Synthesis and characterization of size controlled bimetallic nanosponges

-

Dong Wang

Dr Dong Wang studied chemical engineering at TU Wuhan for his B.Sc., and materials science at RWTH Aachen University for his M.Sc. He obtained his PhD from Karlsruhe Institute of Technology in 2007. He conducted his two years PostDoc research at Hannover University, and then has moved to TU Ilmenau. In 2016, he finished the Habilitation at TU Ilmenau, and currently is working as Privatdozent there. His research interest is focused on tailored nanostructures and nanomaterials for photonic and energy applications.and Peter Schaaf

Professor Dr Peter Schaaf studied material physics at Saarland University and obtained his diploma degree there in 1988. This is followed by earning his doctoral degree (PhD) in 1991 with honors at the same university. After that, he moved to Göttingen University for a PostDoc position in 1992. In 1995, he got an assistant professorship and was promoted to associate professor there in 1999. He accomplished habilitation at Göttingen University in 1999. Since 2008, he is full professor at TU Ilmenau. Currently, he is chair of Materials of Electrical Engineering and Electronics in the Institute of Materials Science and Engineering and the Institute of Micro and Nanotechnologies MacroNano® and dean of the Department of Electrical Engineering and Information Technology of TU Ilmenau. His research interests lie in nanomaterials, electronic materials, nanotechnologies, thin films, functional materials and materials analysis.

Abstract

Metallic and bimetallic nanosponges with well-defined size and form have attracted increasing attention due to their unique structural properties and their potential for many applications. In this chapter, the recently developed methods for the synthesis and preparation of metallic and bimetallic nanosponges are presented. These methods can be mainly cataloged in two groups: dealloying-based methods and reduction reaction-based methods. Different topographical reconstruction methods for the investigation of their structural properties are then reviewed briefly. The optical properties of the metallic nanosponges are clearly different from those of the solid counterparts due to the tailored disordered structure. The recent advances in the exploration of the distinct linear and non-linear optical properties of the nanosponges are summarized.

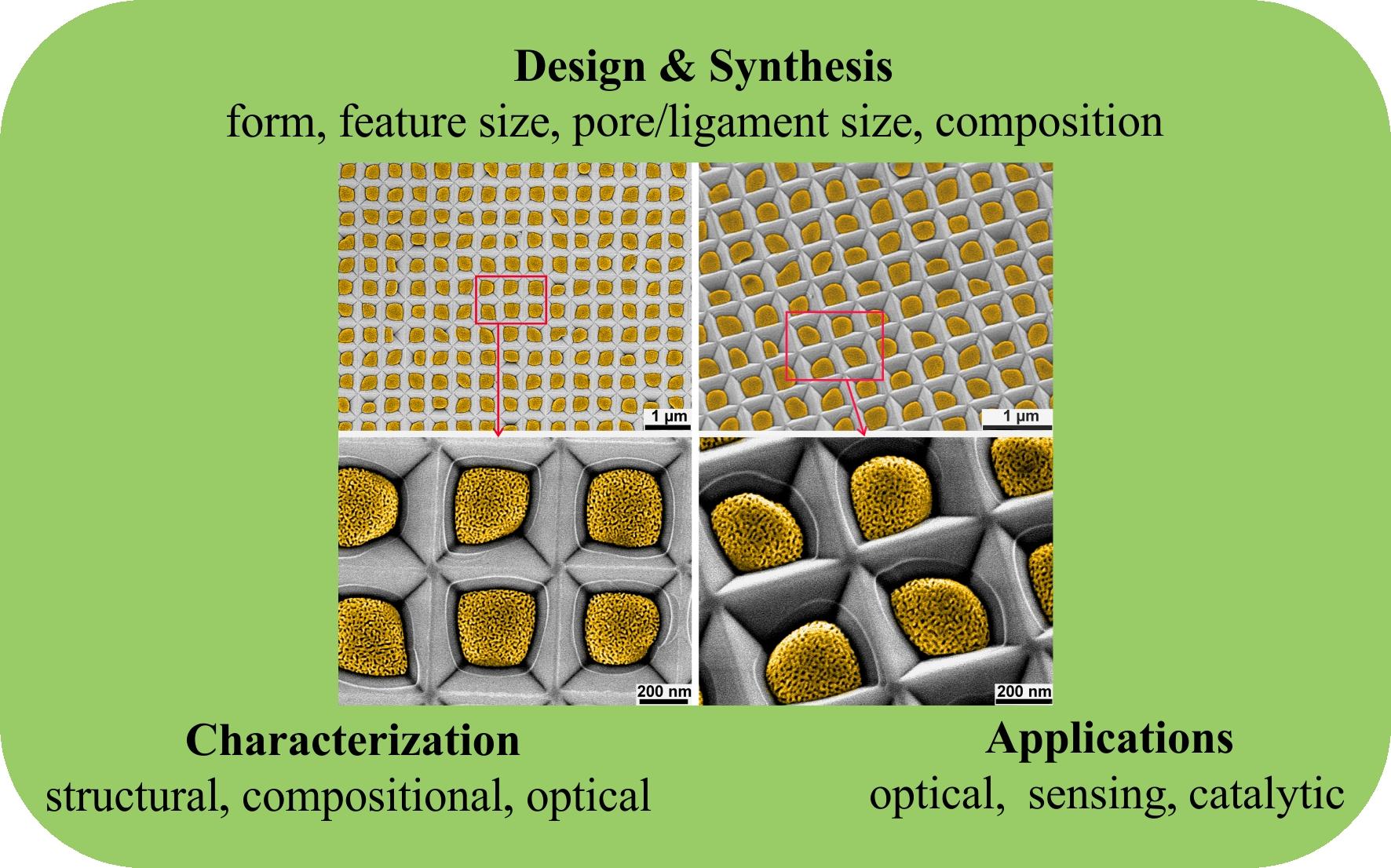

Graphical Abstract:

About the authors

Dr Dong Wang studied chemical engineering at TU Wuhan for his B.Sc., and materials science at RWTH Aachen University for his M.Sc. He obtained his PhD from Karlsruhe Institute of Technology in 2007. He conducted his two years PostDoc research at Hannover University, and then has moved to TU Ilmenau. In 2016, he finished the Habilitation at TU Ilmenau, and currently is working as Privatdozent there. His research interest is focused on tailored nanostructures and nanomaterials for photonic and energy applications.

Professor Dr Peter Schaaf studied material physics at Saarland University and obtained his diploma degree there in 1988. This is followed by earning his doctoral degree (PhD) in 1991 with honors at the same university. After that, he moved to Göttingen University for a PostDoc position in 1992. In 1995, he got an assistant professorship and was promoted to associate professor there in 1999. He accomplished habilitation at Göttingen University in 1999. Since 2008, he is full professor at TU Ilmenau. Currently, he is chair of Materials of Electrical Engineering and Electronics in the Institute of Materials Science and Engineering and the Institute of Micro and Nanotechnologies MacroNano® and dean of the Department of Electrical Engineering and Information Technology of TU Ilmenau. His research interests lie in nanomaterials, electronic materials, nanotechnologies, thin films, functional materials and materials analysis.

References

[1] Morriss RH, Collins LF. Optical properties of multilayer colloids. J Chem Phys. 1964;41:3357–63.10.1063/1.1725733Search in Google Scholar

[2] Sinfelt JH. Catalysis by alloys and bimetallic clusters. Acc Chem Res. 1977;10:15–20.10.1021/ar50109a003Search in Google Scholar

[3] Gilroy KD, Ruditskiy A, Peng H-C, Qin D, Xia Y. Bimetallic nanocrystals: syntheses, properties, and applications. Chem Rev. 2016;116:10414–72.10.1021/acs.chemrev.6b00211Search in Google Scholar PubMed

[4] Ding Y, Chen M, Erlebacher J. Metallic mesoporous nanocomposites for electrocatalysis. J Am Chem Soc. 2004;126:6876–7.10.1021/ja0320119Search in Google Scholar PubMed

[5] Wittstock A, Biener J, Baumer M. Nanoporous gold: a new material for catalytic and sensor applications. Phys Chem Chem Phys. 2010;12:12919–30.10.1039/c0cp00757aSearch in Google Scholar PubMed

[6] Ding Y, Chen M. Nanoporous metals for catalytic and optical applications. MRS Bulletin. 2009;34:569–76.10.1557/mrs2009.156Search in Google Scholar

[7] Zielasek V, Jürgens B, Schulz C, Biener J, Biener MM, Hamza AV, et al. Gold catalysts: nanoporous gold foams. Angew Chem Int Ed. 2006;45:8241–4.10.1002/anie.200602484Search in Google Scholar PubMed

[8] Luc W, Jiao F. Nanoporous metals as electrocatalysts: state-of-the-art, opportunities, and challenges. ACS Catal. 2017;7:5856–61.10.1021/acscatal.7b01803Search in Google Scholar

[9] Stenner C, Shao L-H, Mameka N, Weissmüller J. Piezoelectric gold: strong charge-load response in a metal-based hybrid nanomaterial. Adv Funct Mater. 2016;26:5174–81.10.1002/adfm.201600938Search in Google Scholar

[10] Forty AJ. Corrosion micromorphology of noble metal alloys and depletion gilding. Nature. 1979;282:597–8.10.1038/282597a0Search in Google Scholar

[11] Erlebacher J, Aziz MJ, Karma A, Dimitrov N, Sieradzki K. Evolution of nanoporosity in dealloying. Nature. 2001;410:450–3.10.1038/35068529Search in Google Scholar PubMed

[12] Erlebacher J. An atomistic description of dealloying - Porosity evolution, the critical potential, and rate-limiting behavior. J Electrochem Soc. 2004;151:C614–26.10.1149/1.1784820Search in Google Scholar

[13] Ding Y, Kim YJ, Erlebacher J. Nanoporous gold leaf: “ancient technology”/advanced material. Adv Mater. 2004;16:1897–900.10.1002/adma.200400792Search in Google Scholar

[14] Chen L, Guo H, Fujita T, Hirata A, Zhang W, Inoue A, et al. Nanoporous PdNi bimetallic catalyst with enhanced electrocatalytic performances for electro-oxidation and oxygen reduction reactions. Adv Funct Mater. 2011;21:4364–70.10.1002/adfm.201101227Search in Google Scholar

[15] Chen LY, Chen N, Hou Y, Wang ZC, Lv SH, Fujita T, et al. Geometrically controlled nanoporous pdau bimetallic catalysts with tunable Pd/Au ratio for direct ethanol fuel cells. ACS Catal. 2013;3:1220–30.10.1021/cs400135kSearch in Google Scholar

[16] Chen LY, Fujita T, Ding Y, Chen MW. A three-dimensional gold-decorated nanoporous copper core–shell composite for electrocatalysis and nonenzymatic biosensing. Adv Funct Mater. 2010;20:2279–85.10.1002/adfm.201000326Search in Google Scholar

[17] Chen LY, Guo XW, Han JH, Liu P, Xu XD, Hirata A, et al. Nanoporous metal/oxide hybrid materials for rechargeable lithium–oxygen batteries. J Mater Chem A. 2015;3:3620–6.10.1039/C4TA05738DSearch in Google Scholar

[18] Ge X, Chen L, Kang J, Fujita T, Hirata A, Zhang W, et al. A core-shell nanoporous Pt-Cu catalyst with tunable composition and high catalytic activity. Adv Funct Mater. 2013;23:4156–62.10.1002/adfm.201300114Search in Google Scholar

[19] Kang J, Hirata A, Qiu H-J, Chen L, Ge X, Fujita T, et al. Self-grown oxy-hydroxide@ nanoporous metal electrode for high-performance supercapacitors. Adv Mater. 2014;26:269–72.10.1002/adma.201302975Search in Google Scholar PubMed

[20] Lang X, Zhang L, Fujita T, Ding Y, Chen M. Three-dimensional bicontinuous nanoporous Au/polyaniline hybrid films for high-performance electrochemical supercapacitors. J Power Sources. 2012;197:325–9.10.1016/j.jpowsour.2011.09.006Search in Google Scholar

[21] Lang XY, Guo H, Chen LY, Kudo A, Yu JS, Zhang W, et al. Novel nanoporous Au−Pd alloy with high catalytic activity and excellent electrochemical stability. J Physl Chem C. 2010;114:2600–3.10.1021/jp907682xSearch in Google Scholar

[22] Qiu HJ, Shen X, Wang JQ, Hirata A, Fujita T, Wang Y, et al. Aligned nanoporous Pt–cu bimetallic microwires with high catalytic activity toward methanol electrooxidation. ACS Catal. 2015;5:3779–85.10.1021/acscatal.5b00073Search in Google Scholar

[23] Qiu HJ, Wang JQ, Liu P, Wang Y, Chen MW. Hierarchical nanoporous metal/metal-oxide composite by dealloying metallic glass for high-performance energy storage. Corros Sci. 2015;96:196–202.10.1016/j.corsci.2015.04.003Search in Google Scholar

[24] Wang K, Kobler A, Kübel C, Jelitto H, Schneider G, Weissmüller J. Nanoporous-gold-based composites: toward tensile ductility. Npg Asia Mater. 2015;7:e187.10.1038/am.2015.58Search in Google Scholar

[25] Wang K, Weissmüller J. Composites of nanoporous gold and polymer. Adv Mater. 2013;25:1280–4.10.1002/adma.201203740Search in Google Scholar PubMed PubMed Central

[26] Xu C, Wang R, Chen M, Zhang Y, Ding Y. Dealloying to nanoporous Au/Pt alloys and their structure sensitive electrocatalytic properties. Phys Chem Chem Phys. 2010;12:239–46.10.1039/B917788DSearch in Google Scholar PubMed

[27] Malgras V, Ataee-Esfahani H, Wang H, Jiang B, Li C, Wu KC, et al. Nanoarchitectures for mesoporous metals. Adv Mater. 2016;28:993–1010.10.1002/adma.201502593Search in Google Scholar PubMed

[28] Wang D, Schaaf P. Nanoporous gold nanoparticles. J Mater Chem. 2012;22:5344–8.10.1039/c2jm15727fSearch in Google Scholar

[29] Li X, Chen Q, McCue I, Snyder J, Crozier P, Erlebacher J, et al. Dealloying of noble-metal alloy nanoparticles. Nano Lett. 2014;14:2569–77.10.1021/nl500377gSearch in Google Scholar PubMed

[30] Qi J, Motwani P, Gheewala M, Brennan C, Wolfe JC, Shih W-C. Surface-enhanced Raman spectroscopy with monolithic nanoporous gold disk substrates. Nanoscale. 2013;5:4105–9.10.1039/c2nr33242fSearch in Google Scholar PubMed

[31] Santos GM, Zhao F, Zeng J, Shih W-C. Characterization of nanoporous gold disks for photothermal light harvesting and light-gated molecular release. Nanoscale. 2014;6:5718–24.10.1039/C4NR01266FSearch in Google Scholar PubMed

[32] Ji C, Searson PC. Synthesis and characterization of nanoporous gold nanowires. J Phys Chem B. 2003;107:4494–9.10.1021/jp0222200Search in Google Scholar

[33] Chauvin A, Delacôte C, Molina-Luna L, Duerrschnabel M, Boujtita M, Thiry D, et al. Planar arrays of nanoporous gold nanowires: when electrochemical dealloying meets nanopatterning. ACS Appl Mater Interfaces. 2016;8:6611–20.10.1021/acsami.5b11244Search in Google Scholar PubMed

[34] Shin T-Y, Yoo S-H, Park S. Gold nanotubes with a nanoporous wall: their ultrathin platinum coating and superior electrocatalytic activity toward methanol oxidation. Chem Mater. 2008;20:5682–6.10.1021/cm800859kSearch in Google Scholar

[35] Pedireddy S, Lee HK, Koh CS, Tan JM, Tjiu WW, Ling XY. Nanoporous gold bowls: a kinetic approach to control open shell structures and size-tunable lattice strain for electrocatalytic applications. Small. 2016;12:4531–40.10.1002/smll.201601371Search in Google Scholar PubMed

[36] Vidal C, Wang D, Schaaf P, Hrelescu C, Klar TA. Optical plasmons of individual gold nanosponges. ACS Photonics. 2015;2:1436–42.10.1021/acsphotonics.5b00281Search in Google Scholar PubMed PubMed Central

[37] Vidal C, Sivun D, Ziegler J, Wang D, Schaaf P, Hrelescu C, et al. Plasmonic horizon in gold nanosponges. Nano Lett. 2018;18:1269–73.10.1021/acs.nanolett.7b04875Search in Google Scholar PubMed

[38] Rao W, Wang D, Kups T, Baradács E, Parditka B, Erdélyi Z, et al. Nanoporous gold nanoparticles and Au/Al2O3 hybrid nanoparticles with large tunability of plasmonic properties. ACS Appl Mater Interfaces. 2017;9:6273–81.10.1021/acsami.6b13602Search in Google Scholar PubMed

[39] Hergert G, Vogelsang J, Schwarz F, Wang D, Kollmann H, Groß P, et al. Long-lived electron emission reveals localized plasmon modes in disordered nanosponge antennas. Light Sci Appl. 2017;6:e17075.10.1038/lsa.2017.75Search in Google Scholar PubMed PubMed Central

[40] Wang D, Schaaf P. Plasmonic nanosponges. Adv Phys: X. 2018;3:1456361.10.1080/23746149.2018.1456361Search in Google Scholar

[41] Arnob MM, Zhao F, Li J, Shih W-C. EBL-based fabrication and different modeling approaches for nanoporous gold nanodisks. ACS Photonics. 2017;4:1870–8.10.1021/acsphotonics.7b00239Search in Google Scholar

[42] Qi J, Zeng J, Zhao F, Lin SH, Raja B, Strych U, et al. Label-free, in situ SERS monitoring of individual DNA hybridization in microfluidics. Nanoscale. 2014;6:8521–6.10.1039/C4NR01951BSearch in Google Scholar PubMed

[43] Shih W-C, Santos GM, Zhao F, Zenasni O, Arnob MM. Simultaneous chemical and refractive index sensing in the 1–2.5 μm near-infrared wavelength range on nanoporous gold disks. Nano Lett. 2016;16:4641–7.10.1021/acs.nanolett.6b01959Search in Google Scholar PubMed

[44] Yan Y, Radu AI, Rao W, Wang H, Chen G, Weber K, et al. Mesoscopically bi-continuous Ag-Au hybrid nanosponges with tunable plasmon resonances as bottom-up substrates for surface-enhanced Raman spectroscopy. Chem Mater. 2016;28:7673–82.10.1021/acs.chemmater.6b02637Search in Google Scholar

[45] Liu K, Bai Y, Zhang L, Yang Z, Fan Q, Zheng H, et al. Porous Au–ag nanospheres with high-density and highly accessible hotspots for SERS analysis. Nano Lett. 2016;16:3675–81.10.1021/acs.nanolett.6b00868Search in Google Scholar PubMed

[46] Wittstock A, Biener J, Bäumer M. Nanoporous gold: from an ancient technology to a high-tech material. Cambridge,UK: RSC Publishing, 201210.1039/9781849735285Search in Google Scholar

[47] McCue I, Benn E, Gaskey B, Erlebacher J. Dealloying and dealloyed materials. Annu Rev Mater Res. 2016;46:263–86.10.1146/annurev-matsci-070115-031739Search in Google Scholar

[48] Collinson MM. Nanoporous gold electrodes and their applications in analytical chemistry. ISRN Anal Chem. 2013;2013:21.10.1155/2013/692484Search in Google Scholar

[49] Seker E, Reed M, Begley M. Nanoporous gold: fabrication, characterization, and applications. Materials. 2009;2:2188.10.3390/ma2042188Search in Google Scholar

[50] Li GG, Wang H. Dealloyed nanoporous gold catalysts: from macroscopic foams to nanoparticulate architectures. ChemNanoMat. 2018;4:897–908.10.1002/cnma.201800161Search in Google Scholar

[51] Wittstock A, Wichmann A, Biener J, Bäumer M. Nanoporous gold: a new gold catalyst with tunable properties. Faraday Discuss. 2011;152:87–98.10.1039/c1fd00022eSearch in Google Scholar PubMed

[52] Qiu HJ, Xu H-T, Liu L, Wang Y. Correlation of the structure and applications of dealloyed nanoporous metals in catalysis and energy conversion/storage. Nanoscale. 2015;7:386–400.10.1039/C4NR05778CSearch in Google Scholar PubMed

[53] Juarez T, Biener J, Weissmüller J, Hodge AM. Nanoporous metals with structural hierarchy: a review. Adv Eng Mater. 2017;19:1700389.10.1002/adem.201700389Search in Google Scholar

[54] Fujita T. Hierarchical nanoporous metals as a path toward the ultimate three-dimensional functionality. Sci Technol Adv Mater. 2017;18:724–40.10.1080/14686996.2017.1377047Search in Google Scholar PubMed PubMed Central

[55] Li H, Zhang A, Fang Z, Zeng J. Bimetallic nanoframes and nanoporous structures. In: Zhang Y-W, editor(s). Bimetallic Nanostructures. Weinheim: Wiley, 2018Search in Google Scholar

[56] Detsi E, Vuković Z, Punzhin S, Bronsveld PM, Onck PR, Hosson JT. Fine-tuning the feature size of nanoporous silver. CrystEngComm. 2012;14:5402–6.10.1039/c2ce25313eSearch in Google Scholar

[57] Zhang Z, Wang Y, Qi Z, Zhang W, Qin J, Frenzel J. Generalized fabrication of nanoporous metals (Au, Pd, Pt, Ag, and Cu) through chemical dealloying. J Physl Chem C. 2009;113:12629–36.10.1021/jp811445aSearch in Google Scholar

[58] Dursun A, Pugh DV, Corcoran SG. Dealloying of Ag-Au alloys in halide-containing electrolytes: affect on critical potential and pore size. J Electrochem Soc. 2003;150:B355–60.10.1149/1.1580824Search in Google Scholar

[59] Artymowicz DM, Erlebacher J, Newman RC. Relationship between the parting limit for de-alloying and a particular geometric high-density site percolation threshold. Philos Mag. 2009;89:1663–93.10.1080/14786430903025708Search in Google Scholar

[60] Parida S, Kramer D, Volkert CA, Ouml, Sner H, Erlebacher J, et al. Volume change during the formation of nanoporous gold by dealloying. Phys Rev Lett. 2006;97:035504.10.1103/PhysRevLett.97.035504Search in Google Scholar PubMed

[61] Bai Q, Wang Y, Zhang J, Ding Y, Peng Z, Zhang Z. Hierarchically nanoporous nickel-based actuators with giant reversible strain and ultrahigh work density. J Mater Chem C. 2016;4:45–52.10.1039/C5TC03048JSearch in Google Scholar

[62] Wada T, Yubuta K, Inoue A, Kato H. Dealloying by metallic melt. Mater Lett. 2011;65:1076–8.10.1016/j.matlet.2011.01.054Search in Google Scholar

[63] Lu Z, Li C, Han J, Zhang F, Liu P, Wang H, et al. Three-dimensional bicontinuous nanoporous materials by vapor phase dealloying. Nat Commun. 2018;9:276.10.1038/s41467-017-02167-ySearch in Google Scholar PubMed PubMed Central

[64] Coaty C, Zhou H, Liu H, Liu P. A scalable synthesis pathway to nanoporous metal structures. ACS Nano. 2018;12:432–40.10.1021/acsnano.7b06667Search in Google Scholar PubMed

[65] Kosinova A, Wang D, Schaaf P, Kovalenko O, Klinger L, Rabkin E. Fabrication of hollow gold nanoparticles by dewetting, dealloying and coarsening. Acta Mater. 2016;102:108–15.10.1016/j.actamat.2015.09.024Search in Google Scholar

[66] Thompson CV. Solid-state dewetting of thin films. Annu Rev Mater Res. 2012;42:399–434.10.1146/annurev-matsci-070511-155048Search in Google Scholar

[67] Wang D, Schaaf P. Ni–Au bi-metallic nanoparticles formed via dewetting. Mater Lett. 2012;70:30–3.10.1016/j.matlet.2011.11.102Search in Google Scholar

[68] Herz A, Wang D, Kups T, Schaaf P. Solid-state dewetting of Au/Ni bilayers: the effect of alloying on morphology evolution. J Appl Phys. 2014;116:044307.10.1063/1.4891448Search in Google Scholar

[69] Herz A, Friák M, Rossberg D, Hentschel M, Theska F, Wang D, et al. Facet-controlled phase separation in supersaturated Au-Ni nanoparticles upon shape equilibration. Appl Phys Lett. 2015;107:073109.10.1063/1.4928627Search in Google Scholar

[70] Wang D, Schaaf P. Solid-state dewetting for fabrication of metallic nanoparticles and influences of nanostructured substrates and dealloying. Phys Status Solidi (A). 2013;210:1544–51.10.1002/pssa.201200895Search in Google Scholar

[71] Herz A, Theska F, Rossberg D, Kups T, Wang D, Schaaf P. Solid-state dewetting of Au–ni bi-layer films mediated through individual layer thickness and stacking sequence. Appl Surf Sci. 2018;444:505–10.10.1016/j.apsusc.2018.03.096Search in Google Scholar

[72] Herz A, Franz A, Theska F, Hentschel M, Kups T, Wang D, et al. Solid-state dewetting of single- and bilayer Au-W thin films: unraveling the role of individual layer thickness, stacking sequence and oxidation on morphology evolution. AIP Adv. 2016;6:035109.10.1063/1.4944348Search in Google Scholar

[73] Wang D, Ji R, Albrecht A, Schaaf P. Ordered arrays of nanoporous gold nanoparticles. Beilstein J Nanotechnol. 2012;3:651–7.10.3762/bjnano.3.74Search in Google Scholar PubMed PubMed Central

[74] Wang D, Ji R, Schaaf P. Formation of precise 2D Au particle arrays via thermally induced dewetting on pre-patterned substrates. Beilstein J Nanotechnol. 2011;2:318–26.10.3762/bjnano.2.37Search in Google Scholar PubMed PubMed Central

[75] Herz A, Wang D, Schaaf P. Dewetting of Au/Ni bilayer films on prepatterned substrates and the formation of arrays of supersaturated Au-Ni nanoparticles. J Vac Sci Technol B. 2014;32:021802.10.1116/1.4863320Search in Google Scholar

[76] Giermann AL, Thompson CV. Solid-state dewetting for ordered arrays of crystallographically oriented metal particles. Appl Phys Lett. 2005;86:121903.10.1063/1.1885180Search in Google Scholar

[77] Wang D, Schaaf P. Thermal dewetting of thin Au films deposited onto line-patterned substrates. J Mater Sci. 2012;47:1605–8.10.1007/s10853-011-5716-0Search in Google Scholar

[78] Wang D, Schaaf P. Two-dimensional nanoparticle arrays formed by dewetting of thin gold films deposited on pre-patterned substrates. J Mater Sci: Mater Electron. 2011;22:1067–70.10.1007/s10854-010-0260-2Search in Google Scholar

[79] Khristosov MK, Bloch L, Burghammer M, Kauffmann Y, Katsman A, Pokroy B. Sponge-like nanoporous single crystals of gold. Nat Commun. 2015;6:8841.10.1038/ncomms9841Search in Google Scholar PubMed PubMed Central

[80] Zhao F, Zeng J, Parvez Arnob MM, Sun P, Qi J, Motwani P, et al. Monolithic NPG nanoparticles with large surface area, tunable plasmonics, and high-density internal hot-spots. Nanoscale. 2014;6:8199–207.10.1039/C4NR01645ASearch in Google Scholar PubMed

[81] Cai S, Jia X, Han Q, Yan X, Yang R, Wang C. Porous Pt/Ag nanoparticles with excellent multifunctional enzyme mimic activities and antibacterial effects. Nano Res. 2017;10:2056–69.10.1007/s12274-016-1395-0Search in Google Scholar

[82] Nishi H, Tatsuma T. Photoregulated nanopore formation via plasmon-induced dealloying of Au–ag alloy nanoparticles. J Physl Chem C. 2017;121:2473–80.10.1021/acs.jpcc.6b12131Search in Google Scholar

[83] Qian L-H, Ding Y, Fujita T, Chen M-W. Synthesis and optical properties of three-dimensional porous core−shell nanoarchitectures. Langmuir. 2008;24:4426–9.10.1021/la703621cSearch in Google Scholar PubMed

[84] Zeis R, Mathur A, Fritz G, Lee J, Erlebacher J. Platinum-plated nanoporous gold: an efficient, low Pt loading electrocatalyst for PEM fuel cells. J Power Sources. 2007;165:65–72.10.1016/j.jpowsour.2006.12.007Search in Google Scholar

[85] Xiao S, Xiao F, Hu Y, Yuan S, Wang S, Qian L, et al. Hierarchical nanoporous gold-platinum with heterogeneous interfaces for methanol electrooxidation. Sci Rep. 2014;4:4370.10.1038/srep04370Search in Google Scholar PubMed PubMed Central

[86] Du Y, Xu J-J, Chen H-Y. Ultrathin platinum film covered high-surface-area nanoporous gold for methanol electro-oxidation. Electrochem commun. 2009;11:1717–20.10.1016/j.elecom.2009.07.004Search in Google Scholar

[87] Jia C, Yin H, Ma H, Wang R, Ge X, Zhou A, et al. Enhanced photoelectrocatalytic activity of methanol oxidation on TiO2-decorated nanoporous gold. J Physl Chem C. 2009;113:16138–43.10.1021/jp904191kSearch in Google Scholar

[88] Biener MM, Biener J, Wichmann A, Wittstock A, Baumann TF, Bäumer M, et al. ALD functionalized nanoporous gold: thermal stability, mechanical properties, and catalytic activity. Nano Lett. 2011;11:3085–90.10.1021/nl200993gSearch in Google Scholar PubMed

[89] Kosinova A, Wang D, Baradács E, Parditka B, Kups T, Klinger L, et al. Tuning the nanoscale morphology and optical properties of porous gold nanoparticles by surface passivation and annealing. Acta Mater. 2017;127:108–16.10.1016/j.actamat.2017.01.014Search in Google Scholar

[90] Lang X, Hirata A, Fujita T, Chen M. Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors. Nat Nanotechnol. 2011;6:232.10.1038/nnano.2011.13Search in Google Scholar PubMed

[91] Kang J, Chen L, Hou Y, Li C, Fujita T, Lang X, et al. Electroplated thick manganese oxide films with ultrahigh capacitance. Adv Energy Mater. 2013;3:857–63.10.1002/aenm.201201046Search in Google Scholar

[92] Yu Y, Gu L, Lang X, Zhu C, Fujita T, Chen M, et al. Li storage in 3D nanoporous au-supported nanocrystalline tin. Adv Mater. 2011;23:2443–7.10.1002/adma.201004331Search in Google Scholar PubMed

[93] Chen LY, Hou Y, Kang JL, Hirata A, Fujita T, Chen MW. Toward the theoretical capacitance of RuO2 Reinforced by highly conductive nanoporous gold. Adv Energy Mater. 2013;3:851–6.10.1002/aenm.201300024Search in Google Scholar

[94] Ge X, Chen L, Zhang L, Wen Y, Hirata A, Chen M. Nanoporous metal enhanced catalytic activities of amorphous molybdenum sulfide for high-efficiency hydrogen production. Adv Mater. 2014;26:3100–4.10.1002/adma.201305678Search in Google Scholar PubMed

[95] Tan Y, Liu P, Chen L, Cong W, Ito Y, Han J, et al. Monolayer MoS2 films supported by 3D nanoporous metals for high-efficiency electrocatalytic hydrogen production. Adv Mater. 2014;26:8023–8.10.1002/adma.201403808Search in Google Scholar PubMed

[96] Hou Y, Chen L, Liu P, Kang J, Fujita T, Chen M. Nanoporous metal based flexible asymmetric pseudocapacitors. J Mater Chem A. 2014;2:10910–6.10.1039/C4TA00969JSearch in Google Scholar

[97] Meng F, Ding Y. Sub-micrometer-thick all-solid-state supercapacitors with high power and energy densities. Adv Mater. 2011;23:4098–102.10.1002/adma.201101678Search in Google Scholar PubMed

[98] Detsi E, Onck P, De Hosson JT. Metallic muscles at work: high rate actuation in nanoporous gold/polyaniline composites. ACS Nano. 2013;7:4299–306.10.1021/nn400803xSearch in Google Scholar PubMed

[99] Wang H, Jeong HY, Imura M, Wang L, Radhakrishnan L, Fujita N, et al. Shape- and size-controlled synthesis in hard templates: sophisticated chemical reduction for mesoporous monocrystalline platinum nanoparticles. J Am Chem Soc. 2011;133:14526–9.10.1021/ja2058617Search in Google Scholar PubMed

[100] Jiang B, Li C, Tang J, Takei T, Kim JH, Ide Y, et al. Tunable-sized polymeric micelles and their assembly for the preparation of large mesoporous platinum nanoparticles. Angew Chem. 2016;128:10191–5.10.1002/ange.201603967Search in Google Scholar

[101] Jiang B, Li C, Dag Ö, Abe H, Takei T, Imai T, et al. Mesoporous metallic rhodium nanoparticles. Nat Commun. 2017;8:15581.10.1038/ncomms15581Search in Google Scholar PubMed PubMed Central

[102] Jiang B, Li C, Imura M, Tang J, Yamauchi Y. Multimetallic mesoporous spheres through surfactant-directed synthesis. Adv Sci. 2015;2:1500112.10.1002/advs.201500112Search in Google Scholar PubMed PubMed Central

[103] Shim K, Lin J, Park M-S, Shahabuddin M, Yamauchi Y, Hossain MS, et al. Tunable porosity in bimetallic core-shell structured palladium-platinum nanoparticles for electrocatalysts. Scr Mater. 2019;158:38–41.10.1016/j.scriptamat.2018.08.015Search in Google Scholar

[104] Jiang B, Li C, Henzie J, Takei T, Bando Y, Yamauchi Y. Morphosynthesis of nanoporous pseudo Pd@Pt bimetallic particles with controlled electrocatalytic activity. J Mater Chem A. 2016;4:6465–71.10.1039/C6TA00037ASearch in Google Scholar

[105] Li C, Xu Y, Li Y, Yu H, Yin S, Xue H, et al. Engineering porosity into trimetallic PtPdNi nanospheres for enhanced electrocatalytic oxygen reduction activity. Green Energy Environ. 2018;3:352–9.10.1016/j.gee.2018.07.004Search in Google Scholar

[106] Eid K, Ahmad YH, Yu H, Li Y, Li X, AlQaradawi SY, et al. Rational one-step synthesis of porous PtPdRu nanodendrites for ethanol oxidation reaction with a superior tolerance for CO-poisoning. Nanoscale. 2017;9:18881–9.10.1039/C7NR07609FSearch in Google Scholar PubMed

[107] Deng K, Xu Y, Li C, Wang Z, Xue H, Li X, et al. PtPdRh mesoporous nanospheres: an efficient catalyst for methanol electro-oxidation. Langmuir. 2019;35:413–9.10.1021/acs.langmuir.8b03656Search in Google Scholar PubMed

[108] Yamauchi Y, Sugiyama A, Morimoto R, Takai A, Kuroda K. Mesoporous platinum with giant mesocages templated from lyotropic liquid crystals consisting of diblock copolymers. Angew Chem Int Ed. 2008;47:5371–3.10.1002/anie.200801381Search in Google Scholar PubMed

[109] Luo K, Walker CT, Edler KJ. Mesoporous silver films from dilute mixed-surfactant solutions by using dip-coating. Adv Mater. 2007;19:1506–9.10.1002/adma.200601244Search in Google Scholar

[110] Attard GS, Bartlett PN, Coleman NR, Elliott JM, Owen JR, Wang JH. Mesoporous platinum films from lyotropic liquid crystalline phases. Science. 1997;278:838–40.10.1126/science.278.5339.838Search in Google Scholar

[111] Jiang B, Li C, Malgras V, Imura M, Tominaka S, Yamauchi Y. Mesoporous Pt nanospheres with designed pore surface as highly active electrocatalyst. Cheml Sci. 2016;7:1575–81.10.1039/C5SC03779DSearch in Google Scholar PubMed PubMed Central

[112] Lv H, Sun L, Zou L, Xu D, Yao H, Liu B. Size-dependent synthesis and catalytic activities of trimetallic PdAgCu mesoporous nanospheres in ethanol electrooxidation. Cheml Sci. in press. 2019. DOI: 10.1039/C8SC04696D.Search in Google Scholar PubMed PubMed Central

[113] Fu G, Liu H, You N, Wu J, Sun D, Xu L, et al. Dendritic platinum–copper bimetallic nanoassemblies with tunable composition and structure: arginine-driven self-assembly and enhanced electrocatalytic activity. Nano Res. 2016;9:755–65.10.1007/s12274-015-0954-0Search in Google Scholar

[114] Xie X-W, Lv J-J, Liu L, Wang A-J, Feng J-J, Xu Q-Q. Amino acid-assisted fabrication of uniform dendrite-like PtAu porous nanoclusters as highly efficient electrocatalyst for methanol oxidation and oxygen reduction reactions. Int J Hydrogen Energy. 2017;42:2104–15.10.1016/j.ijhydene.2016.11.055Search in Google Scholar

[115] Ma A, Xu J, Zhang X, Zhang B, Wang D, Xu H. Interfacial nanodroplets guided construction of hierarchical Au, Au-Pt, and Au-Pd particles as excellent catalysts. Sci Rep. 2014;4:4849.10.1038/srep04849Search in Google Scholar PubMed PubMed Central

[116] Huang X, Zhu E, Chen Y, Li Y, Chiu C-Y, Xu Y, et al. A facile strategy to Pt3Ni nanocrystals with highly porous features as an enhanced oxygen reduction reaction catalyst. Adv Mater. 2013;25:2974–9.10.1002/adma.201205315Search in Google Scholar PubMed

[117] Lu S, Eid K, Deng Y, Guo J, Wang L, Wang H, et al. One-pot synthesis of PtIr tripods with a dendritic surface as an efficient catalyst for the oxygen reduction reaction. J Mater Chem A. 2017;5:9107–12.10.1039/C7TA00533DSearch in Google Scholar

[118] Hu Y, Liu T, Li C, Yuan Q. Facile surfactant-free synthesis of composition-tunable bimetallic PtCu alloy nanosponges for direct methanol fuel cell applications. Aust J Chem. 2018;71:504–10.10.1071/CH18160Search in Google Scholar

[119] Lu Q, Huang J, Han C, Sun L, Yang X. Facile synthesis of composition-tunable PtRh nanosponges for methanol oxidation reaction. Electrochim Acta. 2018;266:305–11.10.1016/j.electacta.2018.02.021Search in Google Scholar

[120] Shi Y-C, Yuan T, Feng J-J, Yuan J, Wang A-J. Rapid fabrication of support-free trimetallic Pt53Ru39Ni8 nanosponges with enhanced electrocatalytic activity for hydrogen evolution and hydrazine oxidation reactions. J Colloid Interface Sci. 2017;505:14–22.10.1016/j.jcis.2017.05.063Search in Google Scholar PubMed

[121] Lee C-L, Huang Y-C, Kuo L-C, Oung J-C, Wu F-C. Preparation and characterization of Pd/Ag and Pd/Ag/Au nanosponges with network nanowires and their high electroactivities toward oxygen reduction. Nanotechnology. 2006;17:2390.10.1088/0957-4484/17/9/053Search in Google Scholar

[122] Lilleodden ET, Voorhees PW. On the topological, morphological, and microstructural characterization of nanoporous metals. MRS Bulletin. 2018;43:20–6.10.1557/mrs.2017.303Search in Google Scholar

[123] Soyarslan C, Bargmann S, Pradas M, Weissmüller J. 3D stochastic bicontinuous microstructures: generation, topology and elasticity. Acta Mater. 2018;149:326–40.10.1016/j.actamat.2018.01.005Search in Google Scholar

[124] Rösner H, Parida S, Kramer D, Volkert CA, Weissmüller J. Reconstructing a nanoporous metal in three dimensions: an electron tomography study of dealloyed gold leaf. Adv Eng Mater. 2007;9:535–41.10.1002/adem.200700063Search in Google Scholar

[125] Fujita T, Qian L-H, Inoke K, Erlebacher J, Chen M-W. Three-dimensional morphology of nanoporous gold. Appl Phys Lett. 2008;92:251902.10.1063/1.2948902Search in Google Scholar

[126] Krekeler T, Straßer AV, Graf M, Wang K, Hartig C, Ritter M, et al. Silver-rich clusters in nanoporous gold. Mater Res Lett. 2017;5:314–21.10.1080/21663831.2016.1276485Search in Google Scholar

[127] Mangipudi KR, Radisch V, Holzer L, Volkert CA. A FIB-nanotomography method for accurate 3D reconstruction of open nanoporous structures. Ultramicroscopy. 2016;163:38–47.10.1016/j.ultramic.2016.01.004Search in Google Scholar PubMed

[128] Hu K, Ziehmer M, Wang K, Lilleodden ET. Nanoporous gold: 3D structural analyses of representative volumes and their implications on scaling relations of mechanical behaviour. Philos Mag. 2016;96:3322–35.10.1080/14786435.2016.1222087Search in Google Scholar

[129] Ziehmer M, Hu K, Wang K, Lilleodden ET. A principle curvatures analysis of the isothermal evolution of nanoporous gold: quantifying the characteristic length-scales. Acta Mater. 2016;120:24–31.10.1016/j.actamat.2016.08.028Search in Google Scholar

[130] Chen Y-C, Chu YS, Yi J, McNulty I, Shen Q, Voorhees PW, et al. Morphological and topological analysis of coarsened nanoporous gold by x-ray nanotomography. Appl Phys Lett. 2010;96:043122.10.1063/1.3285175Search in Google Scholar

[131] Fam Y, Sheppard TL, Diaz A, Scherer T, Holler M, Wang W, et al. Correlative multiscale 3D imaging of a hierarchical nanoporous gold catalyst by electron, ion and X-ray nanotomography. ChemCatChem. 2018;10:2858–67.10.1002/cctc.201800230Search in Google Scholar PubMed PubMed Central

[132] Chen-Wiegart Y-C, Wang S, Chu YS, Liu W, McNulty I, Voorhees PW, et al. Structural evolution of nanoporous gold during thermal coarsening. Acta Mater. 2012;60:4972–81.10.1016/j.actamat.2012.05.012Search in Google Scholar

[133] El-Zoka AA, Langelier B, Botton GA, Newman RC. Enhanced analysis of nanoporous gold by atom probe tomography. Mater Charact. 2017;128:269–77.10.1016/j.matchar.2017.03.013Search in Google Scholar

[134] Kübel C, Voigt A, Schoenmakers R, Otten M, Su D, Lee T-C, et al. Recent advances in electron tomography: TEM and HAADF-STEM tomography for materials science and semiconductor applications. Microsc Microanal. 2005;11:378–400.10.1017/S1431927605050361Search in Google Scholar PubMed

[135] [135] Nattere Frank. The mathematics of computerized tomography. Philadelphia, PA, USA: Society for Industrial and Applied Mathematics, 20010-89871-493-1.10.1137/1.9780898719284Search in Google Scholar

[136] Li R, Sieradzki K. Ductile-brittle transition in random porous Au. Phys Rev Lett. 1992;68:1168–71.10.1103/PhysRevLett.68.1168Search in Google Scholar PubMed

[137] Pfeiffer B, Erichsen T, Epler E, Volkert CA, Trompenaars P, Nowak C. Characterization of nanoporous materials with atom probe tomography. Microsc Microanal. 2015;21:557–63.10.1017/S1431927615000501Search in Google Scholar PubMed

[138] Zhong J, Chimeh A, Korte A, Schwarz F, Yi J, Wang D, et al. Strong spatial and spectral localization of surface plasmons in individual randomly disordered gold nanosponges. Nano Lett. 2018;18:4957–64.10.1021/acs.nanolett.8b01785Search in Google Scholar PubMed

[139] Mei H, Bai H, Bai S, Li X, Zhao X, Cheng L. Tuning Ag content in AuAg nanosponges for superior SERS detection. Mater Lett. 2018;230:24–7.10.1016/j.matlet.2018.07.069Search in Google Scholar

[140] Zhang T, Sun Y, Hang L, Li H, Liu G, Zhang X, et al. Periodic porous alloyed Au–ag nanosphere arrays and their highly sensitive SERS performance with good reproducibility and high density of hotspots. ACS Appl Mater Interfaces. 2018;10:9792–801.10.1021/acsami.7b17461Search in Google Scholar PubMed

[141] Zhang T, Zhou F, Hang L, Sun Y, Liu D, Li H, et al. Controlled synthesis of sponge-like porous Au–ag alloy nanocubes for surface-enhanced Raman scattering properties. J Mater Chem C. 2017;5:11039–45.10.1039/C7TC03855KSearch in Google Scholar

[142] Sufian MM, Khattak JZ, Yousaf S, Rana MS Safety issues associated with the use of nanoparticles in human body. Photodiagn Photodyn Ther. 2017;19:67–72.10.1016/j.pdpdt.2017.05.012Search in Google Scholar PubMed

[143] Berube D, Cummings C, Cacciatore M, Scheufele D, Kalin J. Characteristics and classification of nanoparticles: expert delphi survey. Nanotoxicology. 2011;5:236–43.10.3109/17435390.2010.521633Search in Google Scholar PubMed

[144] Ray PC, Yu H, Fu PP. Toxicity and environmental risks of nanomaterials: challenges and future needs. J Environ Sci Health Part C, Environ Carcinog Ecotoxicol Rev. 2009;27:1–35.10.1080/10590500802708267Search in Google Scholar PubMed PubMed Central

© 2019 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Gas chromatography/mass spectrometry techniques for the characterisation of organic materials in works of art

- Computer-based techniques for lead identification and optimization I: Basics

- 10.1515/psr-2018-0155

- Polyoxometalates in photocatalysis

- A primer on natural product-based virtual screening

- Theoretical principles of Raman spectroscopy

- Secondary metabolites, their structural diversity, bioactivity, and ecological functions: An overview

- Applications in: Environmental Analytics (fine particles)

- Synthesis and characterization of size controlled bimetallic nanosponges

Articles in the same Issue

- Gas chromatography/mass spectrometry techniques for the characterisation of organic materials in works of art

- Computer-based techniques for lead identification and optimization I: Basics

- 10.1515/psr-2018-0155

- Polyoxometalates in photocatalysis

- A primer on natural product-based virtual screening

- Theoretical principles of Raman spectroscopy

- Secondary metabolites, their structural diversity, bioactivity, and ecological functions: An overview

- Applications in: Environmental Analytics (fine particles)

- Synthesis and characterization of size controlled bimetallic nanosponges