Abstract

Mechanical properties of fiber reinforcement that can be obtained by the introduction of basalt fibers in jute fiber-reinforced polyester composites have been analyzed experimentally. Basalt/jute fiber-reinforced hybrid polymer composites were fabricated with a varying fiber percentage by using compression molding techniques. The fabricated composite plates were subjected to mechanical testing to estimate tensile strength, flexural strength and impact strength of the composites. The effect of fiber content on basalt/jute fiber in the composites has been studied. Addition of jute fiber into basalt fiber composite makes it a cost-effective one. Incorporation of basalt fiber into the composites was at approximately 10%, 20%, up to 90%, and the jute fiber percentage was reduced from 90%, 80%, to 10% correspondingly. Mechanical properties were investigated as per ASTM standards. Tensile and flexural strengths were tested by using a computer-assisted universal testing machine, and impact strength by using an Izod impact tester. It has been observed that the addition of jute fiber to the basalt fiber polyester composites enhanced the mechanical properties. Water absorption of hybrid composites was also analyzed and was found to be proportional to fiber percentage.

1 Introduction

Jute fiber is still the most common naturally occurring fiber. It makes up about 65% of all the composites produced today and is used for hulls, surfboards, sporting goods, swimming pool linings, building panels and car bodies. Basalt fiber is a material made from extremely fine fibers of basalt. Modern technologies require materials of different combinations of light weight and high strength with affordable cost.

According to Velmurugan and Manikandan, randomly mixed short palmyra fiber polyester composites yielded maximum mechanical properties at an optimum fiber length of 50 mm at 55 wt%. Also, hybridization of glass fiber with palmyra fiber in the matrix decreases the moisture absorption of the composites with considerable improvement in mechanical properties [1]. Pothan et al. studied the mechanical properties of composites; the fibers used in this study were short banana and glass fibers along with polyester resin [2]. Improvement in tensile and impact properties was reported when the glass fiber content in the hybrid composites was increased. Water absorption behavior showed a multistage mechanism in hybrid composites, which was found to be associated with the delamination in hybrid composites [2]. On comparing the results of the mechanical tests carried out on equivalent basalt and E-glass fiber-reinforced plastic laminates of square plates fabricated through vacuum bag technology, basalt fiber composite showed a high performance in terms of Young’s modulus, compressive and bending strength, impact force and energy [3]. Thwe and Liao focused on resistance of bamboo fiber-reinforced polypropylene composite (BFRP) and bamboo-glass fiber-reinforced polypropylene hybrid composite (BGRP) to hygrothermal aging and their fatigue behavior under cyclic tensile load [4]. Moisture absorption and tensile strength degradation were suppressed due to the use of maleic anhydride polypropylene as a coupling agent in both types of composite systems. With regard to fatigue resistance, BGRP has better fatigue resistance than BFRP at all load levels tested [4]. Rana et al. reported on the effect of compatibilizer on the composite [5]. The fiber loadings were 30, 40, 50 and 60 wt%, and at each fiber loading, compatibilizer doses were 0, 1, 2, 3 and 4 wt%. At 60% by weight of fiber loading, the use of the compatibilizer improved the flexural strength, tensile strength and impact strength. All these results justify the role of jute fiber not as a filler fiber but as a reinforcing fiber in a properly compatibilized system [5].

Basalt fiber-reinforced polypropylene matrix hybrid composites were manufactured by the processes of carding, needle punching and pressing, and hemp, glass and carbon fibers were applied in addition to basalt fiber in these composites. The hybrid effect in these composites was examined as a function of fiber content and fiber combination. It was found that the mechanical behavior of the examined composites depends mainly on the properties of the reinforcing fibers [6]. Wu presented the fatigue behavior of various fiber-reinforced polymer composites, namely, carbon, glass, basalt and polyparaphenylene benzobisoxazole, and the hybrid effect of carbon/glass and carbon/basalt composites [7]. Test parameters considered by them were the applied load range and different types of hybridization. It was observed that the tensile modulus of the fibers influences the failure mode of the composite and that there was significant improvement in the fatigue resistance of carbon/basalt hybrid composites in comparison to that of the homogeneous basalt composite [7]. Cicala investigated the hybridization of glass fibers with natural fibers such as hemp, flax and kenaf for applications in the piping industry. Tensile and flexural properties of hybrid glass/natural fiber-reinforced epoxy composites in the form of lamina and laminates were determined [8]. A hybrid design for the pipe, which makes use of glass woven fabrics and natural fiber mats, was proposed. The adoption of this design allowed for a cost reduction of 20% and a weight saving of 23% compared to the current commercial solution [8].

The static mechanical and dynamic mechanical properties of banana and sisal fiber hybrid composites at various fiber volume fractions fabricated by compression molding and resin transfer molding techniques were studied by Idicula et al. [9]. The composite prepared by compression molding with 0.40 vol% fiber showed the highest tensile, flexural and impact properties [9]. The tensile properties of hybrid composites of polypropylene, reinforced with short glass and carbon fibers and prepared using extrusion compounding and injection molding techniques, were tested. It was noted that the tensile strength and modulus of the hybrid composites increased, whereas the failure strain of the hybrid composites decreased, with increasing relative carbon fiber volume fraction in the mixture [10]. According to Wong et al., the impact strength of the composites improves with fiber content and fiber length [11]. Goud and Rao investigated the mechanical and electrical properties of Roystonea regia/glass fiber-reinforced epoxy hybrid composites by varying glass fiber loading. It has been observed that tensile, flexural, impact and hardness properties of hybrid composites considerably increased with increase in glass fiber loading [12].

From the above, it is obvious that natural fibers are capable of producing better mechanical properties when reinforced with synthetic fiber-reinforced polymer composites. This study is an attempt to find the effect of jute fiber reinforcement in basalt fiber composites considering different volume fractions of jute and basalt fiber reinforcement. Morphological studies have also been carried out to observe causes of failure of the hybrid composites.

2 Experimental details

2.1 Materials

Basalt fibers were supplied by ASA.TECH, Ohlsdorf, Austria. Jute fiber was supplied by S N Brothers, Kerala, India. Polyester resin, methyl ethyl ketone peroxide (MEKP) and cobalt naphthenate were purchased from Sakthi Pvt Ltd, Chennai, India.

2.2 Fabrication of hybrid composites

The basalt fiber and jute fiber-reinforced polymer hybrid composites were fabricated using compression molding method. General polyester resin was used as a matrix. For a proper chemical reaction, cobalt peroxide and methyl ethyl ketone were used as an accelerator and a catalyst, respectively. The basalt fibers and jute fibers were mixed thoroughly. These were weighed to take the corresponding 1:1 amount of general polyester resin. The curing of polyester resin was done by incorporation of 1 vol% MEKP catalyst. Cobalt napthenate (1 vol%) (accelerator) was also added. To achieve homogeneous condition of the mixture, the stirring process was carried out with a stirrer.

The mixed fiber was then filled into a mold of dimension 300 mm×130 mm×3 mm. Further, uniform spreading was ensured with the help of an A4 sheet. Then the resin mixture was poured over the uniformly spread fiber arrangement. The other side of the mold (top mold) was placed on top of the bottom mold via the guide pins installed on either end of the mold. Then the mold was held in a compression molding machine to apply pressure to the mold and kept there for curing for about 3 to 4 h at room temperature. Other specimens with varied proportions were made similarly. The properties of basalt and jute fiber are presented in Tables 1 and 2.

Properties of basalt fiber.

| Property | Value |

|---|---|

| Moisture content (%) | 0.15 |

| Density at room temperature (average) (g/cm3) | 2.64 |

| Diameter of fiber (mm) | 0.0166 |

| Mean breaking strength (G) | 1644.4 |

| CV of strength (%) | 13.6 |

| Mean elongation (%) | 1.15 |

| CV of elongation (%) | 13.37 |

Properties of jute fiber.

| Property | Test value |

|---|---|

| Moisture content (%) | 9.58 |

| Density at room temperature (average) (g/cm3) | 1.347 |

| Diameter of fiber (mm) | 0.4497 |

| Mean breaking strength (G) | 1570.75 |

| CV of strength (%) | 26.97 |

| Mean elongation (%) | 1.56 |

| CV of elongation (%) | 16.91 |

3 Mechanical property evaluations

3.1 Tensile test

A tensile test was performed to determine the stress-strain behavior of the basalt fiber-reinforced polymer composites. This was done using a universal testing machine (UTM) (3906) with a crosshead speed of 2 mm/min according to ASTM D638. Five samples were taken from each combination, and the results were averaged. This showed the tensile strength of the polymer composites.

3.2 Flexural strength

The three-point bending test was used to find the flexural modulus, flexural strength and strain at break of the basalt fiber-reinforced polymer composites. Flexural test was conducted on a Sandeep Polyplast UTM (Ahmedabad, India) with crosshead speed of 2 mm/min according to ASTM 790-98. The sample dimensions were 127 mm×13 mm ×3 mm. The span length of 100 mm was maintained.

3.3 Impact test

An impact test was used to determine the amount of energy that was required to break the specimen. An un-notched Izod impact test was conducted to study the impact energy according to ASTM D256. The un-notched specimens were kept in a cantilever position, and a pendulum was swung around to break the specimen. The impact energy (J) was calculated using a dial gauge that was fitted on the machine. Five samples were taken for each test, and the results were averaged.

3.4 Moisture absorption

Moisture absorption test was conducted for the maximum mechanical properties of the hybrid composites. The calculation of the water absorption rate was calculated by the following mathematical formula:

W (%)=(Wi-Wd)/Wd×100

where W is the water absorption rate, Wi is the specimen weight after the moisture absorption and Wd is the initial sample measured value.

Water absorption testing of basalt and jute fiber-reinforced polyester hybrid composites was carried out. Square specimens of 30 mm×30 mm were cut from a laminated sheet. To measure the water absorption of the composites, all the samples were immersed in water for about 24 h at room temperature. Excess water on the surface of the samples was removed before weighing the samples again. The percentage increase in weight during immersion was calculated. The weighing was done within 30 s in order to avoid error due to evaporation.

4 Result and discussion

4.1 Tensile test

It was seen that the hybrid composites of basalt and jute fibers in the polyester polymer matrix have considerable effect on the tensile properties (shown in Figure 1). The tensile strength of the hybrid composite that contains 30% basalt and 70% jute fiber was 19.8 Mpa greater than that of the composite material containing 40% basalt and 60% jute. Similarly, the tensile strength of composite having 50% basalt and 50% jute fiber was 11.12 Mpa lesser than that of the hybrid composite containing 60% basalt and 40% jute fiber. The tensile strength of composite material having 70% basalt and 30% jute was 21.13 Mpa greater than that of the reinforced hybrid composite having 80% basalt and 20% jute. However, from the overall analysis, it was seen that the tensile strength is found to be the highest, i.e., 80.46 Mpa, for the composite material having 90% basalt and 10% jute and is the highest among all the sample specimens except the pure basalt fiber composites.

Effect of the fiber percentage on tensile strength.

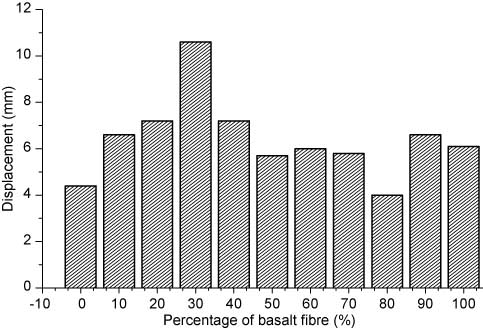

It was seen that the hybrid composites of basalt and jute fibers in the polyester polymer matrix have considerable effect in the percentage of elongation (shown in Figure 2). The hybrid composite that contains 30% basalt and 70% jute had an elongation 3.4 mm greater than that of the composite material containing 40% basalt and 60% jute. Similarly, composite having 50% basalt and 50% jute fiber had an elongation 0.3 mm lesser than that of the hybrid composite containing 60% basalt and 40% jute fiber.

Rate of elongation during tensile test.

The composite material having 70% basalt and 30% jute had an elongation 1.8 mm greater than that of the reinforced hybrid composite having 80% basalt and 20% jute and lesser by 2.6 mm for the composite material having 90% basalt and 10% jute. However, from the overall analysis, it is seen that the elongation is found to be the highest, i.e., 10.6 mm, for the composite material having 30% basalt and 70% jute. When the content of low modulus fibers in the composites is greater than the optimal content, the modulus value of composites decreases [2].

The tensile strength of hybrid composite, which is superior in the 90% basalt and 10% jute fiber because of the basalt fiber, has a maximum value of tensile strength. Normally, synthetic fiber has a higher strength than natural fiber; next to this, 60% basalt and 40% jute fiber has the highest value of tensile strength, which is close to that of the 90% basalt and 10% jute fiber combination.

The tensile properties of the hybrid composites depend on the percentage of elongation at break of the individual fibers in the composite system. The tensile strength will be higher when high-strength material is used [1]. When the basalt fibers are mixed with jute fiber, the high-strength basalt fibers adjacent to the jute fibers prevent crack propagation. Results indicated that the high void content or presence of porosity on the surface of composites contributes to their failure. Higher value of tensile strength of composite is due to good bonding between fiber and matrix. The interfacial bonding plays an important role in the mechanical properties of composites. A scanning electron microscopy (SEM) micrograph shows poor adhesion between the fiber and matrix due to the waxy layer of the jute fiber, void content of the composites and fiber fracture due to tensile load of the composites (Figure 3). Because of the presence of basalt fiber in the composites, the highest load-bearing capacity and proper bonding strength are made possible.

Fractography image of tensile strength-tested specimen.

4.2 Flexural test

Figure 4 shows the flexural strength of basalt fibers in the polyester matrix. The hybrid composite that contains 0% basalt and 100% jute fiber was 7 MPa greater in flexural strength than the composite material containing 10% basalt and 90% jute. The composite material having 20% basalt and 80% jute fiber was 34 MPa greater in flexural strength than the composite containing 30% basalt and 70% jute. Similarly, the composite material having 40% basalt and 60% jute was 58 MPa lesser in flexural strength than the composite material containing 50% basalt and 50% jute. The reinforced hybrid composite having 60% basalt and 40% jute was 15 MPa lesser in flexural strength than the hybrid composite containing 70% basalt and 30% jute fiber.

Effect of fiber percentage on flexural strength.

Similarly, the composite material having 80% basalt and 20% jute was 30 MPa lesser in flexural strength than the reinforced hybrid composite having 90% basalt and 10% jute. However, from the overall analysis, it is seen that the flexural strength is found to be the highest, i.e., 141 MPa, for the composite material having 50% basalt and 50% jute as the mixture ratio.

It was seen that the incorporation of basalt fibers in the polyester matrix has a considerable effect on the flexural modulus (Figure 5). The hybrid composite that contains 0% basalt and 100% jute fiber composite was 230 MPa greater in flexural modulus than the composite material containing 10% basalt and 90% jute. The composite material having 20% basalt and 80% jute fiber was 140 MPa greater in flexural modulus than the composite containing 30% basalt and 70% jute. Similarly, the composite material having 40% basalt and 60% jute was 1260 MPa lesser in flexural modulus than the composite material, containing 50% basalt and 50% jute. The reinforced hybrid composite having 60% basalt and 40% jute was 370 MPa lesser in flexural modulus than the hybrid composite containing 70% basalt and 30% jute fiber.

Effect of fiber percentage on flexural modulus.

Similarly, the composite material having 80% basalt and 20% jute was 1560 MPa lesser in flexural modulus than the reinforced hybrid composite having 90% basalt and 10% jute. However, from the overall analysis, it is seen that the flexural modulus is found to be highest, i.e., 3290 MPa, for the composite material having 90% basalt and 10% jute as mixture ratio except pure basalt fiber composites.

The hybridization effect of synthetic fiber enhances the properties of the composites and increases the durability of the natural fiber [1]. Addition of synthetic fiber to natural fiber composite increases the flexural strength. The wettability of the basalt fiber is high compared to that of jute fiber. Wetting of both fibers at the same time is an important factor that leads to composite failure. SEM (Figure 6) observations have been performed on the fiber-matrix interface and fiber surface to characterize the fiber-matrix bond. The modes of fiber failure, fiber fracture, or fiber pullout from the matrix are greatly influenced by the interfacial bond between fiber and matrix. The flexural strength of basalt fiber is affected by the incorporation of jute fiber except for the 50% basalt and 10% jute fiber. However, when the addition of basalt fiber is increasing by 10%, incorporation of jute fiber should also be increased by 10%.

Fractography image of flexural strength-tested specimen.

4.3 Impact test

It was seen that the hybrid composites of basalt and jute fibers in the polyester polymer matrix have a considerable effect on the impact properties (shown in Figure 7), The hybrid composite that contains 0% basalt and 100% jute had an impact strength 3.823 J/cm2 greater than that of the composite material containing 10% basalt and 90% jute. The impact strength of the composite material having 20% basalt and 80% jute fiber-reinforced composite was 3.194 J/cm2 lesser than that of the composite containing 30% basalt and 70% jute. Similarly, the composite material having 40% basalt and 60% jute had an impact strength 6.324 J/cm2 lesser than that of the composite material containing 50% basalt and 50% jute. The impact strength of reinforced hybrid composite having 60% basalt and 40% jute was 8.499 J/cm2 greater than that of the hybrid composite containing 70% basalt and 30% jute fiber.

Effect of the fiber percentage on impact strength.

Similarly, the impact strength of the composite material having 80% basalt and 20% jute was 9.3605 J/cm2 greater than that of the reinforced hybrid composite having 90% basalt and 10% jute. From the overall analysis, it is seen that the impact strength of the material increases with increase in basalt fiber till it reaches 50% basalt and 50% jute and is highest among all the sample specimens. Further increasing results in decreasing of the impact strength.

The impact strength of the hybridized composite is improved by addition of high energy absorbing basalt fiber [11]. Ahmed et al. observed that increasing the glass fiber content in the glass/jute polyester composite increases impact strength, but increasing the basalt fiber content in the basalt/jute fiber polyester composite causes a decrease in the impact strength [13]. Impact damage characterization was carried out on the hybrid composite using SEM photographs and the impact energies produced were effectively applied on the width of the specimen. Failure of composites was due to the voids and waxy layers in the jute fiber produced in the composites. Due to sudden impact load, fiber fracture and fiber pullout occurred (Figure 8).

Fractography image of impact strength-tested specimen.

4.4 Moisture absorption behavior

The water absorption test was conducted as follows. The specimens were immersed in water and sea water at room temperature. At regular intervals, the specimens were removed from the water and wiped with tissue paper to remove surface water and weighed with a digital balance with 0.0001 mg resolution. The samples were reimmersed in water to permit the continuation of sorption until the saturation limit. In this characterization, the percentage of water absorbed was calculated on different days until it reached saturation. The hybrid effect on water absorption shows the percentage of water absorbed increasing gradually. After a particular time period, it reached the saturation limit. Figure 9 shows the water absorption behavior; it was seen that the saturation limit of absorption was reached on the seventh day of observation. The initial weight of the specimen was measured for each category and absorption was measured every day. The weight of the specimen gradually increased and reached the saturation limit on the seventh day. When the percentage of jute fiber in the composites increased, the water absorption rate also increased [5]. Due to natural fiber content in the composites, water absorption is increased. For the hybrid composite, mixing of more durable synthetic basalt fiber with jute fiber is an effective reinforcement that improves the durability of the natural fiber composite under different environmental conditions [4].

Effect of water absorption of short basalt and jute fiber composites.

5 Conclusion

The hybrid basalt fiber and jute fiber-reinforced polymer matrix composites were fabricated successfully through compression molding technique and the following conclusions were drawn:

Improved tensile strength and flexural strength were observed by incorporation of jute fiber in 90% basalt and 10% jute fiber hybrid composites.

From the impact test, the composite material that contains 50% basalt and 50% jute shows the maximum impact strength among all specimens fabricated with polyester matrix.

The water uptake tendency of hybrid composite was observed; it was found that hybrid composites slightly decreased in hybridization.

We gratefully acknowledge the financial assistance provided by DST (SERC): SR/S3/ME/0038/2007, Government of India for this work. We also thank the Centre for Composite Material, Department of Mechanical Engineering, Kalasalingam University, Krishnankoil, for their help in completing this work.

References

[1] Velmurugan R, Manikandan V. Composites, Part A 2007, 38, 2216–2226.10.1016/j.compositesa.2007.06.006Search in Google Scholar

[2] Pothan LA, George J, Oommen Z, Thomas S. Polimery Nr 1999, 11, 75010.14314/polimery.1999.750Search in Google Scholar

[3] Loprest V, Leone C, De Iorio I. Composites, Part B 2011, 42, 717–723.10.1016/j.compositesb.2011.01.030Search in Google Scholar

[4] Thwe MM, Liao K. Compos. Sci. Technol. 63, 2003, 375–387.10.1016/S0266-3538(02)00225-7Search in Google Scholar

[5] Rana AK, Mandal A, Mitra BC, Jacobson R, Rowell R, Banerjee AN. Appl. Polym. Sci. 1998, 69, 329–338.Search in Google Scholar

[6] Czigany T. Compos. Sci. Technol. 2006, 66, 3210–3220.Search in Google Scholar

[7] Wu Z. Composites, Part B 2010, 41, 396–402.10.1016/j.compositesb.2010.02.001Search in Google Scholar

[8] Cicala G. Mater. Des. 2009, 30, 2538–2542.Search in Google Scholar

[9] Idicula M, Sreekumar PA, Joseph K, Thomas S. Polym. Compos. 2009, 30, 1417–1425.Search in Google Scholar

[10] Fu S-Y, Lauke B, Mäder E, Yue C-Y, Hu X, Mai Y-W. J. Mater. Sci. 2001, 36, 1243–1251.Search in Google Scholar

[11] Wong KJ, Nirmal U, Lim BK. J. Reinf. Plast. Compos. 2010, 29, 3463–3474.Search in Google Scholar

[12] Goud G, Rao RN. Bull. Mater. Sci. 2012, 35, 595–599.Search in Google Scholar

[13] Ahmed KS, Vijayarangan S, Rajput C. J. Reinf. Plast. Compos. 2006, 25, 1549–1569.Search in Google Scholar

©2013 by Walter de Gruyter Berlin Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Wetting and the reaction of multiwalled carbon nanotube-reinforced composite solder with a copper substrate

- Microstructural characteristics of SiC-B4C reinforced laser alloying composite coatings

- Effect of reinforcement percentage on wear behavior of SiCp reinforced ZA43 alloy metal matrix composites

- Prediction and optimization of stability parameters for titanium dioxide nanofluid using response surface methodology and artificial neural networks

- Heat-resistant antiflaming and friction mechanisms in nano-Fe2O3-reinforced silicon rubber

- Properties of orchard pruning and suitability for composite production

- Hybridization effect on mechanical properties of short basalt/jute fiber-reinforced polyester composites

- Influence of fungal infection on the long-term water absorption and morphological behavior of bagasse fiber/polypropylene composites at different exposure times

- Vibration analysis of sandwich beams with variable cross section on variable Winkler elastic foundation

- Utilization of water reed in production of various insulation panels

- Synthesis of AA-based SAR interpenetrated with PVA and AM

- Development of a high-efficiency and long-life 500W class H-Darrieus-type vertical axis wind turbine (VAWT) system using skin-spar-foam sandwich composite structure

- The effects of cement and natural zeolite additives on problematic clay soils

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Wetting and the reaction of multiwalled carbon nanotube-reinforced composite solder with a copper substrate

- Microstructural characteristics of SiC-B4C reinforced laser alloying composite coatings

- Effect of reinforcement percentage on wear behavior of SiCp reinforced ZA43 alloy metal matrix composites

- Prediction and optimization of stability parameters for titanium dioxide nanofluid using response surface methodology and artificial neural networks

- Heat-resistant antiflaming and friction mechanisms in nano-Fe2O3-reinforced silicon rubber

- Properties of orchard pruning and suitability for composite production

- Hybridization effect on mechanical properties of short basalt/jute fiber-reinforced polyester composites

- Influence of fungal infection on the long-term water absorption and morphological behavior of bagasse fiber/polypropylene composites at different exposure times

- Vibration analysis of sandwich beams with variable cross section on variable Winkler elastic foundation

- Utilization of water reed in production of various insulation panels

- Synthesis of AA-based SAR interpenetrated with PVA and AM

- Development of a high-efficiency and long-life 500W class H-Darrieus-type vertical axis wind turbine (VAWT) system using skin-spar-foam sandwich composite structure

- The effects of cement and natural zeolite additives on problematic clay soils