Abstract

A novel mechanism for the elimination of false selvedge in rapier looms was successfully designed and developed, which functions to grip the protruding weft ends after each pick insertion during the weaving process, with subsequent cutting and suction of the protruding ends. The task is otherwise, presently performed by the formation of dummy or false selvedges in the fabric, requiring additional yarn other than that required for the actual fabric. A significant amount of yarn is wasted to form false selvedges, as they are removed and disposed as hard waste post weaving, which consequently increases the cost of fabric and narrows the profit margins. The developed mechanism was successfully installed and commissioned on an indigenous rapier loom leading to a reduction in the amount of hard waste otherwise generated, without affecting the normal functioning of the loom and the weaving process. The amount of reduction in hard waste was estimated and the quality of fabric manufactured before and after the installation was tested and analyzed.

1 Introduction

Shuttleless looms contribute a major portion to the total quantity of woven textiles produced globally. According to an estimate by International Textile Manufacturers Federation (ITMF), there are about 2.8 million looms installed globally of which around 54% are shuttleless [1]. Sanjay et al. state that the installed capacity of shuttleless looms has been increasing continuously since 2000 with a CAGR of 5% [1]. These looms cater not only to the production of apparel textiles but also to the manufacture of industrial and technical textiles. A study by David Rigby Associates (DRA), UK, indicates that the global end-use of technical textiles is predominantly in the fabric form and that too in the woven fabric form (73%) [2]. Owing to their versatility and higher productivity, shuttleless looms are gaining popularity day by day in the weaving industry.

Although the numerous advantages of shuttleless looms provide them with a cutting edge over other conventional fabric manufacturing systems, they do have some inherent problems that impose certain limitations on their effective usage. The formation of false selvedge is one such limitation.

1.1 False selvedge

A firm and strong selvedge is extremely important for producing woven fabrics and their subsequent treatment. Selvedge formation is essential and almost compulsory and is carried out on both sides of the cloth despite certain constraints [3].

Although true selvedges form an indispensable part of any woven fabric (either for apparel or for industrial use), the formation of false selvedge is an additional requirement with the presently available rapier looms. A false selvedge, also referred to as catch-cord, dummy, or auxiliary selvedge, is different from a true selvedge in the sense that it is temporary and is discarded after weaving. Its formation takes place very close to the actual or true selvedges, adjacent to the loom temples, on either side of the fabric. The primary function of this selvedge is to grip the extra length of the weft (protruding weft-ends) on each side after every pick insertion, at a time when the weft is released by the taker rapier on the receiving side of the loom and when the weft end cutter cuts the weft on the picking side until when beat up for the particular pick is performed [4].

1.2 Necessity of false selvedge

In the absence of false selvedge, weaving would become difficult since the protruding ends of weft after each pick would lie loose on the edges of the fabric and get lashed-in, resulting in defective fabric edges. If the weft ends are not properly held, the weft-end cutter on the picking side of the loom could not perform the cutting action to facilitate the next pick insertion. The false selvedge, therefore, acts as a momentary weft-end gripper to facilitate a smoother cutting of weft ends after each pick and preventing their lashing-in into the fabric [4].

Further, the weft needs to be beaten up under certain tension for proper formation of fabric for which the weft needs to be held at its ends during beat up, which, in turn, is facilitated by the false selvedge. Adanur and Qi [5] studied the effects of weft tension on the various properties of denim fabrics woven on air-jet weaving machine. They have also observed greater air permeability of the cloth with an increase in weft tension. The increase in weft tension makes the yarn more compact and produces larger openings to increase air permeability. The weft tension at beat up also influences crimp percentages of the yarns. Neogi [6] stated that the crimp in a given yarn decreases with the increase in weaving tension of the concerned yarn. Also, uncontrolled weft tension may result in defective true selvedges in the fabric. Various defects at the selvedges of the cloth like loopy, curly, kinky selvedge, and so on occur mainly owing to the tensions of the warp or weft yarns [6]. Neogi and Bhattacharya [7] studied the effects of yarn tension on the width of cloth. Neogi [6] stated that the cloth with the least width contraction has the highest warp and weft crimps and that with the highest width contraction has the lowest warp crimp and moderate weft crimp. This indicates that the changes in weaving tensions of the warp and weft cause changes in warp and weft crimps, which, in turn, show their effects on the width of the cloth.

1.3 Critical issues with false selvedge

False selvedge is, in fact, a solid waste and is not useable in any other process, hence increases the cost of woven fabric. Selvedge waste is always a critical problem of weavers because it directly contributes to the cost of fabric. It has been more critical with narrowing profit margins [3]. Even though false selvedge is important for a proper weaving function, it does not come without the additional cost of extra yarn required for its formation [4]. As per the requisition of the process, false selvedge formation needs a continuous supply of extra yarns along with regular warp yarns, numbering anywhere between 12 up to 16 on either side of the fabric. This adds to the cost incurred for raw materials and since false selvedge is discarded after weaving, the net profitability gets affected. A study by Jurasz [8] analyzed the shuttleless weaving machines in terms of false selvedge. It reported that the selvedge wastes could be as much as 4–8% of total yarn consumption. This waste also includes the cut lengths of protruding weft ends gripped by the false selvedge yarns. It is therefore quite obvious that rapier weavers suffer monetary loss to afford the additional cost involved for false selvedge [4].

Keeping in view the significant disadvantages of false selvedge, work was undertaken to design and develop the novel mechanism which can replace false selvedge in performing similar functions without the requirement of extra yarns as with false selvedges. This again without affecting the quality of fabric as manufactured with a false selvedge.

1.4 The mechanism to substitute false selvedge

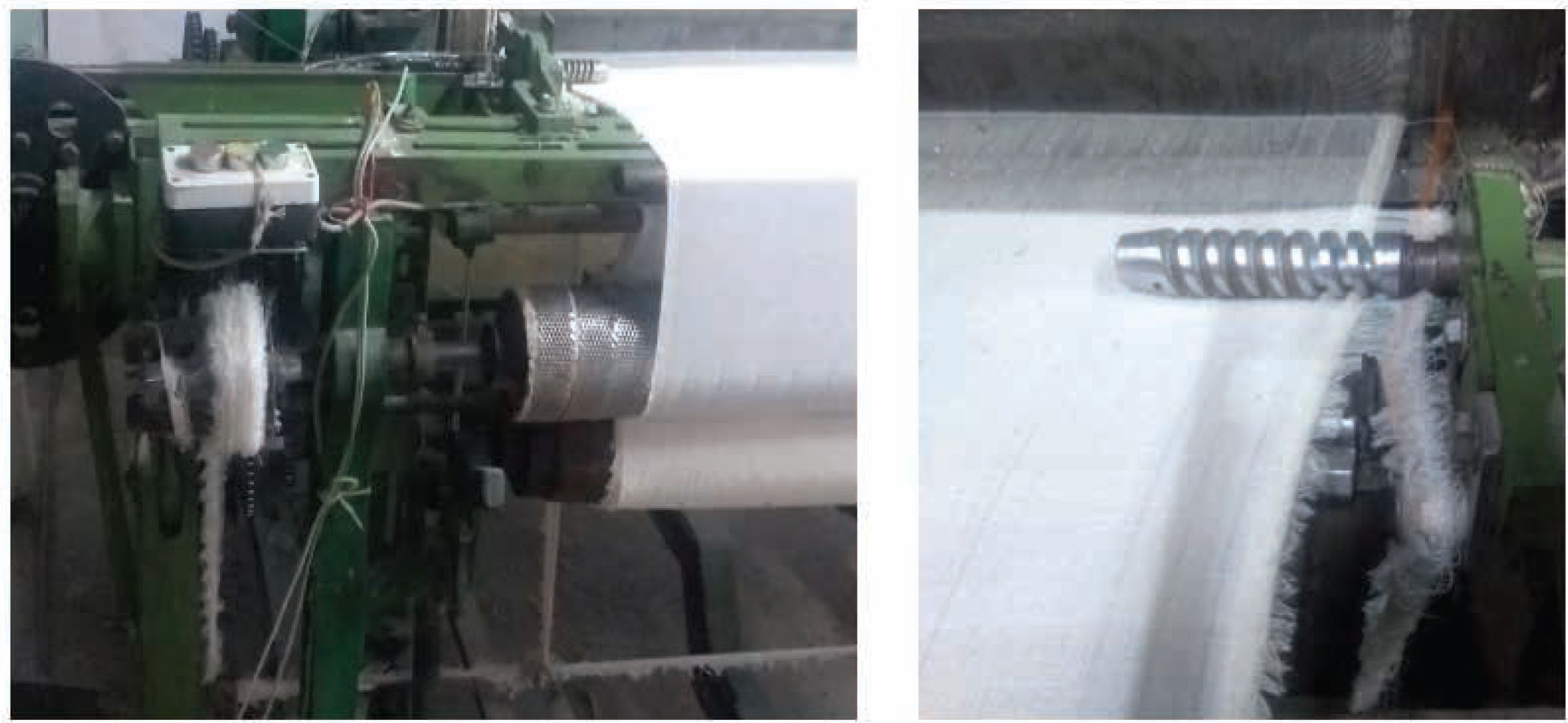

The false selvedge functions by gripping protruding ends of each pick till beat up is performed, the gripping action performed by the false selvedge ends, which form a shed (along with the normal warp) for each pick and subsequently close onto the weft to grip it by forming a weave. The protruding ends thus get permanently “locked” with the false selvedge ends, rendering them unusable. The false selvedge is then severed from the fabric and disposed as shown in Figure 1.

False selvedge on the indigenous rapier loom (courtesy: Surya machinery, Mumbai).

A similar principle is adopted in the developed mechanism except for the significant difference that, in this case, the protruding weft ends do not get permanently locked with the gripper ends due to the formation of any weave as with false selvedge, but are instead gripped temporarily till beat up is over. They then become free during the next shed formation and are subsequently cut and sucked by a vacuum suction, making the gripper ends reusable. Hence, there is no false selvedge formation while the gripper ends (supplied through a separate bobbin) can be reused continuously avoiding the cost of additional yarn as required with false selvedges.

1.5 Components of the mechanism

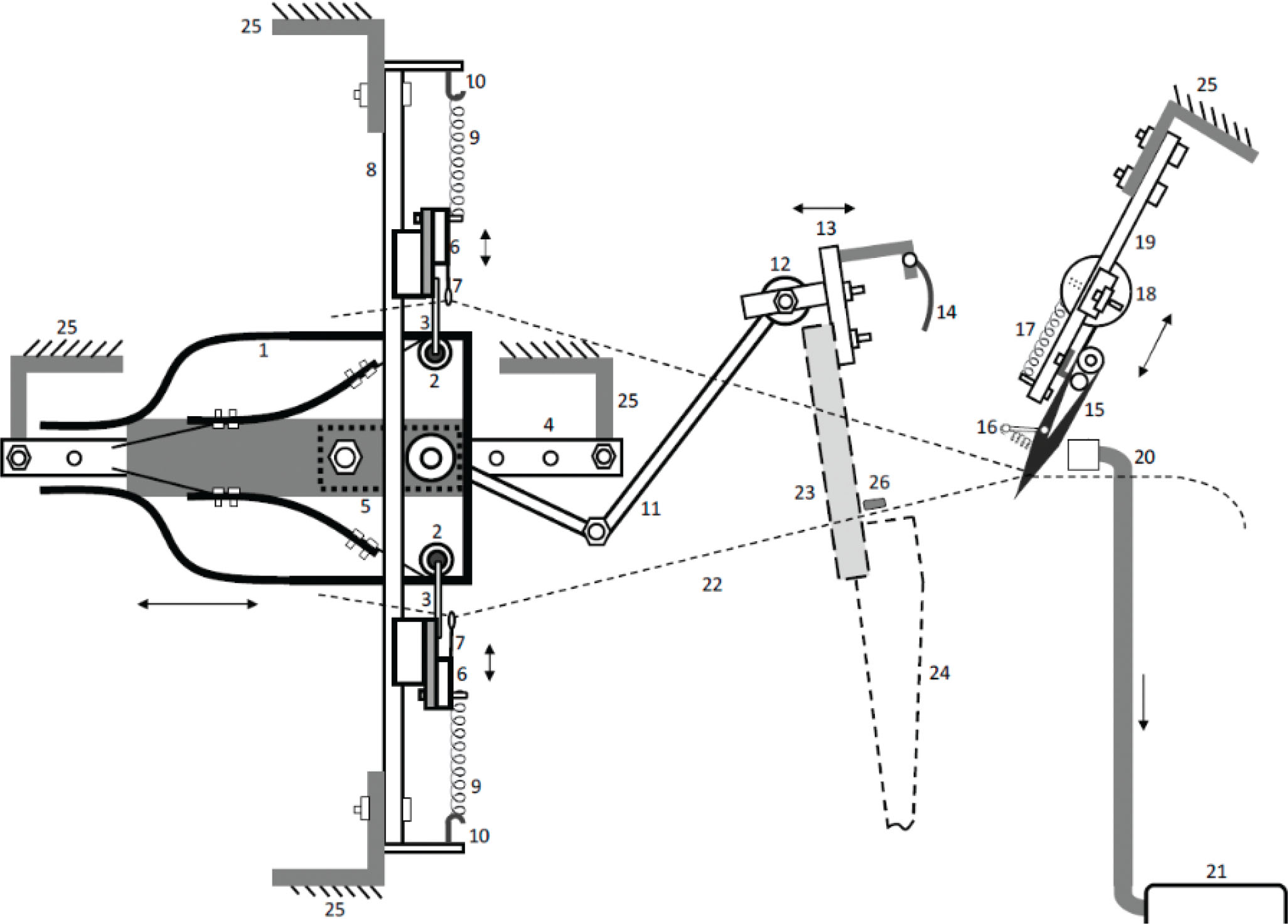

The dimensions and design of components were finalized after due consideration of construction and working of the loom and the type of function that needs to be performed. Table 1 describes the various components involved in the mechanism.

Components of the mechanism

| S. No | Component | Material | Dimensions | Function |

|---|---|---|---|---|

| 1. | Linear cam | MS | L: 140 mm, W: 25 mm, and H: 90 mm | Gives motion to the cam followers for shedding of gripper ends |

| 2. | Cam followers | SS | L: 30 mm and D: 6 mm | Lifts and lowers shedding blocks |

| 3. | Flat springs | Tin alloy | L: 60 mm, W: 20 mm, and T: 1 mm | Facilitates the unidirectional motion of followers along with the cam profile |

| 4. | Linear guide rail for cam | SS | L: 170 mm, W: 17 mm, and T: 12 mm | Facilitates to and fro movement of the linear cam |

| 5. | Mono-block for cam | SS and plastic | L: 30 mm, W: 17 mm, and T: 10 mm | Facilitates to and fro movement of cam on a linear guide rail |

| 6. | Linear guide rail for shedding | SS | L: 120 mm, W: 12 mm, and T: 10 mm | Facilitates to and fro movement of shedding monoblocks |

| 7. | Shedding mono-blocks | SS and plastic | L: 20 mm, W: 15 mm, and T: 7 mm | Carries shedding needles and facilitates shed formation |

| 8. | Shedding needles | SS | L: 18 mm and Eye D: 2 mm | Carries the gripper ends and forms their shed |

| 9. | Roller bearings | SS | D: 20 mm | For a smoother movement of the link connecting the sley sword and cam. |

| 10. | Curved cutter lifter | MS | L: 70 mm, W: 22 mm, and T: 2 mm | Lifts or moves back the cutter assembly during beat up |

| 11. | Cutter | SS | L: 80 mm, W: 20 mm, and T: 2 mm | Cuts the protruding ends of weft after each beat up |

| 12. | Linear guide rail for cutter | SS | L: 120 mm, W: 12 mm, and T: 10 mm; | Facilitates to and fro movement of the cutter assembly |

| 13. | Cutter mono-block | SS and Plastic | L: 20 mm, W: 15 mm, and T: 7 mm | Facilitates to and fro movement of cutter assembly on a guide rail |

| 14. | Cutter roller bearing | SS | D: 20 mm | Takes motion from the curved cutter lifter and moves the cutter back |

| 15. | Suction hose | PVC | D: 15 mm and L: 150 cm | Helps suction of cut ends of the weft |

| 16. | Suction pump | – – | 80 W suction power | Sucks the cut ends of the weft |

| 17. | Gripping ends | PC yarn | 12 re-usable gripping ends supplied from a separate bobbin | Grips the protruding weft ends at each pick till beat up is over |

MS, mild steel; SS, stainless steel; L, length; W, width; H, height; T, thickness; D, diameter.

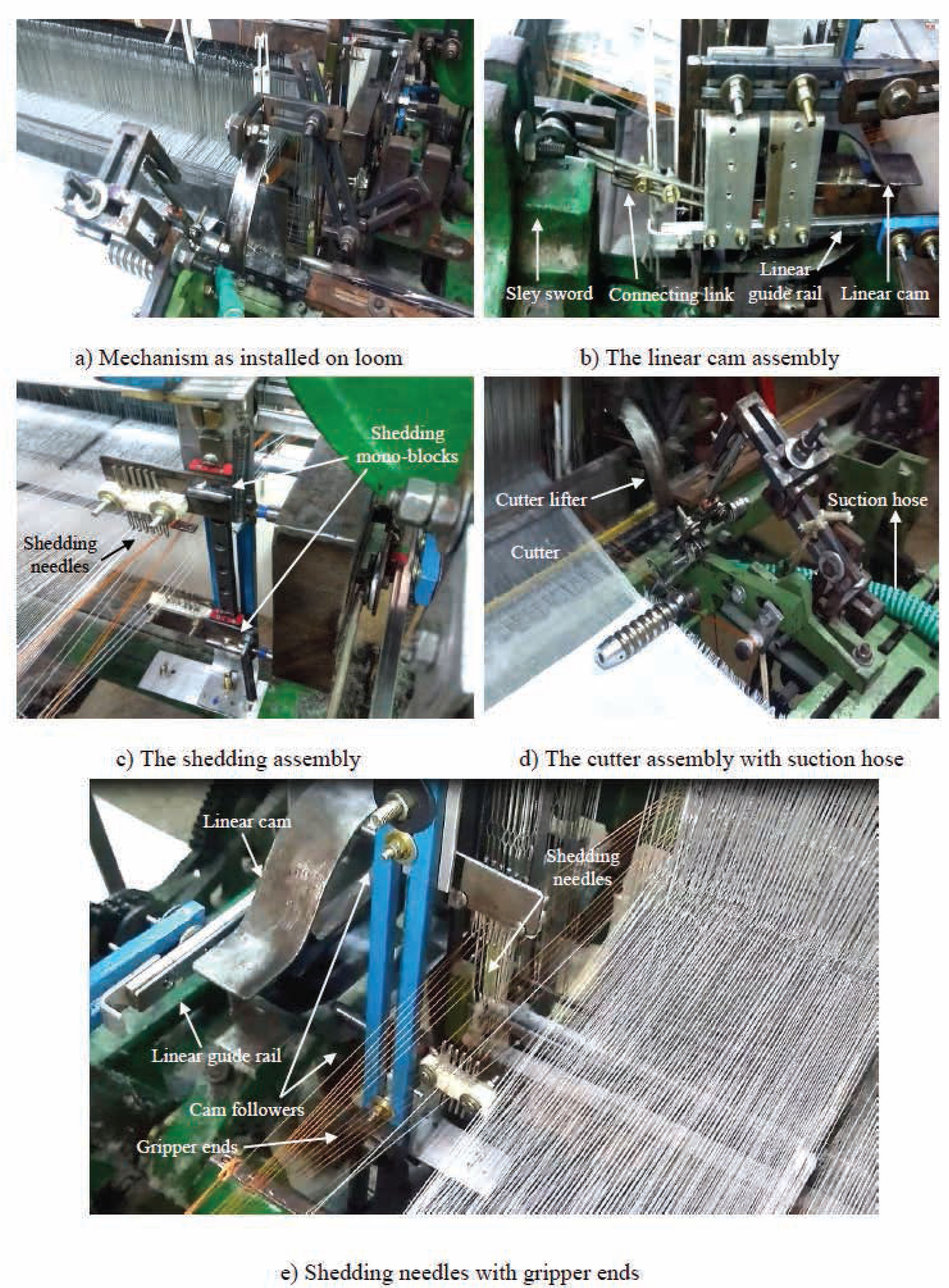

1.6 Installation and commissioning

An indigenous rapier loom manufactured by m/s Surya machinery works, Mumbai, was selected for the installation of the mechanism. The mechanism was installed and a trial run of the loom was taken with it, producing fabric without the formation of false selvedge. Around 10 m of fabric was produced in the trial run. The loom and fabric particulars were kept the same as were prevailing for manufacturing the same fabric with false selvedge. Table 2 indicates the different particulars.

Particulars of loom selected for installation

| S. No | Particulars | |

|---|---|---|

| 1. | Make of loom | Surya Rapier Looms, Mumbai |

| 2. | Type of weft insertion | Rapier |

| 3. | Type of rapiers | Double rapiers (flexible) |

| 4. | Type of weft transfer | Loop system (Gabler) |

| 5. | Width of loom | 142 cm |

| 6. | Loom speed | 230 rpm |

| 7. | Type of shedding | Cam shedding |

| 8. | Type of beat-up | Link beat-up mechanism |

| 9. | Type of weft stop | Piezzo-electric |

| 10. | Type of warp stop | Electrical warp stop (open drop pins) |

| 11. | Type of take-up | 7 – wheel take-up |

| 12. | Type of picking (rapier drive) | Eccentric drive with segment gear |

| 13. | Type of weft accumulator | Drum type |

| 14. | Type of let-off | Negative |

| 15. | Type of true selvedge | Leno |

| 16. | Type of temples | Ring temples |

| 17. | Yarn count/type | 20.6 Tex (warp) and 22.8 Tex (weft)/cotton |

| 18. | Weave/EPC/PPC | Plain/26/24 |

| 19. | No. of ends for false selvedge | 14 on either side |

| 20. | False selvedge ends supply package | False selvedge bobbin |

Loom speed: 230 rpm; Picks per cm: 24; Loom efficiency: 92%; Time: 8

.

.Fabric produced per shift of h = {(230 × 60 × 8)/(24 × 100)} × 0.92 = 42 m.

1.7 Sequence of operations with respect to loom timing

The working of the mechanism was synchronized with the loom timing for primary motions. The degrees of rotation of loom crankshaft and the position of the crank at various degrees were taken as reference for setting the timing of the mechanism concerning the primary motions. Table 3 gives the sequential operation of the mechanism vis-à-vis the loom timing.

Sequence of operations with respect to loom timing

| S. No. | Degrees of crankshaft rotation | Normal loom function | Sequence of operations of the mechanism |

|---|---|---|---|

| 1. | 90° Loom front center | Sley at front center, beat up performed, warp shed crossed, rapiers at rest | Linear cam at its forward most position toward reed, protruding weft ends gripped by the closed shed of gripper ends, cutter at its backward most position and open |

| 2. | 90°–180° | Sley starts to move back, rapiers still at rest, warp threads move to form next shed | Linear cam starts to move back, cam followers and shedding mono blocks start to move to form next shed of gripper ends, weft still in the control of gripper ends |

| 3. | 180° Loom bottom center | Sley in between front and back centers, shed open for next pick, rapiers start an initial movement from rest | The cutter moves forward and cuts the weft ends at 10 mm from true selvedge, gripper ends release the weft ends and form next shed, cut weft ends are sucked by suction |

| 4. | 180°–270° | Sley moving close to back center, warp shed open, rapiers travel into shed | Linear cam toward its backward most position from reed, shed of gripper ends is also open as rapiers travel into the shed |

| 5. | 270° Loom back center | Sley at back center, warp shed is fully open, transfer of weft takes place from giver to taker rapier | Linear cam at its backward most position from reed, shed of gripper ends is also open as transfer of weft takes place between giver and taker rapiers |

| 6. | 270°–360° | Sley starts to move forward, rapiers start retreating from shed, warp shed starts to close | Linear cam starts to move forward, cam followers and shedding mono blocks start to move toward each other, shed formed by gripper ends also starts to close |

| 7. | 360° (0°) Loom top center | Sley in between back and front centers, warp shed still closing, rapiers continue to retreat from warp shed | Linear cam continues to move forward toward reed, shed formed by gripper ends continue to close as rapier continue retreating from warp shed |

| 8. | 0°–90° | Sley moving close to front center, warp shed closes and starts crossing, rapiers fully exit from shed after releasing the weft | Linear cam is very close to its forward most position, gripper ends close on the weft to grip it moments before the rapiers release it while exiting from the shed; weft ends are now in the control of gripper ends |

1.8 Mechanism settings

Table 4 gives the optimized settings for the mechanism in terms of clearances and distances between its relative parts and the loom components involved, as essential for a smooth operation to serve the desired function.

Different settings of the mechanism

| S. No. | Setting/Clearance | Values |

|---|---|---|

| 1. | Total distance moved by linear-cam from front center to back center positions | 140 mm |

| 2. | Clearance between cam outer end and first warp stop motion bar at back center | 20 mm |

| 3. | Distance between cam inner end and sley when cam is at its forward most position | 60 mm |

| 4. | Maximum shed height of the gripper ends | 70 mm |

| 5. | Total displacement of shedding blocks for the maximum shed height of gripper ends | 70 mm |

| 6. | Clearance between shedding mono-blocks at a closing position of gripping ends | 10 mm |

| 7. | Distance between follower rollers at an open shed position of gripper ends | 110 mm |

| 8. | Distance between follower rollers at a closed shed position of gripper ends | 40 mm |

| 9. | Distance between cutter and true selvedge | 10 mm |

| 10. | Clearance between cutter guide rail and reed at front center | 20 mm |

| 11. | Clearance between cutter blade and reed at front center | 9 mm |

| 12. | Total distance moved back by cutter at front center | 30 mm |

| 13. | Distance between cutter blades at a fully open position of blades | 15 mm |

| 14 | Distance between cutter lifter and roller bearing at back center of loom | 85 mm |

| 15. | Clearance between cutter opening roller and fixed upper blade of cutter | 3 mm |

| 16. | Clearance between temple and cutter lower blade | 4 mm |

| 17 | Total displacement of roller bearing at loom front center | 30 mm |

| 18. | Distance between cam and guide rail for shedding mono-blocks | 40 mm |

| 19. | Length of follower rollers to be present inside the cam | 15 mm |

| 20. | Distance between suction hose nozzle and outer most gripper end | 10 mm |

2 Results and discussions

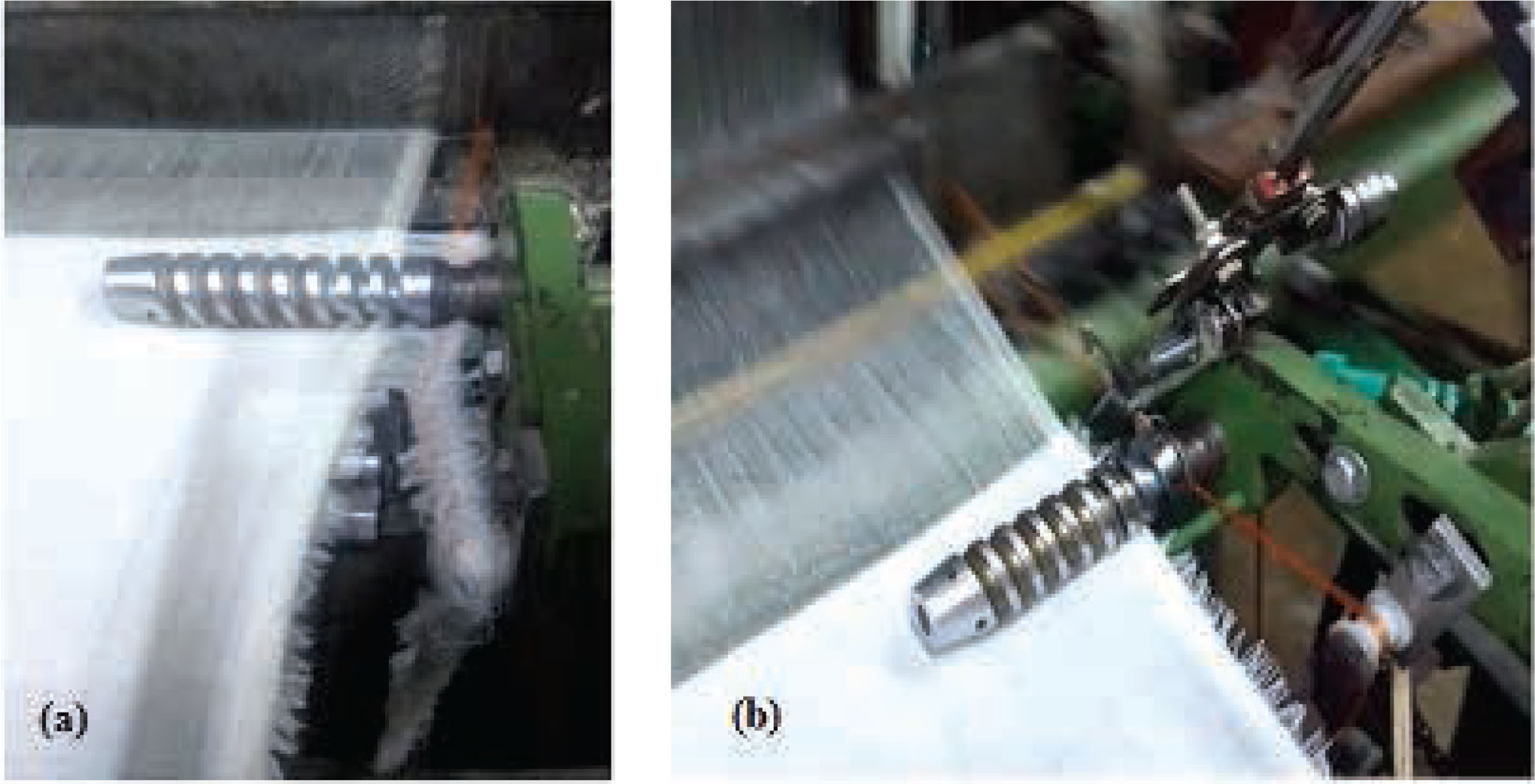

The mechanism was successfully installed and commissioned on the indigenous rapier loom, and fabric was successfully produced without the formation of false selvedge. Figure 4 shows fabric produced with false selvedge before the installation, and the same fabric produced after the mechanism was installed on the loom, with similar loom and fabric particulars.

Schematic of the novel false selvedge eliminating mechanism.

Pictures of the installed mechanism on the loom

Fabric formation with and without the false selvedge. (a) Fabric formed with false selvedge and (b) Fabric formed without false selvedge after installation.

2.1 Reduction in requirement of raw material

It is quite evident that since there is no false selvedge with the new mechanism, the requirement of extra yarn for the false selvedge also ceases, therefore minimizing the yarn cost. The amount of yarn consumed for false selvedge for a shift of 8 h to produce the above fabric on the given loom was estimated by working out the loom production as follows:

The length of each false selvedge end is equal to the length of fabric produced, neglecting the minimum amount of crimp present in this yarn. The length, therefore, of each false selvedge yarn to produce the above fabric is also 42 m. A total of 28 false selvedge ends were used on the loom for producing the given fabric.

The total amount of yarn therefore required for false selvedge per shift of 8 h for the given loom is (42 × 28) = 1,176 m. This estimate would be in multiples of the number of looms operating in the shed if it is for the whole weaving shed.

2.2 Fabric quality tests

Comparative testing of fabric quality manufactured with the mechanism and that with the false selvedge was carried out at V&A Textile Inspection and Testing Services, Tirupur, Tamil Nadu, India. The different results have been tabulated in the succeeding sections.

2.2.1 Dimensional change

Dimensional change in the fabrics was estimated by the ISO 5077:2007/ISO 6330:2012/ISO 3759/1:2008/ISO 15797 and ISO 139 methods, and the results are given in Table 5 (A and B).

Dimensional change in fabrics

| S. No | Particulars | Original (cm) | After wash (cm) | % Change | Average % Change |

|---|---|---|---|---|---|

| (A) For fabric produced with false selvedge | |||||

| 1. | Lengthwise | 35.0 | 29.2 | −16.6 | −16.5 |

| 2. | Lengthwise | 35.0 | 29.3 | −16.3 | |

| 3. | Lengthwise | 35.0 | 29.2 | −16.6 | |

| 4. | Width wise | 35.0 | 32.9 | −6.0 | −5.7 |

| 5. | Width wise | 35.0 | 33.1 | −5.4 | |

| 6. | Width wise | 35.0 | 33.0 | −5.7 | |

| (B) For fabric produced without false selvedge | |||||

| 1. | Lengthwise | 35.0 | 29.4 | −16.0 | −16.0 |

| 2. | Lengthwise | 35.0 | 29.4 | −16.0 | |

| 3. | Lengthwise | 35.0 | 29.4 | −16.0 | |

| 4. | Width wise | 35.0 | 33.0 | −5.7 | −5.7 |

| 5. | Width wise | 35.0 | 33.0 | −5.7 | |

| 6. | Width wise | 35.0 | 33.0 | −5.7 | |

2.2.2 Tensile strength

The tensile strength of both the fabrics was tested by raveled strip method according to ISO 13934-1: 2013. The results are tabulated in Table 6.

Tensile strength in the fabrics

| S. No | Fabric produced with false selvedge | Fabric produced without false selvedge | ||

|---|---|---|---|---|

| Warp way tensile strength (N) | Weft way tensile strength (N) | Warp way tensile strength (N) | Weft way tensile strength (N) | |

| 1. | 342.4 | 298.0 | 347.6 | 295.2 |

| 2. | 343.5 | 298.8 | 348.7 | 296.2 |

| 3. | 341.5 | 297.5 | 347.0 | 295.5 |

| 4. | 340.5 | 299.0 | 348.0 | 296.9 |

| 5. | 342.0 | 297.4 | 347.2 | 296.7 |

| Average | 341.98 | 298.14 | 347.66 | 296.1 |

2.2.3 Tearing strength

The tearing strength was tested by the Elmendorf method in accordance with ISO 13937-I:2001. The results are given in Table 7.

Tearing strength in the fabrics

| S. No | Fabric produced with false selvedge | Fabric produced without false selvedge | ||

|---|---|---|---|---|

| Warp way tearing strength (N) | Weft way tearing strength (N) | Warp way tearing strength (N) | Weft way tearing strength (N) | |

| 1. | 33.55 | 25.61 | 32.27 | 25.61 |

| 2. | 33.56 | 24.63 | 32.29 | 25.62 |

| 3. | 33.58 | 25.62 | 32.26 | 25.64 |

| 4. | 33.59 | 25.60 | 32.28 | 25.63 |

| 5. | 33.55 | 25.61 | 32.29 | 25.63 |

| Average | 33.56 | 25.41 | 32.27 | 25.62 |

2.2.4 Bursting strength

Bursting strength of both the fabrics was tested in accordance with IS 1966:1975. The results are tabulated in Table 8.

Bursting strength in the fabrics

| S. No | Fabric produced with false selvedge | Fabric produced without false selvedge |

|---|---|---|

| Bursting strength (kN/m2) | Bursting strength (kN/m2) | |

| 1. | 767.4 | 792.2 |

| 2. | 761.8 | 799.1 |

| 3. | 774.3 | 797.0 |

| 4. | 765.3 | 785.3 |

| 5. | 766.7 | 790.1 |

| Average | 767.1 | 792.74 |

2.2.5 Air permeability

The air permeability was tested according to ASTM D-737-2004 (CFM) with a pressure of 125 Pa and for a test area of 38 cm2. The obtained results are given in Table 9.

Air permeability of the fabrics

| S. No. | Fabric produced with false selvedge | Fabric produced without false selvedge |

|---|---|---|

| Air permeability (m3/min) | Air permeability (m3/min) | |

| 1. | 5.08 | 4.93 |

| 2. | 5.05 | 4.96 |

| 3. | 5.11 | 4.91 |

| 4. | 5.08 | 4.94 |

| 5. | 5.04 | 4.96 |

| Average | 5.07 | 4.94 |

2.2.6 Thread density and crimp percentage

The threads per centimeter and yarn crimp were measured as per ISO 23606:2009 and ISO 7211-3:1984 methods, respectively. The results are given in Table 10 (A and B).

Thread density and crimp percentage

| S. No | Fabric produced with false selvedge | Fabric produced without false selvedge | ||

|---|---|---|---|---|

| (A) Thread density | ||||

| Ends per cm | Picks per cm | Ends per cm | Picks per cm | |

| 1. | 27 | 23 | 27 | 23 |

| 2. | 27 | 23 | 26 | 23 |

| 3. | 27 | 24 | 27 | 24 |

| 4. | 26 | 23 | 27 | 24 |

| 5. | 27 | 24 | 26 | 23 |

| 6. | 26 | 23 | 27 | 24 |

| Average | 26.7 | 23.3 | 26.7 | 23.5 |

| (B) Crimp % | ||||

| Warp crimp % | Weft crimp % | Warp crimp % | Weft crimp % | |

| 1. | 2.5 | 7.5 | 3.5 | 9.0 |

| 2. | 2.6 | 7.4 | 3.7 | 9.2 |

| 3. | 2.7 | 7.6 | 3.5 | 9.3 |

| 4. | 2.5 | 7.4 | 3.6 | 9.0 |

| 5. | 2.8 | 7.6 | 3.5 | 9.0 |

| 6. | 2.8 | 7.5 | 3.4 | 9.2 |

| Average | 2.65 | 7.5 | 3.53 | 9.1 |

2.2.7 Abrasion resistance

Abrasion resistance of the fabrics was tested in accordance with ISO 12947-2:2016 using 9 kPa load up to 5,000 rubs. The results are given in Table 11.

Abrasion resistance of the fabrics

| Fabric produced with false selvedge | Fabric produced without false selvedge |

|---|---|

| No thread breakage up to 5,000 rubs | No thread breakage up to 5,000 rubs |

2.2.8 Weight per unit area

Weight per unit area was measured as per ISO 3801/EN 12127 method, and the results are given in Table 12.

Weight per unit area of the fabrics

| S. No | Fabric produced with false selvedge | Fabric produced without false selvedge |

|---|---|---|

| Weight per unit area (g/m2) | Weight per unit area (g/m2) | |

| 1. | 116.1 | 114.6 |

| 2. | 113.8 | 115.2 |

| 3. | 113.4 | 112.2 |

| 4. | 113.6 | 114.3 |

| Average | 114.22 | 114.07 |

It is quite evident from the different test results that the fabric manufactured with false selvedge and without the false selvedge (after the installation of the developed mechanism) show very minimal or no difference in their properties. In certain aspects, the fabric manufactured without false selvedge shows comparatively better results. The marginal increase in tensile and bursting strengths of this fabric may be attributed to the slight increase in the crimp of warp and weft yarns. Neogi [6] stated that the crimp decreases with increase in weaving tension, which indicates that the weft tension in the case of fabric produced with the installed mechanism was comparatively slightly lesser, resulting in the increased crimping of the weft yarn (as shown in the results) for a given warp tension. Once out of the loom, the weft yarns tend to recover a part of their crimp making the warp threads to yield so as to slightly increase their crimp as indicated. Adanur and Qi [5] stated that air permeability of a fabric increases with increased weft tension. This shows that the slightly decreased air permeability in the fabric without the false selvedge is indicative of a slightly lesser weft tension than the fabric manufactured with false selvedge. The extensibility of weft can, therefore, be said to be preserved in the former.

3 Conclusion

False selvedge formation on rapier looms is a significant contributor to the amount of hard waste generated in weaving. A research gap does exist in finding alternatives to the false selvedge. This article, therefore, addresses this issue in finding a suitable replacement which can very well substitute the false selvedge in forming the fabric. As is evident from the successful running of the loom with same parameters as with false selvedge, the mechanism caters well to the manufacture of fabric with similar particulars. It is also quite evident from the comparative test data of similar fabrics, manufactured with and without false selvedge, that there is minimal or no difference in their important properties. This is an indicator that the mechanism does not adversely affect the quality of the fabric. On the contrary, certain properties of the fabric manufactured with the mechanism showed an improvement, as is evident from the results. Since false selvedge is generally considered a ‘necessary evil’ in rapier weaving, the developed mechanism and its concept, therefore, have good potential to gain the acceptability of the weaving community because it performs the function of false selvedge without the incurrence of additional yarn cost as required with false selvedges.

References

[1] Sanjay, A. (2019). Weaving sector in India, textile value chain. Wazir Associates (India).Search in Google Scholar

[2] Rigby, D. (2002). World market forecasts for 2010 of technical textiles. David Rigby Associates Limited (Manchester).Search in Google Scholar

[3] Akdeniz, R., Özek, Z., Durusoy, G. (2017). A study of selvedge waste length in rapier weaving by image analysis technique. Tekstil Ve Konfeksiyon, 27(1), 22–26.Search in Google Scholar

[4] Sajid, A. Q., Ramesh Kumar, M., Parthibhan, M. (2019). False selvedge – significance & hindrance in the textile industry. International Journal of Computer Sciences and Engineering, 1(2), 42–45.Search in Google Scholar

[5] Adanur, S., Qi, J. (2008). Property analysis of denim fabrics made on air-jet weaving machine part II: Effects of tension on fabric properties. Textile Research Journal, 78, 10–20.10.1177/0040517507079781Search in Google Scholar

[6] Neogi, S. K. (2016). Role of yarn tension in weaving. Woodhead Pub (New Delhi).10.1201/b19896Search in Google Scholar

[7] Neogi, S. K., Bhattacharya, P. K. (1979). Effect of varying yarn tension on jute fabric. The Indian Textile Journal, 90, 127–132.Search in Google Scholar

[8] Jurasz, J. (2000). Assessment, choice and utilization of selvedge in non-classical weaving. Fibres & Textiles in Eastern Europe, 8(2), 50–53.Search in Google Scholar

© 2021 Sajid Ahmed Qureshi et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- AUTEX 2022 – 21st World Textile Conference Announcement

- Design and Development of a Novel Mechanism for the Removal of False Selvedge and Minimization of its Associated Yarn Wastage in Shuttleless Looms

- Empirical Analysis of the Impact Strength of Textile Knitted Barrier Meshes

- Characteristics of Laminates for Car Seats

- Methodology of Optimum Selection of Material and Semi-Folded Products for Rotors of Open-End Spinning Machine

- Fabrication of Multifunctional Nano Gelatin/Zinc Oxide Composite Fibers

- 3D Design of Clothing in Medical Applications

- Development of Subcontractor Selection Models Using Fuzzy and AHP Methods in the Apparel Industry Supply Chain

- Evaluation of Thermal Properties of Certain Flame-Retardant Fabrics Modified with a Magnetron Sputtering Method

- Comparative Study of Long- and Short-Stretch Woven Compression Bandages

- Natural Polymers on the Global and European Market - Presentation of Research Results in the Łukasiewicz Research Network – Institute of Biopolymers and Chemical Fibers-Case Studies on the Cellulose and Chitosan Fibers

- The Fabrication of Cassava Silk Fibroin-Based Composite Film with Graphene Oxide and Chitosan Quaternary Ammonium Salt as a Biodegradable Membrane Material

- Eco-Fashion Designing to Ensure Corporate Social Responsibility within the Supply Chain in Fashion Industry

- Phototherapy in the Treatment of Diabetic Foot — A Preliminary Study

- Comparison of the Vibration Response of a Rotary Dobby with Cam-Link and Cam-Slider Modulators

- Numerical Simulation of Solar Radiation and Conjugate Heat Transfer through Cabin Seat Textile

Articles in the same Issue

- AUTEX 2022 – 21st World Textile Conference Announcement

- Design and Development of a Novel Mechanism for the Removal of False Selvedge and Minimization of its Associated Yarn Wastage in Shuttleless Looms

- Empirical Analysis of the Impact Strength of Textile Knitted Barrier Meshes

- Characteristics of Laminates for Car Seats

- Methodology of Optimum Selection of Material and Semi-Folded Products for Rotors of Open-End Spinning Machine

- Fabrication of Multifunctional Nano Gelatin/Zinc Oxide Composite Fibers

- 3D Design of Clothing in Medical Applications

- Development of Subcontractor Selection Models Using Fuzzy and AHP Methods in the Apparel Industry Supply Chain

- Evaluation of Thermal Properties of Certain Flame-Retardant Fabrics Modified with a Magnetron Sputtering Method

- Comparative Study of Long- and Short-Stretch Woven Compression Bandages

- Natural Polymers on the Global and European Market - Presentation of Research Results in the Łukasiewicz Research Network – Institute of Biopolymers and Chemical Fibers-Case Studies on the Cellulose and Chitosan Fibers

- The Fabrication of Cassava Silk Fibroin-Based Composite Film with Graphene Oxide and Chitosan Quaternary Ammonium Salt as a Biodegradable Membrane Material

- Eco-Fashion Designing to Ensure Corporate Social Responsibility within the Supply Chain in Fashion Industry

- Phototherapy in the Treatment of Diabetic Foot — A Preliminary Study

- Comparison of the Vibration Response of a Rotary Dobby with Cam-Link and Cam-Slider Modulators

- Numerical Simulation of Solar Radiation and Conjugate Heat Transfer through Cabin Seat Textile