Abstract

Some panels and particleboards were made from reed mats and blends of reed-wood chips to be used inside buildings for sound and heat insulations. It was seen that the outer layers of the reed body (spike) was almost water resistant and exceptionally resistant to the penetration of common adhesives. Therefore, the panels from stitched reed mats exhibited very poor mechanical strength. The sound transmissions of such panels (1–3 km/s) made with various combinations, however, were recorded to be excellent compared with that of particleboards made of wood (17 km/s). Blends of reed chips (2 cm) and wood chips, however, gave particleboards with better mechanical properties (5–17 MPa) than that of panels made from reed mats (2 MPa). An increasing amount of reed chips in tested particleboards was recorded to be improving both sound and heat insulations from 17 to 6 km/s and from 0.34 to 0.27 W/mK, respectively. The bending strength of samples, however, was reduced from 26 to 5 MPa. Thickness swelling was also noted to increase from 18% to 85% due to reed chips addition. It was concluded that the outer layers of water reeds should be modified via chemical and/or enzymatic methods to increase the interfacial bounds between adhesives.

1 Introduction

As a result of the increasing world population, the current natural world reserves are not well enough to supply the demand today. Therefore, almost all developed countries have turned their faces to finding alternative raw materials and recycling over the last decades. Forest and wood-based industries are among the ones suffering the most from this crisis and struggling to find a feasible way out. Many wood-based commodities are not produced from solid wood anymore. Instead, the various wood-based composite materials (fiberboards, particleboards, glued boards, oriented strand boards, etc.) have taken their places in our daily lives today and there are many researches being conducted on bio-based composites [1–3].

Water reed is known to be one of the first natural building materials used by early humans in history. The first human settlers are known to build their first barracks from the mixture of local materials, such as log, grass, reed, and clay. Today, reinforcement, insulating wall panels, and roofing materials are also made out of water reed in some parts of the world. However, the panels made from reeds are generally created by the stitching of reed spikes by galvanized metal wire, screwing, and nailing [4, 5]. It would be more practical if lightweight panels could be produced from reeds and/or reed particles by gluing and pressing.

Water reed can be classified in three species as Phragmites communis Trin, Phragmites australis, and Phragmites vulgaris. It is reported to be one of the farthest spreading plants in the world. It grows from 66°N latitude (polar circle in Europe) to 23° (Tropic of Capricorn). Three essentially climatic conditions are necessary for the growth of water reed [4, 5]:

prolonged water supply;

periodic break of growth by winter frost, dryness, or flood; and

2 m as the maximum of water depth with fluffily subsoil.

The water reed body (spike) is divided by the nonprotruding knops in several internodal segments and grows up to 1.25–8 m (P. australis in Iraq) [4, 5]. The lakes and rivers in Turkey are illustrated in Picture 1. The areas circled in the map show the locations where water reeds are harvested and sold in traditional ways. Because it naturally grows in quite a wide range of water-rich areas and is seen as an invasive species, its farming could be improved and value-added products could be made in economically and environmentally sustainable ways in Turkey and elsewhere.

Map of water reserves and water reed harvesting in Turkey.

2 Materials and methods

Reed plants were obtained from a local farmer who is commercially harvesting and selling reeds growing in Mersin as illustrated by a small circle in the south of Turkey (Picture 1). Reeds were cleaned of leaves and seeds and air dried before used. Especially, thin reeds with a diameter of 5 mm were used in this work.

In this work, urea-formaldehyde, its hardener, dry strength starch used in papermaking, and polyvinyl acetate were supplied by Caran Chemical (Izmir, Turkey). Urea-formaldehyde and polyvinyl acetate were used as-received at approximately 45–50% concentration. Starch, however, was first cooked with deionized water at 90°C for 30 min and prepared at 7.5% concentration. Imitation craft paper (100 g/m2), rough-size wood chips (middle-layer chips in particleboard making), and thin fiberboards in 3 mm thickness were obtained from Kahramanmaras Paper, Yonsan Particleboard, and Kastamonu Entegre, respectively, which are all situated in Turkey.

2.1 Reed panel

In the first part of the experimental study, reeds were stitched together to make mat as seen in Picture 2. The surfaces of the three mats were first sanded then glued and placed on top of each other with counter directions to form a firm and strong but lightweight panel as shown in Picture 3. The sanding of reeds partially removes the plant’s bark and improves the interfacial bonding with adhesives. Three adhesives were separately applied over mats by rolling to find out the best one. Paper layers on and between mats, thin fiberboards on outer layers of mat, and particleboards between reed mats were also placed in different combinations in an attempt to make a panel with better properties. The details of such combinations are given in the results and discussion section. Glued panels were then hot pressed for 10 min at 110°C and 10 bar pressure. The size of panels was set at 30×30 cm, whereas thickness was varied depending on layer combinations.

Reed mat made by stitching.

Simple plate made from three reed mats.

2.2 Reed particleboard

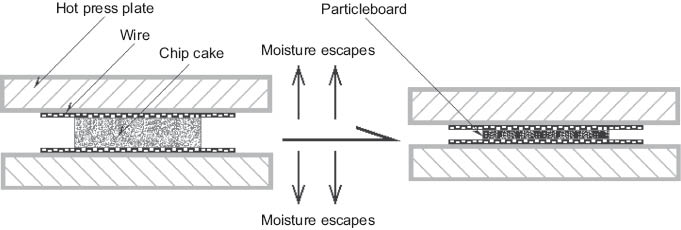

In the second part of the experimental study, reeds were first sanded and then cut in 2 cm length giving reed chips. Reed chips were blended with woodchips at 0%, 15%, 30%, and 45% proportions, glued, and hot pressed. Urea-formaldehyde was diluted with deionized water first at 25% concentration to homogenously spray over chips blends at a total of 10% oven-dried basis in all trials of particleboards. The weight of 150 g oven-dried chips was increased to 210 g after the adhesive application indicating 40% moisture content. These glued chips blends were then carefully and homogenously transferred into a specially designed forming frame measuring 16×16×10 cm (length×width×height), respectively. Loosely formed chips cake was first hand-pressed and then placed between hot plates of a press. Preformed particleboard samples were placed between two metal wires at 50 mesh size during the hot pressing to allow the moisture to be easily removed without damaging the samples (Picture 4). The pressing parameters were optimized after many preexperimental trials as shown below (Table 1).

Wires placed between chip cake and press plates.

Hot press program applied for removing moisture from particleboards.

| Phase | Pressure (bar) | Time (s) | Explanation |

|---|---|---|---|

| 1 | 30 | 30 | Pressing (heating) |

| 2 | 10 | 20 | Release (moisture escape) |

| 3 | 40 | 30 | Pressing (heating) |

| 4 | 15 | 20 | Release (moisture escape) |

| 5 | 50 | 150 | Final pressing (heating and hardening) |

The thickness rods (1 cm) were placed between press plates for regulating the final thickness of particleboards. Reed plates and particleboards were kept in a conditioned room set at 23±2°C and 65±3 relative humidity for at least 4 days before testing. Reed plates were just tested to find for sound transmission properties because they were found to be so weak for the mechanical tests. Particleboards, however, were tested for determining the sound transmission (ASTM C597), thermal conductivity, bending strength (DIN EN ISO 178), thickness swelling (EN 317:1993), and weight gain values. Thermal conductivity and bending strength of samples were determined by employing QTM 500 Kyoto Thermal Conductivity Meter and Zwick/Roel 10 kN Universal Tensile Tester. The samples were cut in 5×5 cm sizes for thickness swelling and weight gain tests. The sizes of the samples for testing bending strength were prepared as 35 mm width and 160 mm length.

3 Results and discussion

3.1 Reed stalks

It was found that, in general, it is quite difficult to create a strong interfacial bonding between reed mats with adhesives used in this work. The types (urea-formaldehyde, starch emulsion, and polyvinyl acetate), application methods of adhesives, and pressing programs did not make any considerable development in the strength of reed panels. The sanding of reeds before adhesive application slightly improved bonding; however, it was still not strong enough. It was believed to be due to high inorganic content (Tables 2 and 3), especially silica- and wax-rich outer layers of the plant body, as reported earlier, which makes liquid penetration almost impossible [6, 7].

Chemical components of reed plant [6, 7].

| Component | Proportion (%) |

|---|---|

| Cellulose | 42.51–45.04 |

| Lignin | 22.09–23.88 |

| Pentozan | 23.88–27.22 |

| Wax, fat, and resin | 1.15–5.63 |

| Minerals | 4.72–5.63 |

Inorganic contents of dry water reed [6, 7].

| Element | Amount (g/kg) | Element | Amount (mg/kg) |

|---|---|---|---|

| Ca | 1.7 | Cu | 4.2 |

| Mg | 0.82 | Co | 0.62 |

| P | 1.4 | Zn | 37 |

| K | 8.1 | Ni | 1.53 |

| Na | 1.1 | Mo | 0.26 |

| Fe | 0.92 | Mn | 166 |

| Si | 21.7 | B | 8.2 |

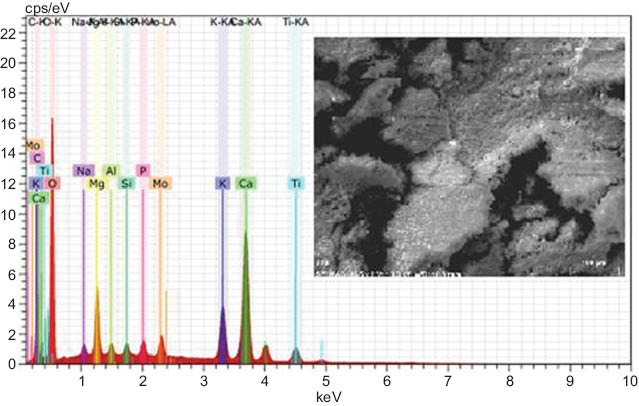

The elemental analysis of reed chips confirmed the early findings that the plant had a high percentage of various inorganic materials as seen in Figure 1. It was reported that, depending on the species, area, and climatic conditions, such as salinity and drought, some differences occur in reed plant such as the chemical and inorganic compositions of cell walls as well as the area of xylem and phloem and their ratios as a result of plant adaptation and survival [8, 9]. The ash content of reed and wood chip (at 550°C) was determined to be 7.7% and 1.5%, respectively, which also indicated the rich mineral composition of reed plant used in this experiment.

Elemental analysis and scanning electron microscopy images of reed chip ash.

It is known that some annual plants such as reed, cereal, and wheat straw produce strong and brittle outer layers on their body through specially engineered silica (and inorganic components) to stand up in addition to creating rod-shaped body with an empty inner part. The outer layer therefore functions like, in a sense, a protecting shield that is extremely resistant to liquid penetration.

3.2 Reed panels

In the first part of this study, some reed panels were made from stitched reed mats, paper sheets, thin fiberboards, and wood chips in different combinations with adhesive application. As clearly seen in Figure 2, reed panels did actually show excellent sound barrier properties compared with that of particleboard in general. However, the mechanical strength of such panels was so low such that they could not even withstand cutting for the test sample preparation. During hot pressing of these panels, 10 bar pressure was applied, which was well enough to tightly keep all layers for bonding. Excessive pressure was noted to break down individual reed stalks and did not improve bonding. It was concluded that the adhesive penetration and bonding on the surface of reed shield was extremely limited and this made reed panel production practically impossible without applying any surface modifications. However, combining such layers created lots of air gaps and voids inside the panels, exhibiting a very good barrier for sound transmission (Figure 2).

Sound transmission of panels made from reed mats and some other materials.

The possible behavior of soundwave touching a barrier like a wall is illustrated in Picture 5. The level of both reflection and absorption by such barrier directly determines the speed of sound transmission and sound intensity passing through such obstacle. The thickness of a material, porous structure, and low density are known to increase its resistance to sound transmission.

Behavior of a sound (noise) when facing an obstacle.

3.3 Reed particleboard

A number of particleboards with various proportion of reed chips were produced as explained in Section 2. It was observed that the adhesive application on chips blends was extremely important because it governs the level of chip coverage by chemical and mixing quality. The viscosity of adhesive was also a key factor that determines the spreading quality of urea-formaldehyde and also the final moisture content of board cake just before hot pressing. The moisture content of preformed particleboard was calculated to be approximately 40% for all samples tested in this work, which required a special hot pressing program. The moisture in such biocomposites actually acts as a heat conductor during hot pressing and helps particles to be more flexible and conformable. However, it must leave the board at the end of pressing operation without deforming or decomposting the board. During hot pressing, the moisture inside the preformed sample turns into water vapor, with huge pressure seeking a gap and passage to escape. For that reason, a special hot pressing was applied as shown in Table 1 to avoid the destructive effects of these hot vapors.

3.3.1 Sound transmission and thermal conductivity

The sound transmission values of particleboards tested in this experiment gradually decreased in parellel to increases of reed chips contents as seen in Figure 3. This clearly shows that the addition of reed chips significantly improved the sound resistance of tested particleboards. The particleboard made from 100% reed chips showed just approximately 6 km/s sound transmission, whereas the particleboard made from wood chips had 17 km/s sound transmission (Figure 3).

Sound transmission of particleboards containing reed chips.

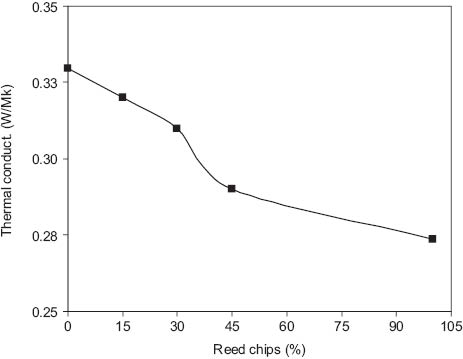

The changes in thermal conductivity values of sample particleboards were similar to that of sound transmission. However, the effects were not so severe and were noted to stay in the moderate level compared with the changes in sound transmission as a result of reed chips addition (Figures 3 and 4). It is clearly seen in the results that 45% reed chips addition reduced the sound transmission and thermal conductivity properties of the control sample (made of 100% wood chips) by, on average, 60% and 14%, respectively.

Thermal conductivity of particleboards containing reed chips.

3.3.2 Bending strength

In general, reed chips improve both the sound and the thermal insulation properties of the tested particleboards. However, the bending strength of samples was recorded to be decreased dramatically as a result of increasing reed chips addition (Figure 5). The differences between bending strengths of particleboards made from wood chips (27 MPa) and reed chips (5 MPa) were enormous and this basically shows the failure of the adhesive in bonding reed chips. Furthermore, it was noted that the final thicknesses of particleboards after conditioning were varied, although the thickness rod was used during hot pressing. It was believed to be due to both the different internal bonding properties and the spring-back behaviors of test samples. It basically shows that behavior and performance of wood chips and reed chips are quite different during adhesive application and hot pressing. Some previous works conducted on the improvements of wood bonding and acetylation of woods with various catalysts could be adapted for producing stronger reed panels [10, 11].

Effects of reed chips addition on bending strength.

3.3.3 Water absorption

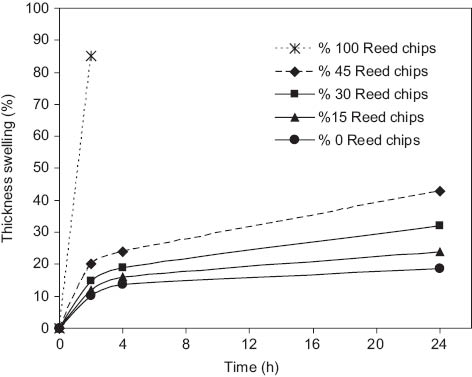

The addition of reed chips resulted in gradual increases in both thickness swelling and weight gain percentages of samples as clearly illustrated in Figures 6 and 7. Although the outer layer of reed chip is quite resistant to water penetration, its inner part takes a big amount of water compared with its bulk. Furthermore, reed chips did damage the proper bonding of particleboards tested in this work. Therefore, it actually resulted in producing loosely formed particleboards with lots of microcapillaries. Therefore, it is believed that reed chips took in more water compared with that of wood chips in the same quantity and also damaged the formation quality of particleboards. These contributed in thickness swelling and weight gain percentages of test samples as a result of water immersion test.

Thickness swelling increased with reed chips addition.

Reed chips increased the water absorption.

4 Conclusion

The thermal conductivity and sound transmission properties of particleboards containing reed chips clearly stressed out that reed chips can be perfectly used in the production of insulation panels and boards. An increasing amount of reed chips can be expected to make a good contribution on the insulation properties of resultant materials. However, the mechanical properties of such products would likely to suffer. It was attributed to the poor interfacial reaction between reed surface and adhesives used in this experiment. It is suggested that probably some kind of chemical modification on reed surfaces would increase the interbonding strength. Some stronger adhesives could be also used in future works.

References

[1] Mengeloglu F, Karakus K. Fresenius Environ. Bull. 2008, 17, 211.Search in Google Scholar

[2] Mengeloglu F, Karakus K. Bioresources 2012, 7, 3293–3305.Search in Google Scholar

[3] Kurt R, Mengeloglu F. Turk. J. Agric. For. 2012, 35, 155.Search in Google Scholar

[4] http://www.hiss-reet.com. Accessed 2012 Jan 11.Search in Google Scholar

[5] http://www.fcps.edu/islandcreekes/ecology/common_reed.htm. Accessed 2012 Jan 11.Search in Google Scholar

[6] Seidel K. Naturwissencchaften 1966, 53, 289.10.1007/BF00712211Search in Google Scholar PubMed

[7] Li G, Benoit F, Ceustermans N, Xu Z. Acta Agric. Zhejiangensis 2002, 14, 87.Search in Google Scholar

[8] Chen K, Wang F, Wang Y, Chen T, Hu Y, Lin J. J. Flora 2005, 201, 555.10.1016/j.flora.2005.12.003Search in Google Scholar

[9] Markus R, Ingo B, Thomas S. J. R. Soc. Interface 2010, 7, 499.Search in Google Scholar

[10] Kurt R, Krause A, Millitz H. Holz Alz Roh- Und Werkstoff 2008, 66, 333.10.1007/s00107-008-0265-1Search in Google Scholar

[11] Cetin NS, Ozmen N, Birinci E. J. Wood Chem. Technol. 2011, 31, 142.Search in Google Scholar

©2013 by Walter de Gruyter Berlin Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Wetting and the reaction of multiwalled carbon nanotube-reinforced composite solder with a copper substrate

- Microstructural characteristics of SiC-B4C reinforced laser alloying composite coatings

- Effect of reinforcement percentage on wear behavior of SiCp reinforced ZA43 alloy metal matrix composites

- Prediction and optimization of stability parameters for titanium dioxide nanofluid using response surface methodology and artificial neural networks

- Heat-resistant antiflaming and friction mechanisms in nano-Fe2O3-reinforced silicon rubber

- Properties of orchard pruning and suitability for composite production

- Hybridization effect on mechanical properties of short basalt/jute fiber-reinforced polyester composites

- Influence of fungal infection on the long-term water absorption and morphological behavior of bagasse fiber/polypropylene composites at different exposure times

- Vibration analysis of sandwich beams with variable cross section on variable Winkler elastic foundation

- Utilization of water reed in production of various insulation panels

- Synthesis of AA-based SAR interpenetrated with PVA and AM

- Development of a high-efficiency and long-life 500W class H-Darrieus-type vertical axis wind turbine (VAWT) system using skin-spar-foam sandwich composite structure

- The effects of cement and natural zeolite additives on problematic clay soils

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Wetting and the reaction of multiwalled carbon nanotube-reinforced composite solder with a copper substrate

- Microstructural characteristics of SiC-B4C reinforced laser alloying composite coatings

- Effect of reinforcement percentage on wear behavior of SiCp reinforced ZA43 alloy metal matrix composites

- Prediction and optimization of stability parameters for titanium dioxide nanofluid using response surface methodology and artificial neural networks

- Heat-resistant antiflaming and friction mechanisms in nano-Fe2O3-reinforced silicon rubber

- Properties of orchard pruning and suitability for composite production

- Hybridization effect on mechanical properties of short basalt/jute fiber-reinforced polyester composites

- Influence of fungal infection on the long-term water absorption and morphological behavior of bagasse fiber/polypropylene composites at different exposure times

- Vibration analysis of sandwich beams with variable cross section on variable Winkler elastic foundation

- Utilization of water reed in production of various insulation panels

- Synthesis of AA-based SAR interpenetrated with PVA and AM

- Development of a high-efficiency and long-life 500W class H-Darrieus-type vertical axis wind turbine (VAWT) system using skin-spar-foam sandwich composite structure

- The effects of cement and natural zeolite additives on problematic clay soils