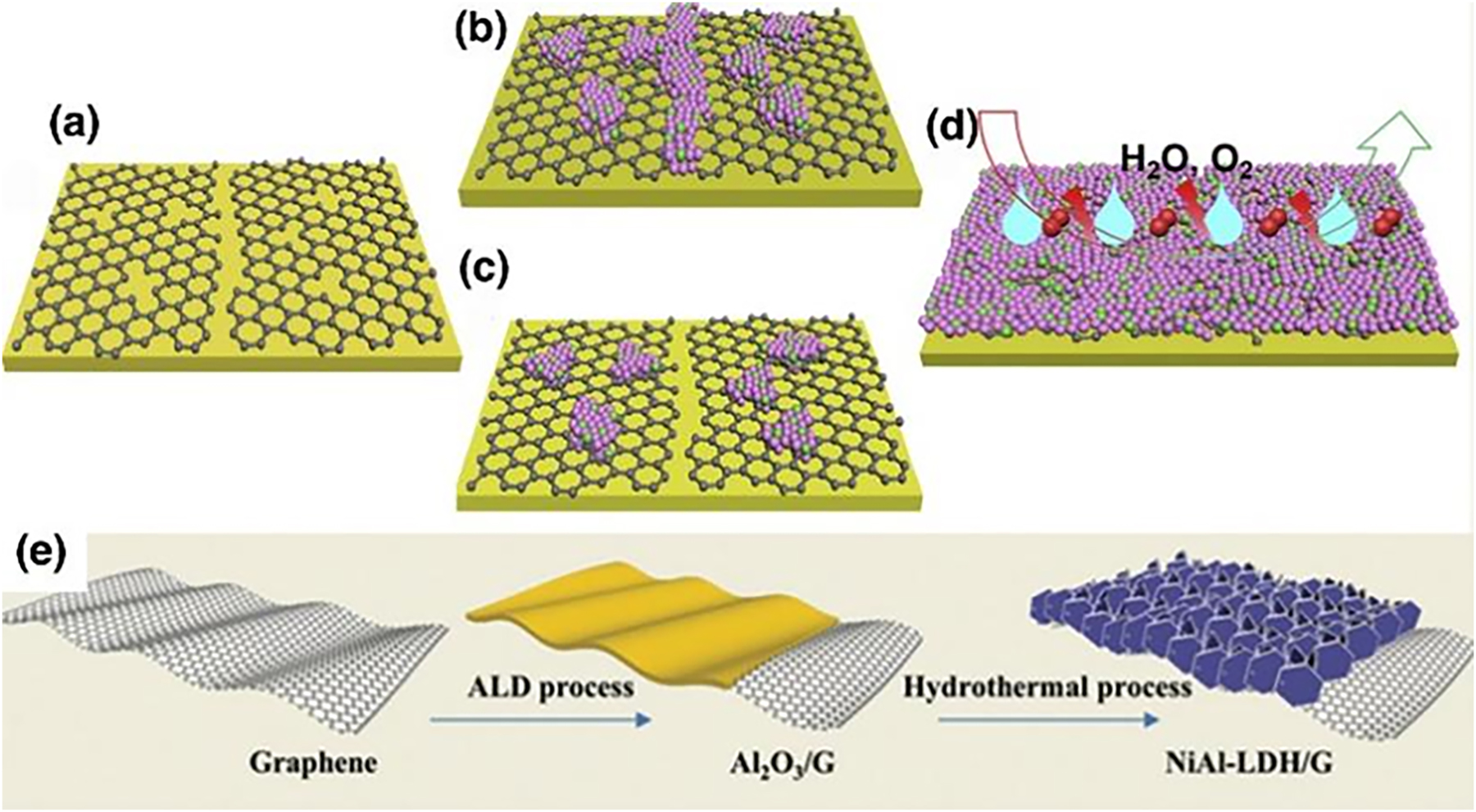

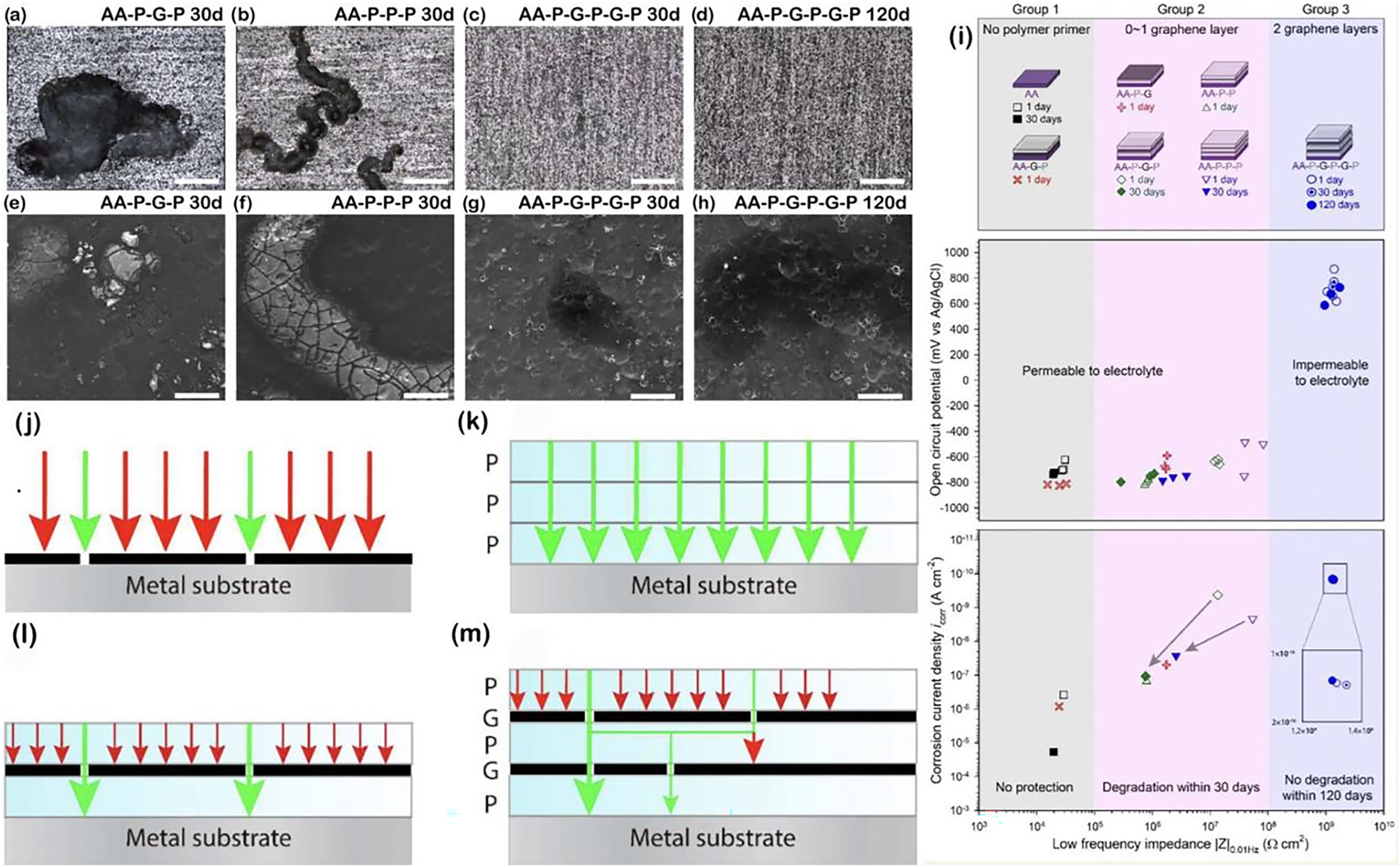

Non-covalent functionalization helps to maintain excellent electrical conductivity and ultra-high specific surface area of graphene (Imani et al. 2018). In addition, the non-covalent functionalization of graphene is easier to manipulate and does not require complex chemical reactions compared to covalent functionalization. For example, embedding non-covalent functionalized graphene flakes in aqueous epoxy resin (EP) coatings led to substantial improve of the corrosion resistance of EP coating (Liu et al. 2015). Yuan et al. prepared a unique bi-layer composite coating using a two-step high-speed spinning method, which consisting of primer thermoplastic polyurethane (TPU) layer and top phenylenediamine (PPD) non-covalent modified orientated graphene (Gr-PPD) incorporated epoxy resin layer. The orientated Gr-PPD nanosheets effectively extend the penetration pathway of the corrosive media. In addition, the interfacial compatibility between Gr-PPD and EP is enhanced by involvement of amino groups on surface of Gr in epoxy curing reaction, which reduces the free volume spaces in composites and thus lowering gas permeability. The experimental results showed that 0.5Gr-PPD-EP/TPU coating had the highest impedance value after 90 days of immersion in NaCl solution and the strongest toleration to continuous salt spray attack for 60 days, making it ideal for industrial applications (Yuan et al. 2023). Ding et al. synthesized a novel hydroxy epoxy phosphate monomer (PGHEP) as an effective dispersant for graphene, which greatly improved the compatibility of graphene in epoxy resins (Ding et al. 2018a). A schematic diagram of the dispersion process of PGHEP functionalized graphene in water is shown in Figure 17a. Raman spectroscopy, ultraviolet-visible spectroscopy (UV–vis) and X-ray photoelectron spectroscopy (XPS) studies confirmed the efficient π-π interaction between PGHEP and graphene sheets. The results of EIS and salt spray tests show that the composite coatings offer greater corrosion resistance, higher contact angles (thus are more hydrophobic) and lower water absorption compared to pure epoxy resin. This excellent corrosion protection is mainly attributed to the good dispersion of the functionalized graphene nanosheets in the coating matrix. In addition, Zheng et al. synthesized polydopamine (pDA)-graphene (pDA-GR) composites on Cu substrate, and found through experiments that pDA can heal the inherent defects of GR through π-π interaction, thus effectively improving the corrosion resistance of the coating (Zheng et al. 2021), as shown in Figure 17b.

Non-covalent functionalization of graphene for optimizing anti-corrosion properties. (a) The dispersion process of PGHEP functionalized graphene in water (Ding et al. 2018a). Reprinted with permission from Elsevier. (b) Schematic representation of pDA healing structure defects of GR via π-π interaction (Zheng et al. 2021). Reprinted with permission from Elsevier.