Abstract

As a sustainable alternative to using virgin polymer, we propose the use of recycled polymer for the fabrication of passive radiative cooling materials to tackle both the increasing demand for cooling systems and to upcycle plastic waste. Using recycled acrylic sheets as the binder for BaSO4 thorough sol–gel method, a sustained 1.2 °C sub-ambient temperature during daytime and 3 °C sub-ambient temperature during nighttime was achieved under the hot and humid conditions of the tropical climate. The coating achieved 97.7 % solar reflectance and 95 % infrared emittance. Separately, when porosity is introduced to recycled acrylic sheets through a phase inversion method, a near-ambient temperature during noontime and sustained sub-ambient temperature of 2.5 °C during nighttime was achieved (with 96.7 % solar reflectance). Comparable performances are also obtained using recycled polyvinyl chloride (PVC) pipe and expanded polystyrene (EPS) foam.

1 Introduction

Conventional methods to indoor-cooling involve the active use of air-conditioning systems which leads to high energy demands. On the other hand, passive radiative cooling (PRC) systems provide free cooling by regulating the amount of heat transmitted indoors through a combination of reflection and emission strategies [1, 2]. It works by transferring radiation heat from an object on the surface of the Earth to the cold outer space (around 3 K) [3–5] through the atmospheric window. Even though the earth’s atmosphere (comprised of a mixture of gases including N2, O2, CO2 and water vapor) absorbs heat, it becomes transparent to thermal radiation in the wavelength of 8–13 µm for heat from terrestrial objects to be directly emitted to the outer space (ultimate heat sink) [6, 7]. Accompanied with reflection of solar radiation in the wavelength of 0.3–2.5 µm, materials exhibiting selective optical properties are able to enhance cooling and even reach sub-ambient temperatures [8–10]. To passive daytime radiative cooling (PDRC), studies have shown that a reflectivity of 95 % and above in the solar spectrum is required for effective cooling performances [8]. However, in a region with tropical climate, the criteria of solar reflectivity becomes more stringent due to the higher solar intensity, ambient temperature and relative humidity [11], where over 97 % solar reflectivity is needed to minimise heat gain from the sun during daytime [12, 13].

Recently, different forms of effective PDRC materials such as paints and films have been proposed for real world applications [14–16]. Among them, polymer-based PDRC materials have shown excellent cooling performances alongside their low cost and high potential for scalability [17]. These organic polymers, including poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP), polyvinylidene fluoride (PVDF) polymethyl methacrylate (PMMA), polystyrene (PS) and polyvinyl chloride (PVC), have displayed strong infrared (IR) emission due to their intrinsic vibrations within 8–13 μm [9, 18], [19], [20], [21]. To achieve high solar reflectivity, white pigment nanoparticles (NPs) with strong Mie scattering efficiency within 0.3–2.5 µm can be embedded within the polymers [22]. Separately, hierarchically porous polymeric structures have also proven to be effective in achieving high solar reflectance and IR emittance concurrently [9, 23, 24]. However, almost all studies thus far have considered the use of virgin polymeric materials, which taps on limited natural resources and potentially leading on to increased landfill burden. In fact, the global demand for plastics has become an environmental concern in recent years as the amount of plastic being disposed annually has seen a steep upward trend [25]. Hence, a possible solution to the sustainable development of PDRC is to substitute virgin polymer with their recycled counterparts during the manufacturing process. Moreover, earlier research have proven that recycled plastics can be modified to provide similar properties and performance when compared to virgin plastics [26, 27], which provide a possibility for the development of recycled radiative coolers [28–31].

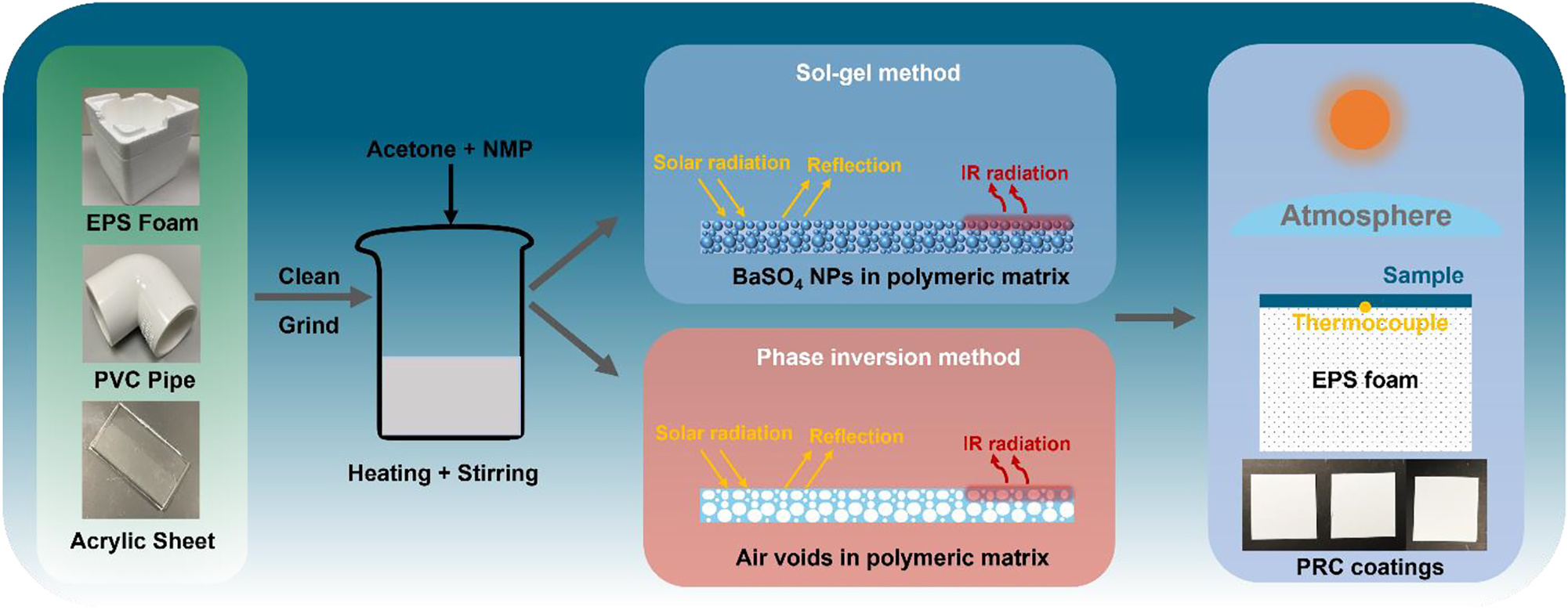

In this work, we investigate the viability of using recycled polymers from commercial plastic waste products to create polymeric coatings through sol–gel and phase inversion methods under the tropical weather testing. Using recycled acrylic sheets as the binder for BaSO4 thorough sol–gel method, a sustained 1.2 °C sub-ambient temperature during daytime and 3 °C sub-ambient temperature during nighttime was achieved under the hot and humid conditions of the tropical climate. Separately, when porosity is introduced to recycled acrylic sheets through a phase inversion method, a near-ambient temperature during noontime and sustained sub-ambient temperature of 2.5 °C during nighttime was achieved. Other commercial plastics such as PVC pipe and EPS foam also exhibited potential for replacing virgin polymers while providing comparable cooling performances.

2 Materials and methods

2.1 Preparation of radiative cooling samples

2.1.1 Sol–gel method

The recycled polymeric products: expanded polystyrene (EPS) foam, polyvinyl chloride (PVC) pipe and acrylic sheet) are cleaned and grinded into small pieces using the grinder. Subsequently, small pieces of the recycled polymer were added to a mixture of N-methyl-2-pyrrolidone (NMP) and acetone as shown in Figure 1. The combined mixture was then heated to 80 °C on a heating plate and stirred until the polymer completely dissolves into the solution. BaSO4 powder (Sigma-Aldrich) was dispersed into the polymer-solvent system and the stirring process was done for another 30 min at 80 °C to ensure homogenous mixing of the BaSO4 particles within the polymer matrix. The coating precursor was subsequently coated onto a polished aluminium plate using a blade coating machine for solvent evaporation. The same steps and solvents were used for the preparation of all recycled plastics in this study and the mass ratio of BaSO4 and polymer was 15:1 to achieve a highly reflective and stable surface without any cracks.

Recycled passive radiative coolers using sol–gel and phase inversion methods, including set-up for radiative cooling performance and optical image of PRC coatings.

2.1.2 Phase inversion method

Once a homogeneous solution is obtained as shown in Figure 1, it is immediately coated onto an aluminium sheet by a blade coating machine. After air drying for 10 min, the sample was moved into a water bath for phase inversion process to obtain a freestanding film with air voids in the polymeric matrix [19].

2.2 Characterizations of radiative cooling performance

The characterizations of radiative cooling performance were performed on the rooftop of Academic Block North in Nanyang Technological University, Singapore. As shown in Figure 1, the sample was facing the sky and thermal insulated by EPS foam with the same size. The surface thermocouple (SA3-K-120, Omega) was attached to the centre of the sample at the bottom surface for measurement of the surface temperature. A nearby weather station was employed to monitor the weather conditions including ambient air temperature, relative humidity, solar irradiance and atmospheric radiation. For the cooling power test, a polyimide film heater powered by a constant current source was attached to the bottom surface of the sample. To obtain effective cooling power, the sample was heated to match the ambient air temperature.

2.3 Characterizations of optical properties

The spectrum solar reflectance within the wavelength of 0.3–2.5 μm was measured using a UV–VIS-NIR spectrometer (PerkinElmer-Lambda 950). The spectrum IR reflectance within the wavelength of 2.5–20 μm was measured with a Fourier transform infrared spectrometer (PerkinElmer Spectrum 3) connected to a gold-coated integrating sphere (PIKE Mid-IR IntegratIR). A field-emission scanning electron microscope (JEOL 7600L) was employed to obtain the SEM images.

3 Optical and radiative cooling performance of BaSO4 coating

To achieve high solar reflectance, BaSO4 particle was added to the polymers during the sol–gel fabrication process. As shown in Figure 2(a), the BaSO4 particles has a broad particle diameter range from 0.1 to 1 μm, and form a dense structure after binding by the recycled acrylic polymer. Owing to the comparable size of the particles with the wavelength of sunlight, strong Mie-scattering is achieved to highly reflect solar heat. Here, the finite-difference time-domain (FDTD) simulation (details in Supporting Information, Note 1 and Figure S1) was employed to calculate the scattering efficiency of BaSO4 particles as a function of diameter from 0.1 to 1 μm according to Mie theory. As shown in Figure 2(b), the particles with diameter of around 0.1–1 μm could generate relative-high scattering efficiency within the wavelength of 0.3–1.5 μm, which means that it can strongly reflect the majority of solar energy. The solar reflectance of the BaSO4 particles with recycled acrylic polymer as binder could reach around 97.7 %, which is almost the same level as that with virgin PMMA as shown in Figure 2(c). Both coatings also have similar infrared emittance, with an average emittance of 95 % within 8–13 μm as shown in Figure 2(d). Likewise, for recycled PVC pipe and EPS foam with BaSO4 particles, the solar reflectance and IR emittance (as shown in Figure S2(a) and (b)) are comparable to the one with recycled acrylic polymer as binder.

![Figure 2:

Optical performance of the radiative cooling sample using sol–gel method. (a) SEM image of the sample. Inset is particle size distribution. (b) Scattering efficiency of the BaSO4 NPs within the solar spectrum from FDTD simulation. (c) Measured solar reflectance of the BaSO4 coating using the recycled acrylic sheet and virgin PMMA (background is AM1 solar spectrum [32]). (d) Measured infrared emittance of the BaSO4 coating using the recycled acrylic sheet and virgin PMMA (background is atmospheric window).](/document/doi/10.1515/nanoph-2023-0593/asset/graphic/j_nanoph-2023-0593_fig_002.jpg)

Optical performance of the radiative cooling sample using sol–gel method. (a) SEM image of the sample. Inset is particle size distribution. (b) Scattering efficiency of the BaSO4 NPs within the solar spectrum from FDTD simulation. (c) Measured solar reflectance of the BaSO4 coating using the recycled acrylic sheet and virgin PMMA (background is AM1 solar spectrum [32]). (d) Measured infrared emittance of the BaSO4 coating using the recycled acrylic sheet and virgin PMMA (background is atmospheric window).

Next, the radiative cooling performance of the BaSO4 coating with recycled acrylic polymer is examined under Singapore’s tropical climate. As shown in Figure 3(a), consistent sub-ambient temperature of 1.2 °C was achieved during noontime when the solar intensity is 900 W/m2 and atmospheric radiation is 500 W/m2. During night-time without solar heat gain, the temperature of the coating was 3 °C below ambient as shown in Figure 3(b). This amount to an effective cooling power of around 56.2 W/m2 as shown in Figure 3(c) and further simulations of radiative cooling power is detailed in Supporting Information, Note 2 and shown in Figure 3(d). Moreover, the cooling performance of BaSO4 coating using virgin PMMA and other recycled polymer (PVC pipe and EPS foam.) as the binder showed similar surface temperatures during the 24 h continuous test (details in Figure S2(c)).

Radiative cooling performance of the sample using sol–gel method. (a) Measured surface temperature during daytime with local ambient air temperature, humidity, solar irradiance and atmospheric radiation. The sunlight was blocked by the clouds in the sky after 15:15 on that day (08-Sep-2023). (b) Measured surface temperature during night-time with local ambient air temperature, humidity, solar irradiance and atmospheric radiation (08-Sep-2023). (c) Measured surface temperature during night-time with heater turned on at time 19:56 for the sample to match ambient temperatures for measurements of cooling power (56.2 W/m2) (11-Sep-2023). (d) Simulated radiative cooling power with different solar intensity and climate.

4 Optical and radiative cooling performance of porous film

Using the phase inversion method, porous films with nano–micro air pores are fabricated using recycled acrylic sheets. As shown in Figure 4(a), the air pores inside the film comprise of a broad size distribution with diameter ranging from 1 to 10 μm. From the FDTD simulations (details in Supporting Information, Note 1 and Figure S1) and as shown in Figure 4(b), relative high scattering efficiency can be achieved across the solar spectrum for pore diameters between 1 and 10 μm. Overall, the solar reflectance of the porous film was 96.7 % as shown in Figure 4(c), with an infrared emittance of 75 % in the atmospheric window as shown in Figure 4(d). The radiative cooling performance of the freestanding porous film under tropical climate was also evaluated and is shown in Figure 4(e). The surface temperature of the sample could reach near-ambient temperatures during noontime where solar intensity and atmospheric radiation are above 1000 W/m2 and 400 W/m2 respectively. During night-time, sustained sub-ambient temperatures of 2.5 °C can be achieved. For the remaining two recycled polymers (PVC pipe and EPS foam), owing to comparable levels of optical properties, their porous films could achieve similar radiative cooling performance compared with the one using recycled acrylic sheet (details in Figure S3).

![Figure 4:

Optical and radiative cooling performance of the radiative cooling sample using phase inversion method. (a) SEM image of the sample. Inset is pore size distribution. (b) Scattering efficiency of the air pores within the solar spectrum from FDTD simulation. (c) Measured solar reflectance of the porous film using the recycled acrylic sheet (background is AM1 solar spectrum [32]). (d) Measured infrared emittance of the porous film using the recycled acrylic sheet (background is atmospheric window). (e) Outdoor radiative cooling performance under tropical climate: measured surface temperature with local ambient air temperature, humidity, solar irradiance and atmospheric radiation (27-Oct-2022).](/document/doi/10.1515/nanoph-2023-0593/asset/graphic/j_nanoph-2023-0593_fig_004.jpg)

Optical and radiative cooling performance of the radiative cooling sample using phase inversion method. (a) SEM image of the sample. Inset is pore size distribution. (b) Scattering efficiency of the air pores within the solar spectrum from FDTD simulation. (c) Measured solar reflectance of the porous film using the recycled acrylic sheet (background is AM1 solar spectrum [32]). (d) Measured infrared emittance of the porous film using the recycled acrylic sheet (background is atmospheric window). (e) Outdoor radiative cooling performance under tropical climate: measured surface temperature with local ambient air temperature, humidity, solar irradiance and atmospheric radiation (27-Oct-2022).

5 Conclusions

The viability of using recycled polymers (acrylic sheet, PVC pipe and EPS foam) as a substitute for virgin polymer in radiative cooling is investigated in this study. Through sol–gel method, BaSO4 coating with recycled acrylic sheet as the binder exhibited 97.7 % solar reflectance and 95 % IR emittance. Under the harsh conditions of the tropical climate that is characterized by high solar irradiance and high humidity, the coating is able to achieve sustained sub-ambient temperatures of 1.2 °C and 3 °C during daytime and nighttime, respectively. Through phase inversion method, the solar reflectance of the porous film using recycled acrylic sheet was 96.7 %. A near-ambient temperature during noontime and sustained sub-ambient temperature of 2.5 °C during nighttime was achieved. Similar performances could be obtained for BaSO4 coating and porous film using recycled PVC pipe and EPS foam.

Funding source: Singapore National Research Foundation

Award Identifier / Grant number: NRF2021-NRF-ANR001

Funding source: Biocool and Mitsubishi Corporation

-

Research funding: The authors would like to acknowledge the funding support of the Singapore National Research Foundation, NRF2021-NRF-ANR001 Biocool and Mitsubishi Corporation.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors declare no conflicts of interest regarding this article.

-

Data availability: Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

[1] M. Santamouris and D. Asimakopoulos, Passive Cooling of Buildings, London, Earthscan, 1996.Suche in Google Scholar

[2] M. Santamouris and D. Kolokotsa, “Passive cooling dissipation techniques for buildings and other structures: the state of the art,” Energy Build., vol. 57, pp. 74–94, 2013. https://doi.org/10.1016/j.enbuild.2012.11.002.Suche in Google Scholar

[3] X. Yu, J. Chan, and C. Chen, “Review of radiative cooling materials: performance evaluation and design approaches,” Nano Energy, vol. 88, p. 106259, 2021. https://doi.org/10.1016/j.nanoen.2021.106259.Suche in Google Scholar

[4] D. Zhao, A. Aili, Y. Zhai, et al.., “Radiative sky cooling: fundamental principles, materials, and applications,” Appl. Phys. Rev., vol. 6, no. 2, p. 021306, 2019. https://doi.org/10.1063/1.5087281.Suche in Google Scholar

[5] B. Zhao, M. Hu, X. Ao, N. Chen, and G. Pei, “Radiative cooling: a review of fundamentals, materials, applications, and prospects,” Appl. Energy, vol. 236, pp. 489–513, 2019. https://doi.org/10.1016/j.apenergy.2018.12.018.Suche in Google Scholar

[6] S. Catalanotti, V. Cuomo, G. Piro, D. Ruggi, V. Silvestrini, and G. Troise, “The radiative cooling of selective surfaces,” Sol. Energy, vol. 17, no. 2, pp. 83–89, 1975. https://doi.org/10.1016/0038-092x(75)90062-6.Suche in Google Scholar

[7] J. Khedari, J. Waewsak, S. Thepa, and J. Hirunlabh, “Field investigation of night radiation cooling under tropical climate,” Renewable Energy, vol. 20, no. 2, pp. 183–193, 2000. https://doi.org/10.1016/s0960-1481(99)00104-4.Suche in Google Scholar

[8] A. P. Raman, M. A. Anoma, L. Zhu, E. Rephaeli, and S. Fan, “Passive radiative cooling below ambient air temperature under direct sunlight,” Nature, vol. 515, no. 7528, pp. 540–544, 2014. https://doi.org/10.1038/nature13883.Suche in Google Scholar PubMed

[9] J. Mandal, Y. Fu, A. C. Overvig, et al.., “Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling,” Science, vol. 362, no. 6412, pp. 315–319, 2018. https://doi.org/10.1126/science.aat9513.Suche in Google Scholar PubMed

[10] T. Li, Y. Zhai, S. He, et al.., “A radiative cooling structural material,” Science, vol. 364, no. 6442, pp. 760–763, 2019. https://doi.org/10.1126/science.aau9101.Suche in Google Scholar PubMed

[11] D. Han, B. F. Ng, and M. P. Wan, “Preliminary study of passive radiative cooling under Singapore’s tropical climate,” Sol. Energy Mater. Sol. Cells, vol. 206, p. 110270, 2020. https://doi.org/10.1016/j.solmat.2019.110270.Suche in Google Scholar

[12] D. Han, J. Fei, J. Mandal, et al.., “Sub-ambient radiative cooling under tropical climate using highly reflective polymeric coating,” Sol. Energy Mater. Sol. Cells, vol. 240, p. 111723, 2022. https://doi.org/10.1016/j.solmat.2022.111723.Suche in Google Scholar

[13] D. Han, J. Fei, H. Li, and B. F. Ng, “The criteria to achieving sub-ambient radiative cooling and its limits in tropical daytime,” Build. Environ., vol. 221, p. 109281, 2022. https://doi.org/10.1016/j.buildenv.2022.109281.Suche in Google Scholar

[14] X. Yin, R. Yang, G. Tan, and S. Fan, “Terrestrial radiative cooling: using the cold universe as a renewable and sustainable energy source,” Science, vol. 370, no. 6518, pp. 786–791, 2020. https://doi.org/10.1126/science.abb0971.Suche in Google Scholar PubMed

[15] J. Liang, J. Wu, J. Guo, et al.., “Radiative cooling for passive thermal management towards sustainable carbon neutrality,” Natl. Sci. Rev., vol. 10, no. 1, 2022, https://doi.org/10.1093/nsr/nwac208.Suche in Google Scholar PubMed PubMed Central

[16] W. Gao and Y. Chen, “Emerging materials and strategies for passive daytime radiative cooling,” Small, vol. 19, no. 18, p. 2206145, 2023. https://doi.org/10.1002/smll.202206145.Suche in Google Scholar PubMed

[17] J. Wang, G. Tan, R. Yang, and D. Zhao, “Materials, structures, and devices for dynamic radiative cooling,” Cell Rep. Phys. Sci., vol. 3, no. 12, p. 101198, 2022. https://doi.org/10.1016/j.xcrp.2022.101198.Suche in Google Scholar

[18] T. Wang, Y. Wu, L. Shi, X. Hu, M. Chen, and L. Wu, “A structural polymer for highly efficient all-day passive radiative cooling,” Nat. Commun., vol. 12, no. 1, p. 365, 2021. https://doi.org/10.1038/s41467-020-20646-7.Suche in Google Scholar PubMed PubMed Central

[19] J. Fei, D. Han, J. Ge, et al.., “Switchable surface coating for bifunctional passive radiative cooling and solar heating,” Adv. Funct. Mater., vol. 32, no. 27, p. 2203582, 2022. https://doi.org/10.1002/adfm.202203582.Suche in Google Scholar

[20] W. A. D. M. Jayathilaka, A. Chinnappan, R. Ghosh, C. Baskar, and S. Ramakrishna, “Highly efficient polystyrene/metal oxide fiber composites for passive radiative cooling,” Adv. Eng. Mater., vol. 24, no. 1, p. 2100694, 2022. https://doi.org/10.1002/adem.202100694.Suche in Google Scholar

[21] B. Orel, M. K. Gunde, and A. Krainer, “Radiative cooling efficiency of white pigmented paints,” Sol. Energy, vol. 50, no. 6, pp. 477–482, 1993. https://doi.org/10.1016/0038-092x(93)90108-z.Suche in Google Scholar

[22] J. Mandal, Y. Yang, N. Yu, and A. P. Raman, “Paints as a scalable and effective radiative cooling technology for buildings,” Joule, vol. 4, no. 7, pp. 1350–1356, 2020. https://doi.org/10.1016/j.joule.2020.04.010.Suche in Google Scholar

[23] K. Zhou, X. Yan, S. J. Oh, et al.., “Hierarchically patterned self-cleaning polymer composites for daytime radiative cooling,” Nano Lett., vol. 23, no. 9, pp. 3669–3677, 2023. https://doi.org/10.1021/acs.nanolett.2c04069.Suche in Google Scholar PubMed

[24] K. Zhou, W. Li, B. B. Patel, et al.., “Three-dimensional printable nanoporous polymer matrix composites for daytime radiative cooling,” Nano Lett., vol. 21, no. 3, pp. 1493–1499, 2021. https://doi.org/10.1021/acs.nanolett.0c04810.Suche in Google Scholar PubMed

[25] R. Geyer, J. R. Jambeck, and K. L. Law, “Production, use, and fate of all plastics ever made,” Sci. Adv., vol. 3, no. 7, p. e1700782, 2017. https://doi.org/10.1126/sciadv.1700782.Suche in Google Scholar PubMed PubMed Central

[26] C. L. Simões, L. M. Costa Pinto, and C. A. Bernardo, “Environmental and economic assessment of a road safety product made with virgin and recycled HDPE: a comparative study,” J. Environ. Manage., vol. 114, pp. 209–215, 2013. https://doi.org/10.1016/j.jenvman.2012.10.001.Suche in Google Scholar PubMed

[27] F. Gu, P. Hall, and N. J. Miles, “Performance evaluation for composites based on recycled polypropylene using principal component analysis and cluster analysis,” J. Clean. Prod., vol. 115, pp. 343–353, 2016. https://doi.org/10.1016/j.jclepro.2015.12.062.Suche in Google Scholar

[28] Y. Liu, X. Liu, F. Chen, et al.., “Eco-friendly passive radiative cooling using recycled packaging plastics,” Mater. Today Sustain., vol. 23, p. 100448, 2023. https://doi.org/10.1016/j.mtsust.2023.100448.Suche in Google Scholar

[29] R. Liu, Z. Zhou, X. Mo, et al.., “Green-manufactured and recyclable coatings for subambient daytime radiative cooling,” ACS Appl. Mater. Interfaces, vol. 14, no. 41, pp. 46972–46979, 2022. https://doi.org/10.1021/acsami.2c12400.Suche in Google Scholar PubMed

[30] Y. Liu, X. Liu, F. Chen, Y. Tian, A. Caratenuto, and Y. Zheng, “Oil-paper-umbrella-inspired passive radiative cooling using recycled packaging foam,” J. Mater. Chem. A, vol. 11, no. 16, pp. 9152–9159, 2023. https://doi.org/10.1039/d3ta00823a.Suche in Google Scholar

[31] H. Sun, F. Tang, Q. Chen, et al.., “A recyclable, up-scalable and eco-friendly radiative cooling material for all-day sub-ambient comfort,” Chem. Eng. J., vol. 455, p. 139786, 2023. https://doi.org/10.1016/j.cej.2022.139786.Suche in Google Scholar

[32] Standard Table for Reference Solar Spectral Distributions: Direct and Diffuse on 20° Tilted and Vertical Surfaces, West Conshohocken, PA, ASTM International, 2014.Suche in Google Scholar

Supplementary Material

This article contains supplementary material (https://doi.org/10.1515/nanoph-2023-0593).

© 2023 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Frontmatter

- Editorial

- Thermal photonics for sustainability

- Review

- Switchable radiative cooling and solar heating for sustainable thermal management

- Perspective

- Radiative cooling: arising from practice and in turn serving practice

- Research Articles

- Superhydrophobic bilayer coating for passive daytime radiative cooling

- Investigation of recycled materials for radiative cooling under tropical climate

- A scalable and durable polydimethylsiloxane-coated nanoporous polyethylene textile for daytime radiative cooling

- Three-dimensionally printable hollow silica nanoparticles for subambient passive cooling

- High albedo daytime radiative cooling for enhanced bifacial PV performance

- Enhanced radiative cooling with Janus optical properties for low-temperature space cooling

- Efficient radiative cooling of low-cost BaSO4 paint-paper dual-layer thin films

- Radiative cooling textiles using industry-standard particle-free nonporous micro-structured fibers

- Aqueous double-layer paint of low thickness for sub-ambient radiative cooling

- Porous polymer bilayer with near-ideal solar reflectance and longwave infrared emittance

- Visible light electrochromism based on reversible dissolution/deposition of MnO2

- Energy scavenging from the diurnal cycle with a temperature-doubler circuit and a self-adaptive photonic design

- Reverse-switching radiative cooling for synchronizing indoor air conditioning

- Porous vanadium dioxide thin film-based Fabry−Perot cavity system for radiative cooling regulating thermochromic windows: experimental and simulation studies

- Theoretical study of a highly fault-tolerant and scalable adaptive radiative cooler

- Ultra-broadband and wide-angle nonreciprocal thermal emitter based on Weyl semimetal metamaterials

- Transparent energy-saving windows based on broadband directional thermal emission

- Lithography-free directional control of thermal emission

- GAGA for nonreciprocal emitters: genetic algorithm gradient ascent optimization of compact magnetophotonic crystals

- Ultra-broadband directional thermal emission

- Tailoring full-Stokes thermal emission from twisted-gratings structures

- Effectiveness of multi-junction cells in near-field thermophotovoltaic devices considering additional losses

Artikel in diesem Heft

- Frontmatter

- Editorial

- Thermal photonics for sustainability

- Review

- Switchable radiative cooling and solar heating for sustainable thermal management

- Perspective

- Radiative cooling: arising from practice and in turn serving practice

- Research Articles

- Superhydrophobic bilayer coating for passive daytime radiative cooling

- Investigation of recycled materials for radiative cooling under tropical climate

- A scalable and durable polydimethylsiloxane-coated nanoporous polyethylene textile for daytime radiative cooling

- Three-dimensionally printable hollow silica nanoparticles for subambient passive cooling

- High albedo daytime radiative cooling for enhanced bifacial PV performance

- Enhanced radiative cooling with Janus optical properties for low-temperature space cooling

- Efficient radiative cooling of low-cost BaSO4 paint-paper dual-layer thin films

- Radiative cooling textiles using industry-standard particle-free nonporous micro-structured fibers

- Aqueous double-layer paint of low thickness for sub-ambient radiative cooling

- Porous polymer bilayer with near-ideal solar reflectance and longwave infrared emittance

- Visible light electrochromism based on reversible dissolution/deposition of MnO2

- Energy scavenging from the diurnal cycle with a temperature-doubler circuit and a self-adaptive photonic design

- Reverse-switching radiative cooling for synchronizing indoor air conditioning

- Porous vanadium dioxide thin film-based Fabry−Perot cavity system for radiative cooling regulating thermochromic windows: experimental and simulation studies

- Theoretical study of a highly fault-tolerant and scalable adaptive radiative cooler

- Ultra-broadband and wide-angle nonreciprocal thermal emitter based on Weyl semimetal metamaterials

- Transparent energy-saving windows based on broadband directional thermal emission

- Lithography-free directional control of thermal emission

- GAGA for nonreciprocal emitters: genetic algorithm gradient ascent optimization of compact magnetophotonic crystals

- Ultra-broadband directional thermal emission

- Tailoring full-Stokes thermal emission from twisted-gratings structures

- Effectiveness of multi-junction cells in near-field thermophotovoltaic devices considering additional losses