Abstract

Image processing of digital images is one of the essential categories of image transformation in the theory and practice of digital pattern analysis and computer vision. Automated pattern recognition systems are much needed in the textile industry more importantly when the quality control of products is a significant problem. The printed fabric pattern segmentation procedure is carried out since human interaction proves to be unsatisfactory and costly. Hence, to reduce the cost and wastage of time, automatic segmentation and pattern recognition are required. Several robust and efficient segmentation algorithms are established for pattern recognition. In this paper, different automated methods are presented to segregate printed patterns from textiles fabric. This has become necessary because quality product devoid of any disturbances is the ultimate aim of the textile printing industry.

1 Introduction

Printed fabric pattern segmentation is the partitioning of fabric pattern into a set of disjoint regions with uniform and similar characteristics [1, 2]. Printed fabric patterns are incorporate textiles that have value-added colors, design elements, and texture at a divergent region on the textile material surface [3]. Image segmentation plays a dynamic role in evaluating industrially printed fabric patterns that are needed for further processing to detect any disturbances to prevent the risk of producing poor quality products [4]. This is one of the most important quality control measures in textiles industries. Printed patterns in the past were obtained manually which resulted in imprecisions, time-, and labor-consuming [5, 6]. Since the inception of automatic fabric pattern segmentation, the objectives of printed fabric pattern segmentation have been evaluated with several algorithms and methodologies which yielded good results of segmentation accuracies and reduced cost of time and labor [7,8,9]. Zaitoun and Aqel stated that several general-purpose algorithms and methods had been established for pattern image segmentation [10]. Even though there is no general solution to the pattern image segmentation problem, techniques frequently have to be combined with domain knowledge to solve an image segmentation problem successfully [11]. Several improved segmentation methodologies for printed fabric patterns have been projected over the years which demonstrated inherently appropriate in textiles quality control evaluation. Fuzzy segmentation algorithms, exclusively the fuzzy c-means (FCM) algorithm, have been generally used in the image segmentation [12]. Its success typically characterized the overview of fuzziness for the belongingness of each image pixel [13]. FCM is a data clustering method in which a dataset is gathered into n clusters indicating every data point in the dataset is allied to every cluster with a high degree of connection to that cluster and another which will have a low degree of belonging to the cluster [14, 15]. The FCM is basically similar to the k-means algorithm but can retain more information from the original pattern; although k-means performs faster in operation, it produces slightly poor quality clustering [16,17,18]. Since accuracy in the segmentation of color image depends not only on the algorithm but also on the color space, the algorithms as mentioned earlier successfully categorize patterns, and extract features involve in various color space such red, green, blue (RGB), hue, saturation, value (HSV), and CIEL*A*B. Self-organizing map (SOM) on the other hand, automatically classifies colors on multi-color fabrics without predefining clusters, it has no generally admitted rule for the various parameters such as map size, neighboring function, and time evolution of the learning rate [19]. Spatial operations in SOM help to eliminate noise and small regions that are formed from clustering result. This system countenances the entire segmentation process to become automatic and unsupervised. This clustering technique is based on an artificial neural network, it studies each input component and then classifies into the corresponding class and does not require a predefined number of cluster. When a pattern image is used as an input, it is initially transformed into an i*j*l matrix, where i*j is the dimension in pixels of the image and l, the number of layers of the model [20, 21]. The method above was used to determine the precise borders of detected clusters for colored regions to enable colorfastness evaluation for printed fabrics. Kuo et al. established a system to analyze the repeat patterns on printed fabrics automatically. This approach resolves the difficulties in stating and relating printing patterns manually. Hough transform augmented with FCM clustering algorithm displays different repeat patterns automatically by classifying the color segmentation and pattern elements with a FCM clustering algorithm where a specific cluster-validity criterion is used to find the pattern image [22]. In a related development, Chung-Feng et al. established that the FCM fuzzy clustering algorithm and the SC cluster-validity index are very real for evaluating color features and pattern features of printed fabric automatically [18, 23, 24]. This method examines colors and patterns on printed material without a priori information about data structures, and the clustering algorithm segregates the dataset into clusters such that data within a group are more similar objects to each other than to those belonging to different clusters. To substantially analyze automatic color and pattern separation of printed fabrics, [24, 25] adopted region splitting method where all color variance points in the pattern image are subjected to subregion to reduce the interfering [26]. This method is enhanced with the FCM algorithm with a specific clustering number to automatically segment the image into two subdivisions and then decide whether further separation is necessary by assessing automatic color uniformity [27]. The segmentation process is iterative if needed with the specific clustering number until the consistency of each subregion is achieved and can no longer be segmented.

2 Working model

A working model here describes the systematic proposed or expected application of the system for the image analysis that shares essential characteristics of the image. It is usually considered to be a simplified representation of a system or phenomenon with an integrated algorithm designed specifically to describe the software system.

2.1 Computational complexity

This describes the classification of computational problems according to their fundamental difficulty and relating those classes to each other. The problem is solved by a computer application which requires mathematical implementation such as an algorithm.

The complexity of an image expresses many features of the image content, and it is an essential factor in the selection of source material for testing various image processing methods [28]. In pattern image segmentation analysis, clustering techniques or algorithms seek to group pixels that are same to each other and different to objects of other groups. The algorithms are applied based on the data object types and suitability for a specific grouping [29]. Fundamentally, supervised classification and cluster analysis aim at measuring the similarity obtained from the dataset and how a large dataset should be clustered efficiently and the evaluation of cluster analysis [30, 31]. Technically, image segmentation operation can be grouped under the following:

Manual: this operation is tedious user interaction because the user controls the entire segmentation procedure.

Semi-automatic: this is the search for suitable parameter for the algorithm (parameter tweaking, initialization, and approximation).

Automatic: this operation is completely autonomous and reliable without any form of interaction.

In the last decades, cluster analysis uses an automatic method for finding classes. Nonetheless, in many instances, cluster analysis is a suitable preliminary point for other determinations such as data summarization, image information reduction, and finding the nearest neighbor [27, 32].

2.2 Summarization

Image summarization is the process of extracting the most critical features from an image because there may be multiple or duplicate instances that will appear many times differently in the same image [33, 34]. Classically, the usefulness of segmentation method is established only by the presentation of segmented images [35]. This perhaps only allows subjective and qualitative inferences that are collected about that method [36]. Several segmentation methods have time or space complexities that are not applicable enough for segmenting large objects [37]. The segmentation method should, however, be applied to reduce the object comprising only cluster models, and its efficiency can be used to measure against the result that would have been obtained using the entire object [38]. Vital image information such as different characteristics, elements regions based on intensity, position, and region shape must be considered during summarization [39].

2.3 Image information reduction

Image reduction aims at reducing the number of bits required to represent an image by removing the less crucial features which makes the image one of the most suitable and commercially successful in the field of digital image processing [40]. Reduction of image information enhances result desired from the segmentation process as well as improves its speed [41]. It is observed that [42], cluster prototype can also be used for image compression which makes it more interactive to determine whether segmentation should take parallelization, multiple phases, or combination of different methods. According to Tan et al. [32, 43], reduction of image information is applied to images due to the fact that many of the data objects are remarkably similar [44, 45], specific loss of information is satisfactory, and considerable reduction in the data size is also preferred for effective image segmentation [40].

2.4 Finding nearest neighbor

Clustering, also known as pixel classification, is a globally assigning of each pixel to one of the distinct classes, for instance objects A, objects B, or background, without respect to object consistency. According to Bieniecki [46], the classification can be sped up by reference set reduction where clusters and their cluster prototype can be established much more efficiently [47, 48]. If the objects are comparatively local to the prototype of their cluster, then it could be used to reduce the number of distance computations that are needed to find the nearest neighbor of the object [49]. Considering that two cluster prototypes are distant from each other, the corresponding objects cannot be the nearest neighbor to each other [50]. Finding an object nearest neighbor, however, [51] will require only calculating the distance to the objects in a nearby cluster where the gap existing between them measures the proximity of the two groups. The method is often based on thresholding the intensity level of each pixel [46, 52].

3 Applications

A careful and detailed study is conducted into digital image analysis based on the concept of segmentation algorithms and pieces of evidence of their usefulness to printed fabric pattern segmentation and pattern recognition. Several researchers have established methodologies to detect fabric defects that are valuable in assessing the qualities of fabric. Figure 1 shows the automatic inspection system flow of defect detection of fabrics [53].

Automated inspection system flow.

Image capture: Image capture basically involves camera and image acquisition system with constant lighting system.

Image processing: consists of contrast enhancement, equalization, noise removal, image segmentation, which will help in detecting defects from the original image.

Labeling: this consists of transforming input data where a set of features are extracted for further analysis.

Database setting: classification of image subdivisions as a result of nonparametric nature and ability to describe complex decision regions.

Scheme initialization: separation of parts with defects from non-defects parts.

Extraction of RGB features: abstraction of RGB values from segmented regions.

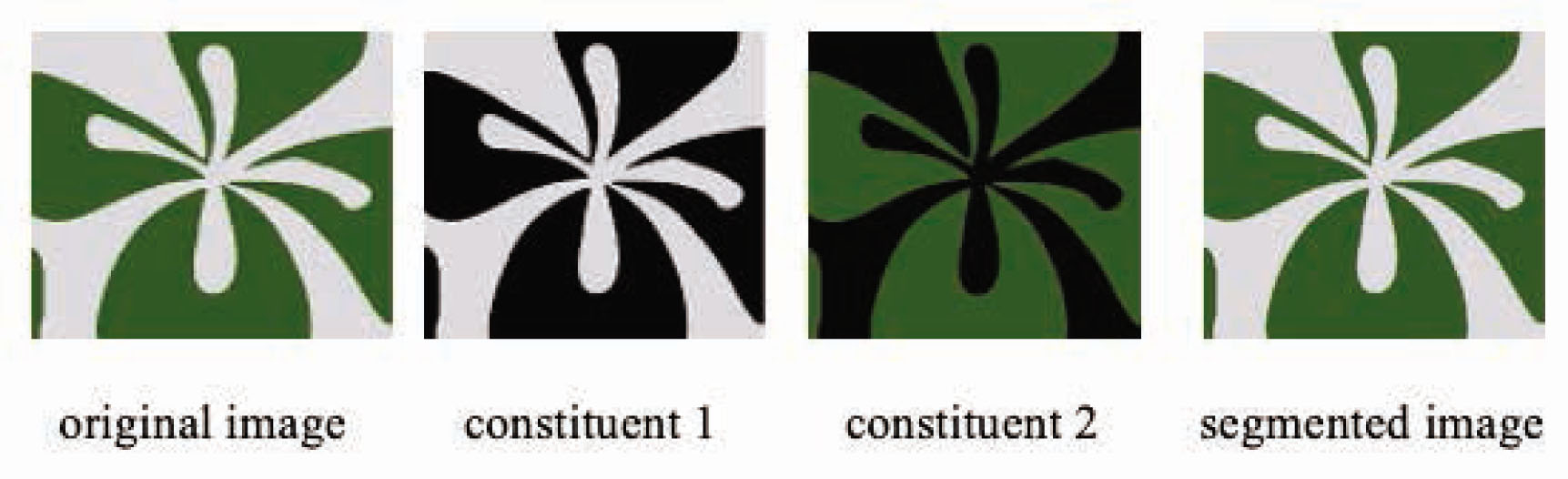

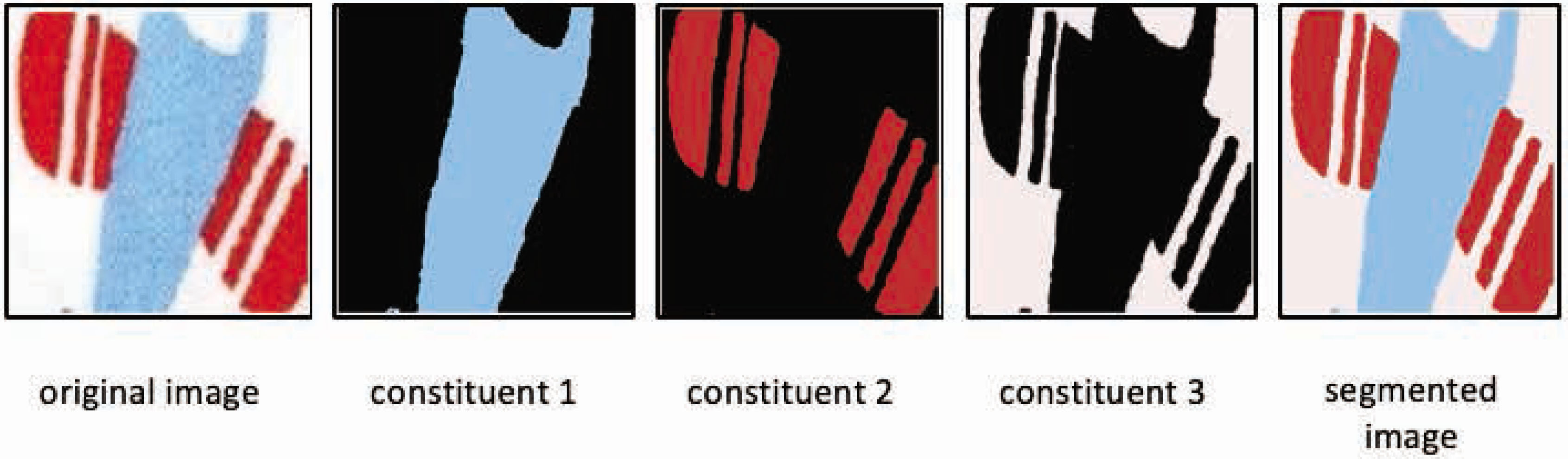

In Figures 2 and 3, an automatic inspection system with integrated algorithm partitioned the printed fabric patterns into an ideal number of clusters spontaneously such that the segmented regions are objectively notable with proper application specific, less computational cost, and time sensitive. Figure 2 is a two-colored printed pattern, whereas Figure 3 is a four-colored printed fabric pattern with their respective partitioned images.

Two-colored printed pattern and their segmented constituents.

Four-colored printed pattern and their segmented constituents.

The partitions were based on the premise that x = {x1, x2, …, xn} and a uniformity predicate P where data are then segregated into a disjoint non-empty group x = {v1, v2, …, vk}. This is relatively defined on the following condition:

According to our research [54], computer vision in textile industries has developed to the point that viable applications such as image segmentation and pattern recognition technology have become enormous [55]. Many applications have indeed generated variability of computer vision products and services from the traditional human system to a sophisticated automated machine inspection [56]. Even though image segmentation and object recognition are versatile, Hirano et al. [57] stated some significant challenges that are common and definite vis-à-vis object recognition that is hindering widespread commercial use. They include the following:

Robustness with respect to variation in viewpoint, illumination, scale, and imaging conditions.

Scaling up to thousands of object classes. Although some applications may only require class libraries of loads of objects. Many need much larger class diversity requiring human-level performance.

Notwithstanding the challenges as mentioned earlier, there are advanced system applications that are centered on various algorithms to detect patches or significant points in an image due to its heterogeneous nature, where local points are computed around each spot to define the visually discriminant parts of the image [57, 58]. Figures 4 and 5 demonstrate the defected printed fabric patterns and manifestations after segmentation. Figure 4 is a three-colored defected printed pattern and Figure 5 is also a three-colored defected pattern, all the figures showing obscuring patterns in their respective images.

Three-colored defected printed pattern.

Three-colored defected printed pattern

In recent times, several automated segmentation methods were anticipated to address segmentation challenges in textile industries. Hewage and Sonnadara [59] developed an approach to crack color image segmentation using a combined approach of k-means clustering and principal component analysis. This research focused on screen printing industry and the selection of parameter k (number of a cluster) most critical element, and the user interacts with the system to limit the number of colors to be separated (user interactive) [60]. It should, however, be noted that if the random initial parameter is wrongly selected, arbitrary selection of initial clusters in k-means clustering causes the entire system failure. Defect detection in textile industries is yet another vital area that saw the use of computer vision [61]. Bavdhan [62], an industrialized automated system, consisting of robust as well as efficient fabric defect identification methods. In this work, there is a comprehensive automated scheme which is based on the use of thresholding segmentation method for defect detection and fuzzy neural network method used for its classification. This application involves morphological procedure-based segmentation, and the designation of fabric defects is extracted in geometric features and moment-based features which are finally stored as defect class in a neural network [63, 64]. Several other methods were combined to improve the segmentation result and reduce the operation time as well automatically.

In a related development, Chung-Feng [23] combined region splitting, FCM and Hough transform methods to separate color and identify repeat pattern through an automatic computerized system for printed fabrics. Color separation is obtained using a genetic algorithm (GA) to examine smaller subregion with the same color distribution and region splitting used to separate the color. FCM performs a calculation on the hue saturation intensity (HSI) image using color clusters (cluster number) and values (cluster centers) obtained from separating the colors of sub-image to quickly classify colors for the pixels [65, 66]. By marking pixels from different color categories, a polychromatic pattern image is formed, and a template matching method is applied to discover distribution of the same element and consequently identify repeat patterns in the image. Then, the Hough transform method is used to find the cutting positions and dimensions of the repeat patterns in the polychromatic pattern image [22]. The images of the repeat patterns are then extracted out from the polychromatic images. The repeat patterns are finally generated based on the color categories.

Perez et al. [67] have established a less automated inspection analysis system with a computationally complex method to detect the pattern in a printing process. This approach has two different inspection systems with the implementation of a fast Fourier transform (FFT) algorithm on windows throughout the image. The criteria are mechanical structure and the hardware that is accountable for fabric image acquisition and software responsible for image processing, analysis, and possible actions conducted. The system analyses the production process and stops the machine automatically whenever relevant defects are identified. During fabric analyses, the method begins a new thread acquisition of the images where an alternative thread is also programmed to process the frame where reports are stored when faults are detected. The problem is resolved using the correction vector captured from a white image to correct all the acquisition.

Lu projected multi-scale segmentation techniques for textile images to solve the difficulty in fabric appearance (fabric texture structure and texture noise) [68]. In this approach, there were predetermined numbers of distinct colors in the textile image, and since the images contain uniform distributed texture structure, the color information was the main feature considered during segmentation. The dominant colors were picked and their average calculated for similar regions in the input textile image [69,70,71]. For the cross-scale relationships of texture regions, the learning-based supervised technique was used to pick similar areas from the image.

An automated GA for textile pattern recognition by Dobrea was designed with the purpose of discovering different kinds of textile printing errors and to stop the printing process in the event of a mistake occurring [65]. The system consists of two main parts: the image processing module (IPM) and the genetic detection module. The IPM is to reveal the specific patterns that appear only when a printing error occurs and to preprocess the acquired image in a mode to minimize the data storage and the computing costs of the entire system. This application deals with images and all these types of applications are considered data-intensive and computing-intensive. The final aim is a very important intelligent system that can discover, in real time, different types of printing defects. The GA evaluates many solutions to an assigned problem. One crucial aspect of the GA-based search methods is the maintenance population of potential solutions while all other means process a single point of the search space. GA does not require functional derivative information to search for a set of parameters that minimizes or maximizes a given objective function. This system replaces parameter with the convergence time. Pengfei Li et al. establish a low cost, high performance, and excellent expansibility for fabric defect detection with a combined approach. In the work of a real-time machine vision detection system, hardware platform and software algorithm were included. The hardware was responsible for image acquisition subsystem and transmission operated synchronously to achieve synchronization between signal and acquisition through the encoder and video capture card. In making the system more real time, a double-buffer technique with an acquisition mode was applied. Each defect detection algorithm is regarded as a single detection unit that is combined in the software system, and different detection units also engaged at different fabrics and defects to achieve efficient detection of the system [72]. Figure 6 demonstrates the real-time machine vision detection system based on computer-aided software for fabric defect detection.

Fabric defect detection.

Image segmentation algorithms have successfully been employed in other digital fields since most existing industrial products depend on searching similar characteristics of images or products [73,74,75]. The primary objective of digital image analysis is image segmentation, division of an image into fragments identical separate, noticeable on the image objects [58] finding analyzed image cohesive areas which are categorized by equal value of some attribute or set of features to be able to define geometric features of objects precisely with minimum computational complexity [76]. This is because global descriptions of image segmentation are aiming at extracting feature vectors that summarize the content of the images in terms of luminance, color, or texture [57, 77]. In a nutshell, these feature vectors are conventionally statistical summaries of the color distribution in different color spaces and surfaces in different forms.

Industrial application computer vision systems, on the other hand, require more considerable robustness, reliability, and stability compared to research applications. According to COGNEX. 2018 [78], Cognex ViDi Suite develops a simple automatic inspection system for analyzing complex printed webs that identify problems during printing. Misalignment of the different color channel during printing is also recognized and corrected automatically. The automated software algorithm with specialized optics automatically acquire fabric images and create a reference model to process, analyze, and measure the various characteristics for decision-making.

Guruprasad and Behera [79] made a clear distinction between an automatic and manual inspections and stated that price of textile fabric has reduced by 45% to 65% due to defects. They assessed that with manual inspection where a trained personnel inspects the system, maximum concentration is sustained only for a period of 20–30 minutes and perhaps much attention is also given when the fabric is of interest to the personnel. All of these seldom yield 50% production by human inspection and wastage of time. On the contrary, the automated inspection systems produce reliable and accuracy devoid of subjective deficiencies. This evaluation was based on automatic fabric inspection systems gathered from the following industries:

Usters Fabriscan system inspects fabric at about 30 meters per minute online speed and 120 meters per minute speed offline. Defects detection based on transmitted and reflective lights is as low as 0.3 mm and the system controls fabric widths from 110 to 440 cm.

Defects are classified in a matrix called Uster Fabriclass which shows y-axis as the contrast of the defects and x-axis as the length of the defects depicting the differences in disturbance and non-disturbing defects and rendering over-detection practically omitted. Data on defects can also be stored in a relational database which is generated in future.

I-TEX system at the ITMA’91, Hannover in Germany, is the most recognized operator in automatic optical inspection. The system operates inspection at speed up to 300 meters per minute and can deal with fabric widths up to 5 m. The system's software algorithms are structured to emulate human inspection system by identification of typical fabric pattern and able to detects subsequent variations that occur. These variations are evaluated with multiple detection algorithms isolate actual defects from arbitrary variations in the fabric patterns. The digital image of the defect map is recorded and saved in the x and y location. The industry marked PRIN-TEX as quality monitoring for detection of printing fabric defects is a way of adapting essential manual vision interpretation technologies for their application.

Unlike the two systems mentioned above, Barco Vision Cyclops has a roving scanning head that organized weaving machine. The production of off-quality fabric is automatically prevented by Cyclops during weaving process if defect is identified. The Cyclops is designed with camera and illumination system explicitly for detection of optimal defects in woven structures. The system is as well registered with algorithms to perform processing hardware and an industrial personal computer (PC) to carry out image processing concurrently.

The system features of the software are made up of calibration of the camera and illumination, alternating image processing algorithms for warp/weft compactness and weave, boundary detection, and JPEG-encoded image storage of fabric defects. Cyclops system takes fabrics widths up to 280 cm for single panel with installed dual camera-based image acquisition head.

4 Conclusions

Although there is neither a general image segmentation method nor an objective judgment criterion whether the segmentation is successful or not, there is an improvement of automation classification of printed pattern segmentation and pattern recognition considering accuracy, precision, and computational speed. Often, some methods are combined with specific theories and practices due to diversity and uncertainty of the image. However, a systematic study of segmented image features is the premise of a perfect segmentation algorithm even though mostly subjective. It can also be seen that analysis of the results leads to the conclusion that the inappropriate selection of the segmentation method will not help the process of recognition of patterns’ region of interest.

The segmentation process may also be considered as one that reduces the uncertainty in the image as well as one that results in obtaining adequate information about an image. It was perceived that some of the conventional cluster validity procedures could broadly be considered to automatically select the number of patterns (clusters) in the image. It is proven that even if an industry opts not to reduce the available workforce, the automatic inspection system is still advantageous due to the number of products grades and also reduce the number of defects.

However, analysis from this study discovered that developing an automatically incorporated segmentation algorithm, which will be suitable for extracting patterns from printed fabric, should be comprehensive and consistent with creating a quality of goods to enhance automated fabric pattern inspection.

Acknowledgments

This work was financially supported by the Fundamental Research Funds for the Central Universities (JUSRP 41804).

References

[1] Gonzalez, R. C., Woods, R. E. (1992). Digital image processing. Addison-Wesley (Reading).Search in Google Scholar

[2] Lo, W. Y., Puchalski, S. M. (2008). Digital image processing. Veterinary Radiology & Ultrasound, 49, S42–S47.10.1111/j.1740-8261.2007.00333.xSearch in Google Scholar PubMed

[3] Rafsanjani, M. K., Varzaneh, Z. A., Chukanlo, N. E. (2012). A survey of hierarchical clustering algorithms. The Journal of Mathematics and Computer Science, 5(3), 229–240.10.22436/jmcs.05.03.11Search in Google Scholar

[4] Burney, S. A., Tariq, H. (2014). K-means cluster analysis for image segmentation. International Journal of Computer Applications, 96(4), 1–8.10.5120/16779-6360Search in Google Scholar

[5] Chabrier, S., Rosenberger, C., Emile, B., Laurent, H. (2008). Optimization-based image segmentation by genetic algorithms. Journal on Image and Video Processing, 2008, 10.10.1155/2008/842029Search in Google Scholar

[6] Chung, F.-L., Fu, T. C., Ng, V., Luk, R. W. P. (2004). An evolutionary approach to pattern-based time series segmentation. IEEE Transactions on Evolutionary Computation, 8(5), 471–489.10.1109/TEVC.2004.832863Search in Google Scholar

[7] Freixenet, J., Muñoz, X., Raba, D., Martí, J., Cufí, X. (2002). Yet another survey on image segmentation: region and boundary information integration. Computer Vision—ECCV 2002, 2002, 21–25.10.1007/3-540-47977-5_27Search in Google Scholar

[8] Kang, W.-X., Yang, Q.-Q., Liang, R.-P. (2009). The comparative research on image segmentation algorithms. In Education Technology and Computer Science, 2009. ETCS’09. First International Workshop on. 2009. IEEE.10.1109/ETCS.2009.417Search in Google Scholar

[9] Jeon, B. S., Bae, J. H., Suh, M. W. (2003). Automatic recognition of woven fabric patterns by an artificial neural network. Textile Research Journal, 73(7), 645–650.10.1177/004051750307300714Search in Google Scholar

[10] Zaitoun, N. M., Aqel, M. J. (2015). Survey on image segmentation techniques. Procedia Computer Science, 65, 797–806.10.1016/j.procs.2015.09.027Search in Google Scholar

[11] Gionis, A., Terzi, E. (2007). Segmentations with rearrangements. In Proceedings of the 2007 SIAM International Conference on Data Mining, SIAM.10.1137/1.9781611972771.26Search in Google Scholar

[12] Xing, Y., Ou, Y., Englander, S., Schnall, M., Shen, D. (2007). Simultaneous estimation and segmentation of T1 map for breast parenchyma measurement. In Biomedical Imaging: from Nano to Macro, 2007. ISBI 2007. 4th IEEE International Symposium on, IEEE.10.1109/ISBI.2007.356856Search in Google Scholar

[13] Kuo, C.-F.J., Su, T.-L., Huang, Y.-J. (2007). Computerized color separation system for printed fabrics by using backward-propagation neural network. Fibers and Polymers, 8(5), 529–536.10.1007/BF02875876Search in Google Scholar

[14] Hann, M. (2003). Conceptual developments in the analysis of patterns part two: the application of the principles of symmetry.Search in Google Scholar

[15] Hann, M. (2003). Conceptual developments in the analysis of patterns part one: the identification of fundamental geometrical elements.Search in Google Scholar

[16] Bezdek, J. C. (1981). Objective function clustering, in Pattern recognition with fuzzy objective function algorithms. Springer, 43–93.10.1007/978-1-4757-0450-1_3Search in Google Scholar

[17] Bezdek, J. C., Hall, L., Clarke, L. P. (1993). Review of MR image segmentation techniques using pattern recognition. Medical Physics, 20(4), 1033–1048.10.1118/1.597000Search in Google Scholar PubMed

[18] Kuo, C.-F. J., Shih, C.-Y., Kao, C.-Y., Lee, J.-Y. (2005). Color and pattern analysis of printed fabric by an unsupervised clustering method. Textile Research Journal, 75(1), 9–12.10.1177/004051750507500103Search in Google Scholar

[19] Mo, H., Xu, B., Ouyang, W., Wang, J. (2017). Color segmentation of multi-colored fabrics using self-organizing-map based clustering algorithm. Textile Research Journal, 87(3), 369–380.10.1177/0040517516631307Search in Google Scholar

[20] Awad, M. (2010). Segmentation of satellite images using Self-Organizing Maps, in Self-Organizing Maps. InTech.10.5772/9167Search in Google Scholar

[21] El-Melegy, M., et al. (2007). On cluster validity indexes in fuzzy and hard clustering algorithms for image segmentation. In Image Processing, 2007. ICIP 2007. IEEE International Conference on. IEEE.10.1109/ICIP.2007.4379507Search in Google Scholar

[22] Kuo, C.-F.J., Shih, C.-Y., Lee, J.-Y. (2005). Repeat pattern segmentation of printed fabrics by Hough transform method. Textile Research Journal, 75(11), 779–783.10.1177/0040517505058848Search in Google Scholar

[23] Kuo, C.-F.J., Shih, C.-Y., Lee, J.-Y. (2008). Separating color and identifying repeat pattern through the automatic computerized analysis system for printed fabrics. Journal of Information Science & Engineering, 24(2), 453–467.Search in Google Scholar

[24] Kuo, C.-F.J., Shih, C.-Y. (2011). Printed fabric computerized automatic color separating system. Textile Research Journal, 81(7), 706–713.10.1177/0040517510383619Search in Google Scholar

[25] Lucieer, V., Lucieer, A. (2009). Fuzzy clustering for seafloor classification. Marine Geology, 264(3–4), 230–241.10.1016/j.margeo.2009.06.006Search in Google Scholar

[26] Fujiwara, H., Zhang, Z., Hatta, H., Koshimizu, H. (2004). Visual inspection of textile surfaces with translation invariant wavelet shrinkage. In Industrial Electronics Society, 2004. IECON 2004. 30th Annual Conference of IEEE, IEEE.10.1109/IECON.2004.1431755Search in Google Scholar

[27] Firdaus, S., Uddin, M. A. (2015). A survey on clustering algorithms and complexity analysis. International Journal of Computer Science Issues (IJCSI), 12(2), 62.Search in Google Scholar

[28] Willis, K. D., Xu, C., Wu, K. J., Levin, G., Gross, M. D. (2011). Interactive fabrication: new interfaces for digital fabrication. In Proceedings of the fifth international conference on Tangible, Embedded, and Embodied Interaction, ACM.10.1145/1935701.1935716Search in Google Scholar

[29] Clarke, S. E. B., Harris, J. (2012). Digital visions for fashion and textiles: Made in code. Thames and Hudson Ltd.Search in Google Scholar

[30] Yu, H., Winkler, S. (2013). Image complexity and spatial information. In Quality of Multimedia Experience (QoMEX), 2013 Fifth International Workshop on, IEEE.10.1109/QoMEX.2013.6603194Search in Google Scholar

[31] Guruprasad, R., Behera, B. (2010). Soft computing in textiles.Search in Google Scholar

[32] Tan, P.-N., Steinbach, M., Kumar, V. (2013). Data mining cluster analysis: basic concepts and algorithms. Introduction to Data Mining.Search in Google Scholar

[33] Baratis, E., Petrakis, E. G., Milios, E. E. (2008). Automatic website summarization by image content: a case study with logo and trademark images. IEEE Transactions on Knowledge & Data Engineering, 9, 1195–1204.10.1109/TKDE.2008.34Search in Google Scholar

[34] Jia, W., McKenna, S. J., Ward, A. A. (2009). Extracting printed designs and woven patterns from textile images. In VISAPP, 1, Citeseer.Search in Google Scholar

[35] Milanović, M., Stamenković, M. (2010). Data mining and segmentation of time series for knowledge discovery. In Proceedings of the International Scientific Conference – The Challenges of Economic Science and Practice in the 21st Century.Search in Google Scholar

[36] Everingham, M., Muller, H., Thomas, B. (2002). Evaluating image segmentation algorithms using the Pareto front. In European Conference on Computer Vision. Springer.10.1007/3-540-47979-1_3Search in Google Scholar

[37] Gionis, A., Mannila, H. (2005). Segmentation algorithms for time series and sequence data. In Tutorial at 5th SIAM International Conference on Data Mining.Search in Google Scholar

[38] Kopenkov, V. (2016). Development of computational procedure of local image processing, based on the usage of hierarchical regression.10.18287/2412-6179-2016-40-5-713-720Search in Google Scholar

[39] Drobina, R., Machnio, M. S. (2006). Application of the image analysis technique for textile identification. Autex Research Journal, 6(1), 40–48.10.1515/aut-2006-060106Search in Google Scholar

[40] Jeyakumar, M. (2012). Time complexity analysis of binary space partitioning scheme for image compression. arXiv preprint arXiv:1211.2037.Search in Google Scholar

[41] Kugiumtzis, D., Tsimpiris, A. (2010). Measures of analysis of time series (MATS): a MATLAB toolkit for computation of multiple measures on time series data bases. arXiv preprint arXiv:1002.1940.10.18637/jss.v033.i05Search in Google Scholar

[42] Carreira-Perpinan, M. A. (2001). Continuous latent variable models for dimensionality reduction and sequential data reconstruction. University of Sheffield (UK).Search in Google Scholar

[43] Raj, D., Singal, P. (2017). Reducing the computational complexity of A 2d Gaussian filter for image processing (an overview). International Journal of Advance Research, Ideas and Innovations in Technology, 3(3), 514–517.Search in Google Scholar

[44] Bingham, E., Gionis, A., Haiminen, N., Hiisilä, H., Mannila, H., et al. (2006). Segmentation and dimensionality reduction. In Proceedings of the 2006 SIAM International Conference on Data Mining. SIAM (Bethesda).10.1137/1.9781611972764.33Search in Google Scholar

[45] Hand, D. J. (2007). Principles of data mining. Drug Safety, 30(7), 621–622.10.2165/00002018-200730070-00010Search in Google Scholar PubMed

[46] Bieniecki, W., Grabowski, S. (2004). Nearest neighbor classifiers for color image segmentation. In Modern Problems of Radio Engineering, Telecommunications and Computer Science, 2004. Proceedings of the International Conference, IEEE.Search in Google Scholar

[47] Ueno, K., Xi, X., Keogh, E. J., Dah-Jye, L (2006). Anytime classification using the nearest neighbor algorithm with applications to stream mining. In null, IEEE.10.1109/ICDM.2006.21Search in Google Scholar

[48] Acharjya, P. P., Ghoshal, D. (2012). A new image segmentation algorithm for grid computing. International Journal of Scientific and Research Publications, 2(10).Search in Google Scholar

[49] Raj, D., Singal, P. (2017). The computation complexity reduction of 2-D Gaussian filter. International Research Journal of Engineering and Technology, 4(6).10.18535/ijsrm/v5i5.09Search in Google Scholar

[50] Vidyarthi, A., Kansal, A. (2012). A survey report on digital images segmentation algorithms. International Journal of Computer Engineering &Technology (IJCET), 3(2), 85–91.Search in Google Scholar

[51] Araujo, A. (2010). Repetition, pattern, and the domestic: notes on the relationship between pattern and homemaking. Textile, 8(2), 180–201.10.2752/175183510X12791896965574Search in Google Scholar

[52] López-Rodríguez, P., Fernández-Recio, R., Bravo, I., Gardel, A., Lázaro, J. L., et al. (2013). Computational burden resulting from image recognition of high resolution radar sensors. Sensors, 13(4), 5381–5402.10.3390/s130405381Search in Google Scholar PubMed PubMed Central

[53] Ngan, H. Y., Pang, G. K., Yung, N. H. (2011). Automated fabric defect detection – a review. Image and Vision Computing, 29(7), 442–458.10.1016/j.imavis.2011.02.002Search in Google Scholar

[54] Kumah, C., Zhang, N., Raji, R.K. and Pan, R. (2019) Color Measurement of Segmented Printed Fabric Patterns in Lab Color Space from RGB Digital Images. Journal of Textile Science and Technology, 5, 1–18. https://doi.org/10.4236/jtst.2019.5100110.4236/jtst.2019.51001Search in Google Scholar

[55] Aly, A. A., Deris, S. B., Zaki, N. (2011). Research review for digital image segmentation techniques. International Journal of Computer Science & Information Technology, 3(5), 99.10.5121/ijcsit.2011.3509Search in Google Scholar

[56] Murtagh, F. (2002). Clustering in massive data sets. In Abello, J., Pardalos, P. M., Resende, M. G. C. (eds), Handbook of massive data sets. Springer (Boston, MA), 501–543.10.1007/978-1-4615-0005-6_14Search in Google Scholar

[57] Hirano, Y., Garcia, C., Sukthankar, R., Hoogs, A. (2006). Industry and object recognition: Applications, applied research and challenges. In Ponce, J., Hebert, M., Schmid, C., Zisserman, A. (eds.), Toward Category-Level Object Recognition, Springer (Berlin, Heidelberg), 49–64.10.1007/11957959_3Search in Google Scholar

[58] Strzecha, K., Fabijańska, A., Sankowski, D. (2006). Segmentation algorithms for industrial image quantitative analysis systems. In XVIII IMEKO World Congress Metrology for a Sustainable Development.Search in Google Scholar

[59] Hewage, R., Sonnadara, D. (2011). Colour image segmentation technique for screen printing. Proceedings of the Technical Sessions, 27, 60–67.Search in Google Scholar

[60] Rajarajan, J., Kalivarathan, D. G. (2012). Influence of local segmentation in the context of digital image processing–a feasibility study. International Journal of Computer Engineering & Technology (IJCET), 3(3), 340–347.Search in Google Scholar

[61] Zhang, Y., Lu, Z., Li, J. (2010). Fabric defect classification using radial basis function network. Pattern Recognition Letters, 31(13), 2033–2042.10.1016/j.patrec.2010.05.030Search in Google Scholar

[62] PVPIT, B. Fabric Defect Detection with Thresholding and Morphological based Segmentation Methods and Classification Using Neural Network.Search in Google Scholar

[63] Boydell, C., Schoeser, M. (2008). Disentangling textiles: techniques for the study of designed objects (with authored chapter Textiles in the modern home pp 81–94). Middlesex University Press.Search in Google Scholar

[64] Kristensen Johnstone, T. (2014). The impact of scale on a block-repeated surface pattern in spatial contexts.Search in Google Scholar

[65] Dobrea, D. M., Blaga, M. (2007). Genetic algorithm for textile pattern recognition. in 1st Aachen–Dresden International Textile Conference.Search in Google Scholar

[66] Chen, S., Zhang, D. (2004). Robust image segmentation using FCM with spatial constraints based on new kernel-induced distance measure. IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics), 34(4), 1907–1916.10.1109/TSMCB.2004.831165Search in Google Scholar

[67] Perez, R., Silvestre, J., Munoz, J. (2004). Defect detection in repetitive fabric patterns. Proceeding of Visualization, Imaging and Image Processing, September, 6–8.Search in Google Scholar

[68] Lu, X. (2011). Multiscale Segmentation Techniques for Textile Images. In Image Segmentation. 2011, InTech.10.5772/14508Search in Google Scholar

[69] Cheng, H., Bouman, C. A. (2001). Multiscale Bayesian segmentation using a trainable context model. IEEE Transactions on Image Processing, 10(4), 511–525.10.1109/83.913586Search in Google Scholar PubMed

[70] Choi, H., Baraniuk, R. G. (2001). Multiscale image segmentation using wavelet-domain hidden Markov models. IEEE Transactions on Image Processing, 10(9), 1309–1321.10.1109/83.941855Search in Google Scholar PubMed

[71] Fan, G., Xia, X.-G. (2000). Maximum likelihood texture analysis and classification using wavelet-domain hidden Markov models. IN ASILOMAR Conference on Signals Systems and Computers. Citeseer.10.1109/ACSSC.2000.910649Search in Google Scholar

[72] Li, P., et al. (2015). The real-time vision system for fabric defect detection with combined approach. In International Conference on Image and Graphics. Springer.10.1007/978-3-319-21969-1_41Search in Google Scholar

[73] Erhardt-Ferron, A. (2000). Theory and applications of digital image processing. University of Applied Sciences Offenburg, 1(2), 3.Search in Google Scholar

[74] Gupta, G. (2014). Introduction to data mining with case studies. PHI Learning Pvt. Ltd (Delhi).Search in Google Scholar

[75] Kraft, K. (2004). Textile patterns and their epistemological functions. Textile, 2(3), 274–289.10.2752/147597504778052711Search in Google Scholar

[76] Chen, X., Huang, X. (2004). Evaluating fabric pilling with light-projected image analysis. Textile Research Journal, 74(11), 977–981.10.1177/004051750407401107Search in Google Scholar

[77] Briggs-Goode, A., Russell, A. (2011). Printed textile design, in Textile Design. Elsevier, 105–129e.10.1533/9780857092564.2.105Search in Google Scholar

[78] COGNEX. 2018 [cited 2018 7/8/2018]; Web site: https://www.cognex.com/.Search in Google Scholar

[79] Guruprasad, R., Behera, B. K. (2009). Automatic fabric inspection systems. [cited 2018 8/9/2018]; Web site: http://www.indiantextilejournal.com/articles/FAdetails.asp?id=2131.Search in Google Scholar

© 2020 Charles Kumah et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Statistical Analysis of Standard Allowed Minute on Sewing Efficiency in Apparel Industry

- Study on the Relationship Between Structure Parameters and Filtration Performance of Polypropylene Meltblown Nonwovens

- Merging Footwear Design and Functionality

- Nonwovens: Global Trends in World Economy, European Foreign Trade, and Selected Case Studies from Poland and Asian Brics Countries

- Sewing Thread Consumption for Different Lockstitches of Class 300 Using Geometrical and Multi-Linear Regression Models

- Electrospinning of Chitosan Biopolymer and Polyethylene Oxide Blends

- Antibacterial Fibers Containing Nanosilica with Immobilized Silver Nanoparticles

- Influence of Structural Parameters of Nonwoven Geotextiles on Separation and Filtration in Road Construction

- Optimization of Dynamic Mechanical Properties of Knitted Barrier Meshes

- Influence of Ultraviolet Irradiation and Protease on Scale Structure of Alpaca Wool Fibers

- Influence of Woven Fabric Width and Human Body Types on the Fabric Efficiencies in the Apparel Manufacturing

- The Effect of Electric Field on Nanofibers Preparation in Cylindrical-Electrode-Assisted Solution Blowing Spinning

- Antibacterial Effect of Graphene and Graphene Oxide as a Potential Material for Fiber Finishes

- Investigation of the Influence of Technology Parameters and Thread Type on Embroidered Textile Element Quality

- The Hydrophobization of a Nanofiber Layer Using Low-Vacuum Plasma

- Review of Printed Fabric Pattern Segmentation Analysis and Application

- Influence of Technology Process on Responsiveness of Footwear Nonwovens

- Performance of Electrospun Polyvinylidene Fluoride Nanofibrous Membrane in Air Filtration

Articles in the same Issue

- Statistical Analysis of Standard Allowed Minute on Sewing Efficiency in Apparel Industry

- Study on the Relationship Between Structure Parameters and Filtration Performance of Polypropylene Meltblown Nonwovens

- Merging Footwear Design and Functionality

- Nonwovens: Global Trends in World Economy, European Foreign Trade, and Selected Case Studies from Poland and Asian Brics Countries

- Sewing Thread Consumption for Different Lockstitches of Class 300 Using Geometrical and Multi-Linear Regression Models

- Electrospinning of Chitosan Biopolymer and Polyethylene Oxide Blends

- Antibacterial Fibers Containing Nanosilica with Immobilized Silver Nanoparticles

- Influence of Structural Parameters of Nonwoven Geotextiles on Separation and Filtration in Road Construction

- Optimization of Dynamic Mechanical Properties of Knitted Barrier Meshes

- Influence of Ultraviolet Irradiation and Protease on Scale Structure of Alpaca Wool Fibers

- Influence of Woven Fabric Width and Human Body Types on the Fabric Efficiencies in the Apparel Manufacturing

- The Effect of Electric Field on Nanofibers Preparation in Cylindrical-Electrode-Assisted Solution Blowing Spinning

- Antibacterial Effect of Graphene and Graphene Oxide as a Potential Material for Fiber Finishes

- Investigation of the Influence of Technology Parameters and Thread Type on Embroidered Textile Element Quality

- The Hydrophobization of a Nanofiber Layer Using Low-Vacuum Plasma

- Review of Printed Fabric Pattern Segmentation Analysis and Application

- Influence of Technology Process on Responsiveness of Footwear Nonwovens

- Performance of Electrospun Polyvinylidene Fluoride Nanofibrous Membrane in Air Filtration