Abstract

In order to prepare high-performance foaming agent for field-cast foamed lightweight soil, the fiber compound foaming agent was prepared by the combination of anionic surfactant sodium dodecyl sulfate (SDS) and nonionic surfactant alkyl polyglucoside (APG), supplemented by hydrolyzed polyacryamide (HPAM) as the foam stabilizer. The effects of the mass ratio of surfactant and the content of foam stabilizer on the properties of fiber compound foaming agent were compared and analyzed by testing the surface tension, viscosity, foam volume, and foam half-life. Based on the analysis of foam volume and foam stability of foaming agent, the optimal mass ratio of surfactant and the optimal content of foam stabilizer were optimized. In addition, based on the optimized fiber compound foaming agent to prepare foamed lightweight soil, the influence of different foaming agent concentrations on the application performance of foamed lightweight soil was studied, and the appropriate concentration of fiber compound foaming agent solution was further optimized. Thus, the optimum reaction conditions for preparing SDS-APG compound foaming agent containing foam stabilizer HPAM were proposed as follows: mass ratio of SDS to APG was 2:1, concentration of HPAM was 3.75 wt‰, and concentration of foaming agent was 9.21 wt%.

1 Introduction

Foamed lightweight soil is a porous lightweight material obtained by mixing cement slurry with prefabricated foam [1,2]. It is often used as a lightweight thermal insulation material in the construction industry because of its high mobility and sound-absorbing insulation properties [3]. The development and application of foam light soil in the construction industry are more mature, and its application in the transportation field is still short. When foamed lightweight soil is used as roadbed filling under special geological conditions, it can reduce foundation settlement, improve subgrade stability, and speed up construction by taking advantage of its own characteristics such as lightweight, high mobility, and curing self-reliance [4,5,6]. It provides a lightweight treatment technology to solve the problems of soft soil foundation reinforcement, bridge head jump, subgrade differential settlement, high embankment stability, cold subgrade heat insulation, and other engineering problems [7,8,9,10,11].

However, in the practical application process, there are still many problems of foamed lightweight soil to be solved, such as low compressive strength, poor toughness, many cracks, and so on [12,13]. In particular, how to achieve high compressive strength of foamed concrete under low density conditions has become a technical problem. Through the research on the properties of foamed concrete by scholars and technicians in the past, it is found that the quality of raw materials and foaming agent, construction technology, etc., would all have an impact on it [14,15,16,17,18], among which the quality of foaming agent has the most significant impact. At present, there are many types of foaming agents in the domestic and international markets, but there are significant differences in performance. There are common shortcomings such as poor foaming ability, uneven foaming, and poor foam stability. There are few foaming agents that can be directly applied in engineering construction to prepare high-quality foamed lightweight soil, which limits the application of famed lightweight soil. Therefore, the research and development of high-quality foaming agent is particularly important for the preparation of high-quality foamed lightweight soil.

It is very important to select suitable surfactant for foaming agent. Surfactants mainly include anionic, cationic, nonionic, amphoteric, and polymer types [19,20]. Anionic surfactants generally have good permeability, wetting, emulsification, antistatic, lubricating properties, decontamination ability, etc. Cationic surfactants have the functions of emulsification, solubilization, dispersion, wetting, antibacterial, etc. Amphoteric surfactants are mainly used to prepare detergents, foaming agents, antistatic agents, and fungicides, which are anionic or cationic in different pH values, while nonionic surfactants have better water solubility. Polymer surfactants are not easy to foam, but it is very stable once foam is formed. In summary, anionic and amphoteric surfactants are more suitable for foaming components of foaming agents, while nonionic and polymer surfactants are more suitable for foaming stabilization components.

Sodium dodecyl sulfate (SDS) is widely used as an anionic surfactant because of its excellent foaming ability and low price, but the foam stability is poor when used as a foaming agent alone. Nonionic surfactants generally form hydrogen bonds between oxygen-containing groups and water molecules, so they have good water solubility and water retention ability, especially for alkyl polyglucoside (APG). It has many advantages such as good water solubility, delicate and rich foam, insensitivity to pH and salt, good foam stability, and non-toxicity, but its foaming ability is relatively poor. Hydrolyzed polyacryamide (HPAM) is an anionic polymer fiber with good water solubility, which can improve the viscosity and elasticity of the liquid foam film, and enhance the flow resistance between molecules in the liquid film, so as to effectively improve the stability of the foam.

Similar to other composite materials, the composite method can synthesize the advantages of various surfactants through screening, so as to produce high-quality foaming agents with foaming properties and foam stability that meet the expectations. When anion and nonionic surfactant compound form mixed micelles in solution, nonionic surfactant molecules “insert” between ionic surfactants, so that the original ionic surfactant’s “ionic head base” between the electrostatic repulsion is weakened, resulting in the reduction in the surface tension of the mixed solution, and the foam is easy to produce. At present, there is no research on anion-nonionic-water soluble polymer fiber composite foaming agent and related foamed concrete in domestic and foreign literature, and its composition and performance mechanism are not clear.

In order to solve the problem of poor foam stability of existing foaming agents, this study selects SDS with low price and high foaming ratio, and APG with fine foam, excellent foam stability, and green environmental protection to compound. Through the hydrophobic interaction between APG and SDS, the weakening of electrostatic repulsion between ionic groups by nonionic groups, and the excellent water retention and water carrying capacity of alkyl glucosides, supplemented with HPAM foam stabilization, the SDS–APG–HPAM composite foaming agent was prepared at relatively low price. In addition, by exploring the effect of blowing agent concentration on the application performance of foamed lightweight soil, the SDS–APG–HPAM composite blowing agent system was further optimized to expand its application level in foamed lightweight soil.

2 Experimental scheme

2.1 Tested raw materials and equipment

2.1.1 Raw materials of compound foaming agent

The characteristics and specifications of the compound foaming agent raw materials selected in this study are shown in Table 1.

Raw material characteristics and specifications of the compound foaming agent

| Raw material name | Purity specification | Advantages | Disadvantages |

|---|---|---|---|

| SDS (anionic surfactant) | Analytically pure | Strong foaming ability, cheap price | Weak foam stability |

| APG (nonionic surfactant) | 50% | Excellent water solubility and biodegradation | Poor foamability |

| HPAM (fiber foam stabilizer) | Analytically pure | Good water solubility and foam stability | — |

2.1.2 Raw materials of foamed lightweight soil

In addition to the abovementioned compound foaming agent, the raw materials required for the preparation of foamed lightweight soil also include cement, fly ash, and water, and the main parameters are shown in Table 2.

Main parameters of foamed lightweight soil raw materials

| Raw material name | Parameter index | Measured value |

|---|---|---|

| Cement | Cement type | Ordinary Portland cement |

| Strength grade | P.O 42.5 | |

| Density (kg/m³) | 3,154 | |

| Initial setting time (min) | 160 | |

| Final setting time (min) | 220 | |

| Fly ash | Category | F Class Ⅱ |

| Density (kg/m³) | 2,305 | |

| Water content (%) | 0.6 | |

| Fineness (%) | 17.8 |

2.1.3 Test equipment

The specifications and manufacturers of the main test equipment used in this study are shown in Table 3.

Specification and manufacturer of the main test equipment

| Name of equipment | Specification | Manufacturer |

|---|---|---|

| Electronic balance | 10 kg/0.01 g | Sartorius Scientific Instruments (Beijing) Co., Ltd |

| Heat collection type magnetic agitator | DF-101S | Gongyi Yuhua Instrument Co., Ltd |

| Electric air blowing drying box | DHG-9123A | Shanghai Yiheng Technology Instrument Co., Ltd |

| Conductivity meter | DDSJ-318 | INESA Scientific Instrument Co., Ltd. |

| Surface tension meter | DCAT-21 | Beijing Odlino Instrument Co., Ltd |

| Intelligent Brookfield viscometer | SNB-AI | Shanghai Ni Run Intelligent Technology Co., Ltd |

| High speed mixer | S-250H | Shanghai Shensheng Technology Co., Ltd |

| Foaming machine | HH-30B | Hebei Huahan Machinery Manufacturing Co., Ltd |

| Pavement material strength tester | LD127-Ⅱ | Shanghai Leiyunshiyan Instrument Manufacturing Co., Ltd |

2.2 Experimental procedure

2.2.1 Determination scheme of SDS-APG ratio

In order to investigate the impact of the ratio of SDS-APG on the foaming characteristics of the compound foaming agent and determine the appropriate ratio of SDS-APG, SDS-APG were added into deionized water according to the mass ratio of 1:0, 2:1, 1:1, 1:2, and 0:1, and were heated in a 55°C water bath or ultrasonic until completely dissolved. The aqueous solution with mass fraction of 6.69 wt% was prepared, and the surface tension, viscosity, foam volume, and half-life of the solution were measured.

2.2.2 Determination scheme of foam stabilizer content

In order to investigate the effect of foam stabilizer content on the foaming properties of compound foaming agent, on the basis of determining the appropriate ratio of SDS-APG in the compound foaming agent mentioned above, different qualities of HPAM were weighed as foam stabilizer and added into the optimized SDS-APG compound system to prepare the SDS–APG–HPAM compound foaming agent solution, and determined the corresponding performance indexes to optimize the foam stabilizer content.

2.2.3 Determination scheme of foaming agent concentration

In order to investigate the effects of foaming agent concentration on the foaming performance of compound foaming agents, based on the previous optimization of foaming agents, SDS-APG with the same mass ratio and HPAM with a different dosage were added into deionized water, respectively, and then heated in a water bath at 55°C or ultrasonic until completely dissolved. Thus, aqueous solutions with mass fractions of 5.64, 6.69, 7.46, 8.22, 9.21, and 12.95 wt% were prepared. The mass ratio of SDS to APG was 2:1, and the content of HPAM was 3.16, 3.75, 4.18, 4.60, 5.16, and 7.25 wt‰, respectively.

On the other hand, in order to investigate the effects of foaming agent concentration on the application performance of foamed lightweight soil, the concentration of SDS–APG–HPAM compound foaming system is adjusted according to the above method, and the foam density of the compound foaming system with different concentrations diluted 40 times is measured. Then, according to the calculation formula of mixture ratio design of foamed lightweight soil in “Technical Specification for Design and Construction of Cast-in-situ Lightweight foamed concrete Subgrade” (TJG F10 01-2011), the raw material consumption of preparing foamed lightweight soil is obtained.

To sum up, the preparation and optimization process of the above compound foaming agent is shown in Figure 1.

Preparation process of compound foaming agent.

2.2.4 Preparation of foamed lightweight soil

In this study, prefabricated foam mixing method is adopted to prepare foamed lightweight soil. The detailed steps are as below.

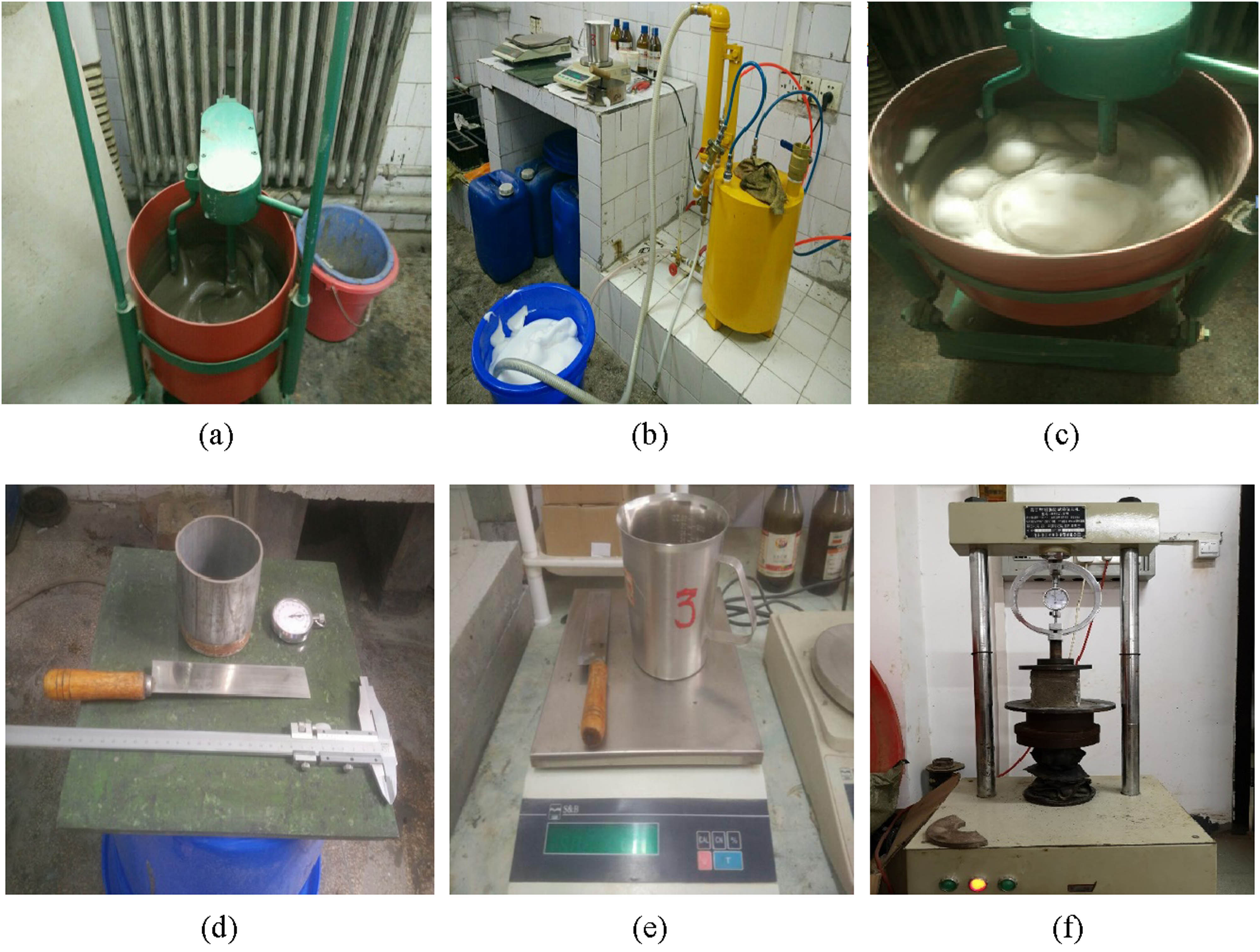

According to the pre-designed mix ratio scheme, a certain amount of water, fly ash, and cement are weighed by the electronic balance, and then added to the mixer for the first mixing (Figure 2(a)).

According to the dilution rate of 40 times, 10 L of water and 250 mL of the abovementioned foaming agent are respectively measured and added to the foaming machine for dilution. The foaming solution is introduced into the air under the action of pressure to produce a large number of stable foams (Figure 2(b)).

A certain amount of foam is immediately weighed through the electronic balance, and then the foam is poured into a mixer and mixed with the cement slurry for a second stirring until the mixture is stable and even (Figure 2(c)).

After mixing the mixture evenly, the flow value is first measured according to the relevant standard [21] (Figure 2(d)), and then weighed and its wet density is calculated (Figure 2(e)). Then, the mixture is poured evenly into the test mold of 100 mm × 100 mm × 100 mm, and manually vibrated to make it compact. After 7 days of natural curing, the mold is removed and the compressive strength of the foamed lightweight soil is measured (Figure 2(f)).

Preparation process and basic properties tests of foamed lightweight soil. (a) Cement slurry mixing. (b) Foam formation. (c) Stir in foam. (d) Flow value test. (e) Wet density test. (f) Compressive strength test.

The preparation process and basic performance test of foamed lightweight soil at each stage are shown in Figure 2.

3 Test results and discussion

3.1 The impact of SDS-APG ratio on foaming properties of compound foaming agent

Figure 3(a) and (b) are the test results of surface tension and viscosity of SDS-APG compound foaming agent solution at varying surfactant ratios, respectively.

Test results of surface tension (a) and viscosity (b) of SDS-APG compound foaming system at varying surfactant ratios.

As shown in Figure 3(a), the surface tension of the compound foaming system developed in this work changes with the ratio of SDS-APG mass, but the overall change is little and the range of change is less than 1 mN/m. When the ratio of SDS-APG mass is 2:1, the surface tension of the compound foaming agent system is the lowest, which is smaller than that of the two surfactants. This indicates that SDS-APG have some interaction in this compound foaming system. The reason may be that the insertion of APG molecules into SDS decreases the electrostatic repulsion between the head groups of the hydrophilic ions of SDS molecules, thus improving the surface activity of the system and reducing the surface tension. As shown in Figure 3(b), the viscosity does not change significantly with the mass ratio of SDS-APG. Compared with SDS, the viscosity of APG is two orders of magnitude higher, which may be related to the easy formation of hydrogen bonds between glycoside APG molecules. However, the viscosity of the compound foaming agent is less than the minimum value of the viscosity of SDS and APG, this also indicates that SDS-APG have some interaction in the compound system.

The foaming ability and foam stability of foaming agents are expressed by foam volume and the half-life of the foam. To further reveal the impact of the SDS-APG ratio on the properties of the compound foaming agent, the foam volume of the 40-fold dilute solution of the agent and the half-life of the prepared foam were tested. The results can be seen in Table 4.

Test results of foam volume and half-life of SDS-APG compound foaming system under different proportions

| Ratio of SDS-APG | Foam volume (mL) | Half-time (min) |

|---|---|---|

| ∞ | 960 ± 10 | 7.34 ± 0.12 |

| 0 | Difficult to form foam | — |

| 2:1 | 948 ± 48 | 10.34 ± 0.24 |

| 1:1 | 929 ± 24 | 9.52 ± 0.21 |

| 1:2 | 920 ± 15 | 9.03 ± 0.33 |

Under the test conditions, pure APG system solution could not fully foam into dense foam, almost liquid with tiny foam. As can be seen from Table 4, the foam volume of SDS-APG compound system decreases slightly with the increase in APG content, which may be related to the increase in solution viscosity and viscosity to be overcome by stirring solution. This indicates that APG has a certain ability to stabilize bubbles, which may be related to the easy formation of hydrogen bond between APG and water, as well as the improvement of water retention capacity of the foam film. When the ratio of SDS-APG mass is 2:1, the maximum half-life is 10 min. The results show that the compound foaming agent had better foam stability when SDS-APG are combined at the mass ratio of 2:1. Therefore, the mass ratio of SDS-APG in compound foaming system should be 2:1.

3.2 Impact of foam stabilizer content on foaming characteristics of compound foaming agent

Figure 4(a) and (b) shows the surface tension and viscosity test results of the compound foaming system solution with different dosages of HPAM when SDS-APG are combined at the mass ratio of 2:1. As depicted in Figure 4, the surface tension of foaming system solution changed slightly with different contents of HPAM. However, the viscosity of the foaming system solution enhances significantly with the increase in HPAM content, which may be due to the intertwine of the macromolecular chains of the water-soluble polymer HPAM, resulting in the increase in molecular motion resistance and the enhancement of the interaction force between molecules.

Test results of surface tension (a) and viscosity (b) of SDS–APG–HPAM compound foaming system with different contents of HPAM.

Figure 5(a) and (b), respectively, show the foam volume and drainage half-life of SDS–APG–HPAM compound foaming system solution with different contents of HPAM diluted 40 times when SDS and APG were combined at the mass ratio of 2:1. As can be seen from Figure 5(b), the drainage half-life enhances with the increase in HPAM content; however the increase in speed reaches a turning point and the increase rate decreases significantly when the HPAM content is 3.75 wt‰ of foaming agent concentration. This phenomenon may be attributed to the improved elasticity of the foam film when the viscosity of the liquid foam film is excessively high, which in turn leads to the reduced susceptibility of the larger bubbles to rupture, thereby leading to a decline in the foam uniformity. According to Figure 5(a), it can be observed that the foaming volume of the compound foam system exhibits a trend of initially increasing and then decreasing with an increase in the addition of HPAM. Comparing the results of viscosity and foam stability, it can be inferred that with an increase in the addition of HPAM, the viscosity of the system increases and the foam stability improves. but the mechanical resistance required to produce foam is greater. In short, as bubbles burst more slowly, bubbles are created more slowly. When the content of HPAM starts to increase, the foam production rate decreased slightly and the foam stability increased significantly, indicating that the appropriate content of HPAM was helpful to improve the foaming ability of the foaming agent. When the content of HPAM continues to increase, the increase rate of foam stability decreases, and the production rate decreases, resulting in the decrease of foam volume, and the inflection point of the change in foam volume is the best content of HPAM. Therefore, the optimal content of HPAM in SDS–APG–HPAM compound foaming system is 3.75 wt‰.

Test results of foam volume (a) and half-life (b) of SDS–APG–HPAM compound foaming system solution with different contents of HPAM.

3.3 Impact of foaming agent concentration on foaming properties and application performance of foamed lightweight soil

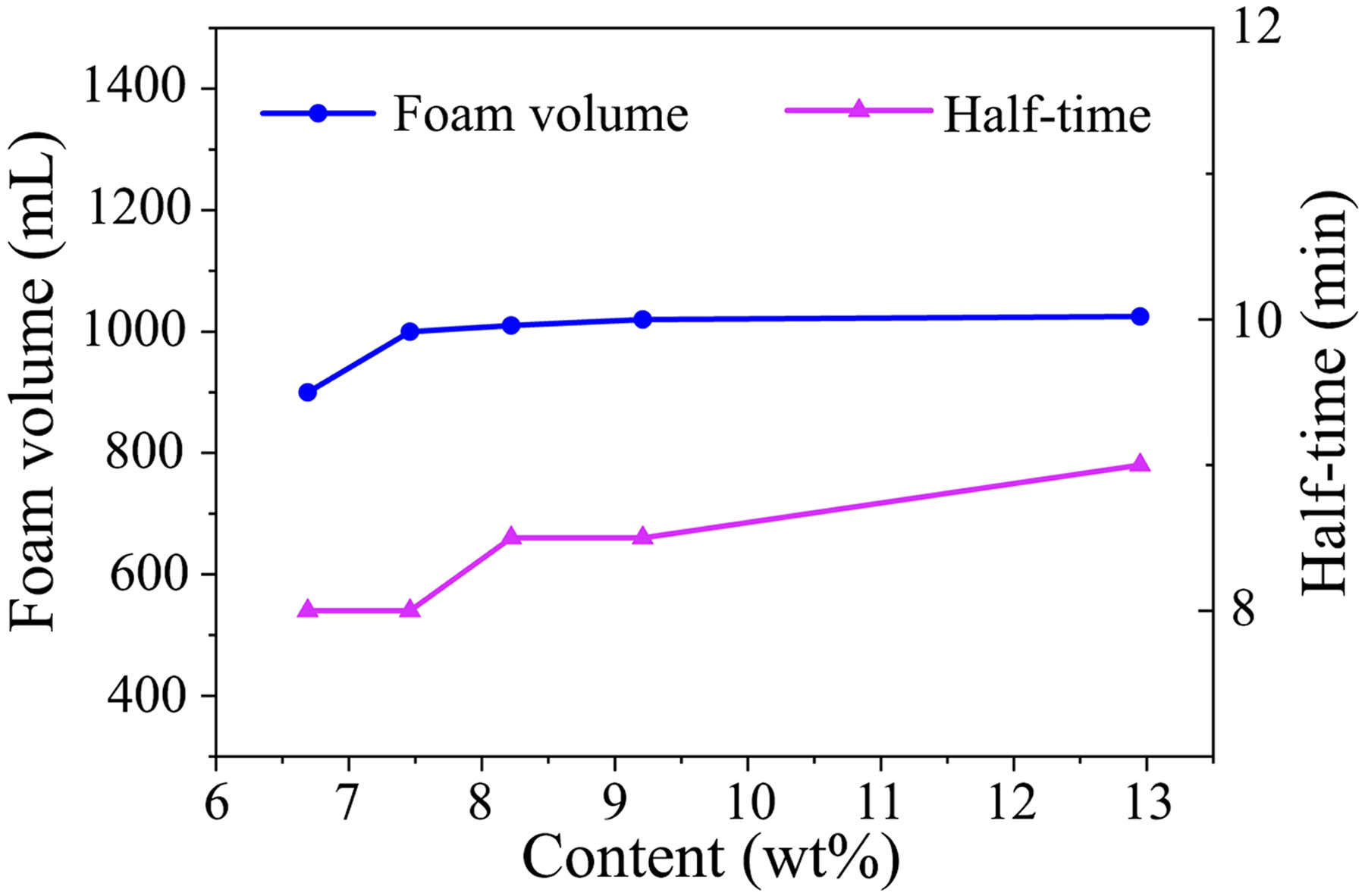

Figures 6 and 7 are the test results of surface tension, viscosity, foaming volume, and half-life of SDS–APG–HPAM foaming system solutions with different concentrations.

Test results of surface tension (a) and viscosity (b) of SDS–APG–HPAM compound foaming system with different concentrations.

Test results of foam volume and half-time of SDS–APG–HPAM compound foaming system with different concentrations.

As shown in Figure 6, with the increase in the concentration of foaming system, the surface tension of foaming agent solution slightly decreases; however, its viscosity gradually increases. As the concentration of HPAM is proportional to foaming agent concentration in the preparation process of complex foaming agent in this study, the increase in viscosity of the system cannot be simply attributed to the increase in foaming agent concentration. As can be seen from Figure 7, with the increase in the concentration of the foaming system, the foaming volume of the foaming agent solution showed a trend of first increasing and then was basically unchanged, but the half-life of the drained solution showed a trend of increasing. By comparing the viscosity data, it can be inferred that as the viscosity increases, the stirring resistance increases, and the foaming volume of the prepared foam decreases. However, the liquid fluidity in the foam film decreases and the foam stability improves due to the increase in flow resistance.

Table 5 shows the calculation results of raw material consumption for the preparation of foamed lightweight soil by SDS–APG–HPAM foaming system with different concentrations. As shown in Table 5, when the concentration of the compound foaming agent mixed with fiber foam stabilizer changes from 5.64 to 9.21 wt%, the compound foaming agent diluted 40 times can not only produce the foam required by the appearance of the compound, but also the foam density is almost within the standard range (30–50 g/L).

Amount of raw materials for preparation of foamed lightweight soil by SDS–APG–HPAM foaming system with different concentrations

| No. | Sample | Foam density (g/L) | Water–solid ratio | Mass of raw materials (g) | |||

|---|---|---|---|---|---|---|---|

| Cement | Fly ash | Water | Foam | ||||

| 1 | SAH-3.16-5.64 | 28.28 | 1:1.8 | 1,570 | 673 | 1,246 | 111 |

| 2 | SAH-3.75-6.69 | 30.02 | 1:1.9 | 1,597 | 684 | 1,200 | 119 |

| 3 | SAH-4.18-7.46 | 45.19 | 1:1.8 | 1,508 | 646 | 1,267 | 178 |

| 4 | SAH-4.60-8.22 | 39.53 | 1:1.55 | 1,467 | 629 | 1,352 | 153 |

| 1:1.8 | 1,550 | 664 | 1,230 | 156 | |||

| 1:1.6 | 1,484 | 636 | 1,325 | 154 | |||

| 5 | SAH-5.16-9.21 | 49.12 | 1:1.7 | 1,507 | 646 | 1,266 | 181 |

According to the amount of raw materials in Table 5, engineering indexes such as flow value, wet density, and compressive strength of foamed lightweight soil prepared by compound foaming system solutions of different concentrations were measured. The results are shown in Table 6. From Table 6, it can be concluded that the flow value, wet density, and compressive strength of foamed lightweight soil are closer to the standard [21] range (16−19 cm, 0.55−0.65 g/cm3, ≥0.3 MPa) with the increase in the concentration of compound foaming agent solution. When the concentration of the compound foaming agent solution is 9.21 wt%, the flow value and wet density of the foamed lightweight soil are 16.5 cm and 0.55 g/cm3, and the 7 days compressive strength is 0.91 MPa, which meet the engineering requirements of the foamed lightweight soil, indicating that the foamed lightweight soil prepared at this concentration has relatively good application performance.

Performance indexes of foamed lightweight soil prepared by SDS–APG–HPAM foaming system with different concentrations

| No. | Sample | Water–solid ratio | Flow value (cm) | Wet density (g/cm³) | 7 days compressive strength (MPa) |

|---|---|---|---|---|---|

| 1 | SAH-3.16-5.64 | 1:1.8 | 19.32 | 0.98 | 2.13 |

| 2 | SAH-3.75-6.69 | 1:1.9 | 16.90 | 0.93 | 1.74 |

| 3 | SAH-4.18-7.46 | 1:1.8 | 19.30 | 0.74 | 1.62 |

| 4 | SAH-4.60-8.22 | 1:1.55 | 21.00 | 0.77 | 1.35 |

| 1:1.8 | 15.80 | 0.73 | 1.25 | ||

| 1:1.6 | 17.78 | 0.66 | 1.05 | ||

| 5 | SAH-5.16-9.21 | 1:1.7 | 16.50 | 0.55 | 0.91 |

In summary, combined with the surface tension, viscosity, foam volume, and half-life test results of SDS–APG–HPAM compound foaming system, as well as the flow value, wet density, and 7 days compressive strength test results of prepared foamed lightweight soil, it can be concluded that the foaming system has excellent performance when the solution concentration of SDS–APG–HPAM compound foaming system is 9.21 wt%, which can meet the requirements of foamed lightweight soil engineering.

4 Conclusion

In this study, fiber compound foaming agent with HPAM as foam stabilizer is prepared by SDS-APG. Through a range of performance test and analysis, the effects of different surfactant ratio, foam stabilizer content, and foaming agent density on fiber compound foaming agent are studied. At the same time, the fiber compound foaming agent system is further optimized by combining the performance test and requirements of foamed lightweight soil. The following conclusions are drawn:

(1) The mass ratio of SDS-APG almost has no impact on the surface tension of foaming agent solution, the increase in APG will decrease the viscosity of foaming agent solution, foaming volume, and foam half-life. When the mass ratio of SDS-APG is 2:1, the half-life of the foam is the longest and its foam stability is better.

(2) For fiber-based compound foaming agents, there is a rational critical value for the dosage of stabilizing agents. With the increase in HPAM content, the surface tension of fiber foaming agent solution did not change much, but the solution viscosity and foam half-life showed a trend of increasing, while the foaming volume showed a trend of first increasing and then decreasing. The inflection point of foam volume change is the optimal content of HPAM. Therefore, the content of HPAM in the fiber compound foaming system developed in this work should be 3.75 wt‰.

(3) The concentration of foaming agent has a notable impact on the foaming properties of fiber compound foaming agent and the application properties of foamed lightweight soil. For SDS–APG–HPAM compound foaming system, the surface tension of solution decreases slightly with the increase in foaming agent concentration, while the solution viscosity and foam half-life increase gradually, but the foaming volume increased slightly at first and then almost had no obvious change. When the density of foaming agent reaches 9.21 wt%, the flow value, wet density, and 7 days compressive strength of foamed lightweight soil are 16.5 cm, 0.55 g/cm3, and 0.91 MPa, which all meet the engineering requirements and further verifies the excellent performance of the prepared SDS–APG–HPAM compound foaming agent.

(4) Based on the foaming capacity and foam stability analysis, the optimum reaction conditions for preparation of SDS–APG–HPAM compound foaming agent are as follows: the mass ratio of SDS-APG is 2:1, the concentration of HPAM and foaming agent is 3.75 and 9.21 wt‰, respectively. In addition, compared with the foamed lightweight soil of the same density grade as the Chinese standard, the foamed lightweight soil prepared by the fiber compound foaming agent developed in this work has exceptional application performance. Its wet density is within the range of 0.55–0.65 g/cm3, and its 7 days compressive strength is within the range of 0.6–0.9 MPa, both of which meet the main technical indexes required by the project.

Acknowledgements

We would like to thank Shaanxi Provincial Science and Technology Association for providing research funding support.

-

Funding information: Young Talent Fund of Association for Science and Technology in Shaanxi, China (No. CLGC202206), and National Key Research and Development Program of China (No. 2016YFC0802203).

-

Author contributions: Conceptualization: Youqiang Qiu; methodology: Yang Liu, Liujun Zhang, and Yashao Chen; investigation: Yijun Wang and Chenyang Li; data curation: Yijun Wang and Chenyang Li; formal analysis: Youqiang Qiu, Yijun Wang, and Chenyang Li; writing – original draft preparation: Youqiang Qiu, Tong Wu, and Chaoxiang Wang; writing – review and editing: Yang Liu, Liujun Zhang, and Yashao Chen; visualization: Tong Wu; and funding acquisition: Youqiang Qiu.

-

Conflict of interest: The authors state no conflict of interest.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Nambiar E, Ramamurthy K. Influence of filler type on the properties of foam concrete. Cement Concrete Comp. 2006;28:475–80.10.1016/j.cemconcomp.2005.12.001Search in Google Scholar

[2] Ramamurthy K, Nambiar E, Ranjani G. A classification of studies on properties of foam concrete. Cement Concrete Comp. 2009;31:388–96.10.1016/j.cemconcomp.2009.04.006Search in Google Scholar

[3] Wu H, Zhang H, Zhang G, Liu J, Liu Z, Du F. Study on preparation and performance of advanced aerogel foamed concrete with ultra-light aerogel. Constr Build Mater. 2023;366:130166.10.1016/j.conbuildmat.2022.130166Search in Google Scholar

[4] Wu J, Lv C, Pi R, Zhang H, Bi Y, Song X, et al. The stability and durability of silt-based foamed concrete: A new type of road engineering material. Constr Build Mater. 2021;304:124674.10.1016/j.conbuildmat.2021.124674Search in Google Scholar

[5] Guan L, Chen Y, Ye W, Wu D, Deng Y. Foamed concrete utilizing excavated soil and fly ash for urban underground space backfilling: physical properties, mechanical properties, and microstructure. Tunn Undergr Sp Tech. 2023;134:104995.10.1016/j.tust.2023.104995Search in Google Scholar

[6] Samson G, Phelipot-Mardelé A, Lanos C. A review of thermomechanical properties of lightweight concrete. Mag Concrete Res. 2016;69:201–16.10.1680/jmacr.16.00324Search in Google Scholar

[7] Que Y, Zhang H, Zhu T, Leung A, Lu D, Jiang Z. Amending foamed lightweight soil with tailings sand for embankment applications: Physical properties, durability, and microstructure. Constr Build Mater. 2022;350:128912.10.1016/j.conbuildmat.2022.128912Search in Google Scholar

[8] Shi X, Huang J, Su Q. Experimental and numerical analyses of lightweight foamed concrete as filler for widening embankment. Constr Build Mater. 2020;250:128897.10.1016/j.conbuildmat.2020.118897Search in Google Scholar

[9] Kim T, Kim T, Kang G. Performance evaluation of road embankment constructed using lightweight soils on an unimproved soft soil layer. Eng Geol. 2013;160:34–43.10.1016/j.enggeo.2013.03.024Search in Google Scholar

[10] Zhou Z, Ali A, Zhu C, Mehta Y, Lein W, DeCarlo C, et al. Evaluating the potential of using foamed concrete as the insulation layer for pavements in cold regions. Constr Build Mater. 2022;341:127903.10.1016/j.conbuildmat.2022.127903Search in Google Scholar

[11] Zhang H, Qi X, Wan L, Zuo Z, Ge Z, Wu J, et al. Properties of silt-based foamed concrete: A type of material for use in backfill behind an abutment. Constr Build Mater. 2020;261:119966.10.1016/j.conbuildmat.2020.119966Search in Google Scholar

[12] Tran N, Nguyen T, Ngo T, Le P, Le T. Strategic progress in foam stabilisation towards high-performance foam concrete for building sustainability: A state-of-the-art review. J Clean Prod. 2022;375:133939.10.1016/j.jclepro.2022.133939Search in Google Scholar

[13] Yang S, Yao X, Li J, Wang X, Zhang C, Wu S, et al. Preparation and properties of ready-to-use low-density foamed concrete derived from industrial solid wastes. Constr Build Mater. 2021;287:122946.10.1016/j.conbuildmat.2021.122946Search in Google Scholar

[14] Selija K, Gandhi I. Comprehensive investigation into the effect of the newly developed natural foaming agents and water to solids ratio on foam concrete behaviour. J Build Eng. 2022;58:105042.10.1016/j.jobe.2022.105042Search in Google Scholar

[15] Hou L, Li J, Lu Z, Niu Y. Influence of foaming agent on cement and foam concrete. Constr Build Mater. 2021;280:122399.10.1016/j.conbuildmat.2021.122399Search in Google Scholar

[16] Zhang S, Qi X, Guo S, Zhang L, Ren J. A systematic research on foamed concrete: the effects of foam content, fly ash, slag, silica fume and water-to-binder ratio. Constr Build Mater. 2022;339:127683.10.1016/j.conbuildmat.2022.127683Search in Google Scholar

[17] Siva M, Ramamurthy K, Dhamodharan R. Development of a green foaming agent and its performance evaluation. Cement Concrete Comp. 2017;80:245–57.10.1016/j.cemconcomp.2017.03.012Search in Google Scholar

[18] Stevenson P, Li X. Foam fractionation: Principles and process design. Florida, USA: CRC Press; 2014.10.1201/b16483Search in Google Scholar

[19] Cederlund H, Börjesson E. Hot foam for weed control—Do alkyl polyglucoside surfactants used as foaming agents affect the mobility of organic contaminants in soil? J Hazard Mater. 2016;314:312–7.10.1016/j.jhazmat.2016.04.061Search in Google Scholar PubMed

[20] Micheau C, Bauduin P, Diat O, Faure S. Specific salt and pH effects on foam film of a pH sensitive surfactant. Langmuir. 2013;29:8472–81.10.1021/la400879tSearch in Google Scholar PubMed

[21] TJG F10 01–2011, Technical Specification for Design and Construction of Cast-in-situ Lightweight foamed concrete Subgrade (in Chinese), Tianjin Municipal Road Administration: Tianjin, China; 2011.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Vibrational wave scattering in disordered ultra-thin film with integrated nanostructures

- Optimization of lead-free CsSnI3-based perovskite solar cell structure

- Determination of the velocity of seismic waves for the location of seismic station of Zatriq, Kosovo

- Seismic hazard analysis by neo-deterministic seismic hazard analysis approach (NDSHA) for Kosovo

- Ultimate strength of hyper-ellipse flanged-perforated plates under uniaxial compression loading

- Development of an adaptive coaxial concrete rheometer and rheological characterisation of fresh concrete

- Synthesis and characterization of a new complex based on antibiotic: Zirconium complex

- Exergy–energy analysis for a feasibility trigeneration system at Kocaeli University Umuttepe Campus

- Transient particle tracking microrheology of plasma coagulation via the intrinsic pathway

- Analysis of complex fluid discharge from consumer dispensing bottles using rheology and flow visualization

- A method of safety monitoring and measurement of overall frost heaving pressure of tunnel in seasonal frozen area

- Application of isolation technology in shallow super-large comprehensive pipe galleries in seismically vulnerable areas with weak soils

- Application of the ramp test from a closed cavity rheometer to obtain the steady-state shear viscosity η(γ̇)

- Research on large deformation control technology of highly weathered carbonaceous slate tunnel

- Tailoring a symmetry for material properties of tellurite glasses through tungsten(vi) oxide addition: Mechanical properties and gamma-ray transmissions properties

- An experimental investigation into the radiation-shielding performance of newly developed polyester containing recycled waste marble and bismuth oxide

- A study on the fractal and permeability characteristics of coal-based porous graphite for filtration and impregnation

- Creep behavior of layered salt rock under triaxial loading and unloading cycles

- Research and optimization of tunnel construction scheme for super-large span high-speed railway tunnel in poor tuff strata

- Elongational flow mixing: A novel innovative approach to elaborate high-performance SBR-based elastomer compounds

- The ductility performance of concrete using glass fiber mesh in beam specimens

- Thickened fluids classification based on the rheological and tribological characteristics

- Strength characteristics and damage constitutive model of sandstone under hydro-mechanical coupling

- Experimental study of uniaxial compressive mechanical properties of rough jointed rock masses based on 3D printing

- Study on stress distribution and extrusion load threshold of compressed filled rock joints

- Special Issue on Rheological Behavior and Engineering Stability of Rock Mass - Part II

- Seismic response and damage mechanism of tunnel lining in sensitive environment of soft rock stratum

- Correlation analysis of physical and mechanical parameters of inland fluvial-lacustrine soft soil based on different survey techniques

- An effective method for real-time estimation of slope stability with numerical back analysis based on particle swarm optimization

- An efficient method for computing slope reliability calculation based on rigorous limit equilibrium

- Mechanical behavior of a new similar material for weathered limestone in karst area: An experimental investigation

- Semi-analytical method for solving stresses in slope under general loading conditions

- Study on the risk of seepage field of Qiantang River underground space excavated in water-rich rheological rock area

- Numerical analysis of the impact of excavation for undercrossing Yellow River tunnel on adjacent bridge foundations

- Deformation rules of deep foundation pit of a subway station in Lanzhou collapsible loess stratum

- Development of fiber compound foaming agent and experimental study on application performance of foamed lightweight soil

- Monitoring and numerical simulation analysis of a pit-in-pit excavation of the first branch line of Lanzhou Metro

- CT measurement of damage characteristics of meso-structure of freeze-thawed granite in cold regions and preliminary exploration of its mechanical behavior during a single freeze-thaw process

Articles in the same Issue

- Research Articles

- Vibrational wave scattering in disordered ultra-thin film with integrated nanostructures

- Optimization of lead-free CsSnI3-based perovskite solar cell structure

- Determination of the velocity of seismic waves for the location of seismic station of Zatriq, Kosovo

- Seismic hazard analysis by neo-deterministic seismic hazard analysis approach (NDSHA) for Kosovo

- Ultimate strength of hyper-ellipse flanged-perforated plates under uniaxial compression loading

- Development of an adaptive coaxial concrete rheometer and rheological characterisation of fresh concrete

- Synthesis and characterization of a new complex based on antibiotic: Zirconium complex

- Exergy–energy analysis for a feasibility trigeneration system at Kocaeli University Umuttepe Campus

- Transient particle tracking microrheology of plasma coagulation via the intrinsic pathway

- Analysis of complex fluid discharge from consumer dispensing bottles using rheology and flow visualization

- A method of safety monitoring and measurement of overall frost heaving pressure of tunnel in seasonal frozen area

- Application of isolation technology in shallow super-large comprehensive pipe galleries in seismically vulnerable areas with weak soils

- Application of the ramp test from a closed cavity rheometer to obtain the steady-state shear viscosity η(γ̇)

- Research on large deformation control technology of highly weathered carbonaceous slate tunnel

- Tailoring a symmetry for material properties of tellurite glasses through tungsten(vi) oxide addition: Mechanical properties and gamma-ray transmissions properties

- An experimental investigation into the radiation-shielding performance of newly developed polyester containing recycled waste marble and bismuth oxide

- A study on the fractal and permeability characteristics of coal-based porous graphite for filtration and impregnation

- Creep behavior of layered salt rock under triaxial loading and unloading cycles

- Research and optimization of tunnel construction scheme for super-large span high-speed railway tunnel in poor tuff strata

- Elongational flow mixing: A novel innovative approach to elaborate high-performance SBR-based elastomer compounds

- The ductility performance of concrete using glass fiber mesh in beam specimens

- Thickened fluids classification based on the rheological and tribological characteristics

- Strength characteristics and damage constitutive model of sandstone under hydro-mechanical coupling

- Experimental study of uniaxial compressive mechanical properties of rough jointed rock masses based on 3D printing

- Study on stress distribution and extrusion load threshold of compressed filled rock joints

- Special Issue on Rheological Behavior and Engineering Stability of Rock Mass - Part II

- Seismic response and damage mechanism of tunnel lining in sensitive environment of soft rock stratum

- Correlation analysis of physical and mechanical parameters of inland fluvial-lacustrine soft soil based on different survey techniques

- An effective method for real-time estimation of slope stability with numerical back analysis based on particle swarm optimization

- An efficient method for computing slope reliability calculation based on rigorous limit equilibrium

- Mechanical behavior of a new similar material for weathered limestone in karst area: An experimental investigation

- Semi-analytical method for solving stresses in slope under general loading conditions

- Study on the risk of seepage field of Qiantang River underground space excavated in water-rich rheological rock area

- Numerical analysis of the impact of excavation for undercrossing Yellow River tunnel on adjacent bridge foundations

- Deformation rules of deep foundation pit of a subway station in Lanzhou collapsible loess stratum

- Development of fiber compound foaming agent and experimental study on application performance of foamed lightweight soil

- Monitoring and numerical simulation analysis of a pit-in-pit excavation of the first branch line of Lanzhou Metro

- CT measurement of damage characteristics of meso-structure of freeze-thawed granite in cold regions and preliminary exploration of its mechanical behavior during a single freeze-thaw process