Abstract

The uncontrolled increase in population and human activities has led to a significant rise in the demand for energy resources. The excessive use of limited fuel sources, unplanned deforestation, and greenhouse gas emissions have necessitated the search for and development of alternative, sustainable energy resources that cause minimal or no harm to the environment. The introduction of green and eco-friendly technologies offers a potential solution to address the growing demand in fields such as petroleum and hydrogen production, with the ultimate goal of promoting environmental sustainability. This review article highlights recent innovations in the field of heterogeneous catalysis, focusing on the development of various catalytic materials and processes, as well as their future prospects for both industrial and academic advancements. A brief discussion is presented on the efficient performance of solid acid and base catalysts, metal-organic frameworks (MOFs), electrocatalysts, and photocatalysts. The discussed catalytic systems have been explored for their potential applications, including biodiesel and hydrogen production as alternative energy sources, as well as CO2 reduction and the degradation of toxic dyes and organic pollutants for environmental remediation. Overall, the significance of heterogeneous catalysts has been explored, emphasizing their critical role in driving industrial progress and economic growth.

1 Introduction

Catalysis is a fundamental element of many chemical processes and hence it is a main strength of all chemical industries. 1 It is proven and now a day there is a growing concern about the catalysts that are environmentally friendly and safer technologies for the better industrial productions. Not less than 15 Nobel prizes have been awarded for studies on catalysis and many chemists around the world are repeatedly advancing the catalysts they have, and are motivated to discover new ones.

All the catalytic process can be applied either homogeneous or heterogeneous catalysis. Heterogeneous catalysis is a process in which catalyst being used is in a different phase than the reactants, i.e. the catalysis is usually in a solid phase and the reactant is in a liquid or in gaseous phase. As a part of catalysis, heterogeneous catalysis has prior importance in many areas of the chemical research for energy and environmental applications. 2 , 3 Although, there are many advantages of homogeneous catalysis which is pH dependent and can function with wide pH range. 3 Further, overall, most of (>80 %) chemical and bio-catalytic processes well established with heterogeneous catalysis and thus it is much successive catalytic process of vibrant branch of chemistry as well as pharmaceutical world. Figures 1–3 emphasizing the importance of the catalytic process and among all the process, how heterogeneous catalysis being a large part of chemistry itself can be found here. 4 , 5

Global catalyst market share 2018 (%) by applications 4

Involvement of catalytic and non-catalytic process to the chemical industries 5

Involvement of heterogeneous catalytic systems to various fields 5

The beginning era of heterogeneous catalysis, academic research and industrial processes were focusing on production of bulk chemicals and refining the oil as fuel on large scale requirement and it has been expanded rapidly in the recent decades. 6 , 7 Heterogeneous Catalysis is now become a key factor for many industries for the conversion of petroleum and natural gas into cleaner and efficient fuels, but now there is a demand for the production of alternative fuels such as hydrogen and biofuels. 6 , 7 , 8 Heterogeneous catalysis is still in use for the selective synthesis of special intermediates or products and fine chemicals in bulk production. Now a day it is possible to find the alternative route for the energy and environmental issues due to major advances in the design and development of catalyst at the molecular level.

In continuation, there are many efforts in progress to unlock energy sources that are much more difficult to use than fossil fuels, but are “greener”, where heterogeneous photocatalysis could make it economically feasible to produce hydrogen fuel from water splitting and leads to find novel methods to produce efficient energy sources from the raw resources such as CO2, 8 biomass 9 etc. Green technologies have included heterogeneous catalysis as being advantageous for regeneration and reusability, production of no waste or very less amount of waste, easy set up process with lower cost, high thermal and chemical stabilities and good selectivity of final product. Indeed, heterogeneous catalysis is being used for the environmental remediation for water, air and soil by applying an environmentally benign approach.

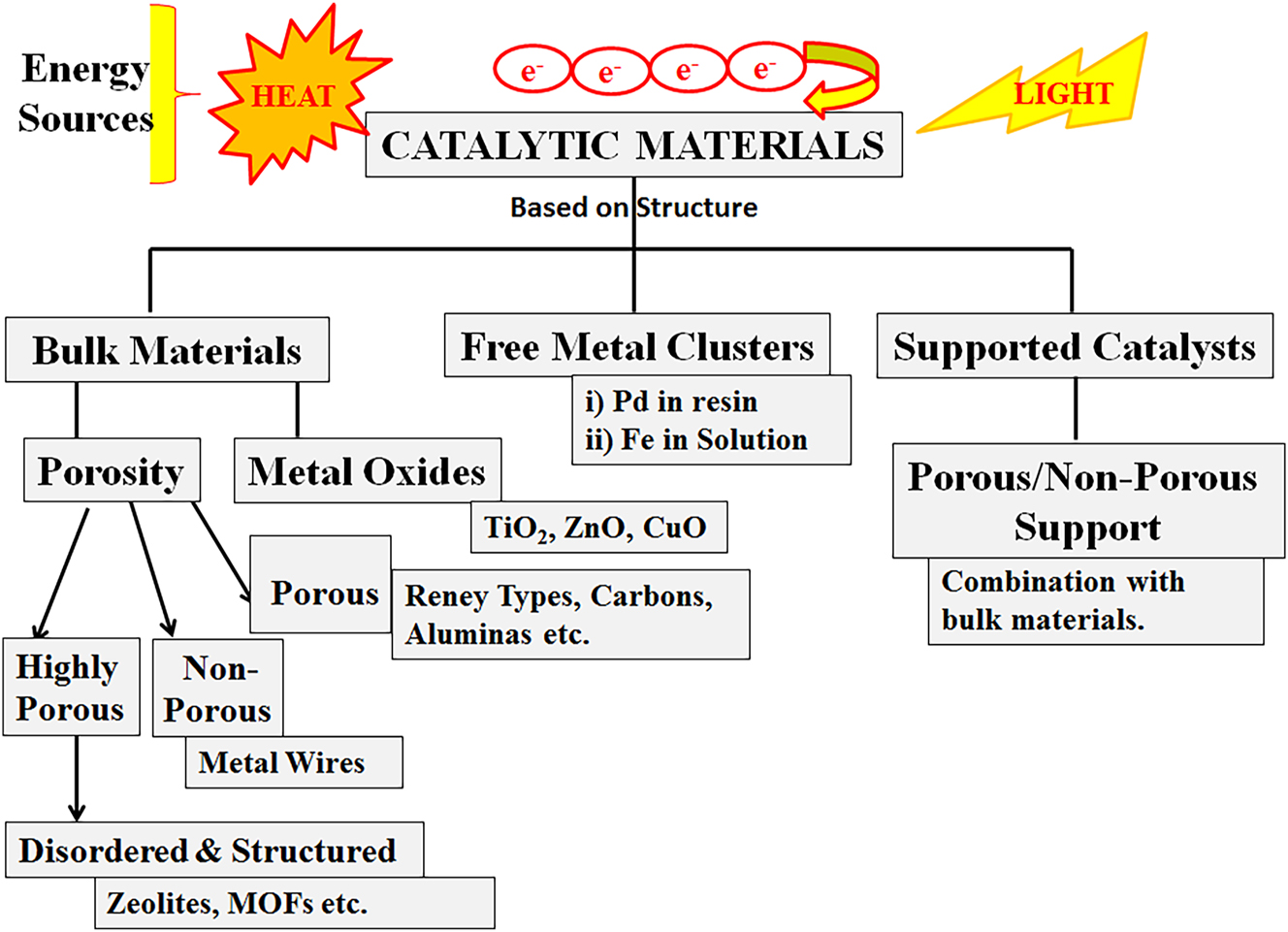

The conceptual platform for the practicable uses of catalytic systems can be defined by energy and mass dimensions. It consists of processes and materials being used with mass inputs in terms of raw materials to be converted into added-value ones directly or indirectly equal to the energy resources with or without emissions to be treated. 10 , 11 In this context, the consumed energy can be considered an input for endothermic reactions, while the energy generated serves as an output for exothermic reactions. Light, heat and electrons are often considered specific resources that promote catalytic systems by adding energy, leading to processes such as photocatalysis or photoelectrocatalysis. 10 , 12 , 13

The types of catalytic systems can be identified based on the structure and nature of the catalytic materials, which impart their catalytic functionality. Table 1, 14 , 15 , 16 , 17 , 18 , 19 , 20 , 21 , 22 , 23 , 24 , 25 , 26 , 27 , 28 , 29 , 30 , 31 and Figure 4 illustrate the most commonly used catalytic processes and materials.

Types of catalytic processes commonly used.

| No. | Catalytic processes | Ref. |

|---|---|---|

| A | Oxidation | |

| 1 | Advanced oxidation process

|

14 , 15 , 16 , 17 |

| 2 | Oxidation of SOx, NOx and COx | 18 |

| Oxidation of carbon monoxide to carbon dioxide (CO2) | 19 | |

| 3 | Oxidation of alkanes, alkenes and aromatics | 20 |

| 4 | Oxidation of alcohol (methanol to CO2) | 21 |

| B | Hydrogenation | |

| 5 | Hydrogenation process of vegetable oils | 22 |

| 6 | Hydrogenation of alkenes and aromatics | 23 |

| 7 | Formation of ammonia | 24 |

| 8 | Hydrogenation process of CO2 | 25 |

| 9 | Hydrogenation or hydrocracking of plastic and rubber waste | 26 |

| C | Dehydrogenation | |

| 10 | Dehydrogenation for H2 production | 27 |

| D | Reforming | |

| 11 | Catalytic dry reforming of methane | 28 |

| 12 | Catalytic reforming of biofuels | 29 |

| 13 | Catalytic reforming of oxygenates | 30 |

| 14 | Dry reforming processes for hydrogen production | 31 |

The types of catalytic systems based on structure.

There are also some drawbacks of heterogeneous catalysis such as it requires higher temperature and pressure for the reaction to occur, thus it requires higher energy consumption and therefore utility and energy related costs are very high. 2 To develop and design a highly efficient and environmentally-friendly catalytic materials and systems are very effective approaches to generate novel energy sources and remediation of contaminated soil, air and wastewater. 6 , 7b Thus, the bridging connection between a material structure and chemistry with efficient performance of heterogeneous catalyst would provide rational informations for catalyst design and addressing the challenges in promising use in the research area of energy resources.

The current review article shows recent development and progress in heterogeneous catalysis for energy and environmental applications. Heterogeneous catalysis consists of many subclasses depending on nature and structure of the catalyst used in solid phase such as solid acid catalyst, solid base catalyst and nano catalyst.

2 Energy applications

2.1 Biodiesel production

Currently, the use and storage of fuel energy for economic development and finding of an alternative fuel sources are in prior demand due to the ever-increasing world population. It is now an urgent worldwide issue to implement the possible all the efforts for the sustainable automotive fuels. 7 Since, last few decades, the biodiesel production has been promoted on the large scale as a safe and novel technology. Biodiesel belongs to the class of renewable and sustainable fuel source receiving more attention as rapidly growing field with high potential rather than other energy sources and evidently beneficial for a long-term investment. 32 , 33 , 34

Processes for biodiesel production can be classified as catalytically, chemically (base or acid catalysis), biologically (enzyme catalysis) and non-catalytic processes. Chemically, biodiesel (alkyl-ester derivatives) is usually produced by chemical catalytic transesterification of refined vegetable oils/waste cooking oils (long chain fatty acids) or animal fats. The chemical catalysts used earlier are strong acidic (HCl, H2SO4, HF, p-toluenesulfonic acid) or basic solutions (NaOH, CH3ONa and KOH).7b

Now days, a “green” approach for biodiesel production has been adopted the use of sustainable solid acid catalysts as replacements for such liquid acid catalysts so that the use of harmful/corrosive substances and unwanted formation of toxic wastes could be avoided. With remarkable developments and fruitful researches reported in the past few years for the industrial production, heterogeneous catalysis is growing up in the market for the biodiesel production.7b , 33a Heterogeneous catalytic transesterification is a process where the catalysts remain in different phase to that of the reactants and provides easier separation of biodiesel from glycerol. 35 , 36 , 37 The catalytic conversion of oil into biodiesel is slowly but the resulting biodiesel could be possible in an economical way. 38 , 39 Firstly, surface morphology characteristics, having large pore size to minimize diffusion problems is an ideal characteristic of a solid catalyst as being a part of heterogeneous catalysis. Another one, is deactivation, mainly achieved because of availability more active catalytic sites, high catalytic stability versus leaching and the probability to tune the hydrophobicity of the surface with the repulsion of highly polar compounds. 40 From the literature, solid base catalysts such as base zeolites, alkali earth metal oxides, hydrotalcites (or layered double hydroxides), alumina loaded with various compounds and mixed oxide have been quite successful with high conversion and yield of biodiesel obtained.33b

2.1.1 Solid acid catalyst (SAC)

SAC can be defined on the basis of nature and number of present active acid sites (Brønsted or Lewis acidity), arability of the acid sites and morphology of the support. Therefore, the acid catalysts could be used directly for biodiesel formation from low-grade, highly-acidic and water-containing oils. Thus, solid acid catalysis is now well established as benign alternatives to the unrecyclable-homogeneous acid catalysts and succeeds in the petrochemical industries. Many more benefits avail to this class of catalysts such as, (i) the catalysts could be modified and tunable, selective and easy regenerate and reuse, (ii) minimize product contamination through easy separation from target product, (iii) elimination of washing step particular for biodiesel production, (iv) replaced use of corrosive liquid acids and thus corrosion issue could be minimized, (v) could be employed in continuous flow process, (vi) minimum catalyst deactivation, (vii) catalyst could be rapidly prepared through economically and environmentally affordable process. 3 The surface morphology of the solid catalyst plays a key role for better catalytic performance through selective adsorption of reactant molecules and converts into the desired product. However, many more finding has to search out to connect and fill the knowledge gap between the fundamental concept of reaction pathway and the mechanisms of reactants on the solid catalysts.

They are mainly used for important acid catalyzed organic transformations such as Friedel-Craft alkylation/acylation, esterification/transesterification, acetal/ketal formation etc.7b Literature report highlighting the extensive use of solid acid catalysts for biodiesel production through esterification or transesterification processes. For example, the mechanism of the acid catalyzed transesterification reaction of triglycerides is well understood. 6 , 41 , 42 Still there are some challenges facing for biodiesel production such as to increase rate of reaction and to reduce unwanted side reaction. Thus, these challenges lead to develop a novel, efficient and stable catalytic system and more efforts for reduction in cost of preparation the catalyst and sequentially reduced biodiesel production costs. There is lots of research work in progress to overcome the said challenges through potential application of various solid acid catalysts for biodiesel production.

The ideal characteristics of a solid acid catalyst are strong Brønsted and/or Lewis acid properties, unique porosity or textural properties and a hydrophobic surface. Till date, the catalytic potential of solid acids have been reported for the biodiesel production such as acidic inorganic ion exchangers, acidic clays, metal oxides, mixed metal oxides, H-form zeolites, heteropolyacids (HPAs), modified silica, acidic ionic liquids, hybrid organo-inorganic materials and carbon based materials.

The Brønsted acid sites are highly polarized hydroxyl groups at the surface of the catalyst that serve as the H+-donor, while the Lewis acid sites are coordinatively unsaturated cationic sites, which leave the exposed M+ ion to interact with guest molecules and act as the acceptor of the electron-pair. With respect to base catalysts, biodiesel production processes based on the use of solid acid catalysts are effective alternatives to the conventional processes because of their easy workup and the simultaneous promotion of esterification and transesterification reactions without soap formation.

Zeolites and zeolite type materials : Zeolites are naturally abundant three dimensional frameworks with crystalline structures of aluminosilicates interlinked by oxygen atoms. They contain Al, Si and O in their framework, and cations, water and/or other molecules within their pores. 34 They are well established and robust materials because of having molecular porous structure with channel of uniform sizes gives materials to be ion exchange characteristic. The catalytic activity depends on replacement of Si4+ by Al3+ with crystalline SiO2 framework which generates negative charges in the catalyst framework and thus improves catalytic activity. Interestingly, the adsorption ability could be modified through synthesis methods as expected due to the strong electric field created by the loosely held cations within the catalyst framework. Thus, desired catalytic performance in term of good activity and selectivity could be obtained as it has ability to introduce active sites within the pores and channels. 3

Zeolite can accommodate number of cations such as Na+, K+, Ca2+, Mg2+ and many more from which it has its basic nature. H-ZSM-5, H-MOR, H-BETA and H-USY are H+ ion exchanged acid form zeolites found to be not much catalytic active for esterification or transesterification reactions of biodiesel production due to internal diffusion limitations of the bulky reactant molecules into the micro-pores of zeolites. 3 Zeolites Y are weak solid acid catalyst while Zeolites β are three-dimensional structure of 12-membered ring channels with high silica content having both Lewis and Brønsted-acid sites. Lewis-acid sites are mainly present in the micro-porous walls. Zeolite β does not exhibit high activity in transesterification, but it could be used for selective removal of FFAs in waste oil. Silicoalumino-phosphates, the recently developed Zeolite types materials foe examples, SAPO4, ALPO4, MeAPSO4 and MeAPO4 could be synthesized with coordinated Al, Si, P, transition metals and other elements. 3

The catalytic activity of the protonated form of H–Y zeolite (Faujasite with high Si/Al ratio) has been investigated as solid acid catalyst for esterification of oleic acid with methanol. 43 At optimized conditions, methyl esters production yield reaches up to ∼95 % and the used catalyst could be regenerated easily and reused for the same. Septiani et al. 44 have prepared Zeolite ZSM-5 and studied its catalytic activity for the transesterification of vegetable oil for biodiesel production. The results of the catalytic reaction show a maximum biodiesel yield of ∼92 % at the optimized reaction time and temperature. Zeolite and zeolite-based heterogeneous catalysts 43 , 44 , 45 , 46 , 47 , 48 , 49 , 50 , 51 , 52 , 53 , 54 , 55 , 56 , 57 , 58 , 59 , 60 , 61 , 62 , 63 , 64 , 65 , 66 , 67 , 68 , 69 for biodiesel production have been summarized in Table 2.

Zeolites and zeolite-based heterogeneous catalysts for biodiesel production using esterification or transesterification reactions.

| Sr. No. | Catalysts | Esterification/transesterification reactions molar ratio of oil: alcohol | Ref. |

|---|---|---|---|

| 1 | H–Y(80) zeolite (faujasite with high Si/Al ratio) | Esterification of soybean oil Oil: methanol = 1:3, 1:6 and 1:9 |

43 |

| 2 | Zeolite ZSM-5 prepared from rice husk ash | Transesterification of vegetable oil Oil: methanol = 1:3 |

44 |

| 3 | H-zeolite | Transesterification of vegetable oil Oil: methanol = 19.4:1 |

45 |

| 4 | Y-type zeolites with Al2O3 and Na2O | Transesterification sunflower and waste oil Oil: methanol = 12:1 to 48:1 |

46 |

| 5 | Faujasite (FAU)-type zeolite prepared using Irish shale rock | Esterification of vegetable oil Oleic acid: ethanol = 4:1–15:1 by mass |

47 |

| 6 | KOH/zeolite prepared by impregnation in KOH | Transesterification of waste sunflower oil Oil: methanol = 1:1.51 |

48 |

| 7 | KOH/Bentonite prepared by impregnation method | Transesterification of refined soybean oil Oil: methanol = 6:1 −14:1 |

49 |

| 8 | Y-type zeolites, with different Al2O3 and Na2O percentage | Transesterification of vegetable oil Oleic acid: methanol = 6:1 |

50 |

| 9 | ZSM-5 and beta hierarchical zeolites | Transesterification of algae oil Oil: methanol = 100:1 |

51 |

| 10 | Alkali loaded low-Al zeolite beta | Transesterification of triolein Oil: methanol = 1:15 (w/w) |

52 |

| 11 | Zeolite linde type a (LTA, dehydrate form) | Transesterification of triolein (methanol in excess) | 53 |

| 12 | KOH/Zeolite prepared by impregnation method | Transesterification of triglyceride with excess methanol | 54 |

| 13 | Natural zeolite bayah banten with KOH impregnation method | Transesterification using vegetable oil Jatropha oil: methanol = 1:1 | 55 |

| 14 | Zeolite based catalysts prepared from fine powder and kaolinite using pelletization method | Simultaneous transesterification and esterification of waste cooking oil Oil: methanol = 1:5 |

56 |

| 15 | Natural zeolite with potassium impregnation | Transesterification of rice bran oil Oil: methanol = 1:6 to 1:12 |

57 |

| 16 | Zirconia supported on Indonesia natural zeolite | Esterification of palm oil sludge Oil: methanol = 1:4 |

58 |

| 17 | KOH/NaY zeolite prepared by the impregnation method | Transesterification of palm oil Oil: methanol = 1:15 |

59 |

| 18 | KOH/Al2O3 with varying KOH loadings prepared by the impregnation of the Al2O3 support | Transesterification of vegetable oil Oleic acid: methanol = 1:15 |

60 |

| 19 | NaX zeolite impregnated with mixture of CaO nanoparticles/ethanol | Transesterification sunflower Oil: methanol = 1:6 |

61 |

| 20 | Sodic potassic clinoptilolite and sodic potassic calcic clinoptilolite zeolites | Transesterification of waste cooking oil Oil: methanol = 68–27 (vol%) |

62 |

| 21 | Lanthanum-natural zeolite (La/Zeolite) | Transesterification crude palm oil Oil: methanol = 1:9 |

63 |

| 22 | ZnO/Zeolite, PbO/Zeolite | Esterification of Jatropha oil Oil: methanol = 1:6 |

64 |

| 23 | Zeolite X and a from flyash using hydrothermal treatment | Transesterification of refined mustard oil Oil: methanol = 1:6 |

65 |

| 24 | Zeolite MCM-22 and zeolite beta | Transesterification of triolein in excess methanol | 66 |

| 25 | Zeolites loaded with CH3COOK | Transesterification of Jatropha curcas

Oil: methanol = 1:10 |

67 |

| 26 | HZSM-5 and HZSM-5 impregnated with sulfated lanthanum oxide (SO4 2−/La2O3) | Esterification of oleic acid Acid: methanol = 1:5, 1:10 and 1:20 |

68 |

| 27 | Commercial H–Y and ZSM-5 zeolite | Esterification of palmitic acid Acid: methanol = 1:2 |

69 |

Metal oxides: Metal oxides are materials of typical characteristics such as thermal and mechanical stability, high specific surface area, and large pore size and pore volume. Thus, they are extensively being used as catalyst supports for catalytic purpose.

The typical superacids such as SO4 2−/ZrO2, SO4 2−/TiO2, SO4 2−/Ta2O5, SO4 2−/Nb2O5 etc.7b They possess potential economic and green benefits for a number of hydrocarbon reactions under mild reaction condition and thus, interest has been generated to use of such materials for transesterification and esterification reactions to produce biodiesel. 70 Herein, an interesting factor about the metal oxides (ZrO2, TiO2, Ta2O5, Nb2O5), they possess the both Brønsted and Lewis acidity that can be improved by modifying its surface by sulfate groups which makes materials to be promising catalyst to promote protonation in the esterification process. 71 Castro et al. 72 have studied heterogeneous solid acid catalysis for esterification and transesterification processes for biodiesel production as renewable fuels to meet the future societal requirements. The authors have prepared sulfated niobium oxide (Nb2O5/SO4) impregnation method and used as solid acid catalyst for biodiesel production from macaw palm oil via high free fatty acid content transesterification with ethanol. As results, the catalyst Nb2O5/SO4, exhibits excellent catalytic activity towards biodiesel production (about ∼99 % ester content). The spent catalyst could be reused up to five consecutive catalytic cycles which shows excellent yield of the desired products and the reducing of the yield after fifth catalytic cycle could be due to the handling/physical loss of the catalyst during recycles and regeneration. 72 Sulfated zinc oxides SO4 2−-ZnO and SO4 2−/ZnO have been synthesized by co-precipitation and impregnation respectively and characterized as active solid acid catalyst. 73 The prepared catalysts have been used for trans-esterification of soybean oil with methanol to compare their performance for biodiesel production. As results at optimized reaction conditions, SO4 2–ZnO prepared by co-precipitation method exhibit highest catalytic activity and obtained FAME yields of ∼80 %.

Sulfonic ion exchange resins such as Amberlyst-15, –16, −35, −36 and −131, 74 , 75 Nafion resins 76 , 77 , 78 , 79 , 80 as SAC-13 and NR50 and EBD-100, -200 and −300, 81 were commonly used heterogeneous catalysts and found to be effective in liquid phase esterification and trans-esterification reactions. The protons bonded to the sulfonic groups are the responsible for the strong acidic active sites which are available on the cross-linked polymeric matrix of these ion exchange resins. The catalytic activity more depend on their surface properties which in turn effective populations of the acidic active sites for the trans-esterification and esterification reactions.

Mesoporous silica (SBA-15) supported ZnO/SBA-15 and MgO/SBA-15 have been prepared and characterized for solid acid catalytic activity. The results show that catalysts exhibit good catalytic activity and promote the esterification of lauric acid with 1-butanol to produce biodiesel (∼81 % yield of butyl ester) under atmospheric pressure and reflux conditions. 82 Tesser et al. have prepared Niobia supported catalyst by impregnation of silica pallets with loading of Nb and characterized for catalytic characteristics. The prepared solid acid catalyst has been used in both transesterification (free acid methyl ester conversion) and esterification (free fatty acid conversion) reactions of triglycerides for biodiesel production. The study, Nb supported on silica found to be much active in both the mentioned reactions with no loss of catalytic activity in the continuous run of 100 h but slow leaching of Nb observed which could be reduced the catalytic potential. 83 Xie et al. prepared lithium doped zinc oxide (Li/ZnO) using impregnation method followed by calcination at different temperatures and evaluated its catalytic activity for transesterification of soybean oil with methanol at optimized reaction conditions. 84 As results, Li/ZnO exhibits good catalytic activities towards soybean conversion to ester as obtained ∼96 % yields. The catalytic sites are in basic nature which is due to formation of Li2O from thermal decomposition of LiNO3 at higher calcination temperatures. The authors also have prepared CaO–MoO3-SBA-15 by incipient impregnation method with different calcination temperatures and tested for the similar transesterification reaction of soybean oil with methanol for biodiesel production. 85 The prepared solid catalysts, a catalyst with loading of 40 % and calcined at 550 °C shows highest catalytic activity (∼83 % yield of oil conversion) at the optimized the reaction conditions. The catalyst could be easily revered and reused without loss of its potential catalytic activity. 85 Viswanathan et al. 86 prepared sulfated Fe2O3–TiO2 from ilmenite and calcined for different temperatures. The prepared catalyst examined for its acidic active sites and used for conversion of vegetable oil to biodiesel via transesterification reaction with methanol. As results, the catalyst calcined below 500 °C shows higher conversion of vegetable oil with remarkable yield of biodiesel which is attributed to the high affinity of hydroxyl groups of methanol on Fe2O3–TiO2. The removal of sulfate groups has been observed during calcination on above 500 °C could reduce % yield of biodiesel production. 86

Mixture of strontium and nickel oxide has been synthesized by coprecipitation method followed by different calcination temperatures and characterized for catalyst properties. 87 The prepared catalysts have been used as heterogeneous catalysts for the transesterification of macaw palm oil with methanol for biodiesel production. The catalyst with the calcination temperature of 1,100 °C has highest catalytic activity as achieved ∼97 % conversion at the optimized reaction conditions as well as recycling studies also favoring the good % yield for the five catalytic runs. 87 Ong et al. 88 have studied catalytic activity of the carbon supported CuO catalyst in which the copper nanoparticles have been synthesized by sol-gel method and the nanoparticles impregnated into the pore network of the carbon supported. The prepared catalysts used in esterification of free fatty acid in the rubber seed oil and ∼95 % of the free fatty acid conversion was obtained at the optimized reaction conditions. The catalytic performance is comparable to the liquid acid H2SO4 as well as compared with other heterogeneous catalysts, the carbon supported-CuO could performed at lower temperature. The reusability study also shows about easy recovery and separation of the catalyst after process completion however it found with lower activity in the use of first catalytic cycle. Zhang et al. 89 have prepared sulfonic/carboxylic dual-acid catalyst based on sulfur-rich graphene oxide (GO-S) as cost effective SAC used for the esterification of the oleic acid with methanol to produce methyl-ester as biodiesel. The results show, GO-S exhibits good catalytic performance in term of activity and reusability which has high TON factor compared to other carbon based SACs. Having a two-dimensional layered structure and the strong synergetic effect between–SO3H and–COOH groups on the graphene nano-sheets, are the key factors for the catalytic activity of GO-S. 89 The study reveals the promising use of the GO-S in the esterification of the waste fatty acids to convert into the valuable biofuels.

2.1.2 Solid base catalysts

Metal oxides: Recently, alumina has been exhibited as a good support for catalytic material in catalytic process due to having good characteristics such as thermal and mechanical stabilities, high surface area, large pore size and pore volume. 90 Anisuzaman et al. have prepared CaO-supported basic alumina catalyst by impregnation method followed by calcination temperatures and characterized for their catalytic properties. 90

Alkali metal oxides (CaO, MgO and BaO) doped silica (SiO2) has been synthesized using sol-gel method followed by different calcination temperatures and used as base catalysts for the biodiesel production. 91 The catalytic transesterification reaction of corn oil with methanol shows that the catalyst CaO/SiO2 exhibits highest biodiesel production compared to other catalysts with the purity and yield of ∼97 % and ∼82 % respectively. 91 Ismail et al. have synthesized calcium oxide (CaO) from mud clam shell and used as potential heterogeneous catalyst for the biodiesel production. 92 The results of the catalytic transesterification reaction of castor oil with methanol show a good efficiency of CaO catalyst with the obtained ∼96 % yield of biodiesel formation using the optimum reaction conditions as well as the CaO catalyst from mud clam shell could be recycled and reused up to five catalytic runs. 92 Thitsartarn et al. also have reported calcium doped cerium-incorporated SBA-15 (Ca/CeS) synthesized by direct synthesis of Ca-incorporated-SBA-15 followed by impregnation of CaO. 93 The catalytic studies, the Ca/CeS shows excellent catalytic performance for biodiesel production trough catalytic transesterification of palm oil with methanol and also the highest catalytic activity found amongst the other supported catalyst such as CaO/CeO2 and CaO/CeO2-SBA-15. As being heterogeneous catalysis, negligible leaching of elements was observed due to strong interaction between CaO and CeS support. Furthermore, beneficially the catalyst could be reused for 15 catalytic runs with insignificant decrease in catalytic activity which reveals the very good efficiency of the catalyst for the biodiesel production. 93 Heterogeneous strontium oxide/calcium oxide (SrO–CaO) mixed metal oxides catalyst has been used in the ultrasonic-assisted transesterification of Jatropha oil into biodiesel. The catalyst characterization and the catalytic studies show that the prepared catalyst exhibits high efficiency for the conversion of Jatropha oil into biofuels. 94

Biodiesel production from non-edible Jatropha oil has been reported using acid-base bi-functionalized CaO–La2O3 heterogeneous catalyst. 95 The catalyst comprising CaO and La2O3 mixed metal oxides with different Ca/La ratios have been prepared by using co-precipitation method. As results, the highest biodiesel yield of ∼98 % has been achieved and binary catalyst system found to be more stable which was supported by recycling and reusability of the catalyst even after four catalytic cycles. The observed very good catalytic activity in the mixed metal-metal oxide is due to well dispersion of CaO on composite surface which enhance both surface acidic and basic sites as compared to that of bulk CaO and La2O3 metal oxide. 95 Wang et al. 96 have reported a series of acid-base bi-functional metal-boron catalysts prepared by sol-gel method followed by calcination temperatures and characterized by spectral and surface characteristics. Amongst the prepared catalysts, the Ca-Boron (700 °C) catalyst shows highest catalytic performance for the production of biodiesel with high acid value (yield of ∼98 %) through transesterification reaction of non-edible oil (Jatropha) with methanol using optimized reaction conditions. The catalyst exhibits a good stability and reusability which makes it promising acid-base bi-functional catalytic material for the biodiesel production. 96

Lee et al. 97 have studied the catalytic activity of mixed metal oxides (MMOs) (CaO–MgO, CaO–ZnO, CaO–La2O3 and MgO–ZnO) synthesized by co-precipitation method followed by calcination at different temperatures. MMOs contained high basicity and strong basic strength compared to single metal oxide which shows excellent catalytic performance in the transesterification process. As results of the studied catalytic reactions, the Ca-based MMOs catalysts exhibit highest catalytic activity in term of ∼90 % yields of biodiesel production and reusability with low metal leaching. Amongst three Ca-based MMOs, CaO–ZnO has comparative high conversion rate with ∼94 % yield of biodiesel and could be used for four catalytic cycles with negligible loss of activity. 97 Yigezu et al. 98 have studied catalytic activity of metal oxides such as Co3O4, KOH, MoO3, NiO, V2O5 and ZnO for catalytic conversion of oil into organic liquid products. As results, the catalysts are found to be suitable and active solid catalysts for the catalytic cracking of vegetable oil for bio-fuel production. 98

The review chapter more discussed on basic mixed-metal oxides (CaO and MgO based), acidic mixed-metal oxides (SiO2, SnO2 and Fe2O3 based) and acid-base bi-functional mixed-metal oxide (ZnO–La2O3, MnCeO2 and SrO–ZrO2). 60 Many of the catalysts studied are excellent in the catalytic performance for the biodiesel production through esterification or in-situ esterification and transesterification processes. 60 Refaat has briefly presented a review chapter on synthesis methods and characterization of various metal oxides commonly being used in the esterification and transesterification of oil with alcohol for the biodiesel production. 99 The chapter highlighting about the catalytic activity of alkali earth metal oxides, transition metal oxides, mixed metal oxides and supported metal oxides as heterogeneous catalysts in the transesterification reaction. The author has discussed about the catalyst selection and catalyst preparation for efficient transesterification process as well as explained the deactivation issue of the catalyst as important as catalyst activity. The author has concluded about the synergy between emerging technologies as ultra-sonication and microwave irradiation, on one side, and heterogeneous catalysis, on the other side, for the production of biodiesel appears to be very promising. 99 Cardoso et al. 100 have reported a review article about the importance characteristics related to the synthetic route, stability and activity of the tin catalysts in the esterification of triglycerides for biodiesel production with high free acid methyl ester content. They have explained the main structural features and physical properties of the solid tin catalysts such as SnO2, SO4 2−–SnO2, SO4 2−–SnO2–Al2O3, SO4 2−–SnO2–Fe2O3 with different Sn to Al and Fe molar ratio, for better understanding and significant contribution for the biodiesel production. 100

Vedrine has reported a review chapter on the fundamentals of heterogeneous catalysis and on metal oxides special members of heterogeneous catalyst family, acid-base catalyzed reactions, selective partial and total oxidation, de-pollution, biomass conversion and green chemistry including photocatalysis. 61 The main focus of the article is discussion on current industrial applications of supported and non-supported metal oxide catalysts. Chouhan et al. have presented a comprehensive review on a large number of modern heterogeneous catalysts for biodiesel production. 6 The report content discussed on alkali metal oxides, alkaline metal oxides and their derivatives, transition metal oxides, mixed-metal oxides (MMOs), ion exchange resin type oxides, sulfated oxides as solid acid catalysts, carbon and boron group base solids and enzyme based solid catalysts. The authors have discussed on the catalytic activity, selectivity, catalyst loading, catalyst reusability and summary of the future scopes. 6 Diamantopoulos et al. have introduced heterogeneous catalysts as important materials for the biodiesel production. 101 The authors have discussed on zeolite, mixed oxides, sulfonic acid group catalysts, sulfonic acid modified SiO2, HPAs and polyoxonetalates, supported and substituted HPAs and solid acid catalyst based in waste carbon. They have explained the catalytic activity of these catalysts in terms of their efficiency and reusability. The review revels the fact about the advantages of the solid acid catalysts although they are not much active than base catalysts, benefits such as procedure simplification and positive environmental impacts, support the utility of biodiesel production by using various efficient solid acid catalysts. The lower catalytic activity of the solid acids compared to other catalyst for transesterification reactions is usually compensated by operating at higher calcination temperatures (120–450 °C). 101

Table 3 summarizing the metal oxides and mixed-metal oxides (MMOs) 73 , 74 , 75 , 76 , 77 , 78 , 79 , 80 , 81 , 82 , 83 , 84 , 85 , 86 , 87 , 88 , 89 , 90 , 91 , 92 , 93 , 94 , 95 , 96 , 97 , 98 , 99 , 100 , 101 , 102 , 103 , 104 , 105 as heterogeneous catalysts for biodiesel production via esterification or/and transesterification reactions.

Metal-oxides and mixed-metal oxides as heterogeneous catalysts for biodiesel production using esterification or transesterification reactions.

| Sr. No. | Catalysts | Esterification/transesterification reactions molar ratio of oil: alcohol | Ref. |

|---|---|---|---|

| 1 | Sulphated zinc oxide (SO4 2−-ZnO and SO4 2−/ZnO prepared by coprecipitation and impregnation method respectively | Transesterification of soybean oil Oil: methanol = 6:1 |

73 |

| 2 | Lithium-doped ZnO prepared by using impregnation method followed by calcinations | Transesterification of vegetable oil Oil: methanol = 1:12 |

74 |

| 3 | CaO–MoO3-SBA-15 prepared by incipient impregnation method | Transesterification of soybean oil Oil: methanol = 1:50 |

75 |

| 4 | Sulfated Fe2O3–TiO2 using conc. H2SO4 | Esterification of vegetable oil Oil: methanol = 1:20 |

76 |

| 5 | Strontium and nickel- oxides prepared by using a co-precipitation method | Transesterification using macaw palm oil Oil: methanol = 1:9 |

77 |

| 6 | Cu-nanoparticles impregnated in porous carbon support | Transesterification of pail oil/animal fat Oil: methanol = 1:10 |

78 |

| 7 | Dual-acid catalyst sulfur-rich graphene oxide prepared by simple modified Hummer’s method | Esterification of oleic acid with methanol Acid: methanol = 20:50 (w/w; g) |

79 |

| 8 | Alkali earth metal oxides (CaO, MgO and BaO) doped SiO2 | Transesterification of vegetable oil/animal fat oil: methanol = 1:16 | 81 |

| 9 | Calcium oxide derived from mud clam shell | Transesterification of caster oil Oil: methanol = 1:14 |

92 |

| 10 | Ca-doped Ce-incorporated SBA-15 impregnated with CaO. (CaO/CeO2 and CaO–CeO2/SBA-15) | Transesterification of palm oil Oil: methanol = 1:20 |

93 |

| 11 | SrO–CaO mixed metal oxides | Transesterification of Jatropha oil Oil: methanol = 1:10 |

94 |

| 12 | CaO/La2O3 prepared by co-precipitation method | Transesterification of crude Jatropha oil Oil: methanol = 1:25 |

95 |

| 13 | Acid-base bi-functional metal-boron catalysts prepared by sol-gel method (metal = Ca2+,Al3+, Mg2+, Zr4+) | Transesterification of crude Jatropha oil Oil: methanol = 1:20 |

96 |

| 14 | Mixed metal oxides (CaO–MgO, CaO–ZnO, CaO–La2O3 and MgO–ZnO) | Transesterification of high acid Jatropha

Oil: methanol = 1:25 |

97 |

| 15 | Metal oxides (Co3O4, KOH, MoO3, NiO, V2O5 and ZnO) | Transesterification vegetable oil with excess methanol | 98 |

| 16 | NaY zeolite-supported La2O3 | Transesterification of castor oil. Oil: methanol = 1:25 |

102 |

| 17 | Alkaline earth metal oxides (BaO, CaO, MgO and SrO) | Transesterification of palm oil Oil: methanol = 1:3 −1:15 (% w/w) |

103 |

| 18 | CsHPW12O40, Nb2O5, sulfated titania (TiO2/SO4 2−), sulfated zirconia (ZrO2/SO4 2−) and SnO2/SO4 2− | Esterification of dodecanoic (lauric) acid with methanol, propanol, 2-ethylhexanol Acid: alcohol = 1:1 up to 1:5 |

104 |

| 19 | ZnO/zeolite and PbO/zeolite prepared by hydrothermal impregnation precipitation method | Transesterification of Jatropha curcas and Pongomia pinnata oil Oil: methanol (excess) = 1:>3 |

105 |

Hydrotalcites: The hydroxyl carbonates of magnesium and aluminum, hydrotalcites (HTs) are minerals belonging to the family of anionic clays, containing anionic species in the inter-lamellar space. HTs are being used as solid catalysts due to their physicochemical properties, such as thermal stability, porosity, specific large surface area (after calcination), memory effect, basicity or/and acidity, and anion exchange capacity. 106 , 107 Since last many years, researchers are developing Mg/Al as well as Ca/Al and mixed metal-based HTs materials using various synthesis routes and applied as heterogeneous catalytic materials for base catalyzed organic synthesis. 108 , 109 Herein, such studies have been noted about the performance of HTs for the biodiesel production.

Xie et al. have developed calcined Mg/Al hydrotalcites as heterogeneous base catalyst by using coprecipitation method for transesterification process of soybean oil and methanol to produce FAME through optimization of reaction conditions. 110 The catalyst calcined at 500 °C with Mg/Al ratio of 3.0 found to be most active having higher basicity and suitable for the reaction having ∼67 % FAME conversion. Yagiz et al. 111 have studied catalytic performances of the lipase enzyme immobilized hydrotalcites prepared by co-precipitation method by using commercial zeolites as immobilization materials. The obtained immobilized lipase materials have been used for transesterification reaction of oil. As results, HT was found to be the suitable supporting material for lipase than the other four types of zeolites used and it observed to be able to catalyze the transesterification of waste cooking oil with methanol to produce methyl esters. 111 Mg/Al hydrotalcites prepared by co-precipitation of Mg2+ and Al3+ ions in alkaline solution of NaOH followed by calcination at 400 °C. 112 The prepared catalyst used biodiesel production from pongamia oil with methanol through transesterification under optimized reaction conditions and resulted ∼90 % yield of pongamia oil methyl ester showing potential activity of the present catalyst. 112 The hydrotalcites catalyst with Mg/Al molar ratio of 3.0, calcined at 450 °C under argon (Ar) flow for 6 h has been characterized for spectral analysis. 113 The prepared material has been tested for transesterification reaction of soybean oil with methanol under mild conditions of temperature and pressure to produce biodiesel. The results show highest fatty acid methyl ester conversion of ∼94 % at optimized reaction conditions which makes material to be a promising heterogeneous base catalyst for biodiesel formation. 113 Chelladurai et al. 114 have studied an environmentally benign process for the transesterification reaction of neem oil with methanol to yield fatty acid methyl esters (FAME) using Zn–Mg–Al hydrotalcites as heterogeneous solid base catalysts thorough optimization of reaction conditions. The obtained highest triglyceride conversion rate was ∼92 % at optimized conditions and this could be attributed to the incorporation of Zn into the Mg–Al hydrotalcite material.

Diserio et al. 115 have reported catalytic performances of Mg/Al hydrotalcites (Pural©MG76) for biodiesel production through transesterification of soybean oil with methanol using both an autoclave and continuous packed bed reactor. The observations confirmed about the calcined Mg/Al hydrotalcites as effective heterogeneous catalyst for the transesterification of triglycerides with methanol where the used catalysts could be regenerated by washing with acetone and reused for the economical way without loss of significant performance. 115 Costarrosa et al. 116 have studied influences of the reaction parameters in terms of response surface methodology (RSM) for the heterogeneous transesterification of waste cooking oil with methanol to produce biodiesel using calcined Mg–Al hydrotalcite catalyst. The study has proved RSM as good indicative tool for predicting the biodiesel yield and also about the calcined Mg/Al hydrotalcites as an effective basic catalyst for the production of biodiesel from waste cooking oil. 116 Mg/Al hydrotalcites has been synthesized by urea hydrolysis and co-precipitation methods and characterized. 117 The prepared material tested for transesterification process of waste cooking oil (a triglyceride) with methanol and optimized the reaction conditions using hexane and glycerol as co-solvents. At optimized reaction condition, Mg/Al hydrotalcites as solid base catalyst gives maximum biodiesel yield and compared with the results of KOH as liquid homogeneous base catalyst. 117 A series of solid base catalysts, KF-doped three-metal mixed hydrotalcites (KF/Ca–Mg–Al) with different cation ratio have been synthesized and applied in transesterification process of palm oil with methanol to yield FAME. 118 The doping of KF and synergetic effect of Ca2+ and Mg2+ broadly improved the catalytic activity of the HT catalysts. As results, the prepared three-metal mixed hydrotalcites found to be highly active for biodiesel production and obtained ∼99 % FAME yield at optimized reaction conditions. 118 The spent catalysts could be regenerated and reused in the transesterification reaction where the FAME yield decreased apparently compared to fresh catalyst due to the fact that the layer structure of the catalyst helped raise the activity of the catalyst.

The Mg/Al based catalysts (double oxides of Mg and Al) prepared by coprecipitation method and characterized for structural properties. 119 The formed double lamellar hydroxides followed by calcination gives double oxides show interesting catalyst properties such as a large superficial area, synergic effect between its elements (which favors the development of the its basic characteristics) and also a shape memory effect, which allows the regeneration of the original structure. The prepared catalysts have been tested through heterogeneous catalytic transesterification reaction of vegetable oil with methanol and resulted in ∼97 % FAME formation. The study shows the potential use of the MgAl based hydrotalcites for the biodiesel production and suggesting further structural modification for the improved catalytic activity. 119 Mg/Al hydrotalcites doped with lanthanum and zinc cations with different amounts prepared by using co-precipitation method followed by calcination and the materials have been used as solid base catalyst in transesterification of soybean oil with methanol and n-octanol for biodiesel and biolubricants production respectively. 120 The transesterification reaction of canola oil with methanol has been reported using Mg/Al hydrotalcites heterogeneous solid base catalyst prepared by coprecipitation method followed by calcination. 121 The results of the catalytic reaction have been compared with KOH as conventional homogeneous catalyst where the present catalyst found to be less active than KOH.

The potential contribution of Mg/Al hydrotalcites prepared through layered double hydroxide has been reported for the biodiesel production using transesterification of triglycerides. 122 The interesting physico-chemical characteristics such as texture and surface morphology as well as basicity of the prepared materials could be modified through synthesis routes and chemical composition. The present report shows useful catalytic characteristic of the hydrotalcites as mixture of mixed oxides catalysts and as supports of active species like alkaline and alkaline earth metals compound. 122 Simonetti et al. have reported use of Ca/Al based hydrotalcites catalysts prepared by impregnation method using KOH solution followed by calcination for the transesterification reaction of soybean oil in methanol and ethanol to produce biodiesel. 108 The catalytic performance of impregnated and non-impregnated catalysts has been compared for the transesterification reaction and as a result, the non-impregnated exhibited with higher activity and hence better performances due to availability of active sites used in the transesterification process. 108 Mg/Al hydrotalcites prepared by co-precipitation followed by calcination and loaded with K2CO3. 123 The obtained material used as solid base catalyst for transesterification reaction of Jatropha curcas oil with methanol to produce FAME. In the study, spectral analysis confirmed the metal oxide formation which makes catalyst to be highly active and it could produce about ∼96 % yield of biodiesel (FAME) under optimized reaction condition. 123 Xue et al. 124 have synthesized activated Mg/Al hydrotalcites NPs by co-precipitation and hydrothermal activation with aqueous Ca(OH)2 solution and characterized its catalytic properties. 124 The prepared Ca-hydrotalcite contained both acidic and basic active sites due to which it could be used for esterification and transesterification of different oils with high acid value. The results show high catalytic activity for production of biodiesel (∼93 % yield) from crude oils with high acid value without pretreatment. 124

Table 4 highlighting the use of various HTs as heterogeneous base catalysts for biodiesel production through esterification or transesterification process of oil with methanol/ethanol using optimization of oil to alcohol molar ratio. 108 , 109 , 110 , 111 , 112 , 113 , 114 , 115 , 116 , 117 , 118 , 119 , 120 , 121 , 122 , 123 , 124

Hydrotalcites (HTs) as heterogeneous base catalysts for biodiesel production using esterification or transesterification reactions.

| Sr. No. | HTs as base catalysts | Esterification/transesterification reactions molar ratio of oil: alcohol | Ref. |

|---|---|---|---|

| 1 | Ca/Al based HTs (Ca/Al ratio of 2:0) prepared by impregnation method using KOH solution | Transesterification of soybean oil Oil: methanol/Ethanol = 1:30 (∼90–95 % FAME conversion) |

108 |

| 2 | Calcined Mg/Al HTs prepared by coprecipitation using alkaline solution | Transesterification process of soybean oil Oil: methanol = 15:1 (∼67 % FAME conversion) |

110 |

| 3 | HT-immobilized and zeolites-immobilized lipase enzymatic materials | Transesterification waste cooking oil Oil: methanol = 1:4 (∼91 % FAME conversion |

111 |

| 4 | Calcined Mg/Al HTs prepared by coprecipitation using alkaline solution | Transesterification pongamia oil Oil: methanol = 1:6 (∼90 % yield of pongamia oil methyl ester) |

112 |

| 5 | Calcined Mg/Al HTs under Ar flow (Mg/Al ratio of 3.0) prepared by coprecipitation using alkaline solution | Transesterification of soybean oil Oil: methanol = 1:20 (∼94 % FAME conversion) |

113 |

| 6 | Calcined Zn–Mg–Al HTs | Transesterification reaction of neem oil Oil: methanol = 1:10 (∼91 % FAME conversion) |

114 |

| 7 | Mg/Al HTs (Pural©MG76) | Transesterification of soybean oil in autoclave and in a continuous packed bed reactor Oil: methanol = 160 g :160 g (w/w) (∼80–85 % FAME conversion) |

115 |

| 8 | Calcined Mg/Al HTs (Mg/Al ratio of 3.1) prepared by coprecipitation using alkaline solution | Transesterification of waste cooking oil Oil: methanol = 1:8 (∼95–98 % FAME conversion) |

116 |

| 9 | Calcined Mg/Al HTs (Mg/Al ratio of 3.1) prepared by urea hydrolysis and coprecipitation methods | Transesterification of waste cooking oil Oil: methanol = 1:6 (∼78–96 % FAME conversion) |

117 |

| 10 | KF-doped three-metal mixed HTs (KF/Ca–Mg–Al) | Transesterification process of palm oil Oil: methanol = 1:12 (∼99 % FAME conversion) |

118 |

| 11 | Calcined Mg/Al based double oxides of Mg and Al prepared by coprecipitation using NaOH solution | Transesterification of soybean oil Oil: methanol = 1:9 and 1:12 (∼97 % FAME conversion) |

119 |

| 12 | Mg/Al HTs (Mg/Al ratio of 2.0) doped with lanthanum (La3+) and zinc(Zn2+) cations | Transesterification of soybean oil Oil: methanol = 1:15 (∼97 % FAME conversion) |

120 |

| 13 | Calcined Mg/Al HTs prepared by coprecipitation using alkaline solution | Transesterification of canola oil Oil: methanol = 1:6 and 1:12 (∼71 % FAME conversion) |

121 |

| 14 | Mg/Al HTs (Mg/Al ratio of 2:3) prepared by layered double hydroxide | Transesterification of triglycerides Oil: methanol = 1:12 (∼96 % FAME conversion) |

122 |

| 15 | Calcined K2CO3 loaded Mg/Al HTs (Mg/Al ratio of 3:1) prepared by coprecipitation using alkaline solution | Transesterification of Jatropha curcas oil Oil: methanol = 1:6 and 1:12 (∼96 % FAME conversion) |

123 |

| 16 | Mg/Al hydrotalcites NPs by coprecipitation and hydrothermal activation with aqueous Ca(OH)2 | Transesterification of Jatropha curcas oil Oil: methanol = 1:30 (∼93 % FAME conversion) |

124 |

Metal Organic Frameworks (MOFs): MOFs are porous materials, composed of metal sites and organic linkers, have become a research hotspot due to their exceptional advantages, such as versatile synthetic strategies for controlled morphology, abundant pores, and high surface area. 125 These properties grant MOFs versatile functionalities, which have attracted significant interest from the scientific community in recent years. 125 Their crystalline-to-amorphous nature, consisting of metal ions or clusters linked to organic ligands, offers remarkable surface areas, a high degree of structural diversity, and tunable porosity, making them ideal for a wide range of applications. 125

With the advantageous character of polyporous materials, MOFs have gained the most suitability for biodiesel synthesis. 126 Molybdenum-MOFs has been synthesized by solvothermal method and applied as catalyst in the esterification reactions of oleic acid and palmitic acid to obtain biodiesel. 127 As a result, a 95 % yield was achieved with the fresh Mo-MOFs, and it was successfully recycled for four cycles, maintaining ∼92 % efficiency. A hydrothermal synthesis of chromium(III) nitrate nonahydrate salt with EDTA as an organic ligand has been reported to prepare Cr(III)-EDTA MOF, which demonstrates efficient and promising performance for the esterification of oleic and palmitic acids under mild reaction conditions. 128 Copper(II) based MOFs, Cu-benzenedicarboxylic acid (Cu-BDC), Cu-benzenetricarboxylic acid (Cu-BTC) and MOF-74, provide many active sides that act as Lewis acid species and therefore, used as catalysts in the esterification process of waste cooking oil. 129 The synthesis of 75 % and 50 % oil content with Cu-BDC catalyst converted in FFA content of 5.49 % and 4.826 %, respectively.

2.2 Hydrogen production

Hydrogen (H2), as a fuel and one of the most extensively studied substitute energy resources for available sources those are being consumed rapidly. 130 , 131 The combustion of hydrogen can be considered as environmentally benign because it produces only water as by-product, and its adoption as fuel in internal combustion engines, would lead to a remarkable reduction in atmospheric pollution. 132 Now days, hydrogen-based technologies are being proposed for having economically and environmentally efficient system to produce hydrogen such as photo-catalytic water-splitting, 133 , 134 , 135 , 136 , 137 hydrocarbon decomposition, 138 , 139 photo-reforming 140 , 141 , 142 , 143 , 144 aqueous phase reforming, 145 , 146 , 147 , 148 , 149 , 150 and auto-thermal/oxidative steam reforming. 151 , 152 , 153 In this view, mono-metallic, bi-metallic or poly-metallic heterogeneous catalysts based on NPs (oxide supported) are well established catalytic systems for hydrogen production. Several Pd, Pt, Ru, Rh-based heterogeneous catalysts with comparable hydrogen production rate have been reported.

Santo et al. 132 have reviewed the specific catalytic applications of reforming processes such as steam, auto-thermal/oxidative steam, aqueous phase and dry reforming, catalytic partial oxidations, decomposition, photocatalytic water-splitting and photo-reforming reactions. The authors have reported heterogeneous catalysis based on supported bimetallic NPs, to the reactions favorable for the hydrogen production from the renewable raw materials. 132 They have discussed on advantageous applications of bimetallic versus monometallic catalytic systems, as well as focused on characterizations of structural properties. The correlation between structure and catalytic properties has an influence on the promoter addition. The potential of bimetallic catalyst NPs could be seen from the number of examples of the industrial applications significantly such as hydrogen production using photo-reforming and photocatalytic water-splitting those are discussed in the present article. 132

Furthermore, metal-supported heterogeneous catalysts can induce changes in the electronic properties of the catalyst surface, offering numerous opportunities for developing advanced catalysts with enhanced catalytic performance. 26 The noble metal catalysts are also interesting aspects of catalysis for hydrogen production through HER because of their ΔGH* is closed to zero. 154 Zhou et al. have related the catalytic activity with the electronic structure and chemical composition of noble metal-based electrocatalysts. 154 In continuation, a series of lanthanum based heterogeneous catalysts of 1 wt% Pt/LaMO3 where M = Al, Cr, Mn, Fe, Co, Ni has been synthesized and used in the catalytic study of aqueous phase reforming of waste biomass, such as glycerol for sustainable hydrogen production. 155

Nagaoka et al. 156 have demonstrated hydrogen production by oxidative decomposition of ammonia at room temperature to an acidic RuO2/γ-Al2O3 catalyst. In the study ammonia chemisorbed onto RuO2/γ-Al2O3 catalyst which further increased the amount of the multilayer physisorbed ammonia which causes strong heat evolution that enables to initiate the oxidative decomposition of the ammonia onto large surface of RuO2 NPs. The authors have measured and compared the autoignition temperatures of the RuO2/γ-Al2O3 and RuO2/γ-La2O3 catalysts. 156 As results, on ammonia and oxygen supply to the catalyst at room temperature, it has produced hydrogen along with nitrogen and water vapor. The process requires neither an external energy source nor the use of any complex procedures. The present study briefly introduces a conceptual idea of self-heating of catalysts by adsorption of reactant molecules which is a novel strategy for the cold-start process for hydrogen production from ammonia and other reactions.

Recently, a study discussed the progress and challenges in using non-noble metal cobalt-based heterogeneous supported catalysts, particularly carbon materials, metal oxides, MOFs, and nickel foams, for hydrogen generation from ammonia borane. 157 It provides insights into how the preparation of the electronic and spatial structures of Co-based catalysts can significantly influence the decomposition of ammonia borane for hydrogen generation. 157 Brack et al. 158 have introduced heterogeneous catalysis for the hydrogen production from the hydrolysis process of sodium borohydride (NaBH4). The authors have discussed about the factors affecting the catalytic hydrolysis process of aqueous solution of NaBH4 such as catalyst role, reaction conditions (temperature, time, concentration and volume of NaBH4 and the used stabilizers). The article has brief discussion about the catalysts based on noble metals, mainly focus on Pt and Ru as most efficient at rapid production of hydrogen from the aqueous NaBH4 solution. As noble-metal based catalysts resulting much expensive, transition metal-based particularly Co and Ni-based catalytic system would be a desirable alternative and much more work has been done for the hydrogen generation. Cobalt-borides are found to be emerging catalyst of choice due to low cost and simple synthesis procedures with high catalytic activity leading to maximum hydrogen production yields. They also have explained other transition metal-based as well as metal free-based heterogeneous catalysts for practical applications of the hydrogen generation. 158 Srifa et al. 159 also have studied hydrogen generation by ammonia decomposition using Cs-modified Co3Mo3N catalysts prepared by a facile single-step decomposition of a mixture of hexamethylenetetramine and corresponding metal salts under the flow of nitrogen at 700 °C. The kinetic study of the catalytic process shows influence of the presence of the Cs species as it significantly enhanced the catalytic activity of Co3Mo3N, an excess amount of Cs could be reduced the activity and hence lower the H2 production rate. The observed enhancement could be due to electronic modification of Co3Mo3N by the electron donation of Cs promoter. 159

Yan et al. 160 have compared catalytic activities of Ni, Co and W with ZrO2 support for hydrogen production from PEG-contaminated wastewater by supercritical water gasification process. The results of the analysis show Ni/ZrO2 exhibits highest hydrogen yields which could be due to catalyst inhibition of toxic intermediate production. The study demonstrated the promising use of Ni/ZrO2 as heterogeneous catalyst for hydrogen production in a supercritical water gasification process with high activity and stability. 160 Yuranov et al. 161 have developed a heterogeneous catalytic reactor for continuous production of hydrogen via formic acid dehydrogenation. The catalyst support consisting of cross-linked polystyrene beads and polymer electrolyte fuel cell operated on H2 + CO2 mixtures to produce neat hydrogen. The model presented could help to use formic acid as hydrogen carrier medium and to make maximum industrial application for the sustainable technology. Yamashita et al. 162 have addressed most relevant research approaches in hydrogen generation from two of the most promising hydrogen storage materials such as formic acid and ammonia-borane over carbon supported metal NPs based catalysts. The authors have highlighted recent advancement in mono-metallic and bi-metallic Pd-based and Ru-based catalytic system, also discussed about the important features like nano-particle size, electronic features and composition, functionality of the support and influence of the used additives present in the medium. They have concluded about the prior meet of the high performance heterogeneous catalysts for the hydrogen production with efficiency, economic and reusability. 162 The authors also have reported design and development of efficient Pd-based heterogeneous catalysts supported on carbon or carbon containing materials for the formic acid dehydration process in liquid phase for hydrogen production. 163 They have described important features of metal active phase and catalytic support for finding the efficient catalyst under the optimum experimental conditions. The main issue has been noted about the stability of the catalyst which has to be improved for the practical applications. In this context, modulating the nanoparticle-support interaction could be of great significance in achieving catalysts with notable stability. The incorporation of an adequate heteroatom through doping in the carbon material could be an effective tool to form interesting catalytic system for the current demand through appropriate surface fictionalization. Another way of modification in the synthesis route so that porosity of the carbon material support could be utilized in anchoring and dispersing the metallic active phase would be effective work of interest through which active and durable catalytic system could be developed, and searching useful capping agent to inhibit the nano-particle sintering under using experimental conditions. Also, they have concluded about future investigation to be initiated the use of non-noble metallic NPs as cost effective and durable active catalysts for the hydrogen production from dehydrogenation of the formic acid. 163 Yamaguchi et al. 164 have reported gaseous fuel production from non-recyclable paper wastes such as shredded documents and paper sludge over supported metal catalysts. The gasification catalytic reactions show, a charcoal-supported ruthenium (Ru/C) catalyst found to most active and among to the metal used, the order of the catalytic activity was found to be Ru > Rh > Pt. The gas fuel yield increases by ball-milling treatment of the recycled paper and cellulose powder. 164 The present conceptual technique indicating the possibility of fuel gas production from paper wastes in high-temperature liquid water.

Sikander et al. 165 have introduced scientific approaches reported by researchers for the hydrogen production using HTs based catalysts through describing synthesis methods and structural properties. The authors have briefly explained co-precipitation, urea hydrolysis, microwave treatment and sol-gel method of synthesis for HTs. Various methods of hydrogen production have been discussed such as steam reforming of methane, methanol, ethanol and dry hydrocarbons and partial oxidation of methane. The catalysts, HTs are observed to be more active in almost all hydrogen production processes because of high surface area. Furthermore, the compositional ratios of active metallic cations along with their interaction with the interlayers are a key role for catalytic efficiency. 166 , 167 Doping of element is another way to enhance the catalytic performance where use of noble metals (Pd, 168 , 169 Pt, 170 Rh 171 ) have been reported successfully. The rigorous operating conditions of hydrogen production processes could damage structural properties of the catalyst, sintering of the cations and deactivation of the catalyst also affects the catalytic efficiency of the HTs. The authors also have developed double layered HT based Mg–Ni–Al catalyst using co-precipitation method by varying Ni content and studied its catalytic performance for the hydrogen production through methane decomposition. 172 The nickel concentration has not been effective to the overall methane decomposition reactions due to the sintering of active sites species leads to depriving of the overall rate of methane conversion. The used catalyst support have played a typical role in the diffusion of the deposited carbon, resulted improved the overall performance rate.

Three metal-based HTs (Ni/Zn/Al-HT) with different Ni/Zn ratios have been prepared by a coprecipitation method and characterized for structural properties where HT and ZnO phases observed along with Zn2+ into the layer. 145 The prepared material has been used for hydrogen production via aqueous phase reforming of ethylene glycol and resulting high H2 generation rate with high selectivity. 145 Ni–Fe mixed oxides obtained from reevesite, a HTs type material prepared by co-precipitation method and tested for steam reforming of ethanol for hydrogen production. 145 The comparative performance of hybrid materials comprising a Ni-based reforming catalyst and HT (Ni-HT) or calcium based sorbents (Ni–CaO/Al2O3) has been reported for sorption-enhanced steam methane reforming for H2 production. 173 The prepared hybrid material (Ni-HTs) exhibited with superior adsorption characteristics and stability compared to powdered mixtures of commercial Ni/Al2O3 catalyst and the respective sorbent (CaO). 174 He et al. 175 have studied catalytic performances of noble-metal free-catalyst obtained from Ni/Al HTs for hydrogen production through hydrous hydrazine (N2H4·H2O) decomposition and compared with the ∼78 wt % Ni/Al2O3-IMP sample. The results show that supported Ni catalyst with a high loading and good dispersion exhibits ∼100 % conversion and ∼93 % H2 selectivity for the N2H4·H2O decomposition at room temperature. The observed activity is due to the cooperation of Ni NPs and strong basic sites which make catalyst as a promising candidate to replace noble-metals for hydrogen production under ambient conditions. 174 Homsi et al. 176 have prepared Co-based HTs (Co6Al2 oxide) and thermally stabilized and impregnated using metal precursors of Cu and Ru followed by calcination. The characterization results show formation of CuO, RuO2, Co3O4 and CoAl2O4 after calcination of the impregnated materials. Both, impregnated and non-impregnated samples have been used for the steam-reforming of the ethanol for H2 production. 176 As results, Ru with impregnated samples exhibit high catalytic activity compared to Cu-impregnated sample which is attributed to the formation of easily reducible Ru and Co-oxide species at the surface of the support. 176 The authors also have studied catalytic performances of Cu/Co–Mg–Al-based catalysts in the ethanol steam reforming reaction under atmospheric pressure in a fixed catalytic bed reactor coupled to a micro-gas chromatography. 177 From the reaction, H2 and CO2 evolved and it increased with the cobalt content and 5Cu/Co6Al2 gives very good conversion of H2 and CO2. The presence of copper as an active phase has improved ethanol conversion and H2 production compared to the results obtained in the case of the supports alone. The study leads to develop a catalyst operate at low temperature with high selectivity to avoid formation of by-products. 177 Tuza et al. 178 have reported hydrogen production by aqueous-phase reforming of glycerol using Ni/Cu catalysts derived from HT precursors. The obtained materials have been characterized for structural and surface properties. A clear improvement in the orderliness of the layer has been noted with decreasing copper content and samples with higher amount of copper have larger BET surface areas. The Ni-catalyst without Cu shows high catalytic glycerol conversion observed with good H2 selectivity and Ni5Cu catalyst also shows high H2 selectivity with the smallest amount of CO and CH4. 178

The compositional variation and structural advantages such as highly ordered and tunable metal nodes and organic linkers, MOFs enable rapid ion transport and high capacitance. With their abundance of active energy storage sites, MOFs have emerged as attractive candidates to meet the demands of next-generation energy storage technologies in batteries and supercapacitors.125c MOFs and their nanocomposites have been widely synthesized, particularly for their potential applications as hydrogen storage materials in proton exchange membrane fuel cells (PEMFCs). 179 MOFs are also of interest as potential materials for use as electrode in lithium, zinc and sodium-ion batteries. 180

The catalysts used in the hydrogen production process have been summarized 26 , 132 , 145 , 154 , 155 , 156 , 157 , 158 , 159 , 160 , 161 , 162 , 163 , 164 , 165 , 166 , 167 , 168 , 169 , 170 , 171 , 172 , 173 , 174 , 175 , 176 , 177 , 178 , 179 , 180 , 181 , 182 in Table 5.

Hydrogen production using various catalysts.

| Sr. No. | Catalysts | Catalytic process | Ref. |

|---|---|---|---|

| 1 | Supported bimetallic NPs | Photo-reforming and photocatalytic water-splitting | 132 |

| 2 | Acidic RuO2/γ-Al2O3 catalyst | oxidative decomposition of ammonia | 156 |

| 2 | 1 wt% Pt/LaMO3 where M = Al, Cr, Mn, Fe, Co, Ni prepared by harsh hydrothermal conditions | Aqueous phase reforming of waste biomass | 157 |

| 3 | Noble-metal (Pt, Ru and Rh), transition metal (Ni and co) based catalysts | Hydrolysis process of sodium borohydride | 158 |

| 4 | Cs-modified Co3Mo3N | Ammonia decomposition | 159 |

| 5 | Ni, Co and W with ZrO2 support (Ni/ZrO2, Co/ZrO2, W/ZrO2) | PEG-contaminated wastewater by supercritical water gasification process. | 160 |

| 6 | Different active Ru complexes supports on zeolite ZSM-5, mesoporous MCM-41 silica and functionalized polystyrene beads | Formic acid dehydrogenation | 161 |

| 7 | Monometallic and bimetallic Pd-based catalytic systems, (Pd, Pd/Ag, Pd/Au) | Formic acid dehydrogenation | 162 |

| 8 | Carbon supported metal NPs | Dehydrogenation of formic acid and ammonia-borane | 163 |

| 9 | Charcoal-supported ruthenium (Ru/C) | Gasification catalytic reactions (gaseous fuel production from non-recyclable paper wastes) | 164 |

| 10 | Hydrotalcite (HTs) consisting of different metals like Fe, Ni, Cu, Pt | Steam reforming of methane, methanol, ethanol and dry hydrocarbons and partial oxidation of methane | 165 |

| 11 | Ce-promoted Ni/Mg–Al catalysts | Dry reforming of methane | 166 |

| 12 | HTs supported Pd2Ga and PdZn intermetallic NPs | Methanol steam reforming | 168 |

| 13 | PdZnAl-HTs supported catalyst | Oxidative methanol steam reforming | 169 |

| 14 | Ni, Co and pt/hydrotalcites-WO x | Ethanol steam reforming | 170 |

| 15 | Rh-doped Ni/Mg(Al)O catalysts | Methane steam reforming | 171 |

| 16 | Double layered HT based Mg–Ni–Al | Methane decomposition | 172 |

| 17 | Ni/Zn/Al derived HTs | Aqueous-phase reforming of ethylene glycol | 145 |

| 18 | HTs- and calcium-based hybrid materials | Methane steam reforming | 173 |

| 19 | Ni/Fe derived HTs | Ethanol steam reforming | 174 |

| 20 | Noble-metal-free catalyst derived from Ni–Al HTs | Hydrazine (N2H4·H2O) decomposition | 175 |

| 21 | Ru and Cu supported HTs | Methane steam reforming | 176 |

| 22 | Cu/Co–Mg–Al-based catalysts prepared by HTs route (5Cu/Co6Al2) | Ethanol steam reforming | 177 |

| 23 | Ni and Cu supported HTs | Aqueous-phase reforming of glycerol | 178 |

| 24 | Prussian blue analogues | Hydrolysis of NaBH4 | 181 |

| 25 | Fluorine-doped NiO and Ni@C prepared through organic-inorganic hybrid approach | Urea oxidation reaction | 182 |

3 Environmental applications

Currently, the problem associated to the energy and environment has no universal solution to solve it. Most of human activities and more, rapidly increasing population and thus, even faster increasing global energy consumption and environmental burdens lead to generate the said unsolved problems. Many more awareness and progressively efforts are being applied to improve the efficiency and accessibility of environmental remediation and Green Chemistry processes. Environmental catalysis certainly plays a typical role in the design and development of efficient processes and technologies to reduce or to minimize waste generation throughout saving energy. 183 Herein, different heterogeneous catalytic systems have been discussed to understand relation between the structure/chemistry and the performance in heterogeneous catalysis which would help to design novel efficient materials for addressing the challenges in potential applications for environmental remediation. These include metal-based and/or metal-free-based catalysts and carbon-based catalysts for green chemistry, semiconductors-based catalysts for photocatalysis and other catalytic systems for environmental technologies.

3.1 Carbon dioxide (CO2) reduction

Faster deforestation makes sudden increment of CO2 concentration in atmosphere and thus, global warming problem and climate change become the interest of attention. 150 Therefore, now it is become necessary to find out a significant alternative to capture CO2 and convert it into useful chemicals and sources of fuel. 183 The availability of the alternative energy source is connected to the source of hydrogen which is carbon neutral and economically feasible. In this view, the hydrogenation of CO2 to methanol synthesis is providing a renewable or sustainable source of hydrogen.