Abstract

Hydrogen transport by blending hydrogen into natural gas transmission pipelines and by pure-hydrogen pipelines is a prospective mode of energy transmission during the transition to renewables. The risk of hydrogen embrittlement (HE) in pipeline steels must first be quantified to ensure safe pipeline operation. This review provides an overview of HE in pipeline steels. Most pipeline steels have reduced ductility when exposed to hydrogen partial pressures of 100 bar and above. Higher-strength pipeline steels (X80 and X100) have been found to undergo HE at ∼50 bar hydrogen. Hydrogen-induced subcritical crack growth in pipeline steels has not been reported in the literature. There are few articles on HE in pipeline welds, with some indications that the weld is more susceptible to HE, and some indications that it is less. The relationship between hydrogen pressure and absorbed hydrogen concentration has not been evaluated. Gaps in knowledge are identified in the conclusions.

1 Introduction

Hydrogen as an energy vector is an important part of the transition from fossil fuels to renewable energy to reduce greenhouse gases. Hydrogen can facilitate decarbonisation in applications where the exclusive use of electricity is challenging such as steelmaking, transportation and energy storage. The prospective use of hydrogen as an energy vector is known as the hydrogen economy (Atrens et al. 2020; Edwards et al. 2007).

Hydrogen is produced from carbon-based fuels or by the electrolysis of water. In 2015, 96% of hydrogen production used carbon-based fuels in processes such as steam methane reforming and coal gasification, both of which produce carbon dioxide (Dincer and Acar 2015). Currently, hydrogen is mainly used in the cracking of petrochemicals and in ammonia production (COAG Energy Council 2019). A major prospective application for hydrogen is as a renewable energy vector. Electricity generated from renewable sources such as solar and wind can be transformed into hydrogen via electrolysis, allowing the energy to be transported by pipelines, shipped overseas, and stored.

Hydrogen transport by gas transmission pipelines may use existing gas transmission pipelines if it is safe and economical to blend hydrogen into existing streams of natural gas. Suggested mixtures for hydrogen blending into gas transmission pipelines in the initial stages range from 5–20% hydrogen by volume. Hydrogen-methane mixtures have previously been used for domestic purposes such as cooking and heating under the names coal gas and town gas (Melaina et al. 2013).

Hydrogen poses some safety risks. Hydrogen gas burns in air within the combustible limits of 4.1–75% by volume (Ordin 1997). Hydrogen gas is invisible and odourless, necessitating the use of hydrogen detectors to establish the presence of hydrogen. In addition, hydrogen embrittlement (HE) can occur in steels exposed to hydrogen which results in a decrease of the ductility and fracture resistance.

HE was first described in the 1870s (Johnson 1875) and has since been extensively reviewed (Liu and Atrens 2013; Louthan 2008; Lynch 2011a; Nagumo 2016; Ohaeri et al. 2018; Venezuela et al. 2016a). Typically, HE reduces the ductility of the steels, and may alter the fracture mode to a more brittle mode, but often has little influence on strength. HE may also cause subcritical crack growth, which is the propagation of a crack at a stress-intensity factor below the fracture toughness of the steel. Hydrogen-induced subcritical crack growth can lead to delayed failure. Hydrogen can also increase susceptibility to creep and fatigue failure (Louthan 2008). Hydrogen-assisted fracture often has characteristic brittle surface features, such as faceted surfaces due to cracking along grain boundaries or cleavage planes, and ‘fish-eyes’: circular regions of cleavage failure centred around an initial defect in the steel such as an inclusion (Lynch 2011a). HE susceptibility depends upon the properties of the steel. HE susceptibility in steels typically increases with increasing hydrogen concentration, increasing steel strength, decreasing applied strain rate, and tends to a maximum at around room temperature.

Internal hydrogen embrittlement (IHE) is caused by hydrogen pre-existing within the steel, whereas hydrogen-environment embrittlement (HEE) is caused by an environment that induces hydrogen entry into the steel (Jewett et al. 1973; Lee 2016; Lynch 2011a). The HE mechanisms involved in both IHE and HEE are the same, but their study differs due to the source of hydrogen, the time frames before embrittlement occurs, and the initiation sites for hydrogen-induced cracking (Louthan 2008). The occurrence of IHE in service often indicates that hydrogen was introduced by a previous stage in the steel processing, such as high-temperature processing, or by an electrochemical process, such as acid pickling (Lee 2016). This internal hydrogen can initiate cracking on the application of a sufficient stress. In contrast, HEE typically causes cracks to initiate at and propagate from surface defects such as scratches, notches, or other stress concentrators, because (i) the hydrogen content is typically higher at the surface where the hydrogen enters into the steel, and (ii) the stress intensity factor of a surface defect is twice that of an internal defect (Jewett et al. 1973).

Hydrogen can cause damage by mechanisms other than HE, such as high-temperature hydrogen attack (HTHA), blistering, and hydride formation. Hydrides typically do not occur in steels (Louthan 2008). These other mechanisms are not the focus of this review.

HE can occur in alloys of iron, nickel, copper, cobalt, tungsten, molybdenum, and aluminium (Barthélémy 2006; Carter and Cornish 2001; Jewett et al. 1973; Lee 2016; Louthan 2008; Lynch 2011a; Oriani 1978). Among the most susceptible metals are the high-strength martensitic steels (Jewett et al. 1973; Lee 2016; Lynch 2011a). Martensitic steels can undergo delayed fracture at low hydrogen concentrations (less than a part per million by weight). In lower-strength ferritic steels, reports of subcritical crack growth are rare, but hydrogen can reduce the yield strength and ductility (Atrens et al. 2020; Barthélémy 2006). HE is a concern in the safety of gas transmission pipelines transporting hydrogen. This review focuses on HE of the steels used in gas transmission pipelines. The basics of HE are covered first, and then HE of pipeline steels is reviewed in Section 5. Gaps in knowledge are identified in the conclusions.

2 Nature of hydrogen in steels

2.1 Hydrogen entry

Two commons sources of hydrogen absorbed into steels are (i) gaseous hydrogen in steel pressure vessels and (ii) hydrogen produced at the steel surface by a chemical or electrochemical reaction.

Hydrogen gas is used as a fuel in the aerospace industries, as a feedstock in oil refining and in producing chemicals such as ammonia and methanol, and more recently in steelmaking (Lynch 2011a). Steel vessels, casings and pipelines are used widely due to the cost efficiency of steel. In oil and gas wells, steel can be exposed to environments containing hydrogen sulphide (H2S) which produces high amounts of hydrogen and can cause HE (Shadravan and Amani 2019). Gaseous hydrogen is expected to become more widespread due to its use in hydrogen fuel cells, in domestic heating and cooking, and as an energy vector in the hydrogen economy (Edwards et al. 2007).

Exposure to chemically produced hydrogen is often a consequence of some other chemical process. During steelmaking, hydrogen can form by the reaction of moisture with molten steel (Carter and Cornish 2001; Sezgin et al. 2019). A similar reaction can cause hydrogen entry into steel during welding if moisture is present in the air, in welding consumables, on the welding electrodes, or on the steel surfaces (Carter and Cornish 2001; Lee 2016). Hydrogen is produced electrochemically when steel is exposed to acidic solutions, such as those used in pickling, etching, cleaning, phosphating, and paint-stripping. Other electrochemical sources of hydrogen include cathodic protection, electroplating, and aqueous corrosion (Carter and Cornish 2001; Jewett et al. 1973; Lynch 2011a; Venezuela et al. 2016a).

Hydrogen entry into steel from gaseous hydrogen requires dissociation of the hydrogen molecule (H2) into hydrogen atoms. The process consists of three steps: physisorption, chemisorption, and absorption (Barnoush 2009; Oriani 1978).

In physisorption, the hydrogen molecule is drawn to the metal surface by van der Waals forces. The second step, chemisorption, involves the cleavage of the hydrogen molecule into two hydrogen atoms, and results in covalent bonds between adsorbed hydrogen atoms and surface atoms (Barnoush 2009; Christmann 1981). Absorption occurs when the hydrogen atom enters the steel lattice (Barnoush 2009). In iron at room temperature, the rate-limiting step of gaseous hydrogen entry is likely the final absorption step (Oriani 1978). Absorbed hydrogen can escape from steel by the reverse of these three steps.

Electrochemical hydrogen entry occurs by the production of atomic hydrogen at the steel surface by the cathodic partial reaction known as the hydrogen evolution reaction (HER), which can be written as:

The adsorbed hydrogen atoms on the metal surface can either combine with other hydrogen atoms and form hydrogen molecules (which is called desorption or recombination) or be absorbed into the metal.

Some chemical species slow the rate of the recombination of adsorbed hydrogen and result in more hydrogen being absorbed into the steel. These species are called poisons, as they act as poisons for hydrogen recombination and promote hydrogen entry into the steel (Venezuela et al. 2016a). These species include compounds of arsenic, phosphorus, sulphur, antimony, selenium, tellurium and tin, and carbon compounds such as carbon sulphide (CS2), carbon monoxide (CO), cyanide (CN⁻), thiocyanate (CNS⁻), urea (CON2H4), thiourea (CSN2H4), and hydrogen sulphide (H2S) (Barnoush 2009; Berkowitz et al. 1976; Bockris et al. 2001; Venezuela et al. 2016a). Relatively small concentrations are effective in promoting hydrogen entry.

The influence of internal hydrogen depends solely on the hydrogen content in the steel. This means that for IHE, once hydrogen is contained in the steel, the effects are the same regardless of whether the hydrogen was from gaseous hydrogen or from an electrochemical reaction (Atrens et al. 1980; Lee 2016; Liu et al. 2014). HE studies are therefore often conducted using electrochemical hydrogen charging, and the electrochemical hydrogen charging condition can be equated to an equivalent gaseous hydrogen pressure. This topic is discussed more in Section 4.2.

2.2 Hydrogen diffusion

Hydrogen atoms inside the steel randomly jump between interstitial sites in the lattice. This random movement leads to hydrogen diffusion through the crystal lattice according to the hydrogen concentration gradient. The hydrogen flux,

where

As an example, consider a thin sheet of thickness

where

If the subsurface concentration

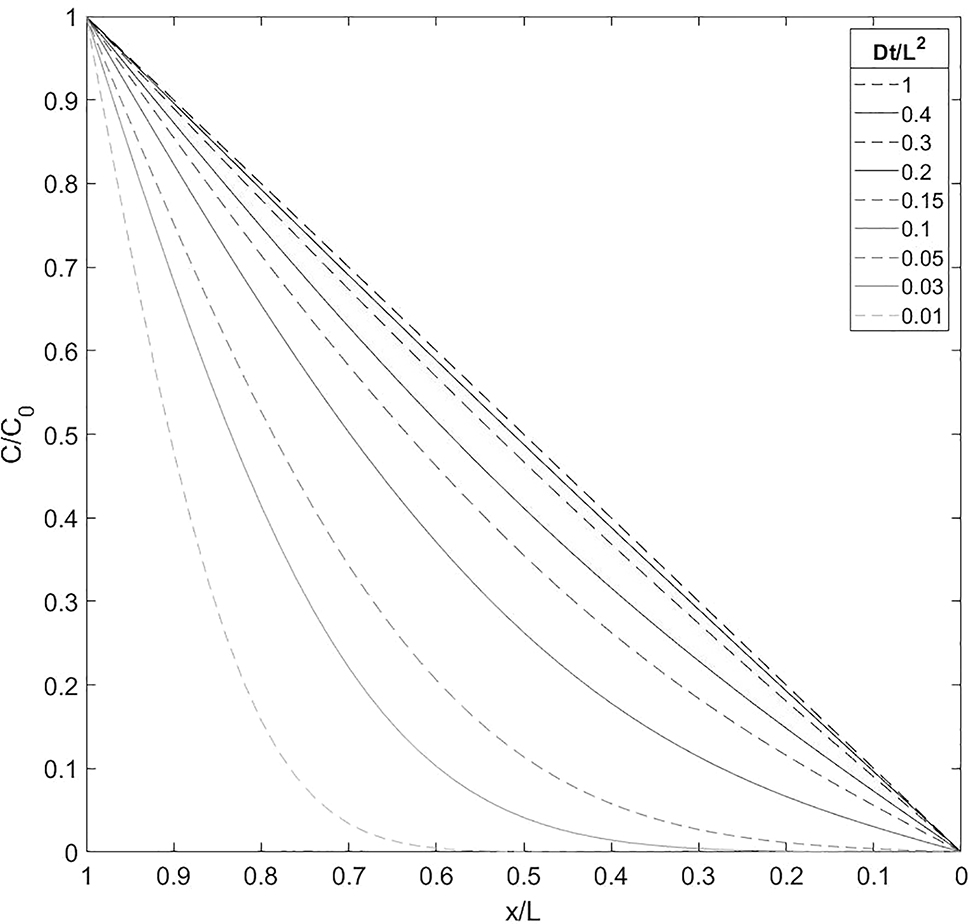

Figure 1 shows the normalised hydrogen concentration evaluated using Equation (5) for different values of the dimensionless time parameter. Once the dimensionless time parameter reaches 0.4, the concentration is close to the steady-state linear distribution.

Diffusive normalised hydrogen concentration across a sheet of infinite width, with hydrogen entering at one surface (

A second example is a cylindrical tensile specimen with an initial uniform concentration

where

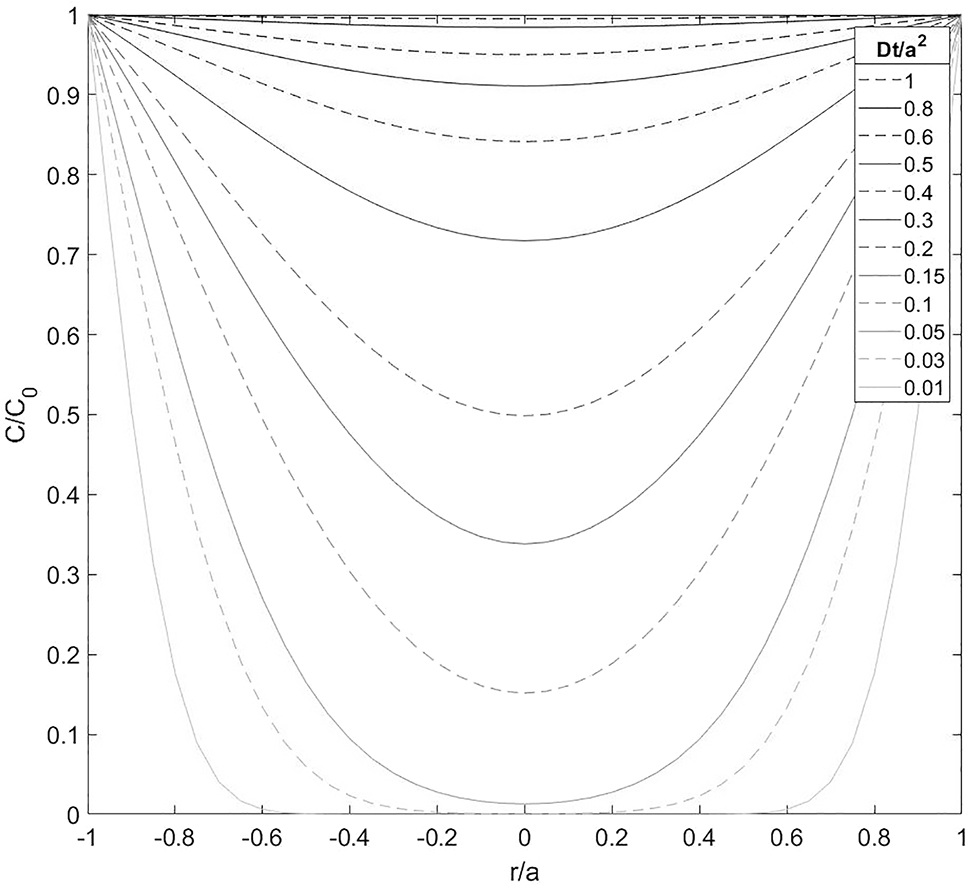

Figure 2 shows the normalised hydrogen concentration (

Diffusive normalised hydrogen concentration across a cross-section of a cylindrical specimen, which initially contains no hydrogen. The specimen is charged with a constant hydrogen fugacity resulting in a constant surface hydrogen concentration (

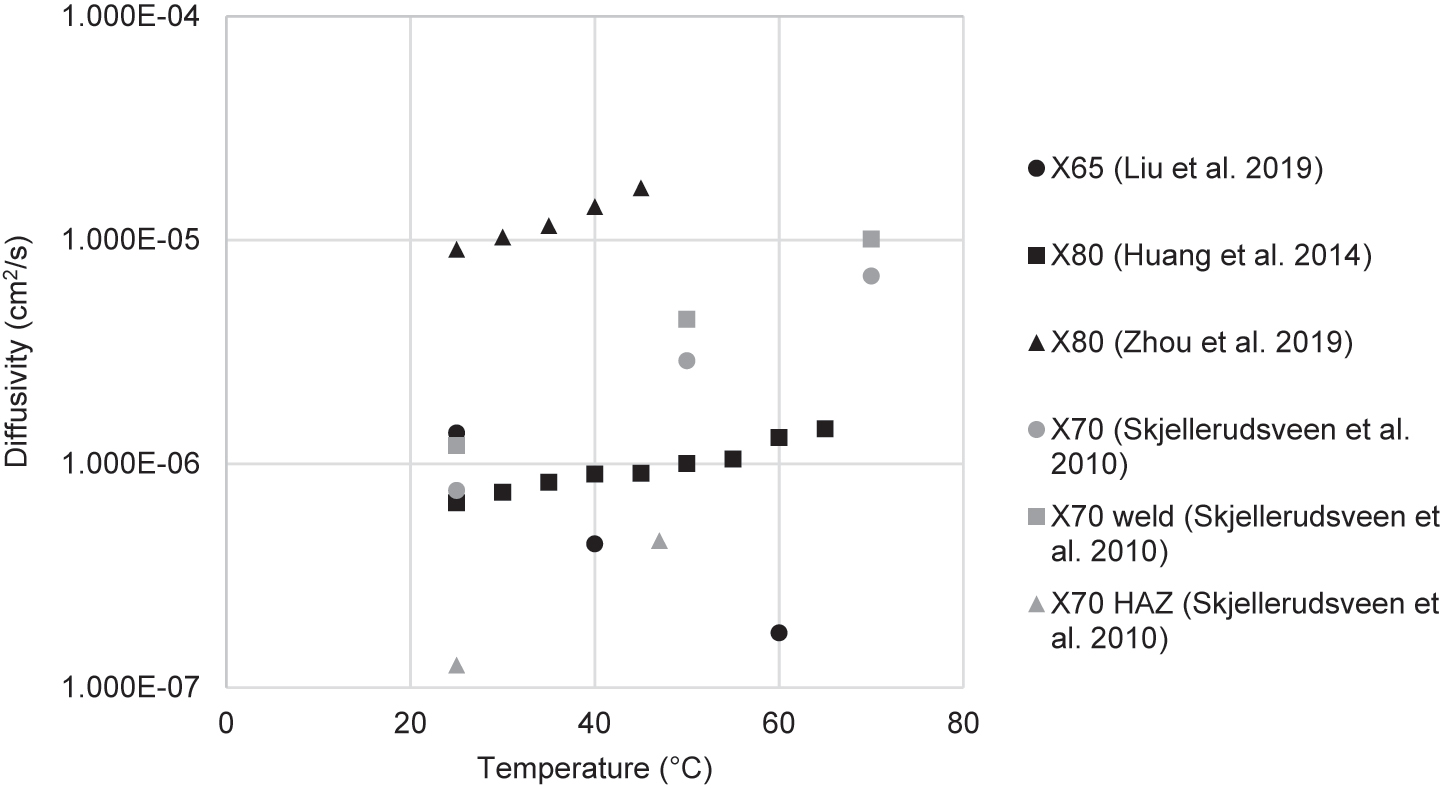

Hydrogen diffusivity varies with material, crystal structure, temperature, and stress (Lynch 2011a). Diffusivity increases with increasing temperature, as hydrogen atoms have greater kinetic energy and can more easily jump between interstitial sites. For a given material, the microstructure can also lead to variation in the diffusivity, especially in materials with complex microstructures. Ferritic steels, for example, have diffusivities that span 3 to 4 orders of magnitude at room temperature (Lynch 2011a). This is attributed to differences in hydrogen trap types and densities, which are discussed in greater detail in the following section on hydrogen trapping.

2.3 Hydrogen trapping

Hydrogen atoms are slightly larger than the interstitial sites between iron atoms that they occupy. This strains the lattice surrounding a hydrogen atom. Therefore, hydrogen tends to move to imperfections in the metal where the crystal lattice is slightly expanded (Birnbaum 2003; Louthan 2008). Such imperfections include (i) solute atoms, (ii) vacancies, (iii) boundaries such as grain boundaries and phase boundaries, (iv) dislocations, (v) interstitial sites in the first few atomic layers below free surfaces, (vi) interfaces between precipitates or inclusions and the matrix, (viii) crack tips, and (ix) voids. Hydrogen has a lower-potential energy at these sites, and as a result, these sites are known as traps (Carter and Cornish 2001; Lynch 2011a; Venezuela et al. 2016a). The binding energies of various traps in iron and steels have been tabulated by Ohaeri et al. (2021), Bhadeshia (2016), and Szost et al. (2013).

The average residence time of hydrogen at a trap increases with increasing binding energy. Increasing temperature increases the kinetic energy of the hydrogen atom, increasing the possibility of the hydrogen atom jumping out of the trap. Traps are referred to as irreversible if the binding energy exceeds a threshold binding energy. In irreversible traps, hydrogen atoms remain essentially completely trapped at room temperature.

The diffusivity of hydrogen at room temperature decreases with increasing number of traps and increasing trap strength (Lynch 2011a). Therefore, traps can reduce the degree of HEE by preventing hydrogen accumulation at potential crack initiation sites (Bhadeshia 2016). Some hydrogen traps, however, can also exacerbate HE by (i) accumulating hydrogen at regions of concentrated stress, (ii) by allowing hydrogen to recombine at large voids which causes pressure damage, or (iii) by acting as sources of internal hydrogen after diffusible hydrogen has egressed (Bhadeshia 2016; Lynch 2011a; Venezuela et al. 2016a). For these reasons, the interactions between hydrogen and trap sites often determine the mechanisms and manifestations of HE (Barnoush 2009; Barrera et al. 2018). The effective diffusivity (

2.4 Hydrogen solubility

The hydrogen concentration inside the steel in equilibrium depends on how much hydrogen is available at the surface. For steel exposed to pure gaseous hydrogen, the equilibrium hydrogen concentration in the steel depends on the external hydrogen partial pressure (Barthélémy 2006). If hydrogen trapping is ignored (for example, in pure annealed iron), the hydrogen concentration is related to hydrogen pressure by Sieverts’ law such that the hydrogen concentration,

where

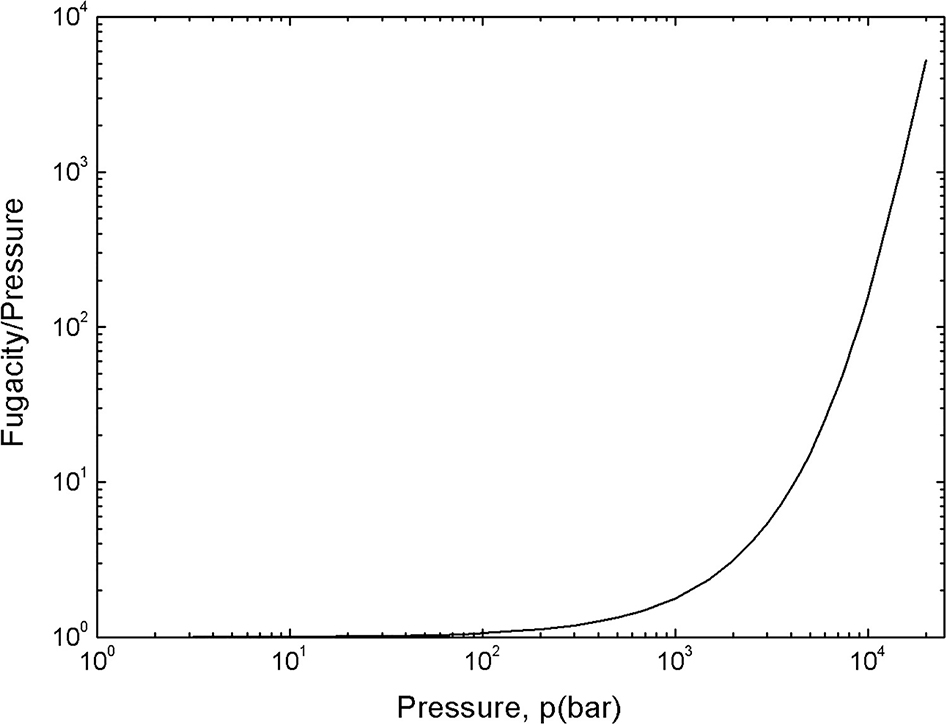

Fugacity/pressure plotted against hydrogen pressure. Reproduced from Venezuela et al. (2018) with permission.

For steels, hydrogen trapping needs to be incorporated into Sieverts’ law (Equation (8)) (Alraeesi and Gardner 2021; Lee 2016; Venezuela et al. 2018) by adding a trapped hydrogen concentration

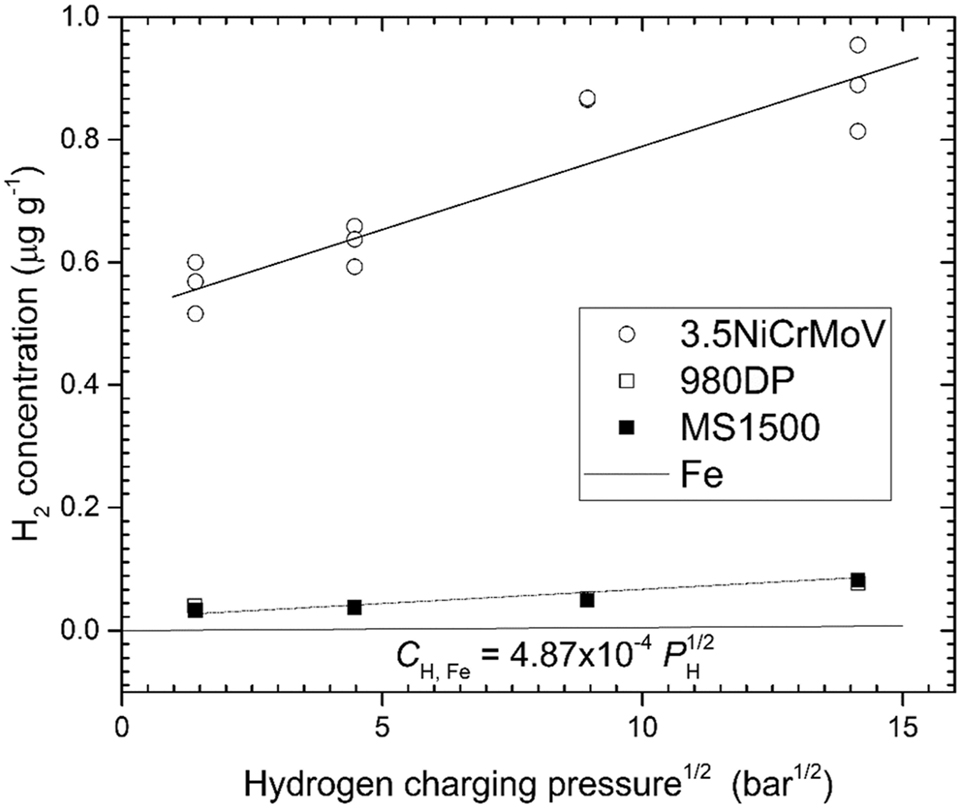

This modified version of Sieverts’ law can be derived using statistical mechanics, as shown by Venezuela et al. (2018). Figure 4 shows the equilibrium hydrogen concentration for gaseous hydrogen charging of a medium-strength steel (3.5NiCrMoV), two advanced high-strength steels (980DP and MS1500) compared with literature data for pure annealed Fe (designated as Fe). The vertical intercepts in Figure 4 represent

The equilibrium hydrogen concentration for gaseous hydrogen charging of a medium-strength steel (3.5NiCrMoV) (Venezuela et al. 2018), two advanced high-strength steels (980DP and MS1500) (Liu et al. 2018; Venezuela et al. 2017) compared with literature data for pure annealed Fe (designated as Fe) (Kiuchi and McLellan 1983). The equilibrium hydrogen concentration was measured using thermal desorption spectroscopy (TDS) and includes hydrogen in traps. Reproduced from Atrens et al. (2022) with permission.

3 HE in steels

3.1 Manifestations of HE

Typical manifestations of HE include a decrease in ductility, a decrease in fracture toughness, subcritical crack growth and altered fracture surfaces. Commonly, hydrogen causes a change from ductile to brittle fracture.

Subcritical crack growth is the propagation of a crack at an applied stress intensity factor below the critical stress intensity factor for the steel (the fracture toughness). Cracks can initiate at hydrogen traps at defects in the steel lattice or surface defects such as scratches (Lee 2016; Louthan 2008; Serebrinsky et al. 2004). The combination of a stress concentrator and hydrogen can lead to localised fracture, extending the crack tip. Hydrogen can then migrate to the new crack tip, and the process can repeat until the crack grows to a critical length whereupon brittle fracture occurs suddenly (Atrens et al. 2020; Louthan 2008; Serebrinsky et al. 2004). Subcritical cracking in the presence of hydrogen can be characterised using the threshold stress

Subcritical crack growth can lead to hydrogen-induced delayed fracture, which occurs when an applied stress (typically below the yield strength) leads to sudden fracture (Bhadeshia 2016; Jewett et al. 1973; Louthan 2008). The degree of HE increases with decreasing strain rate. Delayed fracture is the extreme case at a strain rate of 0, with a constant applied stress (Louthan 2008; Serebrinsky et al. 2004).

In low strength steels, HE appears not to result in subcritical crack growth (Atrens et al. 2020). Hydrogen can, however, decrease mechanical properties, particularly ductility, fracture properties and strength. HE is often characterised using the decrease in reduction-in-area (RA) and elongation (Jewett et al. 1973; Lee 2016; Oriani 1978). In low strength steels the yield strength can be reduced by up to 30% for moderate hydrogen contents (Atrens et al. 2020; Hirth 1980). Hydrogen generally does not affect the modulus of elasticity (Jewett et al. 1973; Lee 2016).

Hydrogen introduces new cracking mechanisms and decreases the fracture toughness of steels. Hydrogen decreases the strength of notched tensile steel specimens (Jewett et al. 1973; Lee 2016). Hydrogen reduces the stress intensity factor required for crack growth (i.e. subcritical crack growth) and larger amounts of hydrogen may also increase the subcritical crack velocity (Barnoush 2009; Louthan 2008). Hydrogen also increases susceptibility to fatigue and creep failure (Jewett et al. 1973; Lee 2016; Louthan 2008). The influence of hydrogen on fatigue depends on the frequency, as a lower frequency results in a lower strain rate which increases susceptibility to HE (Louthan 2008).

HE often changes the appearance of fracture surfaces. However, there is no single fracture mode common to all hydrogen embrittled materials as the fracture varies according to the steel and the environment (Louthan 2008; Oriani 1978). Intergranular fracture – fracture along grain boundaries – is common in hydrogen embrittled high-strength steels (Louthan 2008; Lynch 2011a; Serebrinsky et al. 2004). Intergranular fracture surfaces are bright and faceted, and can be covered in microscopic dimples. For some martensitic steels embrittled by hydrogen, the fracture is transgranular, as in the absence of hydrogen, but the dimples on the fracture surface are smaller and less deep (Lynch 2011a). Iron and low-carbon steels typically undergo ductile fracture without hydrogen, and undergo brittle quasi-cleavage in the presence of hydrogen. Quasi-cleavage is a kind of transgranular fracture, similar in appearance to cleavage but not along any known cleavage plane (Lynch 2011a; Xu and Rana 2008).

Other fractographical features in hydrogen embrittled steel include: (i) many surface cracks on the external surface perpendicular to and near the fracture; (ii) fish-eyes, especially in lower-strength steels, which are small, bright, circular regions of cleavage-like fracture that form during tensile failure, centred around hydrogen traps such as inclusions; and (iii) flakes or shatter cracks, which appear as small shiny regions on the fracture surface and form during solidification (Jewett et al. 1973; Louthan 2008; Lynch 2011a).

3.2 Steel attributes

In general, stronger steels are more susceptible to HE. High-strength martensitic steels are highly susceptible to HE, while lower-strength ferritic steels are less so (Lee 2016; Lynch 2011a). However, many attributes other than strength can influence HE susceptibility, such as microstructure, residual stresses, impurities, and hydrogen traps.

HE in martensitic steels (especially IHE) has been well studied due to (i) the embrittling influence of even small hydrogen concentrations and (ii) the potential for catastrophic delayed failure. In contrast, lower-strength ferritic steels require higher hydrogen concentrations for significant HE. Martensitic steels can undergo significant HE at hydrogen concentrations of ∼0.5 wt ppm, whereas ferritic steels may require hydrogen concentrations of ∼10 wt ppm (Lynch 2011a).

Low strength, stable austenitic steels have low susceptibility to HE (Barthélémy 2006; Lee 2016; Lynch 2011a; Michler et al. 2012). In addition, the austenitic FCC crystal structure has a much lower hydrogen diffusivity and higher hydrogen solubility than ferritic BCC and martensitic BCT structures (Lynch 2011a; Venezuela et al. 2016a). Many of the alloying elements that stabilise austenitic steel, such as nickel, carbon and manganese, have been reported to reduce HE (Barthélémy 2006).

Impurities such as sulphur, phosphorus and oxygen can exacerbate HE (Barthélémy 2006). These impurities can segregate at grain boundaries, weakening them, and large inclusions such as sulphides and oxides can trap enough hydrogen to act as crack initiation or void nucleation sites (Barthélémy 2006; Lynch 2011a). There is also some evidence that the presence of some impurities is necessary for hydrogen to alter the fracture mode by forming localised microvoids (Oriani 1978). The presence of strong hydrogen traps that do not serve as crack initiation sites can reduce HE susceptibility. This can be achieved by the presence of solute atoms, such as chromium, manganese, molybdenum, vanadium, and rare earth metals (Barthélémy 2006; Bhadeshia 2016). Titanium solute atoms trap hydrogen by forming carbides. Aluminium in martensitic steels also reduces HE (Bhadeshia 2016), which may be due to surface aluminium oxides hindering hydrogen entry.

Resistance to HE in steels can also be improved by subsequent processes that affect the microstructure. Heat treatments such as tempering, and normalising and quenching have been found to improve hydrogen resistance (Barthélémy 2006; Bhadeshia 2016). Cold working can create dislocations and internal cracks that may impede hydrogen diffusion (Bhadeshia 2016; Hirth 1980). In addition, component design features have a large influence on susceptibility. For example, stress concentrators can act as crack initiation sites in HEE (Barthélémy 2006).

3.3 Environmental factors

Environmental factors influencing HE include (Barthélémy 2006; Lynch 2011a; Venezuela et al. 2016a):

Hydrogen content

Stress, both applied and residual

Strain rate

Temperature

Surface condition of the steel

Presence of chemicals that facilitate or inhibit hydrogen uptake at the external surface.

3.3.1 Hydrogen concentration

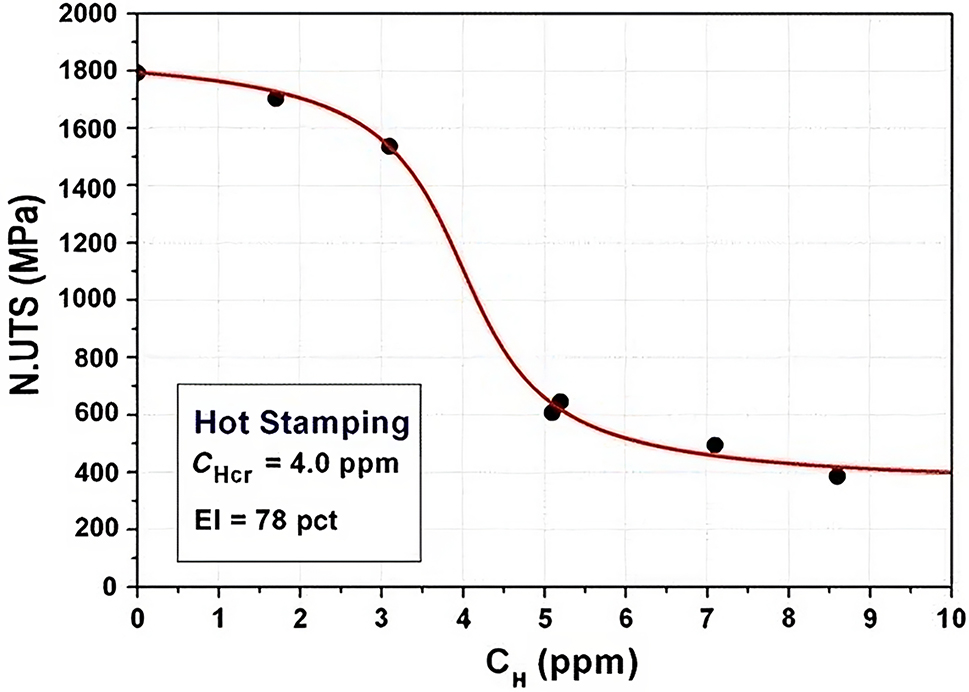

The degree of hydrogen embrittlement increases with increasing hydrogen concentration. Figure 5 shows the notched tensile strength of a typical hot stamping steel against hydrogen concentration. The decrease in the notched tensile strength was accompanied by the change of fracture mode from microvoid coalescence for no hydrogen or for a low hydrogen concentration) to quasi-cleavage (at 2.6 wt ppm) to quasi-cleavage plus intergranular fracture for higher hydrogen concentrations (Lovicu et al. 2012).

Notched tensile strength for a typical hot stamping steel decreased with increasing hydrogen concentration. Reproduced from Lovicu et al. (2012) with permission.

Even though HE generally increases with increasing hydrogen concentration, at high concentrations there exists a saturation point beyond which the effects of HE are relatively constant (Barthélémy 2006; Lynch 2011a). There also exists a similar minimum HE concentration, below which there are few HE effects (Bhadeshia 2016; Louthan 2008; Venezuela et al. 2016a).

3.3.2 Stress

The effects of HE, such as a brittle transition and subcritical cracking, usually require the steel to be stressed (Lee 2016). Without a sufficient applied or residual stress, the effects of hydrogen may be reversible after the hydrogen has egressed, provided that the hydrogen charging process did not cause damage such as blistering (Oriani 1978). Stress gradients, particularly at a crack tip, are also important because they cause hydrogen to accumulate at regions of high stress triaxiality (Barthélémy 2006; Serebrinsky et al. 2004).

3.3.3 Strain rate

The degree of HE increases with decreasing strain rate, in contrast to steel deformation in the absence of hydrogen, where strain rate usually has a relatively small effect on strength and fracture. The lowest strain rate of zero occurs hydrogen delayed fracture, where a constant applied stress below the yield strength can lead to fracture (Louthan 2008). There may be no observable influence of hydrogen above a critical strain rate, at which point the material fractures as it would in an inert environment (Lee 2016; Louthan 2008; Venezuela et al. 2016a).

An explanation for the greater influence of hydrogen at low strain rates is that hydrogen needs time to diffuse to successive regions of concentrated stress as cracking occurs (Lee 2016; Louthan 2008). In addition, HE may involve hydrogen trapped in dislocations, and at high strain-rates hydrogen cannot move as quickly as the dislocations.

3.3.4 Temperature

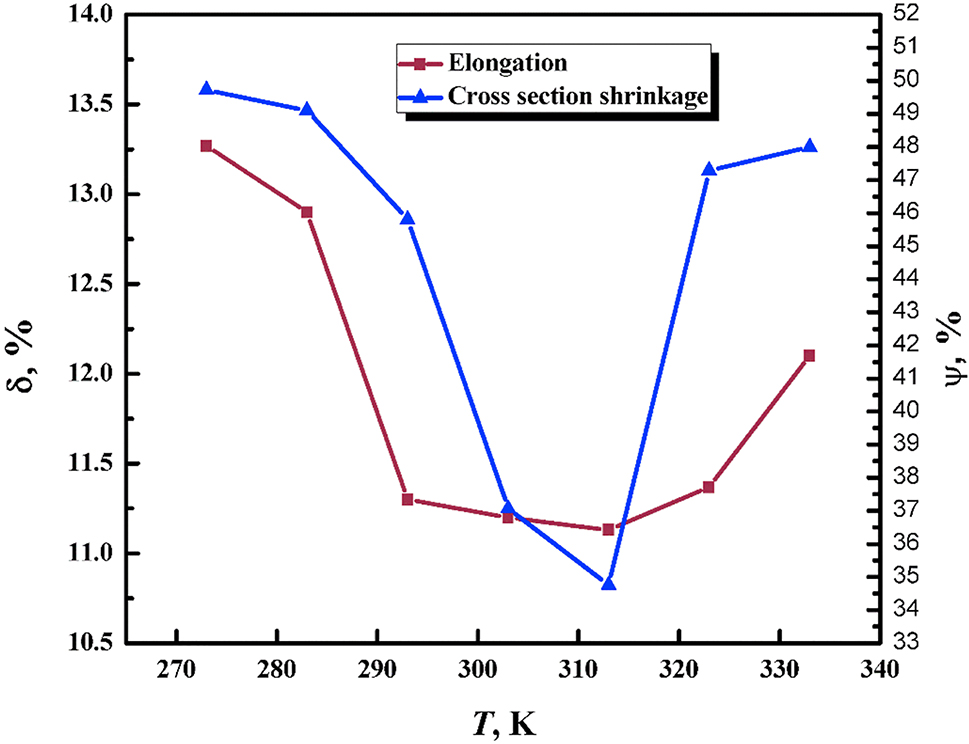

The influence of temperature on HE is associated with two important effects. First, hydrogen mobility increases with temperature, so that there is little hydrogen mobility at sufficiently low temperatures. Second, hydrogen is more likely to accumulate in traps at lower temperatures (Louthan 2008). In any case, there exists an intermediate temperature range over which HE may occur, as shown in Figure 6 for tensile tests carried out by Xing et al. (2021). The maximum HE in steels usually occurs near room temperature (Barthélémy 2006; Lee 2016; Louthan 2008). Above 100 °C HE is often negligible (Barthélémy 2006).

Influence of temperature on HE measured using tensile tests of X90 pipeline steel as measured by reductions in elongation (δ) and RA (Ψ). The hydrogen was charged electrochemically. Reproduced from Xing et al. (2021) with permission.

3.3.5 Surface conditions

A steel surface quickly forms an oxide film when exposed to air. These oxide films can significantly reduce hydrogen adsorption because (Bhadeshia 2016; Louthan 2008) diffusion through these films is greatly reduced. The diffusivities can be twelve orders of magnitude lower than in ferritic steel, so that even thin oxide films can slow hydrogen transport significantly (Bhadeshia 2016). Surface oxides are difficult to use to prevent HE, however, because (i) any scratches or corrosive pits on the surface can provide an entry point for hydrogen, (ii) applied tensile stresses tend to fracture brittle oxides, and (iii) hydrogen tends to reduce surface oxides as the oxides are typically not stable in the presence of hydrogen.

Surface treatments to impede HE can encounter the same issues. HE-reducing surface treatments that have been studied include (i) electroplated cadmium and nickel, which have low hydrogen diffusivities, (ii) black oxides, which reduce diffusion and surface crack nucleation, and (iii) coatings of hard ceramics such as aluminium oxide (Al2O3, aka. alumina), titanium carbide (TiC) and titanium nitride (TiN), which have low diffusivities (Barrera et al. 2018; Bhadeshia 2016).

3.3.6 Hydrogen absorption inhibitors

Certain impurities in hydrogen gas, such as oxygen and water vapour, act as inhibitors to the absorption of hydrogen (Barthélémy 2006; Jewett et al. 1973; Oriani 1978). Oxygen preferentially adsorbs onto the steel surface, decreasing the amount of adsorbed hydrogen. For example, Deimel et al. (1993) found that 19 vol ppm of oxygen was enough to significantly reduce ductility losses due to HE. This indicates that, for vessels with high hydrogen pressures, relatively low oxygen pressures could impede HE.

Other impurities that may also impede HE include carbon monoxide (CO), nitrous oxide (N2O) and sulphur dioxide (SO2) (Barthélémy 2006; Helmi 2016; Lee 2016). In liquid environments where hydrogen evolves electrochemically, other aqueous compounds can inhibit embrittlement, such as nitrites, organic nitrogen compounds, and phosphates (Lee 2016). In contrast, some gaseous impurities have been found to accelerate embrittling effects more than pure hydrogen, including hydrogen sulphide (H2S) and carbon dioxide (CO2) (Lee 2016).

3.4 Mechanisms of HE

Numerous mechanisms have been proposed for the HE of steels. The most popular include hydrogen enhanced local plasticity (HELP), hydrogen enhanced decohesion (HEDE), adsorption-induced dislocation emission (AIDE), hydrogen-enhanced strain-induced vacancy (HESIV), and the defactant concept.

It has also been proposed that in most cases, a combination of mechanisms occurs (Djukic et al. 2019; Lynch 2011a), and that the relative contributions of the various mechanisms vary according to material and environmental factors. HE mechanisms have been the subject of several recent in-depth reviews (Barrera et al. 2018; Birnbaum 2003; Djukic et al. 2019; Lynch 2011a; Robertson et al. 2015).

3.4.1 Hydrogen-enhanced decohesion

Hydrogen-enhanced decohesion (HEDE), also designated hydrogen-induced decohesion (HID) or simply decohesion, proposed that hydrogen lowers the bond strength between metal atoms (Barnoush 2009; Barrera et al. 2018; Lynch 2011a; Oriani 1978; Robertson et al. 2015). Hydrogen accumulated in the stress concentration region at a crack tip lowers the cohesive strength sufficiently to allow localised rupture, and thus crack propagation occurs at a lower stress intensity factor in the presence of hydrogen.

The HEDE theory was developed in 1959 by Troiano (2016) and subsequently by Oriani (1970). Evidence for HEDE has been developed for extremely high-strength steels (Barnoush 2009; Barrera et al. 2018; Birnbaum 2003; Lynch 2011a; Nagumo 2004). Difficulties in finding evidence for HEDE arise because (i) observing at the atomic scale at crack tips within the material is not yet possible and (ii) HEDE cannot be observed macroscopically as it requires high hydrogen concentrations that cannot be reproduced throughout the bulk material due to limited hydrogen solubility (Barrera et al. 2018; Lynch 2011a). Atomic simulations suggest that hydrogen does weaken interatomic bonds (Barrera et al. 2018; Birnbaum 2003; Lynch 2011a), and models based on HEDE have been used to effectively predict some experimental results (Barnoush 2009; Barrera et al. 2018).

Whether the localised stress levels and hydrogen concentrations required for HEDE occur in steels has been a source of controversy (Barnoush 2009; Birnbaum 2003; Lynch 2011a). Smooth intergranular fracture surfaces are sometimes used as evidence for the occurrence of HEDE as other proposed mechanisms should theoretically lead to dimpled fracture surfaces. It is sometimes concluded that HEDE is the dominant mechanism when the hydrogen concentration is high, and that intergranular fractures occur primarily by the HEDE mechanism (Barrera et al. 2018; Birnbaum 2003; Lynch 2011a).

3.4.2 Hydrogen-enhanced local plasticity

Hydrogen-enhanced local plasticity (HELP) proposes that hydrogen facilitates the localised movement of dislocations at a crack tip, causing the crack to propagate. HELP appears to be counterintuitive as increased dislocation motion might be expected to increase ductility. However, the HELP mechanism proposes that the increased plasticity is localised to the crack tip. This leads to crack propagation at stress intensity factors below the fracture toughness, manifesting as reduced macroscopic ductility (Barrera et al. 2018; Birnbaum 2003; Lynch 2011a; Oriani 1978).

Beachem (1972) was the first to suggest that HE occurred because hydrogen facilitated the movement of dislocations, proposing that hydrogen reduced the stress required for the initiation of dislocation movement. The HELP mechanism was based on the observation of ductile features on HE fracture surfaces, such as dimples which are indicative of ductile microvoid-coalescence (Barrera et al. 2018; Lynch 2011a; Robertson et al. 2015). The HELP mechanism was developed further by Birnbaum, Robertson and Sofronis, who provided experimental evidence of increased dislocation motion in the presence of hydrogen in thin iron films (Birnbaum 1989; Birnbaum 2003; Birnbaum et al. 2000). HELP is considered to be caused by trapped hydrogen in a dislocation core (i) reducing the activation stress required for dislocation motion, (ii) reducing resistance to dislocation motion through the lattice, and (iii) reducing interactions between dislocations and barriers to their motion, allowing dislocations to move through obstacles and group closer with other dislocations (Birnbaum 2003; Robertson et al. 2015). These interactions are caused by hydrogen modifying the stress fields of dislocations, reducing the strength of forces between dislocations and obstacles. This theory is known as ‘hydrogen shielding’ (Barrera et al. 2018; Birnbaum 2003; Lynch 2011a; Robertson et al. 2015). The HELP mechanism suggests that the influence of strain rate on HE is caused by the requirement that hydrogen moves along with dislocations, which travel too quickly at high strain rates (Lynch 2011a; Robertson et al. 2015).

Experiments in thin films have found that hydrogen increases the dislocation velocity, the rate of dislocation nucleation, and the density of dislocations when bunching together at an interface. The HELP mechanism is supported by theoretical simulations that show hydrogen lowers the stresses required for initiating dislocation motion (Lynch 2011a). In single crystals of iron tested at low strain rates, hydrogen has also been found to increase ductility, causing softening (Birnbaum 2003; Hirth 1980). Dimples on the fracture surface are often used as evidence for HELP causing microvoid coalescence.

Nonetheless, the HELP mechanism is controversial because hydrogen has elsewhere been found to obstruct the motion of dislocations, leading to strengthening. Proponents claim that these interactions between hydrogen and dislocations occur under different circumstances, and that the HELP mechanism is limited by the temperatures, stresses and strain rates during which hydrogen can follow a moving dislocation (Djukic et al. 2019; Robertson et al. 2015). In addition, much of the supporting evidence for enhanced dislocation motion was found in thin foils, which opponents to HELP claim is not applicable to HE in bulk metals (Barnoush 2009).

3.4.3 Adsorption-induced dislocation emission

Adsorption-induced dislocation emission (AIDE) proposes that HE occurs by the nucleation and propagation of dislocations at a crack tip. AIDE was developed by Lynch (1988, 2011a). AIDE proposes that hydrogen adsorption at the internal surface of a crack tip facilitates the nucleation of a dislocation by weakening interatomic bonds. This causes the crack to extend by an equivalent length. The dislocation motion away from the crack tip leads to the growth of microvoids ahead of the crack, further extending the crack. Lynch suggests that the mechanisms that depend on diffused hydrogen, such as HELP and HEDE, cannot explain the observations of HE at high crack velocities as diffusible hydrogen travels at much slower speeds. AIDE, in contrast, depends on adsorbed hydrogen, which can quickly adsorb from the crack interior onto the crack tip, and AIDE is therefore suggested to allow crack extension at high velocities (Lynch 2011a).

3.4.4 Hydrogen-enhanced strain-induced vacancy

Hydrogen-enhanced strain-induced vacancy (HESIV), sometimes called hydrogen-vacancy interactions, proposes that hydrogen enhances the creation of vacancies, and that the coalescence of these vacancies leads to crack growth. HESIV was proposed by Nagumo (2004) because of experimental observations of increased vacancy density in the presence of hydrogen. The HESIV mechanism suggests that, when strained, these vacancies coalesce into progressively larger voids in the high-strain region ahead of a crack. The phenomenon of delayed failure is then directly caused by the slow agglomeration of vacancies. HESIV is similar to HELP in that it results in ductile crack growth and is expected to produce dimples on the fracture surface (Nagumo 2004).

3.4.5 Defactant concept

The defactant concept proposes that hydrogen atoms lower the energy required to form defects such as vacancies, stacking faults and dislocations. Hydrogen stabilises vacancies, stacking faults and dislocations which is why these defects are hydrogen traps. The defactant concept attempts to provide a general explanation for multiple HE phenomena. This relatively recent proposal was developed by Kirchheim (2010) and Barnoush and Vehoff (2010).

4 Techniques to study HE

4.1 Tensile testing

Tensile testing is used to assess (i) how hydrogen influences strength and ductility and (ii) the HE mechanism from an evaluation of the fractography. Tensile testing to study HE is usually carried out at a slow strain rate because HE is exacerbated at slow strain rates. Tensile testing allows the evaluation of the influence of hydrogen on strength, ductility, and fracture mode. Tensile testing can also be used to detect subcritical crack growth by applying a constant stress below the yield stress for an extended period.

The ductility can be measured using the elongation (

where the subscript indicates tests in air or in the hydrogen environment. I closer to 100% indicates high HE, while I closer to 0% indicates low HE. Other hydrogen susceptibility indices can be calculated for reductions in other mechanical properties such as the ultimate tensile strength (UTS), and fracture toughness (Briottet et al. 2012; Venezuela et al. 2016b, 2020, 2021). The hydrogen susceptibility indices

The influence of strain rate on SCC and HE led to the development of the slow strain rate test (SSRT), standardised in ASTM G129 (ASTM International 2013). The SSRT is also designated the constant extension rate test (CERT). The extension of the specimen is typically increased linearly, so the (engineering) strain rate is kept constant in the initial linearly elastic region of the tensile test. The strain rate is usually between 10−5 s−1 and 10−7 s−1 (Henthorne 2016; Martínez-Pañeda et al. 2020). Throughout the test, the specimen is exposed to the embrittling environment. Various specimen designs have been used: (i) rectangular cross-section specimens; (ii) circular cross-section specimens; (iii) notched specimens to investigate the influence of stress-concentration; and (iv) hollow specimens to maintain a corrosive environment in a small volume inside the specimen.

An alternative to the SSRT is the linearly increasing stress test (LIST) in which the load is increased at a constant rate. The LIST and SSRT produce equivalent results in the initial elastic part of the tensile test up to the threshold stress (Atrens et al. 1993; Liu and Atrens 2013). The LIST has the advantage that it is concluded when the stress reaches the UTS, so it is typically much shorter than the SSRT. Like the SSRT, the LIST is used to expose specimens to a corrosive environment to study HE and SCC. Typically, LISTs are conducted along with the potential drop technique. The potential drop technique allows measurement of the threshold stress for the initiation of subcritical crack growth (or the initiation of stress corrosion cracking), or the yield stress if the HE begins at a stress greater than the yield stress (Ramamurthy and Atrens 1993; 2010; Ramamurthy and Atrens 2013; Ramamurthy et al. 2011).

4.2 Permeation testing

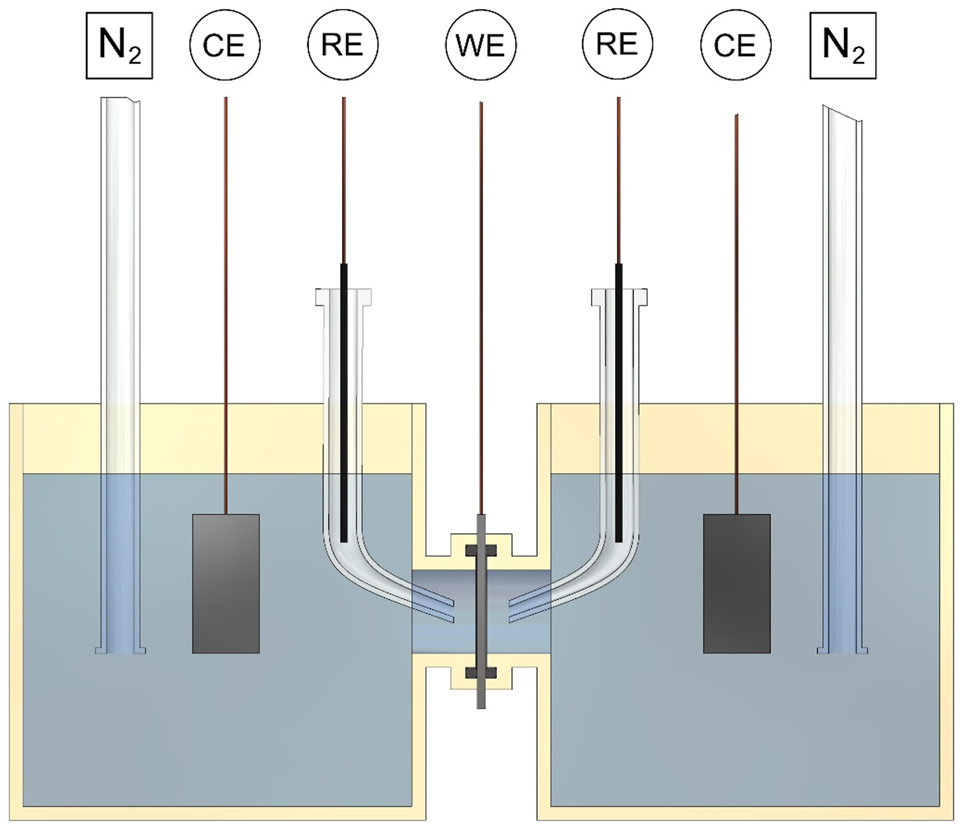

Permeation testing is used to determine the subsurface hydrogen concentration and the hydrogen diffusion coefficient, which determines the speed of hydrogen diffusion within the steel. Hydrogen permeation experiments typically use the Devanathan-Stachurski cell (Devanathan and Stachurski 1962, 1964). A schematic of the Devanathan-Stachurski cell is shown in Figure 7.

Design for the Devanathan-Stachurski cell used to measure hydrogen permeation electrochemically. The cell contains two three-electrode cells, each connected to a potentiostat. CE is the counter electrode, RE is the reference electrode, and WE is the working electrode. Nitrogen is bubbled through the solution to purge oxygen to low concentrations. Other inert gases can be used for this purpose, such as argon.

The Devanathan-Stachurski cell is made up of two three-electrode electrochemical cells, joined together by the thin steel specimen which is the working electrode for both cells. At the specimen surface in the cathodic cell (typically the left-hand cell), a constant potential is often applied which electrochemically produces a constant hydrogen fugacity so that hydrogen diffuses into the specimen. At the specimen surface in the anodic cell (typically the right-hand cell), a constant potential is applied, which oxidises the hydrogen atoms exiting the specimen. The diffusive hydrogen flux (

where

The analysis assumes that the subsurface concentration at the cathodic (entry) side is a constant (

The advantage of the Devanathan-Stachurski technique over other methods is that the accuracy depends on the accuracy of the measurement of the current, which can be more accurate than other measurement devices such as pressure transducers and mass flow meters used in gaseous permeation (Barrera et al. 2018; Devanathan and Stachurski 1962). This allows the measurement of small amounts of permeating hydrogen. The Devanathan-Stachurski cell can be inaccurate if hydrogen does not immediately exit the exit side of the specimen, causing the exit concentration to be greater than 0. Thus, the exit side is often electrochemically plated with a thin layer of palladium to facilitate hydrogen egress and oxidation (Oriani 1978). Other issues with the method can arise if the specimen surfaces are corroded due to the presence of a corrosive electrolyte.

Multiple methods have been used to evaluate the diffusivity from a permeation test (Haq et al. 2013). The breakthrough time (

The time lag method evaluates the diffusivity from the time (

A better approach is to use the whole permeation transient to evaluate the diffusivity. This method uses the Laplace transformation of Fick’s first law. The method evaluates the diffusivity which gives the best fit of the measured permeation transient to the theoretical permeation transients given by (Fallahmohammadi et al. 2013; Liu et al. 2014; Zakroczymski 2006):

where

Often in permeation experiments the area of the specimen available for hydrogen permeation is limited by the mounting of the specimen in the permeation cell. This permeation area is typically defined by O-rings that provide the seal that contains the electrolyte in each permeation cell. Such an arrangement means that the exposed area of the specimen is smaller than the total area of the specimen. Some hydrogen can diffuse into the outside regions of the specimen, a phenomenon known as an ‘edge effect’. Edge effects introduce some errors into the permeation evaluations. For a circular specimen, a thicker specimen (larger

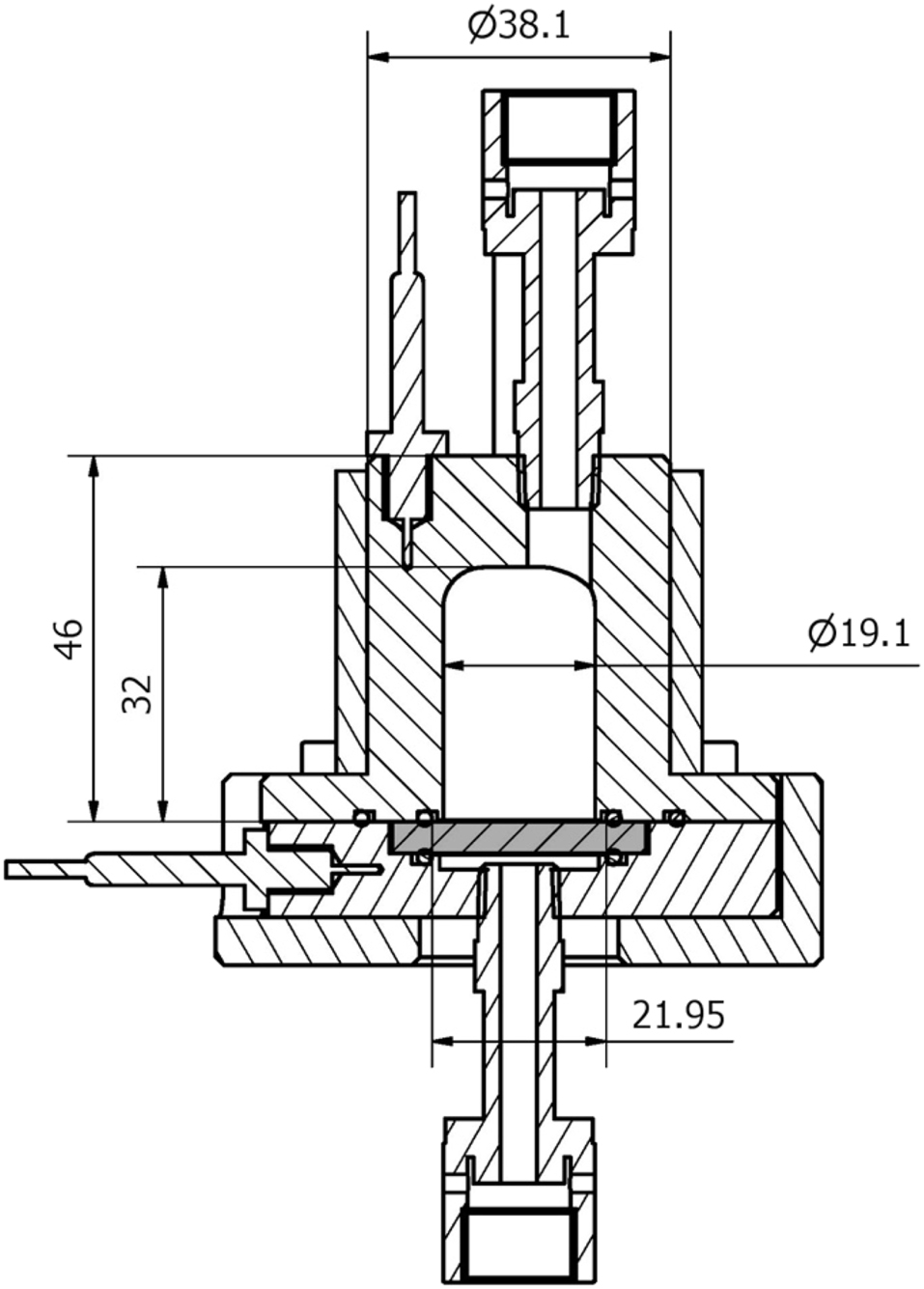

Permeation experiments can also be conducted using a specimen exposed to gaseous hydrogen. These experiments are less common than electrochemical permeation experiments due to the difficulty in accurately measuring the small amounts of hydrogen exiting the specimen to determine the hydrogen flux. Gaseous hydrogen egress has been measured using a mass flow meter (Pizzi et al. 2008), a mass spectrometer (Frauenfelder 1968), an ion pump (Tsong-Pyng and Altstetter 1986), or a pressure transducer (Robertson and Thompson 1980). An example of a gas phase permeability cell that measures hydrogen flux using a pressure transducer is given in Figure 8.

Diagram of a cell for gas phase hydrogen permeation. The steel specimen is identified by the grey colour. Hydrogen gas enters the cell at the top and diffuses to below the specimen. The pressure increase in the volume below the specimen is used to measure the amount of hydrogen diffusing through. Reproduced from Atrens et al. (2022) with permission.

The hydrogen permeation equations derived for electrochemical permeation experiments also apply to gas-phase permeation experiments, with the current densities replaced by fluxes in Equations (17) and (18), as indicated by:

Gas-phase permeation experiments give information that complements that from electrochemical permeation experiments. Gas-phase experiments allow the relationship between hydrogen partial pressure and subsurface hydrogen concentration to be evaluated. This allows the results of other HE studies that use electrochemical charging, such as tensile and fracture toughness studies, to be related to hydrogen pressure. Gas-phase experiments allow testing at elevated temperatures, whereas the temperature range is limited to below 100 °C in electrochemical experiments which use aqueous solutions. Gas-phase experiments also allow experimentation using gas mixtures containing hydrogen, such as mixtures of gases likely to be encountered in service, or the use of adsorption inhibitors such as oxygen.

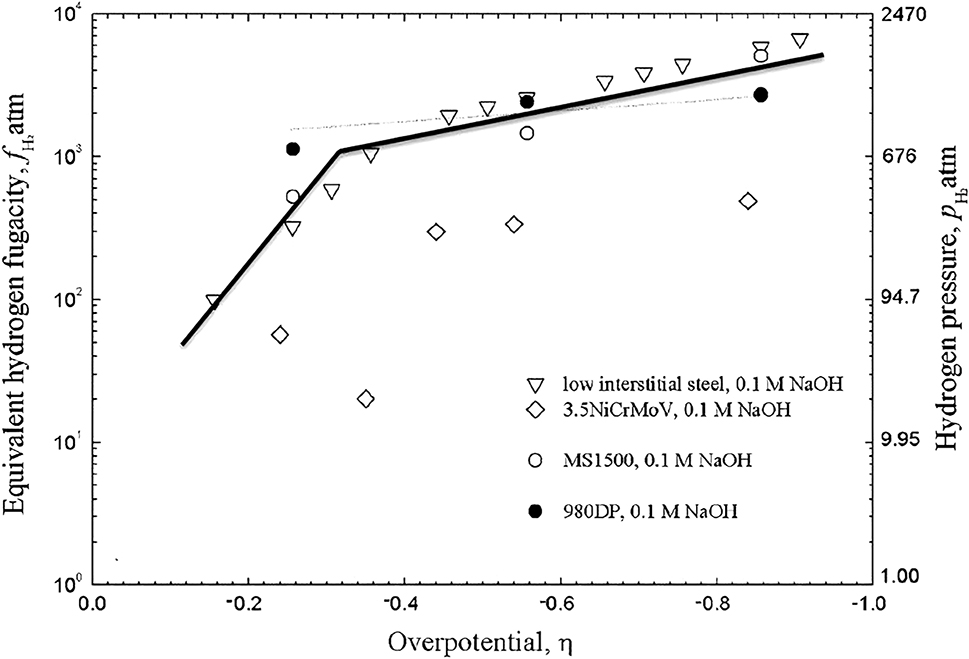

If the same hydrogen concentration is introduced into a steel by both gas-phase and electrochemical charging, and the temperature is the same in both experiments, then the hydrogen fugacity during electrochemical charging and gas phase charging are the same (Liu et al. 2014; Venezuela et al. 2018). This allows evaluation of the hydrogen fugacity during electrochemical charging as indicated in Figure 9 (Liu et al. 2018; Venezuela et al. 2017).

Relationship between hydrogen fugacity and overpotential during electrochemical hydrogen charging. The right-hand scale provides the equivalent hydrogen pressure. The fugacity of a gas corresponds to the pressure that the gas would have if the gas behaved as an ideal gas. Reproduced from Liu et al. (2018) with permission.

4.3 Fracture and fatigue

The impact of hydrogen on fatigue and fracture can be evaluated by comparing the results of experiments in air to those in hydrogen. Fatigue properties include the fatigue limit, the fatigue life, and the fatigue crack growth rate. Fracture mechanics experiments can measure crack velocity and the threshold stress intensity factor (

4.4 Measuring hydrogen content

The hydrogen content can be measured using permeation experiments, hot extraction methods, and using Thermal Desorption Spectroscopy (TDS). Hot extraction methods typically involve measuring the amount of hydrogen released from a specimen as the specimen is heated (sometimes quickly melted) using methods such as thermal conductivity or mass spectrometry. Thermal desorption spectroscopy (TDS) is used to measure the amount of hydrogen in a specimen while recording the temperatures at which hydrogen is released from the specimen, which typically produces a series of peaks at different temperatures. Each peak typically corresponds to a particular hydrogen trap, and TDS therefore allows the characterisation of the trap binding energies (Atrens et al. 2018; Tapia-Bastidas 2016). Other methods used to measure the amount of diffusible hydrogen include measurement of the volume of hydrogen released when the specimen is submerged in a liquid such as glycerol (Wang 2009), liquid paraffin (Dong et al. 2010) or silicone oil (Wang et al. 2015a).

4.5 Microanalysis

The location of hydrogen within steel is of interest in the study of HE. Direct imaging of hydrogen within iron and steel is difficult due to the low solubility of hydrogen and the weak interactions between hydrogen and electrons or X-rays. Imaging using neutron scattering, transmission electron microscopy (TEM), and helium bombardment can identify high concentrations of hydrogen, but not individual hydrogen atoms (Barrera et al. 2018). Individual deuterium atoms and their locations have been imaged using atom probes.

The hydrogen microprinting technique (HMT) is used to indirectly identify the location of hydrogen at a specimen surface. The exit surface of a (permeation) specimen is coated with a salt such as silver bromide (AgBr). Hydrogen exiting the specimen reduces the silver ions to silver crystals. The unreacted salt can then be washed away and the silver crystals can be visualised. HMT provides insight into the distribution of hydrogen and hydrogen trapping, however, it is limited to surface features and cannot be used to image hydrogen within the steel (Barrera et al. 2018; Ovejero-García 1985).

4.6 Stress corrosion cracking

Stress corrosion cracking (SCC) manifests as subcritical cracking under an applied stress in a corrosive solution. Well known SCC conditions include (i) steels in hydroxide solutions (caustic cracking), (ii) brass in ammonium solutions (season cracking), (iii) high pH ground water on the outside of gas-transmission pipelines, and (iv) high-strength steels in water, particularly sea water. SCC likely encompasses many mechanisms including the metal dissolving at the crack tip (frequently called anodic dissolution), or adsorbed ions at the crack tip weakening metallic bonds (Lee 2016; Lynch 2011b; Ramamurthy and Atrens 2013). HE is one of the proposed mechanisms of SCC and is considered the likely SCC mechanism for high-strength steels in water. SCC can be studied using some of the same experimental techniques as HE, such as slow tensile tests.

5 HE in pipeline steels

5.1 Pipeline steel grades

The most common steel grades used in (Australian) natural gas transmission pipelines are those standardised in the American Petroleum Institute (API) 5L standard, ‘Specification for Line Pipe’ (American Petroleum Institute 2018; Ohaeri et al. 2021). These include the low-strength grades A25, A, and B, as well as the X series which ranges from X42 to X120. The numbers in the X series steels designate the minimum yield strength in the non-SI unit of kilo-pounds per square inch (ksi).

API 5L grades are low-carbon steels (in part to ensure good weldability). The maximum carbon content varies across the different grades from 0.21 to 0.28 wt %. The API 5L standard also specifies maximum percentages for alloying elements, as well as a maximum ‘carbon equivalent’ that estimates the contributions of alloying elements to the hardness of the steel and to the weldability of the steel. The heat treatments described in the API 5L standard are tempering, normalising (or annealing), stress relieving, quenching and tempering, and age hardening (American Petroleum Institute 2018). The microstructure of pipeline steels is mostly ferrite and pearlite, with some steels containing bainite and martensite (Ohaeri et al. 2021; Xu 2012). Higher strength pipeline steels (X70 and above) are more recent grades, developed using processing techniques including continuous casting, controlled thermo-mechanical rolling, micro-alloying, and quenching (Ohaeri et al. 2021), although these processes are also used for the production of the lower strength steel grades.

Pipelines may be extruded as pipe or fabricated from rolled metal plate joined longitudinally using a seam weld. Seam welds may be produced with a filler metal, as is the case for submerged-arc welding (SAW) and gas metal-arc welding (GMAW), or without a filler metal, as is the case for continuous welding, electric welding and laser welding. Pipes with seam welds may have one longitudinal weld, two longitudinal welds, or a helical seam weld. Welds which join two pieces of pipe circumferentially are known as girth or jointer welds (American Petroleum Institute 2018).

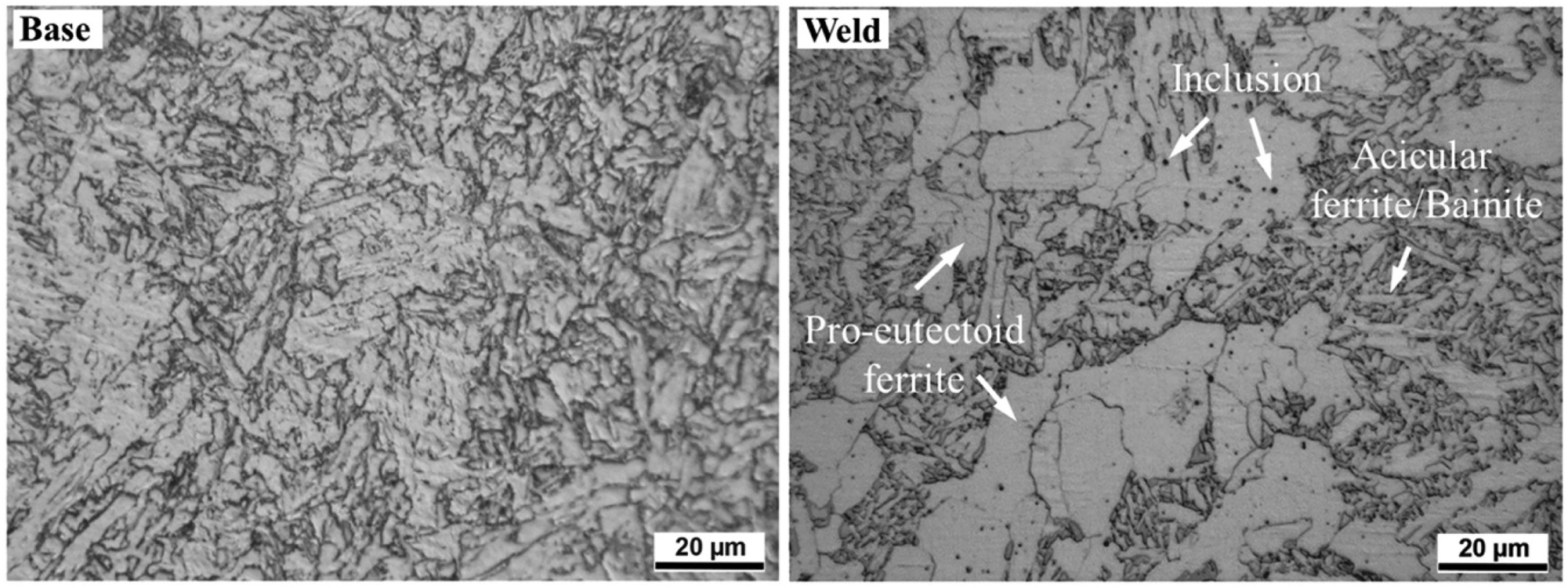

During welding, the microstructure of the steel on either side of the weld may be altered. This area is known as the heat-affected zone (HAZ). The weld may have higher hardness than the base metal, with hardness through the HAZ decreasing with distance from the weld (Olabi and Hashmi 1996). The weld metal frequently contains bainite and different morphologies of ferrite, including acicular ferrite, which resembles needle-shapes and has high toughness (Boumerzoug et al. 2010; Chaveriat et al. 1987; Olabi and Hashmi 1996). The welding method influences the microstructure of the weld and HAZ.

The longest natural gas pipeline in Australia is the 1539 km Dampier Bunbury Natural Gas Pipeline (DBNGP) in WA. Much of the main pipe length is X65 steel (Dampier Bunbury Pipeline (DBP) 2011). Other major Australian pipelines include (i) the Amadeus Gas Pipeline in NT, constructed mostly from X60 steel (APT Pipelines 2015), (ii) the Goldsfields Gas Pipeline in WA, constructed mostly from X70 steel (Goldfields Gas Transmission Joint Venture 1994), and (iii) the South East Australia Gas (SEAGas) pipeline in SA, constructed mostly from X70 steel (Langley et al. 2010). Over time, the construction of gas pipelines in Australia has tended from lower strength to higher strength pipeline steels (Langley et al. 2010), although this trend may change as hydrogen transmission becomes a consideration.

In order to establish the safe limits of hydrogen blending into existing natural gas pipelines, the resistance of these pipeline steels to HE must be evaluated, including the relationship between susceptibility and steel grade, microstructure, and the susceptibilities of the weld and HAZ.

5.2 Summary of HE research

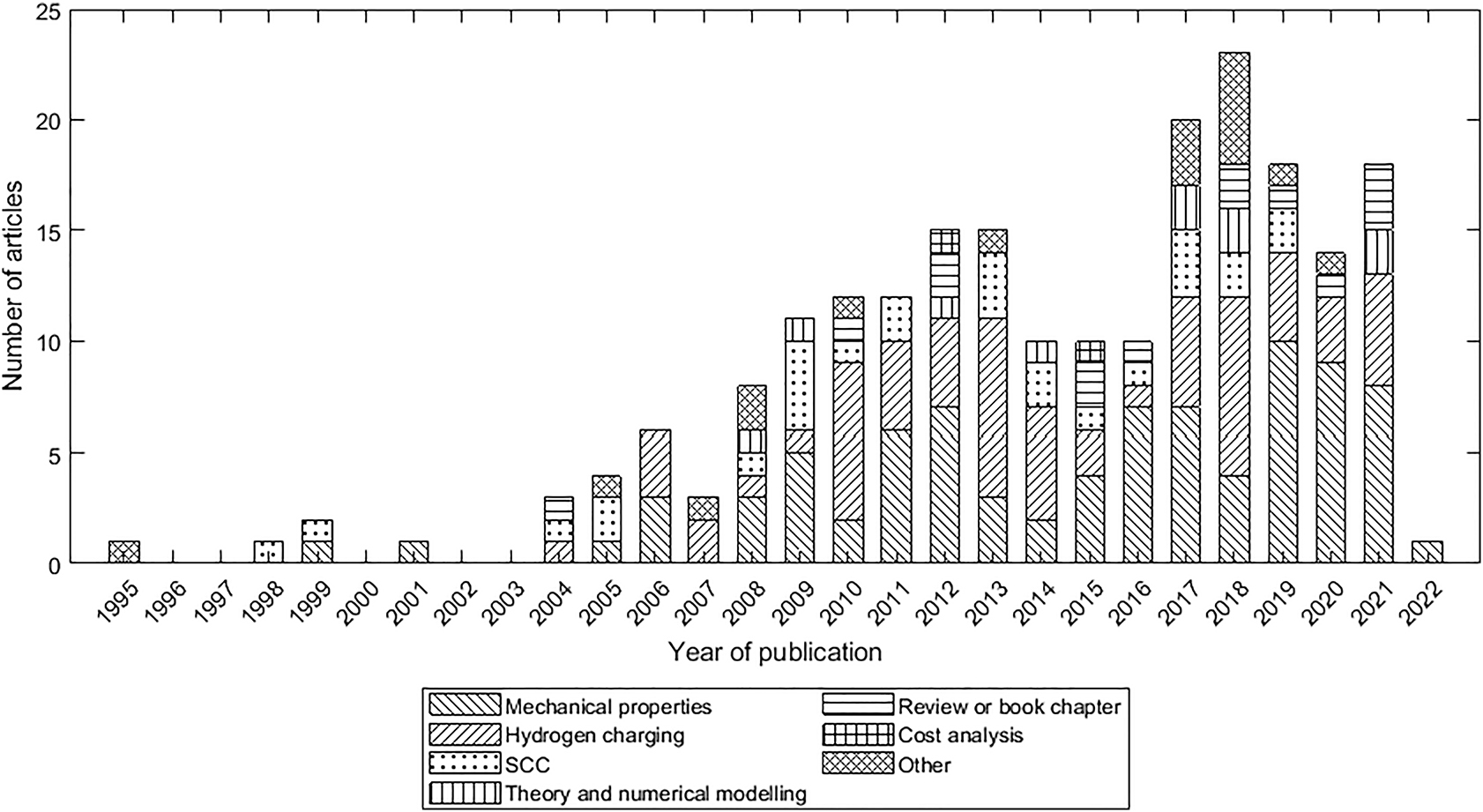

A literature review using the Web of Science found 256 articles relevant to HE in pipeline steels. The number of articles is shown in Figure 10, with articles grouped by topic. The largest share of research articles has focused on the effects of hydrogen on mechanical properties of the pipeline steels. These mechanical properties included tensile properties, fracture and fatigue. ‘Hydrogen charging’ studies typically involved hydrogen induced cracking (HIC) or permeation experiments. Articles listed as ‘SCC’ focused on stress-corrosion cracking but involved hydrogen charging, typically using simulated soil solutions. Articles listed as ‘Other’ studied topics that were tangential to HE such as sulphate-reducing microorganisms and methods of taking field measurements of hydrogen content in pipeline walls. Table 1 lists the specific types of experiments that have been conducted on pipeline steels charged with hydrogen.

Results of a Web of Science search for hydrogen in pipeline steels, showing the number of journal articles published each year from 1995 to 2022. Articles are group according to their focus. SCC articles expose steel to a corrosive environment where hydrogen is an electrochemical by-product and not the primary focus.

HE-experiment types conducted in studies of pipeline steels.

| Type | Experiment | Standards | Number of studies |

|---|---|---|---|

| Tensile | Slow strain rate tensile (SSRT) | ASTM G142, ASTM G129 | 30 |

| Small punch (SP) | ASTM E3205 | 2 | |

| Tensile test | ASTM G142, ASTM E8 | 28 | |

| Permeation | Devanathan-Stachurski method | ASTM G148 | 34 |

| Fatigue | Beam specimen | 2 | |

| Compact tension (CT) | ASTM E647 | 19 | |

| Edge notched tension | 2 | ||

| Eccentrically loaded single-edge notched tension (ESET) | 3 | ||

| Spiral notch torsion test (SNTT) | 1 | ||

| Wedge open loading (WOL) | ISO 7539 | 1 | |

| Fracture toughness | Modified wedge open loading (MWOL) | 1 | |

| Circumferentially notched tension (CRT) | ASTM G142 | 9 | |

| Compact tension (CT) | ASTM E647 | 2 | |

| Hollow circumferentially notched tension | 1 | ||

| Three point bending (TPB)/Single-edge notched bending (SENB) | ASTM E1820 | 7 | |

| Single-edge notch tension (SENT) | 5 | ||

| Impact | Charpy pendulum impact test | ASTM E23 | 7 |

| Distribution | Hydrogen microprint technique | 2 | |

| SCC | Hydrogen-induced cracking | NACE TM0284 | 24 |

| U-bend test | ASTM G30 | 1 | |

| Electrochemical corrosion | Electrochemical impedance spectroscopy (EIS) | ASTM G106 | 11 |

| Potentiodynamic polarisation | ASTM G61 | 18 | |

| Scanning vibrating electron technique (SVET) | 2 | ||

| Hydrogen content | Thermal desorption spectroscopy (TDS) | 6 | |

| Displacement methods | 10 | ||

| Hydrogen analyser | 2 | ||

| Hot extraction method | 2 | ||

| Potentiometer discharging | 4 | ||

| Other | Disc pressure test | 2 |

-

The standards column gives the designations of testing standards for the experiment. Studies grouped under the generic ‘Tensile test’ had a moderate strain rate and did not qualify as SSRT experiments.

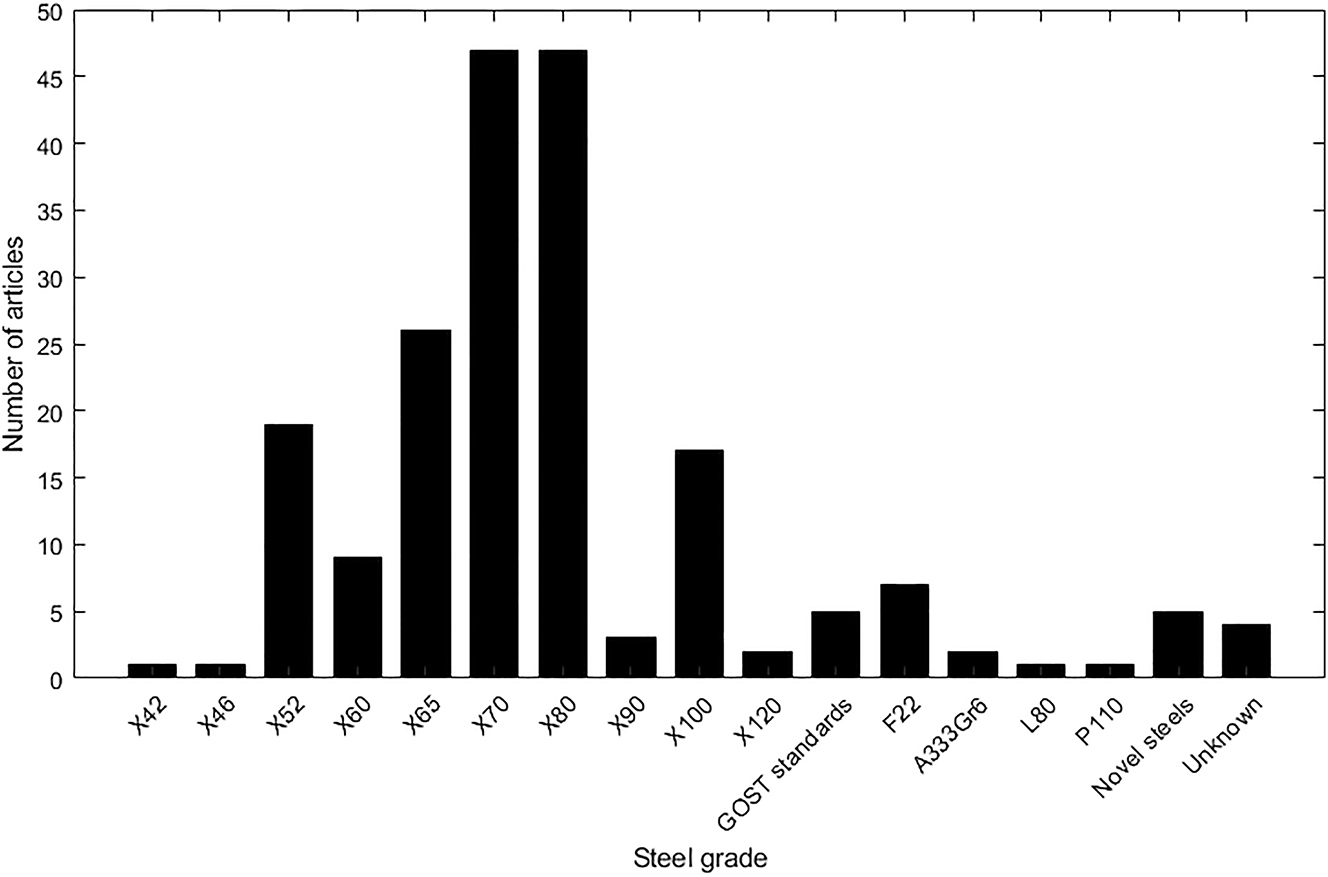

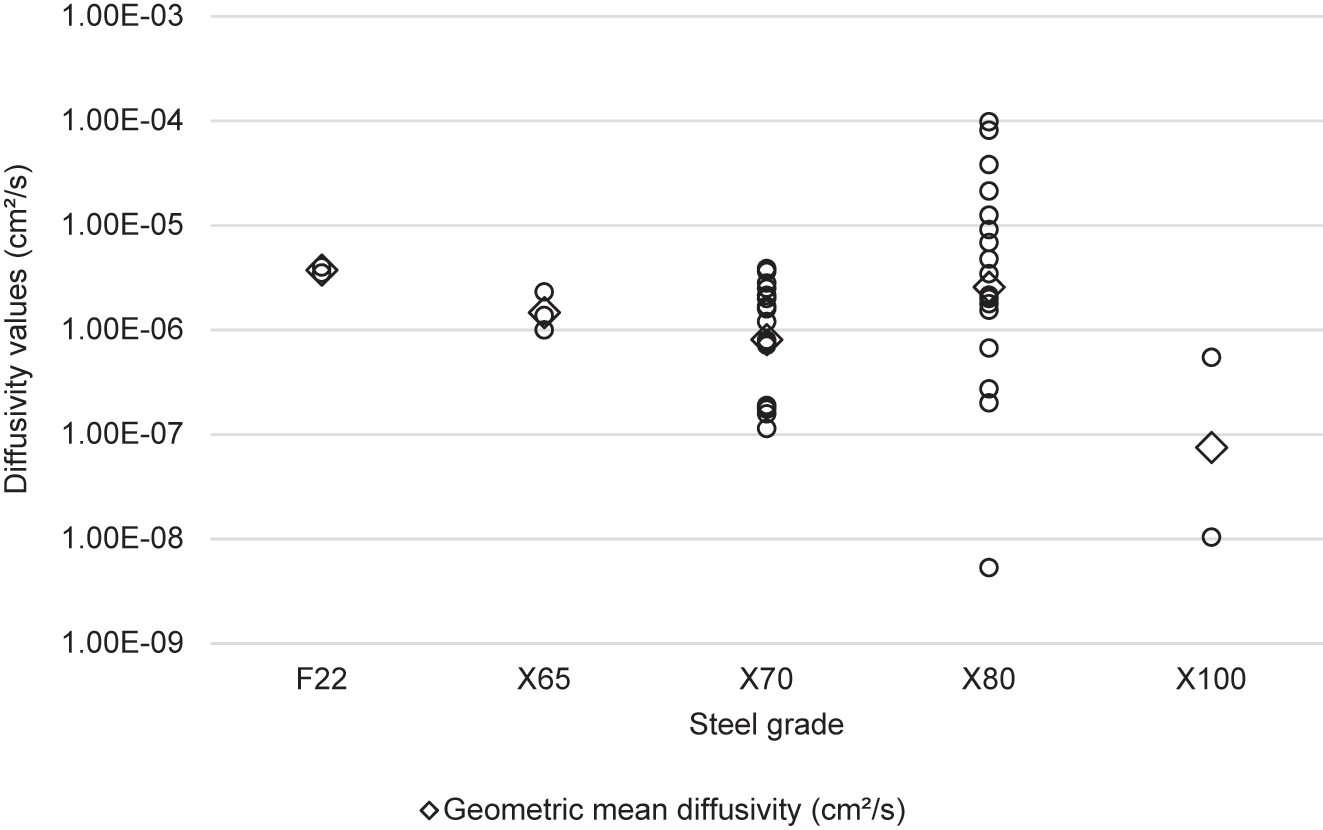

Figure 11 shows the steel grade investigated in journal articles identified in the literature review. The most frequently researched steels were X70 and X80. Both of these steels have been used for natural gas pipelines (Langley et al. 2010), and are more susceptible to HE than lower strength pipeline steels. Fewer articles have been published on lower strength pipeline steels such as X42 and X46. This is presumably because these steels are resistant to HE and therefore research into their hydrogen susceptibility would produce negative results. Some studies investigated steel grades from standards other than API 5L, such as F22 from the ASTM A182 standard (Fassina et al. 2011), A333Gr6 from the ASTM A333 standard (Zheng et al. 2012), and P110 from the API 5CT standard (Majchrowicz et al. 2019). Some researchers investigated steels that did not conform to a standard, listed in Figure 11 under ‘Novel steels’. These included steels with high copper contents (Shi et al. 2016), and steel microalloyed with niobium and titanium (Torres-Islas et al. 2013).

Number of articles relating to different grades of pipeline steel. Novel steels are new steels created for the research that are not graded. Unknown steels were referred to by the authors as pipeline steels but the grade was not defined.

There have been previous reviews of HE in pipeline steels. Eliassen (2004) and Cabrini et al. (2015) focused on hydrogen generated by cathodic protection in submarine pipelines. Findley et al. (2015) reviewed the mechanisms behind the initiation of HIC, concluding that reversibly-trapped hydrogen was chiefly responsible for crack initiation. Ghosh et al. (2018) also reviewed HIC susceptibility and the influence of microstructure and chemical composition on HIC. Ohaeri et al. (2018) covered the many kinds of hydrogen degradation in pipeline steels and their relationships with microstructure. Xu (2012) reviewed the HE susceptibility of low-carbon steels generally, including low-strength pipeline steels. These steels generally had low HE susceptibility, although some mechanical properties were reduced – particularly fracture toughness and elongation to failure. For lower-strength carbon steels, studies reported similar HE susceptibility for the base metal, HAZ and weld. In higher-strength pipeline steels, there was some evidence that the weld and HAZ were most susceptible to HE. No subcritical crack growth was recorded in the base metal of X42 and X70 steels at hydrogen pressures up to 310 bar (Cialone and Holbrook 1985), although there was some evidence of subcritical crack growth in the weld and HAZ. Chemical composition influenced HE: carbon content increased HE susceptibility, as did manganese, chromium, molybdenum and vanadium. There was some evidence that microalloying niobium and titanium decreased HE. In reviewing the HE mechanisms, Xu concluded that HELP was the dominant mechanism in low-carbon steels, due in part to the high diffusivities of these steels which allow hydrogen to follow moving dislocations.

Ohaeri et al. (2021) reviewed hydrogen permeation and the influence of hydrogen on strength and fatigue properties of pipeline steels. Nanninga et al. (2010) reviewed the effect of hydrogen on fatigue crack growth in pipeline steels. They concluded that the crack growth rates in these steels were significantly affected by hydrogen, even in low-strength steels such as X42, and there was no strong relationship between pipeline steel strength and HE fatigue susceptibility. Although fatigue properties are an important consideration in the design of gas transmission pipelines carrying hydrogen, the literature on fatigue has been covered in detail by the previously mentioned reviews. Therefore, fatigue properties are not included in this review. This review will instead give an overview of previous research into tensile properties, hydrogen permeation, and fracture properties.

5.3 Pipeline degradation

A consideration in the repurposing of natural gas pipelines for hydrogen transmission is the possibility of degradation of pipelines during time in service. The mechanical properties of pipeline steels after field operation have been compared to samples of the same steel that have been kept in reserve. This has allowed the effects of service exposure to be isolated. Service exposure has been reported to reduce the impact toughness, fracture toughness, and ductility (Gabetta et al. 2008; Nykyforchyn et al. 2018, 2022b). The results for yield and tensile strength vary, as operation has been found to decrease or increase both yield and tensile strength (Gabetta et al. 2008; Nykyforchyn 2021; Nykyforchyn et al. 2022b; Zvirko et al. 2022). Nykyforchyn et al. (2022b) found service exposure caused the electric potential of the steel fracture surface to become more negative, from which they suggested that electrochemical testing of pipelines in the field could be used to estimate the degree of degradation.

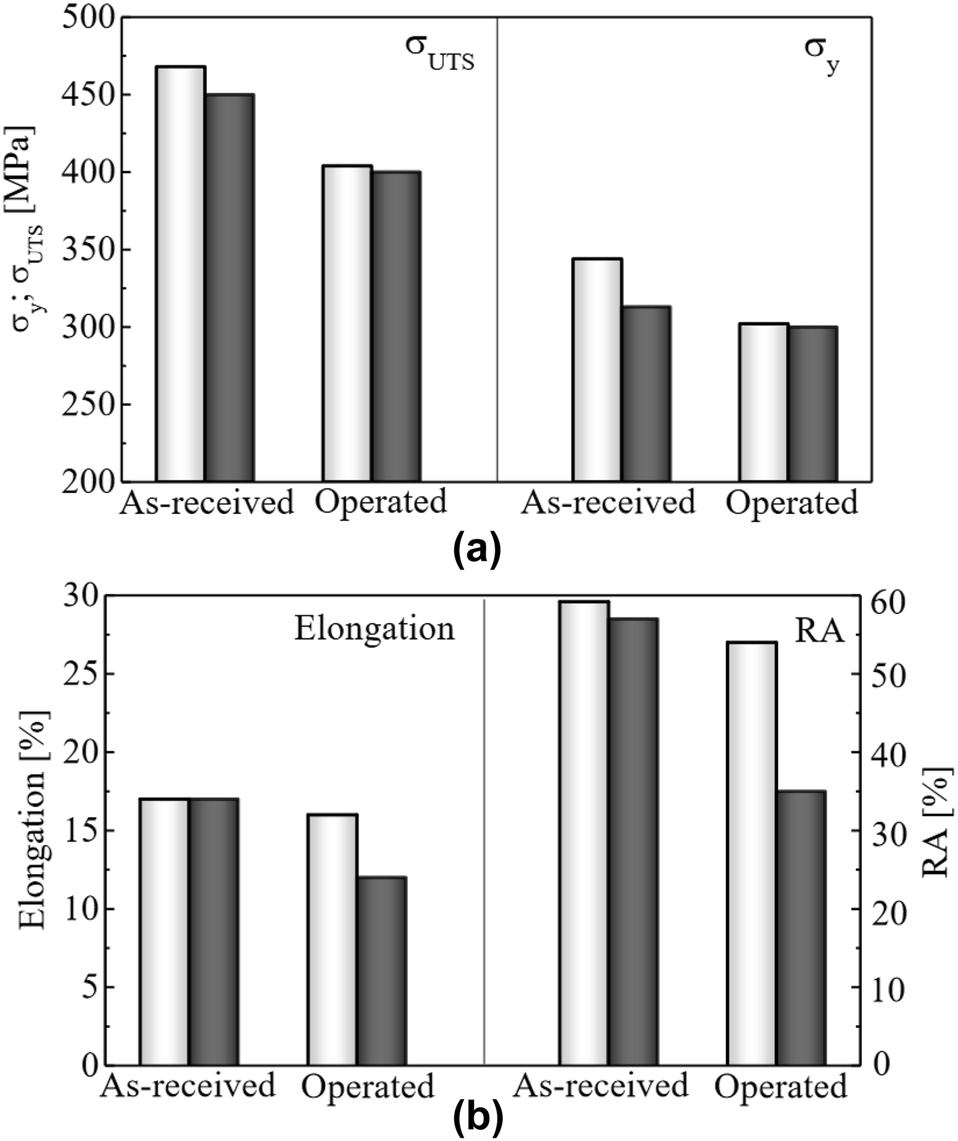

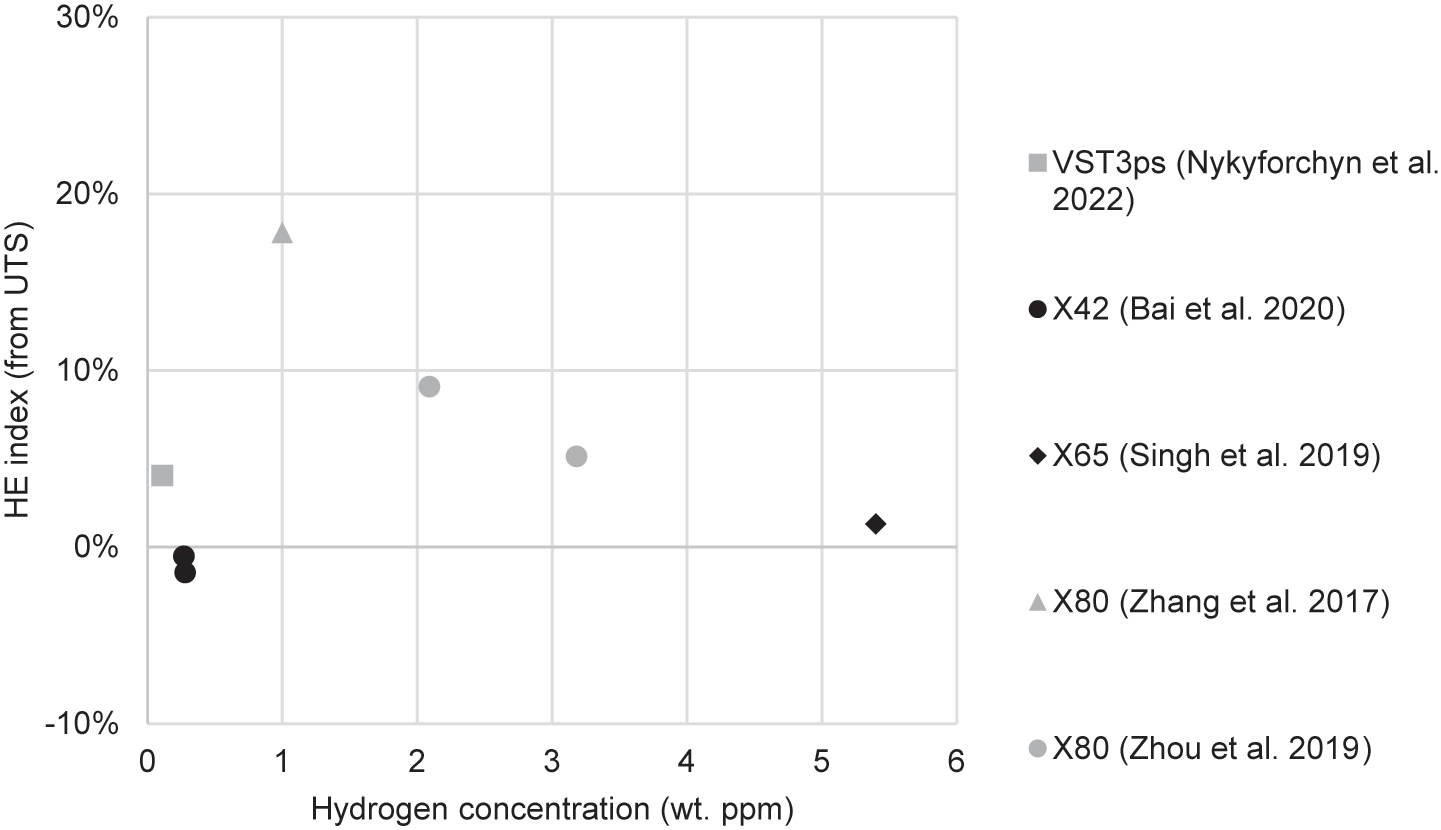

In addition, the HE susceptibility of pipeline steels might increase over the steel lifetime. Figure 12 shows the results of Nykyforchyn et al. (2022a) who found that the effect of hydrogen on strength (YS and UTS) and ductility (elongation and reduction of area) of a VST3ps pipeline steel after 52 years of operation was greater than a reserve sample of the same pipeline steel. Zvirko et al. (2022) conducted tensile tests of 17H1S pipeline steel and found that the steel after 36 years of operation had a hydrogen embrittlement index of 38% compared with 6% for reserve steel.

Results for strength (a) and ductility (b) in VST3ps steel as-received and after 52 years of service exposure (designated operated). White bars are without hydrogen, and black bars are after hydrogen charging for 100 h in an aqueous H2SO4 solution (pH 3.5) at a current density of 1 mA/cm2. Reproduced from Nykyforchyn et al. (2022a) with permission.

Multiple mechanisms were proposed for the observed pipeline degradation. These include (i) natural aging, (ii) stress corrosion cracking, (iii) HIC during service in the field, and (iv) the production of internal defects, such as voids, in the steel over time due to stress (Nykyforchyn 2021; Nykyforchyn et al. 2010, 2018). Nykyforchyn et al. proposed the void model due to the observed increase in HE susceptibility, which they suggested was due to the creation of hydrogen traps. Gabetta et al. (2008) found field operation resulted in reduced hydrogen diffusivity, which would support this theory as traps reduce hydrogen diffusion.

5.4 Tensile properties

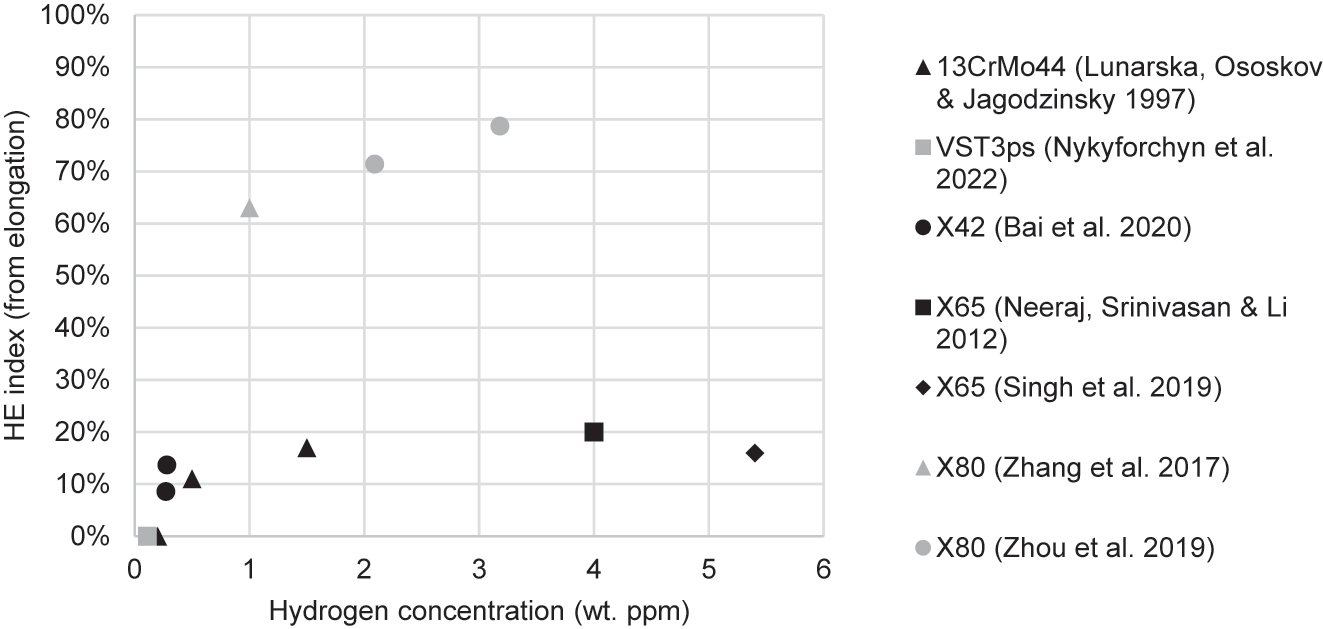

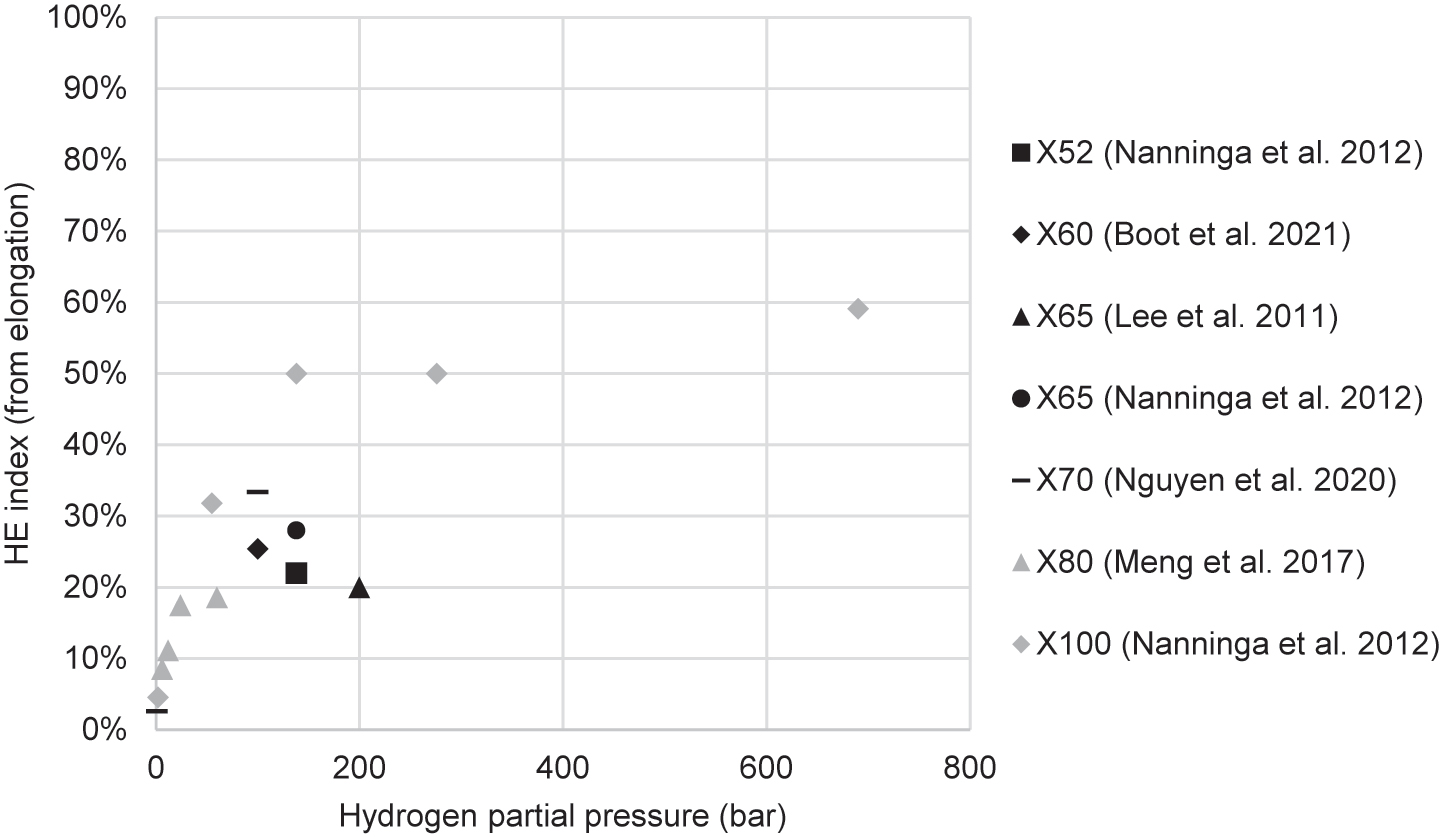

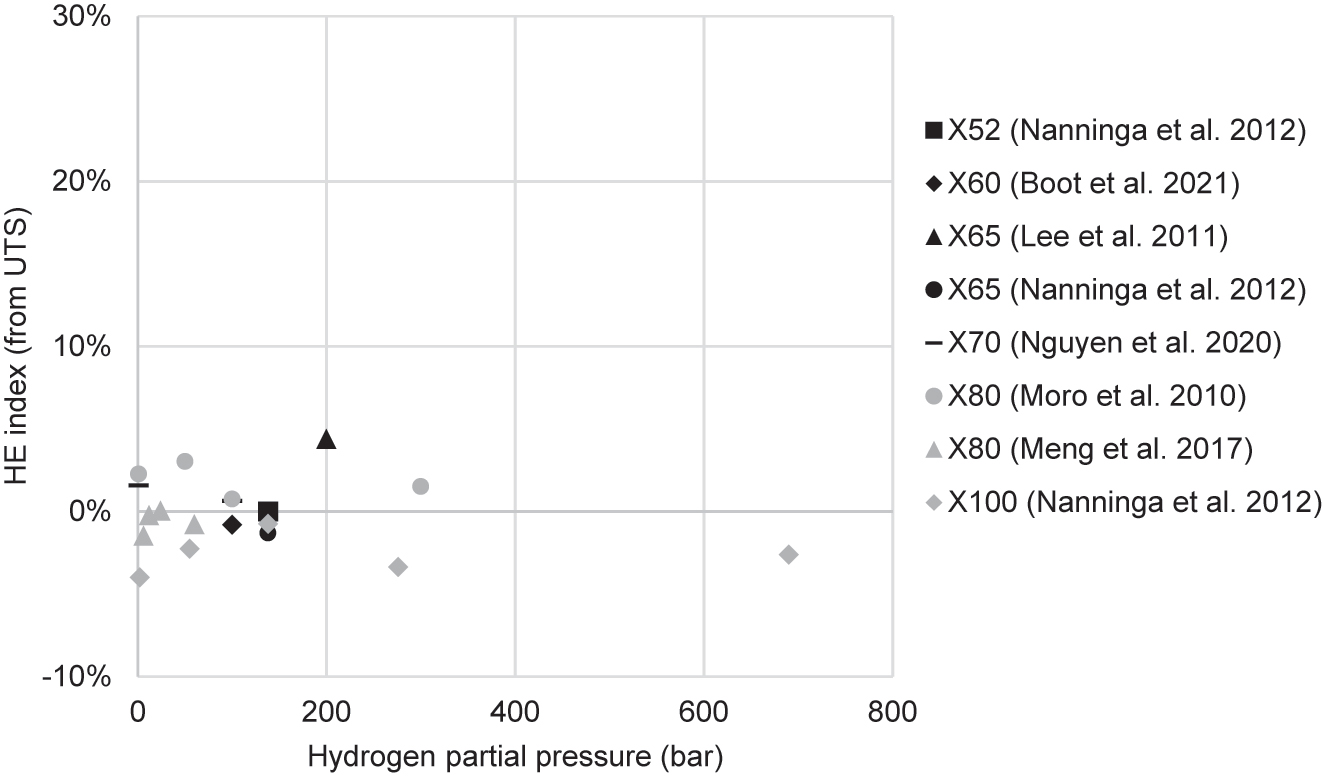

The previous sections of this review indicated that low-carbon ferritic steels, including low-strength pipeline steels, were resistant to HE. The literature review also indicated that higher-strength steels tend to be more susceptible to HE. It was therefore expected that studies into the tensile properties of pipeline steels in hydrogen would find that pipeline steels have low values of the hydrogen embrittlement index (I), which would increase with increasing pipeline steel strength.

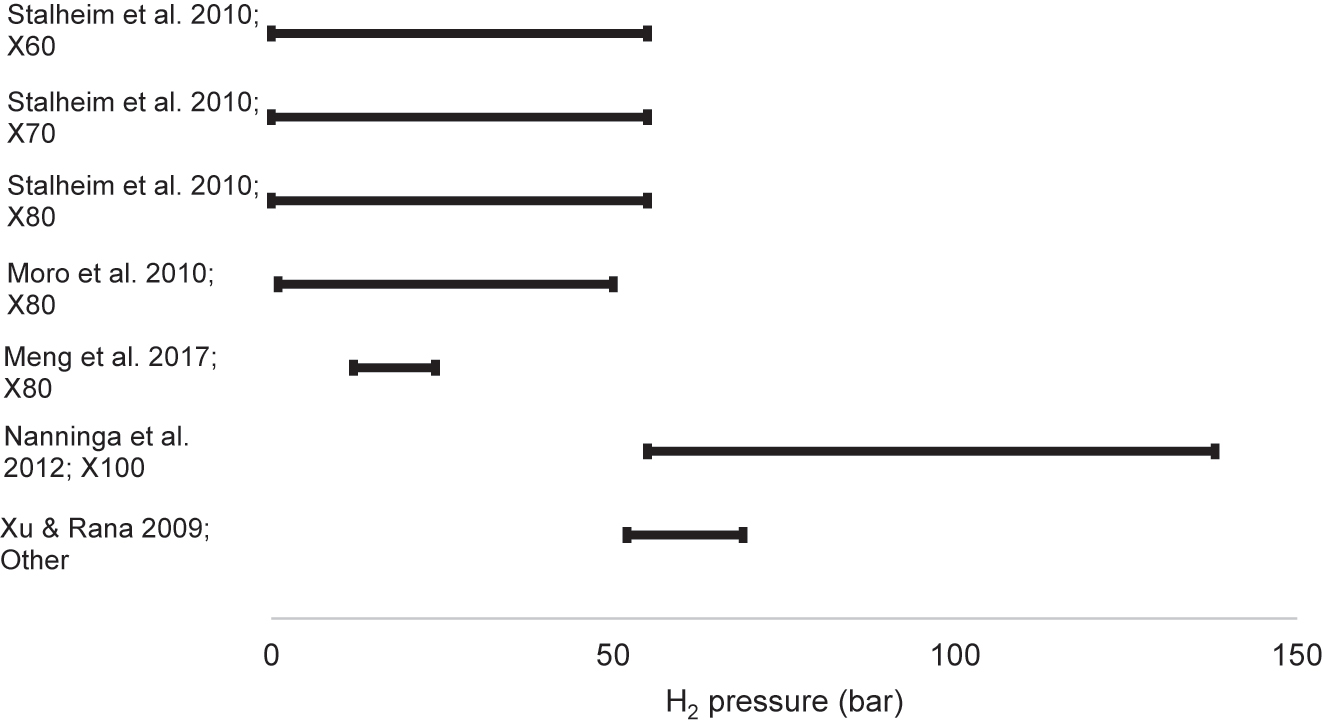

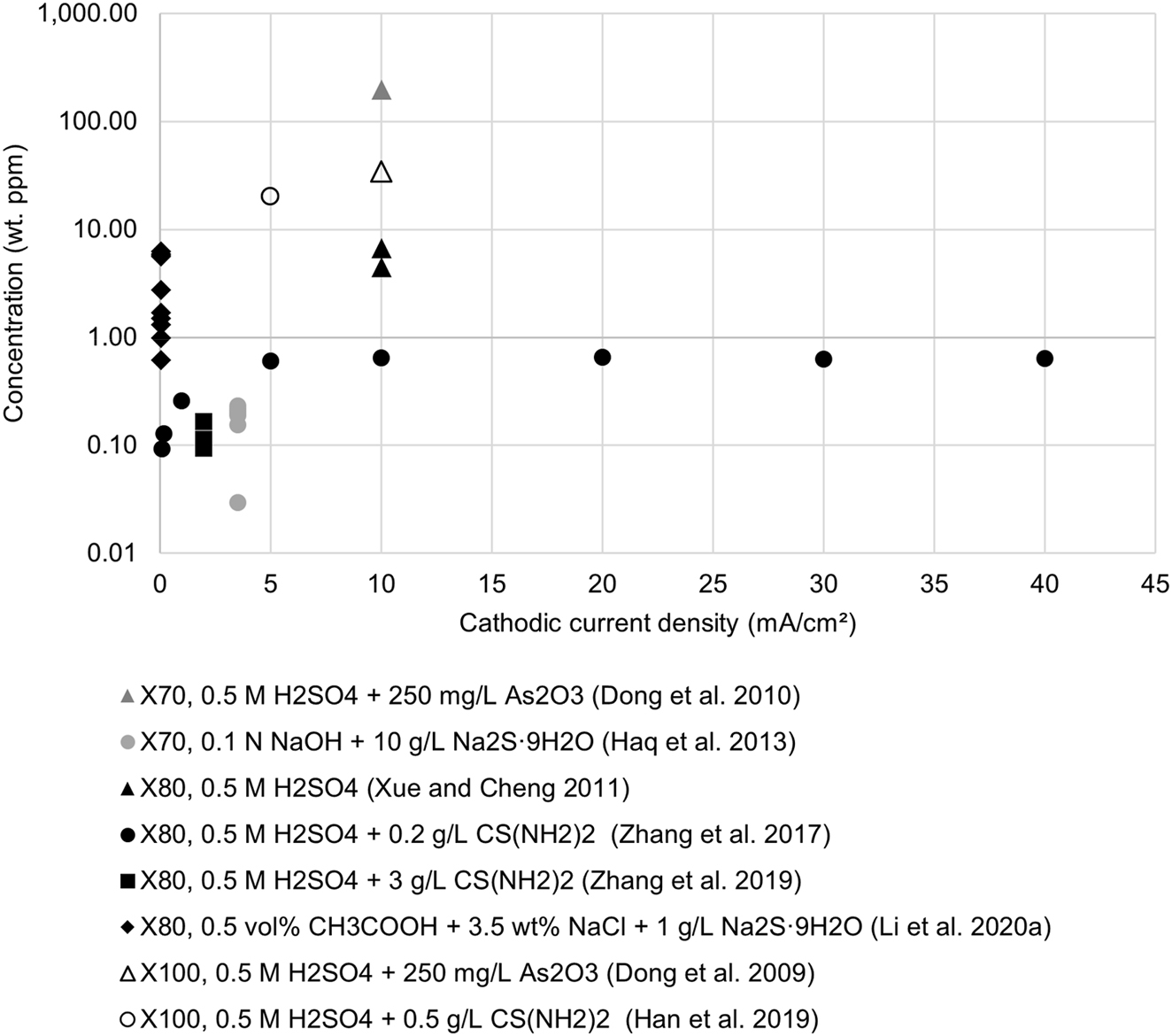

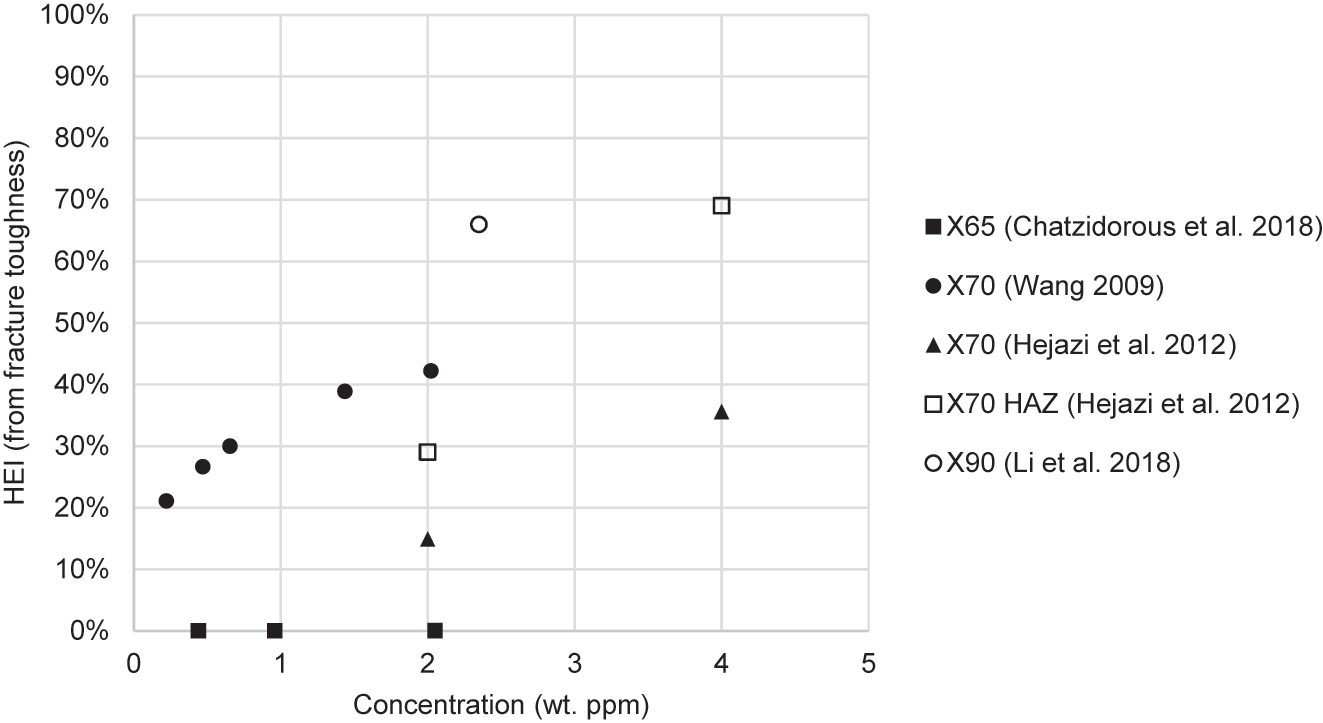

Table 2 summarises the results of studies that conducted tensile tests of pipeline steels in hydrogen, listed in order of publication date. These include studies that used gaseous hydrogen and studies that generated hydrogen electrolytically. The I values (the hydrogen embrittlement index as calculated from either elongation or RA) and changes in strength (YS and UTS) that resulted from the charging conditions are included. In the electrolytic studies, the most frequently used electrolyte was sulfuric acid (H2SO4), used in almost all studies. Most experimenters also used a recombination poison, such as arsenic trioxide (As2O3), potassium arsenate (KH2AsO4), thiourea (SC(NH2)2), and ammonium thiocyanate (NH4SCN). Charging current densities ranged from 0.1 mA/cm2 to 66 mA/cm2. In gaseous hydrogen studies, pressures ranged from 1 to 690 bar. Following Table 2 is an elaboration of these studies, and thereafter there is a synthesis of trends revealed by these studies.

Summary of tensile studies investigating HE in pipeline steels.

| References | Steel grade | Specimen type | Strain rate (s−1) | IHE/HEE | Hydrogen delivery | Charging conditions | Hydrogen embrittlement index (I) | Change in YS/UTS |

|---|---|---|---|---|---|---|---|---|

| Lunarska et al. (1997) | 13CrMo44 | Rectangular, 3 × 2 mm gauge dim. | Not disclosed | IHE | Electrolytic: 0.1 N H2SO4 | Not disclosed | 0.10 ppm: −3% 0.21 ppm: 0% 0.47 ppm: 11% 1.40 ppm: 17% |

Not measured |

| Gu et al. (1999) | X52, X80 | Cylindrical, unspecified dimensions | 2.2 × 10−6 | IHE | Electrolytic: 1 M H2SO4 and 250 ppm As2O3 | 3 mA/cm2 for 24 h | X52: None X80: 9% |

None |

| Torres-Islas et al. (2005) | X70 | Cylindrical, longitudinal, 2.5 mm gauge diameter | 1.36 × 10−6 | IHE | Electrolytic: 0.5 M H2SO4 and 100 ppm As2O3 | 0.1 mA/cm2 for 1 h | As received: 10% Quenched: 85–90% |

Not measured |

| Hardie et al. (2006) | X60, X80, X100 | Cylindrical, longitudinal, 3.21 mm gauge dia. | 2.8 × 10−5 | IHE | Electrolytic: 0.5 M H2SO4 and 5 g/L KH2AsO4 | 3–66 mA/cm2 for 15 min | At 66 mA/cm2, X60: 64% X80: 78% X100: 86% |

No clear change |

| Dong et al. (2009b) | X100 | Rectangular, unspecified orientation, 0.5 mm gauge thickness | 1.25 × 10−3 | IHE | Electrolytic: 0.5 M H2SO4 and 0.25 g/L As2O3 | 20 mA/cm2 for 1–8 h | 1 h precharging: 48% 5 h precharging: 61% 8 h precharging: 76% |

Slightly reduced |

| Moro et al. (2010) | X80 | Cylindrical, longitudinal, 6 mm gauge dia. | 5 × 10−5 | HEE | Gaseous: pure H2 | 1–300 bar | 1 bar: 0% 50 bar: 41% 100 bar: 67% 300 bar: 68% |

Reduced 1–3% |

| Stalheim et al. (2010) | X60, X70, X80 | Cylindrical, not from pipe, unspecified diameter | 10−5 – 10−4 | HEE | Gaseous: pure H2 | 55–207 bar | At 55 bar, X60: 49% X70: 45% X80: 38% |

None |

| Alhussein et al. (2011) | X52 | Rectangular, transverse, 8 × 4 mm gauge dim. | Not disclosed | HEE | Electrolytic: NS4 solution | −1 V (SCE) | 42% | Reduced 7–9% |

| Arafin and Szpunar (2011) | X80, X100 | Cylindrical, transverse, 2.54 mm gauge dia. | 9.3 × 10−7 | HEE | Electrolytic: 1 N Na2CO3 and 1 N NaHCO3 | Potentials from OCP to −1.2 V (SCE) | X80 at OCP, 45%; at −1.0 V, 51%; at −1.2 V, 61% X100 at OCP, 29%; at −1.0 V, 51%; at −1.2 V, 75% |

Not measured |

| Lee et al. (2011) | X65 | Cylindrical, hollow, 6 mm gauge dia. | 7 × 10−6 – 7 × 10−4 | HEE | Gaseous: pure H2 | 200 bar | 20% | Reduced 3–5% |

| Nanninga et al. (2012) | X52, X65, X100 | Unspecified, both longitudinal and transverse | 7 × 10−3 | HEE | Gaseous: pure H2 | Between 2 and 690 bar | At 138 bar H2, X52: 22% X65: 28% X100: 50% |

Possibly increased strength in X100 |

| Neeraj et al. (2012) | X65, X80 | Not disclosed | 1 × 10−5 | IHE | Electrolytic: 0.5 M H2SO4 and 0.005 g/L As2O3 | 5 mA/cm2 for 4 h | X65: 20% X80: 20% |

Not measured |

| Torres-Islas et al. (2013) | Novel steel | Cylindrical, both longitudinal and transverse, 2.5 mm gauge dia. | 1.36 × 10−6 | IHE | Electrolytic: 0.5 M H2SO4 | 0.1 mA/cm2 for 30 min | Longitudinal: 27% Transverse: −10% (A negative I indicates increased ductility in hydrogen) |

Not measured |

| Xiong et al. (2015) | X80 | Cylindrical, not from pipe, 2.5 mm gauge dia. | 1 × 10−5 | HEE | Gaseous: H2 and CO2 | H2 1 bar, CO2 2–10 bar | At H2 1 bar, CO2 10 bar: 3% At H2 1 bar, CO2 5 bar: 6% At H2 1 bar, CO2 2 bar: 22% |

Reduced YS and UTS |

| Hejazi et al. (2016) | X70 | Cylindrical, hollow, transverse, 6 mm gauge dia. | 3.75 × 10−5 | HEE | Gaseous: pure H2 | 100 bar | 22–25% | YS unchanged, UTS reduced by 4% |

| Meng et al. (2017) | X80 | Cylindrical, both smooth and notched, longitudinal, 6 mm gauge dia. | 1.1 × 10−5 | HEE | Gaseous: H2 and N2 | Total 120 bar: H2 partial pressure 6, 12, 24, 60 bar | At H2 60 bar, From ε: 19% From RA: 17% |

None |

| Zhang et al. (2017b) | X80 | Cylindrical, transverse, 5 mm gauge dia. | 1 × 10−6 | HEE | Electrolytic: 0.5 M H2SO4 with 0.2 g/L SC(NH2)2 | 1 mA/cm2 (CH ≈ 1 ppm) | 63% | Strength reduced by ∼20% |

| Cabrini et al. (2019) | X70SS, X80, X100 | Cylindrical, unspecified orientation, 3 mm gauge dia. | 1 × 10−6 | HEE | Electrolytic: 3.5 vol% NaCl | OCP, −1 V, −2 V (SCE) | At −2 V, X70SS: 37% X80: 48% X100: 42% |

Not measured |

| Han et al. (2019) | X100 | Rectangular, transverse, 10 × 2 mm gauge dim. | 2 × 10−4 | IHE | Electrolytic: 0.5 M H2SO4 with 0.5 g/L SC(NH2)2 | 25 mA/cm2 for 3, 6, and 12 h | 12 h precharging: 46.3% | YS and UTS reduced slightly |

| Rahman et al. (2019a) | X60, X60SS, X70 | Rectangular, transverse, 6–12 mm gauge depth × 12.5 mm width | 4.17 × 10−5 | IHE | Electrolytic: 0.2 M H2SO4 with 0.5 g/L NH4SCN | 20 mA/cm2 for 1–24 h | Maximum I: X60: 58% X60SS: 72% X70: 42% |

Increased YS and UTS |

| Rahman et al. (2019b) | X70 | Rectangular, both longitudinal and transverse, 12.5 × 12 mm gauge dim. | Not disclosed | IHE | Electrolytic: 0.2 M H2SO4 with 3 g/L NH4SCN | 20 mA/cm2 for 1, 8, 15 h | 1 h: 33% 8 h: 46% 15 h: 50% |

Strengthened after 1 h, no change at longer charging times |

| Singh et al. (2019) | X65 | Rectangular, not from pipe, 5 × 4 mm gauge dim. | 5 × 10−5 | IHE | Electrolytic: 1 N H2SO4 with 1.4 g/L NH4SCN | 20 mA/cm2 for 4 h (CH ≈ 5.4 ppm) | From ε: 16% From RA: 39% |

Increased YS, unaffected UTS |

| Zhou et al. (2019) | X80 | Rectangular, unspecified orientation, 5 × 2 mm gauge dim. | 2 × 10−4 – 2 × 10−5 | HEE & IHE | Electrolytic: 0.5 M H2SO4 with 2 g/L SC(NH2)2 | 2.5–5.0 mA/cm2, IHE was 12 h | 2.5 mA/cm2: 71% 5.0 mA/cm2: 79% Full results in Table 3 |

None |

| Bai et al. (2020a) | X42 | Rectangular, longitudinal, 5 × 3 mm gauge dim. | 5.4 × 10−5 | HEE | Electrolytic: 0.5 M H2SO4 with 0.5 g/L Na4P2O7 | 0.05–10 mA/cm2 | 0.05 mA/cm2: 34% 1 mA/cm2: 42% 2.5 mA/cm2: 59% |

YS and UTS increased by 1–3% |

| Li et al. (2020a) | X80 | Rectangular, longitudinal, 10 × 1.5 mm gauge dim. | 5.13 × 10−4 | IHE | Electrolytic: 0.5 M H2SO4 and 0.25 g/L As2O3 | 10 mA/cm2 for 1 h | Average 22% | Slightly strengthened |

| Li et al. (2020b) | X80 | Rectangular, longitudinal, 10 × 1.5 mm gauge dim. | 5.13 × 10−4 | IHE | Electrolytic: 0.5 M H2SO4 and 0.25 g/L As2O3 | 10 mA/cm2 for 1 h | Average 19% | UTS and YS increased by 5–15% |

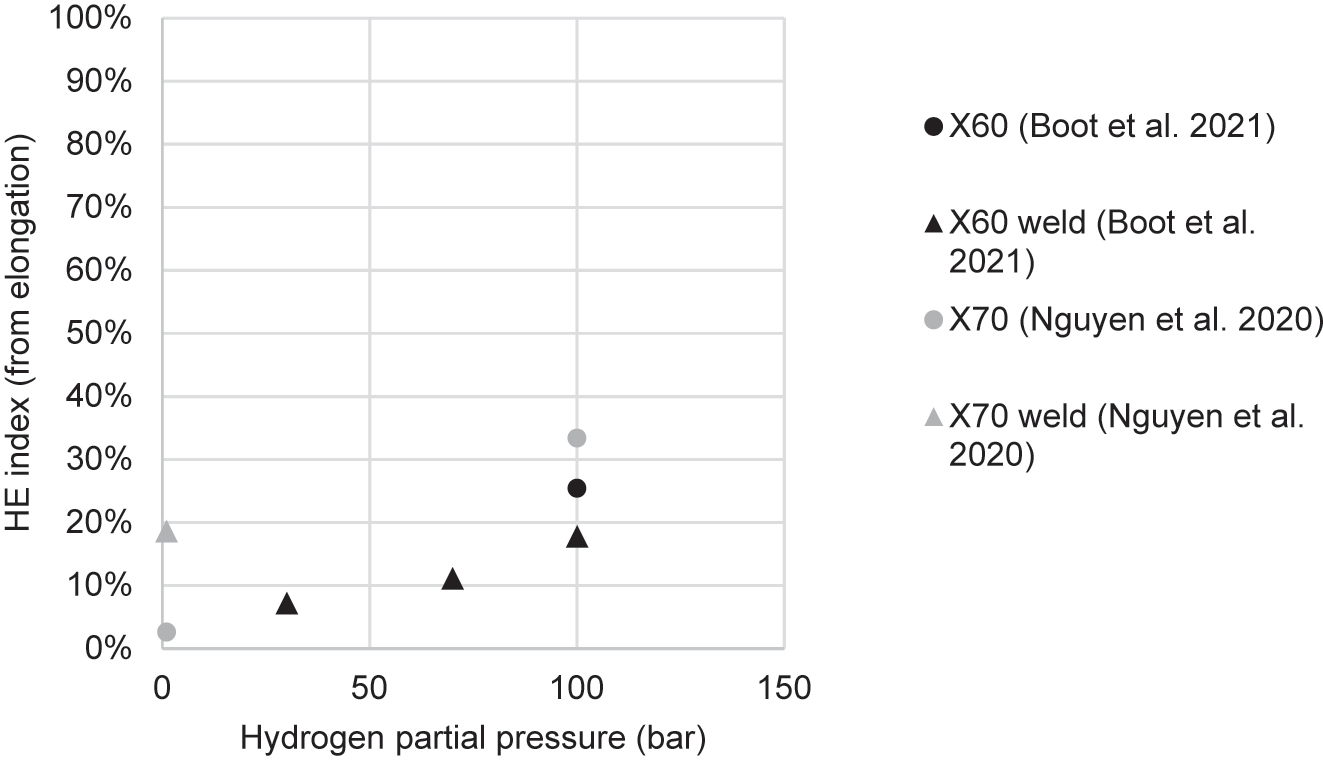

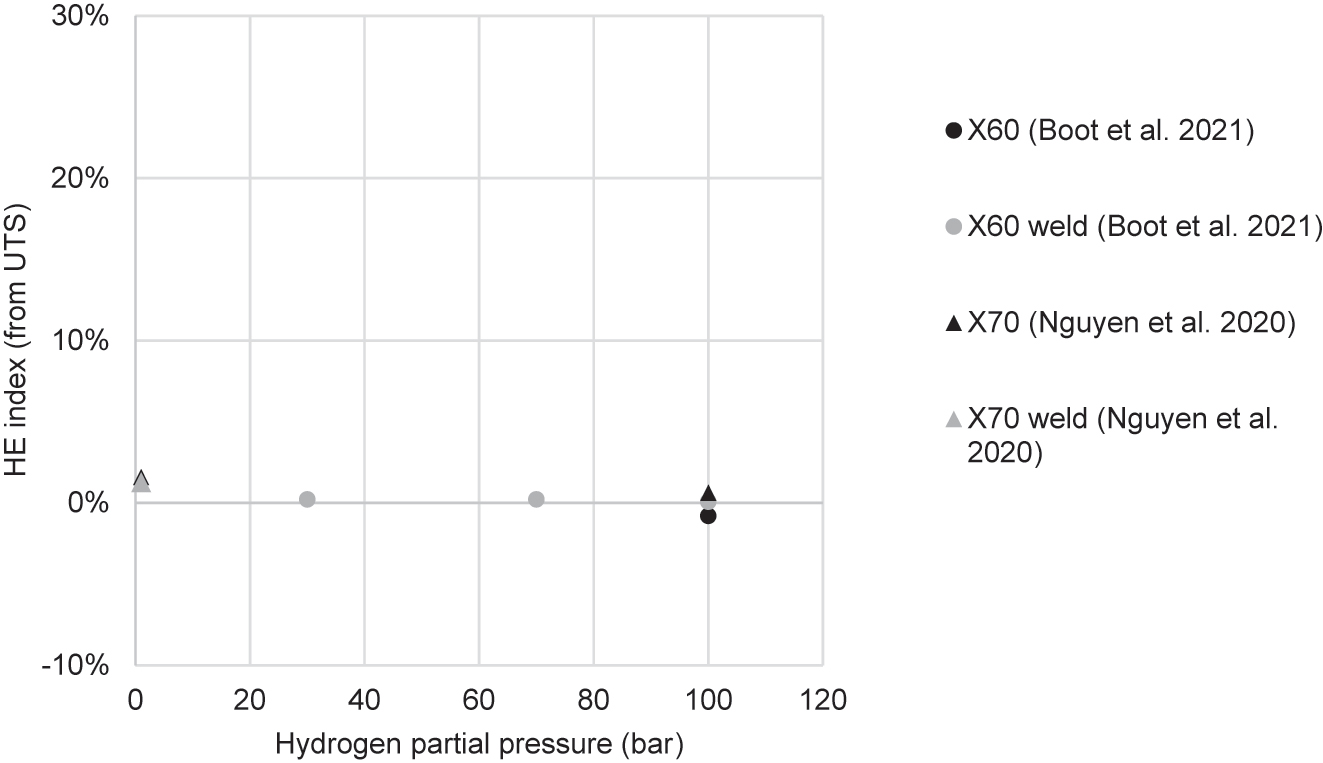

| Nguyen et al. (2020a) | X70 | Cylindrical, transverse, 6 mm gauge dia. | 2.62 × 10−5 | HEE | Gaseous: H2 and CH4 mixture; and pure H2 | 1:99 bar H2/CH4; 100 bar H2 | 1 bar: 3% 100 bar: 33% |

∼1% strength reduction |

| Nguyen et al. (2020c) | X70 weld | Cylindrical, transverse, 6 mm gauge dia. | 2.62 × 10−5 | HEE | Gaseous: H2 and CH4 | 1 bar H2, 99 bar CH4 | From ε: 18% From RA: 25% |

∼1% strength reduction |

| Ohaeri et al. (2020) | X70 | Rectangular, longitudinal, 4 × 3.125 mm gauge dim. | 1 × 10−3 | IHE | Electrolytic: 0.2 M H2SO4 and 3 g/L NH4SCN | 20 mA/cm2 for 12 h | Thermomechanically processed specimen: 50% | UTS increased by 4–8% |

| Boot et al. (2021) | X60 base metal and weld | Cylindrical, hollow, both smooth and notched, longitudinal, 8 mm gauge dia. | 1 × 10−5 | HEE | Gaseous: pure H2 | 30–100 bar | Base 100 bar: 28% Weld 100 bar: 11% Weld 70 bar: 11% Weld 30 bar: 11% |

None |

| Nguyen et al. (2021) | X70 base metal and weld | Cylindrical, transverse, 6 mm gauge dia. | 2.62 × 10−5 | HEE | Gaseous: H2 and CH4 mixture; and pure H2 | 1:99 bar H2/CH4; 100 bar H2 | Base 1 bar: 0.9% Base 100 bar: 51% Weld 1 bar: 25% |

∼1% strength reduction |

| Xing et al. (2021) | X90 | Rectangular, transverse, 6 × 2 mm gauge dim. | 1 × 10−6 | HEE | Electrolytic: NS4 simulated soil | No applied current | 0 °C: 6% 40 °C: 21% 60 °C: 15% |

Possible increased strength |

| Nykyforchyn et al. (2022a) | VST3ps | Rectangular, transverse, 4 × 1.2 mm gauge dim. | 3 × 10−4 | IHE | Electrolytic: H2SO4, unspecified molarity | 1 mA/cm2 for 100 h | 0–2% | Strength reduced by 4–8% |

-

The specimen type column includes the specimen orientation, designated either longitudinal or transverse. Longitudinal means the specimen axis is aligned with the pipe axis, or the rolling direction of the steel. Transverse means the specimen axis is along the curvature in the pipe wall. Transverse specimens represent the typical axis of pipeline fracture due to hoop stresses in the pipe wall. The hydrogen embrittlement index is calculated based on ductility. IHE designates studies precharged with hydrogen, while HEE designates studies with hydrogen charging during the tensile test. The hydrogen embrittlement index was evaluated from the change in ductility.

Tensile experiments have also been used to investigate SCC of pipeline steels. SCC may involve the electrochemical generation of hydrogen alongside other corrosive processes (Ramamurthy and Atrens 2013). Numerous studies have conducted tensile tests with cathodic hydrogen charging in a corrosive solution (Li et al. 2006; Liang et al. 2009; Liu et al. 2012, 2016; Sant’Anna et al. 2016; Song et al. 2020a, b; Torres-Islas and Gonzalez-Rodriguez 2009; Wan et al. 2017; Zhu et al. 2016). Other studies have investigated the effects of hydrogen sulphide (H2S) gas on pipeline steel tensile properties which also involves simultaneous corrosion and HE (Anijdan et al. 2021; Bai et al. 2020b; Silva et al. 2021; Titov et al. 2019; Wang et al. 2015a, b). Though these findings are important for pipeline safety, they are not pertinent to hydrogen pipelines and hydrogen blending into natural gas pipelines and therefore are not included in Table 2.

Gu et al. (1999) investigated IHE as part of a study of the SCC in X52 and X80 pipeline steels. The IHE study involved conducting SSRTs for specimens in air and precharged with hydrogen. The parameters of this precharging are given in Table 2; the resulting hydrogen concentration was not measured. For X80 steel, the hydrogen precharging did not affect the YS or UTS but reduced the strain at fracture by 9%. Both uncharged and hydrogen precharged specimens had similar fracture surfaces that were indicative of ductile fracture. The results for SSRTs of X52 steel were not given, presumably because there was no evidence of HE in this lower-strength steel.

Torres-Islas et al. (2005) investigated the effect of heat treatments on IHE in X70 using SSRT. The specimens were precharged electrolytically and tested in air. The heat treatments investigated were spray quenching, water quenching, and quench and tempering. The as-received steel had a mostly ferritic microstructure, while the water sprayed steel had a mostly bainitic microstructure with some acicular ferrite section. These specimens underwent ductile fracture and had low susceptibility to HE with I values of 10% and 5%, respectively. The water quenched steel and quench and tempered steel had martensitic microstructures, and underwent brittle fracture after hydrogen charging with respective I values of 85% and 90%. In another study, Torres-Islas et al. (2013) investigated HE in a novel microalloyed steel similar to the API 5L class pipeline steels. This study compared tensile specimens from the longitudinal and transverse directions with respect to the pipe axis. Transverse specimens are likely more representative of real pipeline failure as this relates to the probable orientation of fracture in a pipe wall due to hoop stresses. The transverse specimens were somewhat less susceptible to HE than the longitudinal specimens, although this trend was inconsistent.

Hardie et al. (2006) studied the effect of IHE on X60, X80 and X100 pipeline steel using tensile tests precharged with current densities varying from 11 to 70 mA/cm2, with a charging time of 15 min. The hydrogen concentrations resulting from these current densities were not measured. The results were highly variable, possibly due to the low charging time. The changes in RA after hydrogen charging were similar for the three steel grades, dropping from an average of around 80% in the uncharged specimen to around 30% in the specimen charged at 10 mA/cm2. Reductions in elongation after charging in the X80 and X100 were greater than in X60. As the current density increased further, RA and elongation remained mostly constant – this is likely due to the hydrogen concentration reaching the saturation level (Barthélémy 2006; Lynch 2011a). At high current densities (>60 mA/cm2) ductility may have decreased further in the X80 and X100 steels, although this finding may be unreliable due to the variation in results, and the authors had no explanation for this observation. Their fractographic analysis indicated both intergranular and transgranular cracking in the charged specimens, although the fracture was primarily transgranular. Hydrogen induced cracking had occurred on the specimen surface, and the cracks were oriented in the rolling direction of the pipe.