Abstract

The textile industry contributes significantly to the expansion of the world economy, however, it is also notorious for producing large amounts of trash and harming the environment. Effective waste management techniques depend on having a thorough understanding of the forms and makeup of waste from the textile sector. The objective of this paper is to study effluent wastewater technologies to efficiently treat and control the wastewater produced during textile production operations. It is well known that the textile industry generates vast amounts of wastewater, some of which may be contaminated with heavy metals, chemicals, dyes, and organic compounds. This effluent can have serious negative effects on the environment if it is not adequately treated, including contaminating soil and water sources, removing aquatic life, and possibly endangering human health. Due to the inclusion of dyes, heavy metals, and other chemicals, the discharge of untreated or improperly treated effluent from textile processes leads to water contamination. Textile waste can leak hazardous compounds into the environment and contaminate the soil, both of which have an impact on air quality. The environmental impact of the textile industry is further exacerbated by the energy and resource use involved in production. At several points in the textile supply chain, waste is generated. Fibre trimmings, fly waste, and yarn waste are produced during the fibre production, spinning, and weaving operations. There are numerous ways and technologies for treating wastewater, including advanced oxidation processes (AOPs), biological treatment systems, and membrane-based technologies. The formation of eco-friendly materials and advancements in recycling technology help to make the textile industry more closed-loop and sustainable. In conclusion, managing waste from the textile sector is a significant environmental concern that calls for creative solutions and environmentally friendly procedures.

1 Introduction to textile industry waste

The textile sector is a pillar of global manufacturing, generating a wide range of goods from apparel and home textiles to industrial materials that we rely on every day. However, the industry’s quick expansion and size have come at a hefty price: the production of a lot of garbage. Waste from the textile industry has become a significant environmental and social problem that demands a thorough understanding and practical management techniques. Pre- and post-consumer waste are both included in the textile industry’s variety of sorts and sources. Manufacturing procedures produce pre-consumer waste, which includes the dumping of textile offcuts, wasted raw materials, and unsold inventories. Conversely, post-consumer waste includes used clothing and textiles, illustrating the difficulties in disposing of and recycling them. The waste stream generated by the sector poses a danger to ecological systems and natural resources due to its impact on greenhouse gas emissions, air, water, and soil pollution, along with its role in climate change. 1 Additionally, the textile industry’s high consumption of electricity and resource depletion exacerbates these environmental problems. Even though these difficulties can seem overwhelming, the need for reform is being more acknowledged in the sector. Various tactics are utilised in current waste management practises, such as upcycling, recycling, and trash reduction programmes.

To develop efficient waste management programmes and promote sustainable practises, cooperation between industry players, governments, and consumers is essential. The textile sector’s waste environment is changing dramatically because of innovation and new technology. A more sustainable and responsible future is possible because of improvements in textile recycling technologies, the manufacturing of biodegradable and sustainable materials, and the incorporation of digital supply chain transparency systems. 2 Frameworks for policy and regulation offer another crucial basis for tackling textile waste on a worldwide scale. Waste reduction and the promotion of more sustainable consumption habits are made possible through awareness-raising campaigns and initiatives. It is also important to consider the social and economic effects of waste generated by the textile industry. The sector frequently uses low-cost labour, which leads to abusive working conditions for employees, especially in developing nations. Due to inappropriate treatment and disposal of waste materials, communities living close to textile production plants run the danger of harming their residents’ health and safety. The potential for recycling and recovery is further hampered by the financial expenses associated with ineffective waste management, which results in wasted chances for sustainability and circularity.

1.1 Types and composition of textile industry waste

Waste generation is a common and complicated problem in the textile business that needs careful consideration and efficient management techniques. Establishing focused strategies to address this dilemma requires an understanding of the many forms and makeup of textile industry waste. Pre-consumer waste and post-consumer waste are the two primary categories of textile industry waste. While post-consumer waste includes discarded textiles and clothing from end users, pre-consumer waste is trash produced throughout the production processes within the business itself. 3 Pre-consumer waste is produced throughout several phases of the textile production process, including the growth of fibres, spinning of yarn, knitting or weaving of the fabric, dying and printing of textiles, and the production of clothing. This waste can appear in a variety of ways, including textile trims, offcuts, scraps, and rejected materials. Excess raw materials, incomplete items, and unsold inventories are also included. Depending on the precise procedures involved, pre-consumer waste can have a variety of different compositions, but it often includes fibres, textiles, dyes, chemicals, and packaging materials. Textiles and clothing that have outlived their usefulness and are abandoned by customers are included in post-consumer waste. This waste stream is affected by things including shifting customer preferences, product durability, and fashion fads. It comprises things that are no longer wanted or useful, including clothes, textiles for the home, and accessories. Post-consumer trash is made up of a variety of sophisticated materials, including natural, synthetic, and mixed fibre types, fabric structures, dyes, finishes, and trimmings. 4 It also comprises additional components like buttons, zippers, and labels that are affixed to textiles. Chemicals and hazardous materials used in textile production processes also have an impact on the makeup of waste from the textile industry. This comprises chemicals utilised to accomplish desired colour, texture, and performance qualities, such as dyes, bleaches, finishing agents, and others. Additional environmental and health risks might emerge from improper handling and disposal of these compounds.

1.2 Challenges and issues surrounding textile industrial waste

The worldwide textile industry continues to expand, and the problems and challenges related to industrial waste from textile production have become more urgent. The sector confronts major challenges in controlling and reducing the environmental and social effects of waste creation because of its enormous scale and intricate supply systems. Industrial waste from the textile industry poses a variety of problems in many different areas. The industry’s massive amount of trash production comes first. The textile business produces a stunning quantity of waste at every level, from the extraction of raw materials through production procedures and end-of-life disposal. This includes waste items including fabric scraps, trims, returned goods, and worn-out clothing. This massive amount of garbage management and processing is a significant logistical problem that calls for creative solutions. Numerous materials, including various kinds of fibres, textiles, dyes, chemicals, and accessories, are included in the waste stream. The handling of trash is further complicated by the inclusion of dangerous materials such as poisonous finishing chemicals and dyes. It is difficult to dispose of or recycle these materials in an eco-friendly way and this calls for careful assessment of their possible effects on ecosystems and public health. 5 The textile business is a worldwide one, which presents difficulties in managing waste. Waste produced in one place frequently ends up being transferred to and treated in another because industrial and supply networks sometimes span many nations. Inefficiencies, higher transportation emissions, and significant legal and regulatory issues concerning trash import and export are all possible outcomes of this. Significant challenges that need to be overcome include coordinating waste management initiatives across international borders and ensuring that rules are followed. Textile manufacturing waste is also linked to social and financial problems. The sector is well recognised for its labour-intensive nature, frequently hiring employees from poor nations with little funding for worker safety and waste management. 6 Workers and the surrounding communities may be in danger of health and safety issues if garbage is handled improperly. Manufacturers, companies, and retailers all need to implement initiatives to encourage sustainable practises, such as waste reduction, recycling, and circular economy models. Governments and regulatory agencies are essential to the implementation of laws and rules that encourage ethical waste management practises.

1.3 Environmental impact of textile industry waste

The textile industry, despite its well-known global reach and massive manufacturing capacity, has an impact on the environment. The effects of the textile industry’s waste on the environment are among its biggest problems. The sector produces a significant quantity of trash that presents serious risks to ecosystems and natural resources, starting with the extraction of raw materials and ending with the disposal of end-of-life goods. Waste from the textile sector has a wide-ranging and complex influence on the environment. In the beginning, raw materials including cotton, wool, synthetic fibres, and colours are extracted and processed. Large amounts of water, energy, and other natural resources are used in these processes, which results in resource depletion and environmental damage. Pollution is one of the waste products of the textile industry that is most problematic for the environment. Aquatic ecosystems may suffer greatly if dangerous chemicals, dyes, or finishing compounds are released into bodies of water, such as rivers and seas. These contaminants can linger in the environment, causing long-term harm and posing threats to both human and marine life health. Another substantial environmental consequence of textile industry waste is resource use.

Resources are strained due to the industry’s high demand for water, electricity, and raw materials. Processes that need a lot of water, such as dyeing and finishing, make water scarce in areas already under water stress. The exploitation of raw materials depletes finite resources and disturbs ecosystems, especially when using non-renewable resources like petroleum for synthetic fibres. 7 A comprehensive approach is needed to address the environmental effects of textile sector waste. It is important to undertake efforts to lower waste creation through improved production planning, material economy, and waste reduction techniques. Initiatives for recycling and upcycling textile waste can prevent it from ending up in landfills and save precious resources. Additionally, adopting sustainable practises can reduce the discharge of harmful elements into the environment by using eco-friendly chemicals and dyes. Additionally, textile waste that is dumped in landfills adds to the release of greenhouse gases, particularly methane, a powerful climate change contributor. While burning synthetic fibres emits carbon dioxide and other hazardous pollutants into the environment, decomposing natural fibres in landfills produces methane. The delicate equilibrium of our planet’s climatic systems is further upset by these greenhouse gases, which also accelerate global warming.

2 Waste generation in different stages of the textile supply chain

The manufacture, distribution, and consumption of textiles are all part of a complex network of activities and people known as the textile supply chain. Waste is produced at every level of this supply chain, which adds to the severe environmental and social problems the textile sector faces. The production of fibres, the creation of textiles, the creation of apparel, distribution, retail, and consumer usage are the main steps of the textile supply chain. Waste is produced at each of these stages for a variety of reasons, such as process inefficiencies, material excesses, and end-of-life disposal. Analysing waste creation along the whole supply chain reveals particular possibilities and difficulties for resource optimisation and waste reduction. For instance, large volumes of plant waste, including leaves, stems, and seeds, are produced while growing cotton. 8 Similar to how waste materials including fibre trash and dust can be produced during the spinning and combing of fibres, processing of fibres can also produce waste products. Waste is produced during procedures including weaving, knitting, dyeing, printing, and finishing in the later stages of textile manufacture. Offcuts, trimmings, scraps, and rejected items made of cloth are included in this trash. Additionally, utilising too many dyes, chemicals, and water during the dyeing and finishing operations can cause waste to be produced and damage the environment.

Another stage in the textile supply chain that adds to waste formation is garment fabrication. Cutting and stitching operations can produce leftover trimmings, thread waste, and pieces of fabric. Overproduction and ineffective production planning can result in excess inventory and unsold clothing, which adds to waste. 9 Plastic bags and cardboard boxes among other packaging trash are produced during the distribution and retail phases. In addition, the fashion industry’s rapid speed and the quick changes in customer demand may lead to the disposal of unsold or out-of-date inventory, which adds to the waste stream. Finally, waste originates at the consumer use stage when clothing and textiles that have reached the end of their life cycle are discarded. Clothing, home textiles, and accessories that are no longer desirable or functional are included in this post-consumer trash. To establish focused waste management plans, it is essential to understand the sources and types of waste produced at various levels of the textile supply chain. Trash creation can be reduced, resources can be conserved, and environmental effects can be lessened by putting practises such as trash reduction, recycling, and circular economy models into practise. To establish a more sustainable and ethical textile supply chain, industry players, politicians, and consumers must work together.

2.1 Textile processing industry and textile sludge waste generation

Involving several chemical and mechanical processes, the textile processing sector is essential in converting raw materials into finished textiles. However, a lot of times these procedures produce a lot of waste, including textile sludge. Textile sludge is a byproduct of wastewater treatment in textile processing plants. It is sometimes referred to as textile effluent treatment plant (ETP) sludge. To obtain desired colour, texture, and performance attributes for textiles, the textile processing business includes a wide variety of operations, including dyeing, printing, finishing, and other treatments. 10 These procedures require a variety of chemicals, dyes, and auxiliary substances, which produces wastewater that needs to be treated before being discharged. If discharged into the environment untreated, textile effluent contains suspended particles, dissolved chemicals, colourants, and other contaminants that are hazardous to the ecosystem. Effluent treatment plants (ETPs) are commonly present in textile processing units to reduce their negative environmental effects. Before being released into water bodies or recycled, these treatment facilities work to remove or minimise the number of toxins in the wastewater. Solid waste components that are present in the wastewater settle down and build up as sludge throughout the treatment process. This complex combination of organic and inorganic materials, sometimes referred to as textile sludge or ETP sludge, contains leftover dyes, chemicals, fibres, and other pollutants. It is frequently described as having a high moisture content and being challenging to handle.

Waste management is made more difficult by the production of textile sludge. First off, depending on how large the activities are for processing textiles, sludge production might be rather large. Such massive amounts of sludge need to be handled and disposed of with appropriate infrastructure and substantial resources. To avoid contaminating soil and water resources, leftover contaminants including chemicals and dyes must be handled carefully. The difficulties with transportation, storage, and treatment are exacerbated by the high moisture content of the sludge. Concerns have also been raised about textile sludge’s effects on the environment. Sludge’s volume and moisture content may be reduced by the application of modern treatment techniques, such as sludge dewatering and drying procedures, making it easier to dispose of or repurpose. For the proper processing and disposal of textile sludge, industry standards and regulatory procedures are also essential. Sludge formation at the source can be reduced by promoting the utilisation of cleaner industrial techniques, such as lowering the use of water and chemicals.

2.2 Regulatory framework and compliance requirements for textile industry waste

The textile industry has a big influence on the environment and society because of its massive output and international supply networks. In recent years, there has been an increased emphasis on finding solutions for the environmental and social problems brought on by the waste produced by the textile industry. At the national and international levels, numerous regulatory frameworks and compliance requirements have been devised to control and minimise these effects. The operation of the textile industry in a socially and ecologically responsible way is crucially dependent on regulatory frameworks and compliance requirements. With the objective of minimising adverse effects on the environment and human health, these rules include recommendations and standards for waste management, pollution control, and worker safety. Governments from all across the world have enacted laws and rules that are particular to the textile industry. These rules cover a wide variety of topics, such as worker safety, usage of chemicals, waste management techniques, and wastewater treatment. They frequently impose restrictions on the amount of pollutants that may be released, detail the specifications for effluent treatment plants (ETPs), and enforce the implementation of best practises for waste minimization, recycling, and disposal. The regulation of waste from the textile sector is also significantly influenced by international frameworks and agreements. For instance, the Sustainable Development Goals (SDGs) of the United Nations stress the significance of ethical production and consumption while emphasising the necessity of sustainable practises and waste minimization. Furthermore, the transboundary movement of hazardous waste, including specific forms of textile waste, is covered by international treaties including the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal.

However, the textile business may have difficulties in complying with legal standards. The worldwide character of the sector, with manufacturing and supply chains spanning several nations, sometimes leads to complicated compliance requirements and differences in rules between jurisdictions. Manufacturers and brands may have logistical and administrative difficulties in ensuring uniform compliance throughout the supply chain. 11 In addition, the textile industry’s dynamic character and the constantly changing technology and materials it uses provide continual difficulties for regulatory regimes. To successfully address evolving environmental and health risks, new chemicals, fibres, and manufacturing techniques necessitate constant updates and modifications to regulatory standards. Regulatory frameworks are crucial for providing guidance, but they should be reinforced by industry-wide efforts and voluntary standards. Manufacturers, brands, retailers, and industry groups working together may promote responsible waste management practises beyond the requirements of the law. Structures for sustainability and ethical manufacturing methods are provided by voluntary certifications which include the Global Organic Textile Standard (GOTS) and the Sustainable Apparel Coalition’s Higg Index.

2.3 Successful implementation of wastewater technologies in the textile industry

The textile sector is widely recognised for having a substantial negative influence on the environment, especially in terms of pollution and wastewater development. Ecosystems and human health may suffer if effluent from textile manufacturing facilities is dumped after being insufficiently or improperly cleaned. However, resolving these issues and fostering sustainable practises within the sector may be greatly aided by the effective application of wastewater solutions. Water is essential to several operations in the textile business, such as dyeing, printing, and finishing. As a result, the sector produces substantial amounts of wastewater that are tainted with contaminants including dyes, chemicals, and suspended particulates. This effluent can pollute water bodies, reduce oxygen levels, and kill aquatic life if it is dumped without sufficient treatment. Wastewater technologies provide efficient ways to cleanse effluents from the textile sector, lessen pollution, and encourage water conservation. These technologies cover a variety of treatment techniques, including physical, chemical, and biological approaches, intended to eliminate or neutralise pollutants and enhance the quality of water released. The textile sector gains greatly from wastewater solutions when they are successfully implemented. The total operational effectiveness of textile processing units can also be increased by the adoption of wastewater technology. Despite the advantages, there are obstacles to integrating wastewater solutions in the textile sector. The large variety of contaminants found in wastewater and the complexity and diversity of textile processes make it essential to determine the right treatment technologies and tailor them to the unique needs of the process. Challenges might arise from financial factors. 12 A substantial expenditure in infrastructure, gear, and qualified employees is frequently needed to implement modern wastewater treatment systems. It may be challenging for smaller textile businesses or those located in resource-constrained areas to embrace these technologies. The successful use of wastewater technology also depends on knowledge transfer and capacity building. Programmes for training and teaching are required to guarantee the correct operation and upkeep of treatment systems and to increase knowledge of the significance of wastewater management among industrial stakeholders.

3 Need and importance of wastewater technologies in the textile industry

The textile industry plays a significant role in the global economy by creating jobs and fostering expansion. It is also acknowledged as one of the most polluting and water-intensive industries, with wastewater development being a major problem. It is impossible to emphasise the value and necessity of wastewater technologies in the textile sector given their critical role in resolving the environmental and social problems related to wastewater discharge. The textile industry is renowned for utilising a lot of water throughout several manufacturing phases, such as fibre preparation, dyeing, printing, and finishing. Due to the high water consumption, a significant amount of wastewater is produced, which comprises a complex mixture of chemicals, dyes, sediments, and other pollutants. This effluent can have serious negative effects on the environment and human health if it is not properly or timely handled, including water pollution, soil contamination, and harm to aquatic ecosystems. 13 The urgent requirement to reduce and mitigate these negative consequences gives rise to the demand for wastewater technology in the textile sector. Technologies for treating wastewater include a variety of procedures intended to minimise or eliminate contaminants, enhance the quality of water released, and guarantee adherence to environmental standards.

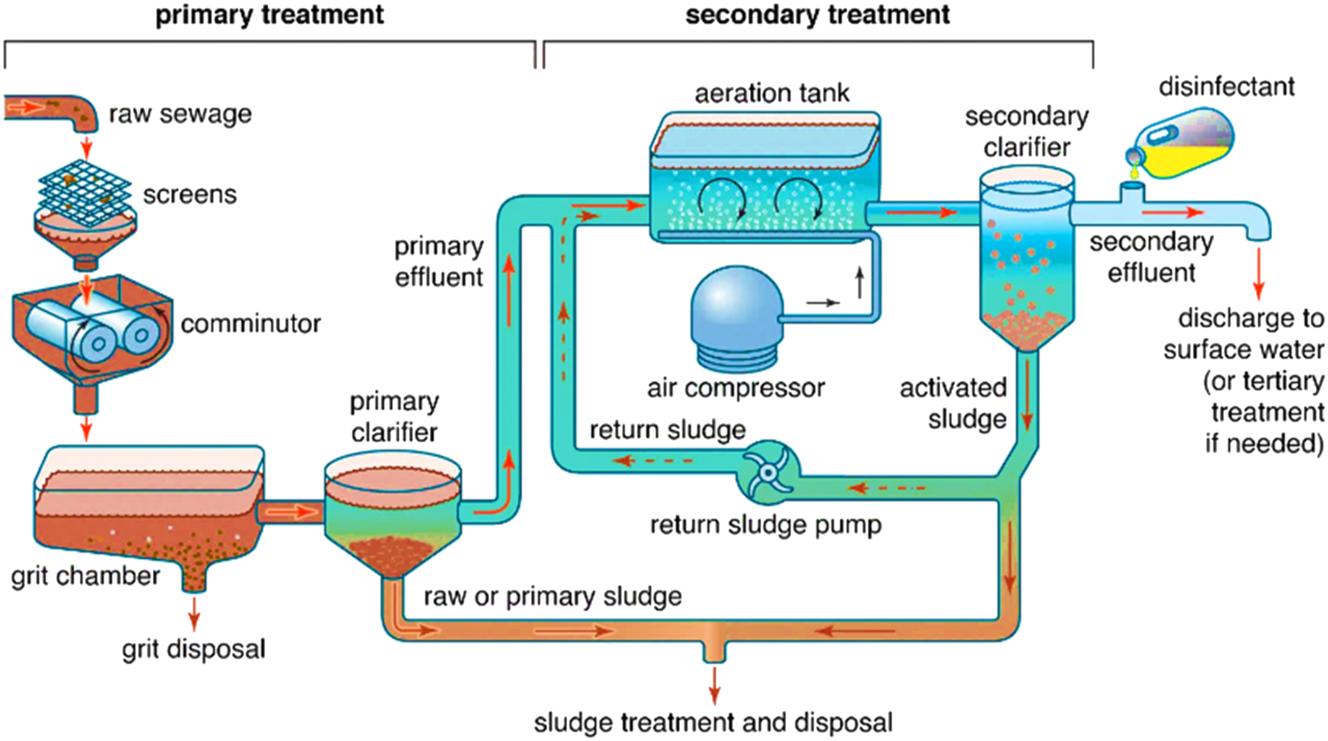

Figure 1 shows the activated sludge process for waste water treatment. The second strategy for managing the wastewater from the textile industry is The iCAP Q inductively-coupled plasma mass spectrometry (iCAP Q ICP/MS) approach has been optimised for the trace measurement of Pb(II) in diverse industrial wastewater effluents. The textile sector must adopt wastewater technology immediately for several reasons. The release of industrial effluents, particularly those from the textile sector, is subject to tight regulations set by governments and regulatory organisations. Textile businesses may comply with these legal standards and avoid fines by implementing efficient wastewater treatment technology. Since high-quality recovered water may be utilised for multiple operations like dyeing and rinsing, water recycling and reuse not only help preserve resources but also improve operational efficiency. 14 The prestige and social responsibility of textile industries are also enhanced by the use of wastewater technology. Businesses that put a high priority on wastewater management and exhibit responsible practises get a competitive edge in the market as sustainability gains popularity among stakeholders, investors, and customers. Consumers are drawn to ethical and environmentally friendly practises, which may foster brand loyalty and a favourable brand reputation. The textile sector faces several difficulties in implementing wastewater technology, nevertheless. Significant infrastructure, equipment, and labour resource expenditures are necessary to implement modern treatment systems. Particularly small and medium-sized textile businesses may experience financial challenges while using these technologies. Additionally, for successful implementation, capacity building and knowledge transfer are crucial. Industry personnel may obtain the information and skills they need to efficiently run and maintain wastewater treatment systems with the aid of training programmes and knowledge-sharing platforms.

Activated sludge process for waste water treatment.

3.1 Sustainable practices and initiatives in textile industry waste reduction

In terms of trash development and disposal, the textile sector has long been linked to serious environmental problems. To minimise waste in the textile sector, however, there has been an increasing awareness of the need for sustainable practises and efforts in recent years. Diverse tactics are being used to reduce waste, advance resource efficiency, and encourage a more sustainable textile sector, from the adoption of cleaner production practises to the implementation of circular economy ideas. The textile sector is renowned for its intricate supply networks, resource-intensive operations, and significant waste generation. 15 Every phase of the textile lifecycle, from fibre production to manufacturing, dyeing, finishing, and consumer disposal, has the potential to produce waste and worsen the environment. To overcome these obstacles and lessen the negative effects of the textile industry’s waste on the environment, it is crucial to embrace sustainable practises and initiatives. Another crucial component of the textile industry’s sustainable waste reduction strategy is the application of circular economy ideas. This entails creating durable products, promoting reuse and repair, and supporting the recycling and upcycling of textile waste. There are several advantages for the textile sector in adopting sustainable practises and waste reduction programmes. Adopting sustainable practises not only satisfies customer expectations but also expands brand loyalty and creates new market prospects. Sustainable waste reduction programmes can also have a positive economic impact. 16 Long-term profitability can be increased as a consequence of decreased costs for raw materials, cheaper disposal costs, and greater operational performance. The adoption of sustainable practises and waste reduction programmes do not, however, come without difficulties. Considering the worldwide supply chain for the textile sector is intricate, encouraging stakeholder cooperation and openness is crucial. It takes efforts to increase awareness among suppliers, manufacturers, retailers, and consumers to get them to adopt sustainable practises.

3.2 Opportunities and innovations for recycling and upcycling of textile waste

The textile sector is well recognised for producing a lot of trash, which makes it a substantial source of worldwide landfill waste and environmental deterioration. The universe of potential and ideas for recycling and upcycling textile waste exist despite these difficulties. Processes for recycling and upcycling waste textiles into useful materials, reducing waste, and fostering a more sustainable and circular economy all present viable possibilities. The environmental problem of disposing of textile waste is urgent. The manufacture, usage, and disposal of textiles according to traditional linear production methods result in resource depletion and waste buildup. However, the textile sector may move towards a more sustainable and circular strategy by embracing recycling and upcycling. Through a variety of procedures, including mechanical recycling, chemical recycling, and fibre-to-fibre recycling, textile waste may be recycled into new raw materials. These procedures disassemble waste textiles into the fibres that make up each one. These individual fibres may then be treated again to create new textile goods. 17 The objective of upcycling, on the other hand, is to utilise inventive and creative design techniques to turn textile waste into higher-value items. Instead of dismantling textiles into their parts, upcycling reuses discarded materials and gives them a new life with value.

The distinctive aesthetics and qualities of upcycled items set them apart from conventional textile products. This strategy encourages creativity, innovation, and customer involvement in addition to waste reduction. There are numerous and varied options for recycling and upcycling textile waste. Companies in the textile industry that support recycling and upcycling may capitalise on this market and set themselves apart by providing cutting-edge, environmentally friendly goods. 18 Furthermore, collaboration and cross-sector alliances are made possible through recycling and upcycling. The creation of integrated systems and value chains is made possible through collaboration with recycling facilities, waste management businesses, designers, and other stakeholders. These partnerships allow for the pooling of knowledge, assets, and infrastructure, which promotes innovation and hastens the implementation of sustainable practises. Scaling up recycling and upcycling projects in the textile business has difficulties, though. Technical difficulties arise when trying to establish effective recycling and upcycling procedures due to the complexity of textile waste, which might vary in content, fibre type, and finishing treatments. The commercial acceptance and long-term viability of recycled or upcycled items depend on the quality and performance of those products.

3.3 Energy recovery from textile industry waste using technologies

Energy recovery technologies provide creative ways to transform textile waste into useful energy sources, lowering the industry’s environmental impact and fostering sustainable business practises. Several energy-intensive processes, including fibre manufacturing, spinning, weaving, dyeing, and finishing, are utilised in the activities of the textile industry. As a result, the sector generates a sizable quantity of trash, such as unused fibres, fabric remnants, and biomass waste. Instead of discarding this trash, it is possible to ameliorate waste management issues, lessen dependency on fossil fuels, and advance a more sustainable energy mix by harnessing its energy potential through recovery technology. 19 Several cutting-edge technologies can be utilised to recover energy from waste produced by the textile industry. Waste-to-energy conversion, which includes transforming textile waste into heat, electricity, or both, is one such strategy.

Modern thermal treatment techniques may effectively convert textile waste into energy-dense products including steam, electricity, or biofuels through incineration, gasification, and pyrolysis. Another energy recovery method uses anaerobic digestion to create biogas, a renewable energy source, from the organic components of textile waste. Bacteria decompose organic materials in a regulated biological process, yielding biogas that is high in methane and may be utilised to generate heat or power. Energy recovery technology usage in the textile sector has several significant advantages. By completing the loop and reincorporating waste materials into the production cycle, energy recovery technologies are in line with the ideas of the circular economy. 20 The widespread utilisation of energy recovery systems in the textile sector, however, faces obstacles. Implementation challenges may arise from technological complexity, budgetary limitations, and regulatory restrictions. It takes coordinated efforts and coordination between industrial stakeholders to develop effective and affordable solutions, ensure the compatibility of various waste streams, and adhere to environmental requirements.

4 Technologies for textile industry wastewater management

With its enormous variety of clothes and fabrics, the textile industry contributes significantly to the world economy. However, this sector is also well known for having a significant negative influence on the environment, particularly in terms of the production of effluent and pollutants. Muhamad et al. 21 examine the potential for using banana peel extract, which is both enzymatic and adsorbent, as a bioremediation agent by assessing its capacity to bind to several reactive colours used in the textile sector. On adsorption capacity, the effects of pH, temperature, dye concentration, polyphenol oxidase and peroxidase enzymes were investigated. The outcome demonstrates that after 24 h of incubation, full adsorption was seen for all concentrations of banana peel extract. The capacity of banana peel to adsorb substances ranged from pH 6 to 11, peaking at 96 % after 24 h. The adsorption capacity grew over time and reached 98 % after 24 h at temperatures higher than 50 C. The strong adsorption ability of banana peel on specific textile colours leads to the conclusion that it can be used as an efficient bioremediation agent.

Azam et al. 22 studied a new solid-phase extraction (SPE) based on treated date pits bio-sorbent. The production of Pb(II) was highest in the battery industry (18.55 g/L), followed by that of iron and steel (14.65 g/L), petroleum (12.38 g/L), printing (5.78 g/L), and textile (3.76 g/L). The recovery percentages ranged from 95 % to 99 %. The outcomes demonstrated the suitability of the proposed technology as a fresh and practical approach for the routine analysis of Pb (II) in industrial wastes. This article examines the most recent developments in wastewater management technology for the textile industry and demonstrates how these developments have the potential to lead to sustainable practices. Textile producers may lessen their environmental impact, preserve water resources, and limit the discharge of hazardous contaminants into the environment by putting these cutting-edge ideas into practice.

4.1 Adsorption and filtration techniques for textile industry wastewater

The wastewater from the textile industry is known to contain several toxins, including dyes, chemicals, suspended particles, and heavy metals, which pose a major threat to aquatic ecosystems and human health. Adsorption and filtration techniques have gained popularity for the treatment of wastewater from the textile industry because they successfully remove contaminants and assist the industry in adhering to stringent environmental criteria. Adsorption is a technique that extracts and gathers pollutants from wastewater using porous materials, sometimes referred to as adsorbents. To treat actual textile wastewater, Badawi et al. 23 watched into the viability of adopting a hybrid treatment system based on coagulation/flocculation, adsorption, and filtration processes. To remove COD, total suspended solids (TSS), colour, total nitrogen (TN), and turbidity from raw textile effluents, ferric chloride (FeCl3) was employed as a coagulant, nano zero-valent iron (nZVI) as an adsorbent, and micro zeolite (MZ) as a filter media. To assess the performance of the integrated treatment system to treat approximately 1.5 L/min of real textile wastewater in about 1.2 h over six operating runs (I, II, III, IV, V, VI), batch and continuous feed scaling-up tests (complete design and set-up studies) were carried out. The acquired results demonstrated improved turbidity, colour, COD, TSS, and TN removal capabilities for all runs. The average removal for COD, TSS, colour, 86.1 % of TN, and 93.5 % of turbidity was 97.5 %, 98 %, 98.4 %, and 98.4 %, respectively. Alardhi et al. 24 investigated three new configurations for the hybrid adsorption-membrane technique (HAMT), which was used to remove the synthetic wastewater-borne methyl green dye (MG). For each system configuration, the effects of feed flow rate (100–200 mL/min), MG concentration (10–50 mg/l), and MCM-41 dose (0.008–0.06 g) were evaluated. The findings demonstrated the importance of the feed flow rate, feed concentration, and MCM-41 dose for MG rejection as well as permeate flux.

4.2 Emerging technologies for sustainable textile wastewater treatment

Wastewater treatment is a crucial part of the transformation the textile industry is going through towards sustainability. Emerging technologies are fundamentally changing wastewater treatment procedures as the demand for eco-friendly textile production rises. These cutting-edge approaches provide effective and sustainable ways to remediate wastewater from the textile sector while reducing its negative environmental effects. Complex contaminants including dyes, chemicals, and organic compounds are frequently left behind by the traditional wastewater treatment techniques used by the textile sector. These techniques also use a lot of water and energy, further taxing already scarce resources. However, there is a renewed focus on sustainable textile wastewater treatment as a result of innovative technologies. Advanced oxidation processes (AOPs), like photocatalysis, electrochemical oxidation, and zonation, are one of the main areas of development. These methods convert organic contaminants into harmless byproducts by using strong oxidants. Biological treatment techniques are not just efficient in terms of energy use and environmental impact.

Alternatives based on nanotechnology are emerging as viable alternatives to AOPs and biological therapies. Adsorption and catalytic degradation capabilities are improved by the special characteristics of nanomaterials like nanoparticles and nanofibers. These substances enhance the general effectiveness of methods used to treat textile wastewater by efficiently removing colours, heavy metals, and other contaminants. Periyasamy et al. 25 addressed the many environmentally friendly wastewater treatment methods, including membrane biological reactors (MBR), electrocoagulation (EC), ultrasonic treatment, granular activated carbon (GAC), advanced oxidation process (AOP), ozonation, and sequencing batch reactors (SBR). In conclusion, there are limitations to the current tools’ suitability. The industry will be able to reduce its environmental impact and adhere to strict regulatory standards by adopting this cutting-edge technology for sustainable textile wastewater treatment. Textile manufacturers may improve the quality of their wastewater treatment and contribute to a cleaner, greener future by putting these cutting-edge strategies into practice.

4.3 Integration of treatment technologies in textile industry wastewater management

The complex composition and wide range of contaminants in the wastewater generated by the textile sector make handling this waste a considerable task. The integration of several treatment methods has come to light as a solution to this problem for effective and long-term wastewater management in the textile sector. This integrated strategy provides improved pollutant removal, increased treatment efficiency, and decreased environmental impact by combining complementing procedures. Biological treatment, chemical coagulation, and primary sedimentation are a few examples of particular treatment procedures that are frequently the focus of traditional wastewater treatment techniques used by the textile industry. These approaches, meanwhile, might not be adequate to deal with the wide variety of contaminants found in textile effluent. The special features and difficulties of the effluents from the textile sector can be addressed by integrating a variety of treatment methods, enabling a holistic and all-encompassing approach to wastewater management.

The integrated Roy et al. 26 model has been established in this work and investigated in the context of the Indian textile sector. It combines environmental process mapping (EPM), decision-making trail and evaluation laboratory (DEMATEL), and analytic network process (ANP). ANP determines the indicators’ weights while DEMATEL describes the cause-and-effect relationship. For the textile sector, indicators including waste production, volatile organic compound (VOC) emission, and energy use are considered to be crucial. Here, technical solutions to the environmental issues relating to CECMIs are suggested. The application of technical solutions leads to a 12 % reduction in waste, a 10 % increase in carbon dioxide emissions, a 90 % increase in nitrogen oxide emissions, and a 5 % increase in energy consumption while improving workplace health (an 8 % and 3 % annual decrease in respiratory and allergy issues, respectively). Panagopoulos et al. 27 demonstrated how MLD and ZLD frameworks are examined and evaluated.

4.4 Different purification techniques for the treatment of textile wastewater

Due to the intricate nature of the contaminants included in the effluent, treating textile wastewater is a significant task for the textile industry. To successfully remove impurities and reduce the environmental impact of textile wastewater, a variety of purification procedures have been produced and put into use to solve this difficulty. These methods cover a variety of physical, chemical, and biological procedures and provide specialised treatments for certain contaminants in textile industry effluents. If released without treatment, textile wastewater contains a variety of contaminants that can be detrimental to ecosystems and human health, including dyes, chemicals, suspended particles, and organic compounds. To effectively treat specific contaminants, a variety of purifying procedures have been devised. Sedimentation, filtration, and flotation are examples of physical treatment methods that concentrate on separating and removing suspended solids and big particles from wastewater. The separation of solids and oils from wastewater can be accomplished using flotation, sedimentation, and filtration, which entail passing wastewater through porous media to catch suspended materials. A facility that uses a combination of several methods (such as physical, chemical, and biological) to treat industrial effluent and remove contaminants is referred to as a wastewater treatment plant.

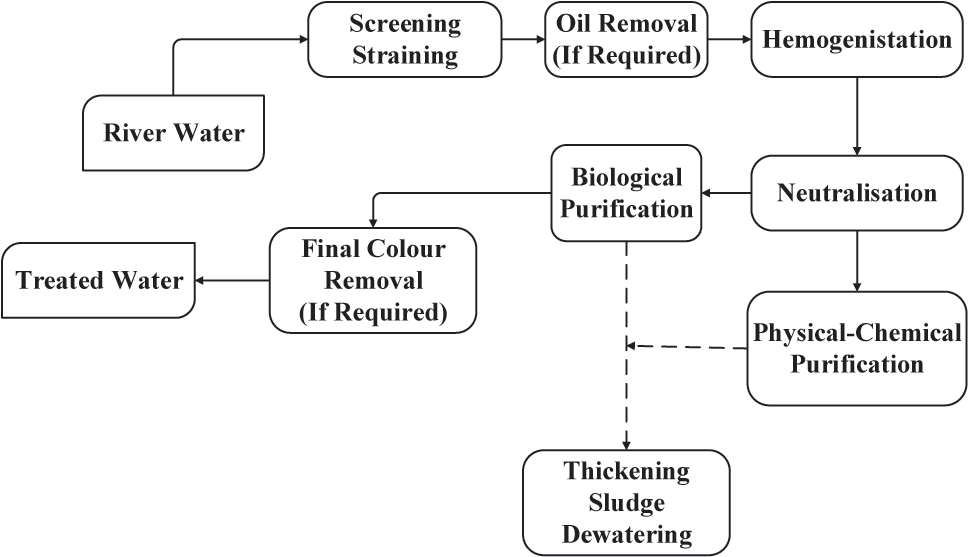

The textile business uses a lot of water, as shown in Figure 2. Water is used throughout production for several rinsing processes as well as for cleaning raw materials. Wastewater must be cleaned of greases, oils, paints, and other chemicals used in various manufacturing processes. The cleaning procedure is influenced by the wastewater type (not all facilities employ the same production process), as well as the quantity of water used. Furthermore, not every factory employs the same chemicals. At every stage of manufacturing, businesses with strict standards (environments) strive to keep the water clean. As a result, many water treatment concepts may differ from one another. Due to the numerous cleaning and removal procedures, water treatment is significant when dealing with various sorts of pollutants. According to Tianzhi et al. 28 different nations have chosen different treatment methods for textile wastewater based on the location and management of textile companies. The challenge of high water consumption, enormous wastewater discharge, and significant pollution risk in the textile industries has been handled. It is typical to treat the wastewater for several industries before transferring the treatment to a municipal wastewater treatment plant because it is not cost-effective to build separate wastewater treatment plants (WWTPs) for each small-scale firm. The results demonstrated that the coagulation process could increase the biodegradability of textile wastewater and that when the control condition of the coagulation process was optimised, the contents of organic matter of rapid and easy bio-treated could be maximised. Gharsallah et al. 29 investigated integrated membrane systems represented by Ultrafiltration/Nanofiltration (UF/NF), Ultrafiltration/Reverse Osmosis (UF/RO), and direct Nanofiltration (D/NF) and Reverse Osmosis (D/RO) applied separately at a semi-pilot scale. Due to its attributes of simplicity, convenience of use, and rapid online installation, this approach also exhibits substantial promise for applications like thoroughly examining wastewater features, treatment technology optimisation, risk control, and management. The membrane system is responsible for absorbing and holding onto light energy. The synthesis of ATP and NADPH is also aided by it. An element of the eukaryotic cell’s membrane is the endomembrane system. A network of suspended membrane organelles is present in the cytoplasm of the cell.

Steps involved in WWPT design for textile industry. 28

4.5 Treatment of textile wastewater using green technologies

As the textile industry works to embrace more sustainable practices, the treatment of textile wastewater utilising green technologies has drawn a lot of attention. Traditional treatment techniques frequently rely on chemical- and energy-intensive operations, which deplete natural resources and pollute the environment. Green technologies, on the other hand, provide eco-friendly substitutes that reduce the environmental impact of treating textile effluent. Environmental protection, resource preservation, and the utilisation of renewable resources are the top priorities for green technology for the treatment of textile wastewater. With the help of these technologies, can use fewer dangerous chemicals, utilise less energy, and encourage resource recovery and reuse. The use of natural coagulants and bio flocculants generated from plant- or microbe-based sources is a significant example of a green technology used in textile wastewater treatment. To remove suspended particles, dyes, and other contaminants from wastewater, these compounds are effective at coagulating and flocculating pollutants. In comparison to traditional chemical coagulants, natural coagulants have advantages such as biodegradability, low toxicity, and reduced sludge creation. These features make them a more environmentally friendly choice. Using built wetlands to treat textile effluent is another environmentally friendly strategy. To clean wastewater, constructed wetlands rely on natural processes and the interactions of plants, bacteria, and the environment. With the help of biological, physical, and chemical processes, these wetlands function as living ecosystems that aid in the elimination of pollutants. In addition to saving energy and requiring little in the way of chemical inputs, constructed wetlands also have aesthetic and habitat-creating value. According to Akhilesh et al. 30 the models built using statistical indices were ANFIS, RSM, and ANN in that order in terms of precision.

Numerical optimisation was done to ensure that both bio-sorbents could remove the most adsorptive material possible. It was discovered that under optimum conditions, MB dye was removed 74.49 % when 1.21 g of sugarcane bagasse, 5.24 pH, 31.24 mg/L of MB dye solution, and 22.29 °C were used, and 67.99 % when 1.37 g of peanut hulls were used. RSM model projected that for both bio-sorbents, the nearest removal would occur. The biosorption of MB onto peanut hulls and sugarcane bagasse was further supported by FTIR spectral analysis. Using vetiver grass (Vetiveria zizanioides), Rohaningsih et al. 31 sought to evaluate the effectiveness of a pilot-scale built wetland system for the elimination of various contaminants in a riparian area polluted by textile effluent. Using a hydraulic retention time of two days, the wastewater moved horizontally through the system’s subsurface layer. RE values varied up to the experiment’s conclusion, which may have happened because the system was not yet stable. The use of green technology for the treatment of textile wastewater not only lessens its negative effects on the environment but also encourages sustainability throughout the textile production process. These environmentally friendly methods can help textile producers remove pollutants effectively, save water, and abide by strict environmental requirements. To safeguard our ecosystems and preserve our natural resources, green technologies are essential in promoting a more sustainable textile sector.

4.6 Successful implementation of wastewater technologies in the textile industry

To achieve sustainable and ecologically friendly practices, wastewater technology must be successfully implemented in the textile sector. Water resource management and environmental protection are significantly hampered by the production of vast amounts of wastewater containing different contaminants by textile manufacturing operations. The textile sector may lessen these difficulties and encourage responsible water use and pollution control, nevertheless, by adopting and successfully implementing wastewater technology. Assessment, selection, design, installation, operation, and monitoring are just a few of the processes that must be included in a thorough strategy for the successful deployment of wastewater solutions in the textile sector. In chemical processes, coagulants, flocculants, and oxidation agents are used to increase the effectiveness of pollution removal. Microorganisms are used by biological processes to break down organic material and extract nutrients from wastewater. Additional possibilities for targeted pollutant removal are provided by advanced treatment technologies such as membrane filtration, adsorption, and advanced oxidation processes.

El Azizi et al. 32 studied heated blends of two naturally occurring clayey materials with biobased additives (up to 20 wt%) using X-ray fluorescence spectrometry (XRF), X-ray diffraction (XRD), thermogravimetric analysis (TDA-TG), mercury porosimetry, scanning electron microscopy/energy dispersive spectroscopy (SEM-EDS), and filtration tests. The impact of the pore-forming agent’s addition on the material’s apparent density, apparent porosity, average pore diameter, and compressive strength was evaluated, and the findings were linked to the microstructural alterations. The results of the mineralogical analyses demonstrated that the neoformation process involved both the original minerals and the byproducts of heat degradation. The neoformed phases (gehlenite and albite) and localised heterogeneous elements were seen in many pores with different forms, sizes, and characteristics as seen in SEM investigations. The results of the experimental filtration tests demonstrate that turbidity and suspended materials are eliminated together with a decrease in the chemical/biological oxygen demand and dye concentration. The textile sector can profit significantly from some technologies that are successfully used in wastewater treatment. Environmental standards must be followed, water pollution is decreased, water resources are conserved, and overall operational sustainability is improved. Implementing wastewater solutions can also improve an industry’s reputation, draw more eco-aware clients, and promote a cleaner, healthier environment.

5 Conventional wastewater treatment methods for the textile industry

The textile industry has traditionally used traditional wastewater treatment techniques to deal with the problems brought on by textile wastewater. These techniques, which typically include primary, secondary, and tertiary treatment processes, are successful in eliminating different pollutants and guaranteeing adherence to environmental requirements. For textile producers watching to develop effective and dependable wastewater management systems, understanding the foundations of conventional wastewater treatment is crucial. The wastewater produced by the textile industry is full of several types of contaminants, including dyes, chemicals, suspended particles, and organic compounds. These systems use microbes to degrade organic chemicals either aerobically or anaerobically, transforming them into less dangerous substances. To make wastewater appropriate for further treatment or disposal, secondary treatment aids in lowering the wastewater’s biochemical oxygen demand (BOD) and chemical oxygen demand (COD) levels.

The viability of EF technology for the advanced treatment of biologically treated textile wastewater was examined by Kuleyin et al. in 2021. 33 The ideal values of operational parameters, such as beginning pH, current intensity, Fe2+ concentration, and reaction duration, were discovered in batch EF experiments. In the pH range of 2.5–3.5, the impact of pH on the removal of colour, COD, and TOC was investigated. The findings indicated that 3.0 was the ideal pH for EF operations. At pH 3.0 and a reaction duration of 30 min, the elimination efficiencies for colour, COD, and TOC were 89 %, 88 %, and 45 %, respectively. The colour, COD, and TOC reductions were a little decreased at pH values of 2.5 and 3.5. The outcomes showed that the performance of the EF system was significantly influenced by the current intensity and Fe2+ concentration. While the removal efficiencies of colour and TOC were comparable, the COD removal efficiency rose with increasing Fe2+ concentration up to 2 mM before remaining constant. Fito et al. 34 used locally generated activated carbon made from Partheniumb hysterophorus stems to examine the MB’s ability to be adsorbed from textile effluent. H3PO4 was used to activate the plant samples. Then, proximate analysis, a scanning electron microscope, and Fourier transform infrared spectroscopy were used to characterise the activated carbon. The Langmuir and Freundlich isotherms models were used to verify the adsorption isotherms. According to the proximate analysis’s findings, the activated carbon was made up of 60.4 % fixed carbon, 5.7 % moisture, 15.3 % ash, and 18.6 % volatile materials. While the maximum MB removal from actual textile wastewater was determined to be 91 %, using an aqueous solution, the maximum MB removal of 94 % was reached at the pH value 11, contact period of 100 min, adsorbent dose of 2 g in 100 mL, and at the starting MB concentration. The experimental measurements and the Langmuir isotherm model fit together best when R2 was 0.99. For textile producers beholding to implement efficient wastewater management practices, it is essential to comprehend the advantages, disadvantages, and operational needs of conventional wastewater treatment technologies. Textile companies can reduce their environmental impact and support sustainable water resource management by following suitable treatment methods, investing in the right infrastructure, and adopting efficient operational procedures.

5.1 Advanced oxidation processes (AOPs) for textile wastewater treatment

Advanced oxidation processes (AOPs), which provide effective and sustainable solutions to tackle the problems posed by complex and persistent contaminants, have emerged as potential methods for the treatment of textile wastewater. The wastewater produced by the textile industry contains a variety of chemicals, organic dyes, and other impurities that are frequently resistant to traditional treatment techniques. AOPs use strong oxidants to effectively break down these contaminants, offering a workable method for accomplishing efficient wastewater treatment and environmental compliance. The capacity of AOPs to produce highly reactive hydroxyl radicals (•OH), which have potent oxidative capabilities, is one of their distinguishing characteristics. Complicated organic molecules, such as colours and refractory chemicals, can be broken down by these radicals into less complicated and more biodegradable forms. AOPs are very effective in treating pollutants that are difficult for biological or traditional chemical treatment methods to break down. Photocatalysis is a frequently used AOP for the treatment of textile wastewater because it uses a photocatalyst (like titanium dioxide) that is activated by UV light to produce •OH radicals. This procedure starts a string of oxidative processes that cause organic contaminants to deteriorate. Photocatalytic AOPs are the method of choice for treating textile wastewater because of their exceptional effectiveness in removing different colours and chemical pollutants.

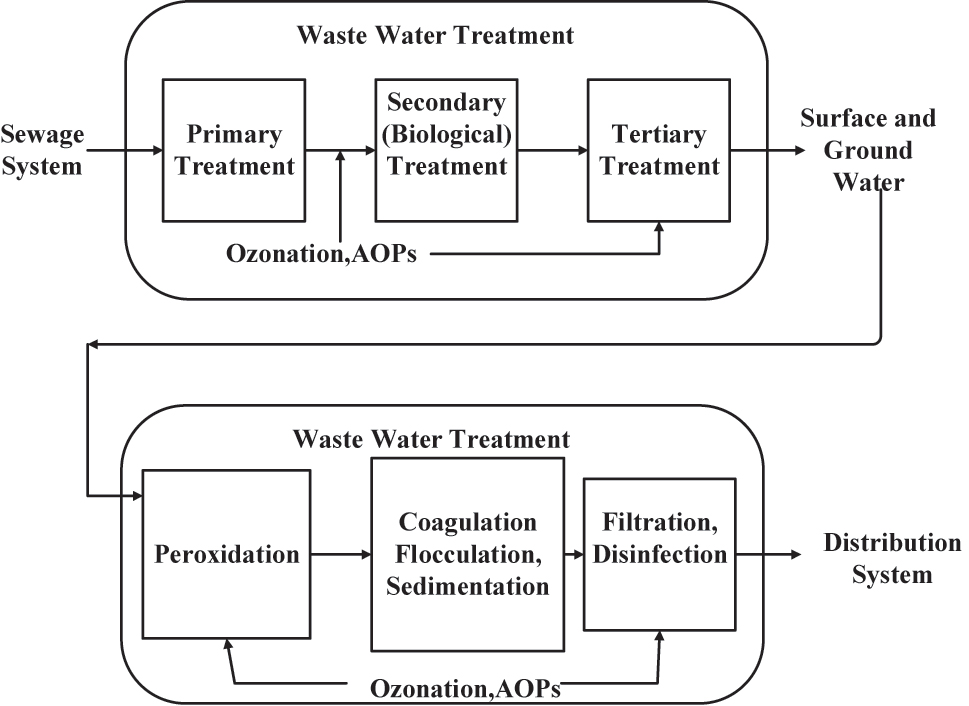

AOPs can be installed at various phases of waste (and also drinking) water treatment plants depending on the composition of the influent and the desired effluent quality, as shown in Figure 3. Thanavel et al. 35 study the effectiveness of a combined biological and advanced oxidation process (AOPs) treatment (B-AOPs) employing Aeromonas hydrophila SK16 and AOPs-H2O2 to remove Remazol Yellow RR dye. At pH 6 and room temperature, A. hydrophila and AOPs individually demonstrated 90 and 63.07 % decolourization of Remazol Yellow RR dye (100 mg L1) within 9 h. The outcome demonstrates that biological treatment shaped by combining A. hydrophila SK16 and 4 % H2O2 with advanced oxidation processes (AOPs) and biodegradation of Remazol Yellow RR dye was reported. This treatment’s combination led to a 100 % decolourization, a reduction in BOD of 84.88 %, and a COD of 82.76 %. The biodegradation process revealed significant laccase and veratryl alcohol oxidase induction. In a broad sense, advanced oxidation processes (AOPs) are a group of chemical treatment methods used to oxidise organic (and occasionally inorganic) compounds in water and wastewater through interactions involving hydroxyl radicals (OH). In a detailed comparison with the other advanced oxidation process (AOPs) technologies, Tekin et al. 36 observed the energy and costs associated with the sonication process. To improve the biodegradability of trace organic pollutants, AOPs can be deployed as a pre-treatment step before to biological (secondary) treatment of wastewater or as a tertiary treatment after that. For operational circumstances, statistical analysis was also viewed. Finally, sonication at 35 kHz was found to be a practical method for the efficient removal of CODdis, colour, and TAAs from TI ww, offering a practical and affordable substitute for removing and detoxifying the refractory compounds from TI ww. Additionally, this study demonstrated that the sonication process had lower energy requirements than the other AOPs. The findings of this investigation demonstrated the value of sonodegradation as a method for removing hazardous and resistant substances from TI ww. In TI research, low-frequency (35 kHz) sonication was found to be an effective method for degrading refractory substances. At 30 °C and 60 °C, the removals increased after 60, 120, and 150 min of sonication. Textile producers can efficiently remove pollutants, satisfy strict regulatory standards, and help protect water resources and ecosystem integrity by utilising the power of cutting-edge oxidation technologies.

Possible applications of ozonation and AOPs in wastewater.

5.2 Biological treatment systems for textile industry effluent

Due to the discharge of wastewater containing different contaminants, such as dyes, chemicals, and organic compounds, the textile industry has a substantial impact on water contamination. The utilisation of biological treatment systems as an efficient and sustainable method for treating effluent from the textile industry has received more attention in recent years. To degrade and eliminate impurities, the biological treatment uses the strength of microorganisms, offering a sustainable response to the difficult problems presented by textile wastewater. Biological treatment systems use a variety of microorganisms, such as bacteria, fungi, and algae, to break down and transform the organic contaminants found in the effluent from the textile industry. In regulated environments, these microorganisms metabolise and change the organic chemicals into simpler and less dangerous substances through biochemical processes. Pollutants are eliminated during this procedure, and the wastewater is also cleaned. In the textile industry effluent treatment, aerobic and anaerobic biological treatment systems are frequently used. The growth and activity of aerobic bacteria depends on the availability of oxygen in aerobic systems. In the textile industry, aerobic biological treatment technologies include membrane bioreactors (MBRs), sequencing batch reactors (SBRs), and activated sludge processes. By encouraging the development of bacteria that use dissolved organic molecules as a food supply, these systems successfully lower the pollutant levels in wastewater (Table 1).

Characteristics of the raw and biologically treated wastewater of the local textile industry. 29

| Parameter | Raw effluent | Biologically treated effluent | Rejection limits |

|---|---|---|---|

| pH | 111 | 8.5 + 0.5 | 7<ph<8<td=“” style=“box-sizing: border-box; padding: 0px; margin: 0px; outline: none;”></ph<8<> |

| Conductivity (ms/cm) | 26 + 5 | 7 11 | – |

| Colour (mg/L (pt-cd)) | 350 + 100 | 150 + 50 | 100 |

| SS (mg/L) | 509 + 60 | 40 88 | 400 |

| COD (mg/L) | 3,020 + 400 | 170 = 50 | 1,000 |

| TDS (mg/L) | 14,030–2,000 | 4,000 8,800 | – |

| Cl (mg/L) | 960 + 100 | 1,000 200 | 700 |

| Na+ (mg/L) | 1,980 + 120 | 2,000–200 | 100 |

| SO42 (mg/L) | 960 100 | 1,150 + 100 | 500 |

| NO3 (mg/L) | – | 12 + 4 | 90 |

To understand the discrepancies found between the active tissue’s microbial population and the municipal sludge produced over the two seasons (winter and summer), Barolia et al. 37 investigated the microbial community in the active tissue. Taxonomy of bacteria, phylogenetic tree, according to the analysis’s findings, reverse osmosis membrane filtering can generate treated effluent that is colourless and has dissolved particles as low as 196 mg/L and no hardness. On the other hand, nanofiltration permits the greatest salt to pass through the permeability, which is employed in the dying process and requires less common salt to be added. Active sludge cloth samples contained higher concentrations of Chloroflexi, Choroid, and Acidobacteria. A combined method of treating a textile industrial effluent with a persulfate-based advanced oxidation process followed by biological treatment was researched. Because different dyes are present in the effluent from the textile industry in a variety of quantities, there is a significant chemical oxygen demand (COD) and biological oxygen demand (BOD). Sulphate radicals are produced in the aqueous medium during the sulphate radical oxidation process by activating persulfate with an alkali-treated external addition. Maximum dye degradation was seen at persulfate doses of 250 mg L1, pH 3, and 200 mg L1 doses of alkali-treated laterite soil. Overall, biological treatment systems provide an effective and sustainable method of regulating the effluent from the textile sector, minimising the negative effects on the environment and fostering the preservation of water resources. The textile sector can play a significant role in adopting proper wastewater management practices and making a significant contribution to a cleaner and more sustainable future by utilising microorganisms.

5.3 Membrane-based technologies for textile wastewater treatment

The textile business produces large amounts of wastewater that contain a variety of organic substances, dyes, and chemicals, and as a result, it plays a significant role in water pollution. Biological treatment methods have come to be seen as viable and efficient solutions to the environmental issues brought on by the effluent from the textile sector. These systems offer a reasonably priced and environmentally responsible method of managing wastewater by utilising the ability of microorganisms to break down and eliminate contaminants. The majority of biological treatment systems used in the textile industry use aerobic or anaerobic procedures. Aerobic bacteria must have access to oxygen to develop and function in systems like activated sludge and sequencing batch reactors (SBRs).

In an integrated MF-NF for the treatment of textile wastewater, Lebron et al. 38 want to evaluate the performance of a Photo-Fenton process. The AOP method was used in the MF permeate as a pre-treatment for NF and as a post-treatment for the NF concentrate in two separate processes. The performance and treatment effectiveness of membranes were discussed, and a preliminary economic analysis validated the technological viability. The results demonstrate that the Photo-Fenton achieved high efficiency in colour and COD removal; nevertheless, the residual COD (131 38 mg/L), iron (29.9 2.4 mg/L), and copper (0.6 0.1 mg/L) prevent this effluent from meeting the conditions to be reused in more noble processes, such as recycling. To maintain the required levels of water quality, dye from wastewater must be removed. To encourage the removal of dyes through adsorption, a variety of organic and inorganic materials can be utilised as adsorbents. Additional methods for the removal of dyes include membrane filtering, coagulation, and reverse osmosis. The groundbreaking two-chambered earthen membrane-based built wetland cum microbial fuel cell (CW-MFC) used in Mittal et al. 39 experiment is the first of its type to improve the detoxification of azo dye and other contaminants including wastewater. The current creative design mimics the shallow unplanted CW-MFC’s core, running the anaerobic and aerobic regimes in succession without mixing the cathodic and anodic wastes. The obtained results showed the removal of azo dye and chemical oxygen demand (COD) from synthetic wastewater with initial COD and azo dye concentrations of 550 mg/L and 50 mg/L, respectively, as well as the production of current density and power density of 544.6 mA/m3 and 148.29 mW/m3, respectively.

5.4 Low-cost absorbent for the treatment of textile industrial effluents

Due to the numerous pollutants present in textile industrial effluents, such as dyes, heavy metals, and organic compounds, there are substantial environmental challenges. The creation of inexpensive absorbents for the treatment of these effluents has attracted interest as a practical and cost-efficient method for managing water resources and pollution control. These absorbents, which are frequently made from waste or natural resources, present a promising way to remove impurities from textile wastewater while also taking economic and environmental considerations into account. Their distinct physicochemical characteristics can be credited to the application of inexpensive absorbents in the treatment of textile wastewater.

The amount of adsorbed material, measured in milligrammes per gramme of adsorbent, rises with equilibrium concentration until it reaches a fixed maximum value and forms a plateau, forming a monolayer on the surface of the adsorbent. After that, due to the repulsions between the adsorbed molecules and the molecules in the solution, no molecules can attach to the adsorbent surface. In Table 2, the outcomes of the MB adsorption isotherm modelling are displayed. According to Hussain et al. 40 the removal of direct rapid scarlet 4BS, direct sky blue 5B, acid navy blue R, and reactive turquoise blue KN-G dyes employed modified coal fly ash (CFA) that had been treated with HCl and NaOH solution. Laboratory tests were performed to evaluate the effectiveness of modified coal fly ash (MCFA) and to test the dyes’ removal and adsorption capacities. At lower dosages of 0.05 g and higher dosages of 0.4 g, the results of MCFA were compared with those of carbon black, chitosan, starch, zeolite, and unmodified coal fly ash (UMCFA). The use of LbL-modified natural fibres for the remediation of textile dye wastewater was demonstrated by Mathew et al. in 2020. 41 The adsorbent we introduced is a brand-new, environmentally friendly composite material that has undergone initial testing for water purification. Similar to other polymer substrates, CHI/PAA deposition on CF exhibits multilayer growth, binding, and other characteristics. For the treatment of textile industrial effluents, CF is better due to its durability even in salty environments. In conclusion, the creation and use of low-cost absorbents for the control of wastewater from the textile industry offer a promising path towards sustainable wastewater management.

Langmuir and Freundlich isotherm parameters for the adsorption of MB onto UCP and UCP/A composite beads.

| Models | Parameters | UCP | UCP/A |

|---|---|---|---|

| Langmuir | q (mg/g) | 185.83 + 5.88 | 964.54 + 23.24 |

| KL (L/mg) | 0.0168 + 0.002 | 0.026 + 0.003 | |

| R2 | 0.983 | 0.989 | |

| RMSE | 8.615 | 36.925 | |

| Freundlich | x2 | 74.154 | 1,363.164 |

| Kp((mg/g)(L/mg)1/) | 25.95 + 8.37 | 131.04 + 36.36 | |

| n | 0.29 + 0.05 | 0.30 + 0.05 | |

| R2 | 0.885 | 0.872 | |

| RMSE | 22.593 | 131.28 | |

| x2 | 510.275 | 17,235.743 |

5.5 Ceramic membrane filtration in wastewater treatment

The removal of pollutants from industrial effluents using ceramic membrane filtration is proving to be an effective and sustainable method of wastewater treatment. Growing interest has been shown in using ceramic membranes to treat different wastewater streams, including those produced by the textile, food processing, and pharmaceutical sectors. Ceramic membranes are preferable to traditional polymeric membranes in that they are more durable, perform better filtration, and have higher chemical resistance. Wastewater produced by the textile sector in particular contains a variety of contaminants, including colours, suspended particles, and organic compounds. The standard wastewater treatment processes are severely hampered by these contaminants. A technology with electrical assistance was generated by Li et al. in 2021 42 to control fouling on flat-sheet ceramic membranes. Dopamine and carbon nanotubes (CNTs) were combined to produce a conductive CNT coating, which was then applied to the surface of an alumina membrane support to build a unique conductive membrane. In paused-charge mode, with a pause period of 15 s, the energy consumption rate for the electrically assisted membrane fouling control was just 22.2 × 103 kWh/m3. The findings indicate that the amount of strongly adhering filthy ants on the CM surface and in the membrane pores was significantly decreased by the applied electric field. The combination of pre-treatment of coagulation and zonation described by Liu et al. 43 is widely used to improve water quality and lessen membrane fouling in wastewater reclamation. Here, it was reported for the first time how an integrated treatment of ferrate pre-treatment and in-situ zonation/ceramic membrane filtration improved water quality and decreased fouling of ceramic membranes in secondary wastewater effluent treatment. The outcomes showed that the combination of in-situ zonation and ferrate pre-treatment significantly reduced the production of N-dimethyl nitrosamine (NDMA) while preventing the production of bromate. The combination of ferrate (0.15 mM) pre-treatment and in-situ zonation (10 mg/L) led to the greatest removal efficiencies of low molecular weight (MW) organics (32.3 %), humic-like compounds (17.8 %), and biopolymers (87.5 %) in the effluent.

6 Research problem definition and motivation

The development and application of efficient effluent wastewater solutions generated especially for the textile industry is the research problem. Significant volumes of effluent comprising different pollutants, including dyes, chemicals, and organic compounds, are produced throughout the textile manufacturing process. If released without proper treatment, these contaminants pose serious dangers to both the environment and human health. The research problem aims to recognise and form sustainable, innovative technologies that can effectively remove pollutants, have a minimal negative impact on the environment, and guarantee regulatory compliance. Several issues with wastewater treatment in the textile sector need to be addressed. First off, a variety of pollutants, including difficult-to-degrade complex organic compounds and non-biodegradable colours, can be found in the effluent from textile processing. Traditional wastewater treatment techniques may be insufficient to effectively eliminate these pollutants. Second, it is vital to research solutions that enable wastewater reuse and resource conservation because textile manufacturing facilities frequently operate in areas with scarce water resources. Additionally, feasibility and cost-effectiveness are crucial factors to take into account because deploying wastewater treatment technology may be financially challenging for textile industries, particularly small and medium-sized businesses. To construct specialised effluent wastewater technologies that specifically address the needs of the textile sector while balancing environmental sustainability, regulatory compliance, and economic viability, it is imperative to address these difficulties through research and innovation.

Several important aspects are the driving forces behind the research and development of effluent wastewater technology for the textile sector. First and foremost, there is a serious concern about wastewater discharged by the textile sector would affect the environment. Wastewater that has been improperly or incompletely treated and contains dyes, chemicals, and other toxins can harm ecosystems by contaminating water sources and upsetting the balance of aquatic life. Solving this problem, can safeguard biodiversity, preserve water resources, and lessen the harm that wastewater discharged by the textile sector has on the environment. Second, the textile industry has an increasing demand for sustainability and regulatory compliance. To reduce the amount of water pollution caused by industrial operations, governments and environmental organisations are enforcing stronger rules and guidelines. These rules must be followed by textile businesses to prevent fines, legal implications, and reputational harm. The textile sector can meet regulatory requirements, improve environmental performance, and show its commitment to sustainable practices by developing and implementing efficient effluent wastewater systems. Adopting effective technology for wastewater treatment can also potentially lead to cost savings because treated wastewater can be reused, lowering the requirement for freshwater intake and lowering operational costs.

7 Current trends and developments in wastewater technologies in the textile industry

There have been major trends and advancements in wastewater technology designed exclusively for the textile sector in recent years. These developments are intended to encourage sustainable practices and address the particular difficulties presented by textile wastewater. The adoption of advanced oxidation processes (AOPs) for wastewater treatment is one noticeable trend. To break down and remove the complex organic compounds, dyes, and other contaminants found in textile wastewater, AOPs employ strong oxidising chemicals or processes. A more thorough and efficient method of treating textile wastewater is now available cheers to technologies like ozonation, photocatalysis, and electrochemical oxidation, which have demonstrated encouraging results in terms of pollutant removal effectiveness and the degradation of difficult-to-treat chemicals. The incorporation of membrane-based technologies, such as ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO), in the procedures used to treat textile wastewater is another important advancement. High removal efficiency for suspended particles, dyes, and other pollutants is provided by membrane filtering systems, enabling the creation of high-quality treated water. The textile manufacturing plant can reuse and recycle water appreciations to membrane-based technologies, which helps with water conservation efforts and lowers the freshwater consumption of the sector. In the textile business, the integration of biological treatment techniques with cutting-edge technology is also picking up steam. To speed up the breakdown of organic contaminants and increase treatment effectiveness overall, bioremediation strategies are being integrated with other treatment methods. These include activated sludge systems, aerobic and anaerobic bioreactors, and artificial wetlands. To improve removal rates, lower energy usage, and promote sustainable wastewater treatment practices in the textile industry, these hybrid treatment systems combine the power of both biological processes and cutting-edge technologies.