Abstract

With the increasing use of recycled paper, its application as a permanent paper for archival purposes has been discussed. Although it was initially thought that recycled paper would not be of sufficient quality for this application, some permanent recycled papers are now commercially available. In this study, recycled papers with declared ISO 9706 standard compliance were purchased and their required properties were verified by laboratory testing. Moreover, a few additional tests not required by the standard were added. The results showed that half of the tested recycled papers are truly permanent according to the ISO 9706 standard and that their properties are comparable to those of the non-recycled paper standards. Therefore, their use for archival purposes should be safe according to the chosen standard. However, the ISO 9706 compliance of the rest of the tested recycled papers is at least questionable even though it was declared by the manufacturer. Consequently, when considering the use of permanent recycled paper, it is strongly recommended to verify its required properties through independent testing.

Zusammenfassung

Mit dem zunehmenden Gebrauch von Recyclingpapier wurde auch dessen Einsatz als alterungsbeständiges Papier für die dauerhafte Aufbewahrung in Archiven diskutiert. Wenngleich man zunächst davon ausgegangen ist, das Recyclingpapier nicht von ausreichender Qualität für den Einsatz als alterungsbeständiges Papier sein kann, sind heute einige als alterungsbeständig deklarierte Recyclingpapiere auf dem Markt. Für diese Studie wurden Recyclingpapiere eingekauft, die mit dem Hinweis, ISO 9706 zu erfüllen, bezeichnet sind, und nach den im Standard geforderten Bedingungen überprüft. Zusätzlich wurden weitere Tests durchgeführt, die nicht in ISO 9706 gefordert sind. Die Ergebnisse zeigen, dass die Hälfte der überprüften Recyclingpapiere tatsächlich alterungsbeständig gemäß ISO 9706 sind und dass ihre Eigenschaften mit denen von aus Frischfasern hergestellten Papieren vergleichbar sind. Diese Papiere können als alterungsbeständiges Papier für die dauerhafte Aufbewahrung in Archiven verwendet werden. Allerdings muss man für die andere Hälfte der getesteten Recyclingpapiere, die vom Hersteller ebenfalls mit ISO 9706 gekennzeichnet worden sind, die dauerhafte Eignung bezweifeln. Aus diesem Grund ist es empfehlenswert, Recyclingpapiere durch unabhängige Tests auf ihre tatsächliche Eignung zu überprüfen.

1 Introduction

Given the increasing global consumption of paper materials, the use of recycled paper is currently strongly recommended, and in some cases even required. In Europe, the primary motivations for recycling are predominantly environmental, with the economic aspect also playing a role in some cases (Grilj et al. 2011). It has been demonstrated that the recycling of paper is, in general, a more energy-efficient process than its incineration (Schenk et al. 2004). In other countries, such as Japan or Mexico, the scarcity of domestic pulpwood resources is an additional reason for using recycled fibres (Grilj et al. 2011).

While recycled paper is generally considered suitable for use as stationery and packaging materials, there may be some reservations about its use in specific applications, such as its use as permanent paper for archival purposes. Permanent paper is defined as paper with a composition and chemical and physical properties that ensure its long-term stability and resistance to natural ageing processes. Over time, the required properties of permanent papers have been defined by a number of standards. At present, the most cited of these standards is likely to be ISO 9706: Information and documentation – Paper for documents – Requirements for permanence, at least within the context of Europe (International Organization for Standardization 1994). This standard specifies permanent paper in terms of set limit values for selected chemical and mechanical properties, regardless of paper composition. Another frequently used standard, ISO 11108: Information and documentation – Archival paper – Requirements for permanence and durability, takes a different approach (International Organization for Standardization 1996a). In this case, the required paper composition is defined first, and the only permitted sources of cellulose fibres are cotton, cotton linters, hemp, and flax, as well as their mixtures. The required chemical and mechanical properties, which are defined subsequently, largely coincide with those defined in ISO 9706. The third standard that may be mentioned is ISO 20494: Paper – Requirements for stability for general graphic applications (International Organization for Standardization 2017). This standard once again determines the required properties of the paper, not its composition. The primary distinction between ISO 20494 and the other two mentioned standards is that the limit value for one particular mechanical property is also defined for artificially aged samples and that the Kappa number is not limited.

There have been concerns that recycled paper may not be of sufficient quality to meet the requirements of these standards due to the degradation of cellulose fibres and the decline of adhesion between the fibres which occur during the recycling process (Schenk et al. 2004). Another potential cause could be the inability to ensure consistent composition of recycled paper and the content of lower quality pulp sources, such as mechanical pulp, with worse mechanical properties and higher content of lignin (Cameron 2004). Over time, a number of studies have been carried out to prove or disprove that recycled paper can meet the requirements of the permanence standards, e.g., Bonham and Rolniczak (2006); France and Kullman (2009). These studies have demonstrated that it is possible to produce recycled paper that can be labelled as permanent. However, none of these studies have mentioned recycled papers that are currently available.

When the Czech Archival Administration expressed interest in the use of recycled paper within public administration, the current offer was examined, and it was found that there were several recycled papers certified according to ISO 9706 on the international market at that time. It was decided to purchase these products and evaluate their characteristics according to the ISO 9706 standard. As there is some debate as to whether this standard is sufficient or whether it should be complemented with additional tests, this study was extended to include additional testing of properties which, from our perspective, are relevant for the long-term preservation of document legibility.

2 Materials and Methods

2.1 Papers and Sample Preparation

Four types of paper with a minimum of 55 % recycled content and declared ISO 9706 compliance were purchased. The individual papers differed not only in the amount of recycled matter they contained, but also in the source of recycled material. Three of them are traditional recycled papers made from secondary pulp, whereas the last one, White Copy Paper, contains recycled matter which comes from secondary manufactured agricultural waste, such as stems and leaves. Two further papers with no recycled content were included in the study as an acknowledged standard of permanent paper (Neograph) and a representative of common office permanent paper (High Standard). All papers were purchased during the second half of 2022. The grammage and dimensions of all tested papers were identical (80 g m−2, A4 format). A more detailed characterisation of all the paper samples is given in Table 1.

Characterisation of paper samples.

| Paper name | Producer/distributor | Abbr. | Recycle content | Recycle source |

|---|---|---|---|---|

| Balance pure | Papyrus | BP | 100 % | Recycled fibre |

| Copy life | Fabriano | CL | 85 % | Recycled pulp |

| Evolution business | Premier paper | EB | 100 % | Post consumer waste |

| White copy paper | PaperWise | WC | 55 % | Agricultural waste |

| High standard | Europapier | HS | 0 % | – |

| Offset permanent | Neograph | NG | 0 % | – |

Tests were carried out on both non-aged and artificially aged samples. Two types of artificial ageing were employed: wet heat ageing and light ageing. The conditions for wet heat ageing were 80 °C and 65 % RH for 28 days, the paper samples were loosely hung in the climate chamber. These conditions were based on the ISO 5630-3:1996 standard, with the exception that a significantly longer treatment period was selected to simulate long-term natural degradation (International Organization for Standardization 1996b). The light ageing process was conducted using light radiation without any UV component, i.e., radiation with a wavelength of less than 400 nm was excluded. The treatment was carried out for 10 days at a temperature of 26 °C with an illuminance of 40 klx and a total irradiance of 20 W m2. The conditions of light ageing were based on ISO 5630-7:2014 standard, once again with prolonged time of treatment (International Organization for Standardization 2014). Another difference was the exclusion of the UV component in order to simulate indoor storage conditions.

2.2 Tests Required by the ISO 9706 Standard

In accordance with the requirements of ISO 9706:1994, four tests must be conducted: determination of pH, determination of alkali reserve, determination of Kappa number and determination of tearing resistance. For each test there is a given standard that must be followed and the paper must meet defined limit values in order to be classified as permanent. The pH value is measured by means of the cold aqueous extract method in accordance with ISO 6588-1:2021 standard, the resulting value must fall within the specified range of 7.5–10.0 (International Organization for Standardization 2021). The alkali reserve, expressed as the molar mass of all alkali substances per kilogram of paper, is determined by titration in accordance with the requirements set out in ISO 10716:2022 (International Organization for Standardization 2022a). The minimum required value is 0.4 mol kg−1. The last chemical test, determination of Kappa number, is used as an indication of the lignin content in papers and is carried out in accordance with the ISO 302:2015 (International Organization for Standardization 2015). The measured values must not exceed 5. Finally, the Elmendorf method, described in the standard ISO 1974:2012, is used for determination of tearing resistance (International Organization for Standardization 1974). For papers with a grammage above 70 g m−2, the threshold value is 350 mN for both the machine and cross directions of the paper. Prior to tearing testing, samples were conditioned at 23 °C and 50 % relative humidity for 48 h.

The aforementioned tests were conducted on both non-aged samples and samples that had undergone artificial ageing by wet heat, despite the ISO 9706 requirements applying solely to the non-aged samples. The aged samples were tested with the aim of estimating the impact of the ageing process on the essential properties of permanent papers. The pH value, alkali reserve and Kappa number were measured on three samples of each paper, both non-aged and artificially aged. The tearing resistance of each type of paper sample was determined by taking 20 measurements in both the machine and cross directions of the paper.

2.3 Additional Tests

In addition to the requisite tests, two further tests were involved. The first one, determination of folding endurance, was selected to characterise another important mechanical property of the tested papers. The selection of this particular mechanical property was induced by the fact that determination of folding endurance is a compulsory test in another standard, ISO 11108. Therefore, it seems that folding endurance could be an important property in terms of the long-term durability of paper. The test itself was conducted in accordance with the ISO 5626:1993 standard, using a Schopper instrument with a preset tensile force between 7.55 N and 9.81 N (International Organization for Standardization 1993). The folding endurance was expressed as the number of double folds required to cause rupture of the tested paper. This test was carried out on non-aged samples and on samples that had been artificially aged by wet heat. In this case, 15 samples in both the machine and cross directions were measured for each combination of paper and its treatment. As with the required tearing test, samples were conditioned at 23 °C and 50 % relative humidity for 48 h before testing.

The final test was focused on the visual properties of the papers, specifically on the determination of paper colour expressed in the CIELAB colour space as described in the ISO 5631-2:2022 standard (International Organization for Standardization 2022b). For this measurement, standard illuminant D65 without an UV component was used. The observed angle was 10° and the specular component was excluded. This configuration enables the evaluation of colour changes as they are perceived by the human eye, thereby enabling the potential impact of colour changes on document readability to be estimated. This test was the only one carried out not only on the non-aged samples and samples aged by wet heat, but also on samples exposed to light ageing as light exposure is known to cause colour changes in paper. The colour of each sample was measured 10 times.

As there are no set values to meet, the data obtained from the additional tests were used to compare the recycled and non-recycled papers and, in addition, to enable an estimation of the impact of natural ageing on the folding endurance and the readability of documents printed on the tested recycled papers.

3 Results and Discussion

3.1 ISO 9706 Test Results

The pH determination showed values within the required alkaline interval for all of the non-aged samples as well as for the aged samples, although there were slight differences between individual samples in both groups (see Tables 2 and 3). The maximal difference was approximately 1 unit in both groups, and there was no clear correlation between the amount of recycled content and pH value. Contrarily, it is evident that artificial ageing caused a slight decrease in pH values for all tested samples.

ISO 9706 measurements of non-treated samples.

| Limit | BP | CL | EB | WC | HS | NG | |

|---|---|---|---|---|---|---|---|

| pH | 7.5–10.0 | 9.1 ± 0.10 | 9.4 ± 0.02 | 8.9 ± 0.02 | 9.7 ± 0.10 | 10.1 ± 0.05 | 8.9 ± 0.08 |

| Alkali reserve | ≥0.4 | 4.1 ± 0.01 | 4.0 ± 0.01 | 4.5 ± 0.02 | 2.9 ± 0.01 | 3.8 ± 0.10 | 2.2 ± 0.02 |

| Kappa number | ≤5 | 5.7 ± 0.15 | 14.6 ± 0.18 | 4.3 ± 0.05 | 1.9 ± 0.05 | 1.4 ± 0.00 | 0.8 ± 0.01 |

ISO 9706 measurements of wet heat aged samples.

| Limit | BP | CL | EB | WC | HS | NG | |

|---|---|---|---|---|---|---|---|

| pH | 7.5–10.0 | 8.6 ± 0.10 | 8.5 ± 0.06 | 8.6 ± 0.06 | 9.1 ± 0.11 | 9.6 ± 0.09 | 8.5 ± 0.01 |

| Alkali reserve | ≥0.4 | 4.1 ± 0.01 | 4.2 ± 0.03 | 4.2 ± 0.16 | 3.0 ± 0.01 | 4.0 ± 0.05 | 2.2 ± 0.02 |

| Kappa number | ≤5 | 6.9 ± 0.13 | 13.3 ± 0.26 | 5.2 ± 0.30 | 2.0 ± 0.03 | 1.8 ± 0.17 | 1.8 ± 0.10 |

As indicated by the pH measurement, the alkali reserve of all samples exceeded the given threshold value regardless of the quantity of recycled content or the sample treatment (Tables 2 and 3). Indeed, the obtained values of alkali reserve were at least five times higher than the required minimum. On the other hand, it was not expected that there would be significant differences between the alkaline reserve values of the individual samples. The recycled papers BP, CL and EB, as well as the office paper HS showed values of approximately four or higher. This is likely due to the relatively high content of calcium carbonate filler usually contained in common copy papers, which could be used as a source of recycled pulp.

The recycled paper WC, containing a significantly lower amount of recycled content which, moreover, derives from agricultural waste rather than recycled paper, showed lower alkali reserve. The lowest values were measured for the standard paper NG, which again should correspond with the use of high-quality pulp sources. For all samples, artificial ageing under used conditions has a negligible impact on alkali reserve.

While the previous two conditions were met without any issues, the determination of Kappa number proved to be a critical step in the evaluation process. The Kappa number is intended to be an indicator of the lignin content in papers or bleachability of pulp, as defined in the ISO 302 standard. However, it could be considered as a general indicator of the amount of all oxidizable components in paper. Since oxidation is one of the main paper degradation processes, the content of these components should be as low as possible to ensure the long-term stability of the paper. Non-recycled papers passed the standard test without any difficulties; their Kappa numbers were very low, regardless of whether the samples were non-aged or artificially aged (Tables 2 and 3). In fact, the standard paper NG showed the lowest Kappa number of all the samples. Two of the recycled papers, WC and EB, were also able to meet the requirements of the standard. The Kappa number of recycled paper WC was notably low and was relatively close to the kappa number of HS non-recycled paper, especially after artificial ageing. The Kappa number of non-aged, recycled paper EB was found to be significantly higher, yet still within the required range. After artificial ageing, the Kappa number exceeded the maximum permitted value. However, as the standard only sets conditions for non-aged papers, the EB paper can still be considered permanent from the perspective of the Kappa number. The measurement of the other two recycled papers, BP and CL, gave results that were somewhat problematic. The Kappa number of BP paper was marginally above the specified limit, raising questions about its permanence. In the case of CL paper, it is evident that this paper did not meet the standard, with its Kappa number being almost three times the specified limit. Once more, there is no evident correlation between the amount of recycled content and the Kappa number.

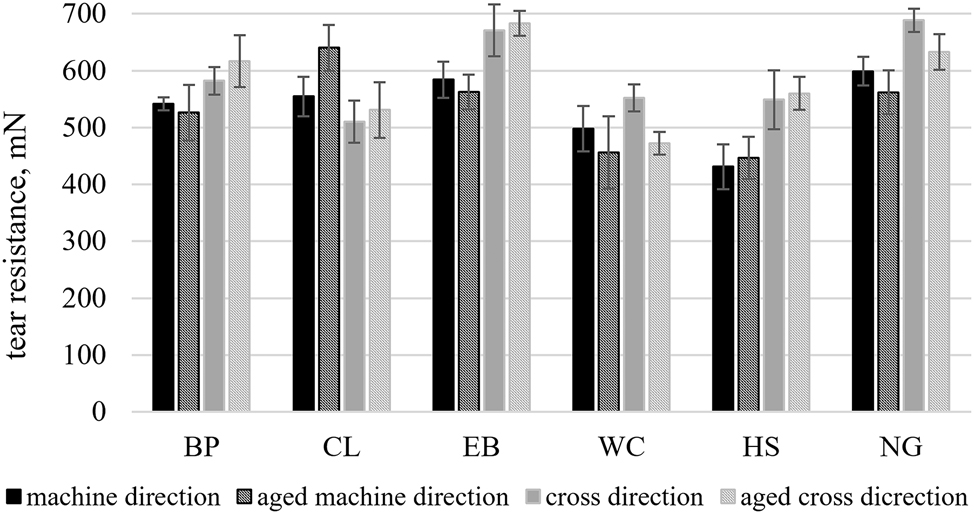

Finally, the only mandatory mechanical test, the determination of tear resistance, did not exclude any other paper from being permanent, all samples passed the test regardless of sample treatment or paper direction (see Figure 1). In general, when using the Elmendorf method, tearing resistance in the machine direction is lower than in the cross direction. This is due to the nature of the broken bonds. When the paper is torn in the machine direction, the weak intermolecular bonds between cellulose fibres are broken, yet the fibres themselves remain intact. Conversely, when the paper is tested in the cross direction, strong intramolecular chemical bonds of cellulose must be broken to tear the paper. The stated rule applies to all papers except recycled paper CL, which showed slightly higher values in the machine direction. This may be due to the presence of additives with strong adhesive characteristics, which effectively somewhat lower the anisotropy of the paper properties. The influence of artificial ageing on the tearing resistance is not determinable, as the changes in measured values are small and mostly negligible within measurement deviations.

Tear resistance of paper samples. Highlighted line represents the required threshold value. Error bars represent the standard deviation.

In light of the above results, it is clear that, in accordance with the ISO 9706 standard, both non-recycled papers (HS and NG) can be labelled as permanent paper without any hesitation. The same can be said of the recycled papers EB and WC, which demonstrate that it is feasible to produce permanent recycled paper. Conversely, it became evident that not all papers bearing the designation “permanent” are in compliance with the ISO 9706 standard. CL recycled paper clearly does not meet the Kappa number requirement and therefore cannot be considered permanent paper. Strictly speaking, the latest tested recycled paper BP also could not be designated as permanent according to the followed standard, despite its Kappa number being only marginally above the maximum permitted value.

Furthermore, it is evident that the WC paper is distinct from the other recycled papers. This could be attributed to the significantly lower amount of recycled matter or the utilisation of a different source of recycled fibres. This paper contains processed agricultural waste, specifically leaves and stems left over from harvest, and not secondary used paper. This could suggest that the cellulose fibres from agricultural waste may be less damaged than cellulose fibres subjected to the recycling process.

3.2 Additional Tests Results

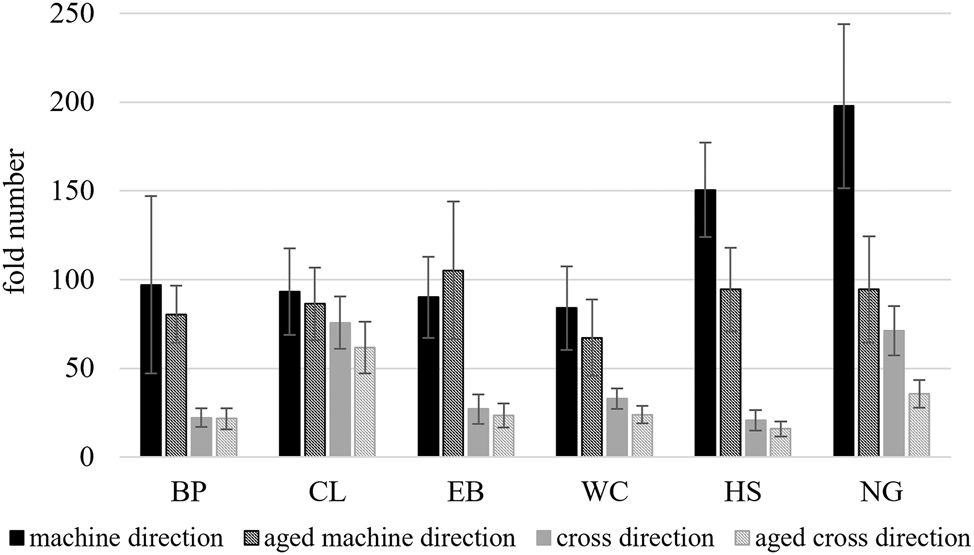

In determining the folding endurance, the grain direction of the paper is once more a significant factor. Due to the different character of the broken bonds (weak intermolecular or strong intramolecular), the folding endurance of the papers was found to be significantly enhanced when folded perpendicularly to the machine direction in comparison to when folded perpendicularly to the cross direction. This rule applies to all samples except for recycled paper CL, which demonstrated unexpectedly high folding endurance in the cross direction. This could confirm the presence of adhesive additives, as already suggested when discussing the results of the determination of tear resistance.

The determination of folding resistance showed a noticeable difference between the recycled and non-recycled papers (Figure 2). When folded across the machine direction, all non-aged, recycled papers exhibited similar values, which were significantly lower than those of the non-aged non-recycled papers. Furthermore, the folding endurance of the recycled papers appeared to be practically unaffected by artificial ageing, whereas that of the non-recycled papers showed a significant decrease, reaching values comparable to those of recycled papers. These results suggest that the initial folding resistance of the non-recycled papers may not have a lasting effect, indicating that, over time, both groups of papers may demonstrate similar folding endurance.

The folding endurance of paper samples. Error bars represent the standard deviation.

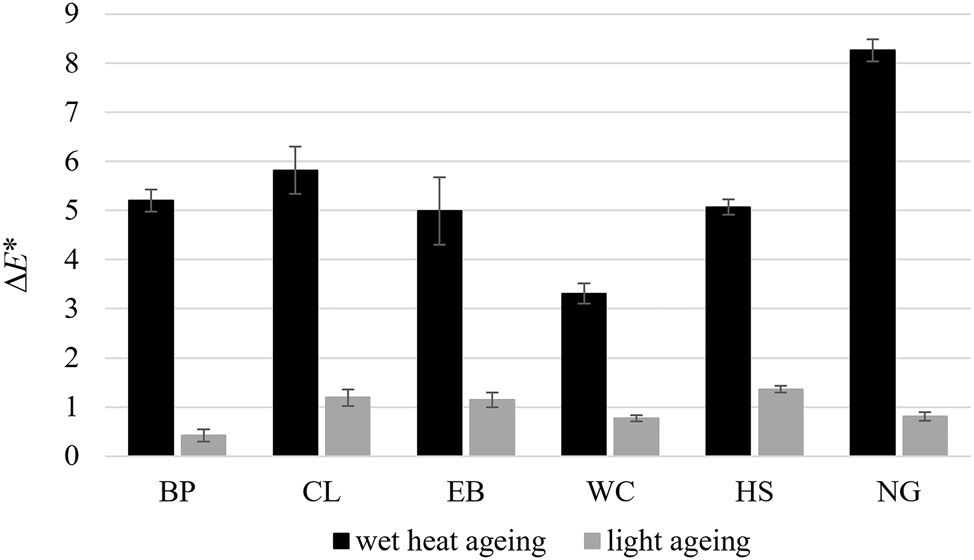

In order to express the colour change of paper, one of the most commonly used parameters is the total colour difference ΔE*, due to its sensitivity to even minor degradation alterations of paper. This parameter includes alterations across all three axes of the CIELAB colour space, allowing simple comparisons between samples. However, ΔE* does not specify the type of colour change that has occurred with the paper. When a more detailed insight is required, a comparison of the average value of each axis provides greater clarity. In the case of paper, the most common colour changes are darkening and yellowing. Therefore, it is advisable to observe the changes of the L* and b* axes.

The determination of ΔE* clearly showed that wet heat ageing caused much more significant colour changes, regardless of the paper type (Figure 3). After this type of artificial ageing, most of the recycled papers, along with the office paper HS, demonstrated comparable ΔE* values. However, the recycled paper WC once again demonstrated a distinctive pattern. Its ΔE* is slightly lower, probably due to the different nature of the recycled material used. In contrast, standard paper NG showed the highest ΔE* of all tested papers, potentially due to the different method of fibre bleaching or the presence of unspecified additives. After light ageing, the ΔE* of all samples was relatively low, indicating that under normal ageing conditions, there will be no significant difference in the optical behaviour of recycled and non-recycled papers.

Total colour difference ΔE of paper samples caused by artificial ageing. Error bars represent the standard deviation.

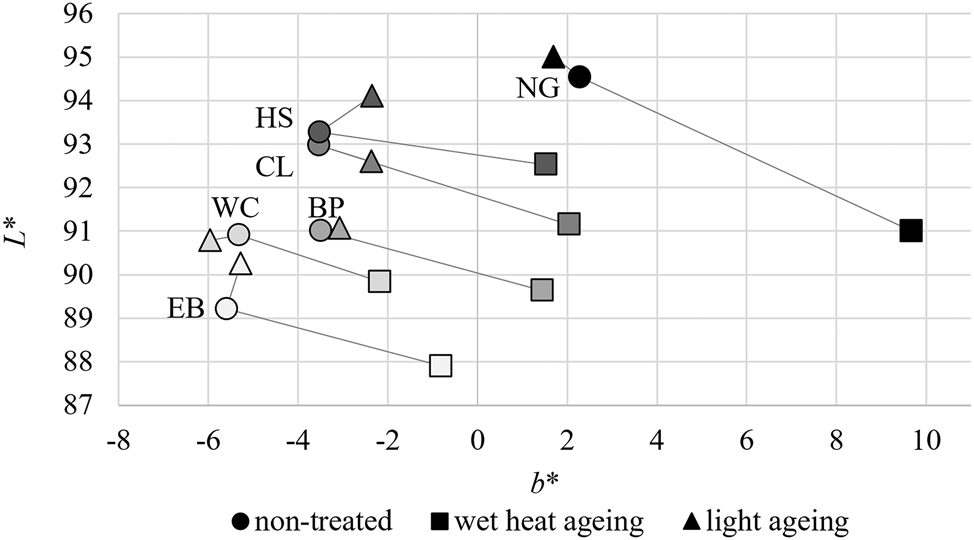

As illustrated in the L*-b* chart, standard paper NG is slightly different from the other papers (Figure 4). Although their visual appearance is similar, the b* values of NG are significantly higher than those of the other papers. The data reveal that all samples exhibited a decrease in L* and an increase in b* following wet heat ageing. This indicates a darkening and yellowing of the papers. When exposed to light ageing, the colour changes were not uniform. Papers WC and NG showed a decrease in b* values, indicating that light exposure resulted in a blue shift. This contrasts with the rest of the papers, which exhibited a yellow shift after light exposure. With regard to the L* parameter, the influence of light was not as evident, therefore it is not possible to estimate whether the recycled paper becomes darker or lighter when exposed to light.

Values of L* and b* parameters of paper samples.

According to the results of additional tests, it is obvious that recycled papers exhibit similar behaviour to non-recycled papers, particularly in regard to the changes in properties that occur after artificial ageing. Consequently, there is no evidence to suggest that recycled papers which comply with ISO 9706 could be unsuitable for archival purposes for another reason.

4 Conclusions

In summary, the research findings showed that it is possible to produce permanent recycled papers that meet the ISO 9706 standard, but that it is always necessary to verify the claimed permanence by independent testing. It was demonstrated that it is feasible to produce permanent recycled paper with comparable or even superior characteristics to those of common permanent office paper.

White Copy Paper (WC) from PaperWise gave the best results of all the recycled papers tested. However, this paper contains only 55 % recycled material, which, moreover, does not originate from secondary used paper. Therefore, in some cases, it may not be considered a sufficiently environmentally friendly solution. On the other hand, its composition could ensure more consistent properties of the paper. When traditional recycled paper is required, the Evolution Business paper (EB) from Premier Paper may be a suitable alternative to the White Copy Paper as it comprises 100 % recycled material yet still demonstrated fairly good results. In contrast, testing of the recycled paper Copy Life (CL) from Fabriano revealed that despite the paper being labelled as permanent paper in accordance with the ISO 9706 standard, it is not able to fully comply with all the requirements of the standard. Therefore, it is advisable to adopt a “trust but verify” approach when evaluating the suitability of any permanent recycled paper.

When the use of recycled paper is discussed, it is also important to consider the economic aspects involved. At the time of the research, the price of White Copy Paper was even lower than the average price of permanent office paper of the High Standard (HS) from Europapier in the Czech Republic. Conversely, the average price of Evolution Business paper was at least two times higher. However, it should be noted that the listed prices exclude delivery fees, which could significantly increase the final product price, particularly when ordering from abroad. Therefore, when considering the use of recycled paper, each organisation should weigh ecological and economical aspects against each other.

References

Bonham, James S., and Barbara Rolniczak. 2006. “Accelerated Ageing of Copy Papers Containing Recycled Fibre.” Appita: Technology, Innovation, Manufacturing, Environment 59 (5): 365–9.Suche in Google Scholar

Cameron, John H. 2004. “PULPING | Mechanical Pulping.” In Encyclopedia of Forest Sciences, edited by Jeffery Burley. Elsevier.10.1016/B0-12-145160-7/00127-7Suche in Google Scholar

France, Fenella G., and Matthew Kullman. 2009. “Recycled Paper Research at the Library of Congress.” International Preservation News 48: 10–6.Suche in Google Scholar

Grilj, Silva, Tadeja Muck, Aleš Hladnik, and Diana Gregor-Svetec. 2011. “Recycled Papers in Everyday Office Use.” Nordic Pulp and Paper Research Journal 26 (3): 349–55.10.3183/npprj-2011-26-03-p349-355Suche in Google Scholar

International Organization for Standardization. 1993. Paper – Determination of folding endurance. ISO 5626:1993.Suche in Google Scholar

International Organization for Standardization. 1994. Information and documentation – Paper for documents – Requirements for permanence. ISO 9706:1994.Suche in Google Scholar

International Organization for Standardization. 1996a. Information and documentation – Archival paper – Requirements for permanence and durability. ISO 11108:1996.Suche in Google Scholar

International Organization for Standardization. 1996b. Paper and board – Accelerated ageing – Part 3: Moist heat treatment at 80 OC and 65 % relative humidity. ISO 5630-3:1996.Suche in Google Scholar

International Organization for Standardization. 2012. Paper – Determination of tearing resistance – Elmendorf method. ISO 1974:2012.Suche in Google Scholar

International Organization for Standardization. 2014. Paper and board – Accelerated ageing – Part 7: Exposure to light. ISO 5630-7:2014.Suche in Google Scholar

International Organization for Standardization. 2015. Pulps – Determination of Kappa number. ISO 302:2015.Suche in Google Scholar

International Organization for Standardization. 2017. Paper – Requirements for stability for general graphic applications. ISO 20494:2017.Suche in Google Scholar

International Organization for Standardization. 2021. Paper, board and pulps – Determination of pH of aqueous extracts – Part 1: Cold extraction. ISO 6588-1:2021.Suche in Google Scholar

International Organization for Standardization. 2022a. Paper and board – Determination of alkali reserve. ISO 10716:2022.Suche in Google Scholar

International Organization for Standardization. 2022b. Paper and board – Determination of colour by diffuse reflectance – Part 2: Outdoor daylight conditions (D65/10°). ISO 5631-2:2022.Suche in Google Scholar

Schenk, Niels J., Henri C. Moll, and José Potting. 2004. “The Nonlinear Relationship Between Paper Recycling and Primary Pulp Requirements.” Journal of Industrial Ecology 8 (3): 141–61.10.1162/1088198042442379Suche in Google Scholar

Supplementary Material

This article contains supplementary material (https://doi.org/10.1515/res-2025-0009).

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.