Abstract

Assessing the stress distribution within the slope in geotechnical engineering is critical. Despite the widely available numerical methods, no analytical solutions are available for determining the stress distribution within a slope under general loading conditions. This study presents a method of analytically approximating elastic stresses within a slope of arbitrary inclination subject to general surcharges and supporting forces. The prototype model of this problem is equivalent to a superposition of two sub-models: a half-plane body subjected to an initial earth stress field as well as surcharges on the crest (Model I) and a slope loaded by the release stresses caused by excavation, together with supporting forces on its inclined surface and bottom (Model II). The former stresses can be calculated analytically using Flamant’s solution, and the latter stresses can be further thought of as being composed of two additional components: one in an infinite plane with a half-infinite hole loaded by virtual tractions upon hole’s boundary (Model II1), which can be analytically approximated, and the other in a half-plane subjected to virtual tractions along the ground surface (Model II2), which can be calculated analytically as well. The two sets of virtual tractions that lead to stresses in Model II are calculated using an iterative process. The current approach provides analytical approximations of elastic stress solutions for slopes that are sufficiently close to the exact ones as accurate as much. A case study demonstrates that such solutions are in good agreement with those of the finite-element method’s over the entire region, the stresses within the region up to 10−11 times the slope’s height away from the slope toe can also be accurately determined using the current method. With this method, contour plots of stresses within a slope inclined at various angles are presented, which can be applied directly in practical engineering.

1 Introduction

Determination of the elastic stress distribution within the slope is extremely important in geotechnical engineering involving the assessment of slope stability and design of slope excavation [1,2,3,4,5]. For this, numerical methods, such as the finite-element method (FEM) [6,7,8,9,10] and the boundary-element method [11,12,13], have been employed extensively. However, searching for analytical or exact solutions has been long challenging and has become a focus of theoretical study in the fields of solid mechanics and geotechnical engineering. An approximate stress solution for the slope was derived using analytic continuation and the Cauchy integral based on Muskhelishvili’s theory [14]. An analytical solution for gravity-induced stress in elastic slopes was obtained by applying virtual loads on its boundary [15]. Another analytical solution for stresses was derived using the Schwarz–Christoffel transformation and the complex variable method along with the Cauchy integral considering gravity [16] and recently using the Schwarz–Christoffel transformation and the complex potentials with body force [17]. However, the complex variable method used in these references is only suitable for a slope with a particular slope angle, and arbitrarily distributed forces acting on the slope’s surfaces cannot be incorporated.

In this study, an alternative approach is proposed to accurately calculate the stress distributions within the slope under general loading conditions with the initial earth stress, surcharge loads, and supporting forces being taken into consideration. Examples are provided to demonstrate the efficacy of this method, and contour plots of stresses within the slope of various inclination angles are provided for practical application.

2 Fundamentals

A slope with an inclination of

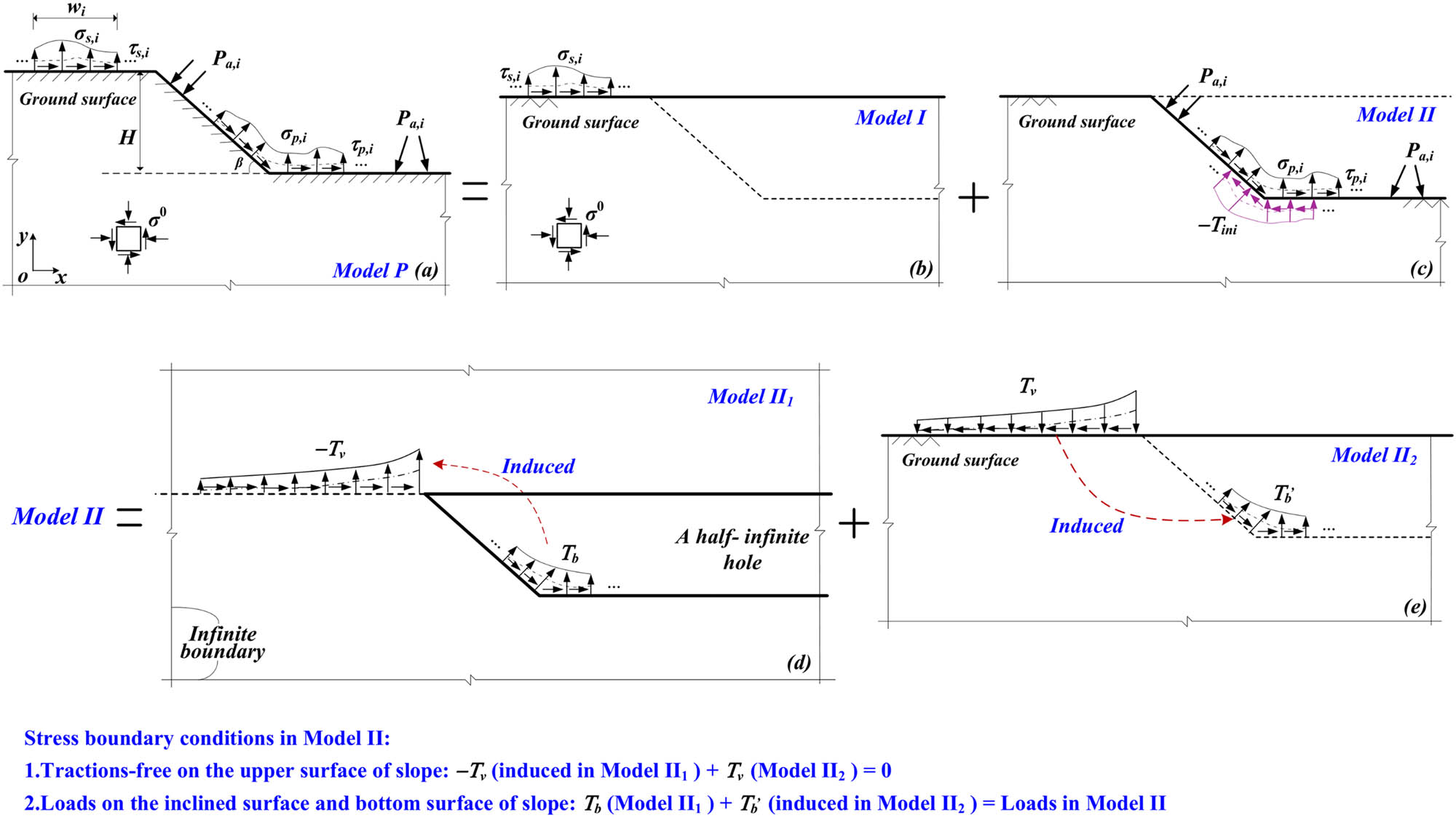

The equivalent model of slope: (a) the prototype model (Model P); (b) a half-plane with surcharges on slope’s crest (Model I); (c) a weightless slope loaded by supporting forces and release stresses (Model II); (d) a half-infinite hole loaded by virtual tractions upon the hole’s boundary in an infinite plane (Model II1); and (e) a half-plane subjected to virtual tractions along the ground surface (Model II2).

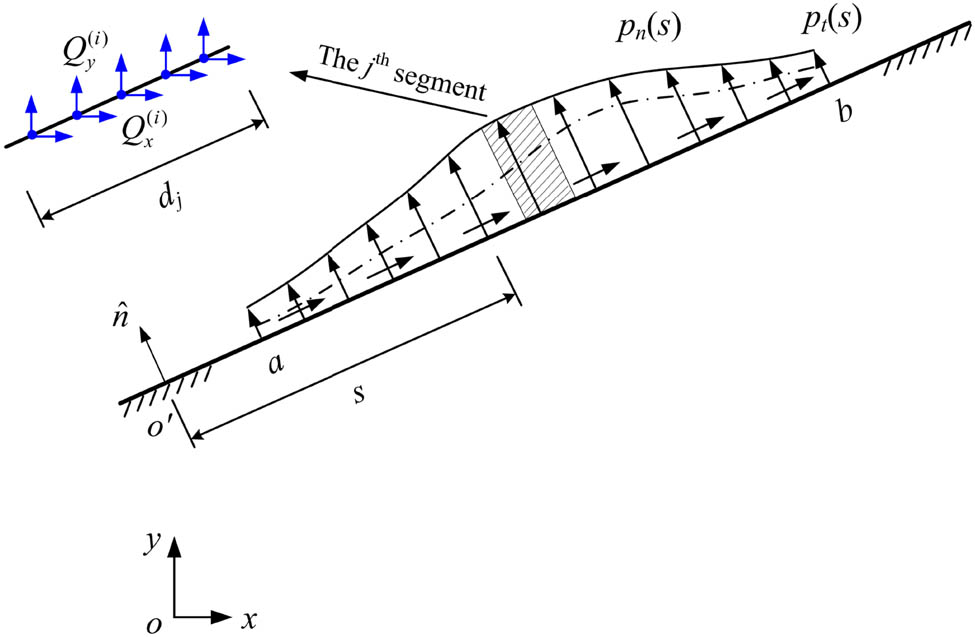

The current issue’s prototype model, known as Model P, is a slope loaded by the initial earth stress, surcharges, as well as supporting forces, as shown in Figure 1(a). The superposition principle is applicable due to the assumption of linear elasticity with tiny strain herein, which means that the summation of stress solutions in Models I and II is equal to the ultimate stress solution. Model I, shown in Figure 1(b), describes a half-plane that is loaded by surcharges on the crest and initial earth stress within the body. Model II, shown in Figure 1(c), depicts a weightless slope subjected to the release stresses resulting from excavation and the supporting pressures together with any other concentrated forces exerted on the inclined surface and bottom of the slope after excavation. With the aid of the analytical stress solution in a half-plane loaded at its upper surface by concentrated forces (Flamant solution [18]), Model I’s solution is easily accessible. Thus, the crucial step in solving the current problem is to acquire Model II’s analytical stress solution, which can be further equivalent to the superposition of Model II1 and Model II2:

Model II1: depicting an infinite plane containing a half-infinite hole loaded by virtual tractions

Model II2: representing a half-plane that is subject to virtual tractions

Be aware that Model II’s two sets of virtual tractions are not known in advance, which will be calculated by fulfilling the stress boundary conditions. Since the slope’s crest in Model II is traction-free, the tractions on the line coinciding with the slope’s crest caused by

3 Procedures of solution

Any sorts of distributed forces, such as virtual tractions, surcharges, and distributed tractions acting on surfaces, can be translated into a sequence of equivalent concentrated forces to simply computation using high-precision numerical integration methods [19]. The stresses created by the distributed forces can thus be identical to those imposed by equivalent concentrated forces. In the subsequent derivation, the Gaussian Quadrature is adopted together with a Legendre polynomial of fifth order [20], which accuracy is suitable for high-precision evaluation of stresses for the problem. The details of transforming tractions to equivalent concentrated forces are described in the Appendix.

3.1 Analytical stress solution for Model I

Model I refers to a pure half-plane loaded by the initial earth stress and surcharge loads upon its upper surface (the same as the slope’s crest), as illustrated in Figure 1(b). The region loaded by the surcharge loads is divided into several segments that are grouped according to type(i) presented in the Appendix. Consequently, the surcharge loads are represented by equivalent concentrated forces,

A half-plane loaded by initial earth stress and equivalent concentrated forces upon the ground surface.

The stresses at any point in Model I caused by

where the components of the matrix

The stresses at any position in Model I, given by

3.2 Analytical approximant stress for Model II1

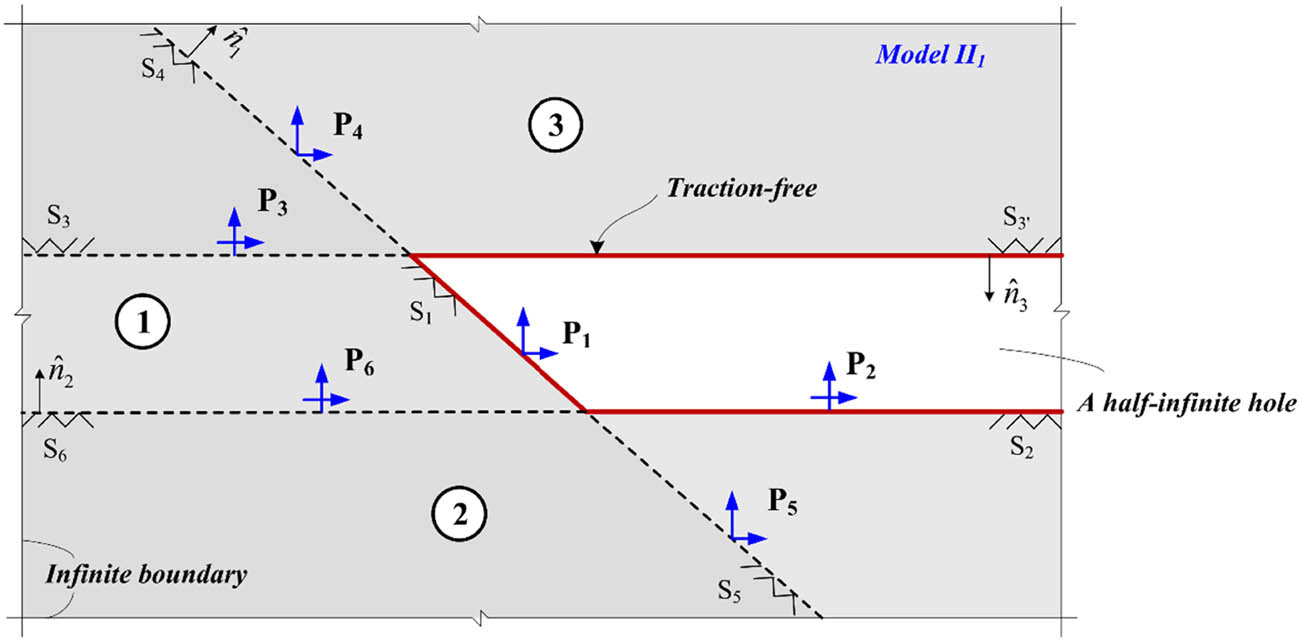

Model II1 corresponds to a half-infinite hole subjected to virtual tractions

The half-infinite hole’s outer region can be considered as the union of three half-planes, each of which corresponds to a specific side of the hole. Consequently, provided that the tractions or the equivalent concentrated forces are known, stresses in the hole’s outer region are the same as those that correspond to a particular half-plane, which can be determined using the Flamant solution. Yet, it is not known beforehand what the tractions will be applied to the half-plane’s outer surfaces that is contained within the adjacent half-plane. Thus, an iterative approach should be used, where the tractions can be initially assumed, typically as zero, and then be updated repeatedly until convergence is achieved to the required degree of accuracy.

It can be seen from Figure 3 that the half-infinite hole’s outer region can be separated into three half-planes by its three sides and their extensions, which are denoted by symbols “①”, “②”, and “③”. The outer surface of the half-plane ① consists of the left external surface

A half-infinite hole subjected to equivalent concentrated forces in an infinite plane.

The surfaces

Therefore, as presented in the Appendix, the distributed tractions applied along surfaces

Now considering the half-plane ③, its external surface

where the components of the matrices

Similarly, the equivalent concentrated forces

Therefore, once virtual tractions

The first modified values of

The stresses at a point in Model II1 after the half-plane including that point has been identified can be calculated using equation (A8) in the Appendix using the convergent values of

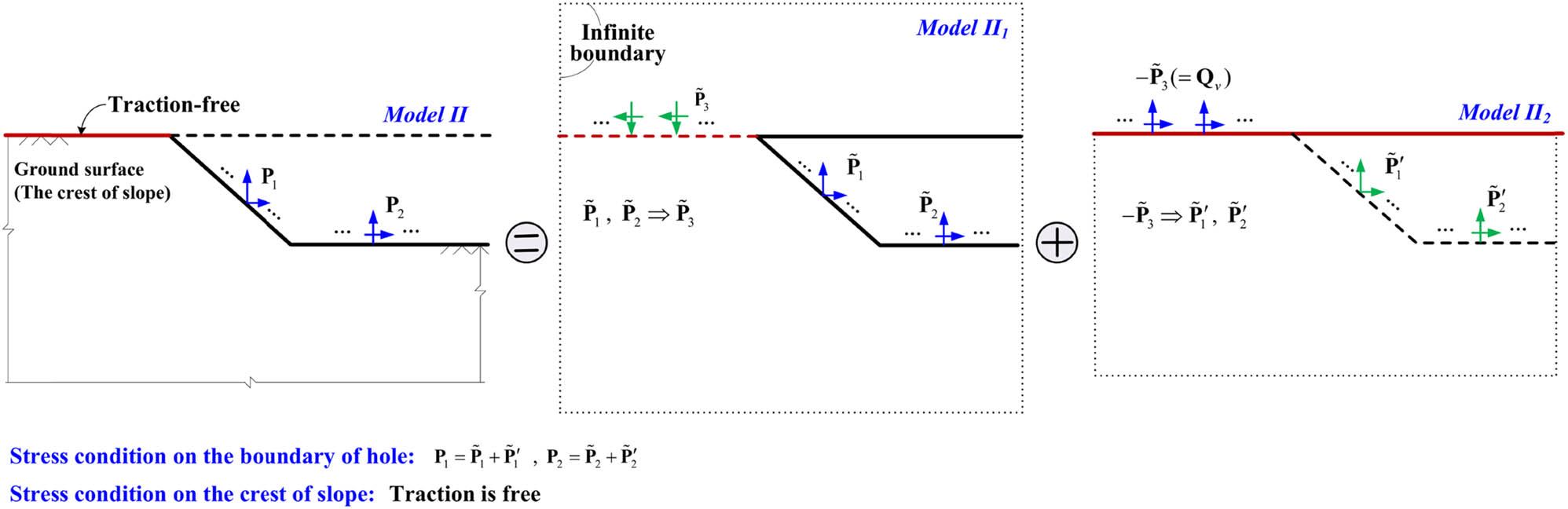

3.3 Analytical stress solutions for Model II2

Model II2 represents a half-plane without a hole loaded by

A pure half-plane loaded by equivalent concentrated forces upon its upper surface.

The stresses in Model II2 induced by

where the components of the matrix

3.4 Iterative process for computing stresses in Model II

Virtual tractions

Schematic diagram of the iterative calculation.

Assuming the initial values of

The negative values of

Subsequently, by fulfilling the stress condition of the hole’s boundary in Model II, the first modified values of

The above procedure is repeated by substituting these values of

Repeating Steps 2 to 3 until convergence is achieved.

With the convergent values of

4 Example study and comparison

A vertical slope with a height of H = 10 m is subjected to surcharge loads along its upper surface with a loading width of

A slope with a slope angle of 90° subjected to surcharge loads and initial earth stress.

Comparisons of contour plots of stress σ y within slope between the present method and FEM (the unit of stress is kPa).

The FEM is employed in this case for comparison. As shown in Figure 6(b), the calculation model is 40 m high and 70 m long in the X-direction, and a total of 18,571 PLANE 42 elements are generated using the commercial FEM package (ANSYS 15.0). The model’ boundary is outside the affected region by slope excavation. Vertical and horizontal constraints were imposed on the slope’s vertical and horizontal-bottom boundaries, respectively. It can be demonstrated from Figure 7 that the results obtained by the proposed method agree well with those by the FEM, with the exception of a tiny discrepancy existing in the vicinity of the slope toe. Meanwhile, the present approach demonstrates a higher stress concentration, whereas the FEM shows a considerably lower stress concentration despite using a huge number of meshes.

To examine the specifics of stress concentration around the slope toe, the stress diagrams are scaled 10 times, 102 times, and 104 times consecutively, with the horizontal lengths of 10−3 H, 10−5 H, and 10−10 H, respectively, as depicted in Figure 8. Figure 8 illustrates that the stress level measured near the slope toe grows as the diagram’s dimension reduces, while the geometric properties of the stress concentration are almost the same. Additionally, it is demonstrated that the proposed method can predict the stresses in the vicinity of the slope toe, even in the region nearby the slope toe in the range of 10−11 H to 10−10 H, which can rarely be obtained using the FEM due to computer capacity and computation time constraints.

Stress diagram at different scales (the unit of stress is kPa).

The distribution of the principal stresses within the slope is presented in Figure 9, from which high-stress concentration appears near the slope toe. It can be seen from Figure 9(a) that the major principal stresses are always compressive, whose contours near the crest and the bottom of the slope are distributed nearly in layers. In contrast, the contours become curves near the inclined surface and the slope toe. From Figure 9(b), the minor principal stresses are also mostly compressive, except for those at the bottom and the region outside the loading region of surcharge loads on the crest of the slope. In the region of the bottom of the slope at a certain distance from the slope toe, the contours are almost horizontal and distributed in the form of layers.

Contour plots of principal stresses within slope subjected to surcharge loads: (a)

It is assumed to be supported by uniform pressure along the slope’s vertical surface to investigate the effect of supporting forces on the stress distribution within the slope. Contour plots of the major and minor principal stresses within the slope are displayed in Figure 10(a) and 10(b), respectively. It is shown in Figure 10 that the magnitude of stress concentration at the slope toe is smaller than that of the unlined slope (Figure 9). Meanwhile, from Figure 10(b), the tensile stresses occur near the bottom of the slope, the values of which are lower than those in Figure 10(b). As a whole, supporting forces have a remarkable effect on the stress field within the slope, and the present method can provide a theoretical tool for the design of slope reinforcements.

Contour plots of stresses within the slope supported by uniform pressure along the slope surface: (a)

5 Application

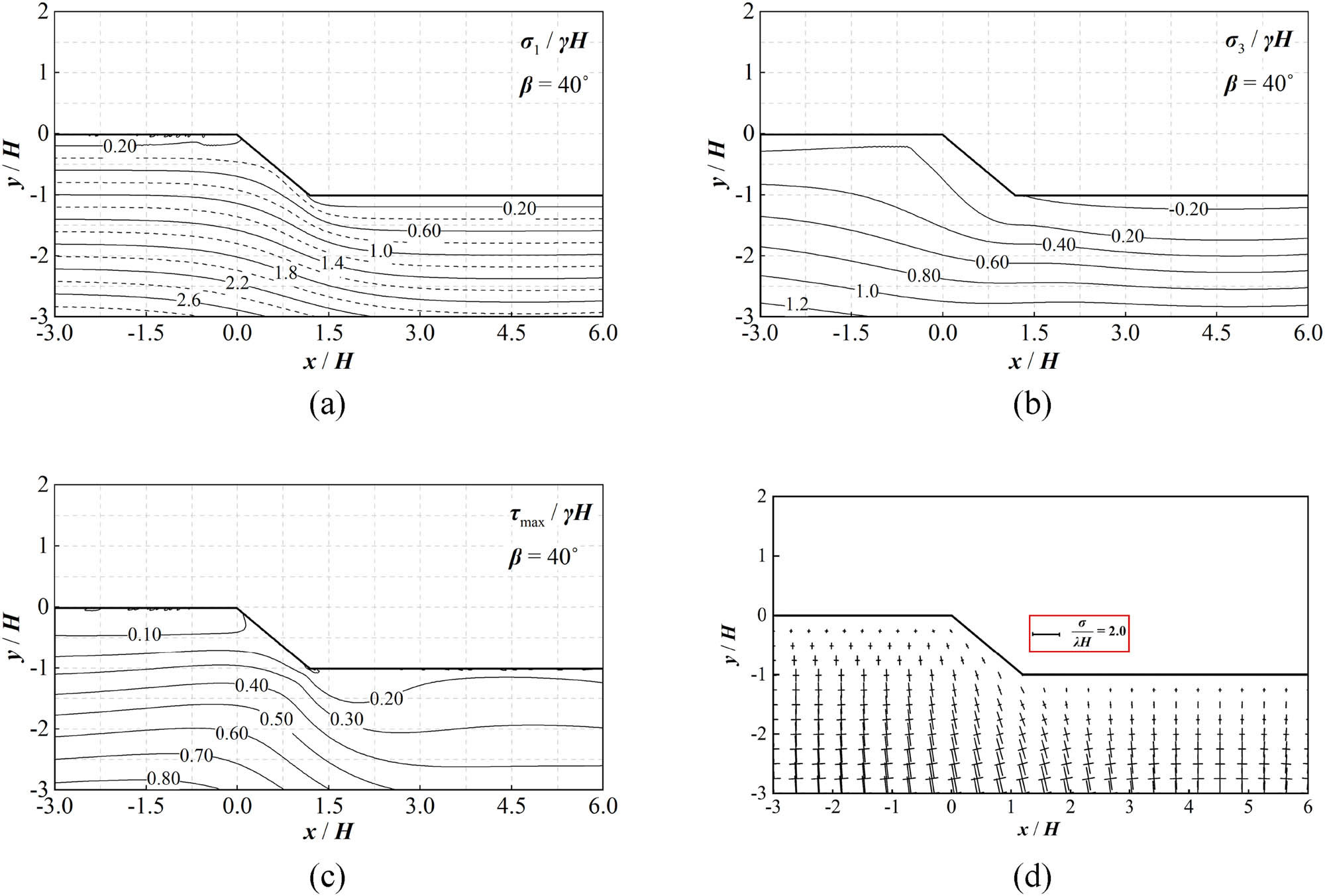

A slope with a height of H = 10 m is considered, as shown in Figure 11, with an inclination of chosen as 10, 20, 30, 40, 50, 60, 70, 80, and 90°. The unit weight γ is 20 kN/m3, and the Poisson’s ratio

where

Geometry of a typical slope.

Values of

It can be seen from Figure 12 that the inclination angle has a remarkable effect on the stress distribution within the slope; the normalized stresses

It is illustrated from Figure 12(a) (Line 1, vertical line at a horizontal distance of H from the slope crown) that the normalized stresses

It can be illustrated from Figure 12(e) (Line 5, vertical line through the slope toe) that high-stress concentration appears at the slope toe when the inclination angle is more than 50°, the magnitude of which increases as the inclination angle increases. When the depth is more than 4H, the curves of the normalized stresses

For the stresses at some distance from the slope toe (Figure 12(g), Line 7), the normalized stresses

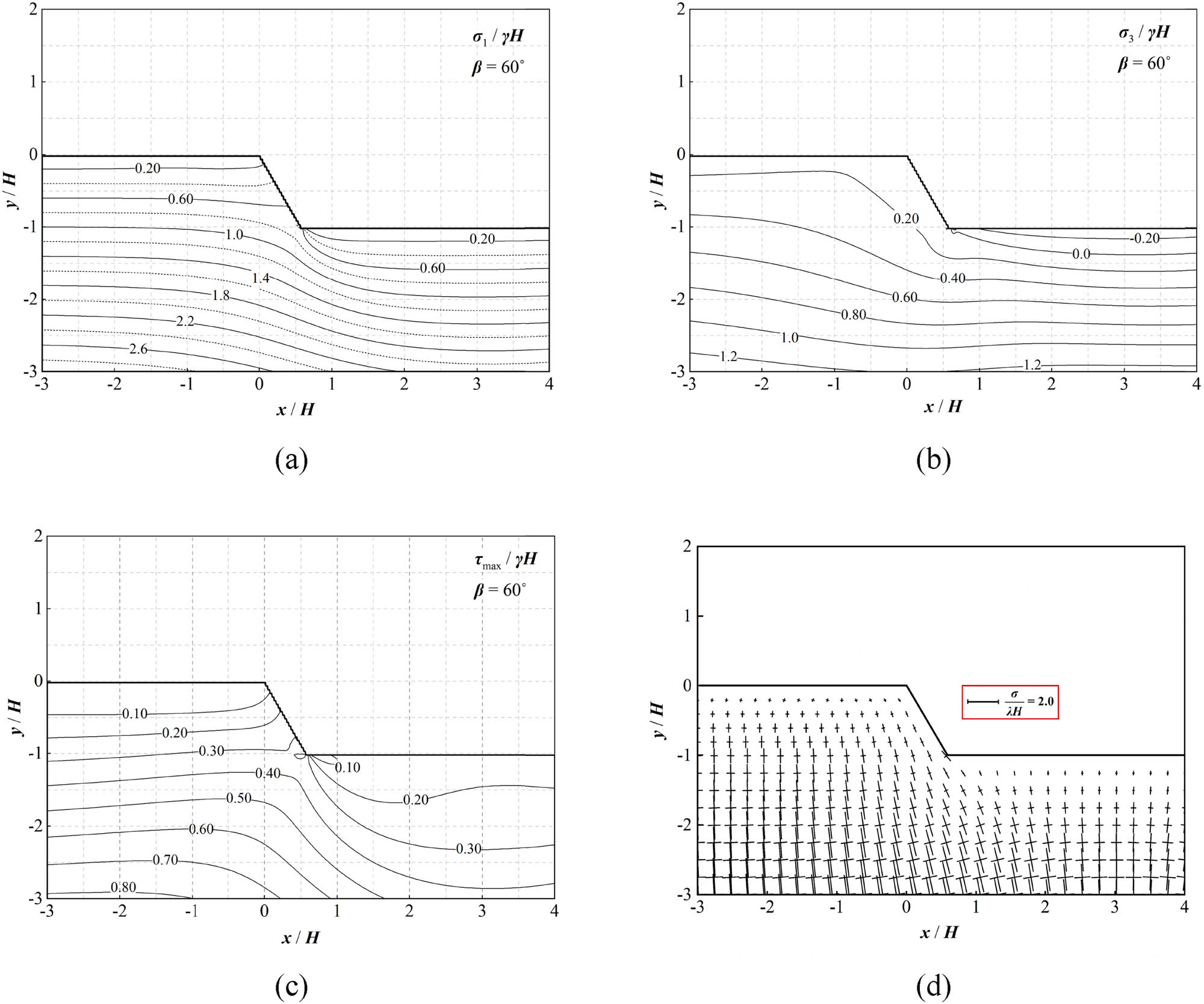

For the sake of practical application, choosing a series of stand slopes with various values of inclination angles, contour plots of stresses are developed for the normalized stresses

Stress distribution within a slope of the inclination angle of 10°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 20°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 30°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 40°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 50°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 60°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 70°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 80°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

Stress distribution within a slope of the inclination angle of 90°: (a)–(c) contour plots of stresses and (d) vectors of major and minor principal stresses.

With these contour plots, the stresses at any point within a given slope can be directly obtained. For example, it is required to determine the stresses

For a standard slope with arbitrary inclination, we can choose two standard slopes with inclinations slightly larger and lesser than that of the specific slope, and the required stresses can be obtained by linear interpolation from the results of the two standard slopes. It has been known that in normal situations with a moderate magnitude of horizontal earth stresses, the effect of horizontal earth stresses on stresses within the slope is insignificant from practical viewpoints. Thus, the effect of the value of Poisson’s ratio

6 Conclusion

In this article, approximate analytic solutions for elastic stresses within a slope subjected to general loading conditions are provided. Surcharge loads and other supporting forces, such as pressure and concentrated forces, can be incorporated into the solution, which can sufficiently approach the analytical solutions with a much high degree of precision. The procedure of the solution is straightforward and easily implementable into a computer program.

The example’s results demonstrate that the stresses calculated using the present method and the FEM are in good agreement. In addition, it is possible to accurately determine the stresses that have not yet been available achieved by any other numerical methods in the region around the proximity of the slope toe, even at distances between 10−11 and 10−10 times the slope’s height. The effect of supporting forces on the stress distribution within the slope is also investigated, and the findings demonstrate that supporting forces have an impact on the stress distribution within the slope.

With the present method, contour plots of stresses are presented for nine standard slopes of various inclination angles. The results show that the inclination angle has a remarkable effect on the stress distribution within slope, and the larger the inclination is, the higher the stress concentration near the slope toe is. For a slope with arbitrary inclination, we can choose two standard slopes with inclinations slightly larger and lesser than that of the specific slope, and the required stresses can be obtained by linear interpolation from the results of the two standard slopes. These contour plots of stresses would have general applications for roughly estimating elastic stress distribution within a slope of any height, inclination and unit weight as well.

Acknowledgements

The authors thank the help and guidance from Prof. Kunlin LU of Hefei University of Technology and Prof. Rongzhu LIANG from China University of Geosciences.

-

Funding information: This research was funded by the National Natural Science Foundation of China (Grant Number 52079121).

-

Author contributions: The whole manuscript was written and edited by Ping WU, the work herein was guided and rechecked thoroughly by Prof. D.Y. Zhu, and the structure and tongue of this work were assisted by Prof. X.J. Sun. All authors rechecked and approved the final manuscript.

-

Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

-

Ethical approval: The conducted research is not related to either human or animal use.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Appendix

A1 Derivation of equations and illustration of some concepts

A1.1 Analytical stress solution for a half-plane subjected to concentrated forces

In the coordinate system oxy, horizontal and vertical concentrated forces,

in which

A half-plane loaded by concentrated forces.

In the framework of a unified cartesian coordinate system, equation (A1) can be transformed into

where

The components

A1.2 Conversion of tractions into equivalent concentrated forces

Given that normal and tangential stresses,

where

A half-plane under distributed tractions.

The region in the interval ab loaded by the distributed tractions is divided into n segments, each comprising five Gaussian points, sufficiently satisfying the need for high precision, as depicted in Figure A2. Thus, there are a total of

where

Thus, the distributed traction is substituted with

where

The equivalent concentrated forces acting at all of the Gaussian points within ab, represented by

A1.3 Equivalent concentrated forces on a line within a half-plane loaded by equivalent concentrated forces

Assuming that a half-plane is loaded by distributed tractions with the width

A half-plane loaded by equivalent concentrated forces upon its upper surface.

The stresses within the half-plane induced by

where

Given that a segment

where

Substituting equation (A8) into equation (A9) yields

Thus, the tractions acting at all Gaussian points within the segment

where

The equivalent concentrated forces acting at all Gaussian points on the segment

where

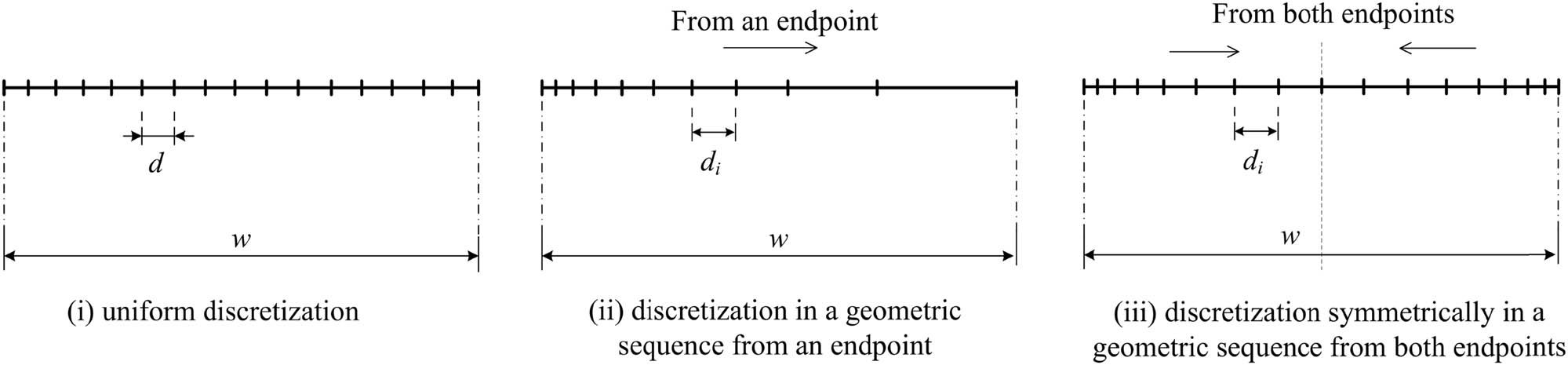

A1.4 General types of discretization of a line into segments

The area subjected to the distributed tractions should be divided into a number of segments, which are recommended to be arranged in accordance with three types of discretization outlined below, as depicted in Figure A4.

General types of discretization of a line into segments: (i) uniform discretization, (ii) discretization in a geometric sequence from an endpoint, and (iii) discretization symmetrically in a geometric sequence from both endpoints.

Type (i): uniform discretization

The segments of the loading region are discretized uniformly with a length of

Type (ii): discretization in a geometric sequence from an endpoint

The region consists of

where

Type (iii): discretization symmetrically in a geometric sequence from both endpoints

The region is divided into

where

References

[1] Wright SG, Kulhawy FH, Duncan JM. Accuracy of equilibrium slope stability analysis. J Soil Mech Found Div J. 1973;99(10):783–91. 10.1061/JSFEAQ.0001933.Search in Google Scholar

[2] Tavenas F, Trak B, Leroueil S. Remarks on the validity of stability analyses. Can Geotech J. 1980;17(1):61–73. 10.1139/t80-006.Search in Google Scholar

[3] Zhu DY, Lee CF, Jiang HD. Generalized framework of limit equilibrium methods for slope stability analysis. Geotechnique. 2003;53(4):377–95. 10.1680/geot.2003.53.4.377.Search in Google Scholar

[4] Zhu DY, Lee CF, Chan DH, Jiang HD. Evaluation of the stability of anchor-reinforced slopes. Can Geotech J. 2005;42(5):1342–9. 10.1139/t05-060.Search in Google Scholar

[5] Cheng H, Zhou X. A novel displacement-based rigorous limit equilibrium method for three-dimensional landslide stability analysis. Can Geotech J. 2015;52(12):2055–66. 10.1139/cgj-2015-0050.Search in Google Scholar

[6] Zienkiewicz OC, Taylor RL, Taylor RL. The finite element method: solid mechanics. Vol. 2. Butterworth-heinemann; 2000.Search in Google Scholar

[7] Matsui T, San K. Finite element slope stability analysis by shear strength reduction technique. Soils Found. 1992;32(1):59–70. 10.3208/sandf1972.32.59.Search in Google Scholar

[8] Kim JY, Lee SR. An improved search strategy for the critical slip surface using finite element stress fields. Comput Geotech. 1997;21(4):295–313. 10.1016/S0266-352X(97)00027-X.Search in Google Scholar

[9] Liu S, Su Z, Li M, Shao L. Slope stability analysis using elastic finite element stress fields. Eng Geol. 2020;273:105673. 10.1016/j.enggeo.2020.105673.Search in Google Scholar

[10] Yang Y, Wu W, Zheng H. Searching for critical slip surfaces of slopes using stress fields by numerical manifold method. J Rock Mech Geotech Eng. 2020;12(6):1313–25. 10.1016/j.jrmge.2020.03.006.Search in Google Scholar

[11] Brebbia CA. The boundary element method for engineers. Plymouth: Pentech Press; 1978.Search in Google Scholar

[12] Martel SJ, Muller JR. A two-dimensional boundary element method for calculating elastic gravitational stresses in slopes. Pure Appl Geophys. 2000;157(6):989–1007. 10.1007/s000240050014.Search in Google Scholar

[13] Ostanin IA, Mogilevskaya SG, Labuz JF, Napier J. Complex variables boundary element method for elasticity problems with constant body force. Eng Anal Bound Elem. 2011;35(4):623–30. 10.1016/j.enganabound.2010.11.008.Search in Google Scholar

[14] Silvestri V, Tabib C. Exact determination of gravity stresses in finite elastic slopes: Part I. Theoretical considerations. Can Geotech J. 1983;20(1):47–54. 10.1139/t83-005.Search in Google Scholar

[15] Savage WZ. Gravity-induced stresses in finite slopes. Int J Rock Mech Min Sci Geomech Abstr.; 1994. p. 471–83. 10.1016/0148-9062(94)90150-3.Search in Google Scholar

[16] Hasebe N, Wang XF. Irregular elastic half-plane gravity problem. Int J Rock Mech Min. 2003;40(6):863–75. 10.1016/S1365-1609(03)00054-6.Search in Google Scholar

[17] Jia X, Lu A, Cai H, Ma Y. An analytical method for solving gravity-induced stresses in slope. Appl Math Model. 2021;98:665–79. 10.1016/j.apm.2021.06.004.Search in Google Scholar

[18] Barber JR. Elasticity. Dordrecht: Kluwer Academic Publishers; 2002.Search in Google Scholar

[19] Zhu DY, Wu P. Asymptotically analytical solution of elastic stress for convex polygonal holes in an infinite plane under various loading conditions. Acta Mech. 2021;232(10):3957–75. 10.1007/s00707-021-03040-2.Search in Google Scholar

[20] Burden RL, Faires JD. Numerical analysis. 9th edn. Boston: Brooks/Cole Cencag Learning; 2011.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Vibrational wave scattering in disordered ultra-thin film with integrated nanostructures

- Optimization of lead-free CsSnI3-based perovskite solar cell structure

- Determination of the velocity of seismic waves for the location of seismic station of Zatriq, Kosovo

- Seismic hazard analysis by neo-deterministic seismic hazard analysis approach (NDSHA) for Kosovo

- Ultimate strength of hyper-ellipse flanged-perforated plates under uniaxial compression loading

- Development of an adaptive coaxial concrete rheometer and rheological characterisation of fresh concrete

- Synthesis and characterization of a new complex based on antibiotic: Zirconium complex

- Exergy–energy analysis for a feasibility trigeneration system at Kocaeli University Umuttepe Campus

- Transient particle tracking microrheology of plasma coagulation via the intrinsic pathway

- Analysis of complex fluid discharge from consumer dispensing bottles using rheology and flow visualization

- A method of safety monitoring and measurement of overall frost heaving pressure of tunnel in seasonal frozen area

- Application of isolation technology in shallow super-large comprehensive pipe galleries in seismically vulnerable areas with weak soils

- Application of the ramp test from a closed cavity rheometer to obtain the steady-state shear viscosity η(γ̇)

- Research on large deformation control technology of highly weathered carbonaceous slate tunnel

- Tailoring a symmetry for material properties of tellurite glasses through tungsten(vi) oxide addition: Mechanical properties and gamma-ray transmissions properties

- An experimental investigation into the radiation-shielding performance of newly developed polyester containing recycled waste marble and bismuth oxide

- A study on the fractal and permeability characteristics of coal-based porous graphite for filtration and impregnation

- Creep behavior of layered salt rock under triaxial loading and unloading cycles

- Research and optimization of tunnel construction scheme for super-large span high-speed railway tunnel in poor tuff strata

- Elongational flow mixing: A novel innovative approach to elaborate high-performance SBR-based elastomer compounds

- The ductility performance of concrete using glass fiber mesh in beam specimens

- Thickened fluids classification based on the rheological and tribological characteristics

- Strength characteristics and damage constitutive model of sandstone under hydro-mechanical coupling

- Experimental study of uniaxial compressive mechanical properties of rough jointed rock masses based on 3D printing

- Study on stress distribution and extrusion load threshold of compressed filled rock joints

- Special Issue on Rheological Behavior and Engineering Stability of Rock Mass - Part II

- Seismic response and damage mechanism of tunnel lining in sensitive environment of soft rock stratum

- Correlation analysis of physical and mechanical parameters of inland fluvial-lacustrine soft soil based on different survey techniques

- An effective method for real-time estimation of slope stability with numerical back analysis based on particle swarm optimization

- An efficient method for computing slope reliability calculation based on rigorous limit equilibrium

- Mechanical behavior of a new similar material for weathered limestone in karst area: An experimental investigation

- Semi-analytical method for solving stresses in slope under general loading conditions

- Study on the risk of seepage field of Qiantang River underground space excavated in water-rich rheological rock area

- Numerical analysis of the impact of excavation for undercrossing Yellow River tunnel on adjacent bridge foundations

- Deformation rules of deep foundation pit of a subway station in Lanzhou collapsible loess stratum

- Development of fiber compound foaming agent and experimental study on application performance of foamed lightweight soil

- Monitoring and numerical simulation analysis of a pit-in-pit excavation of the first branch line of Lanzhou Metro

- CT measurement of damage characteristics of meso-structure of freeze-thawed granite in cold regions and preliminary exploration of its mechanical behavior during a single freeze-thaw process

Articles in the same Issue

- Research Articles

- Vibrational wave scattering in disordered ultra-thin film with integrated nanostructures

- Optimization of lead-free CsSnI3-based perovskite solar cell structure

- Determination of the velocity of seismic waves for the location of seismic station of Zatriq, Kosovo

- Seismic hazard analysis by neo-deterministic seismic hazard analysis approach (NDSHA) for Kosovo

- Ultimate strength of hyper-ellipse flanged-perforated plates under uniaxial compression loading

- Development of an adaptive coaxial concrete rheometer and rheological characterisation of fresh concrete

- Synthesis and characterization of a new complex based on antibiotic: Zirconium complex

- Exergy–energy analysis for a feasibility trigeneration system at Kocaeli University Umuttepe Campus

- Transient particle tracking microrheology of plasma coagulation via the intrinsic pathway

- Analysis of complex fluid discharge from consumer dispensing bottles using rheology and flow visualization

- A method of safety monitoring and measurement of overall frost heaving pressure of tunnel in seasonal frozen area

- Application of isolation technology in shallow super-large comprehensive pipe galleries in seismically vulnerable areas with weak soils

- Application of the ramp test from a closed cavity rheometer to obtain the steady-state shear viscosity η(γ̇)

- Research on large deformation control technology of highly weathered carbonaceous slate tunnel

- Tailoring a symmetry for material properties of tellurite glasses through tungsten(vi) oxide addition: Mechanical properties and gamma-ray transmissions properties

- An experimental investigation into the radiation-shielding performance of newly developed polyester containing recycled waste marble and bismuth oxide

- A study on the fractal and permeability characteristics of coal-based porous graphite for filtration and impregnation

- Creep behavior of layered salt rock under triaxial loading and unloading cycles

- Research and optimization of tunnel construction scheme for super-large span high-speed railway tunnel in poor tuff strata

- Elongational flow mixing: A novel innovative approach to elaborate high-performance SBR-based elastomer compounds

- The ductility performance of concrete using glass fiber mesh in beam specimens

- Thickened fluids classification based on the rheological and tribological characteristics

- Strength characteristics and damage constitutive model of sandstone under hydro-mechanical coupling

- Experimental study of uniaxial compressive mechanical properties of rough jointed rock masses based on 3D printing

- Study on stress distribution and extrusion load threshold of compressed filled rock joints

- Special Issue on Rheological Behavior and Engineering Stability of Rock Mass - Part II

- Seismic response and damage mechanism of tunnel lining in sensitive environment of soft rock stratum

- Correlation analysis of physical and mechanical parameters of inland fluvial-lacustrine soft soil based on different survey techniques

- An effective method for real-time estimation of slope stability with numerical back analysis based on particle swarm optimization

- An efficient method for computing slope reliability calculation based on rigorous limit equilibrium

- Mechanical behavior of a new similar material for weathered limestone in karst area: An experimental investigation

- Semi-analytical method for solving stresses in slope under general loading conditions

- Study on the risk of seepage field of Qiantang River underground space excavated in water-rich rheological rock area

- Numerical analysis of the impact of excavation for undercrossing Yellow River tunnel on adjacent bridge foundations

- Deformation rules of deep foundation pit of a subway station in Lanzhou collapsible loess stratum

- Development of fiber compound foaming agent and experimental study on application performance of foamed lightweight soil

- Monitoring and numerical simulation analysis of a pit-in-pit excavation of the first branch line of Lanzhou Metro

- CT measurement of damage characteristics of meso-structure of freeze-thawed granite in cold regions and preliminary exploration of its mechanical behavior during a single freeze-thaw process