Abstract

The article describes an experimental investigation of the impact of soiling on the photovoltaic modules in northeastern, Iraq. Over five months, the voltage, current power and energy curves of two identical modules with varying cleaning strategies (one was naturally dusty while the other was cleaned regularly) were measured. The impact of soiling on the daily energy produced as well as rain accumulation and particulate matter concentrations are discussed. The results indicated that no losses occurred during wet seasons, but a considerable decline in performance was found during dry periods owing to soiling. Additionally, it was discovered that soiling has a bigger effect on the maximum power than the short-circuit current. After two dry summer months, the greatest power loss of up to 22% was seen. The daily energy loss due to soiling was determined to be 16% on average. Furthermore, there are four polynomial models that have been drowned in prediction photovoltaic module (voltage, current, power, and energy) degradation due to the accumulation of dust.

Introduction

Soiling is a concept used in solar energy systems to describe the degree of uncleanliness on a particular surface caused by particle deposition, either inorganic or natural (Pescheux, Le Baron, and Raccurt 2019; Polo et al. 2021). Particle deposition reduces the efficacy of solar technology by absorbing and dispersing sunlight on photovoltaic (PV) panels, particularly those situated in dry and semi-arid climatic zones. Incident solar irradiance on the solar array photovoltaic researchers discovered that glass samples can lose up to 5% of their absorption coefficient. Environmental and climatic conditions have a variety of effects on the deposition technique and the number of particles attached to surfaces (Kazmerski et al. 2016; Sayyah, Horenstein, and Mazumder 2014). It is important to mention that neighboring places may have varying soiling grades as a result of the regional delivery of certain anthropogenic particle sources, such as farms, industry, airports, and roadways (Mejia and Kleissl 2013). In terms of local evaluation, soiling deposition might vary seasonally, owing to rainfall inequalities (Conceição et al. 2020) and organic pollutants (Conceição et al. 2018; Styszko et al. 2019). Particles in the air are primarily influenced by local vegetation, meteorological conditions, and seasonality, with the latter two being intrinsically tied (Jaszczur et al. 2019a).

In the existing literature, there has been a rising tendency toward soil modeling. Initially, the majority of models were established by correlating environmental variables such as wind speed and direction, air temperature, relative humidity, and soiling data (Goossens and Van Kerschaever 1999; Pennetta et al. 2016). Subsequently, physical and semi-empirical models have been developed (Jaszczur et al. 2019b). Additional analysis was conducted on PV modules to determine the trade-off between dust deposition and optimal tilt angle (Jaszczur et al. 2018a; Ullah et al. 2019). Song, Liu, and Yang (2021) provide an in-depth analysis of the reported influence of environmental pollution and PV dirtying on solar energy and the technoeconomic performance of PV systems. Both air pollution clearance and soiling have the potential to considerably diminish solar PV power output worldwide, with soiling losses accounting for the majority of the overall power loss throughout most locations, save for very polluted places. Additionally, taking into account natural soiling operations, the influencing aspects of soil such as environmental and dispositional variables are explored, as well as their relationship to dust accumulation on the PV module surface. Moreover, this study examines the effect of eliminating air pollution on surface solar irradiance and solar PV energy output. Yazdani and Yaghoubi (2022) used short-circuit current measurements to assess the amplitude of inaccuracy in forecasting soiling power loss of PV modules; presented simple empirical methods for assessing the effect of dust on PV power generation; and optimized cleaning for an electricity solar power plant. The studies indicate that, on average, soiling short-circuit current loss underestimates real soiling power loss by around 9%, and that this value rises with rising dust concentration. The soiling rate during the first week of dust accumulation was estimated to be 0.27 percent per day, whereas it was 0.13 percent per day during the second week. This result reveals that the logarithmic model is more appropriate than the linear and power relationship models for evaluating the influence of dust on PV modules in the case study. The ideal cleaning duration for a solar farm was determined to be every 6 days. Laarabi et al. (2022) investigated soiling losses on glass samples using mass deposition, transparency, and thickness measurement. The impact of soiling on five separate locations in India was compared to soiling on five locations in Morocco capital area. Two distinct tilt angles (0° and 13°) were utilized, and specimens were monitored over a four-day period. According to the study, mass concentrations in five Indian locations ranged from 0.0323 to 1.4208 g/m2/month, while transmittance losses ranged from 0.3476 to 7.4217 percent/month. Additionally, a new relationship between mass density and absorption coefficient loss resulted in the development of a new, more simplistic model for predicting absorption coefficient loss predicated on mass density; the obtained model encompasses a large number of sites, a variety of tilt angles and directions, and a range of time periods.

Gholami et al. (2022a) conducted a sequential inquiry, comparison, and categorization, accompanied by an in-depth and critical examination of the technology. All of the major diode-based models proposed in the scientific literature were categorised. The design variables of the models and their related extraction techniques were presented and compared in terms of their precision, computational costs, and applicability. To accurately forecast the behavior of a solar panel, the derived parameters under normal test settings must be modified to real environmental conditions, according to a review of the relevant literature. Taking this into consideration, all the implemented alterations in the literature were presented and classified. The examined materials were then evaluated thoroughly to identify research gaps and obstacles. Gholami et al. (2022b) performed a comprehensive literature review on the electrical, thermal, and optical modeling of solar systems for their research. All the major models proposed in the literature to predict the behavior of solar systems were examined. The research conducted a systematic examination, comparison, and categorization, followed by an in-depth and critical evaluation of the current state of the art. For electrical modeling, the diode-based transmission line models were chosen for future analysis. Unknown model parameters, associated parameter extraction and change approaches, and their accuracy, computational cost, and applicability were presented and compared. It was discovered that ignoring the variance in environmental circumstances might result in substantial inaccuracies of up to 17 percent. However, changes such as including dust effects into a model may boost forecast accuracy by up to 35 percent. You et al. (2018) presented a methodology was used to examine the effectiveness and economic losses associated with soiling of solar PV modules in the cities of Tokyo and Doha. Doha loses nearly 80% of its efficiency after a 140 day exposure, whereas Tokyo loses less than 4% after a one-year exposure. Valerino et al. (2020) investigated soiling measuring and a reduced digital microscopic examination system, as well as measurements for mass loading data, glass sample slides for shape soiling effects, and rain and PV temperature monitoring to gain insight into meteorological effects on cleaning and soiling rates. Soiling decreases PV energy generation by 0.37% every day, according to the results. The low-cost digital microscope accurately assessed soiling to within 1% of recorded losses, demonstrating the practicality of this low-cost alternative to costly soiling stations.

Schill, Brachmann, and Koehl (2015) studied, with a 10 min accuracy, the impact of soiling on the usual IV-curve of a PV module. The electrical architecture of the monitoring system comprises of distinct electrical loads for each module, which switch to the highest tracking mode after every IV reading. The findings demonstrated a decline in power output and efficiency over time, which was utilized to analyze the influence of soiling. Within five months, the efficiency fell to 20%. Hammad et al. (2018) provide a geographically focused evaluation of the study that has been undertaken on the impact of dust deposition and temperature changes on PV performance. The article presents models to predict these impacts and a financial technique for determining cleaning periodicity in Jordan. Two models have been created to evaluate the efficiency of PV systems based on experimental data on time in contact with natural dust and ambient temperature. The approach to developing models is discussed, as is a comparison of their accuracy. Additionally, methods for measuring dust deposition losses and, as a result, improving cleaning regularity are described. The models are used to calculate performance parameter losses caused by dust collection and to determine the best cleaning period for the systems. Across the 190 days of the study length, the average efficiency loss owing to dust is 0.76% every day. As a result, energy losses total 10.282 kWh/m2 and economic losses are 3.76 US$/m2. The period considered to have the greatest amount of cleaning is determined to be between 12 and 15 days, depending on the model and duration of exposure period used in the research. Urrejola et al. (2016) examined the impact of soiling on the energy loss of PV panels. In Santiago, Chile, the annual production of solar systems was investigated under exposure time for two years, 2014–2015. Observations found that the performance of PV panels subjected to soiling diminishes daily at a rate between 0.13 and 0.56 percent. The yearly degradation of the array system was found to vary between 1.29 and 1.74 percent for polycrystalline, monocrystalline, and thin film arrays, respectively. Khodakaram-Tafti and Yaghoubi (2020) conducted an experimental investigation into the influence of dust on the performance of solar systems at different tilt angles. Eight PV modules with tilt angles were mounted on the roof of a building for examination. Each pair of modules was put at an identical tilt angle. Each pair of modules had one cleaned every two weeks and the other left in its natural habitat. The modules electrical output and climatic parameters were monitored every minute. The findings indicate that the rates at which PV efficiency degrades according to dust collection are highly dependent on the tilt angle. During the multi period invisitation, a dust storm lowered the estimated daily energy provided by modules tilted at 0°, 15°, 30°, and 45° by 58.2, 27.8, 21.7, and 20.7%, respectively. There was a dust storm a few weeks before that, and in those weeks, the average amount of energy provided by PV modules that were collecting dust dropped by 8.6% each day, and by 0.8% for other tilted modules. Malvoni et al. (2017) conducted a performance analysis of a 960 kWp PV system in southern Italy. The energy output monthly average, losses, and efficiency are calculated using monitoring data collected over a 43 month period. The performance and generation capacity were 84.4 and 15.6%, respectively. During the whole year, the efficiency of each module was 15.3%, and the efficiency of the whole system was 14.95, with a loss of 0.6 and 0.1 h per day, respectively. Kazem and Chaichan (2019) discussed their observations and documentation of meteorological conditions, dust, and contaminants gathered in six cities in northern Oman. The research discovered that dew in the early morning for the majority of the year causes raindrops to combine with deposited salts, generating cohesive coatings that are difficult to remove, particularly in the slots within the panels. The research indicated that cleaning the PV panels in the evening would prevent the creation of this layer and keep output losses to a minimum.

The wind influences the performance of PV modules. If the wind is blowing in the direction of the PV modules, the passage of air will clear some of the dust particles that have gathered on them. On the other hand, dust that rises in the air as a result of the wind very tiny diameters will stay stuck in the air and will deposit and collect on the surface of the PV modules when the wind speed decreases. Wind speeds of more than 3 m/s induce dust and sand accumulation, decreasing the amount of solar energy reaching the PV cells and hence their production (Jaszczur et al. 2018b). Ceran et al. (2021) discovered that in such circumstances, the quantity of dust collected was more than the amount eliminated, indicating a high dust concentration. Wind speed enhances the conditioning of the PV modules and lowers their temperatures. Additionally, it decreases the relative humidity of the air, minimizing its destruction. Jaszczur et al. (2019c) and Hassan (2021) established that the key conditions for the buildup of enormous quantities of dust on the PV modules are an average annual wind velocity of more than 4 m/s and a humidity of less than 50%, to address the considerable overlap in external variables causing dust buildup on PV modules. Fountoukis et al. (2018) examined the dust-induced average electricity yield reduction of PV in a dry environment using both experimental and modeling data. For one year span (1 May 2015–1 May 2016), data on PV energy output, solar radiation, environmental particulates, and climatic conditions were gathered in Doha, Qatar. The results indicate a weak association between measured PM concentrations for particles with sizes up to 10 m (PM10) and daily energy production changes. The conclusions of the modeling indicate that the environmental PM intensity, even for particles bigger than 10 m, is an astonishingly poor predictor of average electricity yield loss. The horizontal settling of dust is a prototype characteristic that isn’t very closely linked to the rate at which PV get dirty.

This accumulative dust should be emphasised that many of the elements impacting dust formation cannot be totally controlled. In order to obtain optimal solar irradaince throughout the year, for instance, the installation tilt is often adjusted at the same angle as the location latitude. Moreover, solar collectors and PV panels are commonly oriented southward in the northern hemisphere. Additionally, wind and precipitation conditions depends on the climate and cannot be regulated. To tackle this issue, measurements were done under identical circumstances for clean and dirty modules and samples. This indicates that the sole difference between the clean and dirty modules was the quantity of dust on their surfaces. In this manner, the influence of other climatic parameters, such as relative humidity and temperature, will be reduced, and the variation in the performance of the panels will be attributed only to dust collection.

The following points can be emphasized based on the literature review:

Exposure to external circumstances produces the collection of dust, which degrades the generated energy in proportions that vary depending to the duration of exposure and the geographic location.

Other meteorological factors, including sun irradiance, relative humidity, and temperature, could aid in enhancing the influence of dust on production losses.

The degradation of the performance of a PV module is dependent on the dust ingredients, which vary based on geographic location and adjacent human activities.

The deposition of ash from the combustion of fossil fuels on the PV module surface causes the greatest yield losses.

The tilt angle of the PV module has a significant impact on the amount of collected dust.

On the basis of the previous literature review and conversation, it has been determined that dust affects the PV module, and its influence differs from area to area based on the dust constituents. The impact of dust on the PV module also differs based on the module type and technology. The purpose of this research is to conduct an experiment to determine the effect of dust particles on the performance of two PV modules monocrystalline materials with the same rating were used. First, dust elements are utilized to examine the performance decrease of PV modules in one site of Iraq has been chosen to gather dust for six months in preparation for interior trials. The primary constituents of the accumulated dust were identified, and their effects on the PV module were investigated independently. The novelty of this research allow to establish the optimal type of PV module for each of the analyzed locations. In addition, to allow the determination of cleaning methodology that necessary with the time interval between cleanings. In this the emphasis is on obtaining correct practical outcomes for the usage of PV modules in the examined locations while avoiding dust from interfering with the efficiency of these units. This research observations will make it simpler for decision-makers to adjust their orientations when selecting PV systems for deployment in the locations under consideration. In addition, it will include the price of after-sales services, including the cost of cleaning the units.

Exparemental test procedure

To satisfy the goals of the study, the functioning of two identical PV modules placed at the University of Diyala, Mechanical Engineering Department, was tested and studied for five months, from December 01 to April 30, 2022, to account for both rainy and dry seasons. Diyala is a city in north-eastern Iraq with latitude and longitude of 33.7733° N and 45.1495° E. The two investigated PV modules tybe Sunceco (Monocrystalline, Sunceco PV Module) were positioned at the annual optimum tilt angle for the selected site (30) towards the south, while module output, power, voltage, and current were connected with the data logger and charged individual batteries.

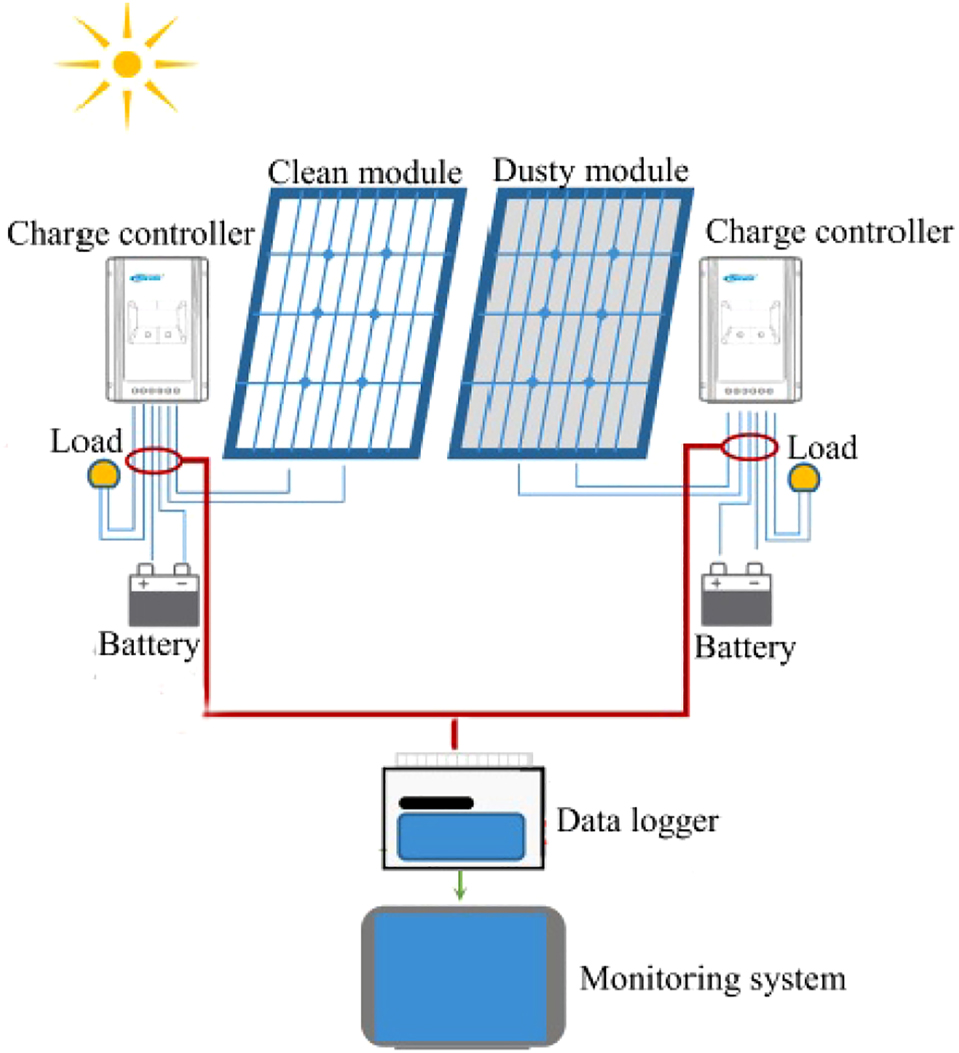

To assess soiling-related losses, one of the modules in each pair was cleaned daily, while the other was left to collect dust naturally. Clean and dirty PV modules were both tested in the same way, so this method cut down on the effect of spectrum irradiance distributions and temperature changes on assessing and measuring soiling loss (Hassan et al. 2022a; Hassan et al. 2022b). It is worth noting here that the production of dew on the surface of PV modules and the difference in wind velocity between clean and dusty modules may add to the error in calculating soiling losses. However, the former aspect was irrelevant in our study owing to the fact that the environment in the analyzed region was not conducive to dew development and the comparison module was cleaned on a frequent basis. Additionally, to mitigate the impact of wind, clean and dusty modules were positioned in close proximity to one another. The statistics on precipitation were gathered from the closest weather stations to the test location. The rain occurrences recorded were genuine based on location measurements and the pattern of soiling loss. Figures 1 and 2 illustrates the experimental setup schematically, and Table 1 shows the selected module technology.

Layout of the PV modules utilized in the experiment.

The experimental modules and controller.

Specifications of PV modules at the standard condition (Fountoukis et al. 2018).

| Model | Rated power |

|---|---|

| Rated peak power (Pmax) | 150 W (peak) |

| Rated current (Imp) | 8.31 |

| Rated voltage (Vmpp) | 18.10 V |

| Short circuit current (Isc) | 8.72 A |

| Open circuit voltage (Voc) | 22.50 V |

| Module efficiency (%) | 20% |

Collecting dust and testing procedure

As stated before, two PV modules were used in the experiment. None were cleaned during the duration of the experiment. Each module’s daily supply of energy was determined by measuring its dusty available energy. The information presented in this study is the mean of these two sets of data. Two reference modules were also used during the investigation. The criterion chosen was the first one. Dust-free output data, including power, energy, current, and voltage, was collected from the dust-free panels by physically cleaning this module each day before measurement. For the manual cleaning, a sodium-based surfactant and alcohol were used. The equipment associated with organizational was used throughout the trial without being cleaned. From this, the requisite output data of the PV modules with dust was collected. In order to assess the I-V characteristics, each clean and dirty cell was electrically coupled to a changing resistance load. The third series was used to determine how much dust had gathered on the panels. To collect dust, glass samples were produced and put on each module surface. As an example, green soda-lime silica window glasses were employed.

PV cell circuit

The input current Iph depicts the current produced by the PV cell, a diode replicates the p-n junction effect, a connected in series Rs, and a shunt resistance rsh. The current–voltage relationship of a PV cell is described as follows (Hassan et al. 2022c):

where Ish denotes the short-circuit current, Id denotes the diode current, Io denotes the current flowing through the diodes whenever a negative voltage is supplied, N denotes the diode ideality ratio, and V denotes the determined voltage (Abbas et al. 2021):

where k denotes the Boltzmann constant, T denotes the cell absolute temperature, and g denotes an electron charge.

In PV nomenclature, series resistance is referred to as ohmic losses. It encompasses all resistances to current densities production caused by incident beam, including circuit, metal connections, and the semiconductor material of the cell. Shunt resistance is a term that refers to the unwanted process of light-generated electron – hole pairs recombinating rather than being washed over the p-n junction and producing energy. This resistance is mostly due to structural flaws in the crystal around the cell borders. Due to the presence of shunt resistance, photons take an alternative route around the joint, which is represented in the circuit model by a short-circuit path. It is self-evident that an effective design of PV cells should reduce resistor in series with the power supply and enhance shunt resistance in parallel with the current generator. It is worth mentioning that series and shunt resistances are not only design-dependent but also vary with irradiation and cell temperature (Hassan 2022).

Ratio of soiling (RS)

In evaluating dust influence on PV performance, outcomes of clean and dusty modules are evaluated based on the measurements of maximum power by computing soiling ratio metric as the given equation (Gholami, Alemrajabi, and Saboonchi 2017a; Gholami, Alemrajabi, and Saboonchi 2017b; Gholami et al. 2018; Gholami et al. 2021):

where the Pd and Pc is the power of clean and dirty modules respectively. The percentage decrease in the dusty module maximum power can determined using the following equation:

Due to the fact that dust decreases sunlight penetration through dirty modules glass, the abovementioned ratio will be less than one. Then, dust level (LD) could be calculated according to the following manner, which indicates the quantity of soiling gathered on dusty module in percentage.

where the Md and Mc is the energy of clean and dirty modules respectively.

Weather data

Figure 3 shows the experimental weather data which has been recorded for the selected period at the weather station located at the Department of mechanical engineering, University of Diyala. The average solar irradiance on a horizontal surface is 124.3 w/m2, the average ambient temperature is 14.2 °C, the average rainfall is 70 mm, and the average wind speed was recorded at 1.2 m/s.

The experimental weather data, solar irradiance (a), ambient temperature (b), rainfall (c), and wind speed (d).

Results and discussion

This section examines the potential variation in power loss between proposed PV modules attributed to dust. The estimated daily voltage, power, and energy loss of a dusty PV module was evaluated and studied for this purpose throughout a five-month testing period, from December 1, 2021, to April 30, 2022. It is worth noting that the average maximum daily temperature of PV modules throughout the investigation was determined to be 68.4 °C. Evidently, at these high working temperatures, the voltage and, thus, the power output of PV modules are dramatically reduced. This occurrence, nevertheless, had no effect on the soiling loss performance measures used for this study because the clean and dusty PV modules had been identical (with identical temperature coefficients) and experienced the same temperature changes, implying that any temperature range between the clean and dusty modules could be attributed to dust impact. Rain has a substantial influence on cleaning PV modules, and so a large number of days without rain is necessary to conduct an accurate and trustworthy examination of the dust effect. Figure 4 shows the variation of the voltage, current, power and energy between the dusty and clean modules for the selected sunny day of February 28, 2022, for which the collected amount of dust on the dusty module is 0.28 g/module. The results showed that the dayly energy drope due to the 0.28 g/mosule by about 20 Wh.

The modules dusty and clean experimental measurements of the voltage, current, power, and energy for the selected day, February 28, 2022.

Figure 5 shows the variation of the voltage, current, power and energy between the dusty and clean modules for the selected cloudy day of March 10, 2022, for which the collected amount of dust on the dusty module is 0.17 g/module. The results showed that the daily energy is similar output for both modules.

The modules both were cleaned experimental measurements of the voltage, current, power, and energy for the selected day, March 10, 2022.

Based on the observed experimental data, the determined dust deposition concentration was between 0.144 and 0.289 g/m2. Figure 6 illustrates the influence of dust accumulation on the moduels performance degradation throughout the months of December–April of 2022. Additionally, there is a fundamental inaccuracy in evaluating module voltage degradation, power degradation, and energy degradation as shown by this figure. For comparable or even larger masses, the impact on moduel efficiency varies from day to day. A polynomial function was identified as perhaps the most acceptable function to construct a practical connection. Due to the very low density of dust accumulation, the range of dust deposition density is quite limited. To increase the model range of applicability, all existing experimental data points were Figure 5 demonstrates a considerable reduction in the derating factor (increased energy loss) as the dust accumulation density rises. The moduel efficiency loss grew polynomially with mass and followed a polynomial pattern. Taking into account all measurement points and confidence intervals, the fitting curves correlation with the data is regarded to be adequately dependable, with an R square of around 0.96 for voltage (see Figure 6(a)), R square of around 0.99 for power (see Figure 6(b)), and R square of around 0.94 for energy (see Figure 6(c)). The presented models are relatively dependent on environmental variables, and once adapted, they may be used in any location to determine the PV energy degradation versus dust density deposited on the module surface.

The average of PV moduel loss (a) voltage, (b) current, (c) power, (d) energy due to the natural dust deposition.

Conclusions

Soiling may be a significant problem for the PV systems globally, growing even more so as the PV sector expands at a breakneck pace. Mitigation methods must be implemented to avoid or mitigate its impacts and must be customized to the unique circumstances and design of each PV site. Additionally, the inherent complexity and variety of soiling make prediction challenging. As a result, it must be regularly checked. Soiling could be determined directly from PV performance information or environmental factors, eliminating the requirement for soiling sensors. The literature has been reviewed in several articels, and the dearth of comparison studies and the resulting necessity for them have been highlighted. The purpose of this article was to explore the influence of dust deposition on the performance of PV modules by continuously monitoring the maximum power of clean and dusty modules in the north-east of Iraq for about five months. Additionally, based on collected data and modeling tools, the ideal cleaning time for a utility-scale PV power plant situated in the Baqubah region was determined. The following conclusions are drawn:

The most effective criteria for determining the appropriate cleaning interval of an energy PV system were found to be variations in weather conditions, which might also have a substantial effect on optimizing the plant cleaning schedule.

While short-circuit current loss is a useful indicator of dust accumulation on PV modules, real power failure under reduced illumination circumstances and high dust concentration levels may be significantly different from the reduction in short-circuit current.

The estimated daily voltage loss from the PV module was about 12% (1.82 Volte), 22% (−47 W) and 16% (−80 Wh) greater than short-circuit current losses throughout the study period.

As with any previous study, the present one necessitates more research in some areas to minimize the issues created by dust deposition on the surfaces of photovoltaic. Since the investigation for this article was conducted over a period of six months, some of the natural events that might impact the density of dust collection may not be taken into account. Therefore, a long-term experiment should be conducted to see if it may result in a more precise connection. In addition, more research may be required to determine the requirement of cleaning or to improve cleaning periodicity.

-

Author contributions: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: None declared.

-

Conflict of interest statement: The authors declare no conflicts of interest regarding this article.

References

Abbas, M. K., Q. Hassan, M. Jaszczur, Z. S. Al-Sagar, A. N. Hussain, A. Hasan, and A. Mohamad. 2021. “Energy Visibility of a Modeled Photovoltaic/diesel Generator Set Connected to the Grid.” Energy Harvesting and Systems 9 (1): 27–38, doi:https://doi.org/10.1515/ehs-2021-0022Search in Google Scholar

Ceran, B., A. Mielcarek, Q. Hassan, J. Teneta, and M. Jaszczur. 2021. “Aging Effects on Modelling and Operation of a Photovoltaic System with Hydrogen Storage.” Applied Energy 297: 117161, https://doi.org/10.1016/j.apenergy.2021.117161.Search in Google Scholar

Conceição, R., H. G. Silva, J. Mirão, and M. Collares-Pereira. 2018. “Organic Soiling: the Role of Pollen in PV Module Performance Degradation.” Energies 11 (2): 294, https://doi.org/10.3390/en11020294.Search in Google Scholar

Conceição, R., I. Vázquez, L. Fialho, and D. García. 2020. “Soiling and Rainfall Effect on PV Technology in Rural Southern Europe.” Renewable Energy 156: 743–7, https://doi.org/10.1016/j.renene.2020.04.119.Search in Google Scholar

Fountoukis, C., B. Figgis, L. Ackermann, and M. A. Ayoub. 2018. “Effects of Atmospheric Dust Deposition on Solar PV Energy Production in a Desert Environment.” Solar Energy 164: 94–100, https://doi.org/10.1016/j.solener.2018.02.010.Search in Google Scholar

Gholami, A., A. A. Alemrajabi, and A. Saboonchi. 2017a. “Experimental Study of Self-Cleaning Property of Titanium Dioxide and Nanospray Coatings in Solar Applications.” Solar Energy 157: 559–65, https://doi.org/10.1016/j.solener.2017.08.075.Search in Google Scholar

Gholami, A., A. Saboonchi, and A. A. Alemrajabi. 2017b. “Experimental Study of Factors Affecting Dust Accumulation and Their Effects on the Transmission Coefficient of Glass for Solar Applications.” Renewable Energy 112: 466–73, https://doi.org/10.1016/j.renene.2017.05.050.Search in Google Scholar

Gholami, A., I. Khazaee, S. Eslami, M. Zandi, and E. Akrami. 2018. “Experimental Investigation of Dust Deposition Effects on Photo-Voltaic Output Performance.” Solar Energy 159: 346–52, https://doi.org/10.1016/j.solener.2017.11.010.Search in Google Scholar

Gholami, A., M. Ameri, M. Zandi, and R. G. Ghoachani. 2021. “A Single-Diode Model for Photovoltaic Panels in Variable Environmental Conditions: Investigating Dust Impacts with Experimental Evaluation.” Sustainable Energy Technologies and Assessments 47: 101392, https://doi.org/10.1016/j.seta.2021.101392.Search in Google Scholar

Gholami, A., M. Ameri, M. Zandi, R. G. Ghoachani, S. Pierfederici, and H. A. Kazem. 2022a. “Step-By-Step Guide to Model Photovoltaic Panels: An Up-To-Date Comparative Review Study.” IEEE Journal of Photovoltaics, https://doi.org/10.1109/jphotov.2022.3169525.Search in Google Scholar

Gholami, A., M. Ameri, M. Zandi, and R. G. Ghoachani. 2022b. “Electrical, Thermal and Optical Modeling of Photovoltaic Systems: Step-by-step Guide and Comparative Review Study.” Sustainable Energy Technologies and Assessments 49: 101711, https://doi.org/10.1016/j.seta.2021.101711.Search in Google Scholar

Goossens, D., and E. Van Kerschaever. 1999. “Aeolian Dust Deposition on Photovoltaic Solar Cells: the Effects of Wind Velocity and Airborne Dust Concentration on Cell Performance.” Solar Energy 66 (4): 277–89, https://doi.org/10.1016/s0038-092x(99)00028-6.Search in Google Scholar

Hammad, B., M. Al–Abed, A. Al–Ghandoor, A. Al–Sardeah, and A. Al–Bashir. 2018. “Modeling and Analysis of Dust and Temperature Effects on Photovoltaic Systems’ Performance and Optimal Cleaning Frequency: Jordan Case Study.” Renewable and Sustainable Energy Reviews 82: 2218–34, https://doi.org/10.1016/j.rser.2017.08.070.Search in Google Scholar

Hassan, Q. 2021. “Assessing of Renewable Energy for Electrical Household Ancillary Based on Photovoltaics and Wind Turbines.” In IOP Conference Series: Materials Science and Engineering, Vol. 1076, No. 1, 012006: IOP Publishing.10.1088/1757-899X/1076/1/012006Search in Google Scholar

Hassan, Q. 2022. “Evaluate the Adequacy of Self-Consumption for Sizing Photovoltaic System.” Energy Reports 8: 239–54, https://doi.org/10.1016/j.egyr.2021.11.205.Search in Google Scholar

Hassan, Q., M. Jaszczur, J. Teneta, M. K. Abbas, A. Hasan, and A. K. Al-Jiboory. 2022a. “Experimental Investigation for the Estimation of the Intensity of Solar Irradiance on Oblique Surfaces by Means of Various Models.” In Energy Harvesting and Systems. Article in press.10.1515/ehs-2021-0087Search in Google Scholar

Hassan, Q., M. Jaszczur, A. K. Al-Jiboory, A. Hasan, and A. Mohamad. 2022b. “Optimizing of Hybrid Renewable Photovoltaic/wind Turbine/super Capacitor for Improving Self-Sustainability.” In Energy Harvesting and Systems. Article in press.10.1515/ehs-2021-0095Search in Google Scholar

Hassan, Q., M. Jaszczur, S. A. Hafedh, M. K. Abbas, A. M. Abdulateef, A. Hasan, J. Abdulateef, and A. Mohamad. 2022c. “Optimizing a Microgrid Photovoltaic-Fuel Cell Energy System at the Highest Renewable Fraction.” International Journal of Hydrogen Energy 47 (28): 13710–31, https://doi.org/10.1016/j.ijhydene.2022.02.108.Search in Google Scholar

Jaszczur, M., Q. Hassan, J. Teneta, K. Styszko, W. Nawrot, and R. Hanus. 2018a. “Study of Dust Deposition and Temperature Impact on Solar Photovoltaic Module.” In MATEC Web of Conferences, Vol. 240, 04005: EDP Sciences.10.1051/matecconf/201824004005Search in Google Scholar

Jaszczur, M., Q. Hassan, J. Teneta, E. Majewska, and M. Zych. 2018b. “An Analysis of Temperature Distribution in Solar Photovoltaic Module under Various Environmental Conditions.” In MATEC Web of Conferences, Vol. 240, 04004: EDP Sciences.10.1051/matecconf/201824004004Search in Google Scholar

Jaszczur, M., J. Teneta, K. Styszko, Q. Hassan, P. Burzyńska, E. Marcinek, and N. Łopian. 2019a. “The Field Experiments and Model of the Natural Dust Deposition Effects on Photovoltaic Module Efficiency.” Environmental Science and Pollution Research 26 (9): 8402–17, https://doi.org/10.1007/s11356-018-1970-x.Search in Google Scholar PubMed PubMed Central

Jaszczur, M., Q. Hassan, K. Styszko, and J. Teneta. 2019b. “Impact of Dust and Temperature on Energy Conversion Process in Photovoltaic Module.” Thermal Science 23 (Suppl. 4): 1199–210, https://doi.org/10.2298/tsci19s4199j.Search in Google Scholar

Jaszczur, M., Q. Hassan, H. N. Al-Anbagi, and P. Palej. 2019c. “A Numerical Analysis of a HYBRID PV+ WT Power System.” In E3S Web of Conferences, Vol. 128, 05001: EDP Sciences.10.1051/e3sconf/201912805001Search in Google Scholar

Kazem, H. A., and M. T. Chaichan. 2019. “The Effect of Dust Accumulation and Cleaning Methods on PV Panels’ Outcomes Based on an Experimental Study of Six Locations in Northern Oman.” Solar Energy 187: 30–8, https://doi.org/10.1016/j.solener.2019.05.036.Search in Google Scholar

Kazmerski, L. L., A. S. A. Diniz, C. B. Maia, M. M. Viana, S. C. Costa, P. P. Brito, C. D. Campos, S. de Morais Hanriot, and L. R. de Oliveira Cruz. 2016. “Soiling Particle Interactions on PV Modules: Surface and Inter-particle Adhesion and Chemistry Effects.” In 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), 1714–7: IEEE.10.1109/PVSC.2016.7749916Search in Google Scholar

Khodakaram-Tafti, A., and M. Yaghoubi. 2020. “Experimental Study on the Effect of Dust Deposition on Photovoltaic Performance at Various Tilts in Semi-arid Environment.” Sustainable Energy Technologies and Assessments 42: 100822, https://doi.org/10.1016/j.seta.2020.100822.Search in Google Scholar

Laarabi, B., S. Sankarkumar, N. Rajasekar, Y. El Baqqal, and A. Barhdadi. 2022. “Modeling Investigation of Soiling Effect on Solar Photovoltaic Systems: New Findings.” Sustainable Energy Technologies and Assessments 52: 102126, https://doi.org/10.1016/j.seta.2022.102126.Search in Google Scholar

Malvoni, M., A. Leggieri, G. Maggiotto, P. M. Congedo, and M. G. De Giorgi. 2017. “Long Term Performance, Losses and Efficiency Analysis of a 960 kWP Photovoltaic System in the Mediterranean Climate.” Energy Conversion and Management 145: 169–81, https://doi.org/10.1016/j.enconman.2017.04.075.Search in Google Scholar

Mejia, F. A., and J. Kleissl. 2013. “Soiling Losses for Solar Photovoltaic Systems in California.” Solar Energy 95: 357–63, https://doi.org/10.1016/j.solener.2013.06.028.Search in Google Scholar

Monocrystalline, Sunceco PV Module online. https://sunceco.com/ (accessed June 01, 2022).Search in Google Scholar

Pennetta, S., S. Yu, P. Borghesani, M. Cholette, J. Barry, and Z. Guan. 2016. “An Investigation on Factors Influencing Dust Accumulation on CSP Mirrors.” AIP Conference Proceedings 1734 (1): 070024.10.1063/1.4949171Search in Google Scholar

Pescheux, A. C., E. Le Baron, and O. Raccurt. 2019. “Characterization of Different Moroccan Sands to Explain Their Potential Negative Impacts on CSP Solar Mirrors.” Solar Energy 194: 959–68, https://doi.org/10.1016/j.solener.2019.11.020.Search in Google Scholar

Polo, J., N. Martín-Chivelet, C. Sanz-Saiz, J. Alonso-Montesinos, G. López, M. Alonso-Abella, F. J. Battles, A. Marzo, and N. Hanrieder. 2021. “Modeling Soiling Losses for Rooftop PV Systems in Suburban Areas with Nearby Forest in Madrid.” Renewable Energy 178: 420–8, https://doi.org/10.1016/j.renene.2021.06.085.Search in Google Scholar

Sayyah, A., M. N. Horenstein, and M. K. Mazumder. 2014. “Energy Yield Loss Caused by Dust Deposition on Photovoltaic Panels.” Solar Energy 107: 576–604, https://doi.org/10.1016/j.solener.2014.05.030.Search in Google Scholar

Schill, C., S. Brachmann, and M. Koehl. 2015. “Impact of Soiling on IV-Curves and Efficiency of PV-Modules.” Solar Energy 112: 259–62, https://doi.org/10.1016/j.solener.2014.12.003.Search in Google Scholar

Song, Z., J. Liu, and H. Yang. 2021. “Air Pollution and Soiling Implications for Solar Photovoltaic Power Generation: A Comprehensive Review.” Applied Energy 298: 117247, https://doi.org/10.1016/j.apenergy.2021.117247.Search in Google Scholar

Styszko, K., M. Jaszczur, J. Teneta, Q. Hassan, P. Burzyńska, E. Marcinek, N. Łopian, and L. Samek. 2019. “An Analysis of the Dust Deposition on Solar Photovoltaic Modules.” Environmental Science and Pollution Research 26 (9): 8393–401, https://doi.org/10.1007/s11356-018-1847-z.Search in Google Scholar PubMed PubMed Central

Ullah, A., H. Imran, Z. Maqsood, and N. Z. Butt. 2019. “Investigation of Optimal Tilt Angles and Effects of Soiling on PV Energy Production in Pakistan.” Renewable Energy 139: 830–43, https://doi.org/10.1016/j.renene.2019.02.114.Search in Google Scholar

Urrejola, E., J. Antonanzas, P. Ayala, M. Salgado, G. Ramírez-Sagner, C. Cortés, A. Pino, and R. Escobar. 2016. “Effect of Soiling and Sunlight Exposure on the Performance Ratio of Photovoltaic Technologies in Santiago, Chile.” Energy Conversion and Management 114: 338–47, https://doi.org/10.1016/j.enconman.2016.02.016.Search in Google Scholar

Valerino, M., M. Bergin, C. Ghoroi, A. Ratnaparkhi, and G. P. Smestad. 2020. “Low-cost Solar PV Soiling Sensor Validation and Size Resolved Soiling Impacts: A Comprehensive Field Study in Western India.” Solar Energy 204: 307–15, https://doi.org/10.1016/j.solener.2020.03.118.Search in Google Scholar

Yazdani, H., and M. Yaghoubi. 2022. “Dust Deposition Effect on Photovoltaic Modules Performance and Optimization of Cleaning Period: A Combined Experimental–Numerical Study.” Sustainable Energy Technologies and Assessments 51: 101946, https://doi.org/10.1016/j.seta.2021.101946.Search in Google Scholar

You, S., Y. J. Lim, Y. Dai, and C. H. Wang. 2018. “On the Temporal Modelling of Solar Photovoltaic Soiling: Energy and Economic Impacts in Seven Cities.” Applied Energy 228: 1136–46, https://doi.org/10.1016/j.apenergy.2018.07.020.Search in Google Scholar

© 2022 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Review

- A comprehensive review on electric vehicles: charging and control techniques, electric vehicle-grid integration

- Research Articles

- Evaluation of parameters influencing the performance of photovoltaic-thermoelectric (PV-TE) hybrid system

- Dispatchable power supply from beam down solar point concentrator coupled to thermal energy storage and a Stirling engine

- Modelling, design and parametric analysis of a levitation based energy harvester

- Performance optimization of flywheel using experimental design approach

- Assessment and optimization of photovoltaic systems at the University Ibn Tofail according to the new law on renewable energy in Morocco using HOMER Pro

- Optimizing hybrid power system at highest sustainability

- Preparation of Na2HPO4⋅12H2O-based composite PCM and its application in air insulated box

- The efficiency of linear electromagnetic vibration-based energy harvester at resistive, capacitive and inductive loads

- A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Experimental investigation of soiling effects on the photovoltaic modules energy generation

- Frequency domain analysis of a piezoelectric energy harvester with impedance matching network

Articles in the same Issue

- Frontmatter

- Review

- A comprehensive review on electric vehicles: charging and control techniques, electric vehicle-grid integration

- Research Articles

- Evaluation of parameters influencing the performance of photovoltaic-thermoelectric (PV-TE) hybrid system

- Dispatchable power supply from beam down solar point concentrator coupled to thermal energy storage and a Stirling engine

- Modelling, design and parametric analysis of a levitation based energy harvester

- Performance optimization of flywheel using experimental design approach

- Assessment and optimization of photovoltaic systems at the University Ibn Tofail according to the new law on renewable energy in Morocco using HOMER Pro

- Optimizing hybrid power system at highest sustainability

- Preparation of Na2HPO4⋅12H2O-based composite PCM and its application in air insulated box

- The efficiency of linear electromagnetic vibration-based energy harvester at resistive, capacitive and inductive loads

- A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Experimental investigation of soiling effects on the photovoltaic modules energy generation

- Frequency domain analysis of a piezoelectric energy harvester with impedance matching network