Abstract

The objective of this study is to enhance the properties of crumb rubber (CR) derived from the tread and sidewalls of passenger and truck waste tires by adding bitumen (B) and oxidized bitumen (OB). On this context, CR was activated and modified by adding different chemical ingredients to convert it into modified crumb rubber (MCR). OB was irradiated at 25 kGy to get irradiated oxidized bitumen (IOB) with the aim of study the effect of irradiation on the samples in the presence and absence of sulfur element. The crosslinking density, mechanical parameters and thermal stability of the developed blend were examined. Furthermore, chemical resistance behavior, vibration tests which reflecting the velocity level and sound proofing performance were discussed. Remarked improvement in the mechanical, thermal and various applications of MCR were achieved by the incorporation of OB especially at 10 phr and gamma irradiation.

1 Introduction

The waste tires are disposal problem. This waste tire or stock piles tire annually. Environmental and health hazards due to burning of tire effect on life by increasing pollution. Therefore used of waste tire rubber in construction of road pavement to replacement of aggregate and bitumen with rubber adding some percentage. Rubbers from waste tire have light weight, thermal insulation properties and hydraulic conductivity [1]. Asphalt modification by polymers improves its mechanical properties, and therefore the properties of road pavements, such as resistance to permanent deformation, low temperature cracking, and load-associated fatigue, wear, and stripping, are improved [2], [3], [4]. The enhanced properties of this modified asphalt can evolve because of aging during mixing, storage, and application in service [5], [6], [7].

Blown bitumen grades or oxidized bitumen are produced by passing air through the penetration grades. This process gives the bitumen more rubbery properties than its original formula and they are simply harder bitumen. Oxidized bitumen is also expected to make up for weight loss under heat. The softening point of oxidized bitumen is much higher than in regular bitumen, causing lower thermal sensitivity. The penetration index (PI) in oxidized bitumen is higher than in road construction bitumen (8 > PI > 2) because the letter has a gel-like structure due to asphalt accumulation [8]. Using crumb rubber (CR) as modifier instead of expensive polymer modifier (SBS, SBR, etc.) can also reduce the cost of road asphalt. Utilization of CR from scrap tires with known grain size subjected to different gamma irradiation doses to enhance the rheological and ageing properties at different temperatures of asphalt binders has been performed and published earlier [9].

Polymer processing by ionizing radiation is environmentally and energetically safe as it does not need solvents or initiators at high temperature and allows one to avoid degradation phenomena and other side reactions typical of polymer processing in the melt [10], [11]. High-energy irradiation offers unique solutions to the problem of recycling due to its ability to induce crosslinking, scission and activation by forming free radicals of a wide range of material without introducing any chemical initiators and without dissolving the sample, thus, avoiding phase separation.

In this article, study was performed to investigate the role of bitumen and oxidized bitumen on the various properties of CR. Conversion of CR to modified crumb rubber (MCR) was achieved by mixing its aggregates with different chemical ingredients to enhance its ability for recombination with bitumen particles. On the other hand, ionizing radiation has been applied to study its impact on the oxidized bitumen which blended with MCR.

2 Experimental

2.1 Materials

The CR was kindly provided by Narobine Company, Cairo, Egypt, of particle size 10 mesh of unclassified ground rubber from the tread and sidewalls of passenger and truck tires. The exact composition of the materials is not known, but from previous works have been published before, it contained roughly hydrocarbon, 59.8% (30% natural rubber (NR), 40% styrene butadiene rubber (SBR), 20% acrylonitrile butadiene rubber (NBR), and 10% butyl and halogenated butyl elastic), 24% carbon black, 15% acetone extract, around 0.92% sulfur, and roughly 0.98% zinc oxide (ZnO) [12]. Chemical ingredients which have been used to obtain MCR were classified as follows: N-tert-butyl-2-benzothiazole sulphenamide (TBBS), 2-mercapto benzothiazole disulfide (MBTS) from Bayer India Ltd., India, Tetramethylthiuram disulfide (TMTD) supplied by Zhedong Rubber Auxiliary Co., Ltd., China, 2-mercaptobenzothiazole (MBT), Zn stearate, Stearic acid from Hebei Liancheng Chemical Co., Ltd., China, Sulfur Standard Chemical Company Ltd., Chennaiand, zinc oxide, Shijiazhuang Golden Color Chemical Co., Ltd., China, concentration, 99.7%. Used bitumen 60/70 penetration grade, and oxidized bitumen supplied from Refinery Suez Company, Egypt. The physical properties of bitumen (B) and oxidized bitumen (OB) are represented in Table 1.

Physical properties of bitumen and oxidized bitumen.

| Physical properties (ASTM D 946) | Bitumen 60/70 (suez co.) | Oxidized bitumen (suez co.) |

|---|---|---|

| Softening point, Ring&Ball, °C | 47 | 88 |

| Penetration, at 25 °C, 0.01 mm | 65 | 15 |

| Ductility, at 25 °C, cm | +150 | 98 |

2.2 Preparation of different blend formulations

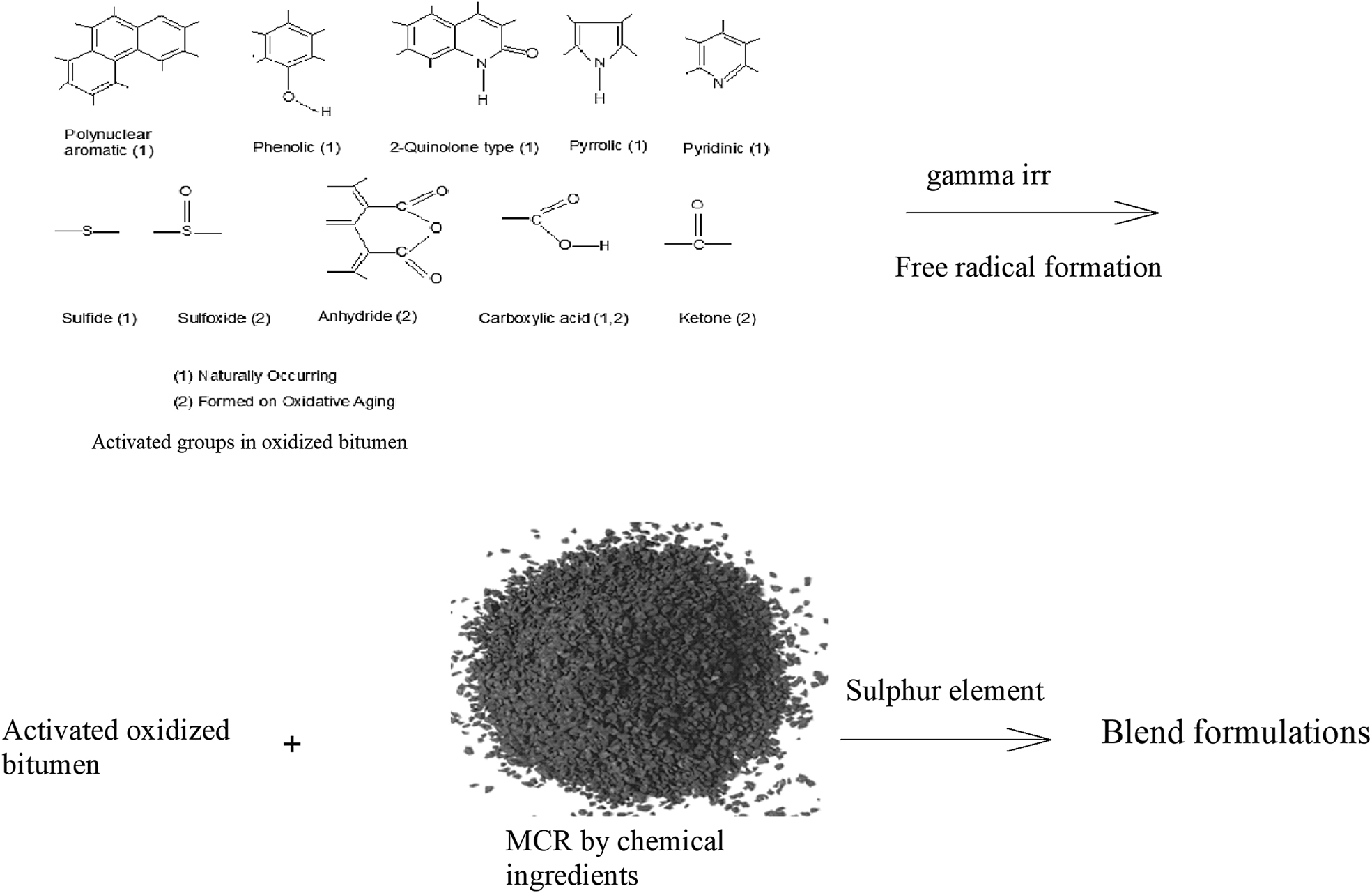

Figure 1 represents a schematic diagram for MCR and blending it with irradiated oxidized bitumen in the presence of sulfur element to fabricate different blend formulations. In this context, modification of CR was performed to convert into MCR as follows: chemical ingredients mixture of (3 phr TBBS, 8 phr MBTS, 2 phr TMTD, 4 phr MBT, 1 phr zinc stearate, 1 phr stearic acid and 1 phr ZnO) was mixed in ceramic pot at room temperature. After that 1% of the last mixture has been mixed with fine CR into the internal mixer under heat at 90 °C. After that the obtained MCR has been fabricated with bitumen and oxidized bitumen as represented in Table 2.

Schematic diagrame of blend formulation.

Blend formulations of modified crumb rubber with bitumen and oxidized bitumen.

| Sample | Blend formulations |

|---|---|

| 1 | MCR + S |

| 2 | MCR + 10B |

| 3 | MCR + 10B + S |

| 4 | MCR + 10 OB |

| 5 | MCR + 10 OB + S |

| 6 | MCR + 10 IOB |

| 7 | MCR + 10 IOB + S |

| 8 | MCR + 30 OB |

| 9 | MCR + 30 OB + S |

| 10 | MCR + 30 IOB |

| 11 | MCR + 30 IOB + S |

2.3 Gamma irradiation treatment

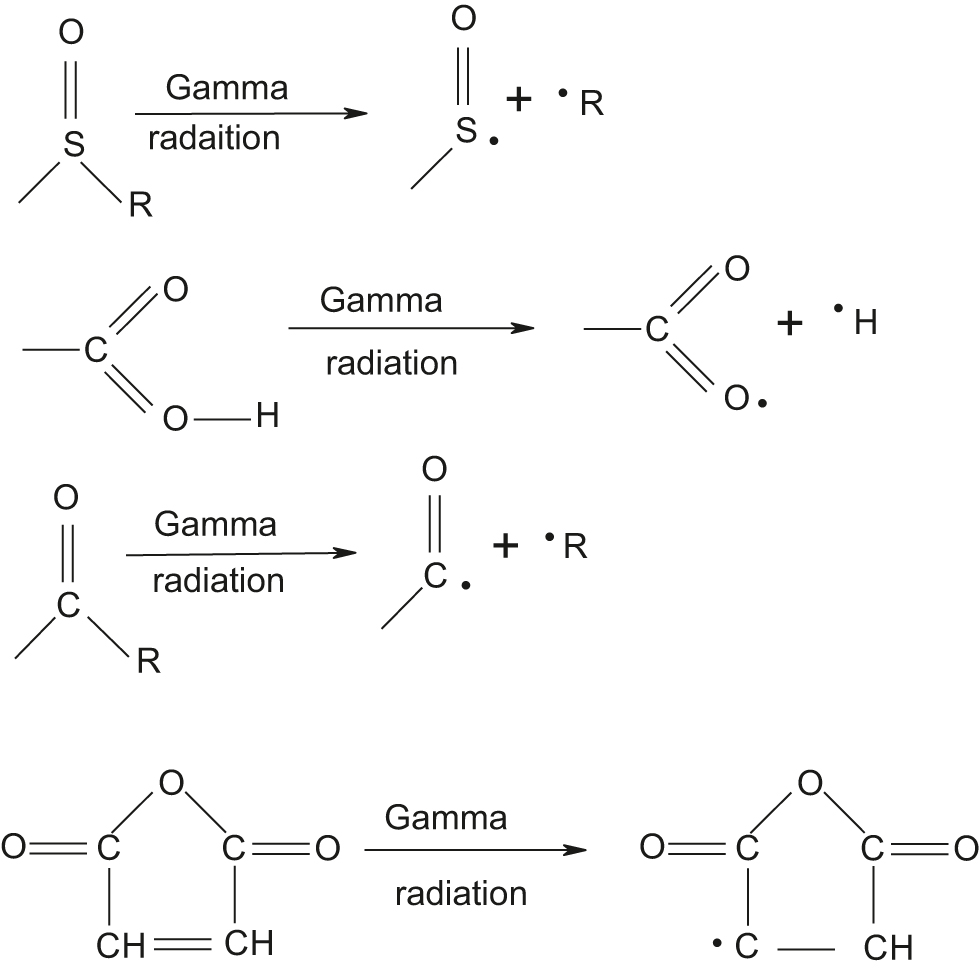

Irradiation was performed at the National Centre for Radiation Research and Technology (NCRRT), Egyptian Atomic Energy Authority (EAEA), Cairo, Egypt. The OB were subjected to gamma radiation, gamma cell type 4000 A, India, at ambient air, humidity and room temperature with the radiation dose 25 kGy at a dose rate of 1.3 kGy/h to obtain irradiated oxidized bitumen (IOB). The mechanism of free radicals formation by gamma radiation on the functional groups of oxidized bitumen represented as follows:

2.4 Characterization techniques

2.4.1 Mechanical properties

The mechanical properties, including tensile strength (TS) and elongation at break were tested at room temperature using Mecmesim; Model 10-I, U.K, using ASTM 412 was followed to measure the mechanical parameters. The mechanical parameters were examined in triplets.

2.4.2 Cross-link density of rubber networks calculated from mechanical data

Measurement of stress-strain response gives an easy method for estimation of the cross-link density of polymer networks. According to the kinetic theory of rubber elasticity [13], the stress–strain cross-link density relationship is given by the following equation:

where, σ is the true stress, σo is the stress, λ is the extension ratio, Ge is a parameter depends on the degree of cross-linking density. The relation between (λ2−λ−1) and true stress (σ) for rubber blends were plotted as straight lines; hence Ge is the slope of this straight line and related to Mc, which is the average molecular weight between two cross-links, by the following equation:

Cross-linking density is calculated depending on Mc and calculated as follows

2.4.3 Compression set

Compression set was carried out according to ASTM D 395-85 on standard test specimen of cylindrical shape of 16 ± 0.1 mm diameter and 6 ± 0.5 mm thicknesses. The test specimen shall be placed between the plates of the compression device with the spacers on each side of it, allowing sufficient clearance for bulging of the rubber when compressed. The bolts shall be tightened so that the plates are drawn together uniformly until they are in contact with the spacers. Then the assembled compression device shall be placed in oven at 70 °C for 22 h. After that, the device shall be taken from the oven and the test specimen removed immediately and allowed to cool for 30 min, after this rest time the final thickness shall be measured by an electronic digital caliber with 0.01 mm accuracy. The compression set is defined as

where, to = the original thickness of the sample; t1 = the thickness of the sample after removed from the clamp; and ts = thickness of the spacer bar used.

2.4.4 Thermogravimetric analysis

Thermogravimetric analysis (TGA) was performed with a Shimadzu TGA-50 system, Japan, within the temperature range of 20–600 °C at a rate of 20 °C/min, under controlled dry nitrogen flow of 20 ml·min−1.

2.4.5 Chemical resistance

This method is carried out according to ANSI/ASTM D543-67. The chemicals used in this test were in the technical grade. All solutions were made with freshly prepared distilled water. Specified concentrations are on a weight percent or specific gravity basis. The standard reagents were as follows: Distilled water (freshly prepared), Acid (H2SO4 10%), Solvents (Acetone), Petrol (Kerosene).

2.4.6 Sound proofing test

It is measured by using a special apparatus, precision integration sound level (Bruel and Kjaer, TYPE 2236), Denmark, A sound proofing box (60 × 20 × 60 cm). The final foam sample noise sources in addition to the microphone were put at equal distances from both sides of the sample. The sound pressure level (SPL) was measured for every sample by the sound level meter at frequency of 31.5 Hz and constant noise level. Sound proofing performance was calculated from the following equation:

where, IL is insertion loss (Sound reduction), SPL air is sound pressure level without material barrier, SPL material is sound pressure level with material barrier

2.4.7 Vibration damping test

The vibration damping performance is generally represented by the velocity level (VL). The test method of the velocity levels mainly encounters attaching the sample. The velocity level is measured by using the Integrating Vibration Meter, Type 2513 (Denmark) for all samples with the same vibrator source. The vibration damping performance is represented in general by the loss factor which is calculated from the following equation:

3 Results and discussion

3.1 Physico-mechanical parameters

3.1.1 Crosslinking density

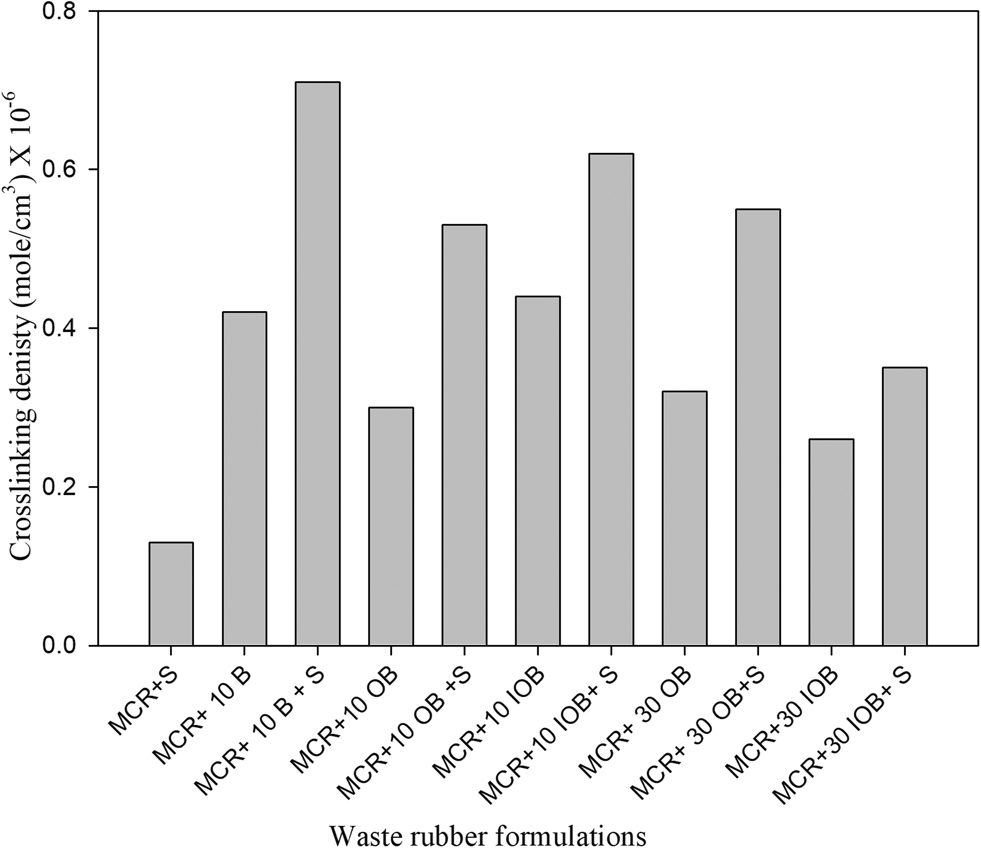

Figure 2 represented the crosslinking density of the MCR and its formulations with bitumen and oxidized bitumen. It is clear that MCR have the lowest value of crosslinking density than all others formulations. Thereby, in general addition of both bitumen and oxidized bitumen increased the values of MCR density. On the other hand MCR/10B/S, MCR/10 OB/S, MCR/10 I OB/S and MCR/30 OB/S have the largest values than the others. Consequently, presence of sulfur with bitumen and oxidized bitumen inside the matrix have been elevated the crosslinking density especially at 10 phr of both. Furthermore, irradiation of 10 OB has been improved the crosslinking density values of polymer matrix from 0.3 to 0.44 for 10 IOB and to 0.62 for 10 IOB/S. Thereby, there is a synergistic effect of radiation treatment and sulfur on the crosslinking density values of modified waste rubber. This result demonstrated that elemental sulfur is an excellent radical scavenger for radicals which produced during radiolysis or chain propagation.

Crosslinking density of modified crumb rubber loaded with bitumen and oxidized bitumen formulations.

3.1.2 Mechanical parameters

Different mechanical parameters including tensile strength, elongation at break, toughness and compression set of polymer formulations are shown in Table 3. It is obvious that MCR/10 IOB/S blend has the largest value of TS than the other compositions. In which TS value of this blend may be about eight times greater than the original polymer MCR/S. Followed by it, blend DWR/10 IOB has TS value larger than original rubber about five times. This result proved the role of irradiated OB which improved the tensile texture of MCR. Moreover it was showed the advantage of radiation-initiated cracking which allowed to the new bond formation especially in a presence of OB and sulfur that work as radical scavenger. On the other hand, either MCR/10 IOB/S or MCR/10 IOB blend were recorded the largest value of elongation at break. Thereby, OB acts as a plasticizer of polymer and also irradiation dose will be participated in crystallization of MCR particles.

Mechanical parameters of unirradiated and irradiated blends of modified crumb rubber with different ratios of bitumen and oxidized bitumen.

| Blend formulations | Mechanical parameters | |||

|---|---|---|---|---|

| TS (MPa) | Elongation (%) | Toughness (J·m−3) | Compression set (%) | |

| MCR + S | 0.95 (±0.02) | 178 (±3.0) | 72.1 (±0.7) | 42.7 (±0.9) |

| MCR + 10 B | 0.25 (±0.01) | 157 (±1.8) | 25.3 (±0.2) | 33.5 (±0.3) |

| MCR + 10 B + S | 0.6 (±0.01) | 204 (±4.0) | 58.2 (±0.2) | 48.1 (±0.2) |

| MCR + 10 OB | 0.16 (±0.01) | 125 (±1.3) | 15.3 (±0.9) | 58.2 (±0.4) |

| MCR + 10 OB + S | 0.34 (±0.05) | 148 (±1.5) | 25.3 (±0.7) | 65.3 (±0.4) |

| MCR + 10 IOB | 4.5 (±0.2) | 278 (±2.0) | 1198 (±20.5) | 44.9 (±0.2) |

| MCR + 10 IOB + S | 7.6 (±0.3) | 361 (±3.6) | 1448 (±18.6) | 48.9 (±0.6) |

| MCR + 30 OB | 0.16 (±0.02) | 76 (±0.8) | 15.3 (±0.8) | 57.7 (±0.5) |

| MCR + 30 OB + S | 0.47 (±0.01) | 226 (±2.6) | 59.4 (±0.2) | 73.6 (±0.8) |

| MCR + 30 IOB | 1.2 (±0.05) | 89 (±1.1) | 89.7 ±(0.3) | 72.3 (±1.0) |

| MCR + 30 IOB + S | 1.4 (±0.03) | 79 (±1.3) | 83.4 (±0.5) | 82.4 (±0.9) |

Toughening data were revealed the same last results which as of TS and elongation at break. In which two blends form MCR/10 IOB/S and MCR/10 IOB were recorded the differences huge in their values between them and other blend formulations. Also, the increase in toughness of MCR/10 IOB/S was larger than that of MCR/10 IOB. Again, the synergistic effect of both sulfur and irradiation treatment in the presence of OB enhanced the MCR texture and increase their toughness. Also Table 3 represented the compression set values of various prepared blends. There are variable results between them but MCR which loaded by both irradiated OB and sulfur have been recorded the largest data. Thereby, in general the presence of both sulfur and irradiated OB dramatically improved the mechanical properties of MCR texture.

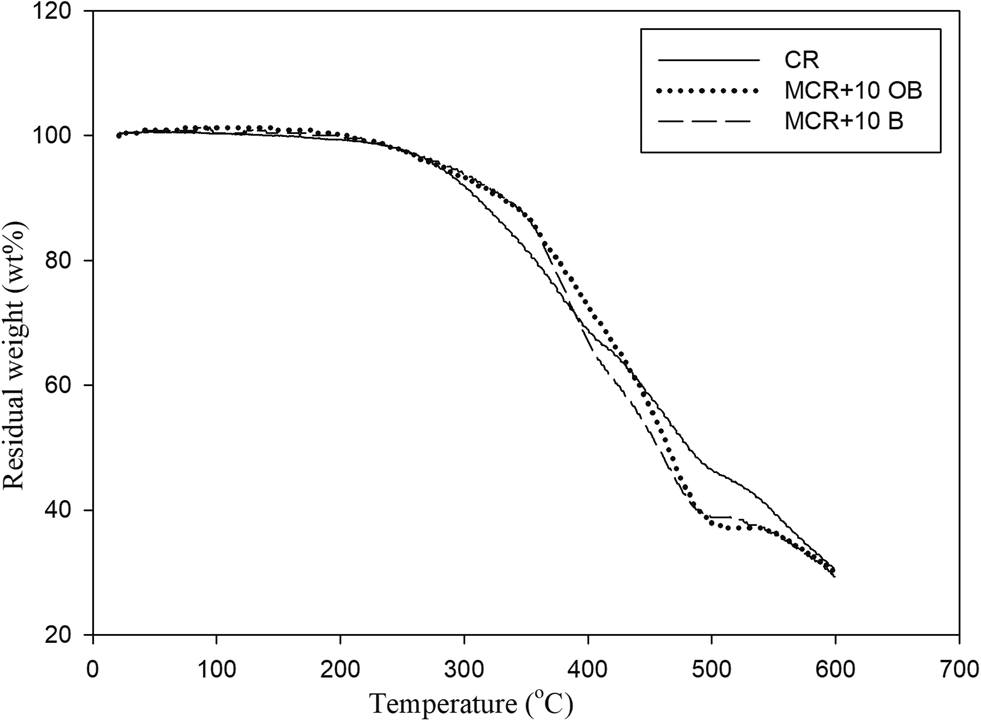

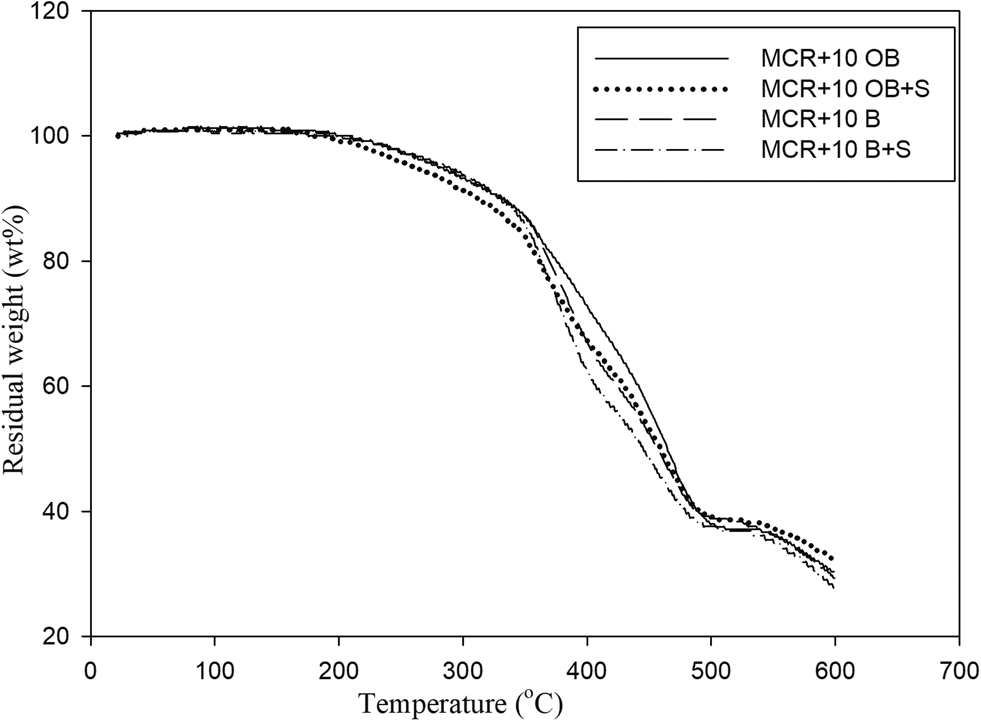

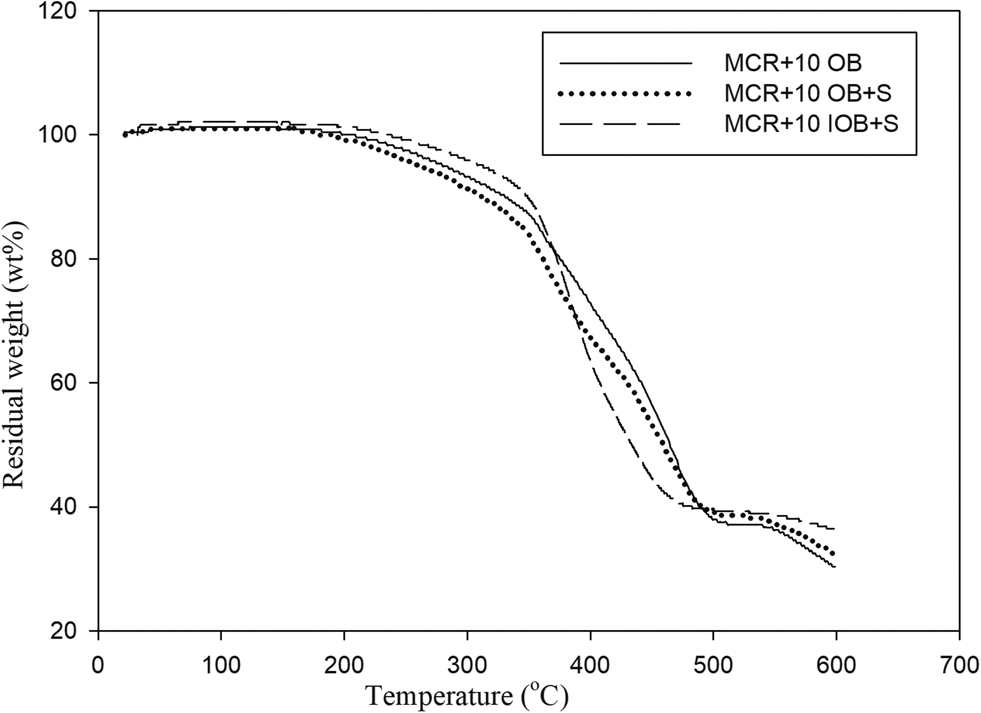

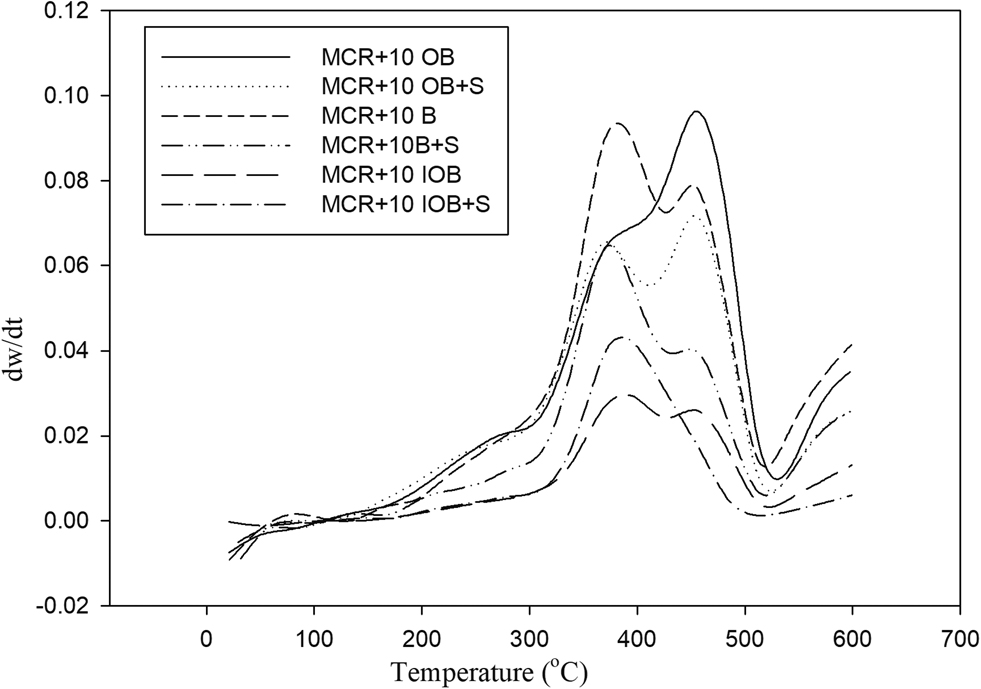

3.1.3 Thermal stability

Thermal behavior of different blend formulations was shown in Figures 3–6 and Table 4. It is clear that by the adding of bitumen and oxidized bitumen, all the samples have been revealed improvements in the thermal stability on the first stage of the mass loss decomposition, Tm10 and Tm25. Hence, both bitumen and oxidized bitumen prevented the elaboration of low molecular weight compounds which present inside waste rubber and then enhanced it’s thermally stability. The derivative thermogravimetric curves represent the weight loss dependences for the tested samples as a function of temperature is illustrated in Figure 6. It is observed that the samples degrade in two steps with two observed peaks. This may be attributed to the various components of waste rubber and the presence of both bitumen and oxidized bitumen as well. On the other hand, Figures 3–5 were demonstrated that the compound MCR/10 OB shows superior thermal stability when compared with the others, in which its curve peak near to Tmax at 460 °C. Also dw/dt of this compound recorded the largest value. This means that the changes in weight of MCR/10 OB with temperature were the best and more thermally stable.

Thermographemetric analysis of crumb rubber and modified crumb rubber formulations.

Thermographemetric analysis of modified crumb rubber with bitumen and oxidized bitumen.

Thermographemetric analysis of modified crumb rubber with oxidized and irradiated oxidized bitumen.

Derivative thermographemetric curves of modified crumb rubber with bitumen and oxidized bitumen.

Thermographemetric analysis of different blend formulations of modified crumb rubber with bitumen and oxidized bitumen.

| Blend formulations | Tm10 (oC) | Tm25 (oC) | Tm50 (oC) | Charred residue at 600 °C |

|---|---|---|---|---|

| CR | 310 (±1.5) | 375 (±2.7) | 480 (±3.5) | 30.4 (±1.0) |

| MCR + 10 B | 334 (±2.2) | 381 (±3.1) | 457 (±2.9) | 29.3 (±1.2) |

| MCR + 10 B + S | 331 (±2.4) | 373 (±3.2) | 445 (±3.6) | 27.6 (±0.9) |

| MCR + 10 OB | 330 (±3.1) | 392 (±2.6) | 464 (±3.1) | 30.4 (±1.1) |

| MCR + 10 OB + S | 311 (±1.8) | 375 (±3.1) | 459 (±2.7) | 32.3 (±1.4) |

| MCR + 10 IOB + S | 349 (±2.7) | 381 (±3.3) | 434 (±2.8) | 36.1 ±(1.5) |

3.2 Applications

3.2.1 Chemical resistance behavior

All the samples formulation without exception either MCR or their blends with bitumen or oxidized bitumen revealed unresponsive to different types of chemical media. In which, after three weeks, all compositions tried were resistant to water, acetone, 10% H2SO4 and kerosene and don’t reveal any physical visual changes. Thereby, complete chemical reaction of CR with chemical ingredients and in turn to enhancement with both bitumen and oxidized bitumen have been presented inside the matrix. We can say that accelerators TBBS, ZMBT, MBT and TMTM; activators zinc oxide and stearic acid; and zinc salts of fatty acids and sulfur which were used to produce the reclaimed rubber is suitable for use in producing high-grade rubber products without adding a binder, or for combining with fresh rubber compounds to produce high-specification rubber products.

3.2.2 Velocity level properties

Vibration tests which reflecting the velocity level of the prepared samples was represented in Table 5. When loss factor is large the sample is the best and used in forbidden the vibration. MCR sample without any additives recorded the highest value of the vibration damping level at 31.5 Hz. In confirming result, rubber formulation MCR/10 IOB was recorded the higher loss factor than the other samples. Hence, presence of both oxidized bitumen and irradiation dose have the synergistic effect on the performance of CR in pavements applications.

Velocity level at 31.5 Hz for unirradiated and irradiated blends of modified crumb rubber with different ratios of bitumen and oxidized bitumen.

| Blend formulations | Vibration test (velocity level), dB | ||

|---|---|---|---|

| Air | Material | Loss factor | |

| MCR + S | 140 (±2.5) | 122.5 (±2.0) | 17.5 (±1.8) |

| MCR + 10 B | 127 (±2.3) | 13 (±1.0) | |

| MCR + 10 B + S | 125.5 (±2.3) | 14.5 (±1.7) | |

| MCR + 10 OB | 123 (±2.7) | 17 (±0.8) | |

| MCR + 10 OB + S | 124 (±2.7) | 16 (±1.2) | |

| MCR + 10 IOB | 111 (±1.3) | 29 (±1.5) | |

| MCR + 10 IOB + S | 127 (±2.4) | 13 (±0.6) | |

| MCR + 30 OB | 126 (±2.1) | 14 (±0.7) | |

| MCR + 30 OB + S | 130 (±2.0) | 10 (±1.0) | |

| MCR + 30 IOB | 122 (±1.8) | 18 (±1.4) | |

| MCR + 30 IOB + S | 126 (±1.9) | 14 (±0.8) | |

3.2.3 Sound pressure level

Sound proofing performance is one of the most important factors in the evaluation of sound proofing materials in many applications such as (automobiles, building construction, etc.). Measurement of sound pressure level at 31.5 Hz of various prepared samples was shown in Table 6. Firstly, MCR sample without any additives recorded the highest value of sound pressure level at 31.5 Hz; whereas MCR/10 OB/S was the lowest. On the other hand, it is obvious that all irradiated rubber formulations have low sound pressure level than the others. Consequently, the triple effect of both oxidized bitumen, sulfur and gamma radiation improved the sound pressure level of MCR samples. Therefore, it is possible through these modifications that we use the MCR better in paving the roads.

Sound pressure level at 31.5 Hz for unirradiated and irradiated blends of modified crumb rubber with different ratios of bitumen and oxidized bitumen.

| Blend formulations | Sound test (sound pressure level SPL, dB) | ||

|---|---|---|---|

| Without additives | With additives | Sound reduction | |

| MCR + S | 120 (±1.8) | 100 (±2.2) | 20 (±0.8) |

| MCR + 10 B | 101 (±2.4) | 19 (±1.0) | |

| MCR + 10 B + S | 96 (±1.6) | 24 (±1.3) | |

| MCR + 10 OB | 98 (±1.5) | 22 (±1.1) | |

| MCR + 10 OB + S | 95 (±1.7) | 25 (±1.6) | |

| MCR + 10 IOB | 107 (±2.3) | 13 (±0.9) | |

| MCR + 10 IOB + S | 99 (±1.6) | 21 (±1.3) | |

| MCR + 30 OB | 102 (±2.0) | 18 (±1.6) | |

| MCR + 30 OB + S | 97 (±1.3) | 23 (±1.2) | |

| MCR + 30 IOB | 105 (±2.5) | 15 (±1.0) | |

| MCR + 30 IOB + S | 103 (±2.1) | 17 (±1.2) | |

4 Conclusions

This article evaluates the effect of oxidized bitumen on the MCR in the presence or absence of sulfur and irradiation for various applications. The concluded data proved the following result: Presence of sulfur with bitumen or oxidized bitumen inside the texture of MCR has been elevated its crosslinking density especially at 10 phr. Furthermore, irradiation of 10 phr OB has been improved the crosslinking density values of polymer matrix. TS value of MCR/10 IOB/S may be about eight times greater than the original polymer MCR/S, followed by it; blend DWR/10 IOB has TS value larger than original rubber about five times. Either MCR/10 IOB/S or MCR/10 IOB blend were recorded the largest value of elongation at break. OB acts as a plasticizer of polymer and also irradiation dose will be participated in the linkage of MCR particles. The synergistic effect of both sulfur and irradiation treatment in the presence of OB enhanced the MCR texture and increase their toughness. Blended of bitumen and oxidized bitumen with MCR have been revealed improvements in the thermal stability on the first stage of the mass loss decomposition, Tm10 and Tm25. After three weeks tested sample in various media, water, acetone, 10% H2SO4 and kerosene don’t affected by any physical visual changes. Rubber formulation, MCR/10 IOB was recorded less vibration damping than the other samples. The triple effect of oxidized bitumen, sulfur and gamma radiation improved the sound pressure level of MCR samples.

Author contribution: All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

Research funding: None declared.

Conflict of interest statement: The authors declare no conflicts of interest regarding this article.

References

1. Ghuge, S., Tambe, N., sahane, V. T., Sonawane, V. A. A study on the properties of bitumen & aggregate by replacing waste tyre rubber with bitumen & aggregate construction of road pavement. Inter. Res. J. Eng. Tech. (IRJET) 2018, 5, 60–64.Search in Google Scholar

2. Le Guern, M., Chailleux, E., Farcas, F., Dreessen, S., Mabille, I. Physico-chemical analysis of five hard bitumens: identification of chemical species and molecular organization before and after artificial aging. Fuel 2010, 89, 3330–3339; https://doi.org/10.1016/j.fuel.2010.04.035.Search in Google Scholar

3. Mouillet, V., Farcas, F., Besson, S. Ageing by UV radiation of an elastomer modified bitumen. Fuel 2008, 87, 2408–2419; https://doi.org/10.1016/j.fuel.2008.02.008.Search in Google Scholar

4. Colbert, B., You, Z. P. Viscoelastic fatigue damage properties of asphalt mixture with different aging degrees. Construct. Build. Mater. 2012, 26, 552–557; https://doi.org/10.1016/j.conbuildmat.2011.06.057.Search in Google Scholar

5. Sugano, M., Kajita, J., Ochiai, M., Takagi, N., Iwai, S., Hirano, K. Laboratory evaluation of rejuvenation effect of reactive rejuvenator on aged SBS modified bitumen. J. Chem. Eng. 2011, 176, 231–233; https://doi.org/10.1617/s11527-017-1106-7.Search in Google Scholar

6. Navarro, F. J., Partal, P., Martínez-Boza, F. J., Gallegos, C. Novel recycled polyethylene/ground tire rubber/bitumen blends for use in roofing applications: thermo-mechanical properties. Polym. Test. 2010, 29, 588–595; https://doi.org/10.1016/j.polymertesting.2010.03.010.Search in Google Scholar

7. Zhang, F., Yu, J. Y., Wu, S. P. Effect of ageing on rheological properties of storage-stable SBS/sulfur-modified asphalts. J. Hazard Mater. 2010, 182, 507–517; https://doi.org/10.1016/j.jhazmat.2010.06.061.Search in Google Scholar

8. RABIT (RAHA BITUMEN) Company 2017, published on September 24 www.rahabitumen.com.Search in Google Scholar

9. Ibrahim, I. M., Faty, E. S., El-Shafie, M., Elnaggar, M. Y. Impact of incorporated gamma irradiated crumb rubber on the short-term aging resistance and rheological properties of asphalt binder. Construct. Build. Mater. 2015, 81, 42–46; https://doi.org/10.1016/j.conbuildmat.2015.01.015.Search in Google Scholar

10. Fathy, E. S., Saleh, H. H., Elnaggar, M. Y., Ali, Z. I. Gamma irradiation of (styrene butadiene rubber)/(devulcanized waste rubber) blends modified by organoclay. J. Vin. Add. Technol. 2018, 24, 50–57; https://doi.org/10.1002/vnl.21524.Search in Google Scholar

11. Fathy, E. S., Elnaggar, M. Y., Raslan, H. A. Thermoplastic elastomer based on waste polyethylene/waste rubber containing activated carbon black: impact of gamma irradiation. J. Vin. Add. Technol. 2019, 25, 166–173; https://doi.org/10.1002/vnl.21675.Search in Google Scholar

12. Hassan, M. M., Badway, N. A., Elnaggar, M. Y., Hegazy, E. A. Thermo-mechanical properties of devulcanized rubber/high crystalline polypropylene blends modified by ionizing radiation. J. Ind. Eng. Chem. 2013, 19, 1241–1250; https://doi.org/10.1016/j.jiec.2012.12.024.Search in Google Scholar

13. Zang, Y.-H., Muller, R., Froelich, D. Determination of crosslinking density of polymer networks by mechanical data in simple extension and by swelling degree at equilibrium. Polymer 1989, 30, 2060–2062; https://doi.org/10.1016/0032-3861(89)90294-2.Search in Google Scholar

© 2020 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Original Papers

- Validation of nuclear reaction models for incident α-particles

- Efficient removal of radiocobalt and manganese from their binary aqueous solutions by batch adsorption process using PAN/HDTMA/KCuHCF composite

- Radioiodination and biological evaluation of irbesartan as a tracer for cardiac imaging

- Effect of gamma irradiation and oxidized bitumen on the performance of the modified crumb rubber for various applications

- CdTe quantum dots on gold-198 nano particles: introducing a novel theranostic agent

- Dosimetry and methodology of gamma irradiation for degradation studies on solvent extraction systems

Articles in the same Issue

- Frontmatter

- Original Papers

- Validation of nuclear reaction models for incident α-particles

- Efficient removal of radiocobalt and manganese from their binary aqueous solutions by batch adsorption process using PAN/HDTMA/KCuHCF composite

- Radioiodination and biological evaluation of irbesartan as a tracer for cardiac imaging

- Effect of gamma irradiation and oxidized bitumen on the performance of the modified crumb rubber for various applications

- CdTe quantum dots on gold-198 nano particles: introducing a novel theranostic agent

- Dosimetry and methodology of gamma irradiation for degradation studies on solvent extraction systems