Abstract

Gas-particle flows in circulating fluidized beds (CFB) with wide particle size distributions were simulated using the Eulerian-Eulerian approach to analyze the effects of the particle phase division and the applicability of the particle-particle drag model. The results indicate that the simulation is not accurate by just using a single average particle diameter when the particle size distribution includes a critical particle diameter. A binary particle phase division criterion was then developed to establish two particle phases representing two types of particles with different flow patterns. Coupling the Eulerian-Eulerian approach with the new criterion enabled accurate predictions of the pressures, particle volume fractions, and particle mass circulation rates that were in agreement with experimental data. The influences of different particle-particle drag models were also investigated to show that the simulation using the Syamlal model was not accurate due to the overestimated particle-particle drag, while the results without particle-particle drag and with the Manger model were similar and much more accurate. Moreover, the flow mechanism for the non-uniformity of particle circulation rates in the parallel circulating loops of the CFB boiler was revealed. This study improves the Eulerian-Eulerian simulations of fluidization with wide particle size distributions and further deepens the understanding of flow characteristics in CFB.

Funding source: Science and Technology Project of China Huaneng Group Co., Ltd.

Award Identifier / Grant number: HNKJ20-H50

Funding source: Tsinghua-Huaneng Basic Energy Joint Research Institute

Award Identifier / Grant number: U20YYJC07

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: This study was supported by the Science and Technology Project of China Huaneng Group Co., Ltd. (Grant no. HNKJ20-H50) and the Tsinghua-Huaneng Basic Energy Joint Research Institute (Grant no. U20YYJC07).

-

Conflict of interest statement: The authors declare no conflicts of interest regarding this article.

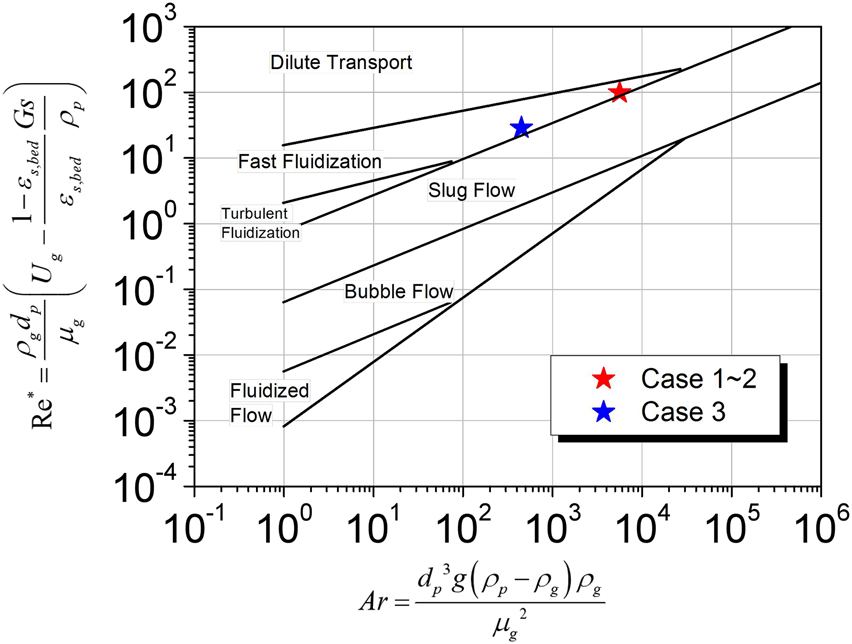

According to the gas-particle flow regime diagram developed by Rabinovich and Kalman (2011), the flow states in the two simulated CFB (Test rig in Figure 1 and riser in Figure 11) are both fast fluidization as shown in Figure A.1. Re* is the Reynolds number representing overall upward gas-particle slip velocity, and Ar is the Archimedes number that characterizes the type of the particles.

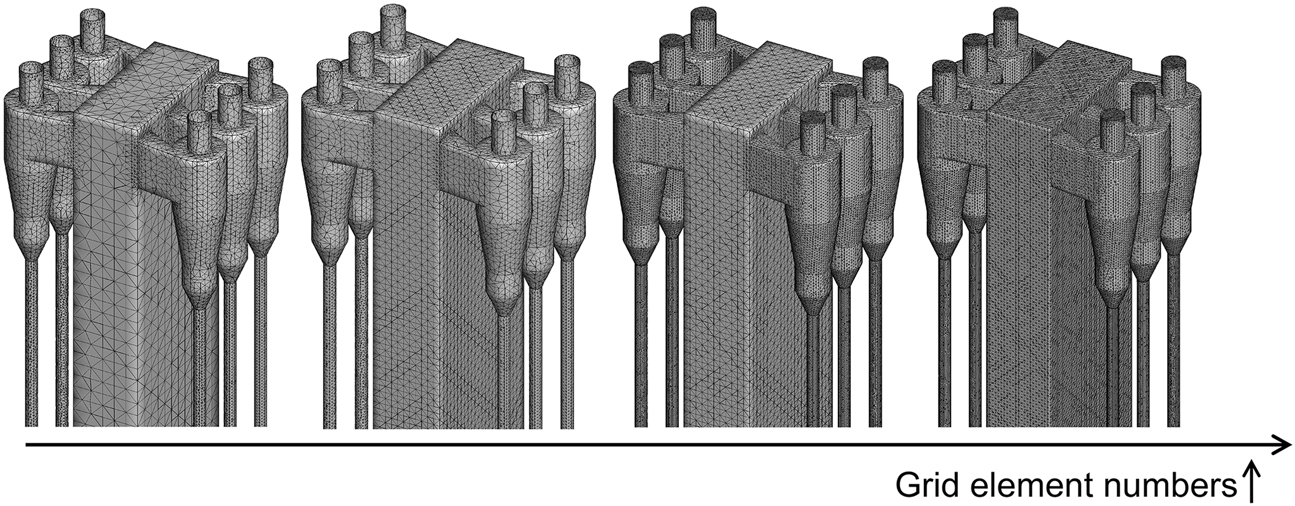

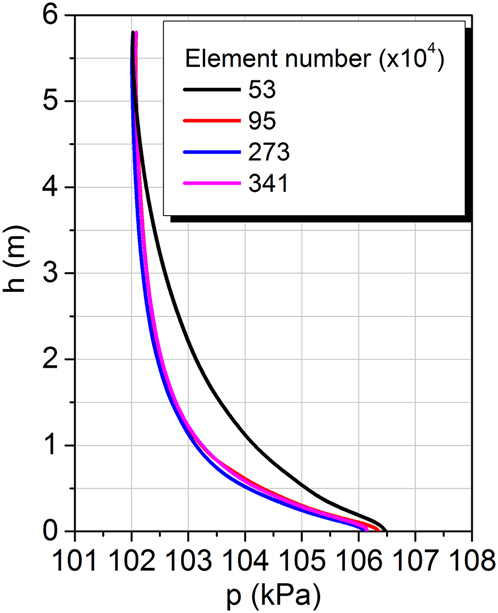

Details about mesh models and grid independence test results.

Flow regime diagram for the simulated CFB (Rabinovich and Kalman 2011).

Mesh models for various grid element numbers.

Axial pressure distributions in the riser for various grid element numbers (Case 1).

References

Azadi, M. 2011. “Multi-Fluid Eulerian Modeling of Limestone Particles’ Elutriation from a Binary Mixture in a Gas-Solid Fluidized Bed.” Journal of Industrial and Engineering Chemistry 17 (2): 229–36, https://doi.org/10.1016/j.jiec.2011.02.011.Search in Google Scholar

Bell, R. A. 2000. “Numerical Modelling of Multi-Particle Flows in Bubbling Gas-Solid Fluidized Beds.” Licentiate thesis, Swinburne University of Technology, Australia.Search in Google Scholar

Chao, Z., Y. Wang, J. P. Jakobsen, M. Fernandino, and H. A. Jakobsen. 2011. “Derivation and Validation of a Binary Multi-Fluid Eulerian Model for Fluidized Beds.” Chemical Engineering Science 66 (16): 3605–16, https://doi.org/10.1016/j.ces.2011.04.027.Search in Google Scholar

Chen, J., W. Yin, S. Wang, G. Yu, J. Li, T. Hu, and F. Lin. 2017. “Modelling of Coal/Biomass Co-Gasification in Internal Circulating Fluidized Bed Using Kinetic Theory of Granular Mixture.” Energy Conversion and Management 148: 506–16, https://doi.org/10.1016/j.enconman.2017.05.080.Search in Google Scholar

Chen, X., J. Wang, and J. Li. 2013. “Coarse Grid Simulation of Heterogeneous Gas-Solid Flow in a CFB Riser with Polydisperse Particles.” Chemical Engineering Journal 234: 173–83, https://doi.org/10.1016/j.cej.2013.08.108.Search in Google Scholar

Dai, Q., C. Chen, and H. Qi. 2015. “A Generalized Drag Law for Heterogeneous Gas-Solid Flows in Fluidized Beds.” Powder Technology 283: 120–7, https://doi.org/10.1016/j.powtec.2015.05.030.Search in Google Scholar

Fan, R., D. L. Marchisio, and R. O. Fox. 2004. “Application of the Direct Quadrature Method of Moments to Polydisperse Gas-Solid Fluidized Beds.” Powder Technology 139 (1): 7–20, https://doi.org/10.1016/j.powtec.2003.10.005.Search in Google Scholar

Gan, J., H. Zhao, A. S. Berrouk, C. Yang, and H. Shan. 2012. “Impact of the Drag Law Formulation on the Predicted Binary-Particle Segregation Patterns in a Gas-Solid Fluidized Bed.” Powder Technology 218: 69–75, https://doi.org/10.1016/j.powtec.2011.11.041.Search in Google Scholar

Gera, D., M. Syamlal, and T. J. O’Brien. 2004. “Hydrodynamics of Particle Segregation in Fluidized Beds.” International Journal of Multiphase Flow 30 (4): 419–28, https://doi.org/10.1016/j.ijmultiphaseflow.2004.01.003.Search in Google Scholar

Gidaspow, D., M. Syamlal, and Y. Seo. 1985. “Hydrodynamics of Fluidization of Single and Binary Size Particles: Super Computer Modelling.” Proceedings of the Fifth Engineering Foundation Conference on Fluidization 5: 1–8.Search in Google Scholar

Lan, B., J. Xu, P. Zhao, Z. Zou, Q. Zhu, and J. Wang. 2020. “Long-Time Coarse-Grained CFD-DEM Simulation of Residence Time Distribution of Polydisperse Particles in a Continuously Operated Multiple-Chamber Fluidized Bed.” Chemical Engineering Science 219: 115599, https://doi.org/10.1016/j.ces.2020.115599.Search in Google Scholar

Lapple, C. E. 1950. “Gravity and Centrifugal Separation.” American Industrial Hygiene Association Quarterly 11: 40–7, https://doi.org/10.1080/00968205009344283.Search in Google Scholar

Liu, Y., P. Huo, X. Li, and H. Qi. 2020. “Numerical Study of Coal Gasification in a Dual-CFB Plant Based on the Generalized Drag Model QC-EMMS.” Fuel Processing Technology 203: 106363, https://doi.org/10.1016/j.fuproc.2020.106363.Search in Google Scholar

Manger, E. 1996. “Modelling and Simulation of Gas-Solids Flow in Curvilinear Coordinates.” Doctoral thesis, Telemark College, Norway.Search in Google Scholar

Murray, J. A., S. Benyahia, P. Metzger, and C. M. Hrenya. 2012. “Continuum Representation of a Continuous Size Distribution of Particles Engaged in Rapid Granular Flow.” Physics of Fluids 24 (8): 083303, https://doi.org/10.1063/1.4744987.Search in Google Scholar

Qin, Z., Q. Zhou, and J. Wang. 2019. “An EMMS Drag Model for Coarse Grid Simulation of Polydisperse Gas–Solid Flow in Circulating Fluidized Bed Risers.” Chemical Engineering Science 207: 358–78, https://doi.org/10.1016/j.ces.2019.06.037.Search in Google Scholar

Rabinovich, E., and H. Kalman. 2011. “Flow Regime Diagram for Vertical Pneumatic Conveying and Fluidized Bed Systems.” Powder Technology 207 (1–3): 119–33, https://doi.org/10.1016/j.powtec.2010.10.017.Search in Google Scholar

Sharma, A., S. Wang, V. Pareek, H. Yang, and D. Zhang. 2015. “Multi-Fluid Reactive Modeling of Fluidized Bed Pyrolysis Process.” Chemical Engineering Science 123: 311–21, https://doi.org/10.1016/j.ces.2014.11.019.Search in Google Scholar

Su, M., H. Zhao, and J. Ma. 2015. “Computational Fluid Dynamics Simulation for Chemical Looping Combustion of Coal in a Dual Circulation Fluidized Bed.” Energy Conversion and Management 105: 1–12, https://doi.org/10.1016/j.enconman.2015.07.042.Search in Google Scholar

Syamlal, M., W. Rogers, and T. J. O’Brien. 1993. MFIX Documentation: Volume1, Theory Guide. Springfield: National Technical Information Service. DOE/METC-9411004, NTIS/DE9400087.10.2172/10145548Search in Google Scholar

Tu, Q., and H. Wang. 2018. “CPFD Study of a Full-Loop Three-Dimensional Pilot-Scale Circulating Fluidized Bed Based on EMMS Drag Model.” Powder Technology 323: 534–47, https://doi.org/10.1016/j.powtec.2017.09.045.Search in Google Scholar

Werther, J., and J. Wein. 1994. “Expansion Behavior of Gas Fluidized Beds in the Turbulent Regime.” AIChE Symposium Series 90: 31–44.Search in Google Scholar

Yang, H., G. Yue, H. Zhang, and J. Lu. 2011. “Updated Design and Operation Experience of CFB Boilers with Energy Saving Process in China.” VGB PowerTech 91 (7): 49–53.Search in Google Scholar

Yue, G., R. Cai, J. Lu, and H. Zhang. 2017. “From a CFB Reactor to a CFB Boiler – The Review of R&D Progress of CFB Coal Combustion Technology in China.” Powder Technology 316: 18–28, https://doi.org/10.1016/j.powtec.2016.10.062.Search in Google Scholar

Zhang, N., B. Lu, W. Wang, and J. Li. 2008. “Virtual Experimentation Through 3D Full-Loop Simulation of a Circulating Fluidized Bed.” Particuology 6 (6): 529–39, https://doi.org/10.1016/j.partic.2008.07.013.Search in Google Scholar

Zhang, N., B. Lu, W. Wang, and J. Li. 2010. “3D CFD Simulation of Hydrodynamics of a 150 MWe Circulating Fluidized Bed Boiler.” Chemical Engineering Journal 162 (2): 821–8, https://doi.org/10.1016/j.cej.2010.06.033.Search in Google Scholar

Zhong, W., A. Yu, G. Zhou, J. Xie, and H. Zhang. 2016. “CFD Simulation of Dense Particulate Reaction System: Approaches, Recent Advances and Applications.” Chemical Engineering Science 140: 16–43, https://doi.org/10.1016/j.ces.2015.09.035.Search in Google Scholar

Zhou, X., L. Cheng, Q. Wang, Z. Luo, and K. Cen. 2012. “Non-Uniform Distribution of Gas-Solid Flow through Six Parallel Cyclones in a CFB System: An Experimental Study.” Particuology 10 (2): 170–5, https://doi.org/10.1016/j.partic.2011.10.006.Search in Google Scholar

© 2021 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Articles

- Tribological characterization of graphene oxide by laser ablation as a grease additive

- Hydro-liquefaction of asphaltene catalyzed by molybdenum-nickel bimetallic catalysts in slurry bed

- Leaching kinetics of copper and valuable metal extraction from copper-cadmium residues of zinc hydrometallurgy by oxidation acid leaching

- Numerical investigation on optimization of wall jet to reduce high temperature corrosion in 660 MW opposed wall fired boiler

- Kinetics of catalytic treatment of coking wastewater (COD, phenol and cyanide) using wet air oxidation

- Controllable oxidation of cyclohexanone to produce sodium adipate in an electrochemical reactor with a Pt NPs/Ti membrane electrode

- Numerical study on key issues in the Eulerian-Eulerian simulation of fluidization with wide particle size distributions

- Dynamics investigation on methane hydrate formation process with combined promotion methods

Articles in the same Issue

- Frontmatter

- Articles

- Tribological characterization of graphene oxide by laser ablation as a grease additive

- Hydro-liquefaction of asphaltene catalyzed by molybdenum-nickel bimetallic catalysts in slurry bed

- Leaching kinetics of copper and valuable metal extraction from copper-cadmium residues of zinc hydrometallurgy by oxidation acid leaching

- Numerical investigation on optimization of wall jet to reduce high temperature corrosion in 660 MW opposed wall fired boiler

- Kinetics of catalytic treatment of coking wastewater (COD, phenol and cyanide) using wet air oxidation

- Controllable oxidation of cyclohexanone to produce sodium adipate in an electrochemical reactor with a Pt NPs/Ti membrane electrode

- Numerical study on key issues in the Eulerian-Eulerian simulation of fluidization with wide particle size distributions

- Dynamics investigation on methane hydrate formation process with combined promotion methods