Building with renewable materials

-

Azra Korjenic

Abstract

Research into sustainable construction is increasingly focusing on the use of renewable materials in construction. These materials represent a promising alternative to conventional building materials as they are derived from renewable sources and are usually more environmentally friendly in terms of production, transport and end-of-life treatment. The Department of Ecological Building Technologies at the Vienna University of Technology has been investigating the hygrothermal behaviour and applicability of renewable materials for many years. Not only traditional building materials such as straw, wood, sheep’s wool and hemp have been investigated, but also innovative materials such as mushroom fabric. The research covered various aspects such as moisture protection, fire protection, thermal insulation, durability and resistance to external influences. The overall aim was to deepen the understanding of ecological building materials, overcome barriers to their use, and develop damage-tolerant constructions from them. The robust properties of wheat straw, sheep’s wool, hemp, cellulose and other materials underline their potential as efficient and environmentally friendly building materials. The data and insights gained will not only help to prove the effectiveness of these materials in the construction industry, but also to address concerns and uncertainties about their functionality.

Kurzfassung

Die Forschung im Bereich des nachhaltigen Bauens konzentriert sich zunehmend auf die Verwendung von Naturmaterialien im Bauwesen. Diese Materialien stellen eine vielversprechende Alternative zu konventionellen Baumaterialien dar, da sie aus erneuerbaren Quellen gewonnen werden und in der Regel in Bezug auf Produktion, Transport und Recycling am Ende des Lebenszyklus umweltfreundlicher sind. Der Forschungs-bereich für ökologische Bautechnologien an der Technischen Universität Wien untersucht seit vielen Jahren das hygrothermische Verhalten und die Anwendbarkeit von nachwachsenden Rohstoffen. Dabei wurden nicht nur traditionelle Baustoffe wie Stroh, Holz, Schafwolle und Hanf untersucht, sondern auch innovative Materialien wie Pilzgewebe. Die Forschung umfasste verschiedene Aspekte wie Feuchtigkeitsschutz, Brandschutz, Wärmedämmung, Haltbarkeit und Beständigkeit gegen äußere Einflüsse. Übergeordnetes Ziel war es, das Verständnis für ökologische Baustoffe zu vertiefen, Hindernisse für ihre Verwendung zu überwinden und schadenstolerante Konstruktionen aus ihnen zu entwickeln. Die robusten Eigenschaften von Weizenstroh, Schafwolle, Hanf, Zellulose und anderen Materialien unterstreichen ihr Potenzial als effiziente und umweltfreundliche Baustoffe. Die gewonnenen Daten und Erkenntnisse werden nicht nur dazu beitragen, die Wirksamkeit dieser Materialien in der Bauindustrie zu beweisen, sondern auch Bedenken und Unsicherheiten hinsichtlich ihrer Funktionalität auszuräumen.

1 Introduction

Biological engineering is an interdisciplinary field that combines the principles of biology and engineering to develop sustainable and innovative solutions for various applications. In sustainable building research, the use of renewable materials in construction is becoming increasingly important. Renewable materials offer a promising alternative to conventional building materials, as they come from renewable sources and are often more environmentally friendly in terms of production, transport and end-of-life treatment.

The Department of Ecological Building Technologies at the Vienna University of Technology has been conducting research in the field of building with renewable materials for several years, demonstrating that bio-based materials are not only ecologically sustainable, but also offer innovative properties for the construction sector. A key area of this research is the development of building materials from biological waste products. Through clever engineering, these waste products could be transformed into structurally stable and environmentally friendly building materials. This approach not only contributes to waste reduction, but also enables the creation of new high-performance building materials. One example is biological composites based on natural fibers. Research has shown that these materials can be used in practice to create lightweight yet strong structures. Such materials could have the potential to replace conventional building materials in many applications, contributing to a more sustainable construction industry.

The natuREbuilt research project [1] looked closely at various renewable materials such as straw, sheep’s wool, cellulose, hemp, etc. The project integrated extensive measurements over an extended period to evaluate the performance of the materials in real conditions. Sensors were attached to different layers of the test structures to record long-term data. The heat flow was measured to record the insulating properties (U-value) of the constructions at different humidity levels. The temperature and humidity in each layer of the construction, as well as the internal and external surface temperatures, were also monitored. In addition, air was sampled from the structures at regular intervals and tested for the presence of mold spores. The thermal conductivity of the various insulation materials was regularly checked using a lambda probe. All in all, this interdisciplinary research project has been pursuing a comprehensive approach to ecological construction since 2021. The focus was not only on well-known building materials such as straw, wood, sheep’s wool and clay, but also on new materials such as mushroom netting. The research covered various aspects, including fire safety, thermal insulation, durability and resistance to external influences, with the aim of deepening the understanding of ecological building materials and overcoming the barriers to their use.

A particular challenge was to investigate the influence of construction errors on the functionality of different green insulation materials. This involved deliberately creating defects, such as drilling through the airtight layer, to understand how the materials react to such situations. The results showed that the green insulation materials, particularly sheep’s wool and cellulose, are robust and resistant to such errors. These findings help to reduce uncertainties in the use of ecological materials in the construction industry and promote the acceptance of these sustainable building materials.

The integration of bio-based materials not only brings environmental benefits, but also economic ones, as waste products are converted into valuable resources. Overall, biological engineering is not just a theoretical possibility, but already has practical applications in the construction industry. The main aim of the tests carried out is to find out how different insulation materials deal with such errors and how they react to increased moisture infiltration.

2 Methodology

At the Research Department for Ecological Building Technologies at TU Wien, the first years of research focused on the design and basic development of insulation materials based on natural fibers. The key advantage of these materials is that they are produced in an environmentally friendly way, using easily renewable or secondary raw materials. This not only saves general material resources, but also prevents the consumption of non-renewable raw materials. These materials also contribute to a healthy environment for the human organism. At the end of their life in the building, they are easily recycled. This is not only a sustainable solution, but also promotes the creation of an environmentally friendly construction industry.

The thermal insulation properties of building materials are generally subject to numerous factors that must be considered both during production and when used in the building structure. In particular, the type and thickness of the fibers, the density and the amount of binder used (in the case of thermal bonding with two-component fibers) play an important role in the production of fiber-based thermal insulation materials. These parameters influence both the thermal and mechanical properties of the product, as well as its price. The overall aim in developing an optimal building material composition is to improve the properties of the product while keeping costs at an acceptable level.

The design of each mix was based on information obtained from extensive literature research on the intended use of the insulation materials in construction. It was therefore necessary to optimize not only the composition of the test specimens, but also their density, which is crucial for the use of these products in construction. A total of nine different compositions of insulating materials were developed in [2]. The exact composition of the mixtures is given in Table 1, with the jute fibers included for comparison purposes only.

Composition of the individual raw materials of the mixtures tested [2].

| Mixture | Fibers | Natural fibers [wt.%]a | Binder fibers [wt.%]a | Shivs [wt.%]a |

|---|---|---|---|---|

| 1 | Jute | 68 | 20 | 12 |

| 2 | Flax | 68 | 20 | 12 |

| 3 | Hemp | 48 | 20 | 32 |

| 4 | Hemp | 68 | 20 | 12 |

| 5 | Hemp | 48 | 20 | 32 |

| 6 | Hemp | 48 | 20 | 32 |

| 7 | Hemp | 48 | 20 | 32 |

| 8 | Hemp | 64 | 20 | 16 |

| 9 | Hemp | 49 | 10 | 41 |

-

aPercentage by weight of input components.

The insulation mats were produced from the selected natural fibers as follows [2]: The delivered natural fiber bales (industrial hemp, flax and jute) were mechanically and then pneumatically torn into fibers, after which an additive against fire and biological pests (soda) was applied. After the addition of soda, the fibers were partially dried (to a moisture content of approximately 6 % by weight). The bicomponent polyester fiber bales were also torn into fibers in parallel, and then pneumatically and mechanically blended with the natural fibers. At this stage of the production process, the fiber waste generated during production was added to the mixture. After thorough homogenization of the fiber mixture, insulation mat boards were produced by heat bonding the prepared mixture under high pressure and temperature. After cooling, the insulation mats were cut to the desired dimensions of 1200 mm × 600 mm. The test specimens prepared in this way were wrapped in foil and prepared for further testing of the hygrothermal properties. The surface texture of the specimens is shown in Figure 1.

![Figure 1:

Surface structure of the test specimens of the developed insulation materials made of natural fibers [2]: (a) jute; (b) flax; (c) hemp.](/document/doi/10.1515/auto-2024-0048/asset/graphic/j_auto-2024-0048_fig_001.jpg)

Surface structure of the test specimens of the developed insulation materials made of natural fibers [2]: (a) jute; (b) flax; (c) hemp.

In another study, a particleboard was produced from agricultural waste and its technical properties were investigated [3]. The aim of this study was to characterize the tensile and compressive strength, modulus of rupture (MOR), modulus of elasticity (MOE) and thermal conductivity of the particleboard as a function of parameters such as waste type (rice straw or flax shives), particleboard density, resin type and content and the use of treated rice straw.

The rice straw used for the test specimens was collected from a farm in Egypt and crushed into different grain sizes of 10–40 mm using a hammer mill. The straw particles were then sieved to remove fine particles and dust. The rice straw was soaked in hot water for two hours at 100 °C, then oven-dried and prepared using a hot compression molding process according to [4]. The starch adhesives were prepared by dispersing starch powder in distilled water at a ratio of 1:10 with stirring for two hours at room temperature with 1.2 wt.% sodium thiosulfate according to [5]. A predetermined amount of straw was sprayed with resin material and then thoroughly mixed for 8 min. The mixture was poured into a steel mold measuring 700 mm × 350 mm and placed on a wooden board. After filling the first layer, the straw was manually compacted to ensure proper filling of the mold. The steel mold was then removed, and the first pressing was carried out using a manually operated hydraulic press, which took approximately 2 min. After the first pressing, the samples were placed between the heated plates of a hot press. These plates were preheated to a constant temperature of 180 °C, and a pressure of 210 bar was applied to ensure optimum curing of the resin material. It took 4 min to reach the constant temperature and the hot-pressing process took 8 min. After trimming the edges of the samples, the finished boards were cut to the desired length and width, with the edges straightened.

Different formulations of particleboards with variable parameters were prepared for the test. The variables included resin content (10 %, 12 % and 14 %), resin type (urea-formaldehyde and corn starch), waste type (rice straw and flax shives), particleboard density (0.3, 0.5 and 0.7 g/cm3) and straw treatment (hot water and sodium hydroxide).

To obtain MOE and MOR for the particleboards, a three-point bending test was performed (Figure 2(a) and (b)). For the tensile tests, which were carried out to determine the cohesion of the board in the direction perpendicular to the board plane, the specimens were prepared by fixing them to aluminum load blocks. The load blocks were first heated and then an adhesive was melted onto their surface. The individual specimens were then placed between two load blocks and the adhesive was applied at room temperature without pressure. The tests were then carried out on the specimens 24 h after this bonding process. The specimens were loaded by clamping the load blocks into the slot to ensure sufficient contact with the arms of the fixture (Figure 2(c) and (d)). The specimens were loaded perpendicular to the plate surface until failure of the specimen occurred. The compression test was used to determine the compressive strength in the plane of the slab (Figure 2(e) and (f)). The specimens were carefully centered in the testing machine in a vertical plane for unsupported specimens using a spherical load block, and then loaded parallel to the plate surface until failure occurred. The maximum load reached during the test before failure of the specimens was recorded and used to calculate the compressive strength.

![Figure 2:

Test specimens of particleboard before (a, c, e) and after (b, d, f) the test procedure [3]: (a, b) static bending test; (c, d) tensile test; (e, f) compressive strength test.](/document/doi/10.1515/auto-2024-0048/asset/graphic/j_auto-2024-0048_fig_002.jpg)

Test specimens of particleboard before (a, c, e) and after (b, d, f) the test procedure [3]: (a, b) static bending test; (c, d) tensile test; (e, f) compressive strength test.

Another possible application of straw in the construction industry is its use as a blown-in insulation material for wooden stud walls. As part of the natuREbuilt research project [1], measurements and calculations of the U-value and thermal conductivity of the different blow-in techniques were carried out at a test stand on the grounds of the Vienna University of Technology, Science Center. The outdoor test facility for in-situ measurements is designed to allow measurements to be made in a real environment, so that data can be collected under natural conditions and real-world results can be obtained in addition to laboratory measurements. For the tests, a 2.09 m × 2.18 m timber-framed exterior wall was constructed and installed in an east-facing wall of the test stand.

The building material tested was untreated wheat straw with a fiber length between approximately 5 and 30 mm [6]. The straw was installed using a conventional blowing machine, with the prepared straw being blown in with air from a nozzle through a long hose into the respective component and compacted to a density of 90–105 kg/m3. In compaction tests according to EN 15101-1 [7], the volume of the insulation decreased by up to 3 %, but remained permanently stable. The straw used here retains this property throughout its service life due to its special fiber processing and structure.

The exterior wall has three cavities, each filled with a different blowing method: one filled horizontally, one filled vertically (see Figure 3), and one filled vertically with used straw, with vertical blowing being the standard blowing method, while the other two methods and their hygrothermal properties have not been previously studied. In the used straw method, the straw was taken from another construction and blown back in. Numerous measurements were made in all three areas.

![Figure 3:

Investigation of different techniques for blowing in chopped straw [6]: (a) vertical blowing technique; (b) horizontal blowing technique.](/document/doi/10.1515/auto-2024-0048/asset/graphic/j_auto-2024-0048_fig_003.jpg)

Investigation of different techniques for blowing in chopped straw [6]: (a) vertical blowing technique; (b) horizontal blowing technique.

In order to establish straw insulation as a common, commercially available insulation material for multi-story urban construction projects, and to significantly increase the applicability of the material by using it in larger construction projects, practical solutions are needed to meet building codes regarding fire protection. For this reason, both fire protection treatments with ecologically harmless flame retardants and constructive fire protection solutions were examined for their applicability in chopped straw blow-in insulation in a study completed in 2022 [6]. The ecological advantages of straw should not be compromised, and the insulation material should remain compostable at the end of its life cycle.

Since the long-term hygrothermal behavior of straw treated with flame retardants is difficult to predict and the increased salt concentration in the blown-in straw due to the flame retardant can lead to potential hygrothermal problems in the building, an exterior wall module in timber frame construction with blown-in straw as insulation material was installed on the outdoor test stand at the Vienna University of Technology. The straw was treated with 12 wt.% flame retardant (Ecoaphos MK 46).

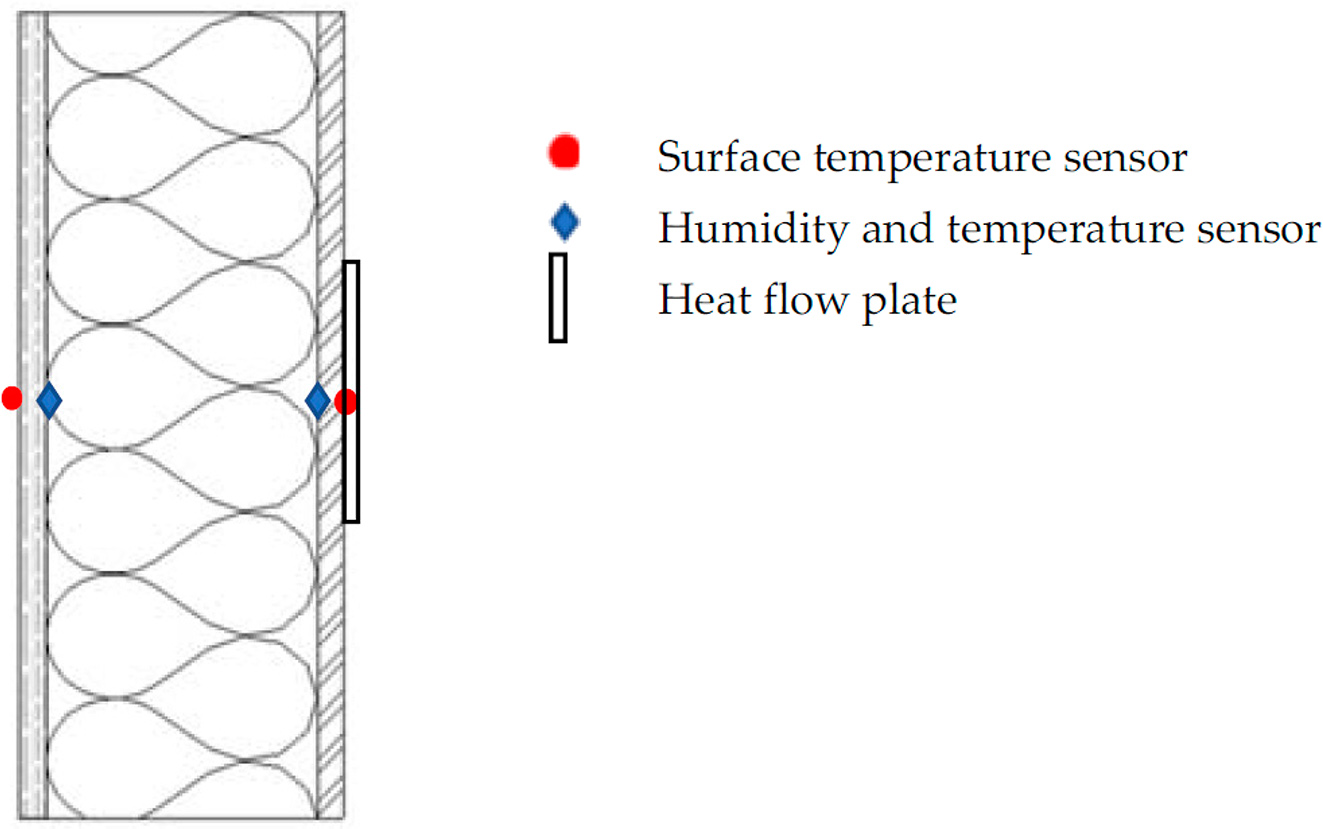

The wall module used consists of three compartments, each filled with the treated straw. To measure the long-term behavior, two humidity and temperature sensors were attached to the boundary layers within the component in each compartment of the wall module. In addition, two temperature sensors were placed on the inner and outer surfaces of the component, and a heat flux foil was attached to the inner surface of the component. The measurement setup is shown in Figure 4.

Measurement setup to monitor the long-term hygrothermal behavior of straw treated with flame retardants.

To investigate the hygrothermal effect of the blowing direction of the treated straw, one compartment was blown horizontally while the other two compartments were blown vertically as usual. These investigations should provide insight into the long-term hygrothermal behavior and the effect of blowing direction on the hygrothermal properties of the insulation material.

Since bio-based building materials are often not used due to concerns about mold or insect infestation in connection with moisture damage, a case of water damage to a single-family residence in Zyklamengasse, 1140 Vienna (see Figure 5) was used as an opportunity to conduct detailed investigations of changes in the technical properties of the insulation material affected. The material investigated was sheep’s wool, which had been used as cavity insulation in a wooden stud construction. The complete wall construction is shown in Table 2.

Facade opening during the restauration of water damage.

Wall assembly of exterior wall Zyklamengasse, 1140 Wien, in the area of the water damage.

| Thickness [cm] | Building material |

|---|---|

| 1.25 | Plasterboard |

| 1.8 | OSB(-board) |

| 12.0 | Sheep’s wool in between glue laminated timber studs |

| 1.8 | OSB(-board) |

| Windpaper | |

| 20.4 | Sheep’s wool in between web joists |

| 6.0 | Soft wood fiberboard |

| 0.5 | Thin plaster |

The focus was on thermal conductivity and mold growth. The goal was to determine if the thermal conductivity of the redried insulation material had been altered by previous exposure to moisture. Thermal conductivity was measured in the field using a needle probe. In addition, the assumption that sheep wool, unlike other bio-based building materials, is not a substrate for mold growth was to be confirmed or refuted. For this purpose, samples of sheep’s wool were compared with samples of other organic materials during the mold measurements in the laboratory.

3 Results

The evaluation of the results of the first studies on insulation materials made from natural fibers confirms the hypothesis that an increased proportion of shives has a positive effect on the thermal insulation properties, especially when the bulk density of the test specimens is higher. The optimum bulk density range seems to be between 70 kg/m3 and 80 kg/m3 [2]. At low densities, the thermal insulation properties deteriorate due to increased convective processes in the insulation material. At higher densities, heat conduction through the fibers increases. It should be noted that a higher density value is associated with higher production costs, as more raw materials are required to produce a unit volume of insulation material.

Nearly all the test blends based on industrial hemp fibers exhibited excellent thermal conductivity values very close to those of currently used insulation materials. The thermal insulation properties are comparable to those of mineral wool, although the production of natural materials is much more energy efficient in comparison.

Experimental measurements also confirmed the vapor diffusion properties of these natural materials. The diffusion resistance was generally low, with mixture no. 1 (see Table 1) having the lowest value. With respect to the short-term water absorption capacity during partial immersion, the higher water absorption capacity of the natural materials was successfully confirmed. These results underscore the promising thermal and hygric properties of hemp fiber-based insulation materials, offering potentially sustainable alternatives for building applications.

The tests on particleboards made from agricultural waste showed that the particleboards made from flax shives had better mechanical properties than those made from rice straw particles. However, the thermal insulation of the rice straw particleboards was better than that of the flax shives particleboards. As for the type of resin, the rice straw particleboards mixed with urea-formaldehyde had better mechanical properties than the particleboards mixed with corn starch or those with no resin material. In contrast, the thermal conductivity of the corn starch-blended particleboard was lower than that of the urea-formaldehyde-blended particleboard and the unblended particleboard. In addition, increasing the resin content improved the mechanical properties of the boards, except for MOR and MOE, which decreased with increasing resin content and peaked at 10 % resin content. A higher urea-formaldehyde resin content resulted in a higher thermal conductivity [3].

Increasing the density generally improved the mechanical properties of the particleboard significantly. The maximum mechanical strength was obtained at a density of 700 kg/m3 and a urea-formaldehyde resin content of 14 %. While the mechanical properties were improved by increasing the density of the boards, this resulted in an increase in thermal conductivity and thus a decrease in insulation. The treatment of rice straw with hot water also resulted in an improvement in the mechanical properties of the particleboards produced, except for the MOE, which peaked at the sodium hydroxide treatment. The thermal conductivity of the particleboards produced with untreated rice straw was the lowest. The treatment of the straw increases the thermal conductivity, which results in a lower insulating effect.

In German-speaking countries, straw, especially wheat straw, has established itself in recent years as a promising building material with convincing ecological advantages compared to traditional insulation materials. The investigation of the hygrothermal properties of chopped wheat straw as an insulation material has shown that the type of blowing, whether vertical or horizontal, surprisingly does not cause a significant difference in the thermal conductivity [6]. This observation could be explained by the fact that the fibers exhibit fluid-like behavior during blowing and the general flow behavior is very turbulent. Interestingly, no noticeable difference in the orientation of the fibers was observed even after opening the wall module. Future investigations could provide further insight by constructing wall elements with a glass front and filming during the blowing process.

Surprisingly, the use of “recycled straw”, which was removed from a test wall element and re-injected, did not result in any significant change in the microstructure of the straw, which was also reflected in the evaluation of the thermal conductivities compared to new straw. Overall, the measured thermal conductivities were even better than the nominal values specified by the manufacturers for blown-in straw. A possible reason for this could be the unjustifiably high moisture surcharge to the thermal conductivity of natural fiber insulation materials according to ÖNORM B 6015-2 [8].

The additional tests on the long-term behavior of wheat straw treated with flame retardants did not show any discernible effects on the hygrothermal properties. In terms of fire protection, the structural shielding of the straw with wood wool lightweight boards proved to be superior to the chemical fire protection of the straw. The fire rating and thickness of the boards played a minor role. In addition, the straw remains completely untreated in the structural fire protection solutions and no adaptation of the production process is necessary. These results support the view that chopped wheat straw can be considered a highly ecological insulation material with great potential for the future.

The evaluation of the thermal conductivity measured on the sheep wool insulation of the single-family house in Zyklamengasse shows that there were no significant differences in thermal conductivity between the damaged area and the reference area with undamaged insulation (see Table 3). The difference between the thermal conductivity measured on site and that measured in the laboratory is due to changes in density and moisture during sampling and transportation.

Results of thermal conductivity measurements of sheep wool at a single-family house in Zyklamengasse, Vienna.

| Location | Thermal conductivity [W/mK] |

|---|---|

| Measurements taken on site | |

| Location of water damage – 1. Measurement | 0.046 |

| Location of water damage – 2. Measurement | 0.044 |

| Sheep’s wool undamaged | 0.045 |

| Measurements taken in the laboratory | |

| Sheep’s wool undamaged, outer insulation layer | 0.040 |

| Sheep’s wool undamaged, inner insulation layer | 0.042 |

| Sheep’s wool sample taken at location of water damage | 0.043 |

-

At the time of measurement, the material had already dried out. However, a distinct brownish discoloration of the sheep’s wool was observed in the area of the water damage. In addition, a clear change in consistency was observed during removal – the fibrous cohesion was no longer present, making the sheep’s wool easy to “pick apart”.

4 Conclusions

Although building with renewable materials is becoming increasingly important, there is a lack of information on the use of wood fiber materials, hemp, straw, clay, lime, sheep’s wool, and similar materials, which prevents building owners and designers from making greater use of ecological materials and components. Over the past few years, the natuREbuilt innovation network [1] has investigated and tested the use of ecological materials in new multi-story buildings and renovations. The results have been incorporated into functional, tested, resilient constructions, which have then been digitalized for BIM and made publicly available on the natuREbuilt-website. This new design tool provides relevant information for designers and contractors, enabling widespread use in the construction industry.

In summary, the extensive research on various ecological materials provides important insights for the future of sustainable building. The robust properties of wheat straw, sheep’s wool, cellulose, and other renewable resources underscore their potential as efficient, environmentally friendly building materials. The data and insights gained will not only help to demonstrate the effectiveness of these materials in the construction industry, but also address concerns and uncertainties about their use. In particular, the error tolerance and high performance under real-world conditions will steadily increase confidence in green building materials.

The research also looks at the challenges and potentials of new materials such as foam glass gravel and mushroom fabric. The comprehensive analysis of fire protection, thermal insulation and mechanical resistance helps to develop an understanding of these innovative building materials and identify potential areas of application.

Overall, the efforts of the natuREbuilt innovation network in Austria make it clear that the future of construction can be shaped by sustainable, ecological building materials. The results of the research not only provide valuable information for architects, civil engineers and construction companies, but also help to steer the entire construction industry towards environmentally friendly practices. The pursuit of sustainable construction will be further strengthened by the research and development of ecological building materials to ensure an environmentally friendly and resource-efficient future.

Funding source: Austrian Research Promotion Agency (FFG)

Award Identifier / Grant number: 881230

About the authors

Univ. Prof. Dipl.-Ing. Dr. Azra Korjenic is a full professor and head of the Institute of Building Physics and the Research Department for Ecological Building Technologies at the Faculty of Civil and Environmental Engineering at the Vienna University of Technology, where she obtained her doctorate in 2003 and habilitation in 2012. She leads numerous research projects, is a board member and reviewer of various international journals and conferences, mentor and member of various commissions for doctoral theses in different countries and member of many scientific organizations. She has received numerous scientific awards and prizes for her research work. Her research activities cover a wide range of topics: Development of new ecological materials and constructions, greening of buildings, green and smart cities, building physics, innovative and sustainable construction, etc.

Florian Teichmann has been a university assistant at the Research Department for Ecological Building Technologies at TU Wien since 2020. His work focuses primarily on greening systems for schools and the impact of facade greening on the immediate microclimate.

Acknowledgments

The authors acknowledge TU Wien Bibliothek for financial support through its Open Access Funding Programme.

-

Research ethics: Not applicable.

-

Author contributions: The authors have accepted responsibility for the entire content of this manuscript and approved its submission. A. Korjenic: conceptualization, writing—original draft preparation, writing—review and editing, supervision, project administration, funding acquisition; F. Teichmann: methodology, investigation, writing—original draft preparation, visualization.

-

Competing interests: The authors states no conflict of interest.

-

Research funding: This research was funded by the Austrian Research Promotion Agency (FFG) under the COIN funding program (FFG grant number 881230).

-

Data availability: The raw data can be obtained on request from the corresponding author.

References

[1] Forschungsbereich Ökologische Bautechnologien, Institut für Werkstofftechnologie, Bauphysik und Bauökologie, TU Wien. Innovationsnetzwerk für regenerative, rezyklierbare, regionale und resiliente Komponenten im Hochbau. Available at: https://www.naturebuilt.at Accessed: Jan. 15, 2024.Search in Google Scholar

[2] A. Korjenic, J. Zach, and J. Hroudova, “The use of insulating materials based on natural fibers in combination with plant facades in building constructions,” Energy Build., vol. 116, pp. 45–58, 2016. https://doi.org/10.1016/j.enbuild.2015.12.037.Search in Google Scholar

[3] Z. Hussein, et al., “Rice straw and flax fiber particleboards as a product of agricultural waste: an evaluation of technical properties,” Appl. Sci., vol. 9, no. 18, p. 3878, 2019. https://doi.org/10.3390/app9183878.Search in Google Scholar

[4] L. Junjun, J. Chanjuan, and H. Chunxia, “Flexural properties of rice straw and starch composites,” AASRI, vol. 3, pp. 89–94, 2012. https://doi.org/10.1016/j.aasri.2012.11.016.Search in Google Scholar

[5] L. Junjun and H. Chuanhui, “Biodegradable composites from rice straw and cornstarch adhesives,” Adv. J. Food Sci. Technol., vol. 5, no. 1, pp. 41–45, 2013. https://doi.org/10.19026/ajfst.5.3309.Search in Google Scholar

[6] T. Salonen, H. Fischer, and A. Korjenic, “Chopped straw as an insulation material: the influence of different blow-in Technologies and flame retardants on hygrothermal properties,” Buildings, vol. 13, no. 10, p. 2555, 2023. https://doi.org/10.3390/buildings13102555.Search in Google Scholar

[7] ÖNORM EN 15101-1, Thermal Insulation Products for Buildings—In-Situ Formed Loose Fill Cellulose (LFCI) Products—Part 1: Specification for the Products before Installation, Wien, Austria, Austrian Standards Institute, 2019.Search in Google Scholar

[8] ÖNORM B 6015-2, Bestimmung der Wärmeleitfähigkeit mit dem Plattengerät – Teil 2: Ermittlung des Nennwertes und des Bemessungswertes der Wärmeleitfähigkeit für homogene Baustoffe, Wien, Austria, Austrian Standards Institute, 2009.Search in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Survey

- Biological engineering – an engineering discipline crucial to the future of our civilization

- Forum

- New biological solutions to the many problems of our time

- Survey

- Biological engineering as a driver of innovation: implications for the economy

- Advancing vertical farming with automation for sustainable food production

- Harnessing microalgae: from biology to innovation in sustainable solutions

- Generation of molecular hydrogen (H2) by microalgae and their biocatalysts

- Biocatalytic approaches for plastic recycling

- Engineered living materials: pushing the boundaries of materials sciences through biological engineering

- The fabrication-assembly challenge in tissue engineering

- Evolution of biofabrication and 3D-bioprinting technologies – from market pull to technology push

- A bio-engineering approach to generate bioinspired (spider) silk protein-based materials

- RNA aptamers: promising tools in synthetic biology

- Automated handling of biological objects with a flexible gripper for biodiversity research

- Building with renewable materials

- Growing new types of building materials: mycelium-based composite materials

- Façade greening – from science to school

Articles in the same Issue

- Frontmatter

- Survey

- Biological engineering – an engineering discipline crucial to the future of our civilization

- Forum

- New biological solutions to the many problems of our time

- Survey

- Biological engineering as a driver of innovation: implications for the economy

- Advancing vertical farming with automation for sustainable food production

- Harnessing microalgae: from biology to innovation in sustainable solutions

- Generation of molecular hydrogen (H2) by microalgae and their biocatalysts

- Biocatalytic approaches for plastic recycling

- Engineered living materials: pushing the boundaries of materials sciences through biological engineering

- The fabrication-assembly challenge in tissue engineering

- Evolution of biofabrication and 3D-bioprinting technologies – from market pull to technology push

- A bio-engineering approach to generate bioinspired (spider) silk protein-based materials

- RNA aptamers: promising tools in synthetic biology

- Automated handling of biological objects with a flexible gripper for biodiversity research

- Building with renewable materials

- Growing new types of building materials: mycelium-based composite materials

- Façade greening – from science to school