Abstract

In this work we present improved design guidelines to support the die designer activity, when searching for the flow channel geometry that allows the achievement of a balanced flow distribution, in complex profile extrusion dies. The proposed methodology relies on surrogate models, obtained through a detailed and extensive numerical study, carried out with the open source computational library OpenFOAM®, in which an appropriate numerical solver for the problems under study was implemented. The main contribution of this work is to further enlarge the applicability of the simplified design methodology (Rajkumar A, Ferrás LL, Fernandes C, Carneiro OS, Becker M, Nóbrega JM. Int. Polym. Proc. 2017, 32, 58–71.) previously proposed by this group for similar purposes, by considering the effect of processing parameters and material rheology. The sensitivity analyses performed showed that, among the studied parameters, the power-law exponent was the only one that affected the system behavior. Thus, the previous proposed surrogate models were modified to include the effect of this parameter. Verification studies performed for three geometries and different rheological and process parameters evidenced the effectiveness of the proposed simplified design methodology.

Acknowledgments

The authors would like to thank for the financial funding by FEDER through the COMPETE 2020 Program, the National Funds through FCT under the project UID/CTM/50025/2013. A. Rajkumar acknowledges the MIT-Portugal program and FCT (Portuguese Foundation for Science and Technology) for the funding through scholarship SFRH/BD/51943/2012, and L.L. Ferrás for the financial support by FCT through scholarship SFRH/BPD/100353/2014.

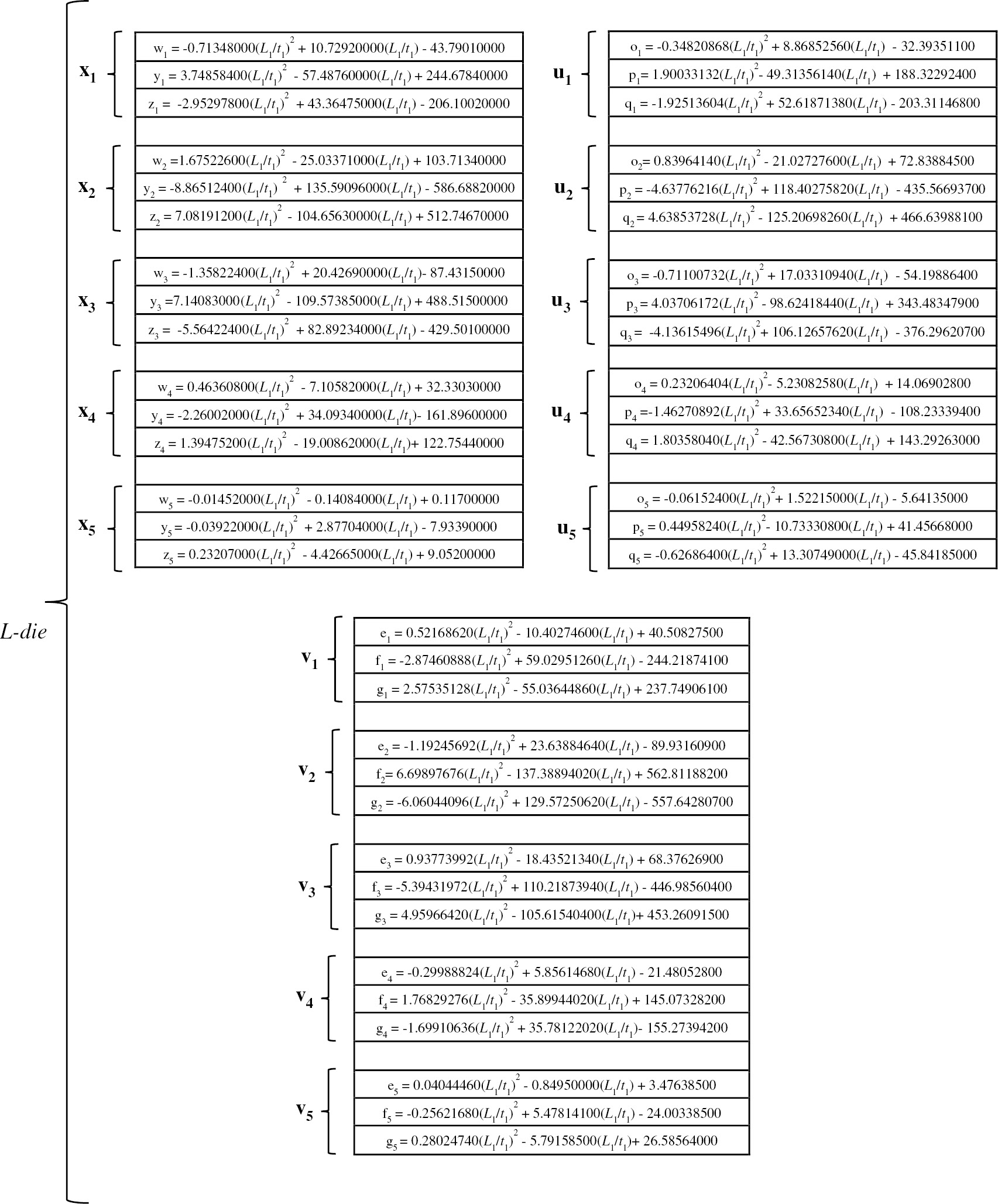

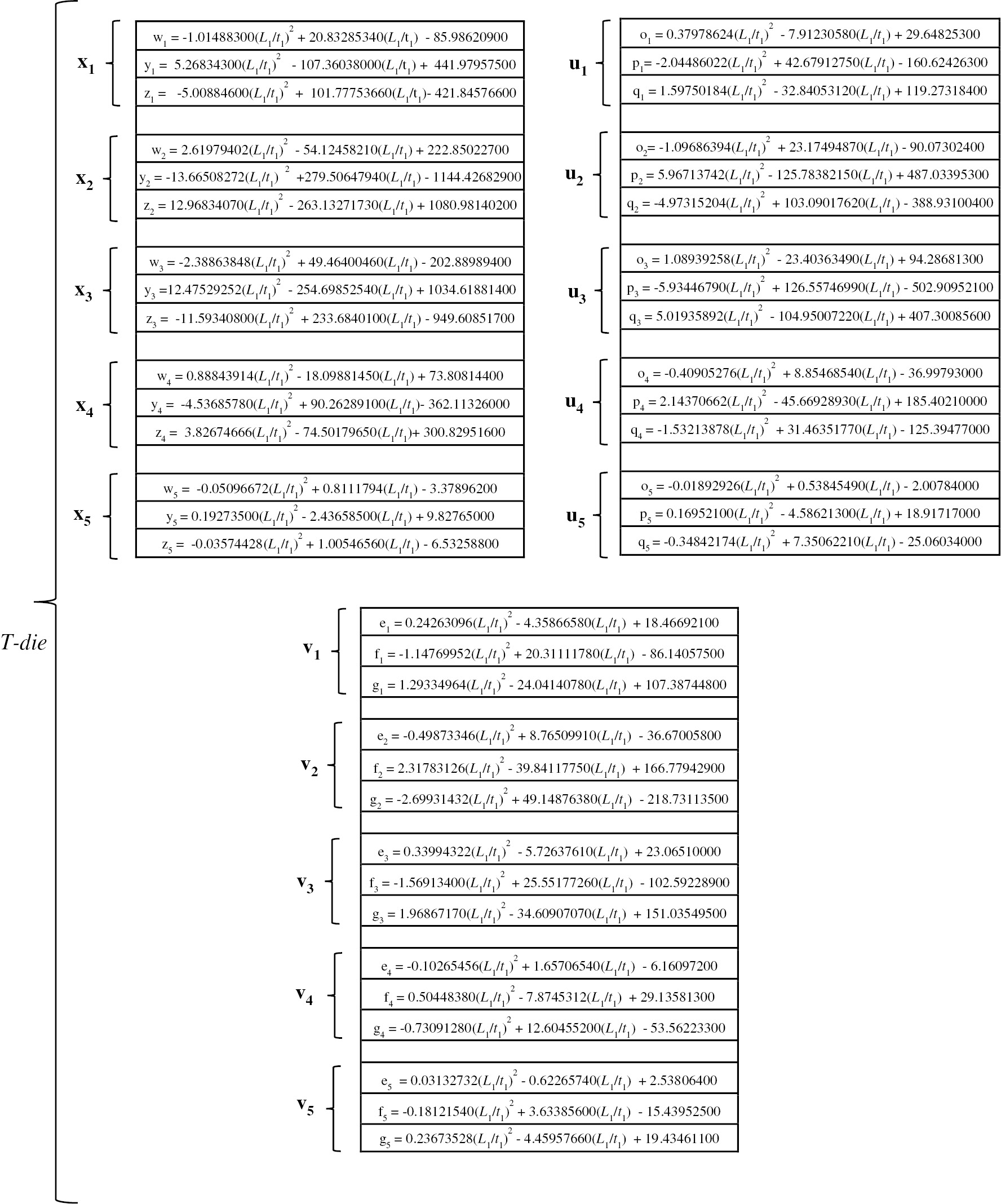

Appendix 1

The fitting function, or model, is given by:

For the L-die and T-die, the coefficients are given as follows:

| x1=w1(t2)2+y1(t2)+z1 | u1=o1(t2)2+p1(t2)+q1 | v1=e1(t2)2+f1(t2)+g1 |

| x2=w2(t2)2+y2(t2)+z2 | u2=o2(t2)2+p2(t2)+q2 | v2=e2(t2)2+f2(t2)+g2 |

| x3=w3(t2)2+y3(t2)+z3 | u3=o3(t2)2+p3(t2)+q3 | v3=e3(t2)2+f3(t2)+g3 |

| x4=w4(t2)2+y4(t2)+z4 | u4=o4(t2)2+p4(t2 )+q4 | v4=e4(t2)2+f4(t2)+g4 |

| x5=w5(t2)2+y5(t2)+z5 | u5=o5(t2)2+p5(t2)+q5 | v5=e5(t2)2+f5(t2)+g5 |

References

[1] Michaeli W, Kaul S. J. Polym. Eng. 2004, 24, 123–136.10.1515/POLYENG.2004.24.1-3.123Search in Google Scholar

[2] Carneiro OS, Nobrega JM. Design of Extrusion forming Tools, Smithers Rapra Technology Ltd: Shawbury, 2012.Search in Google Scholar

[3] Rauwendaal C. Polymer Extrusion, Carl Hanser Verlag GmbH Co KG: Munich, 2014.10.3139/9781569905395Search in Google Scholar

[4] Michaeli W. Extrusion Dies Design and Engineering Computations, Hanser Publishers: Munich, 1984.Search in Google Scholar

[5] Tadmor Z, Gogos CG. Principles of Polymer Processing, John Wiley & Sons: New Jersy, 2006.Search in Google Scholar

[6] Hurez P, Tanguy P, Blouin D. Polym. Eng. Sci. 1996, 36, 626–635.10.1002/pen.10450Search in Google Scholar

[7] Reid J, Campanella O, Corvalan C, Okos M. Polym. Eng. Sci. 2003, 43, 693–703.10.1002/pen.10057Search in Google Scholar

[8] Wu T, Jiang B, Xu S, Bi C. Polym. Eng. Sci. 2006, 46, 406–415.10.1002/pen.20419Search in Google Scholar

[9] McKelvey JM, Ito K. Polym. Eng. Sci. 1971, 11, 258–263.10.1002/pen.760110314Search in Google Scholar

[10] Proctor B. SPE Journal 1972, 28, 34–41.10.1007/BF00716233Search in Google Scholar

[11] Chen C, Jen P, Lai F. Polym. Eng. Sci. 1997, 37, 188–196.10.1002/pen.11661Search in Google Scholar

[12] Carneiro OS, Nóbrega JM, Pinho FT, Oliveira PJ. J. Mater. Process. Tech. 2001, 114, 75–86.10.1016/S0924-0136(01)00574-XSearch in Google Scholar

[13] Nóbrega JM. Computer aided design of forming tools for the production of Extruded profiles, PhD Thesis, University of Minho, Portugal, 2004.Search in Google Scholar

[14] Gonçalves NDF. Computer aided design of extrusion forming tools for complex geometry profiles, PhD Thesis, University of Minho, Portugal, 2013.Search in Google Scholar

[15] Elgeti S, Probst M, Windeck C, Behr M, Michaeli W, Hopmann C. Finite Elem. Anal. Des. 2012, 61, 35–43.10.1016/j.finel.2012.06.008Search in Google Scholar

[16] Lebaal N, Puissant S, Schmidt F, Schläfli D. Polym. Eng. Sci. 2012, 52, 2675–2687.10.1002/pen.23203Search in Google Scholar

[17] Nóbrega JM, Carneiro OS, Oliveira PJ, Pinho FT. Int. Polym. Proc. 2003, 18, 307–312.10.3139/217.1746Search in Google Scholar

[18] ANSYS POLYFLOW: http://www.ansys.com/, Canonsburg, PA, USA.Search in Google Scholar

[19] DIE FLOW: http://www.dieflow.com/, Chippewa Falls, WI, USA.Search in Google Scholar

[20] Compuplast:http://www.compuplast.com/product, Williamsvile, NY, USA.Search in Google Scholar

[21] Polydynamics:http://www.polydynamics.com/index.html, Dundas, Ontario, Canada.Search in Google Scholar

[22] Zolfaghari A, Behravesh A, Shakouri E, Soury E. Polym. Eng. Sci. 2010, 50, 543–549.10.1002/pen.21567Search in Google Scholar

[23] Grieß HJ, Münstedt H. Polym. Eng. Sci. 2012, 52, 2253–2259.10.1002/pen.23187Search in Google Scholar

[24] Rajkumar A, Ferrás LL, Fernandes C, Carneiro OS, Becker M, Nóbrega JM. Int. Polym. Proc. 2017, 32, 58–71.10.3139/217.3272Search in Google Scholar

[25] OpenFOAM 2.3.0: http://openfoam.org/version/2-3-0/, Paris, France.Search in Google Scholar

[26] Nóbrega JM, Carneiro OS, Oliveira PJ, Pinho FT. Int. Polym. Proc. 2003, 18, 298–306.10.3139/217.1745Search in Google Scholar

[27] Nóbrega JM, Carneiro OS, Oliveira PJ, Pinho FT. Int. Polym. Proc. 2004, 19, 225–235.10.3139/217.1825Search in Google Scholar

[28] Burden RL, Faires JD. Numerical Analysis, 9th ed, Brooks/Cole: Boston, 2001, vol 206, p. 432–438.Search in Google Scholar

©2018 Walter de Gruyter GmbH, Berlin/Boston

Articles in the same Issue

- Frontmatter

- Original articles

- Mechanical and rheological properties of polystyrene-block-polybutadiene-block-polystyrene copolymer reinforced with carbon nanotubes: effect of processing conditions

- Effects of surface modification of halloysite nanotubes on the morphology and the thermal and rheological properties of polypropylene/halloysite composites

- Influence of the polyacrylonitrile proportion on the fabricated UF blend membranes’ performance for humic acid removal

- Effects of partial replacement of carbon black with nanocrystalline cellulose on properties of natural rubber nanocomposites

- Conductive mechanism of carbon black/polyimide composite films

- Effects of fiber-surface modification on the properties of bamboo flour/polypropylene composites and their interfacial compatibility

- Highly electrically conducting poly(L-lactic acid)/graphite composites prepared via in situ expansion and subsequent reduction of graphite

- Preparation and performance optimization of PVDF anti-fouling membrane modified by chitin

- Fabrication of bilayer resin-bonded fixed abrasive wires using the pultrusion process

- Guidelines for balancing the flow in extrusion dies: the influence of the material rheology

Articles in the same Issue

- Frontmatter

- Original articles

- Mechanical and rheological properties of polystyrene-block-polybutadiene-block-polystyrene copolymer reinforced with carbon nanotubes: effect of processing conditions

- Effects of surface modification of halloysite nanotubes on the morphology and the thermal and rheological properties of polypropylene/halloysite composites

- Influence of the polyacrylonitrile proportion on the fabricated UF blend membranes’ performance for humic acid removal

- Effects of partial replacement of carbon black with nanocrystalline cellulose on properties of natural rubber nanocomposites

- Conductive mechanism of carbon black/polyimide composite films

- Effects of fiber-surface modification on the properties of bamboo flour/polypropylene composites and their interfacial compatibility

- Highly electrically conducting poly(L-lactic acid)/graphite composites prepared via in situ expansion and subsequent reduction of graphite

- Preparation and performance optimization of PVDF anti-fouling membrane modified by chitin

- Fabrication of bilayer resin-bonded fixed abrasive wires using the pultrusion process

- Guidelines for balancing the flow in extrusion dies: the influence of the material rheology