Abstract

This paper looks at the simultaneous effects of heat and mass transfer in the flow of Williamson fluid over an unsteady stretching surface. The effects of thermal radiation and viscous dissipation are considered in an energy equation. Besides, the energy and concentration equations are coupled with the combined effects of Soret and Dufour. The convective conditions for both temperature and mass concentration are employed. The transformation procedure reduces the time-dependent boundary layer equations of momentum, energy, and concentration to the non-linear ordinary differential equations. Through graphs and numerical values, the velocity, temperature, and concentration fields are discussed for different physical parameters. It is found that the thermal and concentration Biot numbers have an increasing impact on both temperature and concentration fields, respectively.

1 Introduction

The flow induced by a stretching surface with heat transfer is prominent in several engineering processes such as aerodynamic extrusion of plastic sheets, annealing and tinning of copper wire, crystal growing, food processing, paper production, and glass blowing. The end product in such applications greatly depends upon the stretching and cooling rates at the surface. Also the fluids involved mostly in such processes are non-Newtonian. The well-known Navier–Stokes equations are inadequate for the flow analysis of non-Newtonian fluids. Different from viscous fluids, constitutive equations for the description of many rheological properties of non-Newtonian fluids have been suggested (see [1–9]). Further, the combined effects of heat and mass transfer have an important role in the fields such as distribution of temperature and moisture over agricultural fields and groves of fruit trees (crops damage due to freezing, fog formation, and dispersion), cooling towers and food processing. There is no doubt that the driving potentials become intricate in nature when heat and mass transfer occur simultaneously between the fluxes. Obviously both temperature and composition gradients can generate the energy flux. The energy flux due to the composition/temperature gradient is known as the Dufour/Soret effect. The Dufour and Soret effects in general are of small order of magnitude than the effects through Fourier’s or Fick’s laws and are often neglected in heat and mass transfer processes. The Soret or thermal diffusion effect is utilized for isotope separation and a mixture of light molecular weight gases (hydrogen–helium) and of medium molecular weight gases (nitrogen–air); the Dufour effect was found to be of a magnitude such that it cannot be neglected. In recent years, progress has been considerably made for the Soret and Dufour effects in the boundary layer flows (see [10–19]).

In the past, much attention was paid to the heat transfer analysis in the boundary layer flows either through the prescribed surface temperature or through the prescribed heat flux. Recently a convective boundary condition for the heat transfer effect in such flow has been employed by Aziz [20]. Patil et al. [21] analysed the influence of the convective condition along with mass transfer for two-dimensional double diffusive mixed convection. Ramesh and Gireesha [22] employed a numerical method to solve mathematical formulation resulting from the flow of Maxwell fluid with the convective boundary condition. Rashad et al. [23] studied mixed convection boundary layer flow by taking into account the thermal convective condition. Hayat et al. [24] carried out an analysis to examine nanofluid flow near a stretched surface with the convective boundary condition. Hamad et al. [25] investigated heat and mass transfer together with the thermal convective condition. Makinde and Aziz [26] presented a numerical solution of the heat and mass transfer of nanofluid from a horizontal plate with the convective boundary condition. Hayat et al. [27] examined forced convection resulting from the three-dimensional flow of Jeffrey fluid with a convectively heated plate. Das et al. [28] concentrates on the boundary layer flow of nanofluid over a heated stretching sheet with the convective boundary condition. Hayat et al. [29] discussed convective conditions for heat transfer in Maxwell fluid.

Motivated by the above-referenced works, it is of paramount interest in this investigation to examine the effects of heat and mass transfer convective conditions, Soret and Dufour, thermal radiation, and viscous dissipation on the boundary layer flow of Williamson fluid over an unsteady stretching surface. None of the above attempts simultaneously analysed all such effects even in viscous fluid/steady flow over a stretching surface. The momentum, energy, and concentration equations are transformed into a set of ordinary differential systems and then solved implementing the homotopy analysis method (HAM) [30–34]. To reveal the tendency of solutions, the results for velocity, temperature, and concentration are graphically displayed. The local Nusselt number, Sherwood number, and skin friction coefficient are analysed through tabulated values. This paper is organized as follows. Section 2 contains problem formulation. In Section 3, we present the solutions. The convergence of the obtained solutions is presented in Section 4. Sections 5 and 6 consist of discussion and conclusion, respectively.

2 Problem Formulation

Consider a two-dimensional flow of an incompressible Williamson fluid over an unsteady stretching sheet with heat and mass transfer. The horizontal sheet is placed at y= 0 and the flow is confined in the region y>0. The sheet is stretched by two equal and opposite forces. The effects of Soret and Dufour, thermal radiation, and viscous dissipation are considered. Further, we take the convective boundary condition for both temperature and concentration fields.

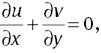

The velocity, temperature, and concentration fields subject to the boundary layer and Rosseland approximations are governed by the following equations:

where u and v represent the velocity components along the x- and y-directions, respectively, Γ>0 is the characteristic time,

The appropriate transformations are defined as follows:

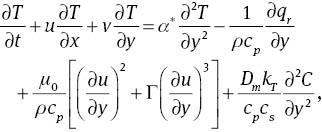

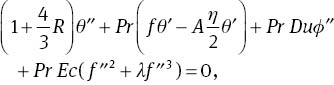

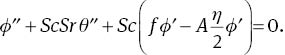

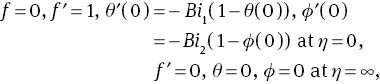

With the help of the above transformations, (1) is identically satisfied and (2)–(5) yield

where A is the unsteadiness parameter, λ is the Williamson fluid parameter, Pr is the Prandtl number, Du is the Dufour number, Sr is the Soret number, Sc is the Schmidt number, Ec is the Eckert number, Bi1 is the thermal Biot number, Bi2 is the concentration Biot number, and R is the radiation parameter. The definitions of these parameters are

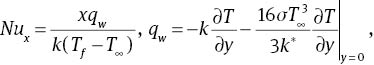

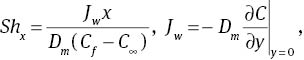

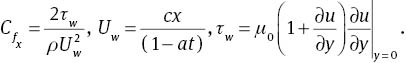

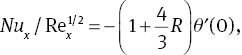

The local Nusselt number Nux, local Sherwood number Shx, and skin friction coefficient

The dimensionless forms of (11)–(13) are

3 Series Solutions

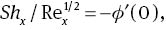

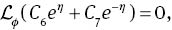

The initial approximations and auxiliary linear operators for the series solutions are chosen as follows:

with

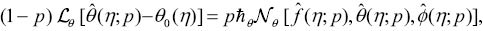

in which Ci (i= 1–7) are the arbitrary constants. If p∈ [0 1] denotes an embedding parameter, and ℏf,ℏθ, and ℏφ are the non-zero auxiliary parameters, then the zeroth-order deformation problems can be put into the forms

For p= 0 and p= 1, we have

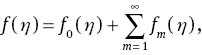

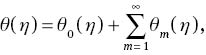

and when p moves from 0 to 1, then f(η, p), θ(η, p), and ϕ(η, p) approach f0(η), θ0(η), and ϕ0(η) to f(η), θ(η), and ϕ(η). Now f, θ, and ϕ in Taylor’s series can be written as follows:

Note that the convergence depends upon ℏf, ℏθ, and ℏφ. By proper choices of ℏf, ℏθ, and ℏφ, the series (30)–(32) converge for p= 1 and hence

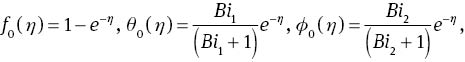

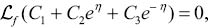

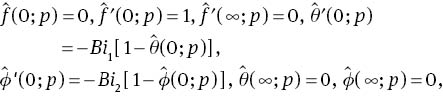

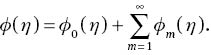

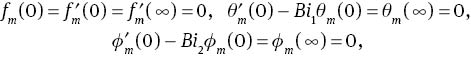

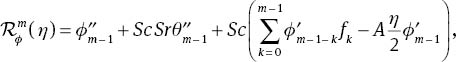

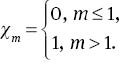

The mth-order deformation problems are given by

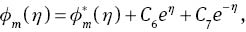

The general solutions of (37)–(39) are given by

in which

4 Convergence Analysis

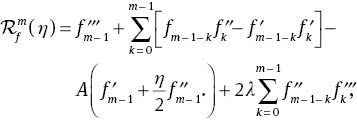

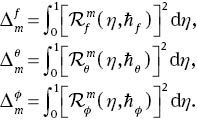

The convergence of series solutions depends upon the involved non-zero auxiliary parameters. To check the convergence of series solutions, we plot the ℏ-curves for the velocity, temperature, and concentration fields. Figure 1 depicts the ℏ-curves of f″(0), θ′(0), and ϕ′(0) for different values of physical parameters involved in the problem. The admissible value of ℏf is –1.6<ℏf<–0.3, for ℏθ it is –1.8<ℏθ<–0.3, and for ℏφ it is –1.8<ℏφ<–0.2. It is clearly seen from these figures that the series solutions converge in the whole region of η when ℏf= –1.1, ℏθ= –1.5, and ℏφ= –1.4. ℏ-curves for the residual error are plotted in Figure 2. Figure 2 may be considered as counter-check to Figure 1 in order to confirm their convergence analysis. The square residual errors are defined as

ℏ-curves for f″(0), θ′(0), and ϕ′(0).

Residual error for f″(0), θ′(0), and ϕ′(0).

Table 1 shows the convergence of series solutions for different orders of approximations. It is obvious from this table that the 25th order of approximations is sufficient for the convergent series solutions.

Convergence of series solutions for different orders of approximations.

| Order of approximations | –f″(0) | –θ′(0) | –φ′(0) |

|---|---|---|---|

| 1 | 1.11458 | 0.08265 | 0.2523 |

| 5 | 1.11715 | 0.07559 | 0.2270 |

| 10 | 1.11704 | 0.07404 | 0.2210 |

| 15 | 1.11703 | 0.07362 | 0.2192 |

| 20 | 1.11703 | 0.07346 | 0.2185 |

| 25 | 1.11703 | 0.07339 | 0.2182 |

| 30 | 1.11703 | 0.07335 | 0.2180 |

| 35 | 1.11703 | 0.07335 | 0.2180 |

| 40 | 1.11703 | 0.07335 | 0.2180 |

5 Results and Discussion

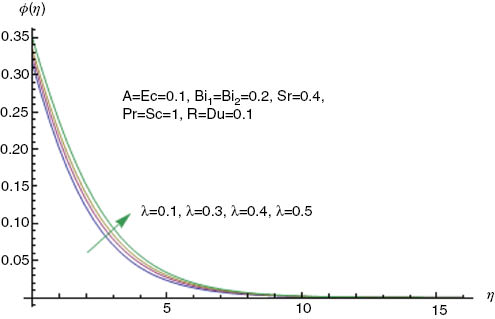

In this section, the effects of different parameters on the velocity, temperature, and concentration fields have been analysed. Figure 3 shows the influence of the unsteadiness parameter A on the velocity profile. An increase in the unsteadiness parameter A decreases the stretching rate c, which in turn reduces the velocity and momentum boundary layer. Opposite behaviour of concentration and temperature fields is observed for the unsteadiness parameter A (see Figs. 4 and 5). The influence of the Williamson fluid parameter λ on the velocity field is displayed in Figure 6. The velocity is found to decrease when λ is increased. Physically, it is true because an increase in relaxation time causes higher resistance to the fluid flow which ultimately reduces the velocity field. This higher resistance also enhances the collisions in the fluid that increases the temperature field (see Fig. 7). Figure 8 demonstrates the increasing behaviour of the concentration field for larger values of λ. Figures 9 and 10 depict that the thermal and concentration Biot numbers have an increasing impact on the temperature and concentration fields, respectively. Larger values of the thermal and concentration Biot numbers enhance the temperature gradient and thermal boundary layer thickness. Soret and Dufour effects on the temperature and concentration profiles are shown in Figures 11 and 12, respectively. The values of the Soret and Dufour numbers are chosen in such a way that their product is constant provided that the mean temperature Tm is kept constant as well. With an increase of the Dufour number (i.e., a decrease of the Soret number) the temperature difference between hot and surrounding fluid decreases, which in result enhances the temperature and thermal boundary layer thickness. Further, the intermolecular forces become weak and, as a result, the concentration decreases. The larger Prandtl number has a relatively lower thermal diffusivity. The influence of the Eckert number Ec on the temperature θ(η) is sketched in Figure 13. The viscous dissipation effect increases with an increase in the Eckert number. Therefore, a significant increase in the temperature and thermal boundary layer thickness is noticed. Figure 14 illustrates the concentration profiles for different values of the Schmidt number. The increase in Sc means lower molecular diffusivity, which results in the reduction of the concentration boundary layer.

Influence of A on f′(η).

Influence of A on θ(η).

Influence of A on ϕ(η).

Influence of λ on f′(η).

Influence of λ on θ(η).

Influence of λ on ϕ(η).

Influence of Bi1 on θ(η) and θ′(η)

Influence of Bi2 on ϕ(η) and ϕ′(η).

Influences of Du and sron θ (η).

Influences of Du and Sr on ϕ(η).

Influence of Ec on θ(η).

Influence of Sc on ϕ(η).

Tables 2 analyses the variations of different physical parameters with the local Nusselt number. The local Nusselt number increases with an increase in Pr, R, and Bi1. A slight variation in the local Nusselt number is noticed by increasing the values of the Soret number Sr. It is observed that an increase in A, λ, Bi2, Ec, Du, and Sc leads to a decrease in the heat transfer rate at the surface. Table 3 presents the numerical values of the local Sherwood number for different values of physical parameters. It is observed that the mass transfer coefficient in terms of the local Sherwood number increases with an increase in Sc, Du, and Bi2, while an increase in A, λ, Sr, and Bi1 leads to a decrease in the value of the local Sherwood number. Table 4 shows the effects of various parameters on the skin friction coefficient. The skin friction coefficient is negative for all physical parameters. Physically, negative values of the skin friction coefficient means that the surface exerts a drag force on the fluid. The magnitude of the skin friction coefficient is increased by increasing the values of A and λ. Table 5 depicts the comparison of the skin friction coefficient from the previous study. From this table we found excellent argument.

Values of the local Nusselt number

| A | λ | Pr | R | Bi1 | |

|---|---|---|---|---|---|

| 0.1 | 0.1 | 1.0 | 0.1 | 0.2 | |

| 0.05 | 0.1472 | ||||

| 0.08 | 0.1451 | ||||

| 0.10 | 0.1434 | ||||

| 0.0 | 0.1443 | ||||

| 0.12 | 0.1431 | ||||

| 0.20 | 0.1422 | ||||

| 1.1 | 0.1466 | ||||

| 1.2 | 0.1494 | ||||

| 1.4 | 0.1538 | ||||

| 0.01 | 0.1313 | ||||

| 0.05 | 0.1367 | ||||

| 0.15 | 0.1498 | ||||

| 0.15 | 0.1161 | ||||

| 0.30 | 0.1874 | ||||

| 0.40 | 0.2213 | ||||

| Bi2 | Du | Ec | Sc | Sr | |

| 0.2 | 0.1 | 0.1 | 1.0 | 0.4 | 0.1407 |

| 0.15 | 0.1440 | ||||

| 0.30 | 0.1424 | ||||

| 0.50 | 0.1410 | ||||

| 0.0 | 0.1466 | ||||

| 0.05 | 0.1450 | ||||

| 0.10 | 0.1434 | ||||

| 0.15 | 0.1369 | ||||

| 0.20 | 0.1304 | ||||

| 0.30 | 0.1175 | ||||

| 0.5 | 0.1440 | ||||

| 0.7 | 0.1437 | ||||

| 1.2 | 0.1432 | ||||

| 0.2 | 0.1433 | ||||

| 0.4 | 0.1434 | ||||

| 0.6 | 0.1435 | ||||

Values of the local Sherwood number

| A | λ | Bi1 | Bi2 | R | Du | Ec | Sr | Sc | |

|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.1 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.4 | 1 | 0.1346 |

| 0.0 | 0.1399 | ||||||||

| 0.05 | 0.1377 | ||||||||

| 0.10 | 0.1346 | ||||||||

| 0.0 | 0.1356 | ||||||||

| 0.2 | 0.1331 | ||||||||

| 0.3 | 0.1310 | ||||||||

| 0.3 | 0.1312 | ||||||||

| 0.4 | 0.1288 | ||||||||

| 0.5 | 0.1268 | ||||||||

| 0.3 | 0.1773 | ||||||||

| 0.4 | 0.1209 | ||||||||

| 0.5 | 0.2377 | ||||||||

| 0.05 | 0.1345 | ||||||||

| 1.0 | 0.1346 | ||||||||

| 0.2 | 0.1349 | ||||||||

| 0.0 | 0.1343 | ||||||||

| 0.1 | 0.1346 | ||||||||

| 0.2 | 0.1348 | ||||||||

| 0.2 | 0.1361 | ||||||||

| 0.4 | 0.1393 | ||||||||

| 0.5 | 0.1409 | ||||||||

| 0.3 | 0.1370 |

Values of the skin friction coefficient

| A | λ | |

|---|---|---|

| 0.1 | 0.1 | 1.1170 |

| 0.1 | 1.1170 | |

| 0.2 | 1.1579 | |

| 0.3 | 1.1986 | |

| 0.0 | 1.0341 | |

| 0.2 | 1.2575 | |

| 0.23 | 1.3289 |

Values of the skin friction coefficient

| A | [35] | Present |

|---|---|---|

| 0.8 | –1.261042 | –1.26104 |

| 1.2 | –1.377722 | –1.37772 |

| 2.0 | –1.587362 | –1.58734 |

6 Conclusions

Salient features of convective heat and mass transfer in the flow of Williamson fluid over an unsteady stretching sheet are investigated in the presence of Soret and Dufour effects. The main outcomes of the present attempt can be mentioned as follows.

The velocity field f′(η) and momentum boundary layer thickness are decreasing functions of A and λ.

The behaviours of concentration and temperature fields corresponding to A and λ are qualitatively similar.

The influences of the radiation parameter R and Eckert number Ec on the temperature field are reverse to that of Pr.

The effects of Soret and Dufour numbers on the temperature and concentration fields are quite opposite.

The Prandtl number Pr and Eckert number Ec have dual behaviour on the concentration field.

Concentration field decays most rapidly for larger values of the Schmidt number Sc.

Effects of thermal and concentration Biot numbers on the temperature and concentration fields are qualitatively similar.

References

[1] K. Das, Int. J. Heat Mass Tran. 54, 3505 (2011).Suche in Google Scholar

[2] T. Hayat, A. Safdar, M. Awais, and Awatif A. Hendi, Z. Naturforsch. 66a, 635 (2011).10.5560/zna.2011-0032Suche in Google Scholar

[3] T. Hayat, M. Awais, and S. Obaidat, J. Heat Transfer 134, 044503 (2012).10.1115/1.4006032Suche in Google Scholar

[4] M. Awais, A. Alsaedi, and T. Hayat, Int. J. Numer. Math. Heat Fluid Flow 24, 483 (2014).10.1108/HFF-04-2012-0084Suche in Google Scholar

[5] R. Ellahi, S. U. Rahman, M. Mudassar Gulzar, S. Nadeem, and K. Vafai, Appl. Math. Inf. Sci. 8, 1567 (2014).Suche in Google Scholar

[6] M. Turkyilmazoglu, and I. Pop, Int. J. Heat Mass Tran. 57, 82 (2013).Suche in Google Scholar

[7] M. M. Rashidi, M. Ali, N. Freidoonimehr, B. Rostami, and A. Hossian, Adv. Mech. Eng. 2014, 735939 (2014).Suche in Google Scholar

[8] M. Sheikholeslami, H. R. Ashorynejad, D. D. Ganji, and M. M. Rashidi, Commun. Numer. Anal. 2014, 00166 (2014).Suche in Google Scholar

[9] T. Hayat, H. Yasmin, and M. Al-Yami, Comput. Fluids 89, 242 (2014).10.1016/j.compfluid.2013.10.038Suche in Google Scholar

[10] S. Shateyi, S. S. Motsa, and P. Sibanda, Math. Prob. Eng. 2010, 627475 (2010).Suche in Google Scholar

[11] T. Hayat, S. A. Shehzad, and A. Alsaedi, Appl. Math. Mech. (Engl. Ed.) 33, 1301 (2012).10.1007/s10483-012-1623-6Suche in Google Scholar

[12] F. E. Alsaadi, S. A. Shehzad, T. Hayat, and S. J. Monaquel, J. Mech. 29, 623 (2013).Suche in Google Scholar

[13] T. Hayat, R. Naz, S. Asghar, and A. Alsaedi, Int. J. Numer. Methods Heat Fluid Flow 24, 498 (2014).10.1108/HFF-03-2012-0076Suche in Google Scholar

[14] T. Hayat, M. Mustafa, and S. Obaidat, ASME J. Fluids Eng. 133, 021202 (2011).Suche in Google Scholar

[15] C. Hsiao, W. Chang, M. Char, and B. Tai, Appl. Math. Comput. 244, 390 (2014).Suche in Google Scholar

[16] S. Wang, and W. Tan, Int. J. Heat Fluid Flow 32, 88 (2011).10.1016/j.ijheatfluidflow.2010.10.005Suche in Google Scholar

[17] M. Turkyilmazoglu, and I. Pop, Int. J. Heat Mass Tran. 55, 7635 (2012).Suche in Google Scholar

[18] M. M. Rashidi, T. Hayat, E. Erfani, S. A. M. Pour, and A. A. Hendi, Commun. Nonlin. Sci. Numer. Simul. 16, 4303 (2011).Suche in Google Scholar

[19] A. Zaib, and S. Shafie, J. Franklin Inst. 351, 1268 (2014).Suche in Google Scholar

[20] A. Aziz, Commun. Nonlin. Sci. Numer. Simul. 14, 1064 (2009).Suche in Google Scholar

[21] P. M. Patil, E. Momoniat, and S. Roy, Int. J. Heat Mass Tran. 70, 313 (2014).Suche in Google Scholar

[22] G. K. Ramesh, and B. J. Gireesha, Ain Shams Eng. J. (2014) (in press).Suche in Google Scholar

[23] A. M. Rashad, A. J. Chamkha, and M. Modather, Comput. Fluids 86, 380 (2013).10.1016/j.compfluid.2013.07.030Suche in Google Scholar

[24] A. Alsaedi, M. Awais, and T. Hayat, Commun. Nonlin. Sci. Numer. Simul. 17, 4210 (2012).Suche in Google Scholar

[25] M. A. A. Hamad, Md. J. Uddin, and A. I. Md. Ismail, Int. J. Heat Mass Tran. 55, 1355 (2012).Suche in Google Scholar

[26] O. D. Makinde, and A. Aziz, Int. J. Ther. Sci. 50, 1326 (2011).Suche in Google Scholar

[27] S. A. Shehzad, A. Alsaedi, and T. Hayat, Int. J. Heat Mass Tran. 55, 3971 (2012).Suche in Google Scholar

[28] K. Das, P. R. Duari, and P. K. Kundu, J. Egypt. Math. Soc. (2014) (in press).Suche in Google Scholar

[29] T. Hayat, Z. Iqbal, M. Mustafa, and A. Alsaedi, Nucl. Eng. Des. 252, 242 (2012).Suche in Google Scholar

[30] S. Liao, Commun. Nonlin. Sci. Numer. Simul. 15, 2003 (2010).Suche in Google Scholar

[31] T. Hayat, S. Asad, and A. Alsaedi, Appl. Math. Mech. (Engl. Ed.) 35, 1 (2014).10.1007/s10483-014-1824-6Suche in Google Scholar

[32] T. Hayat, S. Asad, M. Mustafa, and Hamed H. Alsulami, Chin. Phys. B 23, 084701 (2014).10.1088/1674-1056/23/8/084701Suche in Google Scholar

[33] M. M. Rashidi, B. Rostami, N. Freidoonimehr, and S. Abbasbandy, Ain Shams Eng. J. 5, 901 (2014).Suche in Google Scholar

[34] M. Sheikholeslami, R. Ellahi, H. R. Ashorynejad, G. Domairry, and T. Hayat, J. Comput. Theor. Nanosci. 11, 486 (2014).Suche in Google Scholar

[35] S. Sharidan, T. Mahood, and I. Pop, Int. J. Appl. Mech. Eng. 11, 647 (2006).Suche in Google Scholar

©2015 by De Gruyter

Artikel in diesem Heft

- Frontmatter

- Editorial

- Content matters – the new face of ZNA

- Original Communications

- Nonreciprocal Optical Tunnelling Through Evanescently Coupled Tamm States in Magnetophotonic Crystals

- The Wronskian Solution and Soliton Resonance of the Nonisospectral Generalised Sawada–Kotera Equation

- A Mathematical Study for Three-Dimensional Boundary Layer Flow of Jeffrey Nanofluid

- Soret and Dufour Effects in the Flow of Williamson Fluid over an Unsteady Stretching Surface with Thermal Radiation

- Bound States of Spinless Particles in a Short-Range Potential

- Controllable Nonautonomous Rogue Waves in the Modified Nonlinear Schrödinger Equation with Distributed Coefficients in Inhomogeneous Fibers

- A Study on Rational Solutions to a KP-like Equation

- Extended Trial Equation Method for Nonlinear Partial Differential Equations

- The Study of Peristaltic Motion of Third Grade Fluid under the Effects of Hall Current and Heat Transfer

- 23Na Nuclear Magnetic Resonance Study of the Structure and Dynamic of Natrolite

Artikel in diesem Heft

- Frontmatter

- Editorial

- Content matters – the new face of ZNA

- Original Communications

- Nonreciprocal Optical Tunnelling Through Evanescently Coupled Tamm States in Magnetophotonic Crystals

- The Wronskian Solution and Soliton Resonance of the Nonisospectral Generalised Sawada–Kotera Equation

- A Mathematical Study for Three-Dimensional Boundary Layer Flow of Jeffrey Nanofluid

- Soret and Dufour Effects in the Flow of Williamson Fluid over an Unsteady Stretching Surface with Thermal Radiation

- Bound States of Spinless Particles in a Short-Range Potential

- Controllable Nonautonomous Rogue Waves in the Modified Nonlinear Schrödinger Equation with Distributed Coefficients in Inhomogeneous Fibers

- A Study on Rational Solutions to a KP-like Equation

- Extended Trial Equation Method for Nonlinear Partial Differential Equations

- The Study of Peristaltic Motion of Third Grade Fluid under the Effects of Hall Current and Heat Transfer

- 23Na Nuclear Magnetic Resonance Study of the Structure and Dynamic of Natrolite