Abstract

The aim of this study is to investigate the effect of surface modification through sodium hydroxide (NaOH) treatment and fiber length on the tensile strength of coir fiber of reinforced epoxy composites. The coir fibers were treated with 2%, 4%, 6%, 8%, and 10% concentration of NaOH separately for 10 days. The tensile strength of untreated and alkali-treated fiber was measured. For each group of the coir fiber, experiments were conducted on different fiber lengths, namely, 10, 20, and 30 mm. The experimental results showed that increasing the NaOH concentration leads to a decrease in fiber diameter in a linear fashion. This reduction in diameter naturally ends up with reduced tensile strength. The treated coir fiber was used as a reinforcement and epoxy as a matrix to fabricate the composites. The tensile strength of different samples of composites was measured. Increased NaOH concentration (up to 4%) in fiber treatment was found to increase the tensile strength, and further increase in NaOH concentration reduces the tensile strength; also, increased fiber length was found to increase in tensile strength. The maximum tensile strength of the composite was observed at 4% NaOH-treated samples. On the basis of the nonlinear regression analysis, the tensile strength equation was proposed for coir fiber-reinforced epoxy composites.

1 Introduction

The field of modern engineering makes use of innumerable engineering materials for different applications. Some of these materials like plastics are widely used as they have attractive mechanical properties. However, these materials have objectionable properties such as nondegradability, leading to serious environmental problems. Intensive research is going on throughout the world to replace the above materials with biodegradable substitute materials having comparable or better mechanical properties. Composites using these biodegradable materials are being tried widely for their various advantages. Some of the advantages of using biodegradable materials on composites are their availability worldwide, strength-to-weight ratio, high fatigue life, etc. [1]. Natural fibers from cultivated plants such as coconut fiber, flax, sisal, and cotton have been used in a large variety of products from clothes to house roofing. Today these fibers are appraised as environmentally correct materials owing to their biodegradability and renewable characteristics [2]. Among the numerous natural fibers, coir fiber has shown a great potential in the composite field. Coir fibers are found between the husk and the outer shell of the coconut. The individual fiber cells are narrow and hollow, with thick walls composed of cellulose. They are pale when immature but later become hardened and yellowed as a layer of lignin is deposited on their walls. There are two varieties of coir. Brown coir is harvested from fully ripened coconut. It is thick, strong, and highly resistive to abrasion. It is typically used in mats, brushes, and sacking. Mature brown fibers contain more lignin and less cellulose than fibers such as flax and cotton and so are stronger but less flexible. White coir fibers are harvested from the coconuts before they are ripe. It is a CO2-neutral material. These fibers are abundant, nontoxic in nature, biodegradable, less dense, and very cheap. The coir fiber can retain water to a high degree and is also rich in micronutrients [3, 4]. Coir fibers decompose in 20–30 years in nature; they can be regarded as an environmentally friendly material. Coir fiber may be used as a reinforcement material in composite production [5–9]. Monteiro et al. [10] have proved that lignin, pectin, and other impurities within the coir fiber are considered harmful for its adhesion to the matrix during the composite fabrication. Therefore, alkali treatment of coir fiber improves the adhesion to the polyester matrix and thus increases the composite strength by approximately 50% of the results for a volume fabrication of 30% of treated coir fiber. Many authors [11–14] have carried out their studies on different natural fibers. Khedari et al. [15] have indicated that the incorporation of natural fibers into polymers could improve the mechanical properties. Coconut coir is the most interesting product as it has low thermal conductivity compared to other natural fibers. Rout et al. [16] have conducted experiments and proved that coir fiber loading from 9 to 15 wt% has a flexural strength of about 38 MPa. Coir polyester composites with untreated and treated fibers with fiber loading of 17 wt% were tested. The results revealed that the treated fiber-reinforced composites gave better tensile, flexural, and impact strength. Huang [17] proved that alkali treatment on the coir fiber removed impurities like pectin, fats, and lignin as a result of the rough fiber surface of the fiber. These improve the adhesive ability of the coir fiber with the matrix in the fabricated composites, resulting in a greater tensile strength of the material. Doan et al. [18] stated that fiber length plays an important role in the mechanical performance of fiber-reinforced composites. Among the methods to improve the adhesive character of the coir fiber, alkaline treatment may be considered to be the most economical technique. Although much work has been done on coir fiber-reinforced polymer composites, very limited work has been done on the effect of fiber length with surface treatment through NaOH on the tensile behavior of coir fiber-reinforced composites. Against this background, the present research work has been undertaken, with the object of exploring the potential use of coir fiber as a reinforcing material in polymer composites and to investigate its effect on the tensile strength of the resulting composites. In this investigation, coir fibers were treated with sodium hydroxide (NaOH) of various concentrations. The coir fiber was used as a reinforcement and epoxy as the matrix to fabricate the composite by hand lay-up technique. The tensile strength of the produced specimens was measured, and scanning electron microscopy analysis was performed.

2 Materials and methods

2.1 Materials

The coconut husks were soaked in tap water in a container for 5 months. This process is called retting, which can partially decompose the pulp on the shell, allowing the fiber to be easily removed from the husk. After retting, the husks were beaten with a hammer. The coir fibers were removed from the shell and separated with a comb. After drying at room temperature, the coir fibers were combed in a carding frame to further separate the fibers into an individual state. Epoxy LY556 was used as a matrix with HY951.

2.2 Coir fiber treatment

The coir fibers were treated in the NaOH solution at room temperature (27–29°C) with various concentrations of 2%, 4%, 6%, 8%, and 10%. Each group of the coir fiber was treated for 10 days. The treated fiber was washed with water to remove the excess NaOH sticking to the fibers. Final washing was carried out with distilled water and the fibers were dried in hot air. Finally, the fibers were cut into 10-, 20-, and 30-mm lengths for molding the composites.

2.3 Preparation of coir fiber-reinforced epoxy composite

The coir fiber-reinforced epoxy composites were manufactured using a mold box of size 300 mm×300 mm×3 mm. The fabrication of the composite material was carried out through the hand lay-up technique. The top and bottom surfaces and the walls of the mold were coated with remover and allowed to dry. The chopped fibers were mixed manually with epoxy resin. The epoxy resin and coir fiber mixture was transferred to the mold and the mold was closed; then it was pressed in a compression testing machine and left for 24 h for curing. The setup is illustrated in Figure 1. After the curing process, the samples were cut into the required size prescribed in the ASTM standards.

Mold preparation setup.

2.4 Tensile test

The fiber strength testing of the coir fiber was carried out by using the model INSTRON 5500R single fiber tensile strength tester (SITRA, Coimbatore, TN, India). Thirty samples were tested and the average value is reported. The distance between the two clamps before the test was measured as 60 mm and displacement rate was set as 10 mm/min as most of the researchers have used this strain rate. It was selected in order to compare our results with that available in the literature. Images of the coir fiber before and after the alkali treatment were taken by using a scanning electron microscope (Model KYKY 2800, Amirtha University, Coimbatore, TN, India). The diameter of the coir fiber before and after the alkali treatment was measured using an image analyzer from SITRA (Coimbatore, TN, India).

From the fabricated coir fiber-reinforced epoxy composite, test specimens were cut as per ASTM D3039 and tested for tensile strength using a computerized universal testing machine (INSTRON model 3369). The setup is illustrated in Figure 2. The distance between the two clamps before the test was maintained at 150 mm, and the testing speed was 2 mm/min, the value normally used. Five samples were tested and the average value is reported.

Universal tensile tester model Instron 3369.

3 Results and discussion

3.1 Image of the coir fiber

Figures 3–5 represent the surface appearance of the coir fiber before and after the alkali treatment, respectively. Figure 3 shows that the surface of the coir fiber is covered with a layer of substance, which may include pectin, lignin, and other impurities. The surface is not smooth, but spread with nodes and irregular strips. Figures 4 and 5 represent the surface of the coir fiber after NaOH treatment. The figures show that most of the lignin and pectin are removed, resulting in a rougher surface. There are rows of pits on the surface. These would increase the mechanical bonding between the coir fiber and the matrix in the composite fabrication.

Surface appearance of the coir fiber before alkali treatment.

Surface appearance of the coir fiber after 2% NaOH treatment.

Surface appearance of the coir fiber after 4% NaOH treatment.

3.2 Fiber tensile strength

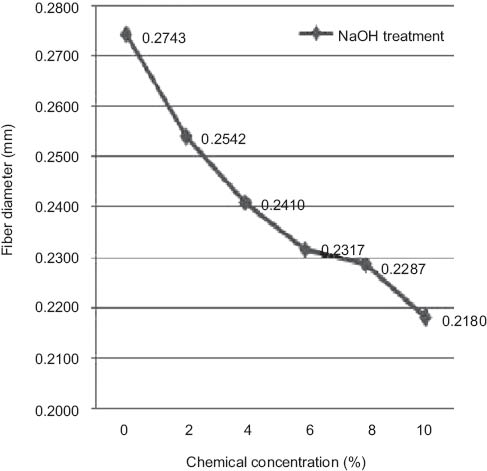

The tensile strength of NaOH-treated fibers is listed in Table 1 for comparison. The tensile strength of the untreated fiber is also included in the table because of the incredible variation of the fiber fitness; the tensile strength of the fiber varies greatly. To observe the influence of the coir fiber variation, 30 samples were used for each group. Table 1 represents the tensile strength of the coir fiber before and after the alkali treatment. The results revealed that a decreasing trend is seen in the fiber tensile strength with increasing alkali density. The difference in the tensile strength among each group was proved to be significant. An increase in alkali concentration causes a greater amount of lignin and pectin to leach out; this would be detrimental to fiber strength. Figure 6 represents the comparison of the coir fiber diameter before and after the alkali treatment. One may note that a decreasing trend is seen in the fiber diameter with increase in alkali density. Figure 6 proved that the NaOH treatment reduces the fiber strength drastically because the pH value of NaOH is high. After the alkali treatment, a rough fiber surface resulted; this might improve the bonding ability of the fiber with the matrix.

Coir fiber tensile strength with NaOH treatment.

| Fiber | Tensile strength (MPa) | Elongation (%) |

|---|---|---|

| Original fiber | 617.6 | 18.8 |

| 2% NaOH | 582.6 | 28.0 |

| 4% NaOH | 568.7 | 27.1 |

| 6% NaOH | 553.3 | 23.1 |

| 8% NaOH | 544 | 23.9 |

| 10% NaOH | 527.7 | 22.9 |

Coir fiber diameter before and after NaOH treatment.

3.3 Tensile strength of the coir fiber- reinforced epoxy composite

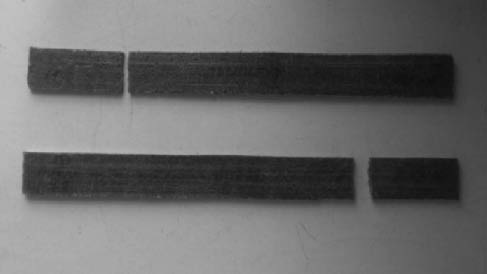

Figure 7 shows the appearance of the specimen of the coir fiber-reinforced epoxy composites. The weight fraction of the coir fiber in the composite was 30%. Each piece of the fabricated board was cut into sets of specimens. Results of the tensile strength tests of coir fiber-reinforced epoxy composites with and without alkali treatment are summarized in Tables 2 and 3.

Effect of fiber length on tensile property of untreated coir fiber-reinforced epoxy composite.

| Fiber length (mm) | Tensile strength (MPa) |

|---|---|

| 10 | 6.208 |

| 20 | 9.155 |

| 30 | 13.05 |

(A) Specimen for impact test (4% NaOH and 20-mm length). (B) Specimen for flexural test (4% NaOH and 10-mm length). (C) Specimen for tensile test (4% NaOH and 30-mm length).

Effect of fiber length on tensile strength of NaOH-treated coir fiber-reinforced epoxy composites.

| Fiber length (mm) | NaOH concentration | |||||

|---|---|---|---|---|---|---|

| 2% | 4% | 6% | 8% | 10% | ||

| Tensile strength (MPa) | ||||||

| 10 | 8.567 | 12.845 | 12.807 | 9.908 | 8.455 | |

| 20 | 9.242 | 13.380 | 13.327 | 10.098 | 8.659 | |

| 30 | 13.171 | 13.782 | 13.702 | 10.498 | 8.941 | |

| Elongation (%) | ||||||

| 10 | 0.882 | 0.3 | 1.01 | 0.743 | 0.72 | |

| 20 | 0.9 | 0.5 | 1.067 | 0.766 | 0.733 | |

| 30 | 0.92 | 0.525 | 1.0 | 0.797 | 0.755 | |

3.4 Effect of fiber length on the tensile property of coir fiber-reinforced epoxy composites

Joseph et al. [19] studied the tensile properties of short sisal fiber/polyethylene composites in relation to processing methods and the effects of fiber content, length, and orientation. For this experiment, it was shown that the chopped fiber distribution in epoxy is random, so the fiber could not hold the load when the matrix was transferred. Arib et al. [20] compared the experimental and theoretical tensile strengths for pineapple leaf fiber-reinforced polypropylene composites and found that the equation for rule of mixture fails to provide a good fit, and the discrepancy increases with the increase in fiber volume fraction. The fiber is not perfectly aligned, and the presence of voids in the composites may also be the factor contributing to the lower experimental values. According to Baiardo et al. [21], the mechanical properties of short fiber-reinforced composites are expected to depend on (i) the intrinsic properties of matrix and fibers, (ii) aspect ratio, content length distribution, and orientation of the fibers in the composites, and (iii) fiber-matrix adhesion that is responsible for the efficiency of load transfer in the composites. Table 3 shows, as expected, that the tensile strength gradually increases with increase in fiber length, reaching a maximum at about 30 mm (13.782 MPa). The reason for this increase in the tensile properties of these composites is that the chemical bonding between the fiber and the matrix may be too strong to transfer the tensile load.

3.5 Effect of alkali treatment on the tensile property of coir fiber-reinforced epoxy composites

We may note the significant difference in the tensile strength between the alkali-treated and the untreated coir fiber-reinforced epoxy composites. The tensile strength of the composites when using the alkali-treated coir fibers is usually greater because after alkali treatment, most of the impurities like lignin and pectin that covered the fiber surface were removed, which improved the fiber adhesive character in combination with the matrix. Table 3 clearly shows the important difference in the tensile strength of NaOH-treated coir fiber-reinforced epoxy composites with varying fiber length and chemical concentration. There is no significant difference in the tensile strength in the case of 4% and 6% NAOH concentration. To achieve a composite with better strength, NaOH concentration of 4% may be recommended for economical considerations. Significant difference is noted for the elongation at break values between the composites made by using the alkali-treated and the untreated coir fiber. The higher elongation at break for the alkali-treated coir fiber composites indicates that the removal of the lignin and pectin improved the elasticity of the coir fiber.

4 Regression analysis

It was observed that the relationship between fiber length (L) and chemical concentration (C) on the tensile strength (Ts) of coir fiber-reinforced epoxy composite varies nonlinearly. From the parametric study, it is ascertained that interaction between parameters like coir fiber length (L) and NaOH concentration (C) influences the tensile strength (Ts) of the coir fiber-reinforced epoxy composite.

The nonlinear regression analysis is carried out using SSPS statistical analysis software to estimate the arbitrary relationship between the dependent variable (Ts) and a set of independent variables (L and C). The following design equation was developed using nonlinear regression analysis,

It is found that for the above-mentioned proposed design equation (1) the R2 value [1-(residual sum of squares/corrected sum of squares)] is found to be 0.962, which is more than 0.95 and hence best fits the data obtained using nonlinear analysis.

The experimental investigation has been extended for 25-mm fiber length with 2% NaOH concentration. The proposed equation was validated with the help of the extended experimental study. The validation is shown in Table 4. Figure 8 represents the specimen after tensile test.

Specimen for after tensile test (2% NaOH and 25-mm length).

Validation of design equation.

| Fiber length (mm) | NaOH concentration (%) | Experimental Ts (MPa) | Predicted Ts (MPa) |

|---|---|---|---|

| 25 | 2 | 11.07 | 11.71 |

5 Conclusion

In this investigation, the effect of fiber length and NaOH treatment of coir fiber on the tensile strength was studied. Conclusions from this study are as follows:

The NaOH treatment on the coir fiber would remove the impurities like pectin and lignin in the fiber. However, a rougher fiber surface may result after the treatment. This would increase the adhesive ability of the coir fiber with the matrix in the fabricated composites, resulting in greater tensile strength of the material.

This study has confirmed that the length of the fiber increases with increase in tensile strength.

The investigation showed that the higher concentration would deteriorate the fiber strength; the higher the concentration, the greater the damage to the fiber.

When the alkali concentration is 10%, the decrease in the fiber strength may play a major role as far as the composite tensile strength is concerned.

The results revealed that the NaOH treatment reduced the fiber strength drastically when the concentration was increased.

The design equation for tensile strength was proposed based on nonlinear regression analysis. From this investigation it is concluded that increase in coir fiber length up to 30 mm increases the tensile strength of the composite.

Increased NaOH concentration in fiber treatment was found to increase the composite elongation up to 6%, and further increase in NaOH concentration reduces the composite elongation. This result revealed that the ductility of the surface-modified coir fiber had been improved.

References

[1] Rowell RM, Hans JS, Rowell JS. Natural Poly. Agro Fibers Comp. 2000, 115–134.Search in Google Scholar

[2] Bledzki AK, Gassan J. Prog. Polym. Sci. 1999, 24, 221–274.Search in Google Scholar

[3] Sudhakaran PM. Fiber Reinf. Compos. Conference (Nelson Mandela Bar, South Africa, June 20), 2007.Search in Google Scholar

[4] Christry F. Coir News 2003, 32.Search in Google Scholar

[5] Sapuan SM, Faiz M, Mohd Zaki AR. Ciencia Technologia Dos Materials. 2001, 13, 37–40.Search in Google Scholar

[6] Lai CY, Sapuan SM, Ahmad M, Yahya N. Polym. Plast. Technol. Eng. 2005, 44, 619–632.Search in Google Scholar

[7] Sindhu K, Joseph K, Joseph JM, Mathew TV. J. Reinf. Plast. Compos. 2009, 26, 1571–1585.Search in Google Scholar

[8] Li ZJ, Wang LJ, Wang XG. J. Compos. Mater. 2007, 41, 1445–1457.Search in Google Scholar

[9] Sharma SC, Krishna M, Narasimha Murty HN, Sanjeeva Murthy. J. Reinf. Plast. Compos. 2006, 25, 925–932.Search in Google Scholar

[10] Monteiro SN, Santaf JR, Costa LL. In TMS Conference, San Francisco, CA, USA, 2009.Search in Google Scholar

[11] Beaucage G, Rane S, Scharfor DW, Long G, Fischer D. J. Polym. Sci. Polym. Phys. 1999, 37, 1105–1119.Search in Google Scholar

[12] Li ZH, Zhang J, Chen SJ. eXPRESS Polym. Lett. 2008, 2, 695–704.Search in Google Scholar

[13] Qian D, Dickey EC, Andrecos R, Rantell T. Appl. Poly. Letter, 2000, 46, 2868.Search in Google Scholar

[14] Joshi SV, Drzal LT, Mohanty AK, Arora S. Composites Part A 2004, 35, 371.10.1016/j.compositesa.2003.09.016Search in Google Scholar

[15] Khedari J, Suttisonk B, Pratintong N, Hirunlabh J. Cem. Concr. Compos. 2001, 23, 65–70.Search in Google Scholar

[16] Rout J, Misra M, Mohanty AK, Nayak SK, Tripathy SS. J. Reinf. Plast. Compos. 2003, 22, 1083–1100.Search in Google Scholar

[17] Huang GU. Mater. Des. 2009, 30, 3931–3934.Search in Google Scholar

[18] Doan TTL, Gao SL, Mader E. Compos. Sci. Technol. 2006, 66, 952.Search in Google Scholar

[19] Joseph K, Filho RDT, James B, Sabu T, Laura HDC. Rev. Bras. Eng. Agric. Ambientale 1999, 3, 367.10.1590/1807-1929/agriambi.v3n3p367-379Search in Google Scholar

[20] Arib RMN, Sapuan SM, Ahmad MMHM, Paridah MT, Khairul Zaman HMD. Mater. Des. 2006, 27, 391.Search in Google Scholar

[21] Baiardo M, Zini E, Scandola M. Appl. Sci. Manuf. 2009, 35, 703–710.Search in Google Scholar

©2014 by Walter de Gruyter Berlin Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Original articles

- Microstructures and physical properties of laser amorphous reinforced composite coatings

- The thermal resistance, flame retardance, and smoke control mechanism of nano MH/GF/NBR composite material

- The effect of sodium hydroxide treatment and fiber length on the tensile property of coir fiber-reinforced epoxy composites

- Evaluation of morphological characteristics and mechanical performance of Rockforce mineral fiber- and glass fiber-reinforced polyamide-6 composites

- Synthesis of superabsorbent resin with the properties of temperature tolerant, salt tolerant, and water absorbency deferred

- A study on tribological characterization of Al-Cu-Mg-B composites subjected to mechanical wear

- Microstructure and wear behavior of TiAl3 matrix self-lubricating composites by addition of fluoride solid lubricants

- Mechanical properties of Ni-nano-Al2O3 composite coatings on AISI 304 stainless steel by pulsed electrodeposition

- Improvement of Khorasan mortar with fly ash for restoration of historical buildings

- Combined effect of waste colemanite and silica fume on properties of cement mortar

- Effect of heat treatment temperature on ground pumice activation in geopolymer composites

- Stress intensity factor analysis of epoxy/SWCNTs based on global-local multiscale method

- Numerical elastoplastic analysis of the shear stress distribution in the adhesive layer for single-lap joints

- Analysis of three-layer composite plates with a new higher-order layerwise formulation

- Ceramic-polytetrafluoroethylene composite material-based miniaturized split-ring patch antenna

- Prediction of the influence of processing parameters on synthesis of Al2024-B4C composite powders in a planetary mill using an artificial neural network

- Different method to make laminates by shear thickening fluid

- Thermal control design for an automated fiber placement machine

- Estimate of cutting forces and surface roughness in end milling of glass fiber reinforced plastic composites using fuzzy logic system

- Electrical discharge machining of Al-TiB2 with a low-frequency vibrating tool

- Vibration behavior of a radially functionally graded annular disc with variable geometry

- Buckling behaviors of the impacted composite plates

Articles in the same Issue

- Frontmatter

- Original articles

- Microstructures and physical properties of laser amorphous reinforced composite coatings

- The thermal resistance, flame retardance, and smoke control mechanism of nano MH/GF/NBR composite material

- The effect of sodium hydroxide treatment and fiber length on the tensile property of coir fiber-reinforced epoxy composites

- Evaluation of morphological characteristics and mechanical performance of Rockforce mineral fiber- and glass fiber-reinforced polyamide-6 composites

- Synthesis of superabsorbent resin with the properties of temperature tolerant, salt tolerant, and water absorbency deferred

- A study on tribological characterization of Al-Cu-Mg-B composites subjected to mechanical wear

- Microstructure and wear behavior of TiAl3 matrix self-lubricating composites by addition of fluoride solid lubricants

- Mechanical properties of Ni-nano-Al2O3 composite coatings on AISI 304 stainless steel by pulsed electrodeposition

- Improvement of Khorasan mortar with fly ash for restoration of historical buildings

- Combined effect of waste colemanite and silica fume on properties of cement mortar

- Effect of heat treatment temperature on ground pumice activation in geopolymer composites

- Stress intensity factor analysis of epoxy/SWCNTs based on global-local multiscale method

- Numerical elastoplastic analysis of the shear stress distribution in the adhesive layer for single-lap joints

- Analysis of three-layer composite plates with a new higher-order layerwise formulation

- Ceramic-polytetrafluoroethylene composite material-based miniaturized split-ring patch antenna

- Prediction of the influence of processing parameters on synthesis of Al2024-B4C composite powders in a planetary mill using an artificial neural network

- Different method to make laminates by shear thickening fluid

- Thermal control design for an automated fiber placement machine

- Estimate of cutting forces and surface roughness in end milling of glass fiber reinforced plastic composites using fuzzy logic system

- Electrical discharge machining of Al-TiB2 with a low-frequency vibrating tool

- Vibration behavior of a radially functionally graded annular disc with variable geometry

- Buckling behaviors of the impacted composite plates