Abstract

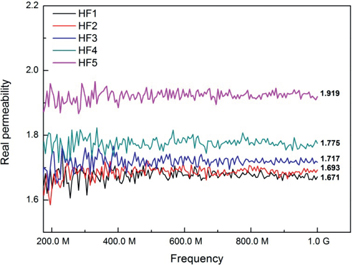

In this study the modification effect of Hf content on the shape memory properties and magnetic permeability of a 75.5-77Ti-20Ta-3-4.5Hf alloy system has been systematically studied by DSC, three-point bend test, vector network analyzer and XRD. The martensitic transformation temperature, heat of reaction and recovery strain increases with the increase of hafnium and tantalum content. A stable high temperature shape memory effect was observed (Ms = 385–390 °C) during the two thermal cycles between 20 °C and 725 °C. Transformation temperatures and heats of reaction were determined by DSC measurements. Recovery strain was determined by three-point bend testing. Also an alloy, 70Ti-26Ta-4Hf, with higher tantalum content was produced to observe the effect of Ta on the shape memory properties. Permeability increases gradually from 1.671 to 1.919 with increasing content of hafnium modification and remains stable in the frequency range of 450 MHz to 1 GHz.

Introduction

Researchers are consistently attempting to develop and characterize the potential high temperature shape memory alloys with higher martensitic transformation temperatures for applications like aerospace, automotive, actuators, sensors, and size reduction efforts for electromagnetic components [1–4]. With the improved knowledge of microstructural and physical properties, the applications of HTSMA’s in different fields are increasing [5–9]. Various reviews of different systems provide the high temperature shape memory and super elastic properties along with processing techniques, processing problems and commercial high temperature applications [10–13].

Ti-Ni based alloys have been successfully developed but their Ms temperature is below 100 °C [14]. Development of β-type Ti-based alloys resulted in excellent workability and stable shape memory effect at higher temperatures, including Ti-Nb and Ti-Ta alloys [15–19]. Ti-Ta30-40 alloys have good shape memory effect and Ti-Ta32 alloys have shown exhibiting stable high temperature shape memory effect with Ms = 167 °C [19]. Ternary alloying elements (V, Cr, Fe, Zr, Hf, Mo, Sn, Al) decreased the Ms temperature of higher tantalum content Ti-alloys and strongly suppressed the formation of omega (ω) phase [20, 21]. Systematic study on the effects of Ta and Sn contents on the shape memory behavior, thermal stability and crystal structure of Ti-Ta-Sn alloy suggested that high transformation temperatures can be achieved by the adjustment of Ta content [22]. In the present study, shape memory and magnetic properties were investigated in hafnium modified Ta alloys.

Experimental

Five experimental Ti-Ta hafnium modified alloys were prepared in an Edmund Buhler non-consumable vacuum arc melting furnace from elemental constituents with 99.95 % purity in a high purity argon atmosphere using a water-cooled copper crucible. Chemical composition (atomic %) and sample ID’s are presented in Table 1. In order to melt 50 g of each sample, appropriate amounts of all the elements were cleaned in mechanical ultrasonic cleaner (BJUC1.3) for 20 min. To get rid of any remaining oxygen in the melting furnace chamber 100 g of pure titanium was melted as getter. Melting was done at 350 amperes of electrode current. Due to the substantial density differences and melting points of Ti and Ta, it was difficult to melt the tantalum completely in one step. Consequently, the buttons were turned over and remelted eight times in an attempt to insure homogeneity. The mass loss after eight melting cycles was 0.14 % so the actual composition was achieved.

Chemical composition (at%) and sample ID of the alloys produced.

| Sample ID | Chemical composition |

|---|---|

| Hf1 | 77Ti-20Ta-3Hf |

| Hf2 | 76.5Ti-20Ta-3.5Hf |

| Hf3 | 76Ti-20Ta-4Hf |

| Hf4 | 75.5Ti-20Ta-4.5Hf |

| Hf5 | 70Ti-26Ta-4Hf |

Each arc melted sample was homogenized at 1,025 °C for six (06) hours in a vertical tube furnace with flowing argon at 90 L/h, followed by a furnace cool to room temperature. Homogenization treatment was employed to remove any atomic segregation. Grain morphology and chemical homogeneity were characterized using a FEI-Nova 600 Nano lab dual beam electron microscope equipped with EDAX system at 25 kV.

After homogenizing annealing samples were hot rolled at 830 °C up to 85 % thickness reduction in a strip form. A thin surface oxide layer formed during hot rolling was removed completely by sand blasting the strips carefully at low pressure. For DSC, XRD and three-point bend test samples were prepared using thin diamond blade slow speed saw, while magnetic permeability specimens were cut by an electro-discharge machine followed by washing in petroleum ether to remove surface contamination. The samples were solution treated to 1,030 °C (rolling temperature plus 300 °C) for 90 min in flowing argon atmosphere, then quenched in iced brine solution. The minor surface oxide formed during quenching was completely removed by polishing the samples.

The martensitic and austenitic transformation temperatures along with magnitude of transformation enthalpy were determined using TA-2920 differential scanning calorimeter with 20 °C/min heating and 5 °C/min cooling rate. In the present study various heating and cooling rates were experimented because the metallic shape memory alloys exhibits thermoelastic transformations involving displacive shear transformations. This heating and cooling regime during DSC measurements was selected, keeping in view the actual working conditions of alloys in service where the heating rate is high but the cooling rate is very slow owing to the low thermal gradient between machinery components and the atmosphere. Each sample was cycled through three hysteresis cycles to ensure the stability of phases and transformation temperatures.

X-ray diffraction (XRD) investigations were conducted on a Bruker DX8 using Cu Kα radiation to identify the RT phase with an accelerating voltage of 40 kV and scanning speed of 1°/min. Indexation of the patterns was performed with the help of Expert high score software which compared the diffraction data with JCPDS powder diffraction file (PDF) database.

The shape memory effect was investigated by three-point bend testing [23, 24] as shown in Figure 1. Rectangular strip specimens, 20 × 4 × 1.5 mm, were deformed at room temperature using a three-point bend test around a 10 mm diameter round bar setup in INSTRON 5567 at a strain rate of 0.1 mm/min.

Schematic illustration of the three-point bend test SME measurement.

After bending the samples were heated to 600 °C for load free recovery in a single zone argon atmosphere furnace. Specimen recovered its shape during heating to its “hot” shape after which it was cooled in the furnace to room temperature corresponding to the “cold” shape position. Bent angles of sheet samples were measured at room temperature after bending and then measured again after recovery when cooled to room temperature. This procedure was repeated twice with the same parameters to confirm the stability of SME. Prestrain, also known as bending deformation strain (εd), was calculated using the following equation at room temperature:

where d = 0.75 mm and R =10 mm.

Shape recovery strain (εre) caused by heating after the bending deformation was calculated by using the equation:

Magnetic induction was measured using Agilent 4396B vector network analyzer as shown in Figure 2(a), consisting of nearly single ideal coil conductors by the principle of parallel plate method in a special fixture Agilent 16454A as shown in Figure 2(b). Dimensions of the samples used were inner and outer diameter of 3 mm and of 8 mm respectively with thickness equals to 1.5 mm. It measures the variation of inductance of sample before and after loading in the fixture, and then calculate the relative permeability using special software in the frequency ranging from 200 MHz to 1 GHz. Calibration of the analyzer was completed with an accuracy of ±0.05 dB/0.3 deg.

Test equipment of permeability and fixture type. (a) 4396B type vector network analyzer, (b) 16454A type fixture.

Results and discussion

Figure 3 shows the XRD profiles taken at room temperature of Ti–20Ta–xHf (where x = 3.0, 3.5, 4.0, 4.5) and 70Ti26Ta4Hf samples hot-rolled and quenched in iced brine solution. Results revealed that all the alloys exhibit the same rhombohedral structure (α//). The intense (110) peak was observed due to the texture development, same kind of behavior was also reported for Ti69Ta30Hf1 [20].

XRD profiles of Ti–20Ta–xHf and 70Ti26Ta4Hf taken at room temperature, quenched in iced brine after solution treated at 1,025 °C.

These results suggest that Hf modification stabilizes martensite phase (α//) in quenched condition and β phase in annealed condition as Hf-Ta has low temperature miscibility gap, also Ti-Ta alloys are sensitive to Ta contents and Ta contents greater than 26 % has been related to the increased recrystallization temperatures of the Ti-Ta alloys which result in the orthorhombic (α//) martensite phase transformation in the alloy from β phase [25], that is also confirmed by the Mf temperatures by DSC which are well above room temperature.

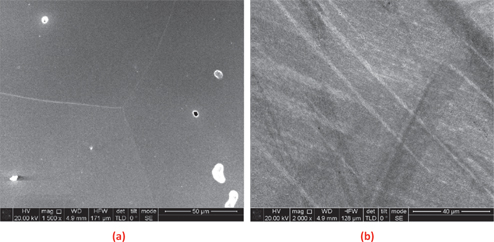

Figure 4(a) show the β phase with clear and distinct grain boundaries in Hf1 sample. The SEM micrograph shows no evidence of omega phase along with β phase. All samples of the series in this research work show the same microstructure when annealed at 1,025 °C for 3 h in flowing argon atmosphere. Figure 4(b) shows the α// martensitic structure from unidirectional to almost multidirectional coarse arrays of plates which are subdivided into several fine platelets.

Microstructure of Hf1 sample, (a) annealed at 1,025 °C for 3 h showing equiaxial β phase grains, (b) quenched in iced brine after solution treated at 1,025 °C showing martensite phase (α//).

In order to determine the effect of Hf% on the transformation temperatures, DSC measurements were performed from room temperature to 725 °C. Thermograms of the DSC measurements are shown in Figure 5(a)–(f). The results show that the Ms temperature increases with the increase of Hf content for Hf1-4 alloys having a fixed amount of Ta, the trend is shown in Figure 5(f). The atomic percentile of Hf was increased slightly in the samples 1–4 to have an in-depth understanding of the change in transformation temperatures. The change is of the order of only a few degrees along with the obvious increase in the heat of reaction. In these metallic samples thermoelastic transformation exhibits fast transformation kinetics resulting in the reaction reaching its equilibrium rapidly which shows that transformation temperatures are not highly heating rate dependent.

Transformation behavior of Hf(1–5) samples quenched in iced brine after solution treated at 1,025 °C.

For Hf5 with 26Ta content, a high Ms = 395.21 °C is determined, which shows that the Ms increases with the increase of Ta content, Figure 5(e). Hf and Ta acts as β-stabilizers and reduces the β transformation temperature, which in turn increases the Ms temperature [22]. The carefully designed composition range showing the stable high temperature shape memory effect based on the Hf and Ta content.

There is no peak corresponding to the omega (ω) phase formation in DSC thermograms depicting the suppression of omega phase resulting in higher Ms temperature. The omega phase is athermal in nature and can affect the transformation temperature drastically by acting as a hindrance to reverse transformation of martensite plates. Hence in the absence of omega phase all of the β phase undergoes martensitic transformation upon cooling and more stable martensitic phase, which is the basis of shape memory behavior of Ti-Ta alloys. The number of valence electrons remains the same with the addition of Hf because both Ti and Hf have four valence electrons so this has no effect on the Ms temperature but the atomic radius of Hf is bigger than the Ti and that factor took part in increasing the Ms temperature, this is also in line with the results presented by Pio John et al. [20] Calculated true value of lattice constant for Hf5 is a = 3.301 Å, bigger than Ti (2.950 Å) and Hf (3.20 Å) but slightly smaller than Ta (3.310 Å).

Shape memory effect was observed in all the samples with increasing value of enthalpies corresponding to the martensitic change during cooling with the highest values confirmed for Hf5 at 6.33 J/g.

The results of three-point bend tests and SME are shown in Table 2 for the two cycles The maximum applied strain obtained after spring back is 5.6 %. According to the results the recovery strain (εre%) accompanying the martensitic transformation increases with the increase of Hf content for Hf1-4 and even increased to higher values for Hf5 with higher Ta content. This result well explains that the alloys with a higher Hf and Ta content exhibited a larger recovery strain as shown in Figure 6.

Effect of Hf modification on SME and the recovered strain during two training cycles.

| Sample ID | Ms Temperature (°C) | Mf Temperature (°C) | Heat of transformation (j/g) | Recovery strain εre % | εre/εd |

|---|---|---|---|---|---|

| Hf1 | 385.34 | 358.04 | 2.308 | 4.29 | 61.55 |

| Hf2 | 387.65 | 367.49 | 4.304 | 4.51 | 64.70 |

| Hf3 | 385.36 | 364.55 | 3.003 | 4.76 | 68.29 |

| Hf4 | 393.06 | 371.94 | 5.738 | 5.22 | 74.89 |

| Hf5 | 395.21 | 378.92 | 6.333 | 5.60 | 87.54 |

Effect of Hf and Ta content on strain recovery during two training cycles of samples after quenching.

These properties increased a little bit after the second training cycle owing to the stabilization of martensite. This indicates that in the first training cycle, the dislocations are increased continuously to create an oriented stress field and the same was suppressed in the second training cycle. This stress field is formed in the same direction of parallel martensitic arrays, helping the recovery of those plates during heating to completely β phase. As a result it is confirmed that the addition of Hf in Ti-Ta alloys can increase the Ms effectively and suppress the omega phase resulting in stable shape memory effect with increasing transformation strain.

Real part of the permeability spectra is shown in Figure 7 from 200 Mhz to 1 Ghz of the frequency range. Permeability increases from 1.671 to 1.919 gradually with increasing content of hafnium modification of samples Hf1 and Hf5, respectively, same as the heat of reaction increased linearly in DSC. It is clear that all samples show a stable permeability in the frequency range of 450 MHz to 1 Ghz. These results show that the Hf modification is beneficial to improve the permeability of TiTaHf systems and can be used in the frequency range of 450 MHz to 1 GHz without appreciable changes.

Real part of relative permeability versus frequency of Hf-modified samples.

Conclusions

Effect of Hf modification and Ta content on the martensitic transformation, stability of shape memory properties and magnetic permeability was investigated. In conclusion, we successfully produced novel TiTaHf high temperature shape memory alloy with:

High Ms temperature increasing with the increase of Hf and Ta content after quenching from above the β-transus temperature and reaching 395.21 °C for Hf5. Hf and Ta acts as β-stabilizers in annealed condition and reduces the β transformation temperature, which in turn increases the Ms temperatures.

Omega phase was successfully suppressed during thermal cycling. The large recovery strain is due to the addition of Hf and Ta. This can help positively in producing larger stroke of new actuators which needs load-based actuation only.

Recovery strain (εre%) accompanying the martensitic transformation increases with the increase of Hf content for Hf1-4 and even increased to higher values for Hf5 with higher Ta content.

Real permeability increases gradually with increasing content of hafnium modification. It is clear that all samples show a stable permeability in the frequency range of 450 MHz to 1 GHz.

Application of these HTSMA’s in the service conditions of turbomachinery and energy industries would benefit in the weight and size reduction at all stages of engineering design and production. The results of this alloy system showed very promising Ms and SME values and make it an interesting material as high temperature shape memory alloy and can be used in the frequency range of 450 MHz to 1 GHz without appreciable changes.

Funding source: Beijing Municipal Commission of Education

Award Identifier / Grant number: B20140902W

Funding statement: Beijing Municipal Commission of Education, B20140902W.

Acknowledgement

This work was sponsored by Beijing Municipal Commission of Education, B20140902W. The support from College of Materials Science and Engineering, Beijing University of Technology, China and Catholic University of Leuven, Belgium is acknowledged.

References

[1] Z.Y. Yang, X.H. Zheng and W. Cai, Scr. Mater., 99 (2015) 97–100.10.1016/j.scriptamat.2014.11.038Search in Google Scholar

[2] I.A. Al-Omari, W.Y. Zhang and L. Yue, IEEE Trans. Magn., 49 (7) (2013) 3394–3397.10.1109/TMAG.2013.2245498Search in Google Scholar

[3] A.O. Moghaddam, M. Ketabchi and R. Bahrami, Nonferrous Met. Soc. China, 23 (2013) 2896–2904.10.1016/S1003-6326(13)62812-5Search in Google Scholar

[4] X.I.N. Yan and L.I. Yan, Trans. Nonferrous Met. Soc. China, 24 (2014) 126–130.10.1016/S1003-6326(14)63037-5Search in Google Scholar

[5] X.L. Meng, W. Cai and Y.D. Fu, Acta Mater., 58 (2010) 3751–3763.10.1016/j.actamat.2010.03.015Search in Google Scholar

[6] X.L. Meng, Y.D. Fu, W. Cai et al., Philos. Mag. Lett., 89 (2009) 431–438.10.1080/09500830903019004Search in Google Scholar

[7] H. Xu, Y. Ma and C. Jiang, Appl. Phys. Lett., 82 (2003) 3206.10.1063/1.1572540Search in Google Scholar

[8] J. Ma, I. Karaman and R.D. Noebe, Int. Mater. Rev., 55 (2010) 257–315.10.1179/095066010X12646898728363Search in Google Scholar

[9] G. Firstov, J. van Humbeeck and Y.U. Koval, J. Intell. Mater. Syst. Struct., 17 (2006) 1041.10.1177/1045389X06063922Search in Google Scholar

[10] K. Otsuka and X. Ren, Intermetallics, 7 (1999) 511.10.1016/S0966-9795(98)00070-3Search in Google Scholar

[11] D. Grummon, JOM., 55 (2003) 24.10.1007/s11837-003-0006-1Search in Google Scholar

[12] J. van Humbeeck, J. Phys. IV France, 7 (1997) 519–524.Search in Google Scholar

[13] T.W. Duerig and A.R. Pelton, Materials Properties Handbook: Titanium Alloys, ASM International, Materials Park, OH (1994), pp. 1035–1048.Search in Google Scholar

[14] H.Y. Kim, S. Hashimoto, J.I. Kim, H. Hosoda and S. Miyazaki, Mater. Trans., 45 (2004) 2443–2448.10.2320/matertrans.45.2443Search in Google Scholar

[15] H.Y. Kim, Y. Ikehara, J.I. Kim, H. Hosoda and S. Miyazaki, Acta Mater., 54 (2006) 2419–2429.10.1016/j.actamat.2006.01.019Search in Google Scholar

[16] M. Ikeda, Y. Nakamura and N. Takahama, J. Jpn. Inst. Metals, 67 (2003) 420–423.10.2320/jinstmet1952.67.9_420Search in Google Scholar

[17] T. Peradze, I. Stamateli, J. Cederstrom, T. Berikashvili, A. Razov and K. Gorga, Int. J. Appl. Electromagnet. Mech., 23 (2006) 39–43.10.3233/JAE-2006-730Search in Google Scholar

[18] P.J.S. Buenconsejo, H.Y. Kim, Y. Ikehara, H. Hosoda and S. Miyazaki, Acta Mater., 57 (2009) 1068–1077.10.1016/j.actamat.2008.10.041Search in Google Scholar

[19] P.J.S. Buenconsejo, H.Y. Kim and S. Miyazaki, Acta Mater., 57 (2009) 2509–2515.10.1016/j.actamat.2009.02.007Search in Google Scholar

[20] K. Yamada, A. Ogawa, C. Ouchi and D. Eylon, Mater. Trans. JIM, 37 (1996) 855–859.10.2320/matertrans1989.37.855Search in Google Scholar

[21] H.Y. Kim, T. Fukushima, P.J.S. Buenconsejo, T.H. Nam and S. Miyazaki, Mat. Sci. Eng. A, 528 (2011) 7238–7246.10.1016/j.msea.2011.06.021Search in Google Scholar

[22] X.L. Meng, Y.F. Zheng, W. Cai and L.C. Zhao, J. Alloys Compd., 372 (2004) 180–186.10.1016/j.jallcom.2003.10.020Search in Google Scholar

[23] M.M. Javadi, M. Belbasi, M.T. Salehi and M.R. Afshar, JMEPEG, 20 (2011) 618–622.10.1007/s11665-011-9885-4Search in Google Scholar

[24] H.O. Mosca and G. Bozzolo, Surf. Sci., 601 (2007) 3224–3232.10.1016/j.susc.2007.05.038Search in Google Scholar

[25] E.W. Collings, The Physical Metallurgy of Titanium Alloys, ASM, ISBN 0-87170-181-2 pp. 43.Search in Google Scholar

©2017 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Research Articles

- Preparation of Co3O4 Nanostructures via a Hydrothermal- Assisted Thermal Treatment Method by Using of New Precursors

- Transformation Temperatures, Shape Memory and Magnetic Properties of Hafnium Modified Ti-Ta Based High Temperature Shape Memory Alloys

- Modified Sol-Gel Processing of NiCr2O4 Nanoparticles; Structural Analysis and Optical Band Gap

- Effect of Proeutectoid Ferrite Morphology on the Microstructure and Mechanical Properties of Hot Rolled 60Si2MnA Spring Steel

- Uniaxial Properties versus Temperature, Creep and Impact Energy of an Austenitic Steel

- Effect of Rare Earth Cerium Addition on Microstructures and Mechanical Properties of Low Carbon High Manganese Steels

- Geometry and Material Constraint Effects on Creep Crack Growth Behavior in Welded Joints

- Preparation and Properties of ZrO2/Mo Alloys

- The Mechanical Properties of the Mo-0.5Ti and Mo-0.1Zr Alloys at Room Temperature and High Temperature Annealing

- Diffusion Kinetics of Chromium in a Novel Super304H Stainless Steel

- Mechanism of Selective Desulphurization in Iron Ore Sintering Process by Adding Urea

- The Characteristics and Generating Mechanism of Large Precipitates in Ti-Containing H13 Tool Steel

Articles in the same Issue

- Frontmatter

- Research Articles

- Preparation of Co3O4 Nanostructures via a Hydrothermal- Assisted Thermal Treatment Method by Using of New Precursors

- Transformation Temperatures, Shape Memory and Magnetic Properties of Hafnium Modified Ti-Ta Based High Temperature Shape Memory Alloys

- Modified Sol-Gel Processing of NiCr2O4 Nanoparticles; Structural Analysis and Optical Band Gap

- Effect of Proeutectoid Ferrite Morphology on the Microstructure and Mechanical Properties of Hot Rolled 60Si2MnA Spring Steel

- Uniaxial Properties versus Temperature, Creep and Impact Energy of an Austenitic Steel

- Effect of Rare Earth Cerium Addition on Microstructures and Mechanical Properties of Low Carbon High Manganese Steels

- Geometry and Material Constraint Effects on Creep Crack Growth Behavior in Welded Joints

- Preparation and Properties of ZrO2/Mo Alloys

- The Mechanical Properties of the Mo-0.5Ti and Mo-0.1Zr Alloys at Room Temperature and High Temperature Annealing

- Diffusion Kinetics of Chromium in a Novel Super304H Stainless Steel

- Mechanism of Selective Desulphurization in Iron Ore Sintering Process by Adding Urea

- The Characteristics and Generating Mechanism of Large Precipitates in Ti-Containing H13 Tool Steel