Abstract

The present work aimed to study the tensile and impact behaviour of fly ash particle reinforced aluminium matrix composites. Fly ash particles reinforced aluminium (Al/3Cu/8.5Si) matrix composites were fabricated by the stir casting technique. Three different size ranges of fly ash particles (50–75, 75–103 and 103–150 μm) were used. The composites were subjected to tensile and impact tests. The tensile and impact fracture surfaces of the aluminium alloy and composites were investigated using a scanning electron microscope to characterise the fracture mechanism of the composites. The tensile strength of composites increased, while the ductility and impact strength of composites decreased with an increase in fly ash particle content. The fracture surface of the unreinforced material was characterised by uneven distribution of a large number of dimples resulting in ductile failure. In the case of composites, the presence of hard and brittle reinforcement particles in the ductile aluminium matrix places constraints on the plastic flow of the matrix leading to brittle failure with an increase in fly ash particles.

1 Introduction

The potential for extensive application of cast composites is very large, especially in the areas of transportation, energy and electromechanical machinery; the extensive use of composites leads to large savings in materials and energy, and, in several instances, reduces environmental pollution [1]. Metal matrix composites are of particular interest as lightweight materials for the aerospace industries particularly as they possess improved modulus, strength, and fatigue and fracture resistance at ambient and elevated temperatures [2]. Discontinuously reinforced metal matrix composites (MMC) are gaining importance primarily in automotive, aerospace and energy applications due to their high specific strength, high stiffness, low density and good wear resistance. Aluminium composites are used in manufacturing automotive components like pistons, cylinder liners, brake rotors and connecting rods [3]. Yield strength, ultimate strength, ductility and wear of Al/SiC metal matrix composites are strongly influenced by its composition [4]. The contents of alloying elements such as Si, Fe, Mg and Cu play a vital role in the mechanical properties of Al/SiC composites [5]. Aluminium matrix composite materials reinforced with silicon nitride, aluminium nitride and zirconium diboride by powder metallurgy improved the ultimate tensile strength and hardness of the extruded materials [6]. The tensile strength and Young’s modulus of silicon dioxide particulate reinforced LM6 aluminium alloy composites decreased gradually with an increase in silicon dioxide due to the dominating nature of the compressive strength of quartz particulate reinforced in LM6 alloy matrix [7]. Matrix hardness and compression strength increased, while porosity and impact toughness decreased with increasing Mg content in Al/Mg reinforced with Al2O3 and SiC hybrid composites [8]. Hardness and tensile strength of aluminium composite materials increased with an increase in boron nitride; precipitation hardening caused an additional increase in hardness of composite materials [9]. Increase in composition of SiC in aluminium matrix increased the hardness, impact strength and normalised displacement in the samples prepared by a two-step stir casting technique [10]. Mechanical properties are determined by the reinforcement content, its distribution, the level of the near contact of the wetting with the matrix materials, and also the porosity content [11]. Through a proper combination of process parameters, uniform particle distribution or a preferential segregation of particles as per the property requirements for different components can be obtained [12]. The properties of cast aluminium matrix composites are greatly influenced by the nature of distribution of reinforcing phase in the matrix and matrix microstructural length scales, such as grain size, dendrite arm spacing, size and morphology of secondary matrix phases, etc. [13]. During tensile deformation in aluminium/SiC composites, the SiC particles will fracture to nucleate microcracks when the interfacial cohesion between the SiC particles and matrix is strong; decohesion between the SiC particles and matrix will nucleate microcracks before the SiC particles are fractured when the interfacial cohesion between the SiC particles and matrix is weak [14]. Internal damage in composites is due to the plastic deformation and takes two forms: particle cracking and matrix voiding [15]. Composites reinforced with larger Al2O3 particles (32 μm) exhibited high tensile strength than composites with smaller Al2O3 particles (16 μm) [16]. The crack initiation and fracture of the coarse particle reinforced composite were mainly associated with voiding in the matrix around individual particles ahead of main crack tip; the boundaries between the particle clusters and surrounding matrix are responsible for the failure of the fine particle reinforced composites [17]. Elimination of residual pores and defects formed during casting, more uniform distribution of reinforcing particles, stronger bonding between the matrix and particles, and refinement of grains improved the impact strength of composites [18].

Components like differential covers, intake manifolds, brake drums and outdoor equipment castings can be made by aluminium fly ash composites [19]. Density and coefficient of thermal expansion decreased, whereas hardness, tensile strength, compression strength, impact strength, damping capacity, dry sliding wear and slurry erosive wear of composites increased with the addition of fly ash in aluminium matrix [20]. Addition of phenolic resin provided consistently better coefficients of friction and low wear rates of brake lining friction in aluminium composites reinforced with fly ash [21]. The mechanical properties and wear resistance of composites with narrow size range of fly ash particles were superior to those of composites with wide size range fly ash particles [22, 23]. The present investigation is an attempt to establish the influence of particle size on tensile strength, hardness and ductility of aluminium (A380) alloy fly ash composites reinforced with fly ash particles of different sizes. Fracture mechanisms were studied using scanning electron microscope (SEM) photographs.

2 Material and experimental procedure

Fly ash (Table 1) obtained from the Tuticorin thermal power plant (Tamil Nadu, India) was sieved using a vibratory type sieving machine into three size ranges: 53–75, 75–103 and 103–150 μm. The required quantities of fly ash (3, 6, 9 and 12 wt.%) were taken in powder containers. Fly ash was preheated to 650°C for 15 min to remove moisture before mixing it with the aluminium melt. Cleaned aluminium ingots (Table 2) were melted above the super heating temperature of about 800°C in graphite crucibles. The melt was degassed at 800°C using a solid dry hexachloroethane (C2Cl6) degasser. Fly ash particulates were then added to the molten metal and stirred continuously for about 8 min at an impeller speed of 600 rpm. Aluminium matrix and fly ash particles were weighed using an electronic weighing machine (accuracy 0.0001 g). During stirring, 1 wt.% magnesium was added to increase the wettability of fly ash particles. The melt with reinforced particles was poured by gravity casting into the dried, cylindrical permanent metallic moulds of size 14 mm diameter and 120 mm length.

Chemical composition of fly ash in weight percentage.

| Constituent | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Loss on ignition |

|---|---|---|---|---|---|---|---|

| Percentage | 53.44 | 22.72 | 4.48 | 7.25 | 3.33 | 1.34 | 1.5 |

Chemical composition of aluminium alloy in weight percentage.

| Constituent | Cu | Si | Mg | Fe | Mn | Zn | Ni | Pb | Sn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage | 3.25 | 8.35 | 0.18 | 0.9 | 0.15 | 1.65 | 0.32 | 0.12 | 0.09 | 0.06 | balance |

Aluminium (Al/3Cu/8.5Si) alloy and composite specimens machined as per American Society for Testing and Materials (ASTM) E-8 standards were subjected to tensile test to study the influence of fly ash particle sizes. The specimen was loaded between two manually adjustable grips of a 200-kN computerised universal testing machine (UTM) with an electronic extensometer (TUE-C model, fine make). A constantly increasing force was applied to the specimen by electronic means at ambient temperature. Each test was repeated thrice, and the average value was taken to calculate the tensile strength of the composites.

The izod impact strength of composites was tested using a standard impact pendulum-type testing machine (ASI make, AMT-8 model, capacity 184 J) as per ASTM-D 256 standard. Standard specimens of 75 mm long with a 10×10 mm2 cross section, having a standard 45° notch and 2 mm deep, were used for the test. Each test was repeated thrice, and the average values were taken for calculating the impact strength.

3 Microstructural studies

A homogeneous distribution of secondary particles in aluminium matrix is critical for achieving a high strengthening effect because an uneven distribution can lead to premature. Scanning electron microscopic studies were carried out to study the microstructure of the composites as well as to confirm the uniform distribution of fly ash particles in the matrix. Figure 1 shows the SEM micrographs of aluminium fly ash composites containing fly ash particles in the eutectic matrix. Fly ash particles can be seen to be distributed more or less uniformly in the matrix. A SEM micrograph of the composite specimens (Figure 1) shows the presence of silicon needles in a eutectic matrix along with CuAl2 intermetallic particles and fly ash particles. It can be further observed that the intermetallic particles are formed around the fly ash particles. The micrograph also confirms the uniform distribution of fly ash particles in matrix with very little clustering, indicating the effectiveness of dispersion of the fly ash particles during stirring.

SEM microstructure of composite specimen

(75–103 μm particle size and 6% fly ash).

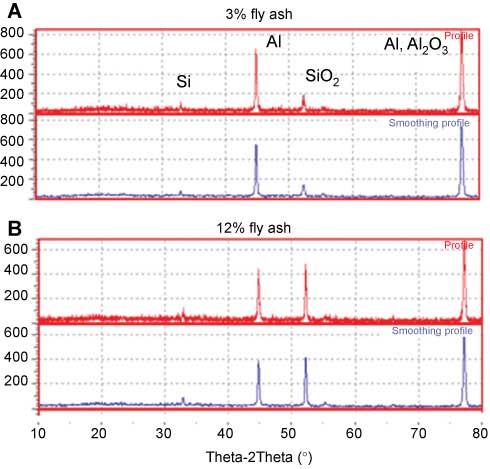

X-ray diffraction (XRD) is a powerful non-destructive technique for characterizing crystalline materials. It provides information on structures, phases, preferred crystal orientations (texture) and other structural parameters, such as average grain size, crystallinity, strain and crystal defects. X-ray diffraction peaks are produced by constructive interference of a monochromatic beam of X-rays scattered at specific angles from each set of lattice planes in a sample. Consequently, the XRD pattern is the fingerprint of periodic atomic arrangements in a given material. The graphs (Figure 2) clearly show the peak points corresponding to Cu and SiC, respectively. As shown in Figure 2A and B, unreacted fly ash and Al and reaction products of SiO2 and Al2O3 phases are present in all the composites. The amount of reaction products, however, is found to depend on the percentage of fly ash particles. It can be observed that, as the composition of fly ash increases, the intensity of the SiO2 peak also increases.

XRD pattern of the composite material (75–103-μm particle size).

4 Influence of fly ash on tensile strength

The variation in ultimate tensile strength of aluminium composites reinforced with fly ash particles of different size ranges as a function of fly ash percentage is shown in Figure 3. Tensile strength of composites increased with an increase in fly ash percentage (wt.%). The lowest tensile strength value (245 MPa) was observed in 3 wt.% fly ash composites reinforced with 53–75-μm particles, while the highest tensile strength of 320 MPa was observed in 12 wt.% fly ash composites reinforced with 103–105-μm particles. Thus an increase in tensile strength by about 40% was observed in composites compared to the unreinforced aluminium alloy. The increase in tensile strength with an increase in fly ash particle content may be a result of closer packing of reinforcement within the soft aluminium matrix.

Influence of fly ash percentage and particle size on tensile strength.

Chennakesava Reddy and Zitoun [5] reported that the failure mode in Al 6063/SiC and Al 7072/SiC metal matrix composites was predominant based on the particle-matrix interface cracking and the overall fracture is ductile in nature. Fogagnolo et al. [6] observed an increase in tensile strength in aluminium matrix composites reinforced with hard particles like AlN produced by conventional powder metallurgy and mechanical alloying. Hamoud et al. [7] observed the split tensile strength and Young’s modulus values decreased gradually as the silica content in the composite increased from 5% to 30% by volume fraction in LM6 alloy matrix. Kok and Ozdin [17] reported that the composites reinforced with larger Al2O3 particles (32 μm) exhibited high tensile strength than composites with smaller Al2O3 particles (16 μm).

The fracture surfaces of the specimens after failure were investigated to identify the mechanisms of failure. Scanning electron microscopy was used to examine the topography of fracture surfaces of the mechanically tested samples. Generally, the fractures of unreinforced aluminium alloys are associated with extensive deformation culminating in void nucleation and growth, with the nucleation essentially occurring at the coarse constituent particles and other second phases present in the microstructure. The fracture surface of the unreinforced material was characterised by uneven distribution of large dimples connected by sheets of smaller dimples indicating a pattern resulting from ductile void growth coalescence and failure. The fracture surfaces surrounded by ductile regions are described as tear ridges. All these features, typical of ductile failure, confirm the ductile nature of aluminium alloy. In the case of composites, however, the presence of hard and brittle reinforcement particles in the ductile aluminium matrix places constraints on the plastic flow of the matrix.

It can be seen that the fracture surface of aluminium alloy (Figure 4A) shows a ductile fracture characteristic consisting of numerous dimples. It can be observed from Figure 4B that the addition of fly ash particles to aluminium decreases the formation of dimples. In addition to these dimples, the fracture surface of the composites also reveals fragmentation and decohesion of the fly ash particles from the matrix, leading to a reduction in ductility (Figure 4C) in the form of ridges. The dimples should be a result of extensive plastic deformation, followed by void nucleation and their subsequent coalescence by strong shear deformation leading to fracture on the shear plane. Strain localisation at sharp corners of the reinforcement particles has been regarded as a dominant fracture initiation mode in these composites. The fracture and decohesion of the fly ash particles can be explained by the fragmentation of the ceramic phase caused by high stress concentration. An increase in fly ash content increases the resistance for dislocations and hence increases in tensile strength. With an increase in fly ash particles, the failure mode becomes more and more brittle in nature. This can be evidenced by the formation of minor cracks as shown in Figure 4D and E. Increase in fly ash particles size from 53–75 to 103–150 μm increased the tensile strength of aluminium fly ash composites. This phenomenon is due to the fact that, in smaller grains, dislocations have less space to move before they hit a grain boundary so that plastic deformation is limited (Figure 4E). It can be observed from Figure 4G that particle cracking was the major reason for the failure of composites with coarse fly ash particles (103–150 μm). A similar kind of observations was reported by researchers in their study. Song [14] reported that the tensile strength increased but the elongation decreased with the increase in the volume fraction of the SiC particles in aluminium composites and observed both ductile and brittle fractures in the composites. Kouzeli et al. [15] observed that the tensile straining of the composites (Al/Al2O3) resulted in accumulation of irreversible microstructural damage in the form of particle fracture and matrix voids and that the particle fracture was observed to be activated by particle-particle interactions. Altinkok and Coban [11] observed some cracks on Al2O3/SiC particles in some regions in their study on aluminium hybrid composites reinforced with Al2O3/SiC particles.

Fracture surfaces of the tensile test specimens.

5 Influence of fly ash on ductility

The ductility of composites reinforced with different weight percentage and particles sizes is shown in Figure 5. The ductility of the unreinforced aluminium alloy (Al/3Cu/8.5Si) was higher than that of the composites. The ductility of the composites decreased with an increase in weight fraction of the fly ash. The percentage elongation of composites also decreased with an increase in particle size. The ductility of the composites with coarse fly ash particles was less than that of the composites reinforced with fine fly ash particles. Maximum ductility was observed in Al/3Cu/8.5Si aluminium alloy (2.41%); the ductility of the composites in the study varied from 0.63% to 1.79%. A sample of the stress-strain curve for the composite with 6% fly ash and 53–75-μm particle size is shown in Figure 6. In the case of composites, the ductility of the base alloy, the interface bonding between the base alloy and the reinforcements, and the volume fraction of the reinforcements are important factors influencing the elongation of the composites. Ductility of the Al alloy-based composites is generally quantified in terms of tensile elongation. The presence of fly ash particles in aluminium matrix during deformation causes crack at the interface between the aluminium matrix and fly ash leading to debonding under a tensile load. This is due to the fact that the matrix undergoes plastic flow, while the particles do not deform. With an increase in fly ash content, the resistance for deformation increases leading to a decrease in ductility. Similarly, with an increase in fly ash particle size, the resistance to deformation at the matrix-particle interface is higher and hence decreases in the amount of deformation. A sample of the stress-strain curve for the composite with 6% fly ash and 53–75-μm particle size is shown in Figure 5. Chennakesava Reddy and Zitoun [5] reported that the% elongation of the composites was less than that of the matrix alloy. A similar kind of decrease in elastic modulus with an increase in reinforcement was reported by Wlodarczyk et al. [9] in their study on aluminium alloy (Cu4Mg1) matrix composite reinforced with BN particles.

Influence of fly ash percentage and particle size on ductility.

Stress-strain for composite (6% fly ash, 53–75 μm).

6 Influence of fly ash on impact strength

Fly ash particle size and weight percentage of fly ash also influence impact strength as shown in Figure 7. It was evident from the graph that impact resistance decreased with an increase in fly ash content. Impact strength showed lower values for fly ash composites than the unreinforced aluminium alloy. Composites with fine fly ash particles exhibited higher impact strength than composites with coarse fly ash particles. Composites with 53–75-μm fly ash particles at 3 wt.% showed the highest impact strength (3.2 nm), and those composites reinforced with 103–105-μm particles at 12 wt.% showed the lowest impact values (1.8 nm). Impact strength decreased by up to 48% in composites compared to the unreinforced aluminium alloy. Impact toughness of composite material was low due to the presence of brittle fly ash particles in the matrix.

Influence of fly ash percentage and particle size on impact strength.

Impact toughness value changed depending on the variation of fly ash. Increase in hardness of composites may be the reason for the decrease in impact strength. Singla et al. [10] observed an increasing trend of impact strength with an increase in weight percentage of SiC in aluminium scrap of up to 25% weight fraction. Ahlatci et al. [8] reported that the impact resistance of composites decreased with an increase in Si content in aluminium alloy.

A material’s toughness is generally decided by the energy consumption for fracturing the material. A metal or an alloy usually shows higher toughness because of the large plastic deformation energy consumed at the crack tips before cracking. For a composite, however, addition of reinforcements decreases the toughness of its matrix. This decrease is a result of competition between the decreased energy consumption for plastic deformation and the increased energy consumption for fracturing the reinforcements, as well as of the debonding or separation of reinforcements and the surrounding matrix.

Plastic deformation characterised by the formation of dimples was observed (Figure 8A) in the fracture surface of A380 aluminium alloy leading to high impact strength. Figure 8B shows a little plastic deformation in the matrix compared to that of the aluminium alloy (Figure 8A). Also, decohesion at the particle-matrix interface of composites leads to a decrease in impact strength. The unreinforced aluminium matrix regions surrounding the lower volume fractions of fly ash will show better fracture toughness due to a relatively higher degree of plastic deformation in the matrix. Therefore any increase in fly ash particle content leads to reduced matrix deformation and hence to an increase in brittleness of the composites (Figure 8C). This, in turn, leads to the formation and propagation of cracks easily, decreasing the impact strength. Increase in fly ash particle content leads to an increased chance of debonding between particle and aluminium, hence a decrease in impact strength. This is characterised by the formation of cracks observed in Figure 4D and E leading to a decrease in impact strength with an increase in fly ash particles. Further increase in fly ash particles to 12% increases the possibility for formation of cracks and hence decreases the impact strength due to the increase in brittleness of the composites (Figure 4E). While ductile fracture in the aluminium matrix is evidenced by the dimple appearance, brittle fracture in the fly ash reinforcements is characterised by cleavage fracture mode. It can be observed in composites with fine fly ash particles of 53–75 μm that the failure mechanism is in the form of cleavage fracture (Figure 8F). In composites reinforced with much finer particles, the energy consumption for voiding, debonding or separation between the reinforcements and surrounding matrix becomes larger accounting for the high fracture toughness of the fine fly ash particle reinforced composites. In composites with coarse fly ash particles of 103–150 μm, the failure was more of particle fracture leading to a decrease in impact strength (Figure 8G). Coarse fly ash particles act as stress concentration sites which lead to easy crack propagation, resulting in low impact toughness.

Fracture surfaces of the impact test specimens.

Qian et al. [16] reported a similar kind of observation that the crack initiation and fracture of the coarse particle reinforced composite were mainly associated with voiding in the matrix around particles ahead of the main crack tip, whereas the boundaries between the particle clusters and surrounding matrix were responsible for the failure of the fine particle reinforced composite. Indumati and Purohit [18] reported that more uniform distribution of reinforcing particles, stronger bonding between the matrix and particles, and refinement of grains during working have a greater bearing on impact strength. In summary, an increase in volume fraction of fly ash decreased the fracture toughness and an increase in fly ash particle size also decreased the fracture toughness of composites.

7 Conclusions

Aluminium alloy (Al/3Cu/8.5Si)/fly ash exhibited higher tensile strength compared to that aluminium alloy, while the ductility and impact strength of the aluminium alloy were higher than those of the composites. The tensile strength of composites increased with an increase in fly ash weight percentage, while the ductility and impact strength of the composites decreased with an increase in fly ash content. Increase in fly ash particle size increased the tensile strength of the composites and decreased the impact strength and elongation of the composites. The tensile and impact fracture of the aluminium alloy was characterised mainly by ductile fracture in the form of dimples. The fractured surface of the reinforced composite material is associated with a relatively lower area fraction of dimples in comparison with unreinforced material. Increase in fly ash particle content leads to an increased chance of debonding between particle and aluminium, leading to brittle fracture in the fly ash reinforced composites characterised by cleavage fracture and particle crack. Strain localisation at sharp corners of the reinforcement particles has been regarded as a dominant fracture initiation mode in these composites. In composites with smaller grains, dislocations have less space to move about before they hit a grain boundary so that plastic deformation is limited. Particle cracking was the major reason for the failure of composites with coarse fly ash particles.

References

[1] Rohatgi PK. Defence Sci. J. 1993, 43, 323–349.Search in Google Scholar

[2] Harris SJ. Mater. Sci. Technol. 1988, 4, 231–239.Search in Google Scholar

[3] Mahendra KV, Radhakrishna K. Part D: J. Automobile Eng. 2007, 221, 135–140.Search in Google Scholar

[4] Adamiak M. J. Ach. Mater. Manuc. Eng. 2006, 14, 43–47.Search in Google Scholar

[5] Chennakesava Reddy A, Zitoun E. Indian J. Sci. Tech. 2010, 3, 1184–1187.Search in Google Scholar

[6] Fogagnolo JB, Robert MH, Velasco F, Torralba JM. KONA, 2004, 22, 143–150.10.14356/kona.2004017Search in Google Scholar

[7] Hamoud AMS, Sulaiman S, Vijayaram TR, Sayuti M, Ahmad MHM. J. Ach. Mat. Manuf. Eng. 2007, 25, 11–16.Search in Google Scholar

[8] Ahlatci H, Candan E, Cimenoglu H. Wear 2004, 257, 625–632.10.1016/j.wear.2004.03.006Search in Google Scholar

[9] Włodarczyk-Fligier A, Adamiak M, Dobrzanski LA. A. Mater. Sci. Eng. 2010 42, 29–36.Search in Google Scholar

[10] Singla M, Dwivedi D, Singh L, Chawla V. J. Min. Mat. Char. Eng. 2009, 8, 455–467.Search in Google Scholar

[11] Altinkok N, Coban A. Int. J. Sci. Adv. Tech. 2012. 2, 78–86.Search in Google Scholar

[12] Surappa MK. J. Mater. Process. Technol. 1997, 63, 325–333.Search in Google Scholar

[13] Nagarajan S, Dutta B, Surappa MK. Compos. Sci. Technol. 1999, 59, 897–902.Search in Google Scholar

[14] Song M. Trans. Nonferrous Metal Soc. China 2009, 19, 1400–1404.10.1016/S1003-6326(09)60040-6Search in Google Scholar

[15] Kouzeli M, Weber L, San Marchi C, Mortensen A. Acta Metall. 2001, 49, 3699–3709.Search in Google Scholar

[16] Qian L, Kobayashi T, Toda H, Goda T, Wang ZG. Mater. Trans. 2002, 43, 2838–2842.Search in Google Scholar

[17] Kok M, Ozdin K. J. Mater. Process. Technol. 2007, 183, 301–309.Search in Google Scholar

[18] Deshmanya IB, Purohit GK. Int. J. Sci. Adv. Tech. 2001, 11, 238–252.Search in Google Scholar

[19] Rohatgi PK. JOM 2006, 58, 71–76.10.1007/s11837-006-0232-4Search in Google Scholar

[20] Ramachandra M, Radhakrishna K. Mater. Sci Poland 2006, 24, 333–349.Search in Google Scholar

[21] Mohanty S, Chugh YP. Tribol. Int. 2007, 40, 1217–1224.Search in Google Scholar

[22] Sudarshan, Surappa MK. Wear 2008, 265, 349–360.10.1016/j.wear.2007.11.009Search in Google Scholar

[23] Sudarshan, Surappa MK. Mater. Sci. Eng. A. 2008, 480, 117–124.Search in Google Scholar

©2014 by Walter de Gruyter Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Synthesis and properties of new clay-reinforced aromatic polyimide/nanocomposite-based 3,3′,4,4′-benzophenonetetracarboxylic dianhydride and 1,3-bis(4-aminophenoxy)propane

- Microstructures and surface performance of laser melting deposited composites on a Ti alloy

- Synthesis of porous carbon nanotubes/activated carbon composite spheres and their application for vitamin B12 adsorption

- Energy absorption capacity of pseudoelastic fiber-reinforced composites

- Influence of fly ash particles on tensile and impact behaviour of aluminium (Al/3Cu/8.5Si) metal matrix composites

- Effect of paraffin application technique on the physical and mechanical properties of particleboard

- Thermal conductivity of flat-pressed wood plastic composites at different temperatures and filler content

- Morphology and properties of a photopolymer/clay nanocomposite prepared by a rapid prototyping system

- Tensile behavior of hybrid epoxy composite laminate containing carbon and basalt fibers

- Prediction of longitudinal modulus of aligned discontinuous fiber-reinforced composites using boundary element method

- Determination of the critical load and energy release rate in mode II delamination using a meshfree method

- Shear strength predicting of FRP-strengthened RC beams by using artificial neural networks

- Free vibration analysis of angle-ply laminate composite beams by mixed finite element formulation using the Gâteaux differential

- Nonlinear dynamic behavior of a long temperature-dependent FGM hollow cylinder subjected to thermal shocking

- Effect of stacking sequence and geometric scaling on the brittleness number of glass fiber composite laminate with stress raiser

- Fabrication of hemp fiber-reinforced green composites with organoclay-filled poly(butylene succinate) matrix by pultrusion process

- Correlation of the heater’s duty cycle and specific energy consumption, and reduction in energy consumption in the pultrusion process

Articles in the same Issue

- Masthead

- Masthead

- Original articles

- Synthesis and properties of new clay-reinforced aromatic polyimide/nanocomposite-based 3,3′,4,4′-benzophenonetetracarboxylic dianhydride and 1,3-bis(4-aminophenoxy)propane

- Microstructures and surface performance of laser melting deposited composites on a Ti alloy

- Synthesis of porous carbon nanotubes/activated carbon composite spheres and their application for vitamin B12 adsorption

- Energy absorption capacity of pseudoelastic fiber-reinforced composites

- Influence of fly ash particles on tensile and impact behaviour of aluminium (Al/3Cu/8.5Si) metal matrix composites

- Effect of paraffin application technique on the physical and mechanical properties of particleboard

- Thermal conductivity of flat-pressed wood plastic composites at different temperatures and filler content

- Morphology and properties of a photopolymer/clay nanocomposite prepared by a rapid prototyping system

- Tensile behavior of hybrid epoxy composite laminate containing carbon and basalt fibers

- Prediction of longitudinal modulus of aligned discontinuous fiber-reinforced composites using boundary element method

- Determination of the critical load and energy release rate in mode II delamination using a meshfree method

- Shear strength predicting of FRP-strengthened RC beams by using artificial neural networks

- Free vibration analysis of angle-ply laminate composite beams by mixed finite element formulation using the Gâteaux differential

- Nonlinear dynamic behavior of a long temperature-dependent FGM hollow cylinder subjected to thermal shocking

- Effect of stacking sequence and geometric scaling on the brittleness number of glass fiber composite laminate with stress raiser

- Fabrication of hemp fiber-reinforced green composites with organoclay-filled poly(butylene succinate) matrix by pultrusion process

- Correlation of the heater’s duty cycle and specific energy consumption, and reduction in energy consumption in the pultrusion process