Abstract

Regardless of colouration for functional or aesthetic purposes, technical polymer parts, like gears, require consistent properties. However, there is a lack of research into the effect of colourants on the tribomechanical properties of gears. Therefore, the effects of two pigments, titanium dioxide (white) and chrome antimony titanium oxide (yellow), and three delivery methods, masterbatch, liquid colour and direct compounding, on part morphology, dimensions, tribological and mechanical performance of injection-moulded polyoxymethylene (POM) spur gears are investigated in this paper. The white pigment accelerates the crystallisation of POM, causing fine and highly-crystalline morphological structures and smaller dimensions. However, the yellow pigment decelerates crystallisation, resulting in a coarser morphology with highly crystalline core material and bigger parts. Furthermore, the delivery method affects only the tribomechanical properties. Using a masterbatch decreases loads at break and increases deflection at break, since the carrier material acts as an impact modifier and a weak spot. The liquid colour decreases wear due to lubricating properties, whereas the pure pigments increases abrasion, especially in combination with a coarse microstructure. However, the effects of carrier systems and changes in morphology are always superimposed. Considering the performance and tolerance of technical components, colourants have to be carefully selected to ensure beneficial properties.

1 Introduction

Due to their high freedom of design, low weight, good dry running capability, beneficial wear behaviour and cost-efficient production, injection-moulded polyoxymethylene (POM) gears have a wide array of applications, from household appliances to actuating drives in the automotive sector. For gears, three main characteristics are important: compliance to geometric tolerances, sufficient mechanical properties and high wear resistance [1]. Due to aesthetical, branding or functional reasons, they are often coloured. However, as a result of the structural complexity of the materials involved, there is no simple model of the interaction of polymers and colourants [2]. Thus, the influence of colourants on the resulting properties of coloured, injection-moulded parts cannot be easily predicted.

Due to the possible migration of soluble dyes from the material, POM and other polymers are mainly coloured using non-soluble pigments [3]. There are three main methods of colouring polymers with pigments [4]. Firstly, pigments can be added to the base material to produce pre-coloured granulate. This is suitable for large batches of material and frequently used colours such as black and white [4]. Secondly, masterbatches, highly pigment-filled granules, are used to colour smaller batches individually. Thirdly, liquid colours can be used instead of masterbatches, allowing for a more flexible mixing of pigments and a wider range of colours without keeping too much stock [3]. Both, masterbatches and liquid colours are more expensive than pre-died material, but they are more flexible [4]. However, liquid colours require additional dosing equipment, which is not necessary for masterbatches, since those can be mixed into the base material [3]. Pigment cost can vary widely from inexpensive carbon to more expensive mineral- or metal-based effect pigments [5]. One of the most thoroughly researched pigments is titanium dioxide (TiO2). Titanium oxide and titanium mixed phase oxide pigments are widely used due to their ability to produce brilliant colours. Pure TiO2 is white in colour and listed in the international Colour Index as C.I. Pigment White 6 [6]. A commercially often applied variety of titanium mixed phase pigments is chrome antimony titanium oxide rutile pigment, known as C.I. Pigment Brown 24, which produces a dark yellow to orange colour [6].

The effects of colourants on part properties can be distinguished in effects due to changes in morphology caused by nucleation or denucleation and effects of the material itself. The effects of the materials can be further divided into effects of the pigment and effects of the carrier materials. In reality, all these effects are superimposed and not easily distinguishable. One main effect of colourants, especially pigments, is the nucleation of the base material. To act as a nucleating agent, the material has to be well dispersed and insoluble [5]. Due to the same requirements applying for successful colouration [4], this is intrinsically fulfilled for pigment-based colourants. Thus, TiO2 pigments could act as nucleating agents for POM, as shown by [7]. Nucleation leads to a finer, higher crystalline structure [4], especially in colourised components, when compared to the base material. This is due to the introduction of additional crystallisation centres. The same effect can be accomplished by lowering cooling rates, as this allows more time for the formation of nucleation centres by the material itself [5]. In any case, a higher crystallinity is a cause of higher shrinkage, leading to different geometric dimensions. A finer microstructure also correlates with increased mechanical properties. Yield strength [8], break elongation, stiffness and impact strength can be increased for POM parts with a higher crystallinity [9]. For the tribologic properties of POM parts, it was determined in pin-on-disk-tests, that a finer morphology correlates with lower wear rates [10]. Furthermore, while there has been evidence of nucleating effects of TiO2 on POM [7], in general there have also been findings of denucleating effects of colourants on POM [11], suggesting the possibility of a decrease in mechanical and tribological properties as a result of incompatible colourants. Due to the complex interactions, it cannot easily be predicted whether a material has a nucleating, denucleating or no effect on the base polymer. For this reason, it is still unclear if chemically similar materials, for example TiO2 and titanium mixed phase oxides, necessarily show similar nucleating effects.

In regard to the effects of the materials themselves, there has been no research on the impact of Cr/Sb/Ti-oxide pigments on the properties of polymers. However, there were investigations into the influence of TiO2, especially for POM. TiO2 has a positive effect on light and heat stability, and material ageing of POM due to the selective absorption of harmful radiation [12]. Although there has been research on the influence of other nanoparticles, like carbon nanotubes [13] or organoclay [14], on the mechanical and tribological properties of polymers, due to the complex interactions there is no general trend. Whether the effect of adding nanoparticles, like TiO2, to a material is positive or negative highly depends on particle material, size and dosage [7]. However, the research on the effects of nanoparticles is focused on dosages of 2% and above, whereas pigment concentration for colouration is usually less than 0.5%. Additionally, those influences on the mechanical and tribological properties are mostly determined in model tests. There is no research on the influence of colourants on the properties of complex parts like gears under static and dynamic loads.

Although the interactions of pigments and other nanoparticles have been the topic of current research, there has been only little research on the influence of carrier systems, like masterbatches or liquid colours. As mentioned, most finely distributed substances can act as nucleating agents [5]; this includes carrier materials. Furthermore, there is research regarding blends, often showing an increase in mechanical properties, mostly impact strength, with increasing blend contents until a material specific threshold is reached and these properties decrease because of agglomerations acting as weak spots [15]. Similarly, there have been studies of compounding materials with low molecular oils, like silicone oils, showing a potential increase in elongation at break and decrease in stiffness, stress at break and wear due to internal and external lubricating effects [16]. However, here also significantly higher dosages are used. However, both blends [17] and low molecular polymers [16] are used as incorporated lubricants in practical applications to reduce wear.

All of those studies, however, do not investigate the combined effects of pigments or other nanoscale particles and carrier materials on the base polymer. It shall therefore be investigated whether different delivery methods have an influence on the nucleating effect of TiO2. Furthermore, it is of interest if nanosized abrasive particles affect the wear reducing properties of incorporated lubricants negatively. In summation, there is little to no comprehensive research on how the dynamic mechanical and tribological properties of polymer parts are affected by certain titanium oxide-based colourants. Especially, the interaction of a carrier material, pigment and base material is largely unclear. This can present issues, especially for polymer gears, due to the high mechanical and tribological loads they are subjected to. Therefore, this article shows the effect of two titanium oxide-based pigments and three delivery methods on the microstructural, geometrical, mechanical and tribological properties of injection-moulded POM gears.

2 Materials and methods

2.1 Materials and specimens

For this research, a commercial grade, non-coloured POM of the type Hostaform C9021 by Celanese Services Germany GmbH (Kelsterbach, Germany), was chosen as the basis and reference material, due to its good processing, crystallisation and tribological properties. The influence of pigment type on part properties was investigated on two types of pigments in direct compounding: Dei®Pow – Weiß, a white TiO2 pigment supplied by Deifel GmbH & Co. KG Buntfarbenfabrik (Schweinfurt, Germany), and Sicotan Gelb K 2001 FG, a yellow chrome antimony titanium oxide rutile pigment (Cr/Sb/Ti oxide) provided by BASF Pigment GmbH (Besigheim, Germany). These pigments were chosen because they are both widely used commercially due to their ability to produce brightly coloured parts.

Furthermore, the influence of three common delivery methods was researched for the TiO2 pigment. Besides direct compounding the pigment in the plasticising extruder of the injection-moulding machine, a masterbatch and a liquid colour were used in premixed batches. The masterbatch of the type Lifocolor-Weiss K 70 PE is based on a polyethylene (PE) carrier material and was supplied by Lifocolor Farben GmbH & Co. KG (Lichtenfels, Germany). The liquid colour of the type FL 1052.01 is based on a polyether polyol carrier material and was provided by Rowasol GmbH (Pinneberg, Germany). Both, masterbatch and liquid colour are commercial grade all-purpose colourants with a pigment concentration in the carrier of 70% by weight. The materials were dosed to achieve a pigment concentration of 0.5% by weight in the injection-moulded part. The masterbatch and the liquid colours were dosed with 0.7% by weight to offset the carrier. The pure pigments were direct compounded with 0.5% by weight. From these materials, gear specimens were produced by injection-moulding and tested against a steel pinion. The gear size was chosen according to VDI 2736 to represent a typical gear size in actuating drives. The gear specifications are shown in Table 1.

Overview of gear specifications.

| Parameter | Unit | Gear | Pinion |

|---|---|---|---|

| Material | – | Hostaform C9021 (with and without pigments) | Steel 100Cr6 |

| Gear type | – | Spur gear | |

| Module | mm | 1 | |

| Number of teeth | – | 39 | 17 |

| Gear width | mm | 6 | 8 |

| Profile shift | mm | −0.3135 | −0.2045 |

| Pressure angle | ° | 20 | |

The specimens were produced using an injection-moulding machine of the type Arburg 370 U-700-30-30, by Arburg GmbH & Co. KG (Loßburg, Germany), with a plasticizing unit with an 18 mm screw diameter. Table 2 shows an overview of the main processing parameters.

Overview of the main processing parameters.

| Processing parameter | Unit | Value |

|---|---|---|

| Cylinder temperature (Nozzle→Hopper) | °C | 205/200/195/190/50 |

| Mould temperature | °C | 105 |

| Injection-/packing-/cooling-/cycle-time | s | 1.5/28.5/15/55 |

| Packing pressure | bar | 1200 |

2.2 Crystallisation behaviour

For the analysis of the crystallisation behaviour of the materials, a calorimeter of the type Q 1000 TMDSC, by TA-Instruments (New Castle, DE, USA) was used. The crystallisation speed of the materials was determined by isothermal differential scanning calorimetry (DSC). The sample was heated to 200°C for 1 min to eliminate the previous thermal history of the material and then cooled to an isothermal holding temperature of 154°C. This temperature was chosen based on previous research by Xu and He [18] for good differentiation between the materials.

2.3 Pigment structure, colourant dispersion, part microstructure and geometry

A scanning electron microscope of the type of the type Zeiss Ultra Plus by Carl Zeiss AG (Oberkochen, Germany) was used to determine the form, structure and size of the pigment particles. In order to characterise the pigment dispersion and morphology of the polymer gears, 10 μm thin cuts were taken from the middle of the gear across the same tooth for one exemplary specimen of each material. For analysis of the thin cuts, a transmitted light microscope of the type Zeiss Axioplan 2, by Carl Zeiss AG was used. Polarised light was used to show the crystalline structure, and bright field micrographs were taken to show pigment dispersion. Additionally, the degree of crystallinity of the specimen was determined using DSC on a 5 mg sample prepared by scalpel from the flank and the core of a representative tooth. The heating rate was 20 K/min. The degree of crystallinity was determined as the ratio of the melting enthalpy of the crystalline phase, Hm, to the theoretical value of 100% crystalline material, H0 (220 J/g [19]).

To investigate the effect of crystallisation on the shrinkage of the material, the geometry of the gears was characterised using the diametric dimension over pins, measured at three equidistant measuring locations over the gear circumference according to DIN 21773. Additionally, the density of the parts was determined on three specimens per category according to DIN 53 479 using the buoyancy method. The effect of the colourant on the density should be negligible due to the low dosage.

2.4 Mechanical properties

A hydraulic pulsator test rig built by LUVRA Hydraulik und Regeltechnik GmbH (Nuremberg, Germany) was used to determine quasistatic tooth root break force F and corresponding tooth deflection s for three representative teeth on three specimens for each material. The force was measured using a load cell, type U2B, and the displacement was recorded with a displacement transducer, type W1T3, both by Hottinger Baldwin Messtechnik GmbH (Darmstadt, Germany). A single metal tooth was used to apply an increasing force on the polymer gear, which was generated by a hydraulic cylinder of the type HS5132 by LUVRA Hydraulik und Regeltechnik GmbH. The force was increased by a rate of 100 N/s until break. In a force-deflection plot, the point where dF/ds first equalled 0 was evaluated as the point of breakage. Furthermore, the damping characteristic of the materials was determined in a hysteresis test. A sinusoidal force between 20 N and 200 N with a frequency of 1 Hz was applied to the specimens for 1000 cycles. Three representative teeth of three specimens were tested for each material. The resulting hysteresis curve was recorded and the damping factor was evaluated as the ratio of the calculated loss energy to the calculated strain energy. The mean damping factor was determined between cycles 500 and 750, after the system had reached a steady state.

2.5 Tribological properties

The tribological tests were performed on a non-mechanically closed loop test rig as specified in VDI 2736 [1] to determine the wear behaviour of the material. Each material was tested with three specimens. Each test consisted of 8 h at 1.0 Nm output torque, generated by a magnetic powder brake, type 2PB43 by Magtrol SA (Rossens, Switzerland). A DC-motor, type DS 71-K by Baumüller GmbH (Nuremberg, Germany), was used to generate an input speed of 2300 rpm at the steel pinion, leading to an output speed at the POM wheel of 1000 rpm, resulting in approximately 480,000 load cycles per test. To characterise wear, the change in diametric dimension over the pins before and after the gear tests was evaluated at three equidistant measuring locations.

3 Results and discussion

3.1 Crystallisation behaviour

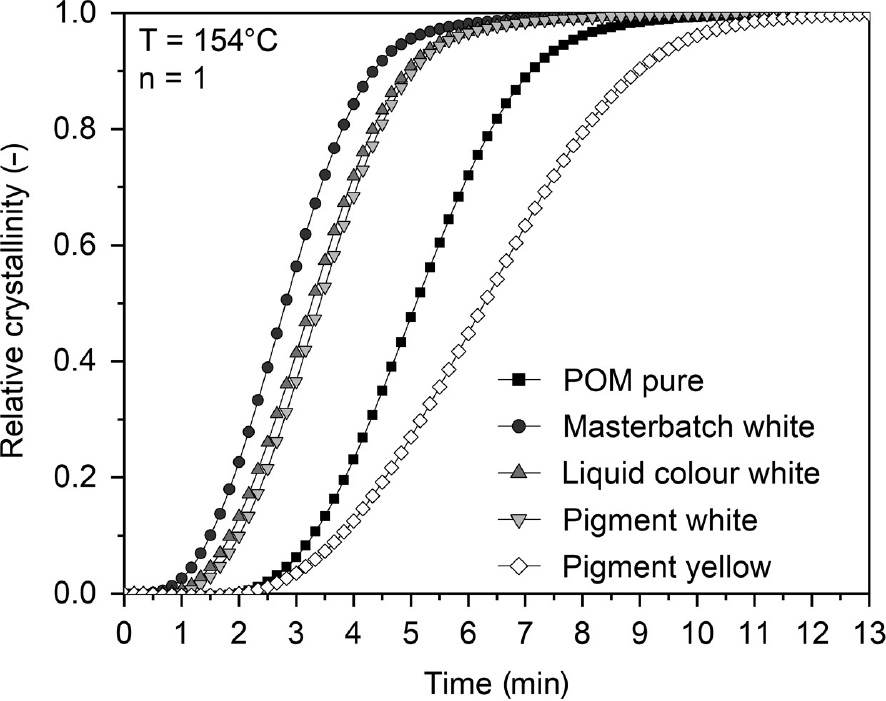

Depending on the choice of pigment, or lack thereof, the materials had significantly different crystallisation behaviours (Figure 1). Compared to the base material, the materials with TiO2 pigments showed an increase in crystallisation speed. This is probably due to the nucleating effects of the pigment particles on the material. The materials with the yellow pigment, however, showed a significantly lower crystallisation speed, suggesting a denucleating effect of the pigment on POM.

Crystallisation behaviour of Hostaform C9021 dependent on choice of pigment and delivery method.

If the delivery methods are compared, the material with the TiO2 masterbatch showed the highest crystallisation speed. However, compared to the base material, there was little to no significant difference in the crystallisation speed between the delivery methods masterbatch, liquid colouring and direct compounding for the TiO2 pigments. This implies that the effect of the pigment on the crystallisation speed is much more prominent than the effect of the carrier systems. As a result of the changes in crystallisation kinetics, the materials will probably display different solidification and crystallisation behaviours. Fast crystallisation in combination with additional nuclei in the form of pigment particles should lead to a fine, highly crystalline structure of the TiO2-based colourants, regardless of the chosen carrier system. Since the particles of the yellow pigment seem to have a hindering effect on the crystallisation, a slower growth of crystalline structures and a coarser structure is expected. Due to the high influence of the resulting microstructure on the mechanical and tribological properties, the choice of pigment has to be carefully considered, whereas the choice of delivery method seems to be of less consequence. In the following, the influence of the changed crystallization behaviour on the resulting microstructure and the dimensional accuracy of the components, as well as their mechanical and tribological behaviour, will be discussed.

3.2 Pigment structure, colourant dispersion, part microstructure and geometry

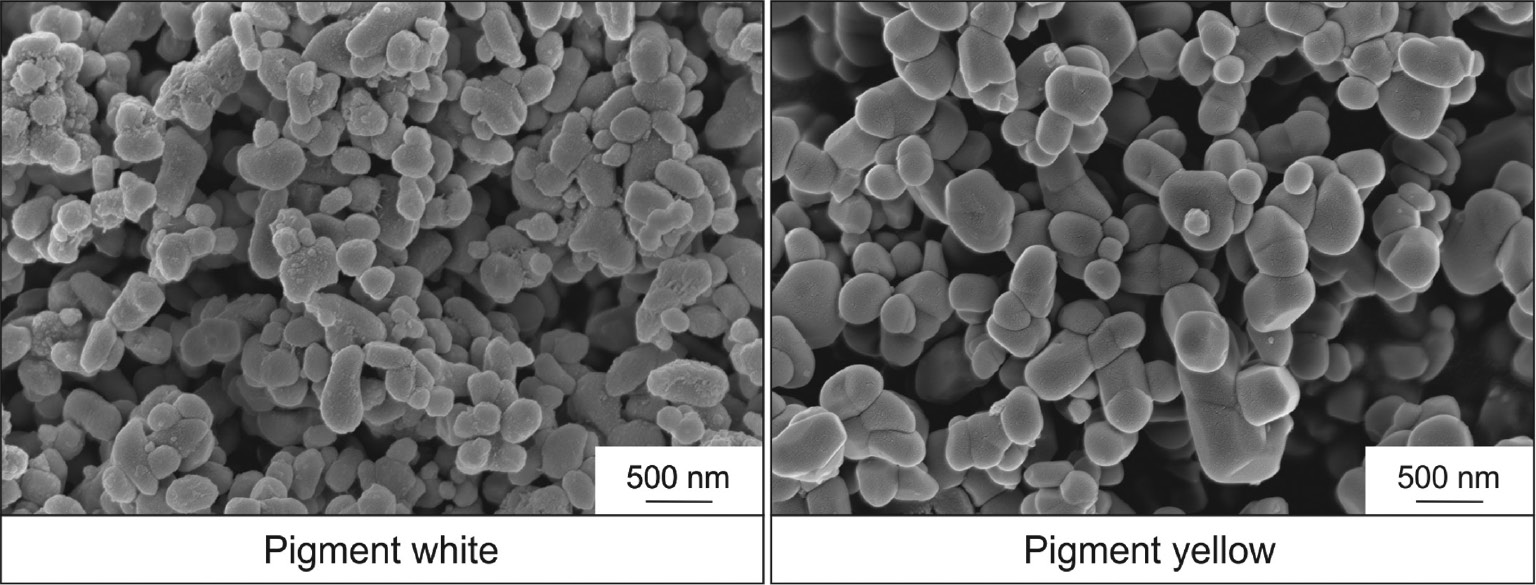

Both pigments showed particles with a similar globular structure and a size range of 200–300 nm, as specified by the manufacturers (Figure 2). The yellow pigment displayed slightly larger particles at about 300 nm, with some particles reaching 500 nm, and the size of the white pigment tended towards 200 nm. Both pigments, however, showed rounded particles. The surface of the white pigment particles looked rougher than the smooth surface of the yellow pigment particles. Since there were no significant differences in the particle size or structure, the different effects of the two pigments is probably due to different surface interactions between the polymer and the pigment, based on chemical composition.

Scanning electron microscopy (SEM) images of the white and yellow pigment particles.

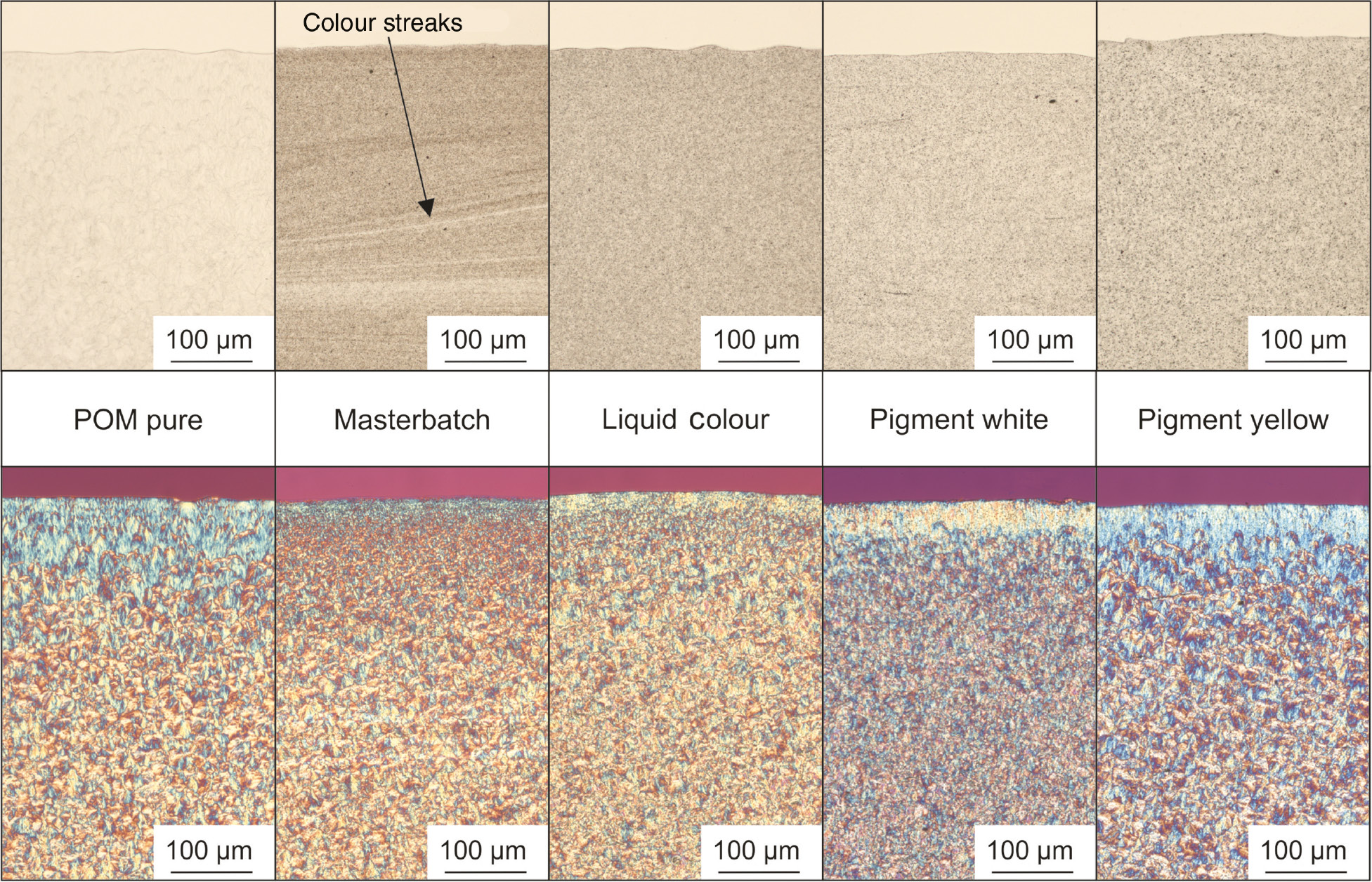

If pigment dispersion is analysed, the delivery methods of liquid colour and direct compounding showed a very good dispersed pigment, whereas the masterbatch exhibited inhomogeneous colouration in the form of colour streaks (Figure 3).

Pigment dispersion (top) and morphology (bottom) of the test specimens.

These colour streaks indicate an issue with the compatibility of the carrier material of the masterbatch, PE, and the base material POM. Usually the carrier is dispersed finely and evenly in the base material. However, unfavourable mixing and flow conditions during melting and injection can lead to inhomogeneous dispersion. This can cause agglomeration of the carrier and pigment and areas of pure base material due to surface tension effects, seen as colour streaks. Thus, potential weak points for the initiation of breaks can be created. This could be avoided if the carrier material is the same as the base material. However, due to the wide variety of polymers, always adapting the carrier material is not cost-efficient. Thus, carrier systems are often developed to work well with a band of polymers. The risk of minor miscibility issues, like colour steaks, is often accepted, as long as they do not constitute optical or mechanical faults in the part. Since no colour streaks were detected during the production of the specimen, changes in the process setup were not considered necessary.

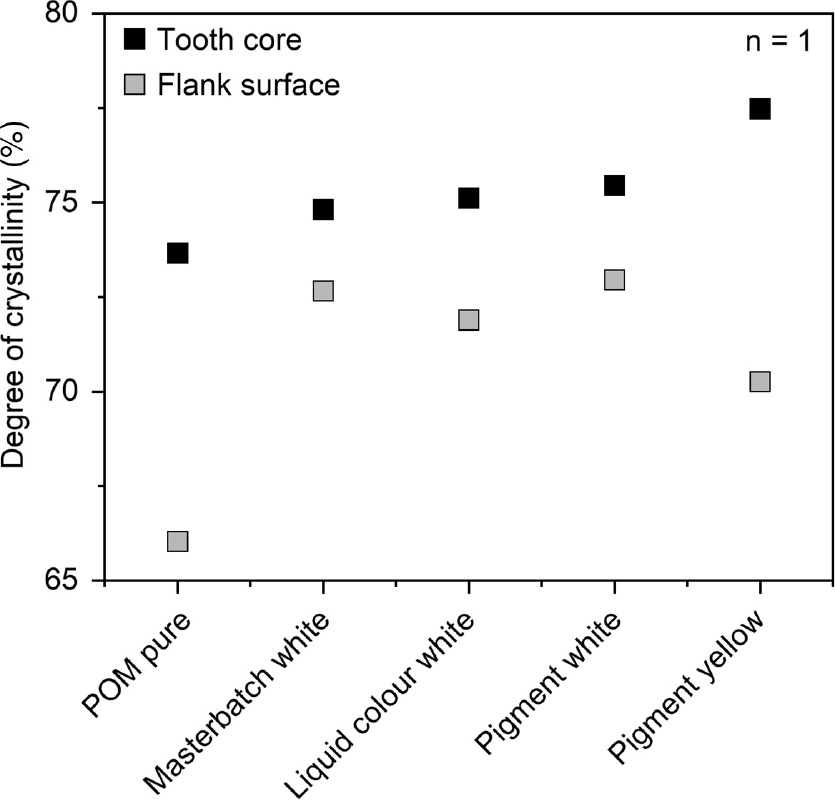

In addition to the variances in dispersion of the pigments, the differences in the crystallisation behaviour of the pigments and delivery methods affected the part morphology significantly. All TiO2-based colourants showed a very fine crystalline structure up to the edge of the part compared to the pure POM material (Figure 3). The edge layer was significantly reduced. The change in morphology can, as hypothesised, be traced back to the pigment increasing the crystallisation speed through presenting additional nuclei. However, the yellow pigment seems to lead to a coarser morphology with no change in the edge layer thickness, which is further indication of a denucleating effect. However, compared to the base material, all other materials showed higher degrees of crystallinity, both in the flank and the core (Figure 4). Although the yellow pigment showed the lowest crystallisation kinetics and the coarsest morphology, it showed the highest degree of crystallinity in the core. One explanation may be that the decreased nucleation allows individual spherulites more time to grow bigger and develop higher lamellar structures. This would lead to the detected coarser microstructure with a higher degree of crystallinity, since higher lamellar structures and bigger spherulites require higher amounts of energy to melt in the DSC. In the flank, however, the yellow pigment shows the lowest degree of crystallinity for all coloured materials, which corresponds to the thicker optically amorphous edge layer. Thus, the DSC results validate the microscopic findings.

Degree of crystallisation in the tooth flank and core determined by differential scanning calorimetry (DSC).

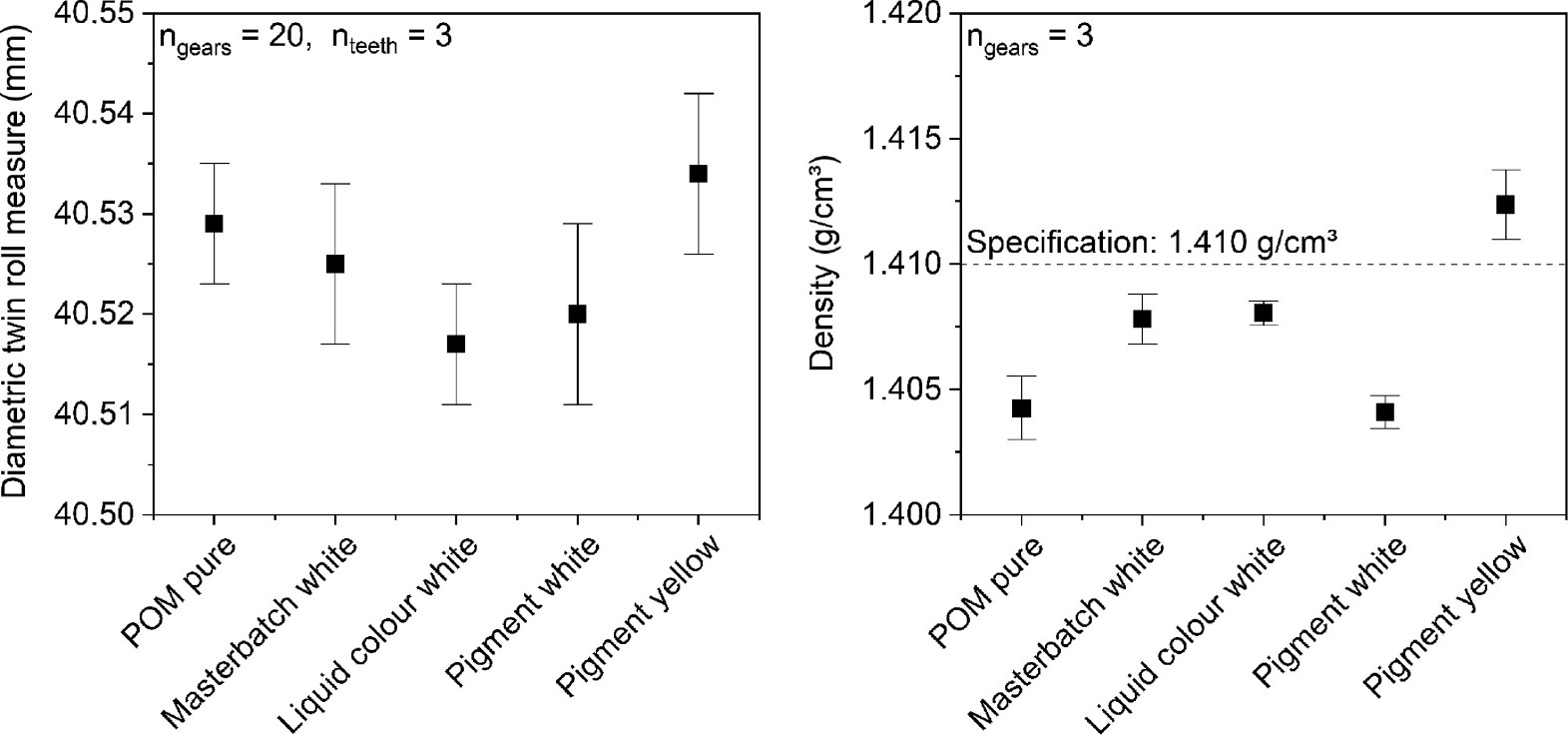

There was also a significant influence of both the delivery method and pigment type on the shrinkage, affecting the gear geometry (Figure 5). Compared to the base material, the parts with TiO2 colourants showed lower diametric twin roll measurements and therefore a higher shrinkage. An explanation for this behaviour could be the higher degree of crystallisation, leading to a higher shrinkage and density. This seems to be the case for the specimens colourised with masterbatch and liquid colour (Figure 5). The specimens with the pure white pigment, however, showed no change in density, but still had a higher shrinkage. This could indicate a reduced effectivity of the packing pressure due to earlier sealing of the sprue gate for this material. While the higher degree of crystallisation would increase the density, the reduced compression of the melt into the cavity would lead to a decrease in density. Both effects together, however, could lead to an increase in the shrinkage, possibly without an effect on the density.

Effect of pigments and carrier systems on the gear geometry (left) and the density (right).

Furthermore, specimens with the yellow pigment show lower shrinkage, despite having the highest degree of crystallisation in the core. This is probably due to the lower crystallisation speed increasing the seal time of the sprue gate. Thus, more material could be compressed into the mould compared to the other materials, reducing shrinkage. This hypothesis is supported by the increase of part density for the gears with the yellow pigment, which corresponds to a higher amount of melt being compacted into the mould during the holding phase (Figure 5).

3.3 Mechanical properties

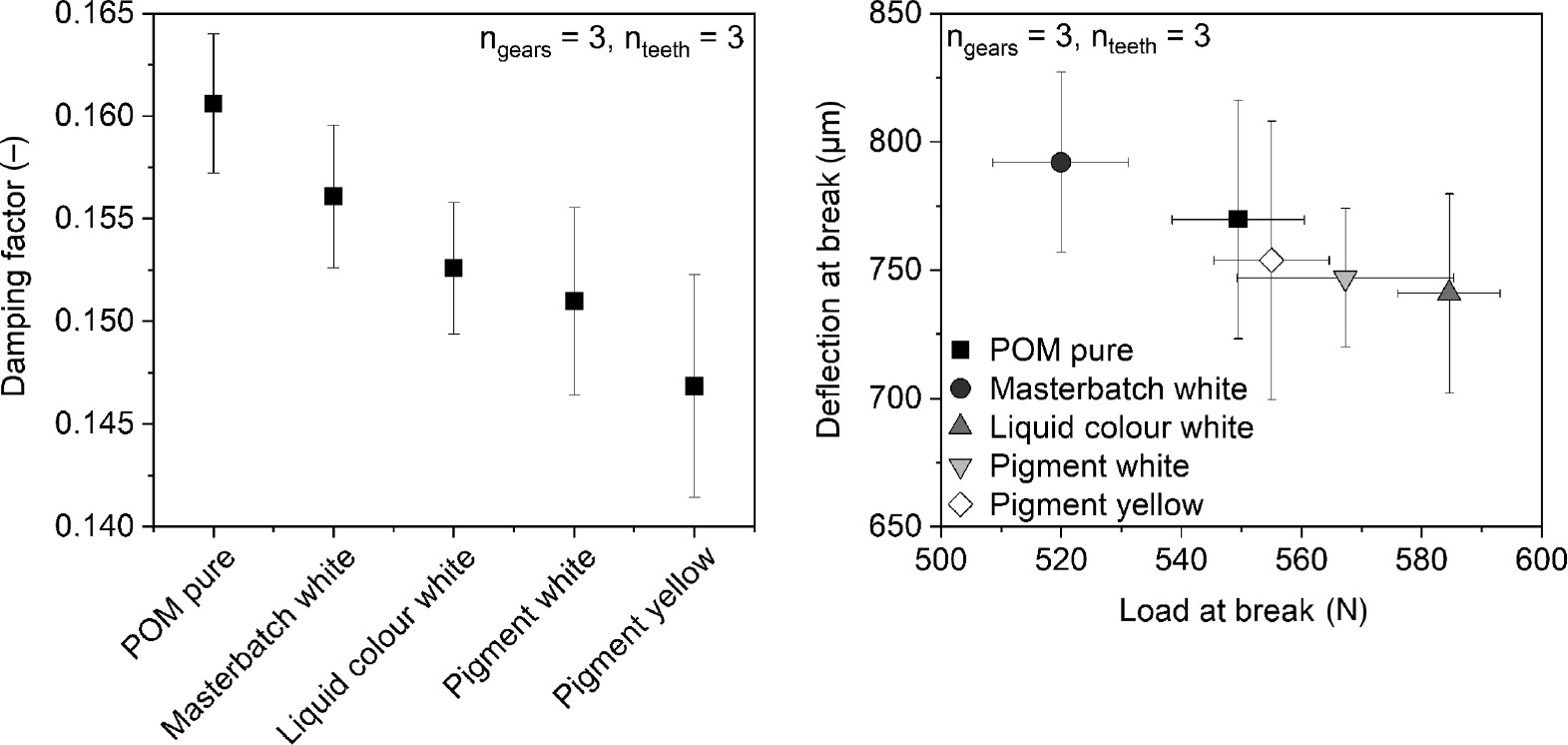

The mechanical properties were significantly influenced by the delivery method and the pigment type. The mechanical damping factor, indicative of energy loss due to warming, correlated highly with the degree of crystallisation (Figure 6). Higher degrees of crystallinity in the core material correlated with lower damping factors. This is due to the differences in the deformation behaviour of the crystalline and amorphous phases in the material. Due to their structure, the amorphous phases display higher viscous behaviour than the crystalline phases. Thus, a higher amount of amorphous phases, or a lower degree of crystallinity for that matter, correlate with higher damping factors and higher loss energy. The degree of crystallinity in the flank or the edge layer seems to have no effect on damping. For a gear system, this results in the effect that the efficiency of the gear set can be increased by optimising the microstructure in the part core to lower the damping factor, in order to reduce the amount of loss energy being converted into heat. Since the choice of colourant can influence the microstructure of the gear, the right colourant could improve the efficiency of the gear set by reducing the damping.

Mean damping factor in dependence of pigment and delivery method (left), effect of pigment choice and carrier system on break deflection and load (right).

Besides the damping characteristic of a material, the material strength is of the upmost importance to ensure product functionality. For gears, the material has to withstand the bending forces created by the applied torque without bending too much, causing the gear to slip. On analysis of the material strength (Figure 6), there was a tendency for the coloured materials towards higher loads at break and a slightly reduced deflection at break compared to the pure material. This is in good accordance to other research, suggesting the finer and more highly crystalline structure of nucleated materials to be the cause of reduced ductility and increased material strength [15]. For the yellow pigment, the change seemed to be insignificantly small. The specimen with the direct compounded white pigment showed a significant increase of load at break from 550 N to 570 N. The liquid colour showed the highest increase in breaking force at 585 N. There seems to be no direct correlation between the investigated properties and the increase in breaking force for the specimens with liquid colour. One hypothesis for the good performance of these gears could be that the low molecular carrier allows for better load distribution in the material by increasing intermolecular forces across the boundaries of spherulites. However, this is the subject of further research.

In contrast to the other materials, significantly lower loads at break and an increase in deflection at break were detected for the masterbatch specimens. This is probably due to the inhomogeneous distribution of the carrier material in the base material. Since PE and POM are not chemically compatible, agglomerations of PE, as in the case of the colour streaks seen in the micrographs (Figure 3), can be potential weak points. However, PE is much more ductile than POM. Thus, the carrier acts as both an impact modifier and a weak spot, increasing break deflection and lowering break load. A more homogeneous distribution could probably alleviate the reducing effect on the load at break; this, however, would require changes in the manufacturing setup to ensure better dispersion. Since there were no visible indicators of the inhomogeneous dispersion during production of the specimens, and those detected in the micrographs were rather minor, this was not further investigated. Additionally, dispersion can only be assessed after production. Thus, optimisation requires complex iterations of setup changes and assessment, which are often considered too costly in practical applications, if there are no visible faults in the product. The results of the masterbatch specimens are therefore representative for results obtained in industrial applications. Thus, if high loads at break are required, it is sensible to prefer pre-pigmented material or liquid colours and avoid masterbatches as colourants, or at least ensure thorough dispersion in the process.

3.4 Tribological properties

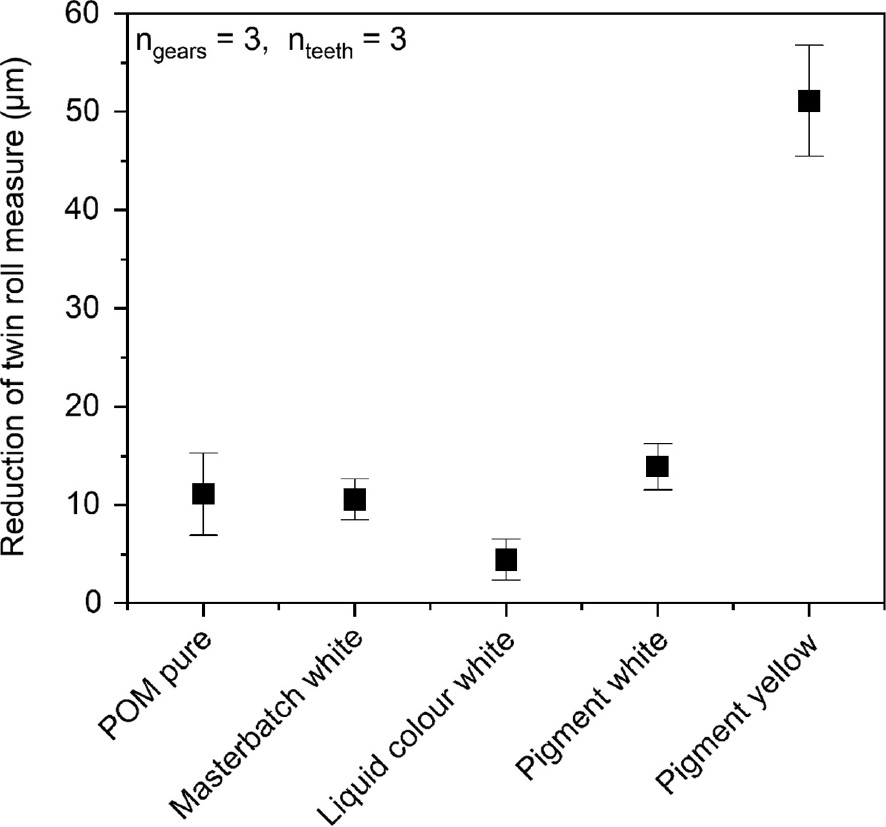

The delivery method and pigment significantly changed the wear behaviour of the materials (Figure 7). The masterbatch specimen and the pure POM specimen exhibited the same reduction in twin roll measure, around 11 μm, whereas both pigment specimens showed increased wear; 14 μm and 57 μm, respectively. The pigment particles have a significantly higher hardness compared to POM and thus wear debris containing these particles could cause increased abrasion, comparable to abrasives in grinding or polishing. For the yellow pigment, wear increased by a factor of 5. This was probably due to the abrasive properties of the wear debris in combination with the coarse microstructure, since crystalline structures are more brittle and are therefore more susceptible to abrasive processes. It could be possible that the yellow pigment displays lower adhesion of the polymer and to the pigment particles compared to the white pigment. This could contribute to the increased wear, as low adhesion would lead to increased removal of abrasive particles. Due to the size of the particles, the adhesion could not be determined on the available equipment. However, due to differences in the chemical composition of the pigments, differences in adhesion may not be unlikely. A special case is the liquid colour, as it actually decreases specimen wear to 5 μm. This wear reduction is probably caused by the low molecular polyether polyol carrier acting as an incorporated lubricant, as similar effects are known for materials compounded with silicone oil. The carrier of the masterbatch, PE, is also known for its very beneficial tribological properties. It is often used as an incorporated lubricant for the reduction of wear. This lubricating effect of the carrier materials would explain why the masterbatch and the liquid colour show low wear despite containing the same abrasive particles.

Effect of pigments and carrier systems on the wear behaviour.

Thus, the combined effect of the incorporated lubricant and a more wear-resistant fine crystalline microstructure could be the cause of the beneficial wear properties of the specimens with liquid colour, despite the abrasive effect of the pure pigment. To reduce wear in application purposes, it is therefore advisable to consider colourants, which act as both, nucleating agents, to ensure a wear-resistant microstructure, and an incorporated lubricant.

4 Conclusions

In summation, the use of colourants significantly alters the properties of POM gears in two ways: direct effects on part properties and effects due to changes in microstructure. A direct effect of the carrier materials on part properties is only seen in the mechanical and tribological properties. It was shown that deformation at break and load at break can be influenced by the carrier material. The masterbatch carrier acted as both an impact modifier, increasing deformation at break, and a weak spot, decreasing load at break. The liquid colour increased load at break, which may be due to an increase in intermolecular forces at the boundaries of spherulites. However, further research on the effect of carrier materials is needed to identify the exact effect mechanisms. Regarding the tribological properties, it was shown that hard pigments can lead to increased wear, especially in combination with coarse microstructures, and potentially weaker adhesion to the base material. This effect could be counteracted if the carrier material also had lubricating properties, as prominently seen for the low molecular polyether polyol carrier material in the liquid colour. However, all these effects are superimposed with effects due to the changes in morphology.

Colourants can have nucleating or denucleating effects on polymers changing their microstructure, depending on the complex interaction of the involved materials. It was shown that pure TiO2 had a nucleating effect on POM, regardless of the delivery method. This led to an increase in crystallisation kinetics, higher degrees of crystallinity in the flank and core, and finer morphological structures with significantly reduced edge layers in injection-moulded gears compared to the base material. This finer, highly crystallised microstructure also leads to higher shrinkage and lower damping. The white pigment also showed less influence on wear. In contrast, the yellow pigment showed a denucleating effect on the material. This leads to a coarser microstructure, as seen in the micrographs of the specimens. However, the degree of crystallisation in the core was elevated compared to the nucleated and the base material. This indicated the formation of larger spherulites with higher lamellar structures due to the slower crystallisation. The degree of crystallisation also correlated inversely with the damping factor, suggesting that the coarser higher crystalline structures were less damping. Furthermore, it was shown that the coarser microstructure of the material in combination with the abrasive properties of the yellow pigment, and possibly a lower adhesion to the base material, leads to a lower wear resistance than the finer microstructures by a factor of 5.

In conclusion, the choice of colourant can significantly influence the geometrical, microstructural, mechanical and tribological properties of a polymer part. They can be both improved and decreased, depending on the compatibility of the chosen pigment. Due to this complex interaction between the pigment and the base material, further research into the effects of pigments is needed, especially into the cause and effect of denucleating properties. The choice of carrier system is of secondary importance. However, liquid colours present additional potential in tribological applications due to their effect as an incorporated lubricant. To ensure the desired product properties, it is therefore of importance to consider the effects of different colourants during product origination to avoid costly corrections during production.

Award Identifier / Grant number: DR 421/21-1

Funding statement: The authors would like to thank the German Research Foundation for funding this research in the research group FOR 2271 “Prozessorientiertes Toleranz-management mit virtuellen Absicherungsmethoden” under grant number [Funder Id: http://dx.doi.org/10.13039/501100001659, DR 421/21-1].

Acknowledgements

The authors would like to thank the companies Celanese Corp., BASF Pigment GmbH, Deifel GmbH & Co. KG Buntfarbenfabrik, Lifocolor Farben GmbH & Co. KG, and Rowasol GmbH for providing research materials.

Conflict of interest statement: The authors declare that there are no conflicts of interest regarding the publication of this paper.

References

[1] Thermoplastische Zahnräder, VDI 2736, 2016.Suche in Google Scholar

[2] Klemchuk PP. Polym. Photochem. 1983, 3, 1–27.10.1016/0144-2880(83)90042-8Suche in Google Scholar

[3] Haastrup S, Yu D, Broch T, Lambertsen Larsen K. Color Res. Appl. 2016, 41, 484–492.10.1002/col.21987Suche in Google Scholar

[4] Müller A. Colouring of Plastics: Fundamentals – Colorants – Preparations. Carl Hanser Verlag: Munich, Germany, 2012.Suche in Google Scholar

[5] Richaud E. In Polyoxymethylene Handbook: Structure, Properties, Applications and Their Nanocomposites, John Wiley & Son: Hoboken, NJ, USA, 2014, 53–104.10.1002/9781118914458.ch3Suche in Google Scholar

[6] Buxbaum G, Ed., Industrial Inorganic Pigments, John Wiley & Sons: Hoboken, NJ, USA, 2008.Suche in Google Scholar

[7] Wacharawichanant S, Sangkhaphan A, Sa-Nguanwong N, Khamnonwat V, Thongyai S, Praserthdam P. J. Appl. Polym. Sci. 2012, 123, 3217–3224.10.1002/app.34984Suche in Google Scholar

[8] Darras O, Seguela R. J. Polym. Sci. Part B: Polym. Phys. 1993, 7, 759–766.10.1002/polb.1993.090310702Suche in Google Scholar

[9] Piorkowska E, Rutledge G. Handbook of Polymer Crystallization, Wiley: New York, 2013.10.1002/9781118541838Suche in Google Scholar

[10] Künkel R. Auswahl und Optimierung für Tribologisch Beanspruchte Systeme, University Erlangen-Nuremberg: PhD thesis at the Institute of Polymer Technology, 2005.Suche in Google Scholar

[11] Archodoulaki V-M, Lüftl S, Seidler S. Adv. Polym. Technol. 2006, 25, 63–72.10.1002/adv.20060Suche in Google Scholar

[12] Wallner GM, Geretschläger KJ, Hintersteiner I, Buchberger W. J. Plast. Film Sheeting 2016, 1, 1–17.Suche in Google Scholar

[13] Yousef S, Visco A, Galtieri G, Njuguna J. Polym. Adv. Technol. 2016, 10, 1338–1344.10.1002/pat.3801Suche in Google Scholar

[14] Jose AJ, Alagar M. Polym. Compos. 2011, 32, 1315–1324.10.1002/pc.21152Suche in Google Scholar

[15] Ouyang C, Xiang X, Xue W, Gao Q, Zhao Z, Zheng K, Zhang W, Zhang D. In 5th International Conference on Advanced Engineering Materials and Technology (AEMT 2015), Guangzhou, China, 2015.Suche in Google Scholar

[16] Bazan P, Kuciel S, Nykiel M. Polym. Eng. Sci. 2019, 59, 935–940.10.1002/pen.25039Suche in Google Scholar

[17] Dearn KD, Hoskins T, Petrov D, Reynolds SC. Wear 2013, 298, 99–108.10.1016/j.wear.2012.11.003Suche in Google Scholar

[18] Xu W, He P. J. Appl. Polym. Sci. 2001, 80, 304–310.10.1002/1097-4628(20010411)80:2<304::AID-APP1100>3.0.CO;2-NSuche in Google Scholar

[19] Ehrenstein GW, Riedel G, Trawiel P. Praxis der Thermischen Analyse von Kunststoffen, Hanser Verlag: Munich, Germany, 2003.Suche in Google Scholar

© 2019 Dominik Schubert et al., published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Artikel in diesem Heft

- Frontmatter

- Material properties

- Chitosan as an emerging object for biological and biomedical applications

- Investigation of the properties of polystyrene-based wood plastic composites: effects of the flame retardant loading and magnetic fields

- An attempt to correlate the physical properties of fossil and subfossil resins with their age and geographic location

- Effect of heat treatment on the thermophysical properties of copper-powder-filled polycarbonate and polycarbonate containing paraffin

- Preparation and assembly

- Preparation of hydrophilic reactive polyurethane and its application of anti-water erodibility in ecological restoration

- Antimicrobial gelatin/sericin/clay films for packaging of hygiene products

- Functional sol-gel coated electrospun polyamide 6,6/ZnO composite nanofibers

- Influence of the incorporation of different chemically functionalized carbon nanotubes in polyurethane resin applied on aluminum

- Engineering and processing

- Influence of shrinkage of polymer on the stationarity of propagation of frontal polymerization heat waves

- Influence of titanium oxide-based colourants on the morphological and tribomechanical properties of injection-moulded polyoxymethylene spur gears

Artikel in diesem Heft

- Frontmatter

- Material properties

- Chitosan as an emerging object for biological and biomedical applications

- Investigation of the properties of polystyrene-based wood plastic composites: effects of the flame retardant loading and magnetic fields

- An attempt to correlate the physical properties of fossil and subfossil resins with their age and geographic location

- Effect of heat treatment on the thermophysical properties of copper-powder-filled polycarbonate and polycarbonate containing paraffin

- Preparation and assembly

- Preparation of hydrophilic reactive polyurethane and its application of anti-water erodibility in ecological restoration

- Antimicrobial gelatin/sericin/clay films for packaging of hygiene products

- Functional sol-gel coated electrospun polyamide 6,6/ZnO composite nanofibers

- Influence of the incorporation of different chemically functionalized carbon nanotubes in polyurethane resin applied on aluminum

- Engineering and processing

- Influence of shrinkage of polymer on the stationarity of propagation of frontal polymerization heat waves

- Influence of titanium oxide-based colourants on the morphological and tribomechanical properties of injection-moulded polyoxymethylene spur gears