Recent development in the formation and surface modification of cellulose-bead nanocomposites as adsorbents for water purification: a comprehensive review

Abstract

Water pollution is an issue of global concern that demands effective and sustainable solutions through water purification. Adsorption is a popular method for water treatment because it is inexpensive and has a high performance rate. Although commercial activated carbon is the generally preferred adsorbent for adsorption, its widespread use is affected by the high cost and challenges encountered during column adsorption. Biopolymers like cellulose and its derivatives have the potential to replace expensive adsorbents due to their unique characteristics. In recent years, cellulose-bead nanocomposites have gained significant attention as promising adsorbents due to their ability to circumvent the challenges encountered when using powdered adsorbents. To fabricate cellulose beads, cellulose fiber is separated from its source, dissolved in appropriate solvents, shaped into spherical particles and subsequently modified (via esterification, oxidation, crosslinking agents, etc.) to improve its adsorption capacity. This comprehensive review paper presents a detailed analysis of the recent development in the formation and surface modification of 3-D structured cellulose nanocomposites. The outcome of this review on modified cellulose-bead demonstrates their successful fabrication and high adsorption capacities for different contaminants. It is anticipated that cellulose beads, as a bio-adsorbent in industrial settings, will be a low-cost alternative to the more expensive adsorbents shortly.

1 Introduction

Water is the world’s most copious natural resource. However, freshwater makes up just approximately 3 % of the existing water sources and less than one-third of it is suitable for various household, agricultural and industrial activities [1, 2]. As global water consumption increases due to rapid population growth and development of the industrial sector and other environmental factors, the limited freshwater supplies are further depleted. In recent times, water-stressed conditions have been worsened by the contamination of available water resources [3]. Industrial effluents (e.g. textile fibre, rubber and leather wastewater, pharmaceutical, dye and plastic industries effluent), agricultural activities (e.g. pesticides application), municipal effluents and other environmental activities are the main sources of water contamination [4]. The water crisis is now an issue of global concern. Wastewater treatment has a vital role in the global augmentation of water supply. However, reclaiming contaminated water for re-use will require some form of effective treatment to remove contaminants [4, 5]. There have been reports of several removal techniques, comprising coagulation/flocculation, floatation, chemical precipitation, biological processes, advanced oxidation processes, membrane filtration and ion exchange resin [6], [7], [8], [9]. However, these methods are not frequently employed because of a number of limitations, such as their high cost, poor selectivity and sensitivity, inadequate removal, delicate working conditions, high energy demand, generation of secondary pollutants and costly disposal processes [6, 9–13]. Table 1 lists the benefits and limitations of the main conventional wastewater treatment methods.

Benefits and limitations of the major conventional methods used for the treatment of contaminated wastewater [6].

| Techniques | Main features | Merits | Limitations |

|---|---|---|---|

| Ion exchange |

|

|

|

| Solvent extraction (liquid-liquid extracion) |

|

|

|

| Chemical precipitation |

|

|

|

| Coagulation/flocculation |

|

|

|

| Electro-coagulation |

|

|

|

| Biological methods |

|

|

|

| Membrane filtration (ultrafilteration, nanofileration, reverse osmosis) |

|

|

|

| Advanced chemical oxidation |

|

|

|

Adsorption treatment technology is the preferred option for water treatment because of the main advantages of the technique which include high selectivity and performance, low cost, simplicity of operation, insensitivity to side effects of toxic pollutants, high regeneration potentials and availability of a wide range of adsorbents [9, 10]. Furthermore, adsorption may be utilized to remove diverse inorganic and organic contaminants without the formation of harmful intermediates or by-products [8, 14–16]. A significant factor in attaining optimal contaminant removal requires choosing an appropriate adsorbent based on the adsorbent type and characteristics of the adsorbate [17]. Many different natural materials including clay minerals, activated carbon (AC) and zeolite, have been explored as promising adsorbents for the removal of pollutants. AC is an extensively employed adsorbent with a wide specific surface area, large porosity and a high degree of surface reactions, which makes it unique [18]. However, the application of commercial AC is usually affected by the high cost of production, its non-selectivivity and scarcity of raw materials. The drawbacks associated with the other natural adsorbents include high manufacturing cost and low adsorption efficiency towards selected toxic compounds which limits their wider application [19], [20], [21].

Several researchers have in recent times, concentrated on the manufacture of adsorbents from sustainable and less expensive precursors such as agricultural wastes [22]. Agricultural residues are lignocellulosic materials that are superior to other adsorbents because they may be used without chemical modification or with minimal processing, thereby, significantly reducing production costs [23, 24]. They are low in ash composition and rich in carbon, which makes them useful precursors for the manufacture of activated carbon and as components of composite materials for the adsorption of organic and inorganic pollutants [25]. For instance, Olorundare et al. [26] chemically modified and converted maize tassels to activate carbon and therafter, utilized the AC for the elimination of phenolic chemicals [bisphenol A (BPA), ortho-nitrophenol (o-NTP) and parachlorophenol (PCP)]. The results obtained showed that the maize tassel-activated carbon (MTAC) was able to effectively remove the phenolic compounds with removal efficiencies of 90.84–98.49 %, 80.75–97.11 %, and 78.27–97.08 % for BPA, o-NTP and PCP respectively). In a similar report, Omo-Okoro et al. [27] created nanocomposite-activated carbon, known as physically activated maize tassel silver (PAMTAg) nanocomposites and chemically activated maize tassel silver (CAMTAg) nanocomposites to remove per and polyfluorinated alkyl substances (PFASs) from aqueous solutions. Omo-okoro and colleagues observed that the maximum adsorption capacity of the CAMTAg adsorbent for PFOS and PFOA were 454.1 mg/g and 321.2 mg/g respectively.

Unfortunately, studies have revealed some limitations in the conversion of plant biomass to AC. This includes the low carbonization energy of plant biomass which could be problematic, especially during thermal treatment. Unlike wood which undergoes thermal treatment at high temperatures, the surface morphology of plant biomass may be destroyed during pyrolysis because they easily burn off at low temperatures (160–200 °C) and generate soft ash. Furthermore, there is a risk of organic matter seeping from the biochar, which might lead to re-contamination of the final treated water (secondary pollution) [28]. To resolve this issue, the active component of the plant biomass could be recovered and directly modified for use. Most often, the total mass of the biomaterial is chemically modified with little consideration to isolate the active component responsible for the adsorption properties. The isolation of the most active component from the plant biomass is deemed crucial since this will eliminate components that may suppress or interfere with the adsorption properties, and yield cleaner, functional materials, resulting in increasing adsorption performance [29]. Cellulose is an important constituent of plant biomass which has been recognized as the most available and sustainable biopolymer on earth with distinctive characteristics that make it ideal for a variety of industrial applications [30, 31]. It is biodegradable, non-toxic with good mechanical capabilities, thus, it is regarded as environmentally friendly. Cellulose can be isolated from its source, chemically modified, and utilized as a nanocomposite for adsorption purposes [32–34]. The synthesized nanocomposites would be in a purer form due to the extraction of the cellulose from the plant biomass before subsequent modification. Studies have shown that the cellulose framework contains many valuable functional groups that facilitate its modification or chemical grafting onto different materials to form products that are ideal for a wide range of applications [29–31, 35, 36]. It has a significant amount of carbon and a proven ability for sorption. Cellulose has been successfully applied as nanocomposites for the potential removal of contaminants from water. Abou-Zeid et al. [37] created nanocomposites from cane pulp-derived cellulose through TEMPO oxidation and magnetic amino-modification and evaluated their effectiveness for removing lead ions from water fibers (FM-NPs). They reported that the nanocomposite had an 80 % effectiveness in eliminating lead ions from water. In a related work, Wang et al. [38] produced carboxymethylated cellulose fiber (CMF) adsorbent from bleached softwood kraft pulp fiber (SKF) using a controlled carboxymethylation modification. According to Wang and colleagues, the CMF adsorbent had good adsorption capacity as an adsorption capacity of 16.90 mg/g and 11.63 mg/g was recorded for Cu (II) and Ni (II), respectively. Similarly, Bawaani et al. [39] investigated the adsorption performance of nanocrystalline cellulose isolated from oil palm empty fruit bunch for the removal of dye from textile effluent. Bawaani and colleagues reported a 50.91 mg/g colour removal at an adsorbent dose as low as 0.066 mg/ml, confirming the efficiency of the NCC adsorbent.

Although the functionalization of cellulose and other powdered biomaterials is known to improve their compatibility and adsorption capacity for pollutants, the soft texture of the adsorbents in water can clog columns and significantly reduce the flow of eluent used to remove adsorbate from the adsorbent surface in adsorption/desorption studies. Cellulose beads/hydrogels are an advanced form of cellulose that has aroused more interest in recent times, due to their distinctive high porosity, functional surface and consequently numerous potential applications in filtration, catalysis, energy storage and drug or cell delivery among others. Furthermore, its large pores provide a wide surface area for interactions with target molecules, allowing for significant adsorption [40]. However, there are limited works in the literature on the fabrication, modification and application of cellulose beads as adsorbents. This article extensively explores the progress made in the development of cellulose beads and their application as adsorbents in water purification. The current study can offer a fundamental framework and a more in-depth perspective into modification techniques and fabrication procedures required for the development of cellulose bead nanocomposite. It provides an overview of cellulose; its composition, nano-forms and derivatives, making it a high-performing natural biopolymer of interest especially when utilized in the form of 3-D adsorbent. The review article further presents an in-depth discussion on the preparation procedures of cellulose beads, the recent modification strategies applied for enhanced adsorption performance of the beads as well as their potential applications/performance as adsorbents for the removal of contaminants from aqueous solutions.

2 The adsorption process and types of adsorbents for contaminants removal

Adsorption is a separation process that occurs when the constituents of a fluid, liquid or gas adhere to the exterior and interior surfaces of a solid substance [41]. The basis for the separation is the selective adsorption (thermodynamic and/or kinetic selectivity) of the contaminants by an adsorbent due to specific interactions between the surface of the adsorbent material and the adsorbed contaminants [41]. The contaminant of interest is the adsorbate present in the fluid phase and the solid phase is any material suitable as an adsorbent. In general, adsorbents exhibit distinct spatial and electrical features, as well as a wide range of activation sites that aids in the binding of the adsorbate and the general adsorption process [15]. Three stages make up the adsorption process: (1) adsorbate transport in the fluid phase to the adsorbent’s surface (film diffusion), (2) adsorbate migration into the pores of the adsorbent (diffusion inside particles) and (3) adsorbate adhesion to the adsorbent’s charged surface (surface bonding) [42]. Some of the parameters that influence the adsorption of molecules onto an adsorbent include the initial contaminant concentration, solution pH, temperature, interfering chemicals, adsorbate characteristics, adsorbent dosage, adsorbent surface type and adsorbent surface area [22].

2.1 Adsorption process in water treatment

The adsorption process is generally influenced by two main types of mechanisms: physical adsorption and chemical adsorption mechanisms. In the presence of interacting forces between the surfaces, the processes may take place at various interfaces, such as solid-liquid and/or solid–gas interfaces [43, 44]. However, the type of contaminants and the structural/chemical characteristics of the adsorbent surface are key factors that determine the adsorption mechanism for removing pollutants [22]. Physical adsorption is a reversible process which is the outcome of the physical contact between the adsorbed chemicals and the solid surface caused by weak interacting forces. Physical adsorption, also referred to as physisorption involves the formation of outer-sphere surface complexes when an adsorbate adheres to the surface of an adsorbent via weak electrostatic forces such as London forces, Van der Waals forces, polarity, steric interactions, hydrogen bonds, hydrophobicity and dipole induced-dipole interactions [45]. Physisorption can occur in either multiple layers or in a single layer because the adsorbate, which is mostly detached from the interacting active plane surface, remains confined by the binding energy [46]. It takes less heat to complete the desorption process in adsorbents involving physiosorption mechanisms, due to the weak binding energy. The majority of adsorbents involved in this type of mechanism have significant potential for regeneration of adsorption capacity, while the effluents discharged have low pollution potential and thus, are acceptable for disposal [47]. The activation energy in the physisorption process often falls between the 20–40 kJ/mol range, indicating a strong tendency for the active sorbent to dissolve in an aqueous media [48]. Though the mechanism correlates with the treatment variables, notably pH, dose, particle size, temperature, contact duration and agitation speed, this low activation energy might undermine the overall adsorption performance [46]. On the other hand, chemical adsorption, also known as chemisorption, is a process in which the adsorbate is permanently bonded to the adsorbent surface via chemical bonds or surface coordination compounds (i.e. inner-sphere surface complexes) between the adsorbate and the adsorbent surface [14, 49, 50]. In chemical sorption, a new bond is formed when the active plane surface of the sorbent and adsorbate breaks as a result of the chemical bonding in the chemisorption process [46]. This means that more intense adsorption energy and temperature; typically between 200 and 400 kJ/mol, are needed. The chemical bonding occurs through electron transfer or pairing, such as ion/ligand exchange, Lewis acid–base interaction and reduction/oxidation, etc. [14, 49, 50]. Single-layer adsorption occurs during chemisorption, and the mechanism is controlled by the treatment variables applicable in physisorption [47]. For a particular water treatment process, multiple adsorption interactions may take place simultaneously. These mechanisms aid in the binding of the contaminants to the surface of the adsorbent. The physisorption and chemisorption mechanisms are depicted in Figure 1.

![Figure 1:

Adsorption mechanisms, (A) physisorption and (B) chemisorption [47].](/document/doi/10.1515/polyeng-2023-0056/asset/graphic/j_polyeng-2023-0056_fig_001.jpg)

Adsorption mechanisms, (A) physisorption and (B) chemisorption [47].

2.2 Composite materials used for contaminants removal

Adsorbent selection is fundamental for a successful adsorption process development, performance and operation. A viable adsorbent should have a high adsorption interaction and removal efficiency toward the target contaminants. Adsorbents may be synthetic or from natural sources. Some of the common adsorbents used for removing contaminants from water include metal-organic frameworks, graphene-based materials, activated carbons (ACs), biomass, carbon nanotubes and polymeric materials [19, 51–54].

2.2.1 Porous organic polymers (co-ordinate polymers)

Co-ordination polymers, which include covalent organic frameworks (COFs) and metal-organic frameworks (MOFs), are a novel class of synthetic porous crystalline material [54]. MOFs are a kind of hybrid organic-inorganic crystalline materials that are connected by metal ions or clusters and organic ligands, giving them the properties of organic polymers and the stability of inorganic substances [54, 55]. In addition to having unsaturated sites and variable pore size; MOFs possess an immense specific surface area and thus, have great prospects as materials for the adsorption of diverse contaminants [55]. Liu et al. [56] created two stable metal-organic frameworks (MOFs) of amine-functionalized MIL-101 based on trivalent metal aluminium and iron [NH2-MIL-101(Al)] and [NH2-MIL-101(Fe)] by simple solvothermal reactions. According to Liu and colleagues, the two MOFs had a high adsorption capacity (>79.414 mg/g at 298 K) for phosphates. Likrwise, Ouyang et al. [57] synthesized a bismuth-based metal-organic framework (Bi-MOF, CAU-17) for the removal of selenite (SeO3 2−) anion from aqueous solution. They reported an ultra-high adsorption capacity of 255.3 mg/g. Furthermore, the adsorbent exhibited fast kinetics and a broad adsorption range of pH 4–11. However, MOF materials have poor mechanical characteristics but they can be mixed with a stable matrix material to enhance their mechanical characteristics [54].

Covalent organic frameworks are large, porous crystalline molecules formed entirely from covalently bonded basic elements (O, B, N, H and C) and organic building blocks. These substances are more extensive in structure and less dense than inorganic substances [53]. COFs have a large surface area of about 6450 m2/g and a stiff, strong structure that is resilient at temperatures as high as 600 °C [53, 58]. Xiong et al. [59] prepared a COF [NH4] +[COF–SO3 −] adsorbent for the selective extraction of thorium (Th IV) from uranium (U), and rare earth elements. Their findings demonstrate that the COF adsorbent had a maximum adsorption capacity of 395 mg/g for Th (IV) and excellent Th(IV) selectivity over uranium and rare earth elements.

2.2.2 Carbon naotubes (CNT)

Carbon nanotubes or one-dimensional carbon nanomaterials are hollow graphitic nanomaterials with well-ordered rolled-up structures, composed entirely of carbon [52]. To comprehend the structure of a carbon nanotube, consider it as a rolled-up sheet of graphene with a planar-hexagonal arrangement of carbon atoms arranged in a honeycomb lattice [60]. CNTs are classified based on their rolling layers of graphene sheets, as single-walled carbon nanotubes (SWCNTs), dual-walled carbon nanotubes (DWCNTs) and multi-walled carbon nanotubes (MWCNTs) [60–62]. They are distinguished from each other by their ability to transport water, specific surface area, chemical inertness and mechanical strength [62]. The SWCNTs are produced from a single graphene sheet that has been folded upon itself with a diameter of 1–2 nm and length determined by varying the production method. The DWCNT are produced from two concentric CNTs, with the outer tube encasing the inner tube. They offer a unique combination of SWNT qualities that are superior to those of SWNT in terms of better stability and stiffness [61]. MWNTs are made up of numerous layers of graphene wrapped up on themselves, with widths ranging from 2 to 50 nm, depending on the number of graphene tubes [63]. CNTs can be produced in large quantities using a variety of techniques, which are typically classified into five types: carbon arc discharge technique, laser ablation, sonochemical or hydrothermal methods, electrolysis and chemical vapour deposition (CVD) [60, 63].

The CNTs are materials of interest in analytical and material sciences due to their various appealing properties which include their strong mechanical and physiochemical stability, larger surface area, high tensile strength, resistance to temperature changes, non-corrosive and good adsorption capacity [52, 64]. Thus, CNTs have been used as adsorbents to remove pollutants from gaseous or aqueous environments, either in their natural form or after some modification treatment. Al-Saidi et al. [65] successfully used pristine MWCNTs as a solid phase for the removal of 95.6–98.91 % bismuth [Bi(III)] ions @ pH 0.1, from aqueous media. Similarly, Ehyaee et al. [66] synthesized magnetic multi-walled carbon nanotube nanocomposites (m-MWCNT) for the adsorptive removal of methyl violet (MV) from aqueous solutions. They reported a MB removal efficiency of 99.51 %. Unfortunately, the application of CNTs has some limitations due to some issues which include (1) the high cost of production, (2) a lack of solubility in most solvents suitable for natural (aqueous) environments, (3) manufacturing batches of CNTs with the same properties and repeatable chemical structure and (4) difficulty in maintaining high quality and low impurity levels during CNTs production [67].

2.2.3 Graphene-based materials

Graphene is a 2D layered sheet composed of single-atom sp2 hybridized carbon that has received notable attention from researchers globally. To create graphene oxide (GO) and reduced graphene oxide (RGO), several oxygen-containing functional groups are incorporated into graphene [54, 68]. Graphene has emerged as a useful nano-adsorbent due to (1) its significant surface area (theoretical value 2630 m2/g (2) its 2D honeycomb lattice structure, which may substantially adsorb contaminants with both sides of a planar sheet; and (3) the hexagonally arranged sp2 carbon atoms which contains a large p-electron delocalized structure that can develop a strong p-stacking interaction and hydrophobic interaction with the contaminants. Graphene may combine with different advanced materials to yield unique composite adsorbents with high adsorption efficiency [54]. A drawback in the use of these adsorbents is the high cost involved when sophisticated methods like chemical vapour deposition are used to produce grapheme-based materials of high quality and quantity while the inexpensive methods produce low-quality materials in lower quantities [69]. Moreover, graphene-based materials develop irreversible aggregates of layers and possess poor bonding affinity for anionic molecules [54, 70]. These disadvantages lower the efficiency of graphene-based adsorbents and limit their applications [19].

2.2.4 Silica-based adsorbents

Silica dioxide, sometimes known as silica, is a key component of sand. Silica has some adsorptive properties such as high surface area and porosity, a large specific surface area, excellent mechanical stability and a high adsorption capacity for dyes and heavy metals [71, 72]. Due to the presence of silanol groups, it exhibits hydrophilic qualities. However, because silica has a low resistance to alkali, it must be utilized in a solution with a pH lower than 8. Furthermore, nonspecific and irreversible adsorption will occur on the surface of siliceous materials containing acidic silanol groups [71]. Silica can be modified by various functional groups (e.g. an amino functional group) to lessen the undesirable properties and improve their adsorption capacities. Silicon alkoxide precursors, most notably tetraethyl orthosilicate (TEOS), are frequently employed as silica sources [73]. Studies on modified silica and mesoporous silica nanoparticles and their efficiency in eliminating environmental toxins from water and wastewater have been reported in the literature [71, 72]. Mesoporous silica (MS), which has pores between 2 and 50 nm in size, is a highly effective synthetic material for adsorption because of its high specific surface areas (as high as 2370 m2/g) and large pore sizes (about 50 nm) [73]. The main benefits of MS materials over other adsorbents with high adsorption capabilities for contaminants are their highly functionable structure and surface chemistry as well as their inexpensive production costs [73]. Organic ligands-based materials with unique physicochemical characteristics can be synthesised and anchored on a silico-based framework to produce adsorbents. For instance, Awual et al. [74] prepared an organic-inorganic based nano-conjugate adsorbent by directly immobilizing organic ligand N,N(octane-1,8-diylidene)di(2-hydroxy-3,5- dimethylaniline) (DHDM) onto mesoporous silica. According to them, the nano-conjugate adsorbent could preferentially adsorb palladium [Pd(II)] under optimal situations. Related studies involving the use of silica-based adsorbents have been reported elsewhere in the literature [21, 75, 76].

2.2.5 Commercial activated carbon (AC)

AC is a highly porous, refined, crushed coal or amorphous solid composed of micro-crystallites with a graphite structure, usually in the form of small pellets or powder [14]. It is the most widely used adsorbent for the adsorption of a broad range of emerging contaminants due to its special properties which include its large specific surface area, highly porous structure and high surface contact [18]. AC can be activated physically or chemically to provide multidimensional application, which substantially increases its adsorption surface area. The large surface area ranges from 500 to 1500 m2/g [14]. The types of AC, according to their particle size classification, are pulverized activated carbon (PAC) and granular activated carbon (GAC). AC can be further grouped according to their pore size as macroporous-structured AC (≥50 nm), mesoporous-structured AC (2–50 nm) and microporous-structured AC (2 ≥ 0.8 nm) [77]. AC has substantial adsorptive capabilities because of its high internal porous network, which provides a wide surface area for adsorption [16, 23, 78]. Ge et al. [79] modified coal-based activated carbon (CAC) with iron nanoparticles via microwave radiation and assessed its performance for the removal of polycyclic aromatic hydrocarbons from aqueous solutions. According to their findings, the modified CAC (0.05Fe-MCAC) had high adsorption capacities of 160.88 mg/g 181.99 mg/g and 199.07 mg/g for naphthalene, phenanthrene and pyrene, respectively. Similarly, Jawad et al. [80] reported that AC derived from Malaysian coal had a high adsorption capacity of 200 mg/g for cationic dye (MB) from an aqueous solution. The use of commercial activated carbon as an adsorbent has some disadvantages. Commercial activated carbon is nonselective and costly (the better the grade, the higher the cost), while the raw materials required for their production are scarce. There are still issues with their rapid saturation and thus regeneration as well as the disposal of used activated carbons. The regeneration of saturated carbon is likewise costly and difficult to regenerate, with the product regenerated having a lower adsorption capacity than the initial activated carbon and results in adsorbent loss [22, 41, 45, 81]. For these reasons, their practical usage is limited. AC derived from wood and plant wastes like coconut shells, nutshells or carbonized plant debris offers a cost-effective approach as a replacement for the petroleum-based AC [81]. Unfortunately, like all powdered adsorbents, they are difficult to use in columns for adsorption due to their clogging tendencies.

2.2.6 Bopolymers

The widespread industrial use of several commercial adsorbents is limited because they are expensive. In addition, these materials have lower mass and heat transfer, long settling time, difficulty in recycling, high-pressure drop, agglomeration at high doses, etc. which limits their wider adsorption applications [41]. Cost is an important parameter for comparing adsorbent materials. A sorbent can be considered low-cost if it requires little processing, is abundant in nature, or is a by-product or waste material from industries [51]. As such, alternative non-conventional adsorbents, mainly products and by-products of biological, industrial and agricultural origin (green adsorbents) were proposed, studied and employed as inexpensive and efficient adsorbents. These include algae, bacteria, fungi, yeasts, sawdust, fruit peels, husks, plant stems and polysaccharides [41]. These are also known as biopolymers since they are from plant and animal-based materials [82, 83]. Natural biopolymers are renewable, degradable and eco-friendly and produce a smaller volume of sludge [84]. Polysaccharides, e.g., starch, cellulose and chitin, are much preferred and researched because they are renewable and naturally abundant [83, 85]. They are an intriguing and appealing alternative as adsorbents because of their unique structure, chemical stability, high reactivity and superior preference towards aromatic compounds and metals. Their unique properties are attributed to the presence of chemically reactive groups (hydroxyl, acetamido or amino functionalities) in their polymer chains [51]. Cellulose is the most abundant, sustainable biopolymer in existence, with a unique composition that enhances its suitability for several industrial purposes [30]. The application of cellulose for making greener and more substantial industrial products is attributed to its no-carbon footprint and unique properties that allow for chemical modification [30].

3 Cellulose, an important biopolymer

3.1 Constituent of agricultural residue

Large amounts of unprocessed refuse are burnt or poorly disposed by the agricultural and manufacturing sectors in many developing nations, thereby polluting the surroundings and endangering the ecosystems. Improper treatment of these wastes before proper disposal may result in similar issues. Therefore, effective agricultural waste management systems via pollution regulation are absolutely important to avoid or decrease the spread of harmful waste to other locations [86, 87]. Many options for the proper disposal of these wastes have been offered in recent years, such as their reuse as precursors for the fabrication of adsorbents for pollution removal [24, 25]. Agricultural wastes are composed of large portions of lignocellulose biomass which consists of mainly three types of polymers namely: cellulose [C6(H2O)5]n, hemicellulose [C5(H2O)4]n and lignin [C10H12O3]n. They are strongly intermeshed and chemically bonded by both non-covalent forces and covalent cross-linkages [16].

The amount of chemical components in any plant residue varies and depends on the type of crop [88, 89]. Lignin biomaterial is a prevalent global natural compound, accounting for around 30 % of lignocellulosic biomass and exclusively occurring within the cell wall structure of plants. It is a complex phenolic and dynamic polymer made from lignin monomers that are primarily known as the three classical monolignols: coniferyl, sinapyl alcohols and p-coumaryl, each with a different degree of methoxylation [89, 90]. Lignin maintains water balance in fibers, protects against biological attack and functions as a stiffener in plant stems, thereby protecting them against gravity and wind. Lignin is a chemical polymer with a complicated three-dimensional structure and molecular mass of above 10,000 units. It is a hydrocarbon with both aliphatic and aromatic properties and it is completely insoluble in most solvents and does not easily decompose into monomeric components. The main phenylpropane repeating components of the lignin structure bind together via a series of linkages to create a complex matrix that includes propyl-phenolic compounds comprising of carbonyl, phenolic, hydroxyl, methoxy and aldehyde functional groups [16].

Cellulose and hemicelluloses are produced in plants through the polymerization of monosaccharides and condensation-dehydration mechanism, which has glucose as its main constituent and consists of other smaller monosaccharides. Cellulose (40–50 %) is a homopolymer consisting of glucose linked by b-1,4-glucosidic linkages while hemicelluloses is a group of polysaccharides made up of a variety of highly branched polymers (monosaccharides) [91]. Hemicellulose is the second most abundant biomolecule in lignocellulosic biomass, accounting for 20–35 % of total biomass. It is composed of different types of uronic acid groups, which are a highly branched heteropolymer of C-5 and C-6 carbon ring sugars, formed from D-glucuronic acid, D-xylose, L-arabinose, D-galactose and D-glucose. These monomers are connected by C=O=C and C=O linkages [92, 93]. Hemicellulose may be distinguished from cellulose in three ways; (1) multiple distinct sugar units (2) several chains branching with about 10 to 100-fold greater degree of polymerization [33] and (3) easily degraded or hydrolysed by alkali, unlike cellulose. However, both hemicellulose and cellulose contain oxygenated functional moieties such as ether, hydroxyl and carbonyl, which are found in lignocellulosic materials and may contribute to the adsorbent production process [94]. Although lignin is the most utilized component in the production of activated carbons, the choice of a precursor as an adsorbent is largely determined by a combination of factors that include its availability and abundance, cost and purity, ease of regeneration or safe disposal, production methodology and intended purpose of the developed adsorbent [25, 95]. Cellulose, therefore, is a suitable precursor for the synthesis of adsorbents since it is widely accessible, renewable and has a substantial amount of carbon as well as an established capability for sorption. The numerous hydroxyl moieties on cellulose can be used as active sites for functionalization, which are essential in the synthesis of adsorbents [16, 96]. The main polymer components of agricultural wastes are depicted in Figure 2.

![Figure 2:

Schematic diagram of lignocellulosic biomass and its constituent: lignin, cellulose and hemicellulose. Adapted from [97].](/document/doi/10.1515/polyeng-2023-0056/asset/graphic/j_polyeng-2023-0056_fig_002.jpg)

Schematic diagram of lignocellulosic biomass and its constituent: lignin, cellulose and hemicellulose. Adapted from [97].

3.2 Cellulose

The word “cellulose,” which means “a living cell,” was derived from the French words “cellule” and “glucose”. Anselme Payen, a French scientist, first used the term ‘cellule’ to describe cellulose in 1838, after discovering that all tender plants have a fibrous material with a homogeneous chemical content. He thereafter determined the chemical formula of the cellule (C6H10O5) through elemental analysis [98]. A year later, the French Academy coined the name “cellulose” to describe the fibrous cellule material of Payen’s work [99].

3.2.1 Chemical (molecular) composition of cellulose

Cellulose in plant fiber is a well-studied precursor for the production of nanocellulose, which can be applied for diverse industrial purposes. Plant fiber is frequently chosen over tunicate and bacteria-based cellulose because it produces thinner nanofibers and is available in larger amounts [100]. Cellulose is a linear isotactic homopolymer which consists of D-anhydrogluco-pyranose units (AGU), having the chemical formula (C6H10O5)n. The glucose-molecular units are held together by b-l-4-glycosidic linkages to form a dimer known as cellobiose, which is a basic unit of cellulose [101–103]. Cellulose is formed when the OH group at the C-4 axis of one glucose unit at the equatorial position forms a covalent bond with the C-1 atom of the closest glucose unit as shown in Figure 3. The hydroxyl functional groups that occur at both ends of the cellulose chain behave differently. For example, the OH moieties of the C-1 located at the end of the chain has reducing properties, composed of a D-glucopyranose unit in resonance with an aldehyde functional group, whereas the OH groups of the C-4 located on the same chain are non-reducing and consists of numeric C atoms bonded by glycosidic linkages. In addition, the interior rings joined at C1 and C-4 are also non-reducing. Each internal AGU has hydroxyl functional groups at C6, C3 and C2 positions that determine the chemical behaviour (reactivity) of the cellulose fiber. The hydroxyl groups at C6 are more reactive than the others and are known as the main alcohols, whilst those at other positions are known as secondary alcohols [102]. The reactive hydroxyl groups on the cellulose surface allow for cellulose functionalization [101, 104]. In addition, the interaction within the oxygen atoms of the glucopyranose ring, the hydroxyl groups of AGU and the glycosidic linkages inside the cellulose structure or the neighbouring chain facilitates the generation of strong intra- and inter-molecular hydrogen bonds which provides rigidity to the molecular chain [32, 34]. Cellulose molecular structure is responsible for its essential properties such as degradability, chirality, solubility and various chemical components [105].

![Figure 3:

Cellulose molecular structure [106].](/document/doi/10.1515/polyeng-2023-0056/asset/graphic/j_polyeng-2023-0056_fig_003.jpg)

Cellulose molecular structure [106].

3.2.2 Order of structural arrangement of cellulose

Cellulose fibers contain long chains of single molecules that may be transformed into fiber agglomerates and in a hierarchical sequence during production in plants’ cell wall. Several separate cellulose chains combine to create elementary fibrils (protofibrils), which occur in a variety of packing orientations, based on the conditions that regulate its biosynthesis [107]. The diameter of the elementary fibrils is influenced by their source and ranges between 2 and 20 nm. A sequence of helically wrapped cellular microfibrils makes up the intermediate layer. The microfibrils are generated through the clustering of elementary fibers by coalescence, which is a process for lowering the free energy of surfaces. These microfibrils, which are composed of 30–100 cellulose molecules in extended chain conformation and provide mechanical strength to the fiber, have around 3.5–30 nm width and length of roughly 7 m [108, 109]. The microfibrils created might merge into larger forms known as macro fibrils that are 60–300 nm wide, which may further rearrange to form cellulose fibers [110].

Intermolecular interactions such as Van der Waals forces, intra-and intermolecular hydrogen bonds, as well as the hydroxyl groups’ high spatial regularity, contribute to the agglomeration of the elementary fibrils. The cellulose molecules that combine to produce micro-fibrillated aggregates are composed of firmly arranged cellulose chains which form crystallites (depending on the source), held by strong, complex, hydrogen bonds, as well as some less-ordered chains that produce amorphous areas [111]. As a result, both amorphous and highly crystalline sections exist in cellulose fibers, which are bound together by complex and rigid hydrogen networks. The hydrogen bond within the C6–OH and C3–OH is recognized to be a very important constituent of cellulose’s structure and regular fiber alignment [110, 112]. The crystalline region, reactive O–H moieties and solubility characteristics of cellulose are all influenced by its strong hydrogen bonding systems. Although documented report shows the crystalline cellulose chains in an extended, flat, two-fold helical conformation, small variations in this conformation still exist. The different cellulose chain arrangements within the crystal result in a variety of crystalline polymorphs that can be altered to various forms by diverse treatment methods [113]. The schematic illustration of the types of cellulose fibrils and their hierarchical arrangement is presented in Figure 4.

![Figure 4:

Schematic hierarchical structure showing the elementary, micro and macro fibers [114].](/document/doi/10.1515/polyeng-2023-0056/asset/graphic/j_polyeng-2023-0056_fig_004.jpg)

Schematic hierarchical structure showing the elementary, micro and macro fibers [114].

3.2.3 Cellulose polymorphs

Cellulose can exist in several polymorphs or allomorphs because of the various inter- and intra-molecular arrangements. It can be categorized into four types of polymorph: cellulose I, II, III and IV. The physicochemical parameters, which include solubility, density, melting temperature, crystal forms and optical and electrical properties vary between these polymorphs [115]. Cellulose I is made up of parallel chains with 1,4-glycosidic linkages pointing in the same direction throughout the microfibrils. This parallel packing is necessitated by the kind of biosynthesis involved in the cellulose production. Investigations using 1H NMR by Atalla and VanderHart in 1984 revealed that natural cellulose has two allomorphs: 1𝛼 and I𝛽, with varying numbers and orientations of glucose units in a unit cell [116]. Cellulose 1𝛼 and I𝛽, also referred to as native cellulose, are the prevailing crystalline forms of cellulose that exist naturally. Cellulose 1𝛼 is composed of a triclinic P 1 crystal that contains one residual cellobiose per unit cell and could be synthesized by bacteria and fungi. The cellulosic chains are aligned in a parallel pattern, as one would anticipate in a single-chain unit cell. In diverse mediums, cellulose 1𝛼 is transformed to a more stable I𝛽 form by annealing at 270 °C. Cellulose I𝛽 form is mostly found in higher plants and bacteria [32, 34, 111]. The unit cell of the cellulose I𝛽 crystal is monoclinic with two cellobiose moieties per unit cell as seen in higher plant species. Furthermore, the ratio of the quantity of cellulose 1𝛼 and I𝛽 in cells is determined by the source of cellulose [103]. Although cellulose linkages are layered in parallel bundles in these polymorph forms, sheets of cellulose are directly layered on top of each other in 1𝛼 form, while layered sheets in cellulose I𝛽 form are staggered between alternate layers. The packing pattern in the lattice differs because different hydrogen bond strength exists between the chains. Hydrogen bonds are generated between intra-layer chains in both allomorphs, while van der Waals forces serve as the only force within sheets that are similar to each other [117]. Cellulose II is made by recrystallizing native cellulose and has an antiparallel chain configuration. It is the main polymorph obtained from industrially processed cellulose. Mercerization via alkali treatment or regeneration (solubilization and subsequent re-crystallization) of cellulose I have been proposed as two possible methods for cellulose II formation [34]. In comparison to Cellulose I, they are tightly packed and strongly bonded, indicating their high thermodynamic stability and low reactivity [118]. Cellulose II is more susceptible to structural alterations, although its structure’s nature is still ambiguous. Cellulose amorphous regions are believed to be one of the main contributors to the shape of cellulose. When water permeates the hydrogen bonds, the internal pressure of the amorphous portion of cellulose I is reduced and the structural chain is converted into a more regular pattern. The inclusion of water molecules can disrupt hydrogen bonds in the crystalline domain, thereby causing the unaligned structures in cellulose II to relax and assume a more enlarged layout of cellulose II [119, 120]. Cellulose type III can be produced by treating cellulose I or cellulose II with an ammonia solution, yielding either cellulose III1 or cellulose III2. The equivalent kind of cellulose type III (III1 and III2) may be converted into cellulose IV1 and IV2 by heat treatment in glycerol solution [103].

3.3 Mechanical properties of cellulose

Many factors including type, climate, yield, age and soil conditions, influence the properties of cellulose fibers. These qualities are further affected by cellulose fiber extraction techniques, such as fermentation, heating, bleaching and spinning, since different mechanical properties may be integrated into natural fibers during processing [115, 121]. Cellulose fibers are stiff and strong, with a low density [108]. The tensile strength of plant cell walls is provided by the cluster of cellulose molecules contained in the micro-fibrils. In experimental conditions, the tensile strength of cellulose microfibrils may reach 110 kg/mm2, which is around 2.5 times stronger than the strongest steel [122]. Conversely, the moistening of cellulose, as it occurs in cell walls, significantly decreases its tensile strength and capacity to offer structural support. However, it occurs within a matrix of hemicellulose, pectin and lignin in biological systems which serve as waterproofing and reinforcing material. Because of its homogenous dispersion, cellulose’s mechanical characteristics are largely determined by both its crystalline and amorphous domains [122, 123]. The amorphous and crystalline regions of nanocellulose induce distinct characteristics, with the crystalline area defining stiffness and elasticity, while flexibility and plasticity are determined by the amorphous area. However, when compared to other nanostructures, the crystalline area is greater, leading to increased stiffness [32, 124]. The Young modulus of cellulose with high crystallinity was reported to range between 100 and 200 GPa, while bacterial cellulose has a modulus of 114 GPa. As a result, nanocellulose is employed as a load-bearing material in a variety of applications [124].

4 Production of cellulose derivatives

Nanocellulose is a cellulose particle with at least one measurement in the nanometre scale (1–100 nm) [85]. Nanocellulose may be generally produced by two methods: top–down (plant fiber-breakdown) or bottom–up (biosynthetic pathway) [125, 126]. Bacteria from the Acetobacter genus are used to digest low-molecular-weight polysaccharides in the bottom-up biosynthesis method. The top-down strategy, on the other hand, entails chemically producing nanocelluloses by reducing or removing the amorphous region [126]. The strategies for creating nanocelluloses, which include mechanical, biological and chemical processes (or a combination of these approaches), will result in natural cellulose with reduced dimensions.

4.1 Classification of nanocellulose derived from cellulose biopolymer

Although multiple cellulose nanomaterials have been produced, the inconsistent and disorganized evaluation of these nanomaterials by numerous research organizations has culminated in a nomenclature of nanoparticles that is contradictory [127]. This has resulted in a plethora of names with no clear definition: nanocellulose, nanowhiskers, cellulose nano-whiskers, cellulose nanocrystals, nanocrystalline cellulose, cellulose microfibrils, cellulose nanofibrils, microcrystalline cellulose, cellulose microfibers, cellulose nanofibers, nanofibrillated cellulose, bacterial cellulose and other variations. Because of these ambiguities in naming nanocelluloses, developing a standard language via rationalization of the diverse name-type based on their size, morphology and synthesis became essential [127, 128]. The nanotechnology department of the Technical Association of Pulp and Paper Industry (TAPPI) was founded a few years ago, to regulate cellulose nanomaterial nomenclature. They created a drafted standard version of “The TAPPI WI: Basic Terms and Their Definition for Cellulose Nanomaterials” for the proper naming of nanocelluloses. Thus, nanocellulose materials may be categorized as nano-objects and nanostructures as shown in Figure 5 [128, 129].

![Figure 5:

Standard nomenclature for cellulose nanomaterials (TAPPIW13021) [130].](/document/doi/10.1515/polyeng-2023-0056/asset/graphic/j_polyeng-2023-0056_fig_005.jpg)

Standard nomenclature for cellulose nanomaterials (TAPPIW13021) [130].

The fundamental disparity between nano-object cellulose and nanostructured is the nanocellulose size. In this review, nanocellulose materials will be classified based on size, into four nomenclature groups: cellulose microfibers (CMF), cellulose microcrystals (CMC), cellulose nanofibers (CNF) and cellulose nanocrystals (CNC). A high mechanical strength, large surface area, unique optical characteristics, high crystallinity and stiffness are only a few of the outstanding qualities of nanocellulose [131, 132].

Cellulose microfibrils (CMF), also known as micro-fibrillated cellulose (MFC), are mainly composed of cellulosic materials that have been mechanically refined from sources such as highly crystalline wood fiber (WF) and plant fiber (PF). The aspect ratio of these particles is quite high; about 20–100 nm in width, a length of 500–2000 nm and a minimum wavelength of 5–50 µm [128]. CMF is prepared by dispersing wood pulp with strong shear pressures, leading to the release of substructural fibrils. Strong mechanical fibrillar networks and gels produced from heavily entangled fibrils can be used as a viable reinforcing material because of their small dimensions and broad surface area and aspect ratio [132, 133].

Cellulose nanofibrils (CNF) are another type of nano-sized cellulose. The terms CNF and CMF are frequently interchanged in literature, which can lead to misunderstandings about organizational structure. Both can be distinguished by their sizes and structure as cellulose nanofibrils (CNF) are smaller and smoother than MFCs in size, due to the longer defibrillation process time during production [134]. When compared to natural cellulose fibers, CNFs become gel in water at low concentrations (2 wt%) due to the considerable expansion in the specific surface area [128]. Nano-fibrils consist of overlaying long thin fiber structures, with a three-dimensional network of disordered (amorphous) and ordered (crystalline) areas. It has a diameter ranging between 5–30 nm and 500–2000 nm long, based on the intensity of disintegration. Cellulose nanofibers (CNF) are produced by dispersing softwood pulp mechanically in homogenizers without any pre-treatment, or little chemical/enzymatic processing [135]. When macro fibers are mechanically peeled off, the inter-fibrillary linkages between cellulose molecules are easily broken, resulting in nanofibrils with a nano-dimensional diameter and a nano-micrometre-to-micrometre fiber length [126]. Therefore, NFC encompasses both crystalline and amorphous regions within its flexible fibrillary chains. Multiple cycles through the homogenizers yield a significant improvement in viscosity. However, the massive amount of energy needed to disintegrate macro-fibers into nanofibers, which requires many defibrillation cycles in the disintegration device, is a major impediment to CNF commercialization. Therefore, the chemical pre-treatment is applied to lower the energy required for subsequent mechanical procedures [136, 137].

Another nanoform of cellulose is the cellulose nanocrystal (CNC), also known as nanocrystalline cellulose (NCC). CNC can be distinguished from CNF by the ratio of amorphous to crystalline components found in each of the nanocelluloses, with CNCs having little or no amorphous areas. Furthermore, CNCs have nano-scale length and breadth dimensions, whereas CNFs have micro and nano-scale lengths and diameters, respectively [138]. CNC is formed when the crystalline and amorphous domains of microfibrils are exposed to a range of enzymatic and chemical hydrolysis, resulting in fiber disintegration. This isolates the highly crystalline domains as rod-like nanocrystals and degrades the unaligned amorphous area. Thus, the production of rod-like or whisker-shaped cellulose nanocrystals is the outcome of strong chemical (acid) hydrolysis or enzymatic treatment of different nano and microfibrils [132, 139]. The tapering of the long edges of the crystals, which is due to the hydrolysis process, gives CNC its ‘whiskers’ shape. The majority of cellulose nanocrystals (CNCs) are elongated, cylindrical, less flexible and rod-like nanoparticles with a diameter of 3–5 nm, a length between 50 and 500 nm and a crystallinity index of 54–88 %. Furthermore, the size (length/diameter) and crystallinity of CNCs are influenced by the cellulose source and extraction procedures [139, 140]. Due to the presence of amorphous areas in microfibrils, the aspect ratios of CNC are substantially lower than MFC while CNC with more crystalline areas, on the other hand, has higher stiffness and modulus than MFC [85, 131]. When employed in composites, cellulose whiskers and other nanocellulose materials have proven to have good characteristics. Processed fibrillated wood pulp in micro-crystal dimensions is the main source of cellulose microcrystals (CMC) or microcrystalline cellulose (MCC). It is a commercially available substance that is made by reacting wood fiber (pulp) with acid and thereafter, back-neutralization with alkali and spray-drying, for usage in the pharmaceutical and food sectors [139]. The porous particles have a diameter within the range of 10–50 µm with a large cellulosic constituent, larger crystallinity and aggregate microfibril bundles of multi-sized cellulose that are tightly hydrogen bonded to each other. Before being incorporated into composites, MCC macromolecules are usually disintegrated into smaller micron-sized rod-like particles (1–10 mm in length) [139].

4.2 Cellulose extraction from plant biomass

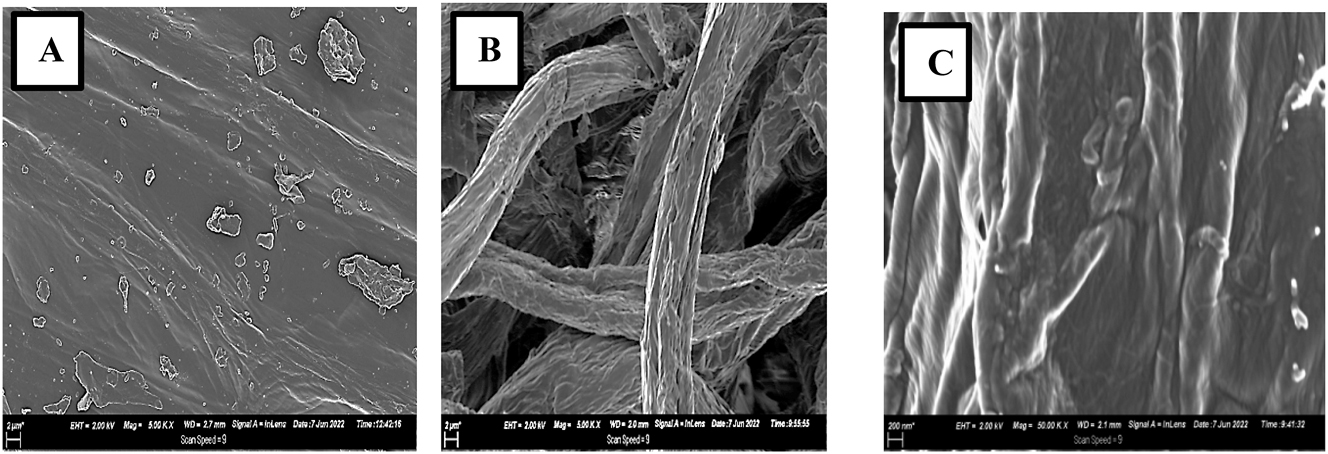

Cellulose is highly hygroscopic in its interaction with water because of the presence of a large number of hydroxyl groups on its surface, although its crystallinity and supramolecular structure makes it insoluble in most solvent [110]. Furthermore, cellulose’s crystallinity renders it resistant to acid and alkali-catalyzed hydrolysis, making chemical treatment of the material difficult. However, it can be hydrolyzed by strong acid to water-soluble sugars [33, 34]. Various mechanical and chemical techniques can be used to extract cellulose from plant fibers, but alkali and enzymatic treatments can be applied as pre-treatment, along with mechanical extraction. These pre-treatment procedures enhance the mechanical extraction process by increasing the inner surface area, accelerating the reactivity of the hydroxyl groups to reagents and disrupting the hydrogen bonds of the cellulose fiber as well [141]. The treatment of lignocellulosic biomass like maize tassels by alkali and acid-chlorite treatment is a common method used for cellulose extraction. Alkali reagents, such as NaOH solution, are a cost-effective reagent used for the hydrolysis of the plant residues during cellulose extraction [89, 142, 143]. Although cellulose’s supramolecular structure makes it resistant to hydrolysis, alkali can activate it and destroy its inner hydrogen bonds, causing it to swell. Alkalization aids in the dissolution and isolation of wax, pectin, lipids and other non-cellulosic materials from the plants’ surface, thereby accelerating the fibrillation of cellulose, as in the case of the extraction of cellulose from maize tassels residues. It also increases the crystallization potential and promotes interfacial bonding. Therefore, alkalization contributes to the improvement of fiber mechanical characteristics [144–146]. To eliminate any hemicellulose or lignin residues, the produced pulp may be bleached using a mixed solution of glacial acetic acid and sodium chlorite or a solution of hydrogen peroxide and NaOH. Thereafter, the bleached pulp fibers are rinsed with NaOH solution and washed with deionized water to obtain a near-neutral pH. The bleached residue is collected and dried in an oven @ 50 °C, resulting in holocellulose devoid of lignin [142]. Figure 6 depicts the morphology of the maize tassel fibers and cellulose fibrils extracted from maize tassels via chemical treatment.

SEM micrographs of (A) maize tassels and (B–C) celluose fibers extracted from maize tassels after chemical treatment at 2000x and 50,000x magnification, respectively.

4.3 Derivatives of cellulose

Pure cellulose is more resistant to chemical treatment due to its reduced solubility in common organic solvents, caused by strong intramolecular and intermolecular interactions. The insolubility of cellulose is also influenced by the length of polymeric chains. According to research, the solubility of celooligomers declines to zero at polymerization degrees greater than celloheptaose [147, 148]. Cellulose is entirely insoluble below 300 °C and rapidly degrades beyond this temperature. Thus, there is no temperature range associated with increasing its solubility. Cellulose derivatives are suitable alternatives to pristine cellulose, due to their unique characteristics and dissolving capabilities of some cellulose derivatives. The most well-known cellulose derivatives include cellulose ethers (e.g., carboxymethyl cellulose, methylcellulose, ethyl cellulose etc.), cellulose esters such as cellulose acetate, cellulose sulphate or sulphated cellulose and cellulose nitrate [149]. A cellulose derivative’s overall chemical structure can be altered by the type of R’ group incorporated via mono-, di- or tri-substitution as shown in Table 2.

Cellulose derivative’s structure with a variety of R’ groups.

| Cellulose derivatives | R’groups |

|---|---|

| Cellulose acetate | H–C2H3O |

| Cellulose nitrate | H–NO2 |

| Carboxymethyl cellulose (CMS) | H–CH2CO2H |

| Ethylcellulose | H–CH2CH3 |

| Methylcellulose | H–CH3 |

| Hydroxypropyl-methylcellulose (HPMC) | H–CH2OCH3 |

| Cellulose sulphate | H–SO3H |

4.3.1 Cellulose acetate (CA)

Various CA preparation procedures, which include ring-opening esterification, trans-esterification and esterification through the use of iminium chloride or N,N-carbonyldiimidazole, have been established in recent years [150]. Paul Schützenberger was the first to synthesise cellulose acetate (CA) from wood pulp treated with acetic anhydride in 1865. Cellulose acetate has also been synthesized via the treatment of cellulose with acetic acid under acidic catalytic conditions [149]. To guarantee uniform acetylation, cellulose is first treated with acetic acid, then dehydrated and reacted with acetic anhydride using a suitable catalyst-solvent system, such as sulphuric acid-anhydrous acetic acid. This produces cellulose triacetate, which may be acid-hydrolyzed to a reduced degree of substitution to obtain cellulose di-acetate and then cellulose acetate. The degree of substitution (DS) of this cellulose ester is crucial since it affects its solubility and biodegradability [151]. The mechanical qualities of cellulose acetate, as well as its hydrophobicity and hydrolytic stability, are noteworthy [149, 152].

Contaminants removal along with the various modified cellulose-based nanocomposites and adsorption performance.

| Adsorbent | Modifying solvent/reagents | Modification method | Features | Contaminant (adsorbate) | Removal/adsorption capacity (mg/g) | References |

|---|---|---|---|---|---|---|

|

|

|

|

|

|

[153] |

|

|

|

|

|

|

[154] |

Functionalized nanostructured cellulose:

|

|

|

|

|

|

[155] |

|

|

|

|

|

|

[156] |

|

|

|

|

|

|

[157] |

|

|

|

|

|

|

[158] |

|

|

|

|

|

|

[159] |

|

|

|

|

|

|

[160] |

|

|

|

|

|

|

[161] |

|

|

|

|

|

|

[162] |

|

|

|

|

|

|

[40] |

|

|

|

|

|

|

[163] |

|

|

|

|

|

|

[164] |

4.3.2 Cellulose nitrate (CN)

Cellulose nitrate (nitrocellulose), often referred to as guncotton, is the essential element in smokeless gunpowder, due to its explosive decomposition properties [165]. The nitration of cellulose produced from wood pulp or cotton fibers with a strong nitrating reagent (e.g., nitric acid), produces CN. The electrophilic reaction of NO2+ ions on the OH moieties cause the hydroxyl groups on the surface of cellulose to be replaced with nitrate esters during the nitration process. This method was initially studied in the context of nitration of alcohols and amines, but further research revealed that it was also relevant to cellulose [166]. According to research, sulphuric acid is an effective additive for stabilizing the nitration solution and preventing inadvertent detonations [167]. In industry, the H2SO4/HNO3 combination is often used for the nitration of a variety of substrates, including glycerol and cellulose. A total nitrogen concentration of 13.5 % or above is considered adequate for the complete nitration of cellulose [166]. The reaction’s success is controlled by factors like the nitrating mixture’s composition, the substrate’s source and the preparatory treatments used for the synthesis of CN [149].

4.3.3 Cellulose ethers

Cellulose ether is a group of cellulose derivatives formed when alkaline cellulose reacts with an etherifying agent under certain conditions. It is the result of ether groups replacing hydroxyl groups on cellulose macromolecules partially or completely [168]. The derivatization reactions of ethers are heterogeneous and require the diffusion of reactants into the mercerized cellulose structure [169]. The etherification of the three hydroxyl moieties of cellulose anhydroglucose units has been used to synthesize water-soluble derivatives, which include methylcellulose (MC), carboxyl methyl cellulose (CMC), ethyl cellulose (EC), hydroxypropyl cellulose (HPC), hydroxypropyl methylcellulose (HPMC) (also known as hypromellose), ethyl hydroxyethyl cellulose (EHEC) and hydroxyethyl cellulose (HEC) [170, 171]. The commonly used ether derivatives are further explained.

4.3.3.1 Carboxymethyl cellulose (CMC)

Carboxymethyl cellulose (CMC) is an important cellulose ether made by treating raw cellulose with an aqueous sodium hydroxide solution, and thereafter, filtering the alkali cellulose and reacting it with monochloroacetic acid or sodium monochloroacetate in an alcohol-supporting medium [43]. Materials containing cellulose such as wood waste, paper sludge, cotton linters, rice or maize husks, have been utilized for the production of CMC. Accordingly, CMC can be categorized as technical, partially purified, or fully purified, depending on its degree of purity [44, 149]. A linear long polysaccharide backbone structure with both carboxyl and hydroxyl surface groups is formed during the etherification process. Chemical reactivity and water solubility are facilitated by CMC’s unique chemical structure [172]. Hydrogels made from Na-CMC with a greater degree of substitution completely dissolve in water, but those made from Na-CMC with a lower DS have a stronger stiffness. The presence of additional COO- groups at greater carboxymethylation DS was thought to produce repulsion between adjacent negatively charged polymeric chains, thereby preventing the development of crosslinks and improving the dissolution properties. Conversely, a lower DS facilitates the formation of covalent bonds between functional groups [173].

4.3.3.2 Ethyl cellulose (EC)

Ethyl cellulose is a cellulosic ether that has been partly ethylated by the reaction between alkali-treated cellulose and ethyl chloride. It is a tasteless, odourless and chemically inert compound, stable in a pH range between 3 and 11, with a glass transition temperature of 120 °C. Although EC is insoluble in water, it may be dissolved in a range of organic solvents/solvent mixtures such as ethanol, methanol, toluene, chloroform, or ethyl acetate [174]. However, EC becomes very impermeable when the degree of substitution exceeds 2.8 [149, 175]. EthocelTM is a brand name for many forms of EC that are characterized by their viscosity, molecular weight and degree of substitution [176].

4.3.3.3 Methylcellulose (MC)

Methylcellulose and ethyl cellulose are both cellulose derivatives with relatively similar chemical composition. Methylcellulose, in its pure state, is a hydrophilic white powder that dissolves in cold water to form a clear viscous liquid or gel. It is indigestible, non-lethal and without allergies, just like cellulose [174]. In aqueous solutions, MC displays thermo-reversible gelation capabilities, gelling between 60 °C and 80 °C and forming a liquid again at lower temperatures [177, 178]. In the methyl ether form, MC consists of long-chain modified cellulose with about 27–32 % of hydroxyl groups. For different grades of MC, the degree of polymerization ranges from 50 to 1000-Da, with average numerical values of molecular weights ranging from 10,000 to 220,000 Da. In addition, the degree of substitution (DS) is an important factor that influences the properties of MC, such as its solubility. The average substituted number of hydroxyl groups per glucose is defined as the degree of substitution of a certain type of methylcellulose. Thus, a DS of 3.0 is the theoretical maximum number required; nevertheless, more frequent values of 1.3–2.6 may be produced. Synthesized MC may occur in two forms; one with a uniform distribution of substituents while the other, with a random distribution of substituents along the chains [179]. On an industrial scale, MC is made by mechanically mixing cellulose with sodium hydroxide and methyl chloride solutions, with the methylation reaction happening more quickly in NaOH-rich and/or higher temperatures, resulting in non-uniform methyl group distribution along the chain. It contains “hydrophobic zones” that are extensively substituted and “hydrophilic zones” that are less substituted [170]. Methoxide can substitute 27–31 % of the hydroxyl moieties in anhydroglucose units after the etherification process (−OCH3 groups). Polymer structure of diverse methyl cellulose formulations can also vary. The MC that has been evenly replaced does attain the DS required for water solubility. As a result, only the heterogeneous kind, which is water-soluble when the DS is between 1.3 and 2.6, is commercially utilized [170, 174, 180].

4.3.3.4 Hydroxypropyl-methylcellulose (HPMC)

HPMC is a derivative of cellulose that has been partially O-methylated and O-(2-hydroxypropylated) [170]. Like MC, the presence of methoxy residues in HPMC causes gelation and the inclusion of hydroxypropyl residues is known to drastically affect the gelation features in a temperature-dependent approach [181]. In addition, HPMC gelation is thought to be caused by the high hydrophobic reactions and the exclusion of water (syneresis) from extensively methoxylated polymer areas [170]. The DS, or the number (average) of hydroxyl groups substituted, which is a maximum of three, is another characteristic of HPMC. The molar substitution or MS (i.e., the reaction between the average amount of reagent molecules like propylene oxide and each anhydroglucose unit), which may be more than 3, determines the number of hydroxypropyl groups attached to the cellulose structure.

4.3.4 Cellulose sulphate (CS)

Cellulose sulphate (CS) is a cellulose ester produced by heterogeneous, homogeneous, or partial sulphation reactions. Compared to pristine cellulose, CS has various benefits, such as improved water solubility and antibacterial characteristics at significant concentrations [182]. During heterogenous sulphation, pure cellulose is treated with a sulphating agent (e.g., sulphuric acid) in a suitable reaction medium, most often isopropyl alcohol which causes the hydroxyl groups on the surface to be replaced with sulphate groups after this reaction. Schweiger R.G. first reported homogeneous sulphation in a study in 1979, where cellulose in SO3-pyridine complex with N,N-dimethylformamide as co-solvent, yielded CS with a relatively high substituted degree (SD) and a reaction intermediate known as cellulose nitrate [149]. The partial-homogeneous procedure is based on aceto-sulphation, which is identified as a gradual dissolution of cellulose in N,N-dimethylformamide combined with a mixture of sulphating and acetylating reagents (e.g. chlorosulphuric acid/acetic anhydride) and subsequent cleaving of acetyl groups upon precipitation. This results in the conversion of cellulose acetate-sulphate into CS. Regioselective sulphation can be achieved depending on the method utilized. For instance, the OH groups at the C2 and C3 locations of the anhydroglucose unit are shielded by acetosulphation, while a larger substitution group is attained at the C6 point. Conversely, C2 and C3 positions can also be influenced by homogenous sulphation [183].

5 Production of cellulose beads

5.1 Physical forms of cellulose adsorbent materials

The physical form in which an adsorbent material exists plays an essential role in removing pollutants from wastewater. Cellulose may be converted into well-defined structures like films or membranes, different-geometry fibers, sponges, powder or granules and round particles (cellulose beads/hydrogels) [184, 185]. The microspheres (aerogel, hydrogel and beads) made from polysaccharide-based materials are the most complex form of adsorbent among all the other forms. Due to the availability, renewability, biocompatibility, biodegradability, specific functionality and great mechanical and chemical resistance of cellulose, well-designed porous cellulose beads are viable candidates for industrial application [158, 186]. Cellulose beads (CB) are tiny spherical particles (in the micro-to millimetre range) that can be porous or nonporous. CBs with a low density and broad surface area are known as porous CBs. They are sometimes referred to as microspheres, pellets, beaded cellulose or pearl cellulose. CBs are more favourable than films or other irregularly shaped particles in flow process because they minimize backpressure and agglomeration during column experiments [187]. In addition, separation in aqueous media becomes difficult when cellulose derivatives are used in the powdery form as absorbents or ion exchangers. Therefore, cellulose beads can circumvent the above-mentioned limitation while the porous surface improves cellulose hydroxyl group availability. The broad surface area to volume ratio of beads facilitates the integration of chemical moieties, thereby improving the contaminants’ binding effectiveness to the adsorbent [185, 188, 189]. Therefore, functionalized porous beads are attracting increasing attention in recent times, due to their distinctive high porosity, functionizable surface and numerous potential applications in filtration, purification, catalysis, energy storage, drug or cell delivery etc. [190, 191].

5.2 Preparation of cellulose beads

A common cellulose bead-making approach consists of the following steps: (1) application of appropriate solvents for dissolving cellulose or its derivatives, (2) polysaccharide solution gelation and shaping into spherical particles and, (3) sol–gel transition and pore adjustment and (4) gel drying [192, 193].

5.2.1 Dissolution of cellulose

The insolubility of cellulose has been attributed to a variety of reasons surrounding the chemical structure of the substance. To start with, native cellulose is a large macropolymer with a high degree of polymerization (DP) that is inherently difficult to dissolve, owing to thermodynamics influence (reduced entropic gain during dissolution for macromolecules, compared to smaller molecules). The presence of five oxygen molecules in the hydroxyl groups, in addition to the ring- and bridge oxygen, results in the formation of complicated hydrogen bond patterns. Moreover, cellulose’s H and C atoms may combine via hydrophobic interactions, indicating the amphiphilic nature of cellulose. Overall, this places a great demand for a cellulose solvent that is effective in disintegrating the bonds and dissolving cellulose [194, 195]. A solvent that is appropriate for dissolving cellulose must be able to permeate through cellulosic linkages and isolate amorphous from crystalline sections. The solvent must target the strongly bonded hydrophobic-hydrogen linkages inside the cellulose chain. Acidic inorganic reagents (e.g., HCl) or a combination of acids at significant concentrations can dissolve cellulose in acidic media [132, 196]. Many possible solvent systems for cellulose dissolution can be categorized into two: derivatizing and non-derivatizing aqueous solvents. Thus, “derivatizing” solvents are those that chemically modify the cellulose during the dissolution process. These solutions react with one or more of the three reactive hydroxyl groups in the cellulose chains, resulting in the formation of “unstable” acetal, ester and ether derivatives that will improve the solubility property of the cellulose in conventional systems [192, 196, 197]. By cleaving the intermediate derivatives, which may be triggered by adding water or changing the pH or temperature, cellulose can be regenerated and moulded into solids such as membranes or beads. Derivatizing solvents transforms cellulose into derivatives that are only metastable under soluble conditions in most situations. Some carboxylic acids (e.g. CF3COOH) and dinitrogen tetroxide (N2O4) (in combination with dimethylsulfoxide (DMSO) or N,N-dimethylformamide) are examples of derivatizing solvents [198]. The term “non-derivatizing” refers to situations in which the polymer dissolves purely through intermolecular interactions instead of chemical conversion of its hydroxyl groups [192, 193]. Non-derivatizing solvents disintegrate cellulose linkages by breaking the forces that keep them intact, without causing any chemical change. They are not just for cellulose dissolution purposes or regeneration procedures, but can also be used to make certain important and highly designed cellulose derivatives. Thus, the non-derivatizing solvents can be further grouped into two categories: aqueous and non-aqueous solvents. A solution of N,N-dimethylacetamide (DMAc) and lithium chloride (LiCl) is a popular non-aqueous cellulose solvent. It is commonly utilized for polysaccharide analytical evaluation and as a reaction medium for uniform cellulose conversion [132]. Conversely, LiOH, NaOH and some inorganic metal complexes that are mainly composed of ions of transition elements and nitrogen ligands like cuprammonium hydroxide (Cuam), which produce brightly coloured solutions, are examples of aqueous solvents [195]. The molten inorganic hydrated salts and concentrated inorganic salt solutions (e.g., magnesium chloride (MgCl2·6H2O), lithium chloride (LiCl·5H2O), lithium perchlorate (LiClO4·3H2O) and zinc chloride (ZnCl2·4H2O) are further examples of aqueous solvents that have been utilized for the homogenous modification of cellulose [132].

5.2.2 Common aqueous solvent for cellulose dissolution

To guarantee the homogeneity of cellulose throughout the solution preparation, different mixed solvent systems will be required for its dissolution. Thus, aqueous NaOH solutions in conjunction with various chemicals that inhibit gelation, such as urea, thiourea or ZnO, have attracted a lot of interest. These reagents are inexpensive, ecologically friendly and nontoxic and they have vast potential applications [193, 199, 200]. Cellulose may be dissolved in NaOH/urea at cold temperatures and in a particular concentration range. According to Chen and his colleagues [201], the reaction occurs when cellulose forms hydrogen-bond-induced complexes in the form of a linked network, after treatment with alkali and urea. The aqueous solvents promptly break down cellulose at lower temperatures of about 10 °C, producing clear solutions from which cellulose may be recovered by agglomeration in diluted acids. The hydrogen link between the cellulose polymer chains is broken by the OH− anion in NaOH, while the Na+ enhances the simultaneous breaking of bonds and modifying of the surrounding water, thereby preventing the re-aggregation of chains [202]. When NaOH/water solvent is employed without additives, the dissolving process is considerably impeded due to the gelation of cellulose solutions. Gelation occurs when hydrogen bonding between cellulose-cellulose molecules is formed, resulting in the agglomeration of cellulose chains and the generation of cellulose-rich areas. The gel formed becomes opaque, suggesting entities that scatter visible light. This heterogeneous structure, with wide pores and dense pore walls, might explain why aerogels formed from gelled solutions have a low specific surface area of 200–250 m2/g. Therefore, a combination of solutions, such as NaOH/urea is preferred [203].

Another environmentally friendly solvent is the NaOH/thiourea solvent system. Separating cellulose chains from each other can also be accomplished by combining NaOH and thiourea hydrates. The hydrates prevent the surface intermolecular hydrogen bond from being regenerated by the cellulose [196, 204]. Complex solvents formed by the combination of NaOH, thiourea and water with the cellulose substrate will likely disrupt the intramolecular hydrogen link in cellulose at low temperatures, unlike NaOH hydrates (NaOH and water), which readily adhere to cellulose linkages to establish a new hydrogen bond [205].