Abstract

The energy efficiency of papermaking critically depends on how much of the web moisture can be removed by wet pressing before the dryer section. Here, we explored an operation where the pressing was conducted over an extended period (70–540 ms) at an elevated temperature (approaching 100 °C). We found a large increase in the solids content for the tissue and board grades studied. The maximum measured solids content was 83 ± 2 % for tissue and 62 ± 2 % for linerboard, with approximately 5 % pt. (tissue) or 1.5 % pt. (linerboard) attributable to moisture evaporation after the pressure pulse based on our drying model. Both solids content levels were notably higher than those achieved with conventional pressure pulses. The results open up intriguing new directions for technological development towards a wet pressing concept that mimics the current metal-belt pilot lines but operates at higher web moisture levels. The high solids content achieved with extended wet pressing significantly reduces the amount of evaporated water. Thus, an ineffective Yankee + hood drying system with high temperature and energy loss would be no longer needed in tissue production. This would enable up to 90 % drying energy savings and a corresponding CO2 emission reduction compared to existing pressing and drying technologies.

1 Introduction

Wet pressing is an important unit process for producing several types of paper and board grades. It is a fast and energy-efficient way of removing water from the formed fibre web and thus to avoid excess heating of water and its evaporating (McDonald 2022). It is estimated that increasing the solids content of the web after the press section by 1 % may lower web drying energy consumption by 4–5 %, when solids content after the press is 40–50 % (Chandoul et al. 2011; Reczulski et al. 2023). Since drying energy is typically generated by burning fossil fuels especially in the tissue production (Valmet 2025), a decrease in drying energy directly translates into a corresponding reduction of CO2 emissions. Furthermore, pressing increases the density of the fibre network, improving its strength by creating more inter-fibre contacts. For these reasons, wet pressing methods have been developed throughout the papermaking era, leading to the current industrial pressing technologies, in which a typical increase in the web solids content is from 20‒25 % to about 40–50 %, depending on the paper grade and process type (Hubbe et al. 2020; Paulapuro 2001).

Much of the process optimisation stemmed from improved understanding of the fundamental mechanisms of water removal. This was based on laboratory experiments, analysis of pilot trial data and modelling work. Due to the large amount of water in the web entering the press section, the press impulse (applied linear loading divided by running speed) plays a major role in overcoming the viscous resistance of the water leaving the web. The behaviour for relatively short pulses in nip presses tends to be dominated by viscous effects (flow-controlled regime), and its understanding has led to the development of, e.g., shoe nips. However, for longer pulses, the viscoelastic structural resistance of the fibre web starts to take over, and the applied pressure is critical, as a longer pulse no longer significantly increases the water removal (pressure-controlled regime). The origin of this structural resistance is not yet understood in detail. Finally, during the reduction of the applied pressure at the end of the pulse, and prior to the full separation of the web from the felt, the elastic expansion of the web causes capillary rewetting of the pores in the web, as they are smaller than those in the felt (McDonald et al. 2014, 2019; McDonald and Kerekes 2017; Paulapuro 2007).

The current pressing technologies are based on either a roll nip or a shoe nip, which correspond to the pressing times of approximately 5 ms or 10–45 ms, respectively. The web temperature in conventional wet pressing is rather low, 40–50 °C, and can be increased slightly by applying a steam box (Kawamizu et al. 2009). Simply increasing the pressing time can be of limited utility if the press already operates near the pressure-controlled regime, where the solids content approaches the equilibrium value (corresponding to an infinitely long pulse at the given pressure). Combining longer pulses with an elevated temperature (Lieshout 1999) could be interesting, as in addition to accelerating the water removal by lower viscosity, high temperatures could reduce the structural resistance of the web to allow greater compression and higher equilibrium solids content. Lobosco and Kaul (2001) studied pulses varying in length from 20 ms to quasistatic at room temperature and at 80 °C with a platen press. The higher temperature gave an increase in solids content of the order of 10 % units. The development of metal belt pressing technology has enabled extended pressing times, also allowing more heat to be transferred to reach high temperatures. Pressing temperatures above the softening temperature of lignin up to 180–300 °C (Joelsson et al. 2020; Mattsson et al. 2021; Norgren et al. 2018) for lignin-containing, pre-dewatered webs were studied as a method to especially improve wet strength. Such high temperatures are likely not feasible for water removal, due to structural integrity considerations, in the context of short nip pulses of 5–30 ms. On the other hand, impulse drying, with high roll surface temperatures up to 450 °C, has been shown to reach solids contents of even 60–70 %. Yet, challenges with, e.g., web quality (delamination) and technical complexity have prevented the commercialisation of impulse drying (Lieshout 1999).

Some authors propose that water removal in the pressure-controlled regime is fundamentally limited by the permeability of the densified web due to the lack of sufficiently large pores for water transport (Kerekes et al. 2013). However, Zamani et al. (2024) showed that up to 90 % solids content could be reached by cyclically pressing micro- and nanofibrillated cellulose films in contact with blotting paper using 60 s cycles. The nearly complete water removal was attributed to the large capillary suction of the blotting paper that was replaced between each cycle. Therefore, it seems that in very long pulses, the driving force is the governing factor rather than permeability. Moreover, Lobosco and Kaul (2001) did not observe a significant difference in water removal from bleached softwood kraft pulp (BSKP) between a 2000 ms and a quasistatic pulse at 80 °C, both reaching a solids content of ca. 75 % during pressing. We thus find it likely that overcoming the structural resistance of the web is paramount in reaching high solids contents with extended pulses, and temperature can play an important role in softening the web to allow more compression. It should be noted that, at very low moisture ratios of 20 % and below, where non-freezing nanopore water needs to be removed to further increase solids content, pressing time could again become important, as diffusion of the water out of the cell wall could become a bottleneck (Ketoja et al. 2001; Larsson and Wågberg 2010; Paajanen et al. 2022).

In this work, we explored a less-studied operational window with a wet pressing period of 70–540 ms at temperatures approaching 100 °C for tissue and board grades. In the future, such pressing times appear industrially achievable using similar technology as in current metal-belt pressing machinery. With designed laboratory experiments, a significant increase in the sample solids content was demonstrated under the above conditions. The results were compared with pulse types that corresponded to conventional wet pressing strategies. To correct our results for any evaporation during the transfer of the sample to the analytical balance for weighing, a numerical model was used to estimate the evaporation so that the solids content immediately after the press pulse could be calculated.

2 Materials and methods

2.1 Materials

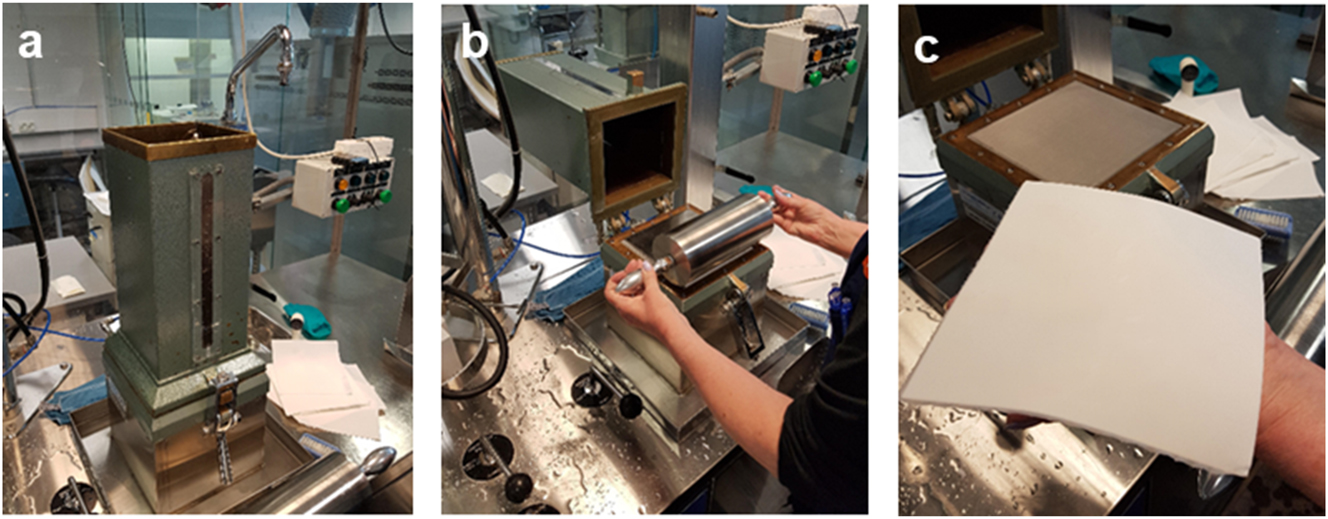

The fibre material of tissue samples (grammage 20 g/m2) was fresh BSKP pulp (mix of pine and spruce) from Metsä Fibre’s Äänekoski mill with a typical fibre length of 2.0 ± 0.1 mm and a Canadian standard freeness (CSF) of 700 ± 50 ml. The old-corrugated-container (OCC) type recycled pulp used for making linerboard samples (grammage 150 g/m2) was obtained by hot disintegrating a brown cardboard box. In both cases, wet laboratory sheets were prepared using a standard Lorentzen & Wettre forming device (Figure 1). After sheet forming, the solids content of the samples was adjusted to 20 ± 1 % by couching them against blotter papers. To prevent evaporation, and to protect wet sheets from damage prior to pressing, the sheets (tissue supported by a blotter paper) were placed between plastic plates and put inside a plastic bag in cold storage.

Preparation of the samples: a) Lorentzen & Wettre forming device used for laboratory sheet preparation. b) Adjusting the solids content to 20 % by couching. c) Final wet tissue sample.

2.2 Experimental setup and procedure

The pressing of a wet sample took place in a modified MTS device (Hii et al. 2012; Järvinen et al. 2018) between heated top and bottom metal plates. The MTS device included a pressure sensor of 100 kN and the Dasylab control software for producing the desired pressure pulse. Based on surface temperature measurements with a contact thermometer (Testo 925), the top plate reached a temperature close to the target value (100 °C for extended pulses), although it oscillated by an amplitude of ca. 5 °C due to the intermittent operation of the on/off controller. The grooved roll surface on the bottom plate was covered by a typical commercial tissue (2.0 mm thick, 1,060 g/m2) or lightboard (3.5 mm thick, 1,110 g/m2) felt (Tamfelt Ltd), and the wet circular web sample was laid on the felt prior to pressing. Although a temperature of 70 °C was applied to the grooved bottom plate, the felt would not reach more than 40–50 °C due to insufficient thermal contact between the plate and the felt. The sample diameter was either 53 or 90 mm, depending on the target peak pressure. The felt diameter was 60 mm for tissue and 140 mm for board. The solids content of the sample was checked just before the pressing operation by comparing its weight to a previously measured average dry weight of products of the same grade. The obtained values for the board samples turned out to be very close to the target, with an average and standard deviation of 20.0 ± 0.2 %. However, some of the thin tissue samples had slightly higher solids content than the target. In such a case, the solids content was lowered by spraying a suitable amount of water on the sample a couple of minutes before the test, so the moisture had sufficient time to stabilise inside the sample. The sprayed sample was subsequently dried slowly until the desired solids content of 20 % (19.6 ± 0.5 %) was achieved. The moisture content of the felt was followed in a similar fashion. During the pressing experiments, the felt was kept moist (containing 500 g/m2 of water for tissue and 800 g/m2 of water for linerboard), because this seemed to improve water removal from a sample.

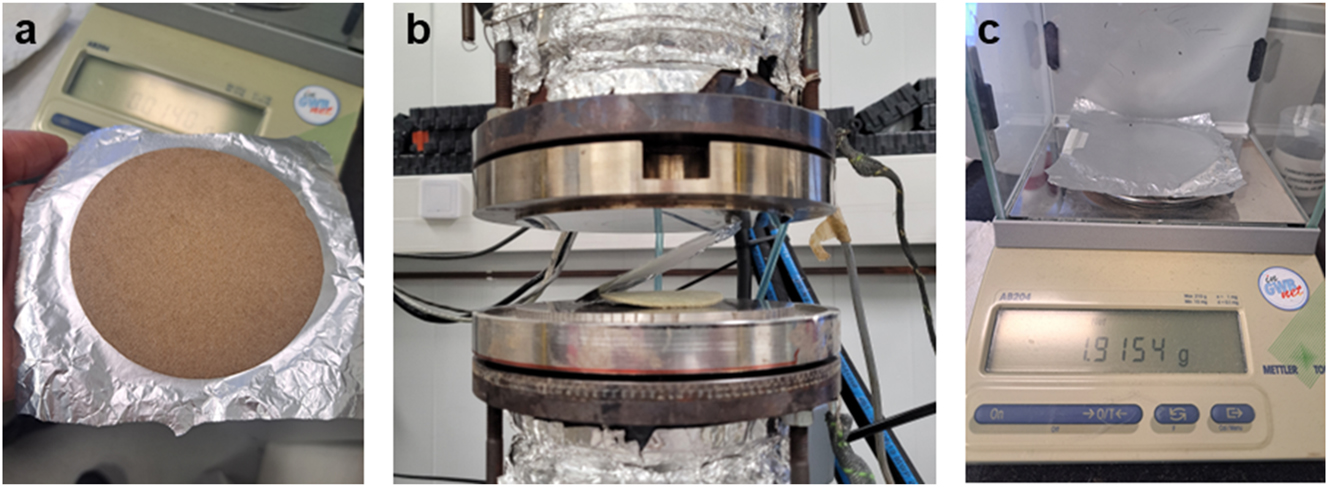

In our experiments, thin aluminium foil (thickness 10 µm) was placed on the top of the sample (Figure 2a) and attached to the top metal plate on one edge with adhesive tape (Figure 2b). The aluminium foil, which adhered to the sample during the pressing, served several purposes: It prevented the sample from adhering to the top plate and being heated by conduction after the pulse; it shielded the sample from radiative heating from the top plate by its reflectivity; and it protected one side of the sample from losing moisture by evaporation before the weighing of the sample on a balance (Figure 2c). The transfer of the pressed foil-sample system from the MTS device to an analytic balance took about 2 s, after which the final solids content (SC) was determined based on the measured weight:

where M fs is the foil-sample weight, M f is the foil mass, and M d is the dry weight of the tested sample as obtained afterwards according to the standard ISO 638-1:2021. The shoe-nip type of pressing for board was always carried out with a felt on both sides of the board sample, and in this case, the aluminium foil was not applied. The pressing experiments were carried out in a laboratory climate of 21 °C temperature and 50 % relative humidity.

Different experimental steps: a) Cutting a wet sample and shielding it from one side with aluminium foil. b) Wet pressing of the sample against a moist felt. After removing the load, the sample-foil system detaches immediately from the top hot metal surface and from the felt. c) Rapid transfer of the pressed sample to the analytical balance. During this step, the foil blocks moisture evaporation through the upper sample surface.

To observe the thermal transfer through the aluminium foil, we included a thermocouple wire (cross section size 0.25 mm × 0.5 mm) between the sample (5–10 mm inside from the edge) and the felt in tests for both the tissue and the board. This allowed us to monitor the temperature of the bottom sample surface. Moreover, a small set of comparison measurements without the aluminium foil were carried out for both tissue and board to assess the effect of the foil and to support our model analysis of moisture evaporation after pressing.

2.3 Studied pressing conditions

In the case of tissue, a 150 ms extended pulse was compared against a short 5 ms pulse mimicking a conventional roll nip. In the case of linerboard, a 540 ms extended pulse was compared against a 42 ms pulse mimicking a shoe nip with felt on both sides on a slower machine (Table 1). The different pulse lengths reflect the different running speeds of tissue and linerboard machines. For linerboard, the extended pulse was preceded by a shoe nip pulse in order to simulate a setup where preliminary dewatering is performed by a shoe nip. The comparison measurements included pressing with either one or two consecutive shoe nip pulses. The extended pulses consisted of several phases with different pressure levels, simulating different phases in a steel belt press. Initially, a low-pressure phase (80 ms for tissue, 250 ms for board) simulated the steel belt tension against the grooved pressing roll on a production machine. Based on the applied tension relative to the roll radius, this pressure was estimated to be 0.15 MPa. For tissue, the initial pulse was followed by a 70 ms main pulse. For board, the initial pulse was followed by a 220 ms intermediate phase at 1 MPa, followed by a 70 ms main pulse. The applied temperatures of the top (100 °C) and bottom (70 °C) plates were equal for the extended pulse for both sample types, but their peak pressures slightly differed (Table 1). Similarly, the peak pressure for the shoe nip (6 MPa) was higher than for the roll nip (3 MPa).

Target experimental parameters for the studied cases.

| Sample type | Tissue | Linerboard | ||

|---|---|---|---|---|

| Grammage (g/m2) | 20 | 150 | ||

| Sample diameter (mm) | 53 | 90 | ||

| Initial solids content (%) | 20 | 20 | ||

|

|

||||

| Pressure pulse type | Extended | Roll nip | Extended | Shoe nip |

|

|

||||

| Pressing temperature (°C) | ||||

| Top | 100 | 100 | 100 | 45 |

| Bottom | 70 | 70 | 70 | 45 |

| Peak pressure (MPa) | 0.15, 8a | 3 | 0.15, 1, 6b | 6 |

| Pulse length (ms) | 80, 70a | 5 | 250, 220, 70b | 42 |

-

aThe extended pulse for the tissue was preceded by 80-ms initial pressing at low 0.15 MPa pressure before the main pulse with duration of 70 ms and peak pressure of 8 MPa. bThe extended pulse for the linerboard consisted of the 250-ms initial pressing at low 0.15 MPa pressure and 220-ms intermediate 1 MPa pressure pulse before the main pulse with a duration of 70 ms and a peak pressure of 6 MPa.

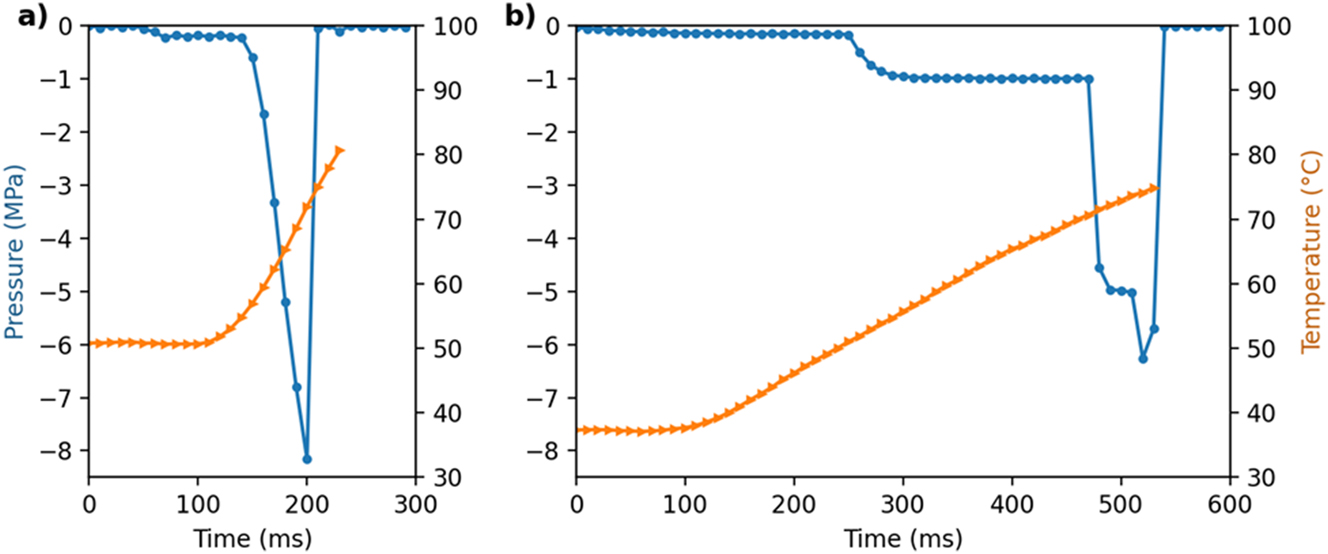

The pressing force and the position of the top plate were recorded with 0.1 ms intervals. Typical pressure curves for the different pulse types are shown in Figure 3. The number of parallel measurements for tissue was 12 for the extended pulse and 9 for the roll-nip pulse. For linerboard, the shoe + extended pulse was repeated 10 times, the shoe nip pulse 15 times and the double shoe nip 5 times.

Typical pressure (blue circles) and temperature (orange triangles) curves for the extended pulses for (a) tissue and (b) board. As the temperature sensor detached from the sample at the end of the pulse, temperature development after the pulse is not shown. The recorded maximum temperature at the end of the pulse was slightly lower than the target top pressing temperature because of the included aluminium foil in the experiments.

3 Results

3.1 Wet pressing of tissue

Pressure and temperature measurements indicated that the target levels of Table 1 for the wet pressing parameters were achieved quite well in the experiments. In general, the reproducibility of the extended pulse (Figure 3a) was good. The actual pulse lengths for tissue were 150–175 ms, the target being 150 ms. The measured nominal peak pressures were 7.9–8.4 MPa (target 8 MPa). The actual pressure on the sample could be slightly lower than the nominal value towards the end of the pulse if the sample sinks into the felt (which is slightly larger than the sample) and the felt around the sample carries some of the load. According to the temperature measurement, sample heating began already during the initial 0.15 MPa pressure pulse. Immediately after the main pulse, the measured temperature of the bottom surface of the sample was about 80 °C (Figure 3).

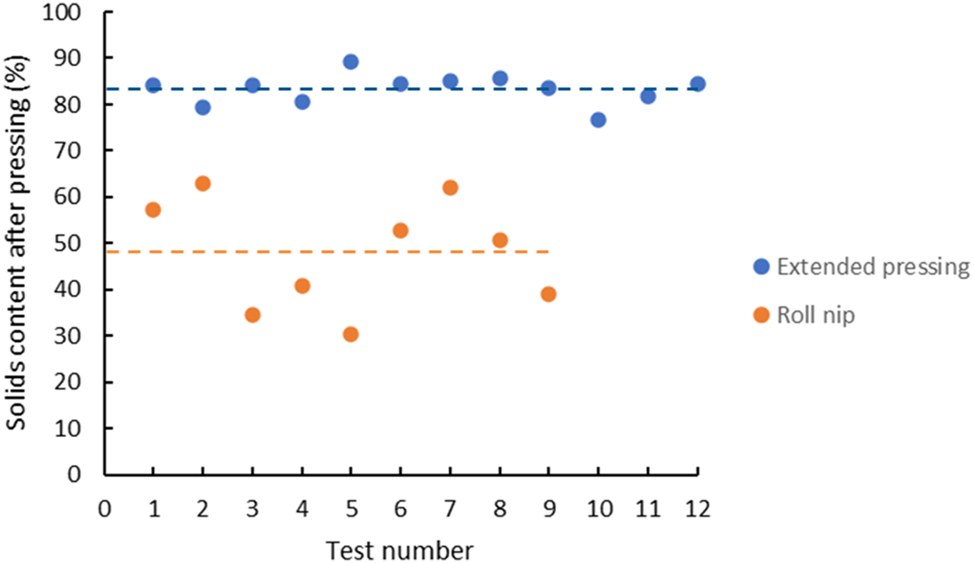

Figure 4 shows the obtained tissue solids content after wet pressing for all parallel tests. The average value was 83 ± 2 % (error estimate given as the 95 % confidence interval for the mean), with 3 % standard deviation among the individual measurements (12 replicates). This result is slightly affected by moisture evaporation through the bottom sample surface during the 2-s delay before the sample weighing. In a later section, we give a quantitative estimate of this effect based on a model analysis.

Measured tissue sample solids content after wet pressing for different tests using the extended pressure pulse (blue dots) and the short roll-nip pulse (orange dots). The dashed lines give the averages of the parallel measurements.

The results with the extended pulse were compared with the much shorter roll-nip pulse. Unfortunately, because of the limitations of the MTS device, it was challenging to sufficiently repeat the short 5-ms pulse in the experiments. This led to a large scatter of the measured solids content values, as shown in Figure 4. However, all measured values were clearly below the level found with the extended pulse, with the average level of 48 ± 8 %, even having equal plate temperatures to the extended pulse. As seen in Figure 3, heating up a tissue sample required at least 100 ms, so with the 5 ms pulse, the temperature change was very limited. Furthermore, the peak pressure of the roll-nip pulse was less than half of that for the extended pulse.

In the current typical tissue production, the roll-nip pulse is limited by the Yankee cylinder deflection (Edwards et al. 2008). When replacing the Yankee cylinder with an extended pulse at high temperature, there is a deflection compensated roll instead of the Yankee cylinder enabling a much higher load (around 1,500–3,000 kN/m) than what is possible with Yankee (max c.a. 150 kN/m).

3.2 Wet pressing of linerboard

We found the realised shoe press pulses to be longer than the target at the root of the pulse due to two soft felts, 65 ± 9 ms, whereas the peak pressure 5.85 ± 0.04 MPa was close to the target (Table 1). The extended pressure pulses were on the mark with a duration of 570 ± 12 ms and a peak pressure of 5.97 ± 0.02 MPa. The main pulse had a stepwise shape as shown in Figure 3b simulating the increasing pressure levels that can be arranged in an extended pressing nip on a production scale. In addition, the applied temperature during the extended pressing was roughly double of the shoe-nip temperature as indicated in Table 1.

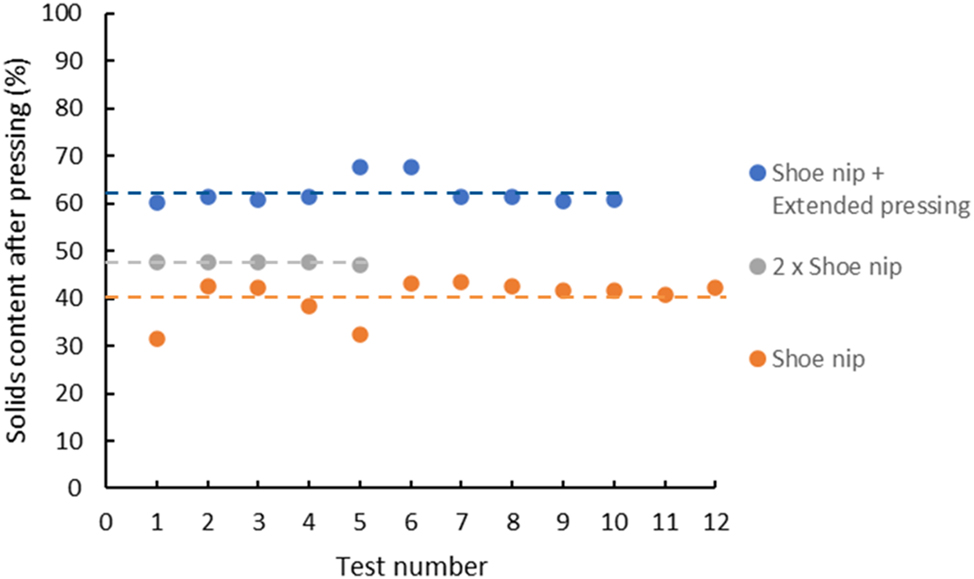

The measured average solids content, achieved with the combination of shoe-nip and extended pulses, was 62 ± 2 % (95 % confidence), with 3 % standard deviation of 10 parallel measurements (Figure 5). This exceeded the solids content obtained with single (40 ± 2 %) or double shoe nips (47.6 ± 0.3) by as much as 14–22 % points.

Measured linerboard sample solids content after wet pressing for different tests using the extended pressure pulse (blue dots), the single shoe-nip pulse (orange dots) and the double shoe-nip pulse (grey dots). The dashed lines give the averages of the parallel measurements.

3.3 Model estimate on the amount of evaporation during the sample transfer

Due to the elevated initial temperature of the sample during the transfer to the analytical balance (taking about 2 s), evaporation from the side not covered by the aluminium foil caused a meaningful increase in the solids content at least in the case of the tissue sample. As the amount of evaporation was not experimentally measurable, we estimated it with the following model, calibrated with an evaporation test in moving air at room temperature.

In the model, we considered vapour transfer through the air boundary layer on the side of the sample not covered by aluminium foil. The mass transfer flux Jv through the boundary layer is governed by the concentrations of the vapour on either side of the layer and a mass transfer coefficient γ:

Here MH2O is the molar mass of water, R is the molar gas constant, Tweb and Text are the temperatures of the web and the surrounding air, respectively. Pv,web=ϕweb(M,Tweb)Ps(Tweb) is the partial pressure of vapour in the web pores given by the desorption, where ϕweb is the relative humidity of the web pores given by the desorption isotherm (in practice, ϕweb is close to unity), and Ps(T) is the saturation vapour pressure. The moisture ratio of the web is denoted by M. The external vapour pressure is given by Pv,ext=ϕextPs(Text), where ϕext is the external relative humidity. As Ps increases sharply with increasing temperature, the flux is very sensitive to the temperature difference across the boundary layer. Therefore, the evaporation is initially fast until the web cools down. Heat is lost from the web by both direct heat convection across the boundary layer as well as by the heat carried by the escaping vapour. The fraction of heat carried away by vapour strongly affects the mass loss before reaching the ambient temperature. For air, the ratio between γ and the heat transfer coefficient κ is given by the Lewis relation (Çengel and Ghajar 2015)

where ρacp is the volumetric heat capacity of the moist air. The heat flux across the boundary is given by

where hv(T) is the enthalpy of the vapour leaving the web. The factor of two accounts for the two sides available for heat convection. Finally, we need to write down the heat equation for the web and aluminium foil:

where

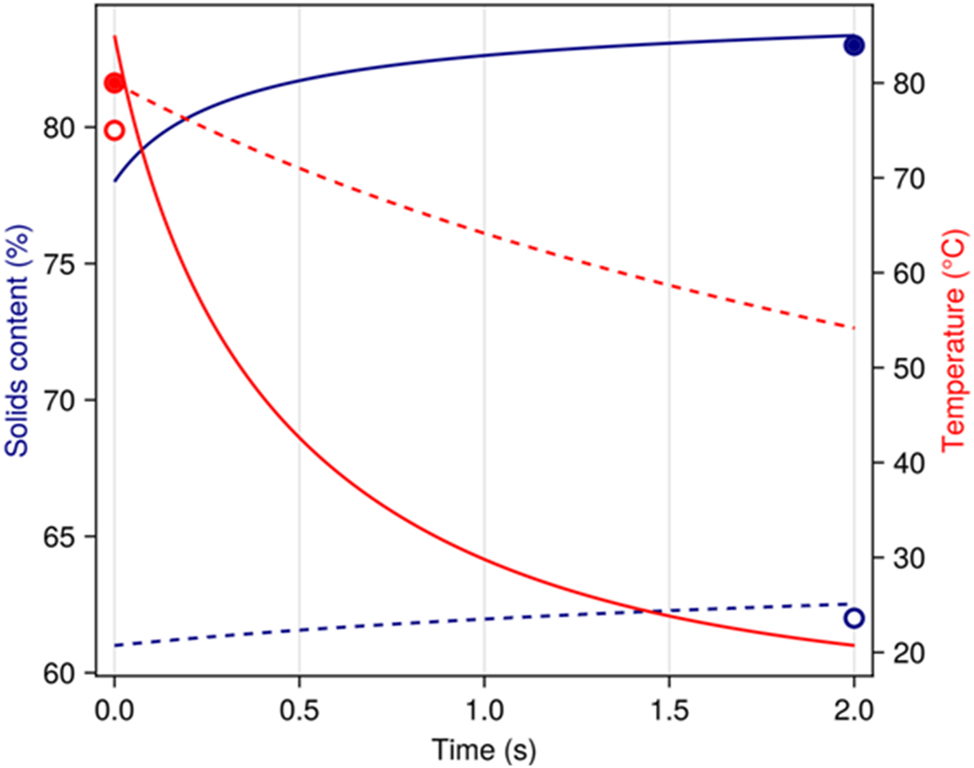

The simulated solids content (blue curves) and the temperature (red curves) of tissue (solid lines) and linerboard (dashed lines) during the transfer of the sample from the press to the analytical balance, considering moisture loss due to evaporation. The temperature of the thermocouple at the end of the pulse is shown by red dots. The measured solids content after the transfer to the balance (taking 2 s) is shown by blue dots. Filled dots stand for tissue, open dots for board.

To fix the heat transfer coefficient using Equation (3), we exposed a sample to moving air by manually waving it in the air (after pressing, with aluminium foil) and recorded the mass loss as a function of time. Fitting to the data yielded γ ≈ 0.015 kg s−1 m−2, corresponding to κ ≈ 20 W K−1 m−2 based on Equation (3). The same κ was used on either side.

The parameters for the drying simulations are shown in Table 2. The initial moisture contents were fitted to approximately yield the measured average solids content of 83 % and 62 % (tissue and board, Figures 4 and 5) at the end of the 2 s simulation. Initial sample temperatures were conservatively assumed to be slightly higher than the measured values after the pulse (Figure 3), as the temperature sensor was under the sample and thus possibly slightly cooler than the average sample temperature. Our results indicate a 5-percentage-point increase in the solids content in the tissue and a 1.5-percentage-point increase in the linerboard (Figure 6). These values can be subtracted from the measured values to obtain the estimated solids content immediately after the pulse.

Parameters for the drying simulation.

| Quantity | Value |

|---|---|

| T(0) | 273.15 + 85 K (tissue), 273.15 + 80 K (board) |

| M(0) | 1/(1 + 0.78) – 1 (tissue), 1/(1 + 0.61) – 1 (board) |

|

|

0.92 × 20 g m−2 (tissue), 0.92 × 150 g m−2 (board) |

|

|

10 µm × 2,700 kg m−3 |

| κ | 20 W K−1 m−2 |

| c p,f | (6.714T/K – 604.53) J m−3 K−1 |

| c p,w | 4185 J m−3 K−1 |

| c p,al | 900 J m−3 K−1 |

| hv(T) | (2,060,500 + 1,379.8T/K + 0.084808T2/K2) J m−3 |

| Ps(T) | exp(25.5058–5,204.9 K/T) Pa |

| T ext | 273.15 + 21 K |

| ϕ ext | 0.5 |

4 Discussion

Our laboratory experiments showed a large increase in the solids content of wet tissue and linerboard samples when an extended pressing pulse was applied to them at an elevated temperature. Our model analysis suggests that the measured solids contents after the extended pulses (83 ± 2 % and 62 ± 2 % for tissue and linerboard, respectively) are slightly inflated by evaporation during the transfer of the hot sample to the balance. However, after adjusting for the evaporation (5 % pt. and 1.5 % pt. for tissue and linerboard, respectively) the obtained solids contents are still remarkably high, 78 ± 2 % for tissue and 60 ± 2 % for board. For the linerboard, the solids content of the sample entering the extended pulse was first reduced by applying a preliminary shoe-press pulse (there are usually 2–4 such presses on a board machine). It would be sufficient to add only one extended pulse in the machine as the last press besides conventional shoe-press unit(s) to achieve the above 60 % web solids. When only applying two subsequent shoe-press pulses without the extended one, the solids content of the board stayed below 50 %. Similarly, the average solids content of the tissue remained at 40–45 % with a pulse closely resembling a roll-nip pulse in an industrial setting.

Especially with tissue, the obtained solids content was very high, implying that, in addition to removing free water from the interfibrillar pores, most of the bound water from within the fibres was also removed. Some of the bound water in cellulose fibres has been shown to be “non-freezing” and bound to microfibril surfaces and hemicelluloses. The amount of this particularly strongly bound water has been found to be 0.21 g/g for bleached hardwood pulp (Paajanen et al. 2019). This corresponds to a solids content of 83 %, i.e., slightly above the level obtained for tissue in the extended wet pressing operation. Below the moisture ratio of 0.2 g/g, the activity of bound water falls sharply (Tryding et al. 2023), and its mobility reduces (Paajanen et al. 2022), suggesting that both driving force and pulse length could limit further water removal. However, applying more heat could still allow further improvements in the solids content.

The above results give a basis for estimating (Pihko 2015) the energy-saving potential in tissue production. Typical solids content of tissue after a roll nip is 40–45 % (Raffaelli 2017; Toscotec 2011). Assuming a 42 % solids content after the press and a 5 % moisture content in the final product, a modern 13.2 tonne/h machine needs to evaporate a high amount, 16.7 tonne/h of water. Assuming the heat of the vaporisation of water to be 0.65 MWh/tonne, the required power for evaporation would be 11 MW without considering losses. In practice, with the existing tissue Yankee and hood technology losses are high due to the need for a high temperature inside the hood, typically doubling the demand to 22 MW. This gives 1725 kWh per tonne of production, which agrees well with the typical range with a Yankee cylinder and a hood of 1,250–1900 kWh/tonne with a 40–45 % solids content after the press (Raffaelli 2017; Toscotec 2011). In the extended pressing, the amount of water to be evaporated is much lower, merely 2.9 tonne/h. Assuming similar losses, this would reduce the drying power to 3.8 MW, i.e. a 83 % decrease. Moreover, the losses would likely be reduced, as a large Yankee cylinder and high hood drying temperature would no longer be required because of the very low amount of water that needs to be evaporated. As in indication, we can consider paper drying where the total consumption is commonly calculated with a multiplier of 1.1–1.3. Assuming the value 1.2, we obtain a drying power of 2.3 MW, suggesting a remarkable reduction of 90 % in drying power consumption and a subsequent significant reduction in CO2 emissions.

In the above estimates, we did not consider a possible increase in the energy spent in heating up the water in the heated press. Heating all of the water in the web entering the press would indeed offset some of the energy savings, as the water content of a web at the initial solids content of 20 % is high. However, as shown by Figure 3, the onset of the temperature rise is after the first half of the press pulse. Because of the initially high permeability of the web, the majority of the water has already been removed at that point, and the solids content at the onset of the temperature rise is likely between 40 % and 50 %. Therefore, we do not think there is additional energy spent on heating the water compared to conventional processes.

Because the extended pressing at an elevated temperature and pressure not only increases solids content but also densifies the web, this pressing strategy is most suitable for product grades where high bulk or bending stiffness are not the primary goals. In the case of a tissue product, sufficient surface area and pore volume for the required absorption functionality can be obtained by applying a creping operation combined with structural layering in post-processing, and the extended pressing should therefore be applicable.

5 Conclusions

We demonstrated a large improvement in the solids content of tissue and linerboard grades after applying an extended press pulse at a high temperature compared to a simulated conventional roll-nip or shoe-nip pulse. The achieved solids content was particularly high for tissue. Model analysis was used to correct the obtained solids content values for evaporation before weighing. The observations open new intriguing directions for technological development in wet pressing (Pihko et al. 2021), potentially allowing significant leaps in the energy efficiency of papermaking. In future, such developments should consider also possible changes in product properties, which were not studied in this work. While the existing industrial wet pressing equipment for continuous web production are not capable of creating such extended pulses at a high temperature, recent developments in metal belt pilot lines suggest that suitable machinery could become available in the future.

Acknowledgments

We would like to thank Heikki Talja for the sheet preparation and Santeri Mäntynen and Meiju Sinkkonen for the experimental help. Moreover, Christian Orassaari is acknowledged for the operation of the MTS pressing equipment at Aalto University.

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: The authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: One of the authors (R.P.) has been involved with an issued patent related to the work: Pihko et al. 2021. Method and apparatus for producing a fibre web. (Patent No. US10954632).

-

Research funding: The research leading to these results was funded by VTT.

-

Data availability: The raw data can be obtained on reasonable request from the corresponding author.

References

Çengel, Y.A. and Ghajar, A.J. (2015). Heat and mass transfer: fundamentals & applications, 5th ed. McGraw-Hill Education, New York, NY.Search in Google Scholar

Chandoul, B., Halleb, M., Bounouh, Z., and Zouari, I. (2011). Importance of the press on the energy performance of paper machine. Int. Rev. of Chem. Eng. 3: 325–330.Search in Google Scholar

Edwards, S., Marinack, R., McDowell, J., and Worry, G. (2008). Method for maximizing water removal in a press nip, (Patent No. US20080035289A1). Online. https://patents.google.com/patent/US20080035289A1/en (Accessed 01 April 2025).Search in Google Scholar

Hii, C., Gregersen, Ø.W., Chinga-Carrasco, G., and Eriksen, Ø. (2012). The effect of newsprint furnish composition and sheet structure on wet pressing efficiency. Nordic. Pulp. Paper. Res. J. 27: 790–797, https://doi.org/10.3183/npprj-2012-27-04-p790-797.Search in Google Scholar

Hubbe, M.A., Sjöstrand, B., Nilsson, L., Koponen, A., and McDonald, J.D. (2020). Rate-limiting mechanisms of water removal during the formation, vacuum dewatering, and wet-pressing of paper webs: a review. BioRes 15: 9672–9755, https://doi.org/10.15376/biores.15.4.hubbe.Search in Google Scholar

Järvinen, M., Pihko, R., and Ketoja, J.A. (2018). Density development in foam forming: wet pressing dynamics. Nord. Pulp Pap. Res. J. 33: 226–236, https://doi.org/10.1515/npprj-2018-3031.Search in Google Scholar

Joelsson, T., Pettersson, G., Norgren, S., Svedberg, A., Höglund, H., and Engstrand, P. (2020). High strength paper from high yield pulps by means of hot-pressing. Nord. Pulp Pap. Res. J. 35: 195–204, https://doi.org/10.1515/npprj-2019-0087.Search in Google Scholar

Kawamizu, T., Kaneko, T., Suzuki, S., and Tsuruta, T. (2009). Study on condensation heat transfer characteristics of wet paper in steam heating process. Int. J. Heat and Mass Tran. 52: 805–813, https://doi.org/10.1016/j.ijheatmasstransfer.2008.07.031.Search in Google Scholar

Kerekes, R., McDonald, E., and McDonald, D. (2013). Decreasing permeability model of wet pressing: extension to equilibrium conditions. J-FOR 3: 46–51.Search in Google Scholar

Ketoja, J.A., Kananen, J., Niskanen, K.J., and Tattari, H. (2001). Sorption and web expansion mechanisms. In: Baker, C.F., (Ed.). The science of papermaking. Trans. of the XIIth Fund. Res. Symp. Oxford. FRC, Manchester, 2018, pp. 1357–1370.Search in Google Scholar

Larsson, P.A. and Wågberg, L. (2010). Diffusion-induced dimensional changes in papers and fibrillar films: influence of hydrophobicity and fibre-wall cross-linking. Cellulose 17: 891–901, https://doi.org/10.1007/s10570-010-9433-7.Search in Google Scholar

Lieshout, M. (1999). Impulse drying: the state-of-the technology. Pap. Technol. 40: 35–40.Search in Google Scholar

Lobosco, V. and Kaul, V. (2001). An elastic/viscoplastic model of the fibre network stress in wet pressing: Part 2 Accounting for pulp properties and web temperature. Nord. Pulp Pap. Res. J. 16: 313–318, https://doi.org/10.3183/npprj-2001-16-04-p313-318.Search in Google Scholar

Mattsson, A., Joelsson, T., Miettinen, A., Ketoja, J.A., Pettersson, G., and Engstrand, P. (2021). Lignin inter-diffusion underlying improved mechanical performance of hot-pressed paper webs. Polymers 13: 2485, https://doi.org/10.3390/polym13152485.Search in Google Scholar PubMed PubMed Central

McDonald, J.D. (2022). Pressing matters - improving pressing operations and its impact on carbon emissions. Pulp & Pap. Canada 123: 20–22.Search in Google Scholar

McDonald, J.D. and Kerekes, R. (2017). Estimating limits of wet pressing on paper machines. TAPPI J 16: 81–87, https://doi.org/10.32964/TJ16.2.81.Search in Google Scholar

McDonald, J.D., McDonald, E.M., and Kerekes, R.J. (2014). The impact of felt design on paper machine press dewatering. J-FOR 3: 53–57.Search in Google Scholar

McDonald, J.D., Kerekes, R.J., and Zhao, J.R. (2019). Wet pressing models to reduce energy consumption in papermaking. Pap. Biomater. 4: 1–6, https://doi.org/10.26599/PBM.2019.9260001.Search in Google Scholar

Norgren, S., Pettersson, G., and Höglund, H.H. (2018). Strong paper from spruce CTMP–Part II: effect of pressing at nip press temperatures above the lignin softening temperature. Nord. Pulp Pap. Res. J. 33: 142–149.10.1515/npprj-2018-3009Search in Google Scholar

Paajanen, A., Ceccherini, S., Maloney, T., and Ketoja, J.A. (2019). Chirality and bound water in the hierarchical cellulose structure. Cellulose 26: 5877–5892, https://doi.org/10.1007/s10570-019-02525-7.Search in Google Scholar

Paajanen, A., Penttilä, P., Zitting, A., and Ketoja, J.A. (2022). New tools to study water interactions of microfibril bundles: molecular modelling based on nanoscale characterization. In: Advances in Pulp and paper research, trans. Of the XVIIth fund. Res. Symp. Cambridge Coffin, D. and Batchelor, W., eds), pp. 483–494. FRC, Manchester, 2022.10.15376/frc.2022.1.483Search in Google Scholar

Paulapuro, H. (2001). Wet pressing – present understanding and future challenges. In: C.F. Baker, (Ed.), The science of papermaking, trans. Of the XIIth fund. Res. Symp. Oxford, 2001, FRC, Manchester, 2018, pp. 639–678.10.15376/frc.2001.1.639Search in Google Scholar

Paulapuro, H. (2007). Papermaking science and technology, book 8, Stock preparation and wet end, Finnish Paper Engineers’ Association. Jyväskylä, Finland, 2007.Search in Google Scholar

Pihko, R. (2015). A novel profit potential calculation method applied to web manufacturing, Doctoral dissertation. Aalto University, pp. 96. http://urn.fi/URN:ISBN:978-952-60-6404-8.Search in Google Scholar

Pihko, R., Lehmonen, J., and Rökman, K. (2021). Method and apparatus for producing a fibre web. Patent US10954632B2.Search in Google Scholar

Raffaelli, P. (2017). Tissue drying strategies – factors to consider to achieve Yankee/hood balance for the highest energy efficiency, Bloc in TissueStory, Online. https://www.tissuestory.com/2017/09/19/tissue-drying-strategies-factors-to-consider-to-achieve-yankeehood-balance-for-the-highest-energy-efficiency/ (Accessed 25 March 2025).Search in Google Scholar

Reczulski, M., Szewczyk, W., and Kuczkowski, M. (2023). Possibilities of reducing the heat energy consumption in a tissue paper machine–case study. Energies 16: 3738, https://doi.org/10.3390/en16093738.Search in Google Scholar

Toscotec (2011). Reduction of thermal energy consumption, Online. https://www.toscotec.com/en/news-article/reduction-of-thermal-energy-consumption/ (Accessed 25 March 2025).Search in Google Scholar

Tryding, J., Askfelt, H., Alexandersson, M., and Ristinmaa, M. (2023). A full-range moisture sorption model for cellulose-based materials yielding consistent net isosteric heat of sorption. Dry. Technol. 41: 61–76, https://doi.org/10.1080/07373937.2022.2084104.Search in Google Scholar

Valmet (2025). Ready to play your winning hand in tissue drying? Online. https://www.valmet.com/insights/articles/tissue/ready-to-play-your-winning-hand-in-tissue-drying/ (Accessed 5 June 2025).Search in Google Scholar

Zamani, E.S., Ahadian, H., and Maloney, T. (2024). Cyclic pressing as a viable approach for dewatering and controlling shrinkage of micro-nanofabricated cellulose films. BioResources 19: 5483–5496, https://doi.org/10.15376/biores.19.3.5483-5496.Search in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Alkali-extracted spruce bark residues for pulping and making of pulp sheets

- Applications of cationic bamboo fibers for the effective reinforcements of secondary fibers

- Paper Technology

- Improving hydrophobicity and mechanical strength of rice straw paper using chitosan nanoparticles and beeswax coatings

- Extended wet pressing at elevated temperature enables enhanced dewatering for tissue and linerboard

- Tissue paper from cabbage leaf – waste paper mixtures

- Inhibition of hornification in simao pine fibers and recycled paper with different beating degrees by microwave expansion treatment

- Preparation of mycelium paper sheets and study on their adsorption properties

- Paper Physics

- Influence of the hybrid effect on the mechanical properties of pulp molds

- Paper Chemistry

- Response surface methodology optimization and anti-age properties in paper protection of carboxymethyl cellulose grafted with β –cyclodextrin

- Printing

- Green innovations in natural paper ink: trends, applications, and future prospects

- Packaging

- Advanced moisture strategy for expanded formability in paper-based packaging

- Production of packaging paper from Populus deltoides NSSC pulp reinforced with rice straw cellulose nanofibrils

- Environmental Impact

- Treatment of regenerated papermaking wastewater by sequencing batch moving bed biofilm reactor and kinetics study

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Alkali-extracted spruce bark residues for pulping and making of pulp sheets

- Applications of cationic bamboo fibers for the effective reinforcements of secondary fibers

- Paper Technology

- Improving hydrophobicity and mechanical strength of rice straw paper using chitosan nanoparticles and beeswax coatings

- Extended wet pressing at elevated temperature enables enhanced dewatering for tissue and linerboard

- Tissue paper from cabbage leaf – waste paper mixtures

- Inhibition of hornification in simao pine fibers and recycled paper with different beating degrees by microwave expansion treatment

- Preparation of mycelium paper sheets and study on their adsorption properties

- Paper Physics

- Influence of the hybrid effect on the mechanical properties of pulp molds

- Paper Chemistry

- Response surface methodology optimization and anti-age properties in paper protection of carboxymethyl cellulose grafted with β –cyclodextrin

- Printing

- Green innovations in natural paper ink: trends, applications, and future prospects

- Packaging

- Advanced moisture strategy for expanded formability in paper-based packaging

- Production of packaging paper from Populus deltoides NSSC pulp reinforced with rice straw cellulose nanofibrils

- Environmental Impact

- Treatment of regenerated papermaking wastewater by sequencing batch moving bed biofilm reactor and kinetics study