Abstract

The wear properties of Mg alloy AZ31 (Al 3%, Zn 1%, rest Mg) nanocomposites reinforced with multi-wall carbon nanotubes (MWCNTs) were studied by conducting experiments on pin-on-disc wear test apparatus. The composites were fabricated by powder metallurgy technique by homogeneously reinforcing variable percentages of MWCNTs (0.33 wt%, 0.66 wt%, and 1.0 wt%) into Mg alloy AZ31 matrix through mechanical alloying. The effect of varying percentages of MWCNTs on the wear properties of AZ31-MWCNT nanocomposites and the mechanism behind that were investigated through scanning electron microscope and energy dispersive spectroscope analysis. The microstructure investigation revealed that an increase in reinforcement of MWCNTs in AZ31 alloy increased the hardness and reduced the wear rate of the composites with 0.33 wt% and 0.66 wt% due to homogeneous distribution and high interfacial strength between AZ31 and MWCNTs. However, with the addition of 1.0 wt% MWCNTs to AZ31 alloy led to high agglomeration of MWCNTs, resulting in poor interfacial strength and weak bonding between AZ31 and conglomerated MWCNTs, subsequently increasing the wear rate.

1 Introduction

Magnesium matrix composites offer a variety of advantages over their monolithic counterpart due to improvements in stiffness, strength, thermal conductivity, and wear resistance. Several researches during last decade have shown that carbon nanotubes (CNTs) can considerably enhance the mechanical and conductive properties of polymer and ceramic matrix [1–3]. In polymer-CNT nanocomposites, the addition of CNT as reinforcement improves the strength of the polymer matrix by several times [4, 5]. However, compared with polymer-CNT and ceramic-CNT nanocomposites, metal-CNT nanocomposites have attracted less attention due to their inferior mechanical properties than expected [6–9]. Even though several researchers have fabricated metal-CNT nanocomposites by powder metallurgy process including mixing of CNTs with metal powders followed by hot pressing, metal-CNT nanocomposites have failed to show anticipated enhancement of mechanical properties [10, 11]. In previous researches on metal-CNT nanocomposites, inferior mechanical properties are caused mainly by agglomeration of CNTs and low relative density of the nanocomposites, which ranged between 85% and 95%.

Cha et al. [12] developed the molecular-level process for homogeneous dispersion of CNTs in metal matrix and used spark plasma sintering process for highly densified metal-CNT nanocomposites. Although most investigations have focused on fabrication process and mechanical properties, very few studies have been reported on the wear properties of metal-CNT nanocomposites. Kagiarova et al. [13] investigated the friction and wear behavior of Si3 N4/SiC nanoceramic composites against Si3 N4 ball using a pin-on-disc wear tester. The friction coefficient varied between 0.4 and 0.6 under the experimental conditions of varying loads of 10, 15, and 20 N with a sliding distance of 600, 900, and 1200 m and sliding speed of 0.1, 0.2, and 0.3 m/s. The erosive wear behavior of Al2 O3/SiC nanocomposites was investigated by Davidge et al. [14], and it was found that the dispersion of secondary SiC nanoparticles in polycrystalline alumina significantly reduced the wear rate, and smooth transgranular fracture paths were observed in the worn nanocomposites. Rodriguez et al. [15] studied the sliding wear properties of Al2 O3/SiC nanocomposites by varying the grain size of SiC and found that intergranular fracture followed by grain pull-out is noted to be the dominant wear mechanisms. Lee et al. [16] studied the tribological behavior of Al2 O3/TiO2 nanocomposites against Si3 N4, carried out using a ball-on-disc tribometer. The highest wear resistance was noted for 10 mol% of TiO2 reinforcement and the governing wear mechanisms were abrasive and plastic deformation.

In the present study, the powders of matrix alloy AZ31 and reinforcement multi-wall CNTs (MWCNTs) were blended by a high-energy ball mill to homogeneously reinforce the MWCNTs in the AZ31 matrix through mechanical alloying. The specimens of Mg alloy AZ31 and AZ31-MWCNT composites were fabricated by powder metallurgy process, and the wear test was carried out using pin-on-disc equipment. The effect of MWCNTs on the wear properties of AZ31-MWCNT nanocomposites and the mechanism behind that were investigated through scanning electron microscope (SEM) and energy dispersive spectroscope (EDS) analysis and were compared with the monolithic AZ31 alloy.

2 Materials and methods

Magnesium (Mg) powder with 99.5% purity, Aluminium (Al) and Zinc (Zn) powder with 99% purity supplied by Neeraj Industries, Rohtak, Haryana, India was used as the matrix material. MWCNTs produced by Nanoshell (USA), supplied by Intelligent Materials Pvt. Ltd., Chandigarh, India was used as reinforcement material. Fabrication and characterization of the composites were carried out at Annamalai University, Chidambaram, Tamilnadu, India and PDVVP College of Engg., Ahmednagar, Maharshtra, India. Powder metallurgy process was used to synthesize both AZ31 alloy and AZ31-MWCNT nanocomposites. Three variations of the reinforcement material MWCNT, 0.33 wt%, 0.66 wt%, and 1 wt%, were added to the matrix of AZ31 alloy and blended using a high-energy ball mill for 2 h at a speed of 300 RPM. Tungston carbide balls were used with a ball-to-powder weight ratio of 5:1. The blended powders were checked through microstructure images of the SEM at 1 h, 1.5 h, and 2 h of ball milling, and it was found that mechanical alloying using high-energy ball milling has helped the MWCNTs to reinforce homogeneously into the AZ31 matrix.

The homogeneously blended powders with different variations of MWCNTs were compacted into cylindrical billets of 30-mm diameter, as shown in Figure 1. The compacted specimens of AZ31 and AZ31-MWCNT composites were sintered at 630°C for 2 h in a tubular sintering furnace under inert atmosphere. Monolithic AZ31 alloy billets without MWCNTs were also fabricated by the same process. The sintered billets were hot extruded using an extrusion die and the pin specimens were prepared with flat ends, a diameter of 8 mm, and length of 20 mm. Pin-on-disc-type wear tester TR20 DUCOM was used to study the wear characteristics of the samples with three different loads of 15.7N, 25.5N, and 35.32N at a sliding speed of 1.04 m/s in dry condition. The hardness was measured using Vickers hardness tester with a load setting of 5 KN and dual time of 15 s at five places on each sample, and the average was taken. Microstructure and EDS investigations of the samples were carried out using a Quanta 200-SEM. The friction force and the wear amounts were obtained through sliding tests, and the wear mechanism was investigated through SEM and EDS images. Finally, the experimental results of hardness, coefficient of friction, wear amount, and the microstructures of AZ31-MWCNT nanocomposites were compared with monolithic AZ31 alloy.

Compacted specimen.

3 Results and discussion

3.1 Microstructure analysis

Mechanical alloying using ball-milling technique was effective in dispersing MWCNTs on the surface of the particles at the beginning of milling and within the particles after a few hours of milling. The microstructures of the ball-milled samples are shown in Figure 2. It is observed from the images that during the process of ball milling, the powders collided with the grinding balls, creating high pulverization energy responsible for introducing lattice defects that caused the powder particles to deform plastically, as shown in Figure 2A. As the process continued, the powder particles fractured and the reinforcement particles were cold welded to the matrix particles; this occurred at the atomic scale. Further milling led to the enlargement of the forming particles with reinforcement as an intermediate phase appearing inside or at the surface of these particles, as shown in Figure 2B. SEM and EDS images of the AZ31-0.33 wt%, AZ31-0.66 wt%, and AZ31-1 wt% MWCNT nanocomposites obtained from the extruded samples are shown in Figures 3 and 4, respectively. The microstructure of sample of 0.33 wt% and 0.66 wt% MWCNTs revealed uniform homogeneity of MWCNTs in the AZ31 matrix; however, with the 1 wt% samples, agglomerations of MWCNTs were noticed and confirmed through the carbon peak of EDS image in Figure 4C. The EDS images also reveal the presence of a small amount of MgO due to oxidation during the ball milling and sintering processes.

SEM images of ball-milled powder.

SEM images of AZ31-MWCNT composites: (A) 0.33 wt%, (B) 0.66 wt%, (C) 1.0 wt%.

EDS images of AZ31-MWCNT composites: (A) 0.33 wt%, (B) 0.66 wt%, (C) 1.0 wt%.

3.2 Wear mechanism

Figure 5 shows the coefficient of friction values of the AZ31-MWCNT samples. For the samples with 0.33 wt% and 0.66 wt% MWCNT, the coefficient of friction was low, and for the sample with 1 wt% MWCNT, the coefficient of friction values were increased. This may be due to the weak coherence between the carbide phase of Al4 C3 developed through intermetallic reaction during the sintering processes and the conglomerated carbon, based on the previous studies [17–20]. The SEM images shown in Figure 6 were used to analyze the characteristics of wear. The surface of the composites with 1 wt% MWCNT was severely deformed and abrasion was caused by the agglomerated MWCNTs into microdebris and large debris due to fatigue. These cracks grow and separate from the surface and become wear debris. The scars of plastic deformation by ploughing are evident in the areas of abrasive wear at the center area. When the hard surface slides on the soft surface or abrasive grits mounted on the top surface slide on the soft surface, these hard asperities or rigidly held grits pass over the surface like a cutting tool; this phenomenon is called “two-body abrasion.” In case the hard surface is a third body, generally, a small particle of abrasive is caught between the two other surfaces and is sufficiently harder, so that it is able to abrade either one or both of the mating surfaces; this is called “three-body abrasion.” However, the wear rate is more by two-body abrasion, as reported in previous studies [12, 21, 22] and also found in the present study with 1.0 wt% MWCNT composite. In case of 0.33 wt% and 0.66 wt% MWCNT composites, the MWCNTs were dispersed uniformly; hence, the wear rate was much less by three-body abrasion of minute particles.

Friction coefficient according to %CNT content.

SEM micrographs of the worn surfaces of (A) 0% CNT, (B) 0.33 wt% CNT, (C) 0.66 wt% CNT, and (D) 1 wt% CNT composites.

3.3 Effect of hardness on wear

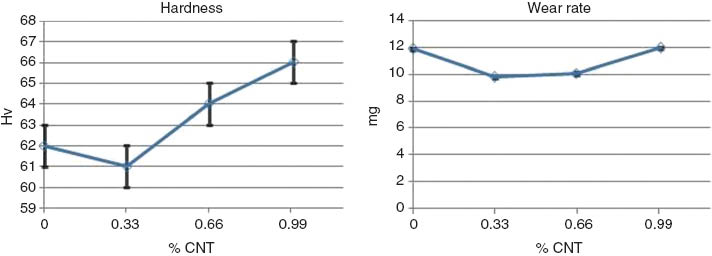

The hardness and wear rate of the nanocomposites according to MWCNT content are shown in Figure 7. It is observed that the hardness increased with increasing MWCNT weight fraction into the AZ31 matrix. When the MWCNTs were reinforced up to 1 wt%, the hardness of the nanocomposite was higher than that of AZ31 without MWCNTs. When metal-CNT or ceramic-CNT nanocomposites are fabricated by molecular-level process, the chemical bonding formed between the MWCNTs and the matrix ions provides homogeneous distribution of MWCNTs as well as high interfacial strength [10, 23]. Therefore, it is confirmed that such remarkable enhancement of hardness by MWCNT reinforcement originated from the high interfacial strength at the Mg-MWCNT interface as well as due to the homogeneous distribution of MWCNTs at the molecular level by mechanical alloying within AZ31 matrix through ball milling.

Hardness and wear rate values.

Owing to the increased hardness of composites with MWCNT compared with those with AZ31, it is believed that MWCNT plays an important role in hardness strengthening. If a small amount of MWCNT is added, the hardness of the composite increases because the MWCNTs fill the microvoids of the Mg particles. However, when a large amount of MWCNT is added, the excess MWCNTs that remain after filling the microvoids form conglomerates with the Mg particles. This conglomeration interrupts the sintering and causes defects [15, 16]. Based on these results, the higher the MWCNT content is, the amount of wear also increases due to the separation of conglomerated particles that have a weak bonding energy with the surface.

4 Conclusions

Powder metallurgy technique followed by mechanical alloying through high-energy ball milling was found to be effective in uniform distribution and homogeneous reinforcement of MWCNTs in AZ31 matrix and fabrication of Mg alloy AZ31-MWCNT nanocomposites.

The hardness and wear resistance of fabricated AZ31-MWCNT nanocomposites were found to be significantly increased with an increase in the fraction of MWCNTs up to 0.66 wt%. The remarkable enhancement of hardness originated from the homogeneously distributed MWCNTs in the AZ31 matrix, and high interfacial strength at the interfaces enhances wear resistance by retarding the peeling of AZ31 grains during the sliding wear process.

Addition of 1.0 wt% MWCNTs to the AZ31 matrix results in high agglomeration of MWCNTs and increases the wear rate due to poor interfacial strength and weak bonding between the matrix and conglomerated MWCNTs.

It is concluded that the homogeneous distribution of MWCNTs with sound interface in the AZ31 matrix is an important technological issue to enhance the mechanical behavior and wear resistance of AZ31-MWCNT nanocomposite.

Acknowledgments

We thank the staff in charge of the Manufacturing Lab, CEMAJOR Lab of Annamalai University, Chidambaram, Tamilnadu, India, and the Metallurgy and Material Testing Lab of PDVVP College of Engineering, Ahmednagar, Maharashtra, India, for their continuous cooperation in the fabrication and study of the wear properties of the materials, respectively. We thank Mr. Kiran Bhotkar of Icon Equipments Pvt. Ltd., Mumbai, India, for his continuous cooperation in analyzing the microstructures of the samples.

References

[1] Zhang Y, Franklin NW, Chen RJ, Dai H. Chem. Phys. Lett. 2000, 331, 35–41.Search in Google Scholar

[2] Lau KT, Hui D. Carbon 2002, 40, 1597–1617.10.1016/S0008-6223(02)00133-1Search in Google Scholar

[3] Dai H. Surf. Sci. 2002, 500, 218–241.10.1016/S0039-6028(01)01558-8Search in Google Scholar

[4] Thostenson ET, Ren Z, Chou TW. Compos. Sci. Technol. 2001, 61, 1899–1912.10.1016/S0266-3538(01)00094-XSearch in Google Scholar

[5] Xu CL, Wei BQ, Ma RZ, Liang J, Ma SK, Wu DH. Carbon 1999, 37, 855–858.10.1016/S0008-6223(98)00285-1Search in Google Scholar

[6] Wang X, Padture NP, Tanaka H. Nat. Mater. 2004, 3, 539–544.10.1038/nmat1161Search in Google Scholar

[7] Zhan GD, Kuntz JD, Wan J, Mukherjee AK. Nat. Mater. 2003, 2, 38–42.10.1038/nmat793Search in Google Scholar

[8] Ning J, Zhang J, Pan Y, Guo J. Mater. Sci. Eng. A 2003, 357, 392–396.10.1016/S0921-5093(03)00256-9Search in Google Scholar

[9] Mo CB, Cha SI, Kim KT, Lee KH, Hong SH. Mater. Sci. Eng. A 2005, 395, 124–128.10.1016/j.msea.2004.12.031Search in Google Scholar

[10] Dong SR, Tu JP, Zhang XB. Mater. Sci. Eng. A 2001, 313, 83–87.10.1016/S0921-5093(01)00963-7Search in Google Scholar

[11] Chen X, Xia J, Peng J, Li W, Xie S. Compos. Sci. Technol. 2000, 60, 301–306.10.1016/S0266-3538(99)00127-XSearch in Google Scholar

[12] Cha SI, Kim KT, Arshad SN, Mo CB, Hong SH. Adv. Mater. 2005, 17, 1377–1381.10.1002/adma.200401933Search in Google Scholar

[13] Kagiarova M, Rudnayova E, Dusza J, Hnatko M, Šajgalík P, Merstallinger A, Kuzsella L. J. Eur. Ceram. Soc. 2004, 24, 3431–3435.10.1016/j.jeurceramsoc.2003.10.029Search in Google Scholar

[14] Davidge RW, Twigg PC, Riley FL. J. Eur. Ceram. Soc. 1996, 16, 700–802.10.1016/0955-2219(95)00198-0Search in Google Scholar

[15] Rodriguez J, Martin A, Pastro JY, Lorce JL, Bartlome JF, Moya JS. J. Am. Ceram. Soc. 1999, 82, 1252–1254.Search in Google Scholar

[16] Lee SW, Morillo C, Olivares JL, Kim SH, Sekino T, Niihara K, Hockey BJ. Wear 2003, 255, 1040–1044.10.1016/S0043-1648(03)00099-1Search in Google Scholar

[17] Bhushan B. Principles and Applications of Tribology, Wiley-Interscience, 1999.10.1108/ilt.1999.51.6.313.1Search in Google Scholar

[18] Rabinowicz E. Friction and Wear of Materials, 2nd ed., Wiley-Interscience, 1995.Search in Google Scholar

[19] Stachowiak GW, Batchelor AW. Engineering Tribology, Elsevier, 1993.Search in Google Scholar

[20] Kim Y II, Lee J-H, Lee G-S, Baik S-H, Kim Y-J, Lee Y-Z. Wear 2009, 267, 593–598.10.1016/j.wear.2008.12.096Search in Google Scholar

[21] Barge M, Rech J, Hamdi H, Bergheau JM. Wear 2008, 264, 382–388.10.1016/j.wear.2006.08.046Search in Google Scholar

[22] Casas B, Wiklund U, Hogmark S, Llanes L. Wear 2008, 265, 490–496.10.1016/j.wear.2007.11.016Search in Google Scholar

[23] Cha SI, Kim KT, Lee KH, Mo CB, Hong SH. Scripta Mater. 2005, 53, 793–797.10.1016/j.scriptamat.2005.06.011Search in Google Scholar

©2016 by De Gruyter

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Review

- The behaviour of aluminium matrix composites under thermal stresses

- Original articles

- Preparation and characterization of graphite/resin composite bipolar plates for polymer electrolyte membrane fuel cells

- Synergistic effect of carbon nanotubes in combination with magnesium hydroxide on the flame retardant poly(ethylene-co-vinyl acetate)

- Preparation and characterization of nano biphasic calcium phosphate/poly-L-lactide composite scaffold

- Durability study of ramie fiber fabric reinforced phenolic plates under humidity conditions

- Synthesis and molecular dynamics simulation of hyperbranched poly(amine-ester)/neodymium nanocomposites

- Investigation on wear properties of AZ31-MWCNT nanocomposites fabricated through mechanical alloying and powder metallurgy

- Probabilistic analysis of a thermosetting pultrusion process

- Analysis of shrinkage and creep behaviors in polymer-coated lightweight concretes

- Investigation of optimum cutting parameters and tool radius in turning glass-fiber-reinforced composite material

- Buckling and vibration analyses of composite laminates with weak interfaces by a coupled meshfree and finite element method

- Free vibration and postbuckling of laminated composite Timoshenko beams

Articles in the same Issue

- Frontmatter

- Review

- The behaviour of aluminium matrix composites under thermal stresses

- Original articles

- Preparation and characterization of graphite/resin composite bipolar plates for polymer electrolyte membrane fuel cells

- Synergistic effect of carbon nanotubes in combination with magnesium hydroxide on the flame retardant poly(ethylene-co-vinyl acetate)

- Preparation and characterization of nano biphasic calcium phosphate/poly-L-lactide composite scaffold

- Durability study of ramie fiber fabric reinforced phenolic plates under humidity conditions

- Synthesis and molecular dynamics simulation of hyperbranched poly(amine-ester)/neodymium nanocomposites

- Investigation on wear properties of AZ31-MWCNT nanocomposites fabricated through mechanical alloying and powder metallurgy

- Probabilistic analysis of a thermosetting pultrusion process

- Analysis of shrinkage and creep behaviors in polymer-coated lightweight concretes

- Investigation of optimum cutting parameters and tool radius in turning glass-fiber-reinforced composite material

- Buckling and vibration analyses of composite laminates with weak interfaces by a coupled meshfree and finite element method

- Free vibration and postbuckling of laminated composite Timoshenko beams