Abstract

Spruce bark residues obtained after alkaline extraction of polyphenols were studied as raw material for pulping and making of pulp sheets. Kraft pulping of mixtures containing wood chips and 5 % or 20 % wt. bark residues produced unbleached pulps with higher screened yields and lower kappa number than wood pulps. During bleaching, the evolution of brightness along with kappa reduction followed a similar trend in all pulps, and bleached mixed pulps with ISO brightness >89 % could be obtained with somewhat lower intrinsic viscosity than wood pulps. The high content of calcium and other metal elements in spruce bark, which was partially reduced by the alkaline extraction, did not seem to impair the pulping and bleaching of the pulps. Sheets made from mixed pulps had rather similar optical and mechanical properties than sheets from wood pulps, and interestingly, sheets produced from mixed pulps with 20 % bark residues showed higher bulk as a function of internal bond strength, which may be exploited in packaging boards. Pulping of bark residues to produce mixed pulps would thus maximize the utilization of spruce bark streams after extracting the polyphenols, while increasing the pulp output in the mills.

1 Introduction

Forest industries in the European Union annually consume 350–400 million m3 of tree logs to manufacture a variety of wood and wood-based products (“FAOSTAT” 2023). The debarking of logs in the mills generates more than 20 million tons of bark that are mainly incinerated to produce energy or sold at low prices for gardening and landscaping purposes (Thorenz et al. 2018). In some cases, the bark is even considered a residue and is burned without energy recovery or landfilled. The low value of bark, coupled with its abundance, has fostered the search for higher-value applications that will support the utilization of natural raw materials in the transition to a circular bioeconomy (Supriyadi et al. 2025). Most of the research on bark revolves around its unique chemical composition because bark contains chemical components that cannot be typically found in wood. For example, the outer bark of birch trees contains large amounts of betulin and suberin that can be extracted with organic solvents (Kwan et al. 2022). Betulin is a triterpenoid mainly used in cosmetic and health applications (Krasutsky 2006) while suberin is a biopolyester with hydrophobic properties that may be used in barrier coatings (Hu et al. 2024; Wang et al. 2024). On the other hand, the bark of softwoods like pine or spruce contains condensed tannins that can be extracted with hot water or aqueous alkali (Bianchi et al. 2015; Borrega et al. 2022; Kemppainen et al. 2014). Condensed tannins find use in a wide range of applications such as leather tanning, flocculants for water purification, or wood adhesives (Pizzi 2019).

Despite the unique chemical composition of bark, its lignocellulosic nature has also been considered for pulp production (Harder et al. 1978). The use of bark in pulping is a rather logical and direct approach because pulp mills generate most of the industrial bark available. Miranda et al. (2012) studied the incorporation of eucalyptus bark in kraft pulping of wood and found that, in levels similar or below the bark content in the tree trunk (<15 %), the addition of bark did not have detrimental effects on the yield and pulp properties compared to eucalyptus wood pulp. Tripathi et al. (2020), however, reported that addition of increasing levels of bark from mixed hardwoods negatively affected the pulp yield and quality as well as the mechanical properties of paper sheets made from those pulps. The main problem commonly associated with the use of bark in pulping and papermaking is the high content of non-process elements in bark, i.e., extractives and inorganics, but these may be partially removed by applying a water or acid leaching treatment (Singhal et al. 2023). Water extraction of eucalyptus bark before pulping has been shown to reduce the extractives and ash content and improve delignification compared to untreated bark (Neiva et al. 2016).

Recently, we investigated the alkaline extraction of spruce bark and found that about 25 % of its dry mass could be extracted as polyphenols, mainly tannins and some lignin (Borrega et al. 2022). This yield is much higher than the 10 % yield or lower typically reported in the literature for water extraction processes (Bianchi et al. 2015; Kemppainen et al. 2014). Alkaline extraction is not only effective in the removal of polyphenols but also extracts considerable amounts of other non-cellulosic bark components. The remaining cellulose-rich bark residue can be used in enzymatic sugar production (Borrega et al. 2022) and may also be a suitable raw material for pulp production.

The aim of this work was to investigate the potential of alkali-extracted spruce bark in pulping and making of pulp sheets to maximize the utilization of bark after extraction of polyphenols. For this purpose, spruce bark residues were subjected to pulping and bleaching processes either alone or mixed with spruce wood chips, and the properties of bark and mixed pulps were evaluated and compared to those of wood pulp. The removal of inorganic elements from bark during alkaline extraction and the application of an acid leaching treatment to further reduce the inorganic content in the bark residues was also studied. Finally, the bleached pulps were refined, and the physical and mechanical properties of paper sheets made from bark, wood, or mixed pulps were compared.

2 Materials and methods

2.1 Spruce bark residues and other materials

Spruce (Picea abies) bark residues were obtained from our previous study as reported in Borrega et al. (2022). Briefly, fresh spruce bark provided by Holmen (Sweden) was screened to remove wood particles that were mixed with the bark. The screened bark, still containing about 10 % wt. of wood, was added to 15 L rotating reactors together with an aqueous solution of NaOH, reaching a liquid to bark ratio of 5:1 L/kg. Alkaline extractions were performed at 100 °C and 15 % wt. NaOH (on dry bark) and at 160 °C and 24 % wt. NaOH (on dry bark), and after 90 min of extraction time, the liquid extract was separated by filtration. The bark residues were then thoroughly washed with water and mechanically disintegrated with a disk refiner prior to pulping. Industrial spruce wood chips (particle size 7–13 mm) and bleached softwood kraft pulp were also used as reference materials in pulping and making of pulp sheets.

2.2 Kraft pulping and bleaching experiments

Kraft pulping was performed in 15 L rotating reactors with spruce wood chips, bark residues from alkaline extraction, and mixtures containing wood chips and 5 % or 20 % wt. bark residues. Kraft pulping was performed at 165 °C with 20 % effective alkali (EA) and 40 % sulphidity. The liquid to solid ratio was 4:1 L:kg except in the experiments with bark extracted at 100 °C, in which the liquid to solid ratio was 5:1 L:kg. The pulping time was 115 min and the resulting H-factor was 1200. The H-factor is a parameter used in wood pulping that combines the effect of temperature and time into a single variable (Vroom 1957). After pulping, the black liquor was removed by filtration and the pulp was washed. The pulp was then disintegrated for 15 min at about 1 % consistency, further diluted with water, and screened through two flat screens in series, with 1.0 mm and 0.3 mm slots. The accepted pulp fibers were centrifuged for 0.5 min and homogenized for 3 min, while the rejected pulp fibers (reject) were collected from the screens and dried in an oven. The yield, kappa number (ISO 302:2015), and ISO brightness (ISO 2470-1:2016) of the screened pulps were determined. Residual alkalinity (SCAN-N 33:94) in the black liquors was also measured.

Pulp bleaching was conducted with an O-D0-Ep-D1-P sequence and the following conditions: O stage: 98 °C, 90 min, 8 bars O2, 2.2–4.5 % NaOH, 0.5 % MgSO4·7H2O, pulp consistency 12 %; D0 stage: 70 °C, 30–60 min, kappa factor 0.2, pulp consistency 9 %; Ep stage: 85 °C, 90 min, 0.9–1.5 % NaOH, 0.3 % H2O2, 0.1 % MgSO4·7H2O, pulp consistency 10 %; D1 stage: 70 °C, 120 min, ClO2 dosage 0.5–1% as active Cl, 0.1–0.2 % NaOH, pulp consistency 9 %; P stage: 80–90 °C, 120–180 min, 0.6–1.8 % NaOH, 0.5–2% H2O2, 0.1–0.2 % MgSO4·7H2O, pulp consistency 10 %. After each bleaching stage except for D0, the kappa number (ISO 302:2015), and ISO brightness (ISO 2470-1:2016) of the pulps were determined. The intrinsic viscosity (ISO 5351:2010) of the final bleached pulps was also determined.

2.3 Metal composition of bark-based materials

The metal composition of the initial spruce bark, bark residues after alkaline extraction, and bark-based kraft pulp (obtained by pulping the bark residues from alkaline extraction at 160 °C) was determined by Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES). A sample of bark residue from the 100 °C extraction was also treated with diluted H2SO4 to study the effect of acid treatment on the leaching of metal elements. The conditions of the acid treatment were: 2 % H2SO4 (on dry bark), pH 2, 60 °C, 60 min, 5 % consistency.

2.4 Pulp refining and making of pulp sheets

Bleached pulps were refined at different revolutions with a PFI mill according to the ISO 5264-2:2011 method. The drainability of the pulps was determined by the Schopper–Riegler (SR) number (ISO 5267-1:99/Cor. 1:2001), and the fiber properties were analyzed with a Valmet FS5 fiber image analyzer according to the ISO 16065-2:2014 method. The pulps were used to make laboratory paper sheets (ISO 5269-1:2005) with grammage of 60 g/m2 and the following properties were determined from the sheets: apparent bulk density (ISO 534:2011; ISO 536:2019), tensile index (ISO 1924-2:08), tear index (ISO 1974:2012), internal bond strength (TAPPI T 569), ISO brightness (ISO 2470-1:2016), light scattering coefficient (ISO 9416:2009), and opacity (ISO 2471:2008).

3 Results and discussion

3.1 Production of bark and wood kraft pulps

Based on chemical composition data reported in our previous study (Borrega et al. 2022), the spruce bark residues had a high cellulose content (∼50 % on dry mass) and low phenolic content (∼15 % on dry mass) because most of the polyphenols in bark, mainly tannins and some lignin, were removed along with other alkali-soluble components during the alkaline extraction process. For comparison, spruce wood contains about 40 % cellulose and 25–30 % lignin (Iakovlev et al. 2014; Lawoko et al. 2005). During kraft pulping, the replacement of wood chips with bark residues with significantly lower phenolic (i.e., lignin) content caused a decrease in the consumption of EA, most notably when pure bark pulps were produced (Table 1). Furthermore, the pulping of bark or mixtures of wood and bark produced unbleached cellulosic pulps with higher yield than the pulping of wood, even after screening for removal of rejects. Previously, Miranda et al. (2012) and Tripathi et al. (2020) reported that mixing hardwood bark with eucalyptus and poplar wood chips in kraft pulping resulted in lower screened pulp yields, probably because the untreated hardwood bark had a higher content of polyphenols and other alkali-soluble components than the wood.

Properties of unbleached and bleached pulps obtained by kraft pulping of spruce wood, bark residues after alkaline extraction, and mixtures of wood and bark residues. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping. nd, not determined.

| Sample | Wood:bark ratio (%) | EA consumption (%) | Unbleached pulp | Bleached pulp | |||||

|---|---|---|---|---|---|---|---|---|---|

| Yield (%) | Rejects (%) | Screened yield (%) | Kappa | ISO brightness (%) | ISO brightness (%) | Intrinsic viscosity (ml/g) | |||

| Wood pulp | 100:0 | 17.3 | 50.1 | 0.5 | 49.6 | 33 | 32 | 91.2 | 810 |

| Bark_100/5 | 95:5 | 16.3 | 51.3 | 1.5 | 49.8 | 43 | 29 | 89.2 | 760 |

| Bark_100/20 | 80:20 | 17.1 | 54.7 | 1.4 | 53.3 | 51 | 26 | 90.4 | 690 |

| Bark_100/100 | 0:100 | 14.0 | 49.3 | 1.3 | 48.0 | 25 | 27 | 89.9 | 490 |

| Bark_160/5 | 95:5 | 16.8 | 51.8 | 0.6 | 51.2 | 30 | 30 | 91.8 | 690 |

| Bark_160/20 | 80:20 | 16.8 | 52.4 | 0.4 | 51.9 | 27 | 28 | 91.5 | 660 |

| Bark_160/100 | 0:100 | 9.9 | 61.8 | 5.7 | 56.1 | 26 | 14 | nd | nd |

The higher yield of bark and mixed pulps compared to wood pulp was also accompanied by a lower kappa number, except for the pulps produced by partial replacement of wood with bark residues from the 100 °C extraction (see samples Bark_100/5 and Bark_100/20 in Table 1). The higher kappa number of these pulps might be explained by the lower alkali concentration in the pulping liquor, resulting from a higher liquid to solid ratio of 5:1 L/kg instead of 4:1 L/kg, which was enough to delignify the bark residue (see Bark_100/100) but not the wood chips.

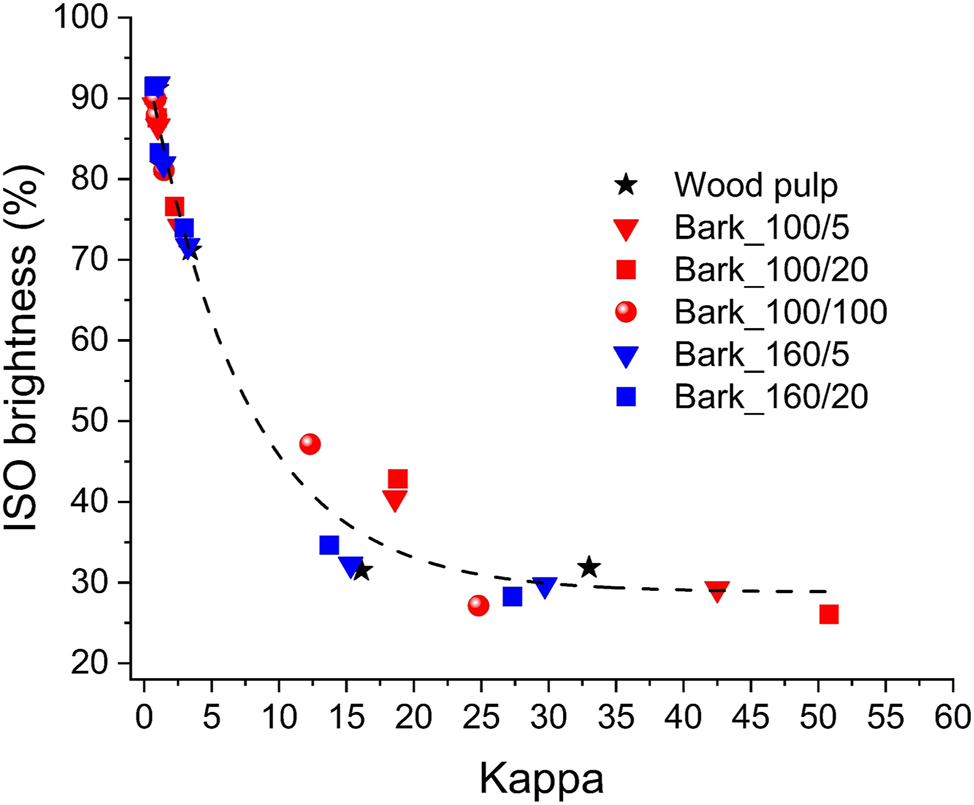

After kraft pulping, the unbleached pulps were subjected to a bleaching sequence O-D0-Ep-D1-P. While the ISO brightness of unbleached bark and mixed pulps was lower than in the unbleached wood pulp (see Table 1), the development of brightness along with reducing kappa during bleaching followed a rather similar trend irrespective of the pulp material (Figure 1). In other words, the mixing of bark residues with wood chips before kraft pulping did not seem to impair the bleaching of the pulps, and ISO brightness values ≥89 % could be obtained for all pulps. The viscosity of pure bark pulp (Bark_100/100) was clearly lower than the viscosity of wood pulp, so increasing the amount of bark residues mixed with wood in pulping led to a general decrease in pulp viscosity (Table 1).

Development of ISO brightness during bleaching of spruce pulps according to an O-D0-Ep-D1-P sequence. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping. The dotted line is included as a visual aid to show that brightness development was similar in all pulps.

3.2 Metal content of bark and bark residues

The metal composition of the initial spruce bark and the bark residues used in this study is shown in Table 2. Calcium (Ca) was by far the most abundant metal element in spruce bark, followed by magnesium (Mg) and manganese (Mn), while the content of potassium (K) was somewhat lower than previously reported (Rothpfeffer and Karltun 2007; Saarela et al. 2005; Wang et al. 2017). The metal content in bark was reduced during alkaline extraction, and the extent of metal reduction was generally greater at 160 °C than at 100 °C, particularly regarding aluminum (Al), silicon (Si) and Ca (Table 2). It should be noted that the values in Table 2 should only be considered as approximate because some inaccuracies can be observed in the elemental composition, most notably for Si in bark extracted at 100 °C and K in bark extracted at 160 °C.

Metal element composition of bark, bark residues and kraft pulp from bark. Values are shown as quantitative (mg/g of bark material) and as % on initial bark. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C).

| Sample | Al | Ca | Fe | K | Mg | Mn | P | Si | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/g | (%) | mg/g | (%) | mg/g | (%) | mg/g | (%) | mg/g | (%) | mg/g | (%) | mg/g | (%) | mg/g | (%) | |

| Bark | 72 | 12,200 | 91 | 235 | 803 | 502 | 220 | 93 | ||||||||

| Bark_100 | 132 | 82 | 13,900 | 51 | 128 | 63 | 158 | 30 | 208 | 12 | 225 | 20 | 166 | 34 | 261 | >100 |

| Bark_100 + acid leaching | 113 | 68 | 10,100 | 36 | 123 | 59 | 55 | 10 | 32 | 2 | 121 | 10 | 27 | 5 | 248 | >100 |

| Bark_160 | 90 | 44 | 4,880 | 14 | 120 | 47 | 759 | >100 | 146 | 6 | 133 | 9 | 155 | 25 | 136 | 52 |

| Bark_160 + Kraft pulping | 167 | 46 | 21,700 | 35 | 128 | 28 | 79 | 7 | 150 | 4 | 212 | 8 | 109 | 10 | 295 | 63 |

Despite the partial removal of metallic elements from bark during alkaline extraction, the bark residues still contained a high metal content. One possibility to further reduce the metal content in bark might be to perform an acid leaching treatment. As shown in Table 2, acid leaching of the bark residue from the 100 °C extraction had the largest impact on the removal of Mg and P, followed by K and Mn. Acid leaching, however, had only a minor effect on the removal of other elements, and the content of Ca was still very high in the acid-leached bark residue (>10,000 mg/kg). Moreover, the application of an acidic treatment between two alkaline processes, i.e., bark extraction and kraft pulping, in an industrial environment would be impractical from a technical and economical perspective. Instead, acid leaching of bark should preferably be considered before the alkaline extraction process.

Without acid leaching, the metal elements in the bark residue from the 160 °C extraction were mostly carried over to the kraft pulp (Table 2). Although the bleachability of the unbleached bark and mixed pulps did not seem to be affected by their metal content (see Figure 1), the large number of metals entering the pulp mill through the bark would most likely have detrimental effects on the digesters, evaporators, and recovery boilers (Karlemo 2019; Ulmgren 1997). Further research on the fate of inorganic elements during the different steps in bark processing and their separation from the extraction, pulping, and bleaching liquors is necessary.

3.3 Pulp refining and properties of pulp sheets

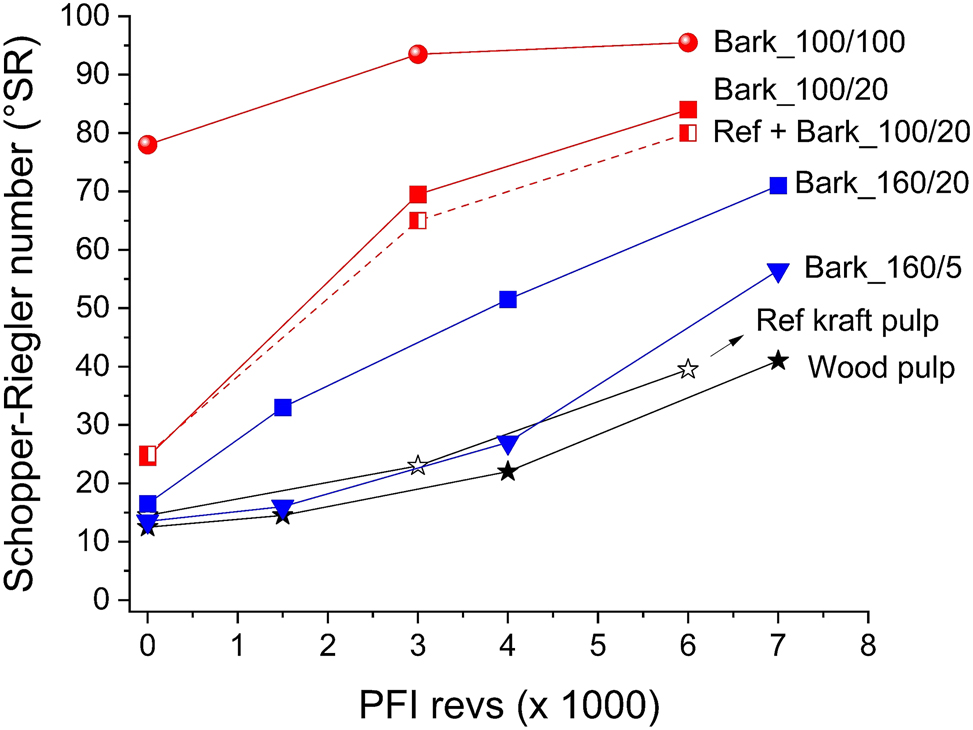

The response of the bleached pulps to PFI refining was determined by the Schopper-Riegler number (°SR), which is a measure of the drainage resistance of pulp suspensions. As shown in Figure 2, the replacement of 5 % wood chips with bark residues from the 160 °C extraction (Bark_160/5) had little effect on the SR number compared to both lab and industrial wood pulps. The replacement of 20 % wood by bark residues, however, clearly increased the SR number as a function of refining. This effect, which was obviously related to the high SR number of the pure bark pulp (Bark_100/100) even without refining, agrees well with previous studies showing that pulps containing eucalyptus bark were easier to refine as their SR number developed faster than in wood pulps (Miranda et al. 2012; Tripathi et al. 2020). In Figure 2, the mixed pulps produced with 20 % bark residues from the 100 °C extraction (Bark_100/20) showed a higher SR number than the pulps produced with 20 % bark residues from the 160 °C extraction (Bark_160/20), which might be related to the use of a disk refiner between the alkaline extraction and the pulping process. Bark residues from the milder extraction at 100 °C were coarser and possibly generated more fines during the disk refining operation, which are known to increase drainage resistance (Mandlez et al. 2022). The mixing of 20 % bark residues with wood chips before pulping (Bark_100/20) had a similar effect on refining than the mixing of 20 % bark pulp with an industrial wood pulp (Ref + Bark_100/20; Figure 2). From an industrial point of view, this would give flexibility to the mills to produce pure bark pulps and adjust their mixing ratios with wood pulps on a need basis.

Evolution of pulp drainability, indicated by the Schopper-Riegler number, as a function of beating revolutions during PFI refining. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference.

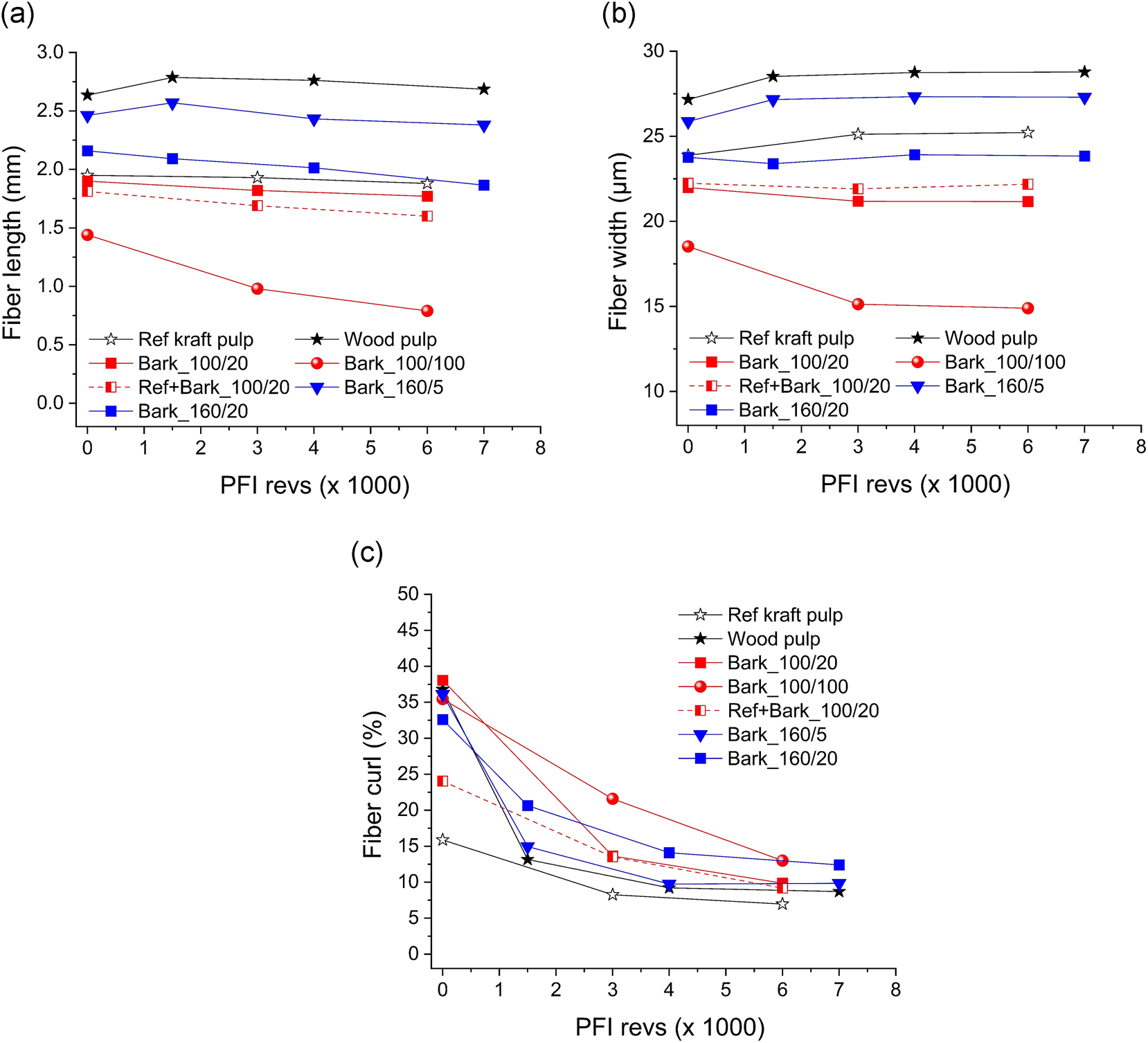

The dimensions of individual pulp fibers and their development with refining is shown in Figure 3. Unrefined fibers in the bark pulp (Bark_100/100) were shorter and narrower than fibers in the wood pulps, and consequently fiber lengths and widths in the mixed pulps were lower than in the lab-scale wood pulp (Figure 3a and b). Fiber length and width in the bark pulp also decreased with refining, but such effect was barely noticeable in mixed and wood pulps even if it is known that pulp refining typically leads to shortening of the fibers (Batchelor et al. 1999; Gharehkhani et al. 2015). Pulp refining up to 4000 PFI revs led to a pronounced reduction in fiber curl, while increased refining had only a minor effect on curl reduction except on the pure bark pulp (Figure 3c). The length, width, and curl of unrefined fibers in the lab-scale wood pulp were markedly higher than in the industrial kraft pulp, but fiber curl in both pulps was rather similar after refining.

Fiber dimensions in pulp sheets as a function of beating revolutions during PFI refining. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference. (a) Fiber length, (b) fiber width, and (c) fiber curl.

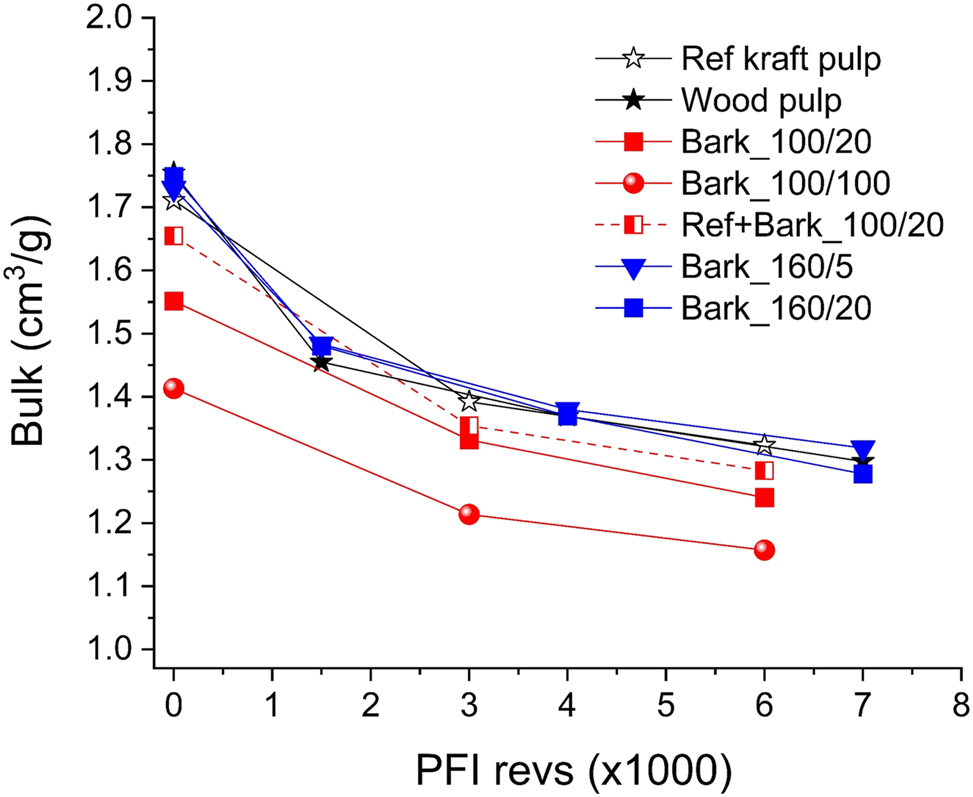

Pulps before and after refining were used to make sheets with a grammage of 60 g/m2. The bulk of the sheets decreased with increased refining, and the bulk of pure bark sheets was the lowest at any pulp refining level (Figure 4). Considering the fiber dimensions shown in Figure 3, one might speculate that the lower bulk of sheets from pure bark pulp was caused by the short and narrow cellulosic fibers, originating from the parenchyma cells found in bark (Franceschi et al. 1998), which filled the voids within the fiber network and formed compact structures similar to the effect produced by fines (Sirviö and Nurminen 2004). On the other hand, Miranda et al. (2012) and Tripathi et al. (2020) reported that sheets made from eucalyptus bark pulp had higher bulk than sheets made from wood pulp. The reason for the bulk discrepancy between sheets from bark and wood pulps in this and other studies is not known, although it might be related to specific anatomical features of hardwoods (e.g., eucalyptus) and softwoods (e.g., spruce).

Bulk of pulp sheets as a function of beating revolutions during PFI refining. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference.

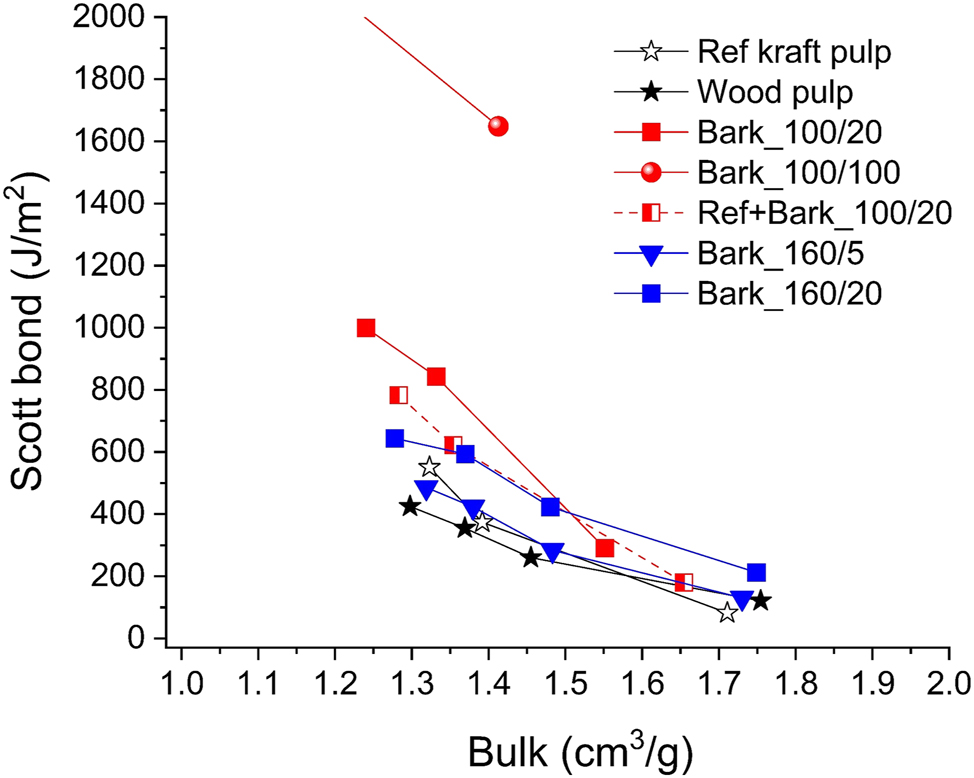

The relationship between bulk and internal bond strength (Scott type) of pulp sheets is shown in Figure 5. Sheets containing 5 % bark residue (Bark_160/5) had a similar evolution of Scott bond versus bulk as sheets from wood pulp, but sheets containing 20 % bark residues had a somewhat higher bond strength at bulks below 1.5 cm3/g. Or in other words, pulp sheets with 20 % bark residues had a 10–15 % higher bulk at a Scott bond of about 400 J/m2. The increase in bulk while maintaining the bond strength of the sheet could be exploited in multilayer boards for packaging applications, and it may lead to substantial economic benefits as less pulp is needed to keep a certain board thickness. In sheets from pure bark pulps (Bark_100/100), the Scott bond was very high even before refining and thus could not be accurately determined after refining because the measuring limit (2000 J/m2) was reached (Figure 5).

Internal bond strength (Scott type) as a function of bulk in pulp sheets with grammage of 60 g/m2. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference.

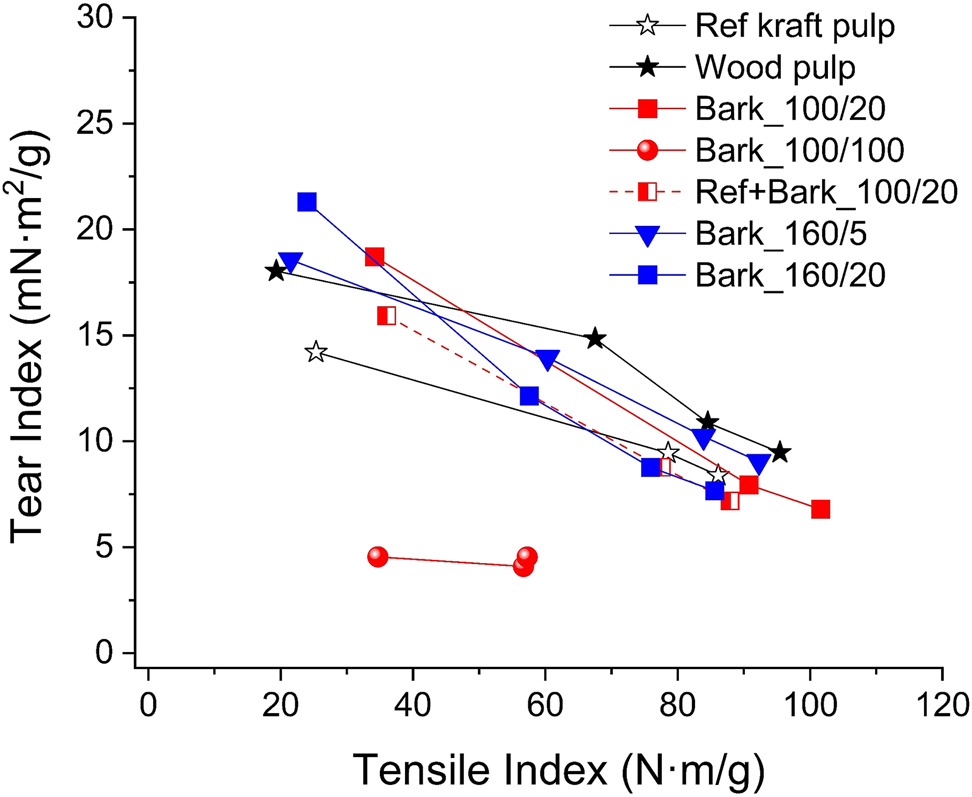

Pulp refining increased the tensile index of the pulp sheets but decreased their tear index (results not shown), possibly due to the straightening of fibers (i.e., less curl, see Figure 3c) and the increased formation of fiber-fiber networks in the sheets (Joutsimo et al. 2005). Sheets made from mixed pulps by addition of up to 20 % bark residues had mechanical properties rather similar to those of commercial and lab wood pulps (Figure 6), which is in agreement with results reported by Miranda et al. (2012) for pulps produced by addition of up to 14 % of eucalyptus bark. On the other hand, Tripathi et al. (2020) observed a 16–24 % decrease in the tensile and tear properties of paper sheets by addition of 20 % eucalyptus bark. Both authors also reported that the tensile and tear properties of sheets from pure bark pulp were lower than those of sheets from mixed and wood pulps, which can also be observed in Figure 6 for spruce bark pulp sheets (Bark_100/100).

Tear index versus tensile strength in pulp sheets with grammage of 60 g/m2. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference.

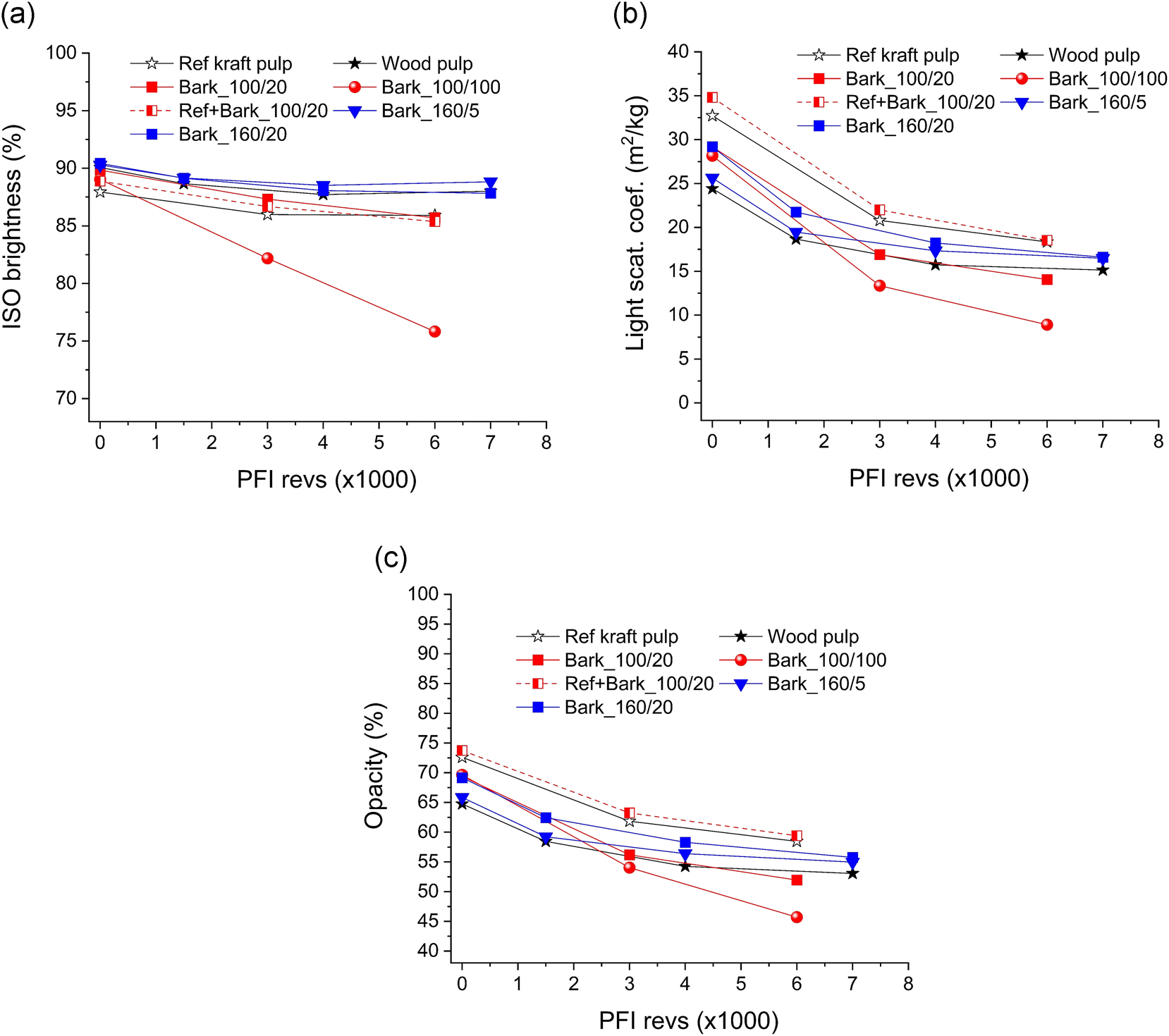

Regarding optical properties, the ISO brightness of sheets from mixed and wood pulps was mostly 85–90 % regardless of the refining level, while sheets from pure bark pulp clearly showed a pronounced reduction in brightness with increased pulp refining (Figure 7a). The light scattering coefficient and opacity decreased in all pulps with increased refining (Figure 7b and c), with sheets containing industrial kraft pulp showing the highest light scattering coefficient and opacity values, and sheets from pure bark pulp showing the lowest values at the highest refining levels.

Optical properties of pulp sheets as a function of beating revolutions during PFI refining. Numbers in the sample name indicate alkaline extraction temperature (100 °C or 160 °C) and proportion of bark residue (5 %, 20 %, 100 %) before pulping; Ref kraft pulp is an industrial softwood kraft pulp used as reference. (a) ISO brightness, (b) light scattering coefficient, and (c) opacity.

4 Conclusions

Spruce bark residues after alkaline extraction of polyphenols may be exploited as raw material for pulping and making of pulp sheets. Replacing up to 20 % of wood chips with bark residues does not seem to impair the pulping and bleaching process and results in higher pulp yields. Furthermore, sheets produced from mixed pulps have similar optical and mechanical properties than wood pulps, while their Scott bond as a function of bulk is about 10–15 % higher, which can be exploited in multilayer boards for packaging applications. The high inorganic content typically found in spruce bark is considerably reduced during the alkaline extraction of polyphenols, but a large amount of calcium and other metal elements still present in the bark residue would enter the pulping and bleaching process. Potential problems caused by these elements to the equipment in the pulp mills need to be investigated, together with possible measures to separate or reduce the inorganic load in the pulping and bleaching liquors. Other pulp parameters such as brightness stability should also be determined to ensure the quality of mixed bark and wood pulps.

Funding source: Business Finland

Award Identifier / Grant number: 6495/31/2019

Acknowledgments

Rauni Seppänen (Project Manager) from Holmen is warmly thanked for providing the softwood bark and for valuable discussions on the results. Olesya Fearon is acknowledged for her support with the metal analyses of bark materials. Technicians at VTT are thanked for their skillful contribution to the technical and analytical work.

-

Research ethics: Not applicable.

-

Informed consent: Informed consent was obtained from all individuals included in this study.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: The authors state no conflict of interest.

-

Research funding: Funding from Business Finland for the project OptiBark – Biobased materials and chemicals from industrial bark and willow by optimized processes (grant number 6495/31/2019) is gratefully acknowledged.

-

Data availability: The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Batchelor, W.J., Kure, K.A., and Ouellet, D. (1999). Refining and the development of fibre properties. Nord. Pulp Pap Res. J. 14: 285–291, https://doi.org/10.3183/npprj-1999-14-04-p285-291.Search in Google Scholar

Bianchi, S., Kroslakova, I., Janzon, R., Mayer, I., Saake, B., and Pichelin, F. (2015). Characterization of condensed tannins and carbohydrates in hot water bark extracts of European softwood species. Phytochemistry 120: 53–61, https://doi.org/10.1016/j.phytochem.2015.10.006.Search in Google Scholar PubMed

Borrega, M., Kalliola, A., Määttänen, M., Borisova, A.S., Mikkelson, A., and Tamminen, T. (2022). Alkaline extraction of polyphenols for valorization of industrial spruce bark. Bioresour. Technol. Rep. 19: 101129, https://doi.org/10.1016/j.biteb.2022.101129.Search in Google Scholar

FAOSTAT (2023). Forestry production and trade, https://www.fao.org/faostat/en/#data/FO (Accessed 23 Jan 2025).Search in Google Scholar

Franceschi, V.R., Krekling, T., Berryman, A.A., and Christiansen, E. (1998). Specialized phloem parenchyma cells in Norway spruce (Pinaceae) bark are an important site of defense reactions. Am. J. Bot. 85: 601–615, https://doi.org/10.2307/2446529.Search in Google Scholar

Gharehkhani, S., Sadeghinezhad, E., Kazi, S.N., Yarmand, H., Badarudin, A., Safaei, M.R., and Zubir, M.N.M. (2015). Basic effects of pulp refining on fiber properties – a review. Carbohydr. Polym. 115: 785–803, https://doi.org/10.1016/j.carbpol.2014.08.047.Search in Google Scholar PubMed

Harder, M.L., Einspahr, D.W., and Parham, R.A. (1978). Bark fibrous yield for 42 pulpwood species. Tappi 61: 121–122.Search in Google Scholar

Hu, L., Koppolu, R., Hämäläinen, R., Kanerva, H., Nick, T., Toivakka, M., Korpinen, R., Saranpää, P., Qasim, U., Liimatainen, H., et al.. (2024). Suberin-based aqueous dispersions for barrier packaging applications. ACS Sustain. Chem. Eng. 12: 8902–8912.10.1021/acssuschemeng.4c02244Search in Google Scholar

Iakovlev, M., You, X., van Heiningen, A., and Sixta, H. (2014). SO 2 –ethanol–water (SEW) fractionation of spruce: kinetics and conditions for paper and viscose-grade dissolving pulps. RSC Adv. 4: 1938–1950, https://doi.org/10.1039/c3ra45573d.Search in Google Scholar

Joutsimo, O., Wathén, R., and Tamminen, T. (2005). Effects of fiber deformations on pulp sheet properties and fiber strength. Pap. Ja Puu 87: 392–397.Search in Google Scholar

Karlemo, C. (2019). Non-process elements in the recovery cycle of six Finnish kraft pulp mills. Åbo Akademi University, Turku, Finland. Correction Statement: Correction (Turku, Finland) added on August 22, 2025 after online publication August 15, 2025.Search in Google Scholar

Kemppainen, K., Siika-aho, M., Pattathil, S., Giovando, S., and Kruus, K. (2014). Spruce bark as an industrial source of condensed tannins and non-cellulosic sugars. Ind. Crops Prod. 52: 158–168, https://doi.org/10.1016/j.indcrop.2013.10.009.Search in Google Scholar

Krasutsky, P.A. (2006). Birch bark research and development. Nat. Prod. Rep. 23: 919–942, https://doi.org/10.1039/b606816b.Search in Google Scholar PubMed

Kwan, I., Huang, T., Ek, M., Seppänen, R., and Skagerlind, P. (2022). Bark from nordic tree species – a sustainable source for amphiphilic polymers and surfactants. Nord. Pulp Pap Res. J. 37: 566–575, https://doi.org/10.1515/npprj-2022-0003.Search in Google Scholar

Lawoko, M., Henriksson, G., and Gellerstedt, G. (2005). Structural differences between the lignin-carbohydrate complexes present in wood and in chemical pulps. Biomacromolecules 6: 3467–3473, https://doi.org/10.1021/bm058014q.Search in Google Scholar PubMed

Mandlez, D., Koller, S., Eckhart, R., Kulachenko, A., Bauer, W., and Hirn, U. (2022). Quantifying the contribution of fines production during refining to the resulting paper strength. Cellulose 29: 8811–8826, https://doi.org/10.1007/s10570-022-04809-x.Search in Google Scholar

Miranda, I., Gominho, J., and Pereira, H. (2012). Incorporation of bark and tops in Eucalyptus globulus wood pulping. Bioresources 7: 4350–4361, https://doi.org/10.15376/biores.7.3.4350-4361.Search in Google Scholar

Neiva, D.M., Gominho, J., Fernandes, L., Lourenço, A., Chemetova, C., Simões, R.M.S., and Pereira, H. (2016). The potential of hydrothermally pretreated industrial barks from E. globulus as a feedstock for pulp production. J. Wood Chem. Technol. 36: 383–392, https://doi.org/10.1080/02773813.2016.1184280.Search in Google Scholar

Pizzi, A. (2019). Tannins: prospectives and actual industrial applications. Biomolecules 9: 344, https://doi.org/10.3390/biom9080344.Search in Google Scholar PubMed PubMed Central

Rothpfeffer, C. and Karltun, E. (2007). Inorganic elements in tree compartments of Picea abies-concentrations versus stem diameter in wood and bark and concentrations in needles and branches. Biomass Bioenergy 31: 717–725, https://doi.org/10.1016/j.biombioe.2007.06.017.Search in Google Scholar

Saarela, K.-E., Harju, L., Lill, J.-O., Heselius, S.-J., Rajander, J., and Lindroos, A. (2005). Quantitative elemental analysis of dry-ashed bark and wood samples of birch, spruce and pine from South-Western Finland using PIXE. Acta Acad. Aboensis – Ser. B 65: 1–27.Search in Google Scholar

Singhal, A., Goel, A., Bhatnagar, A., Roslander, C., Wallberg, O., Konttinen, J., and Joronen, T. (2023). Improving inorganic composition and ash fusion behavior of spruce bark by leaching with water, acetic acid, and steam pre-treatment condensate. Chem. Eng. J. 452: 139351, https://doi.org/10.1016/j.cej.2022.139351.Search in Google Scholar

Sirviö, J. and Nurminen, I. (2004). Systematic changes in paper properties. Pulp Pap. Can. 105: 39–42.Search in Google Scholar

Supriyadi, D., Damayanti, D., Veigel, S., Hansmann, C., and Gindl-Altmutter, W. (2025). Unlocking the potential of tree bark: review of approaches from extractives to materials for higher-added value products. Mater. Today Sustain. 29: 101074, https://doi.org/10.1016/j.mtsust.2025.101074.Search in Google Scholar

Thorenz, A., Wietschel, L., Stindt, D., and Tuma, A. (2018). Assessment of agroforestry residue potentials for the bioeconomy in the European Union. J. Clean. Prod. 176: 348–359, https://doi.org/10.1016/j.jclepro.2017.12.143.Search in Google Scholar PubMed PubMed Central

Tripathi, S.K., Alam, I., and Bhardwaj, N.K. (2020). Effect of bark content in mixed hardwood chips on pulp and papermaking properties. Nord. Pulp Pap Res. J. 35: 325–331, https://doi.org/10.1515/npprj-2020-0017.Search in Google Scholar

Ulmgren, P. (1997). Non-process elements in a bleached kraft pulp mill with a high degree of system closure – state of the art. Nord. Pulp Pap Res. J. 12: 32–40, https://doi.org/10.3183/npprj-1997-12-01-p032-041.Search in Google Scholar

Vroom, K.E. (1957). The H factor: a means of expressing cooking times and temperatures as a single variable. Pulp Pap Res. Inst. Can. 38: 228–231.Search in Google Scholar

Wang, F., Morsali, M., Rizikovs, J., Pylypchuk, I., Mathew, A.P., and Sipponen, M.H. (2024). Fully bio-based water-resistant wood coatings derived from tree bark. Mater. Horiz. 11: 6504–6515, https://doi.org/10.1039/d4mh01010h.Search in Google Scholar PubMed

Wang, L., Moilanen, A., Lehtinen, J., Konttinen, J., and Matas, B.G. (2017). Release of potassium during devolatilization of spruce bark. Energy Proc. 105: 1295–1301, https://doi.org/10.1016/j.egypro.2017.03.463.Search in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Alkali-extracted spruce bark residues for pulping and making of pulp sheets

- Applications of cationic bamboo fibers for the effective reinforcements of secondary fibers

- Paper Technology

- Improving hydrophobicity and mechanical strength of rice straw paper using chitosan nanoparticles and beeswax coatings

- Extended wet pressing at elevated temperature enables enhanced dewatering for tissue and linerboard

- Tissue paper from cabbage leaf – waste paper mixtures

- Inhibition of hornification in simao pine fibers and recycled paper with different beating degrees by microwave expansion treatment

- Preparation of mycelium paper sheets and study on their adsorption properties

- Paper Physics

- Influence of the hybrid effect on the mechanical properties of pulp molds

- Paper Chemistry

- Response surface methodology optimization and anti-age properties in paper protection of carboxymethyl cellulose grafted with β –cyclodextrin

- Printing

- Green innovations in natural paper ink: trends, applications, and future prospects

- Packaging

- Advanced moisture strategy for expanded formability in paper-based packaging

- Production of packaging paper from Populus deltoides NSSC pulp reinforced with rice straw cellulose nanofibrils

- Environmental Impact

- Treatment of regenerated papermaking wastewater by sequencing batch moving bed biofilm reactor and kinetics study

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Alkali-extracted spruce bark residues for pulping and making of pulp sheets

- Applications of cationic bamboo fibers for the effective reinforcements of secondary fibers

- Paper Technology

- Improving hydrophobicity and mechanical strength of rice straw paper using chitosan nanoparticles and beeswax coatings

- Extended wet pressing at elevated temperature enables enhanced dewatering for tissue and linerboard

- Tissue paper from cabbage leaf – waste paper mixtures

- Inhibition of hornification in simao pine fibers and recycled paper with different beating degrees by microwave expansion treatment

- Preparation of mycelium paper sheets and study on their adsorption properties

- Paper Physics

- Influence of the hybrid effect on the mechanical properties of pulp molds

- Paper Chemistry

- Response surface methodology optimization and anti-age properties in paper protection of carboxymethyl cellulose grafted with β –cyclodextrin

- Printing

- Green innovations in natural paper ink: trends, applications, and future prospects

- Packaging

- Advanced moisture strategy for expanded formability in paper-based packaging

- Production of packaging paper from Populus deltoides NSSC pulp reinforced with rice straw cellulose nanofibrils

- Environmental Impact

- Treatment of regenerated papermaking wastewater by sequencing batch moving bed biofilm reactor and kinetics study