Corrigendum to: Preparation and synthesis of water-soluble chitosan derivative incorporated in ultrasonic-assistant wheat straw paper for antibacterial food-packaging

Corrigendum to: Dang, C., Yin, Y. and Pu, J. (2017). Preparation and synthesis of water-soluble chitosan derivative incorporated in ultrasonic-assistant wheat straw paper for antibacterial food-packaging. Nordic Pulp & Paper Research Journal 32: 606–614. https://doi.org/10.3183/npprj-2017-32-04_p606-614_pu.

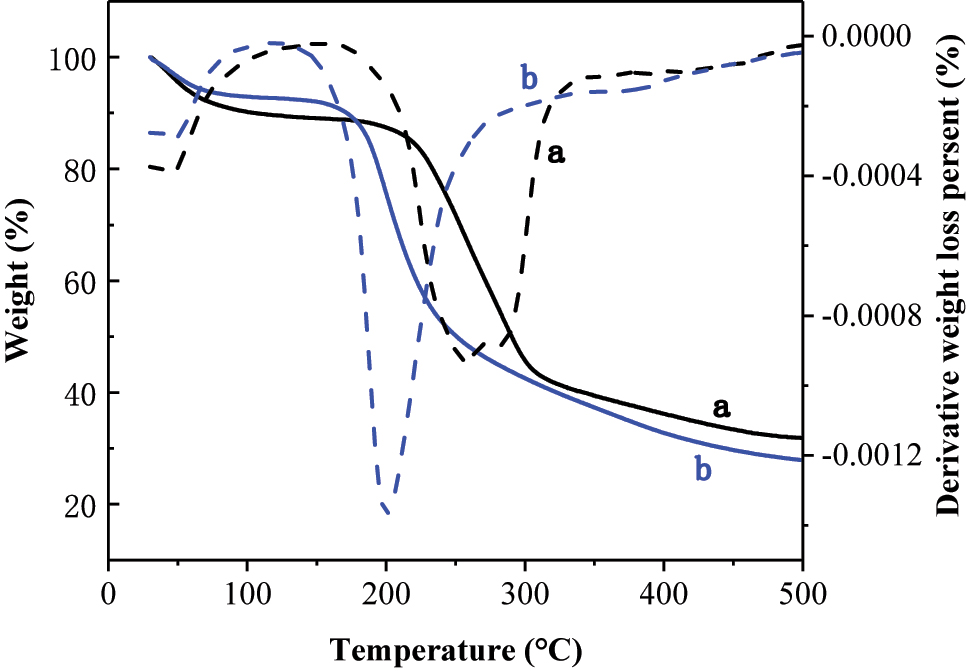

It has come to the authors’ attention that the TGA curves of the chitosan (a) and HTACC (b) in Figure 6 were misassigned and are now corrected. This error did not affect the analysis or interpretation of the results in any way. The authors sincerely apologize to the readers for this error.

TGA and DTG curves of chitosan (a) and HTACC (b).

Corrected discussion reg. original article p. 611 (the corrected parts are highlighted in bold)

Both chitosan and HTACC could be divided into two weight loss stages. Stage I (50 °C to about 177°C) was a dehydration process, the mass loss was associated with the water evaporation. In stage II (177°C to about 330 °C) the most mass was lost, mainly caused by the thermal degradation of the chitosan and the HTACC, including dehydration of the saccharide rings, depolymerization, and decomposition of the side chain (Feng and Xia 2011). In this stage, the HTACC lost mass faster than the chitosan, indicating that the HTACC’s thermal stability was reduced. Meanwhile, DTG curves show maximum rate of the chitosan’s weight loss (approximately 265°C) was higher than the HTACC’s (approximately 202 °C).

© 2025 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Bleaching

- A new strategy for biological enzyme bleaching: combined effects of laccase, xylanase, and mannanase in the bleaching of softwood kraft pulp – a synergistic effect of enzymes

- Mechanical Pulping

- Characterization of the low consistency pulp refining conducted by the plates with different bar-groove width ratios

- Paper Technology

- On the influence of macro-scale stress variations on the dynamic dewatering of water-saturated polymer fibre networks

- Effects of dispersion hydrophobized MgO nanoparticles in low polarity solvent on aged paper

- Preparation and properties of effective low-cost composite filler for bible paper

- Paper Physics

- Normal and shear delamination of paperboards

- Micro-CT analysis of creased and folded multilayer cardboard

- Paper Chemistry

- Preparation of MgO/CaCO3 nanocomposites and their deacidification properties for paper documents

- Effects of sequential plasma modification and alkali treatment applied to cellulose fibers on the properties of the paper

- Coating

- Production of nano silver and nano silica coated paper to be used in active packaging

- Insights into bibliometric review for natural coatings for paper-based food packaging: trends, perspectives, and future directions

- RSM optimization of spray-coating parameters to enhance paper strength using cellulose nanocrystals extracted from young coconut husks

- Chemical Technology/Modifications

- NSSC pulp treatment with the Fenton reaction: fiber modification for reduced energy consumption in papermaking

- Other

- Fenton degradation of biologically pre-treated pulp and paper effluent using zero-valent iron from commercial steel wool

- Corrigendum

- Corrigendum to: Preparation and synthesis of water-soluble chitosan derivative incorporated in ultrasonic-assistant wheat straw paper for antibacterial food-packaging

Articles in the same Issue

- Frontmatter

- Bleaching

- A new strategy for biological enzyme bleaching: combined effects of laccase, xylanase, and mannanase in the bleaching of softwood kraft pulp – a synergistic effect of enzymes

- Mechanical Pulping

- Characterization of the low consistency pulp refining conducted by the plates with different bar-groove width ratios

- Paper Technology

- On the influence of macro-scale stress variations on the dynamic dewatering of water-saturated polymer fibre networks

- Effects of dispersion hydrophobized MgO nanoparticles in low polarity solvent on aged paper

- Preparation and properties of effective low-cost composite filler for bible paper

- Paper Physics

- Normal and shear delamination of paperboards

- Micro-CT analysis of creased and folded multilayer cardboard

- Paper Chemistry

- Preparation of MgO/CaCO3 nanocomposites and their deacidification properties for paper documents

- Effects of sequential plasma modification and alkali treatment applied to cellulose fibers on the properties of the paper

- Coating

- Production of nano silver and nano silica coated paper to be used in active packaging

- Insights into bibliometric review for natural coatings for paper-based food packaging: trends, perspectives, and future directions

- RSM optimization of spray-coating parameters to enhance paper strength using cellulose nanocrystals extracted from young coconut husks

- Chemical Technology/Modifications

- NSSC pulp treatment with the Fenton reaction: fiber modification for reduced energy consumption in papermaking

- Other

- Fenton degradation of biologically pre-treated pulp and paper effluent using zero-valent iron from commercial steel wool

- Corrigendum

- Corrigendum to: Preparation and synthesis of water-soluble chitosan derivative incorporated in ultrasonic-assistant wheat straw paper for antibacterial food-packaging