Study on the Relationship Between Structure Parameters and Filtration Performance of Polypropylene Meltblown Nonwovens

-

Yuanxiang Xiao

Abstract

In this study, polypropylene meltblown nonwoven fabrics with different structure parameters such as fiber diameter, pore size, and areal density were prepared by the industrial production line. The morphology of meltblown nonwoven fibers was evaluated by using scanning electron microscope, and the diameter of fibers was analyzed by using image-pro plus software from at least 200 measurements. The pore size of nonwoven fabric was characterized by a CFP-1500AE type pore size analyzer. The filtration efficiency and pressure drop were evaluated by TSI8130 automatic filter. The results showed that the pressure drop of nonwoven fabrics decreased with the increase in pore size; the filtration efficiency and the pressure drop had a positive correlation with the areal density. However, when the areal density is in the range of 27–29 g/m2, both filtration efficiency and pressure drop decreased with the increase of areal density; when the areal density was kept constant, the filtration efficiency decreased as the pore size decreased; when the pore size of the meltblown nonwoven fabric is less than 17 μm, the filtration efficiency increased as the pore diameter decreased; when the pore diameter of the nonwoven fabric is larger than 17 μm. In a wide range, the pressure drop decreased as the fiber diameter decreased.

1 Introduction

The small suspended particles floating in the air are threat to people's life and health since they act as inducements to a series of respiratory, cardiovascular, and neurological diseases [1, 2]. Therefore, many types of air filters were developed to remove the particles and improve air quality. Compared with other air filters, nonwoven air filters are advantageous as they are easy to handle, tailor-made, of light weight, highly efficient, and has low airflow resistance [3]. Among nonwoven technologies, the meltblown technology was a process for preparing a nonwoven fabric with superfine fiber diameter, large specific surface area, small pore diameter, high void ratio, and uniform distribution, which led to a low air resistance and high depth filtration performance, and hence it is considered the most promising filter material [4, 5, 6, 7, 8, 9]. Dawud [10] studied the influence of air pressure, die-to-collector distance on the number average fiber diameter for the nanofibers and the performance properties of the nonwoven webs. Yu [11] studied the influence of die-to-collector distance on structure and property of the PLA meltblown web. However, there is still a lack of comprehensive research on the fiber diameter, pore size, and the effect of area density on the filtration performance of meltblown nonwovens. Therefore, this work mainly focused on the influence of fiber diameter, pore size, and area density of meltblown nonwoven materials on its filtration performance.

2 Experimental

2.1 Materials

The polypropylene (PP) meltblown nonwoven fabrics of 23 different structural characteristics provided by Tongxiang Jianmin Filter Materials Co. Ltd. were numbered from 1 to 23.

2.2 Methods

The areal density is to determine the mass per unit area. The areal density of nonwoven was calculated according to Equation (1),

where ρA is areal density (g/m2), m is mass (g) measured by an electronic balance, and A is area (m2). Five measurements were taken, the average value and standard deviation (SD) were considered.

The surface morphology of the nonwoven fabric was observed by using a scanning electron microscope (model JSM-5610LV). The diameter of the fiber was analyzed by image-pro plus software. The average diameter and SD from 200 randomly selected fibers were taken for analysis.

The pore size of the nonwoven fabric was characterized by the bubble point method via a pore size analyzer (model CFP-1500AE). The principle of the bubble point method is that the sample was completely infiltrated by the wetting agent with the known surface tension and then placed in the sample cavity. Under a certain pressure, the gas passes through the capillary pores in the dry state and the wet state, respectively. The air pressure and airflow changes were recorded during the whole test, and then the pore size and distribution of the sample were calculated. The testing principle is shown in Figure 1.

Bubble point method for testing the pore size of meltblown nonwoven fabrics

The filtration efficiency of nonwoven fabrics was tested by an automatic filter tester (model US TSI8130). The device contains a highly automatic and self-diagnostic system, which greatly improved the overall measurement performance. The technical performance of the tester fully meets the technical requirements of the filter efficiency test instrument in GB2626-2006 respiratory protective equipment—self-priming filter type antiparticle respirator and its technical parameters have reached the international advanced level and have good stability. The test was carried out with 0.3 μm sodium chloride (NaCl) aerosol particles, and the test air flow rate was 5.3 L/min. The filtration efficiency together with pressure drop can be calculated after testing process. The average values and SD were determined after five measurements for each sample. The equation for filtration efficiency is as follows:

where P is the filtration efficiency (%), C0 is the mass concentration of NaCl in the upstream, and C1 is the mass concentration of NaCl in the downstream.

3 Results and discussions

3.1 Morphology

As shown in Figure 2, the meltblown fiber was randomly arranged, which contributed to the improvement of the filtration efficiency. The fiber diameter in the range of 1–20 μm was measured by image-pro plus software, and the fiber thickness unevenness was large. The formation of a three-dimensional network like the microporous structure [12] between fibers could help to reduce the pressure drop.

Morphology of meltblown nonwoven fabrics

3.2 Relationship between pore size and nonwoven fabric performance

Four groups of samples were selected, and each group contained 4–5 samples with similar fiber diameter (as shown in Table 1). The filtration properties of nonwoven fabrics under different pore size and areal density conditions were investigated when the fiber diameter was kept constant.

Effect of pore diameter and areal density on the filtration performance of nonwoven fabrics under the same fiber diameter

| Fiber diameter (μm) | Pore diameter (μm) | Areal density (g/m2) | Filtration efficiency (%) | Pressure drop (Pa) | |

|---|---|---|---|---|---|

| A1 | 2.4 ± 0.22 | 9.30 ± 0.21 | 27.76 ± 0.57 | 95.91 ± 1.74 | 37.4 ± 0.52 |

| B1 | 15.48 ± 0.87 | 40.40 ± 28.44 | 55.71 ± 23.66 | 86.67 ± 9.94 | 7.7 ± 11.20 |

| C1 | 3.37 ± 0.20 | 12.18 ± 2.80 | 25.25 ± 4.04 | 97.81 ± 0.58 | 37.18 ± 12.80 |

| D1 | 4.15 ± 0.46 | 22.35 ± 7.58 | 23.63 ± 3.35 | 88.85 ± 5.30 | 14.33 ± 14.02 |

Results in Table 1 demonstrated that when the fiber diameter of the nonwoven fabric was kept constant, the SD of other parameters was calculated and analyzed, and the SD of the pore's diameters in the B1 and D1 data was found to be large. The corresponding pressure drop also showed a large fluctuation, followed by the change in areal density in the A1 and C1 data, which led to changes in pressure drop and filtration efficiency. To further explore the correlations, see the graph in Figure 3.

Relationship between pore diameter and pressure drop

It can be seen from the pore diameter value and the pressure drop value corresponding to each sample in Figure 3 that the large pore diameter value corresponds to a small pressure drop value. Also, the pore diameter of the nonwoven fabric increased, while the pressure drop decreased. The reason is that when the fiber diameter and the areal density of the nonwoven fabric are the same, the pore diameter increased, which reduced the energy consumed during filtration. Therefore, the pressure drop was reduced. This demonstrated that the pressure drop can be controlled by controlling the pore diameter of the nonwoven fabric.

3.3 Relationship between areal density and nonwoven fabric performance

Four sets of meltblown nonwoven fabric samples with similar pore size values were selected, and the specific data are shown in Table 2.

Effect of fiber diameter and areal density on the filtration performance of nonwoven fabrics under the same pore diameter

| Pore diameter (μm) | Fiber diameter (μm) | Areal density (g/m2) | Filtration efficiency (%) | Pressure drop (Pa) | |

|---|---|---|---|---|---|

| A2 | 9.15 ± ±0.1 | 2.63 ± ±0.43 | 27.69 ± ±0.55 | 96.06 ± ±1.81 | 37.65 ± ±0.78 |

| B2 | 10.2 ± ±0.64 | 6.46 ± ±5.46 | 27.23 ± ±0.80 | 97.61 ± ±0.78 | 35.43 ± ±4.88 |

| C2 | 15.56 ± ±0.95 | 3.70 ± ±1.38 | 24.75 ± ±4.25 | 98.17 ± ±0.53 | 25.58 ± ±12.89 |

| D2 | 26.71 ± ±2.59 | 7.21 ± ±5.24 | 32.76 ± ±18.48 | 87.12 ± ±2.87 | 5.5 ± ±2.66 |

It can be seen from Table 2 that when the pore size of the nonwoven fabric was constant, the SD of a single variable was analyzed. The larger the SD, the larger the fluctuation range of the data. In A2 and D2, the SD of the areal density was greater than the SD of the fiber diameter. In the corresponding filtration efficiency and pressure drop, the fluctuation of the filtration efficiency is greater than the pressure drop. So it can be speculated that the effect of areal density on filtration efficiency is greater than that of the fiber diameter (with the reference of the A1 data in Table 1). According to the experimental data of the C2 group, the areal density also has a certain influence on the pressure drop. The data of the C1 group in Table 1 can be comprehensively discussed, and the graphs are as follows:

The curve fluctuation of the areal density and the filtration efficiency was observed in a wide range. Figure 4 shows that the filtration efficiency increased as the areal density of the meltblown nonwoven fabric increased, when the pore diameter was kept constant. This is because the increase of areal density within a certain range will increase the bulk density of the surface layer of melt-sprayed nonwovens, so that the disordered arrangement of fibers results in decreased pore diameter and porosity with the same fiber diameter. During air filtration measurement, aerosol particles cannot be intercepted through the medium, and hence the filtration efficiency improved. However, there is a certain critical value. When the areal density is in the range of 27–29 g/m2, the filtration efficiency shows the opposite development of the areal density. At this stage, the porosity of the meltblown nonwoven fabric did not degrade with the increase in areal density, because of the formation of many three-dimensional pores to allow 0.3 μm aerosol particles to pass through, resulting in the degradation of filtration efficiency.

Relationship between areal density and filtration efficiency

By observing the graph of the C2 group data in Figure 5, it is found that the pressure drop increased as the areal density of the meltblown nonwoven fabric increased while maintaining the relative stability of the pore size, which is because of the areal density increases, the number of fibers per unit area increases, and the bulk density increases. From Figure 4 we see that the filtration efficiency was also improved, and the interception effect was enhanced. Therefore, the airflow through the medium requires more energy, leading to increased pressure drop; referring to the graph of the C1 data, it can be seen that when the areal density is greater than 27 g/m2, the pressure drop decreased with the increase of the areal density, and this result verifies the conclusions shown in Figure 4. At this stage, the increase in areal density increases the number of three-dimensional microporous built between the fibers, and the energy required to pass the filter medium through the gas was less, so the pressure drop was lowered.

Relationship between areal density and pressure drop

3.4 Properties of nonwoven fabrics with different fiber diameters and pore sizes

Three groups of samples with similar areal density were selected according to the method in Section 3.2. The specific data are shown in Table 3.

Effect of fiber diameter and pore diameter on the filtration performance of fabrics under the same areal density

| Areal density (g/m2) | Fiber diameter (μm) | Pore diameter (μm) | Filtration efficiency (%) | Pressure drop (Pa) | |

|---|---|---|---|---|---|

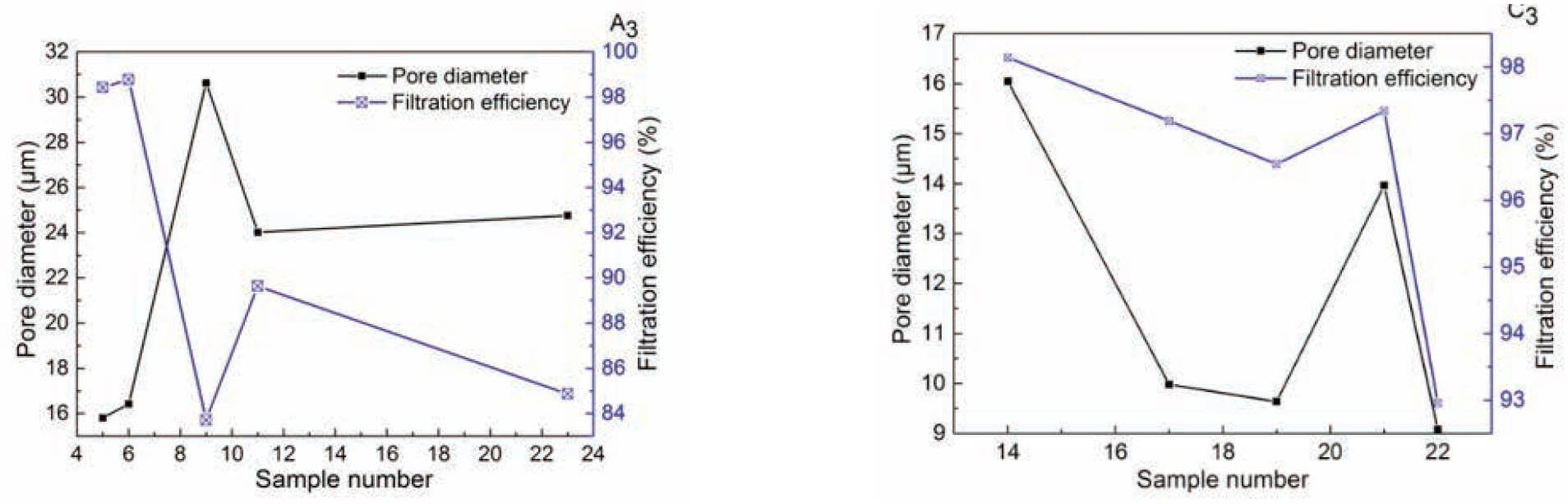

| A3 | 21.67 ± ±2.64 | 4.32 ± ±1.00 | 22.34 ± ±5.57 | 91.08 ± ±6.45 | 9 ± ±4.60 |

| B3 | 27.02 ± ±0.52 | 5.55 ± ±5.17 | 9.74 ± ±0.83 | 97.60 ± ±0.66 | 35.72 ± ±4.43 |

| C3 | 28.34 ± ±0.36 | 2.87 ± ±0.74 | 11.74 ± ±2.76 | 96.43 ± ±1.81 | 38 ± ±0.27 |

From the experimental data in Table 3, the SD of the pore sizes in the A3 and C3 data is larger than the SD of the fiber diameter in the case of a constant surface density, and the fluctuation ranges of the corresponding filtration efficiency are also greater than the fluctuation ranges of the pressure drop. Therefore, it can be guessed that the influence of the pore size on the filtration efficiency is larger than that of the fiber diameter, and the specific influence law is shown in Figure 6. The aerosol particles used in the filtration test were of 0.3 μm. As shown in Figure 6, the pore size of the meltblown nonwoven determines the size of the particles that can be trapped. For aerosol particles with a particle size of 0.3 μm, when the pore diameter of the meltblown nonwoven fabric is less than 17 μm, the filtration efficiency will decrease as the pore size decreases; when the pore diameter of the melt blown nonwoven fabric is larger than 17 μm, the filtration efficiency will increase as the pore diameter decreases.

Relationship between pore diameter and filtration efficiency

Selecting the B3 data to analyze the relationship between fiber diameter and pressure drop and using the B2 data in Table 2 as a reference results in Figure 7.

Relationship between fiber diameter and pressure drop

By observing the curve rise and fall in Figure 7, we found that in the case of maintaining a constant areal density, the sudden decrease of fiber diameter will lead to the increase in pressure drop. By observing the fiber diameter's SD of the B3 data, it is found that the value of SD is too large. It also shows that the fiber diameter distribution range of the meltblown nonwoven fabric in this group of data is large, and the combination of the thick and thin fibers makes the structure of the web more compact, so the energy consumption required when the gas flows through the filter media increased and hence the pressure drop also increased; when the fiber diameter distribution of the meltblown nonwoven fabric was uniform, the fiber diameter increase causes the randomly arranged fiber web become loose, resulting in a decrease in pressure drop [13, 14].

4 Conclusions

The influence of fiber diameter, pore size, and areal density on the filtration performance of the nonwoven fabric was analyzed by the control variable method. Based on the experimental results, the following conclusions were drawn:

The pressure drop of nonwoven fabrics decreased with the increase of pore diameter while the fiber diameter kept constant.

Both the filtration efficiency and pressure drop increased with the increase of areal density when the pore diameter kept constant. However, when the areal density was between 27 and 29 g/m2, both filtration efficiency and pressure drop decreased as the areal density increased.

When the areal density kept constant, the filtration efficiency decreased with the decrease of pore size while the pore size of the meltblown nonwoven fabric was less than 17 μm; when the fiber diameter distribution of the meltblown nonwoven fabric was uniform, the fiber diameter increase causes the randomly arranged fiber web become loose, resulting in a decrease in pressure drop.

The nonwoven fabric with high filtration efficiency and low pressure drop can be achieved by controlling the fiber diameter, the pore diameter, and the areal density. However, there are several factors like porosity and orientation that are to be considered and investigated.

Acknowledgments

The work is funded by The Joint Bilateral Industrial R&D of International Scientific and Technological Cooperation (grant no.: 2017C54005); the National Natural Science Foundation of China (grant no.: 51803182); the Ministry of Education, Youth and Sports of the Czech Republic, the European Union—European Structural and Investment Funds in the frames of Operational Programme Research; Development and Education—project Hybrid Materials for Hierarchical Structures (HyHi, Reg. No. CZ.02.1.01/0.0/0.0/16_019/0000843).

References

[1] Cheng, Z., Luo, L., Wang, S., et al. (2016). Status and characteristics of ambient PM2. 5 pollution in global megacities. Environment International, 89, 212–221.10.1016/j.envint.2016.02.003Search in Google Scholar PubMed

[2] Hoek, G., Krishnan, R. M., Beelen, R., et al. (2013). Long-term air pollution exposure and cardio-respiratory mortality: a review. Environmental Health, 12(1), 43.10.1186/1476-069X-12-43Search in Google Scholar PubMed PubMed Central

[3] PR Newswire. Nonwoven filter media market analysis by technology, by application and segment forecasts to 2024. PR Newswire US. 2016-09-22.Search in Google Scholar

[4] Ellison, C. J., Phatak, A., Giles, D. W., et al. (2007). Melt blown nanofibers: fiber diameter distributions and onset of fiber breakup. Polymer, 48(11), 3306–3316.10.1016/j.polymer.2007.04.005Search in Google Scholar

[5] Wente, V. A. (1956). Superfine thermoplastic fibers. Industrial & Engineering Chemistry, 48(8), 1342–1346.10.1021/ie50560a034Search in Google Scholar

[6] Kim, M. O., Park, T. Y. (2016). The manufacture and physical properties of Hanji Composite nonwovens utilizing the Hydroentanglement process. Fibers and Polymers, 17(6), 932–939.10.1007/s12221-016-5952-7Search in Google Scholar

[7] Handbook of nonwovens. Woodhead Publishing, 2006.Search in Google Scholar

[8] Nonwoven fabrics: raw materials, manufacture, applications, characteristics, testing processes. John Wiley & Sons, 2006.Search in Google Scholar

[9] Hassan, M. A., Yeom, B. Y., Wilkie, A., et al. (2013). Fabrication of nanofiber meltblown membranes and their filtration properties. Journal of Membrane Science, 427, 336–344.10.1016/j.memsci.2012.09.050Search in Google Scholar

[10] Tan, D. H, Zhou, C., Ellison, C. J., et al. (2010). Meltblown fibers: influence of viscosity and elasticity on diameter distribution. Journal of Non-Newtonian Fluid Mechanics, 165(15–16), 892–900.10.1016/j.jnnfm.2010.04.012Search in Google Scholar

[11] Bin, Y., Xuyang, Z., Jinjin, K., et al. (2016). Influence of die-to-collector distance on structure and property of the PLA meltblowing web. Rare Metal Materials and Engineering, 45, 345–349.Search in Google Scholar

[12] Das, D., Das, S., Ishtiaque, S. M. (2014). Optimal design of nonwoven air filter media: effect of fibre shape. Fibers and Polymers, 15(7), 1456–1461.10.1007/s12221-014-1456-5Search in Google Scholar

[13] Payen, J., Vroman, P., Lewandowski, M., et al. (2012). Influence of fiber diameter, fiber combinations and solid volume fraction on air filtration properties in nonwovens. Textile Research Journal, 82(19), 1948–1959.10.1177/0040517512449066Search in Google Scholar

[14] Dolny, S., Rogozinski, T. (2014). Air flow resistance across nonwoven filter fabric covered with microfiber layer used in wood dust separation. Drewno. Prace Naukowe. Doniesienia. Komunikaty, 57(191):125–134.Search in Google Scholar

© 2020 Yuanxiang Xiao et al., published by Sciendo

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Statistical Analysis of Standard Allowed Minute on Sewing Efficiency in Apparel Industry

- Study on the Relationship Between Structure Parameters and Filtration Performance of Polypropylene Meltblown Nonwovens

- Merging Footwear Design and Functionality

- Nonwovens: Global Trends in World Economy, European Foreign Trade, and Selected Case Studies from Poland and Asian Brics Countries

- Sewing Thread Consumption for Different Lockstitches of Class 300 Using Geometrical and Multi-Linear Regression Models

- Electrospinning of Chitosan Biopolymer and Polyethylene Oxide Blends

- Antibacterial Fibers Containing Nanosilica with Immobilized Silver Nanoparticles

- Influence of Structural Parameters of Nonwoven Geotextiles on Separation and Filtration in Road Construction

- Optimization of Dynamic Mechanical Properties of Knitted Barrier Meshes

- Influence of Ultraviolet Irradiation and Protease on Scale Structure of Alpaca Wool Fibers

- Influence of Woven Fabric Width and Human Body Types on the Fabric Efficiencies in the Apparel Manufacturing

- The Effect of Electric Field on Nanofibers Preparation in Cylindrical-Electrode-Assisted Solution Blowing Spinning

- Antibacterial Effect of Graphene and Graphene Oxide as a Potential Material for Fiber Finishes

- Investigation of the Influence of Technology Parameters and Thread Type on Embroidered Textile Element Quality

- The Hydrophobization of a Nanofiber Layer Using Low-Vacuum Plasma

- Review of Printed Fabric Pattern Segmentation Analysis and Application

- Influence of Technology Process on Responsiveness of Footwear Nonwovens

- Performance of Electrospun Polyvinylidene Fluoride Nanofibrous Membrane in Air Filtration

Articles in the same Issue

- Statistical Analysis of Standard Allowed Minute on Sewing Efficiency in Apparel Industry

- Study on the Relationship Between Structure Parameters and Filtration Performance of Polypropylene Meltblown Nonwovens

- Merging Footwear Design and Functionality

- Nonwovens: Global Trends in World Economy, European Foreign Trade, and Selected Case Studies from Poland and Asian Brics Countries

- Sewing Thread Consumption for Different Lockstitches of Class 300 Using Geometrical and Multi-Linear Regression Models

- Electrospinning of Chitosan Biopolymer and Polyethylene Oxide Blends

- Antibacterial Fibers Containing Nanosilica with Immobilized Silver Nanoparticles

- Influence of Structural Parameters of Nonwoven Geotextiles on Separation and Filtration in Road Construction

- Optimization of Dynamic Mechanical Properties of Knitted Barrier Meshes

- Influence of Ultraviolet Irradiation and Protease on Scale Structure of Alpaca Wool Fibers

- Influence of Woven Fabric Width and Human Body Types on the Fabric Efficiencies in the Apparel Manufacturing

- The Effect of Electric Field on Nanofibers Preparation in Cylindrical-Electrode-Assisted Solution Blowing Spinning

- Antibacterial Effect of Graphene and Graphene Oxide as a Potential Material for Fiber Finishes

- Investigation of the Influence of Technology Parameters and Thread Type on Embroidered Textile Element Quality

- The Hydrophobization of a Nanofiber Layer Using Low-Vacuum Plasma

- Review of Printed Fabric Pattern Segmentation Analysis and Application

- Influence of Technology Process on Responsiveness of Footwear Nonwovens

- Performance of Electrospun Polyvinylidene Fluoride Nanofibrous Membrane in Air Filtration