Abstract

The aim of the present article is to investigate the influence of the amount of bis(triethoxysilylpropyl) tetrasulfide on the curing characteristics and mechanical and dynamic properties of rubber composites based on epoxidized natural rubber (Epoxyprene 50) filled with 70 phr silica. The obtained results showed that although the interaction between the epoxy groups of epoxidized natural rubber and the silanol groups of silica through hydrogen bonds improves the dispersion of filler in the rubber matrix, the presence of silane coupling agents is necessary to obtain rubber compounds and vulcanizates with good vulcanization characteristics and mechanical and dynamic properties.

1 Introduction

It is known that styrene-butadiene rubber (SBR) and blends of SBR with polybutadiene or natural rubber are usually compounded with processing oils, fillers, cross-linking agents, and additives [1]. With the growing concerns about the increase in the price of rubber due to deficient petroleum sources, there is nowadays a tendency for replacing synthetic petrol products with renewable sources. In accordance with this tendency, in 2006 SRI Dunlop launched to the market a new type of environmentally friendly “green” tires under the brand name “ENASAVE ES801”. Only 30% of the ingredients in those tires are petrol derivatives. The tires are composed of epoxidized natural rubber (ENR) and silica in the tread; mineral oil has been replaced by vegetable oil, and synthetic fiber by vegetable fiber [2].

Silica is highly polar and hydrophilic owing to the silanol groups on its surface. For this reason, it disperses with more difficulty than carbon black in non-polar elastomers such as natural rubber, SBR, and butadiene rubber; however, it is better compatible with polar rubbers such as polychloroprene rubber [3]. Owing to the epoxide groups in its structure, ENR is more polar than the virgin elastomers typically used in the tire industry. Some researchers illustrated that the epoxy rings of ENR are reactive to the silanol groups located on the silica surface; thus, the dispersion of silica in ENR is extremely good [4–6].

In another article [7], ENR containing 10, 38, and 51 mol% epoxide was studied in different quantities as a coupling agent for silica-reinforced natural rubber tire tread compounds. It has been found that an increase in the ENR content and in the mole percentage of epoxide groups increases the interactions between silica and rubber, and decreases filler-filler interactions as reflected by lower Mooney viscosity, Payne effect, flocculation rate constant, filler networking factor, and higher filler-rubber interaction parameter, chemically bound rubber, and tensile strength. The addition of ENR containing 51 mol% epoxide shows the best overall properties, but still lower when compared with a compound with bis(triethoxysilylpropyl) tetrasulfide (TESPT) silane as the coupling agent.

The literature data show that ENR is a potential material for the tire industry because it can improve silica dispersion in the rubber matrix and hence improve tire performance. However, the use of ENR alone gives lower properties, and some quantity of silane coupling agent should be added to obtain optimal results. In spite of this, there is no reported study on the influence of silane quantity on the properties of ENR-based composites up to now. For this reason, the aim of this article is to answer the question of to what extent could the amount of silane coupling agents be reduced in the production of ENR mixtures containing silica. In connection with the foregoing, the main focus of our work is to investigate the influence of the amount of TESPT on the curing characteristics and mechanical and dynamic properties of rubber composites based on ENR filled with silica. ENR (Epoxyprene 50) was selected as the object of this study because it has the highest content of epoxy groups.

2 Materials and methods

2.1 Materials

The investigations were performed using the following materials:

ENR (Epoxyprene 50) containing 50±2% epoxy groups distributed randomly in the polymer chain was used. Epoxyprene 50 was purchased from San-Thap International Co., Ltd. (Bangkok, Thailand). Its characteristics are as follows: glass transition temperature (Tg), -24°C; density, 1.02 g/cm3; Mooney viscosity ML(1+4)100°C, ∼80–100 MU.

Silica, Ultrasil 7000 GR from Evonik Industries (Rheinfelden, Germany), had the following characteristics: specific surface area (N2), 175 m2/g; specific surface area (CTAB), 160 m2/g; loss on drying, 5.2%; pour density, 270 g/l; and electrical conductivity, ≤1300 μS/cm.

The other ingredients such as zinc oxide (ZnO), stearic acid, TESPT (Si 69), N-tert-butyl-2-benzothiazolesulfenamide (TBBS), and sulfur were also of commercial grades.

2.2 Measurements

The vulcanization characteristics of the studied rubber composites were determined at 150°C on a Moving Die Rheometer (MDR 2000; Alpha Technologies, Heilbronn, Germany) according to ISO 3417:2008. The mechanical properties of the composites studied were determined according to ISO 37:2011. The Shore A hardness of the composites studied were determined according to ISO 7619-1:2010, whereas the wear resistance was determined according to ISO 4649:2010.

The complex dynamic modulus and the heat build-up were determined on a Goodrich flexometer (Moscow, Russia) at an 850 min-1 deformation rate. The dynamic properties [dynamic storage modulus (E′) and mechanical loss angle tangent (tan δ)] of the studied composites were investigated using a Dynamic Mechanical Thermal Analyzer Mk III system (Rheometric Scientific, Epsom, Surrey, UK). The data were obtained at a frequency of 5 Hz and strain amplitude of 64 μm in the temperature range from -80°C to 80°C, using a heating rate of 3°C/min under a single cantilever bending mode. The dimensions of the investigated samples were as follows: width 10 mm, length 25 mm, and the thickness measured with a micrometer varied between 1 and 2 mm.

2.3 Preparation of rubber composites

The formulations of the compounds based on ENR (Epoxyprene 50) are presented in Table 1.

Compositions of the investigated rubber compounds (phr).

| S0 | S1 | S2 | S3 | S4 | S5 | S6 | S7 | |

|---|---|---|---|---|---|---|---|---|

| Epoxidized natural rubber – Epoxyprene 50 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Zinc oxide | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Stearic acid | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Silica, Ultrasil 7000 GR | 70.0 | 70.0 | 70.0 | 70.0 | 70.0 | 70.0 | 70.0 | 70.0 |

| TESPT, Si 69 | 0.0 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 |

| TBBS | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sulfur | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

The rubber compounds were prepared in two stages according to the mixing schedule presented in Table 2. At the first stage, the mixing was performed on a Brabender Plasti-Corder PLE651 (Brabender® GmbH & Co. KG, Duisburg, Germany) fitted with a 300-cm3 cam-type mixer. The silane coupling agent was mixed with the filler before placing the mixture into the mixer chamber. At the second stage, sulfur and the accelerator were added to the mixture compounded on an open two-roll laboratory mill L/D 320×160 and friction 1.27.

Mixing schedule of the investigated rubber compounds.

| Mixing order | Ingredients | Mixing time, min | Cumulative time, min |

|---|---|---|---|

| Stage 1, Brabender Plasti-Corder PLE651, rotor speed 40 rpm, temperature 140°C | |||

| 1 | Epoxyprene 50 | 2 | 2 |

| 2 | ZnO and stearic acid | 2 | 4 |

| 3 | Silica and TESPT | 5 | 9 |

| Stage 2, laboratory two-roll mills, friction 1.27 | |||

| 1 | First stage rubber batch | 2 | 2 |

| 2 | Sulfur and TBBS | 5 | 7 |

The vulcanization process of the ENR-based compounds was carried out in an electrically heated hydraulic press using a special homemade mold at a temperature of 150°C and under a pressure of 10 MPa.

3 Results and discussion

3.1 Curing properties

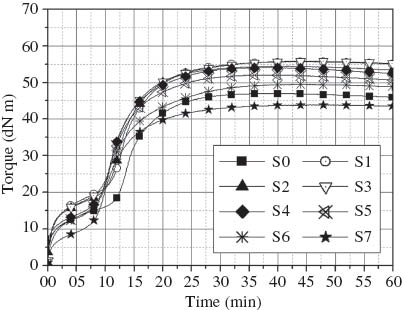

Table 3 summarizes the main curing properties of the studied rubber compounds that were determined from their cure curves (Figure 1).

Cure curves of the investigated rubber compounds taken at 150°C.

Curing properties of the investigated rubber compounds.

| S0 | S1 | S2 | S3 | S4 | S5 | S6 | S7 | |

|---|---|---|---|---|---|---|---|---|

| Minimum torque, ML (dN.m) | 12.18 | 15.00 | 15.00 | 15.00 | 12.10 | 10.88 | 10.88 | 7.64 |

| Maximum torque, MH (dN.m) | 47.02 | 55.69 | 54.45 | 55.84 | 54.07 | 52.06 | 49.49 | 43.87 |

| ΔM=MH-ML (dN.m) | 34.84 | 40.69 | 39.45 | 40.84 | 41.97 | 41.18 | 38.61 | 36.23 |

| Scorch time, Ts2 (min/s) | 10/0 | 10/0 | 8/30 | 8/0 | 7/30 | 7/0 | 7/0 | 6/3 |

| Cure time, T90 (min/s) | 22/30 | 22/30 | 20/30 | 22/30 | 21/30 | 23/00 | 22/30 | 20/0 |

| Cure rate, V (%/min) | 8.0 | 8.0 | 8.3 | 6.9 | 7.1 | 6.3 | 6.5 | 7.4 |

It is known that the minimum torque, determined using a Moving Die Rheometer, gives an idea of the viscosities of the investigated rubber compounds. It can be seen from Table 3 that the value of the minimum torque (ML) of the compound containing no silane coupling agent (S0) is about 12 dN.m. The minimum torque of compounds containing from 1.0 to 3.0 phr TESPT (S1, S2, and S3) does not change with the increase in the amount of the silane coupling agent, and its value is about 15.0 dN.m. The increase in the amount of the silane coupling agent in the compounds, from 4.0 to 7.0 phr TESPT (S4, S5, S6, and S7), leads to a reduction of the minimum torque, respective to the viscosities of the rubber compounds studied. It is obvious that the compound containing the greatest amount of TESPT (S7) has the lowest minimum torque (ML) value. Although the viscosity of the rubber compounds is lower in the presence of greater amounts of the silane coupling agent (S4, S5, S6, and S7), it is obvious that it is commensurate with that of the compound containing no TESPT (S0). This is an indirect evidence that a reaction is taking place between the epoxy group of ENR and the silanol group of silica, which, in turn, improves the dispersion of the filler particles in the rubber matrix, even in the presence of lower amounts of organosilane.

It is considered that the difference between the maximum and minimum torque (ΔM) gives an idea of the cross-link density. It can be seen from Table 3 that the ΔM value of the compound containing no TESPT (S0) is the lowest one – about 35.0 dN.m. The ΔM values of compounds containing from 1.0 to 5.0 phr TESPT (S1–S5) do not change substantially with the increase of the silane coupling agent amount and vary in the range from 39.5 to 42.0 dN.m. In this case, the values of ΔM are about 20% higher than that of the compound containing no TESPT (S0).

In terms of the scorch time (Ts2), a clearly expressed trend is observed – Ts2 decreases with increasing amount of silane coupling agent in the compounds. Therefore, the Ts2 of the TESPT-free compound (S0) is around 10 min, and that of the compound containing the greatest amount of TESPT (S7) is around 6 min 30 s. This could be explained with the assumption that only part of the silanol groups of silica interacts with the epoxy groups of ENR, and the remaining free silanol and epoxy groups interact with the functional groups of the accelerator, causing a prolonged scorch time [8].

From Table 3, it can be seen that the cure time (T90) of the rubber compounds does not change substantially according to the absence or presence of various amounts of TESPT and is in the order of 20–23 min.

3.2 Mechanical properties

The mechanical properties of the investigated ENR composites are summarized in Table 4.

Mechanical properties of the investigated rubber composites.

| S0 | S1 | S2 | S3 | S4 | S5 | S6 | S7 | |

|---|---|---|---|---|---|---|---|---|

| Modulus 100, M100 (MPa) | 7.8 | 9.6 | 10.2 | 10.5 | 10.9 | 12.4 | 11.1 | 10.9 |

| Modulus 300, M300 (MPa) | – | – | – | – | – | – | – | – |

| Tensile strength, σ (MPa) | 20.5 | 20.2 | 20.7 | 17.1 | 19.4 | 20.2 | 17.2 | 18.6 |

| Elongation at break, ε1 (%) | 225 | 190 | 190 | 155 | 170 | 160 | 155 | 150 |

| Residual elongation, ε2 (%) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Shore A hardness | 88 | 88 | 88 | 87 | 87 | 86 | 86 | 87 |

| Abrasion (mm3) | 155 | 160 | 145 | 155 | 150 | 135 | 130 | 145 |

It can be seen from Table 4 that the vulcanizates of the mixture containing no TESPT (S0) have the lowest value of modulus 100 (M100) – about 7.8 MPa. The M100 values of the vulcanizates based on mixtures containing from 1.0 to 5.0 phr TESPT (S1–S5) increased with increasing amount of the silane coupling agent. In this case, the values of M100 are around 20–60% higher than that of the vulcanizates containing no organosilane (S0). An insignificant reduction in the values is observed at a concentration of >5.0 phr TESPT (S6, S7). It is apparent from Table 4 that modulus 300 is not reached for all studied vulcanizates.

In terms of tensile strength (σ), vulcanizates of all the tested rubber compounds have commensurate values, and no trend is observed in σ alteration of the vulcanizates with the increase of the amount of silane coupling agent in the composition of their compounds.

The vulcanizates of the mixtures containing no TESPT (S0) have the highest value of elongation at break (ε1) – 225%. The vulcanizates of mixtures containing different amounts of TESPT have lower values of ε1, varying from 150% to 190%, without a clearly expressed trend of ε1 alteration with the increasing amount of organosilanes in the mixtures.

It can be seen from Table 4 that the residual elongation (ε2) of the vulcanizates of the investigated rubber compounds is not affected by the amount of the silane coupling agent, and its value is the same for all vulcanizates (5%). The Shore A hardness of all vulcanizates varies within the range of 86–88 relative units.

The abrasion values of vulcanizates of rubber compounds studied vary in the range between 130 and 160 mm3, not showing a strict trend of dependence on the amount of the silane coupling agent in the mixtures. However, it could be noted that the vulcanizates of rubber compounds containing 5.0 and 6.0 phr TESPT (S5 and S6) have the lowest values of abrasion.

The data about the mechanical properties of the vulcanizates of rubber compounds studied indicate that the best complex of properties (modulus 100, tensile strength, elongation at break, and abrasion) is observed in composites containing 5.0 phr TESPT (S5). The data obtained also indicate that although the interaction between the epoxy groups of ENR and the silanol groups of silica through the hydrogen bonds improves the dispersion of filler in the rubber matrix, to obtain vulcanizates with good mechanical properties, the presence of some amount of silane coupling agent is necessary.

3.3 Dynamic mechanical properties

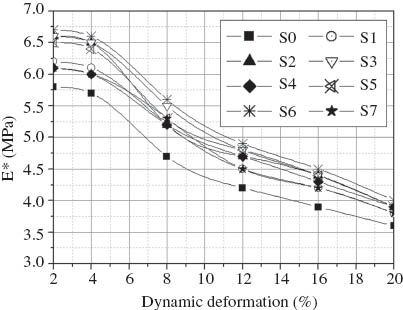

The filler dispersion in the rubber mixtures has an important effect on the dynamic properties of the vulcanizates and particularly on the heat build-up that corresponds to the rolling resistance of tires. Figure 2 presents the complex dynamic modulus (E*) of the composites studied as a function of the dynamic deformation determined on a Goodrich flexometer.

Dynamic mechanical properties: complex dynamic modulus (E*) of the studied composites as a function of dynamic deformation.

Figure 2 shows that the vulcanizates of the rubber compound containing no TESPT (S0) have the lowest values of the complex dynamic modulus (E*) for all dynamic deformations studied. The E* values of vulcanizates of compounds from S1 to S7, containing various amounts of the silane coupling agent (TESPT), are higher by 5–15% than the E* values of the vulcanizates of the mixture without TESPT (S0). However, no clearly expressed trend is observed in the alteration of E* values of the vulcanizates of mixtures S1 to S7 with the increase of organosilane amount. It is apparent from Figure 2 that the decrease in the complex dynamic modulus (E*) of the vulcanizates of the rubber mixture without TESPT (S0), with the increase of dynamic deformation (Payne effect), is higher than that of the vulcanizates containing the silane coupling agent. The filler-filler interaction in the absence of the silane coupling agent is stronger. At lower values of the dynamic deformation (up to 4%), the filler-filler structure is preserved and the E* values remain relatively high. However, with increasing dynamic deformation, the filler-filler structure collapses and the E* values decrease drastically. The phenomenon is accompanied by a higher heat build-up.

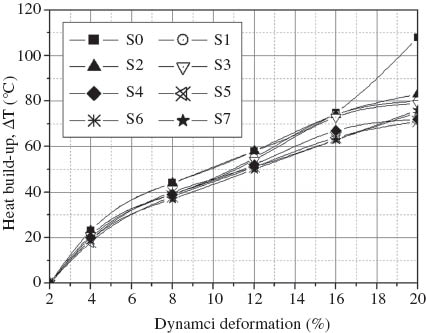

Figure 3 presents the dependence of the heat build-up on the dynamic deformation for the vulcanizates based on the studied compounds, as determined by using a Goodrich flexometer. It can be seen from Figure 3 that the heat build-up data of the investigated vulcanizates are in complete compliance with their complex dynamic modulus. The heat build-up increases with the increase of dynamic deformation. The values of the heat build-up of the vulcanizates of compounds S1 to S7, containing TESPT in different amounts, are commensurate with each other throughout the tested interval. Upon dynamic deformations up to 16%, the heat build-up value of the vulcanizates from the mixture containing no TESPT (S0) is commensurate with those of the vulcanizates containing the silane coupling agent. However, it is obvious that upon dynamic deformations >16%, the heat build-up of the vulcanizates of the mixture containing no TESPT (S0) is greater than that of the vulcanizates from compounds containing organosilane. Thus, upon the highest tested deformation (20%), the value of heat build-up for the vulcanizate of the mixture containing no TESPT (S0) is about 30% higher than those of the vulcanizates from all compounds containing the silane coupling agent.

Dynamic mechanical properties: heat build-up of the studied composites as a function of dynamic deformation.

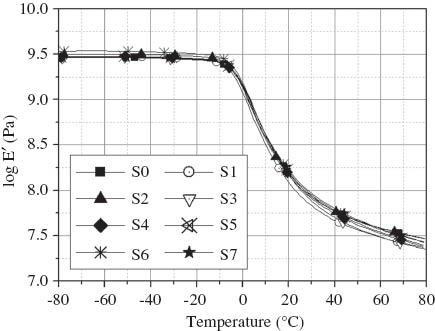

The properties measured by dynamic mechanical thermal analysis (DMTA) were the dynamic storage modulus (E′) and the mechanical loss angle tangent (tan δ). Figure 4 presents the temperature dependence of the storage modulus (E′) of the composites based on the studied ENR composites. Figure 4 shows that all vulcanizates studied are in a glassy state in the temperature range from -80°C to 0°C. In this temperature range, there are no essential differences observed in the values of dynamic storage modulus (E′) according to the quantity of silane coupling agent used in the mixtures, as well as to the temperature change. The decrease of storage modulus with temperature increase, i.e., the transition from a glassy to a rubbery state, occurs at a temperature of about -5°C. In the temperature range from 0°C to 80°C, when the tested samples are in a rubbery state, the values of the storage modulus of vulcanizates of all rubber mixtures studied are completely commensurate and do not depend on the amount of the silane coupling agent in the compounds.

Dynamic mechanical properties: dependence of the storage modulus (E′) on the temperature of the investigated composites.

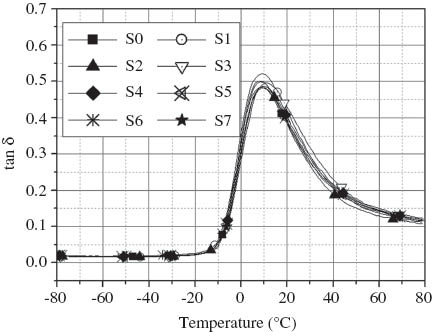

The mechanical loss angle tangent (tan δ), being the ratio between the dynamic loss modulus (E″) and dynamic storage modulus (E′) (tan δ=E″/E′), illustrates the macromolecules’ mobility as well as the phase transitions in the polymers. Noteworthy is the temperature dependence of tan δ, as tan δ at 60°C is considered to correspond to the tire rolling resistance, whereas tan δ at 0°C corresponds to the wet grip. Figure 5 presents the dependence of the mechanical loss angle tangent (tan δ) on the temperature of the investigated composites.

Dynamic mechanical properties: dependence of the mechanical loss angle tangent (tan δ) on the temperature of the investigated composites.

Figure 5 shows that in the whole temperature range, the values of tan δ of the vulcanizates of all rubber compounds tested are entirely commensurate between themselves in spite of the differences in the silane coupling agent amount in their composition. It is known that the tan δ peak corresponds to the glass transition temperature of the investigated vulcanizates. It can be seen from Figure 5 that the glass transition temperature (Tg) of all vulcanizates does not change essentially according to the amount of organosilane in the compounds, and is in the order of +5°C to +10°C.

The data obtained show that the best complex of dynamic properties [complex dynamic modulus (E*), heat build-up, dynamic storage modulus (E′), and tan δ] is observed with the composites containing 5 phr TESPT. The results obtained indicate that although the interaction between the epoxy groups of ENR and the silanol groups of silica through hydrogen bonds improves the filler dispersion in the rubber matrix, to obtain vulcanizates with good dynamic properties, the presence of some quantity of silane coupling agents is necessary.

4 Conclusions

We studied the influence of different amounts TESPT on the vulcanization characteristics and mechanical and dynamic properties of rubber compounds and vulcanizates based on ENR (Epoxyprene 50). The results obtained indicate that although the interaction between the epoxy groups of ENR and the silanol groups of silica through hydrogen bonds improves the dispersion of filler in the rubber matrix, the presence of some quantity of silane coupling agents is necessary to obtain rubber compounds and vulcanizates with good vulcanization characteristics and mechanical and dynamic properties. According to the data obtained, the quantity of the silane coupling agent in the mixtures based on ENR (containing 50±2% epoxy groups) filled with silica can be reduced by 30%.

Acknowledgments

The present research is a result of an international collaboration program between University of Tabuk, Tabuk, Kingdom of Saudi Arabia, and the University of Chemical Technology and Metallurgy, Sofia, Bulgaria. The authors gratefully acknowledge the financial support from the University of Tabuk.

References

[1] Flanigan CM, Beyer L, Klekamp D, Rohweder D, Stuck B, Terrill ER. Rubber World 2012, 245, 18–31.Search in Google Scholar

[2] Chapman AV. In 24th International H.F. Mark-Symposium, ‘Advances in the Field of Elastomers & Thermoplastic Elastomers’, November 15–16, 2007, Vienna.Search in Google Scholar

[3] Das A, Debnath SC, De D, Basu DK. J. Appl. Polym. Sci. 2004, 93, 196–200.10.1002/app.20452Search in Google Scholar

[4] Varughese S, Tripathy DK. J. Appl. Polym. Sci. 1992, 44, 1847–1852.10.1002/app.1992.070441019Search in Google Scholar

[5] Xu HY, Liu JW, Fang L, Wu CF. J. Macromol. Sci. Pt B Phys. 2007, 46, 693–703.10.1080/00222340701388854Search in Google Scholar

[6] Luo YY, Wang YQ, Zhong JP, He CZ, Li YZ, Peng Z. J. Inorg. Organometal. Polym. Mater. 2011, 21, 777–783.10.1007/s10904-011-9539-xSearch in Google Scholar

[7] Sengloyluan K, Sahakaro K, Dierkes WK, Noordermeer JWM. Eur. Polym. J. 2014, 51, 69–79.10.1016/j.eurpolymj.2013.12.010Search in Google Scholar

[8] Bachmann JH, Sellers JW, Wagner MP, Wolf RF. Rubber Chem. Technol. 1959, 32, 1286–1391.10.5254/1.3542491Search in Google Scholar

©2016 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Original articles

- Influence of bis(triethoxysilylpropyl) tetrasulfide amount on the properties of silica-filled epoxidized natural rubber-based composites

- Microstructure-based modeling of the dynamic mechanical properties of SiCp/Al composites

- Effect of moisture content of jute fabric and hybridization structure on the impact properties of jute and jute/glass hybrid composites

- Synthesis, characterization and formulation of sodium calcium silicate bioceramic for drug delivery applications

- Synthesis of iron nanocomposite reinforced by TiC particles via mechanical activation from ilmenite concentrate and carbon black

- The effect of an excessive amount of carbon nanotubes on the properties of zinc oxide-carbon nanotube nanocomposites

- Microstructure and erosion characteristics of Ni-AlN thin films prepared by electrodeposition

- Study on the preparation and characterization of high-dispersibility nanosilica

- Comparing the influence of different kinds of zirconia on properties and microstructure of Al2O3 ceramics

- Structure of intercalated organic montmorillonite and its pyrolysis properties analyzed using the Agrawal integral equation

- Prediction, modeling and characterization of surface texturing by sulfuric etchant on non-toxic titanium bio-material using artificial neural networks and fuzzy logic systems

- Investigation of the WEDM of Al/B4C/Gr reinforced hybrid composites using the Taguchi method and response surface methodology

- A low-cost fiberglass polymer resin dielectric material-based microstrip patch antenna for multiband applications

- Free vibration analysis of axially layered functionally graded short beams using experimental and finite element methods

- Physical properties and microstructures of a BN-NiCoCrAlY laser amorphous-nanocrystal reinforced composite coating

Articles in the same Issue

- Frontmatter

- Original articles

- Influence of bis(triethoxysilylpropyl) tetrasulfide amount on the properties of silica-filled epoxidized natural rubber-based composites

- Microstructure-based modeling of the dynamic mechanical properties of SiCp/Al composites

- Effect of moisture content of jute fabric and hybridization structure on the impact properties of jute and jute/glass hybrid composites

- Synthesis, characterization and formulation of sodium calcium silicate bioceramic for drug delivery applications

- Synthesis of iron nanocomposite reinforced by TiC particles via mechanical activation from ilmenite concentrate and carbon black

- The effect of an excessive amount of carbon nanotubes on the properties of zinc oxide-carbon nanotube nanocomposites

- Microstructure and erosion characteristics of Ni-AlN thin films prepared by electrodeposition

- Study on the preparation and characterization of high-dispersibility nanosilica

- Comparing the influence of different kinds of zirconia on properties and microstructure of Al2O3 ceramics

- Structure of intercalated organic montmorillonite and its pyrolysis properties analyzed using the Agrawal integral equation

- Prediction, modeling and characterization of surface texturing by sulfuric etchant on non-toxic titanium bio-material using artificial neural networks and fuzzy logic systems

- Investigation of the WEDM of Al/B4C/Gr reinforced hybrid composites using the Taguchi method and response surface methodology

- A low-cost fiberglass polymer resin dielectric material-based microstrip patch antenna for multiband applications

- Free vibration analysis of axially layered functionally graded short beams using experimental and finite element methods

- Physical properties and microstructures of a BN-NiCoCrAlY laser amorphous-nanocrystal reinforced composite coating