Abstract

The potential of oxygen delignified fibers to replace fully bleached fibers in tissue products was investigated on softwood pulps. The absorption, mechanical properties and softness of laboratory tissue hand sheets from one commercial fully bleached pulp and five unbleached oxygen delignified lab pulps were compared. The pulps with different lignin content and total fiber charge were evaluated with and without PFI refining. The pulps subjected to oxygen delignification resulted in pulps with much higher total fiber charge content that led to higher swelling and higher wet strength when compared to the commercial fully bleached pulp. Some unbleached oxygen delignified pulps showed great potential in the absorption capacity, while others showed a much higher wet tensile strength when compared to the commercial pulp. Compared to the commercial bleached pulp, a similar softness for a higher wet and dry tensile index in the unbleached fibers was observed for the oxygen delignified pulps. Unbleached pulps subjected to an extended oxygen delignification proved to be a suitable alternative to fully bleached pulps in tissue grades, depending on the desired property (absorption or wet strength).

1 Introduction

Tissue products are present in our everyday lives for different purposes, such as personal use as facial tissue, toilet paper, napkins, household towels, packing tissue paper, among others. The primary required properties are generally good liquid absorption capacity, smoothness, bulk and, strength (de Assis et al. 2018). Those properties are highly dependent on the production process and raw material and they will vary according to the final use. While absorbency and softness are the most required qualities for toilet papers, napkins or facial tissue (Kim et al. 1994), for towel papers, besides the absorption capacity, tensile strength is also a crucial property to take into consideration, especially wet tensile strength (Gigac and Fišerová 2008).

The production and consumption of tissue products have been constantly growing over the years, with the prediction that they will continue to increase, according to CEPI (Central European Paper Industries) statistics. The awareness around health and hygiene issues, population growth and the improved standard of living are some of the causes of the increased demand for tissue. However, the increase in tissue consumption leads to some environmental issues.

Nowadays, fully bleached fibers are the ones typically used in tissue and hygiene products due to their good properties: high-level brightness, good water absorption, softness and lower impurity content (Beuther et al. 2010; Fišerová et al. 2019; Kullander 2012; Rebola et al. 2021). However, fully bleached fibers require bleaching processes that negatively affect the environment and compromise sustainability. Consumer awareness for sustainability is rising every day and there is an increasing preference for products with lower environmental impact, such as recycled or unbleached products (Brito et al. 2023; Feber et al. 2020; Haller et al. 2020; Zambrano et al. 2022).

Unbleached fibers can be a great alternative to fully bleached fibers due to their lower carbon footprint (Jour et al. 2013; Man et al. 2020). Depending on the final product properties, unbleached fibers can probably be tailor-made and eventually replace the fully bleached fibers used nowadays. Studies have shown that unbleached oxygen delignified pulps can have a great swelling ability due to the fiber charge increase during their oxidation reactions (Esteves 2022; Mai 2021; Zambrano et al. 2022; Zhang et al. 2005). Besides that, oxygen delignification tends to result in fibers with higher curl and a higher number of kinks (Esteves et al. 2021a; Mohlin and Alfredsson 1990), which can be beneficial for the bulk of the final product (Rebola et al. 2021). This work aims to maximize the increase in the total fiber charge of the fibers subjected to oxygen delignification assessing kraft cooked pulp with different starting kappa numbers and investigating the potential of using those pulps as a replacement for fully bleached fibers.

2 Materials and methods

2.1 Materials

A mixture of softwood chips from an industrial mill (80 % Spruce and 20 % Pine) was used in this study for kraft cooking and oxygen delignification. A never dried commercial fully bleached pulp (reference pulp) from the same mill was used for comparison. For future comparisons, it is important to highlight that the fully bleached pulp was produced industrially and, therefore subjected to much harsher treatments than the pulps produced in the laboratory.

2.2 Methods

2.2.1 Kraft cooking

Three series of kraft cooks were done in this study to obtain pulps with different kappa numbers, two were produced in one recirculatory digester and one was produced in autoclave.

Recirculator digester: The wood chips were kraft cooked in a recirculated digester with a dry chips capacity of 2 kg, controlled temperature and a forced liquor flow. The wood chips were impregnated in water under 0.5 MPa nitrogen pressure the day before the cooking. The water was then removed and cooking liquor was added to give a liquor/wood ratio of 4.5 l/kg. The impregnation step was performed for 30 min at 100 °C and the cooking step was performed at 160 °C. After the cooking, the steam flow was stopped, and the spent liquor was drained off and collected for analysis.

Autoclave: The trials were performed in steel autoclaves with a volume of 2.5 dm3, which were loaded with 250 g (o. d.) wood chips. With a vacuum pump, the air inside the vessels was removed for 30 min and after that time, the cooking liquor was sucked into the autoclaves. The chips were first subjected to 0.5 MPa nitrogen injection for about 30 min, and then released before starting the cook. For the impregnation step, the autoclaves were placed in a steam-heated glycol bath at 100 °C for 30 min, and at 160 °C for the cooking step. Rotation and slight inclination of the autoclaves ensured good mixing inside. After the cooking step, the autoclaves were cooled down in a water bath for 10 min, and then the spent liquor was drained off the chips and collected for analysis.

The trials were performed with an effective alkali of 22 %, a sulfidity of 30 % and with an ionic strength of 0.1 M. The trials were stopped at different H factors (cooking times) to achieve distinct kappa numbers.

The delignified chips were washed with deionized water for 10 h in self-emptying metal cylinders and subsequently defibrated and screened in an NAF water jet defibrator (Nordiska Armaturfabriken). The shives were collected, dried at 105 °C, and weighed.

2.2.2 Oxygen delignification

Oxygen delignification was carried out with 60 g of oven-dried (o. d.) pulp, placed in polyethylene bags with the required amount of NaOH, MgSO4, and water at a consistency of 12 %. The bags were closed by heat-welding, kneaded initially by hand and then in a vibrational shaker. The pulp was then removed from the bags and transferred to pressurized teflon-coated stainless-steel autoclaves. The autoclaves were closed, pressurized with oxygen and placed in an electrically heated glycol bath, with rotation at a slight inclination. The trials were performed with single or double oxygen stages with no washing in between. The single oxygen stages were pressurized with 0.7 MPa of oxygen and the reaction was carried at 100 °C. For the double stages of oxygen delignification the pressure used in the first stage was 1 MPa and the temperature was 85 °C, while for the second stage the pressure was 0.5 MPa and 110 °C. After the oxygen delignification, the pulps were washed with deionized water and filtrated.

The conditions for each trial are illustrated in Figure 1. Pulps were denominated KX_OY, where X is the kappa number of the cooked pulp and Y is the kappa number after the oxygen delignification stage.

Illustrative representation of the performed kraft cooking and oxygen delignification trials. The black arrows represent the cooking extension and the white arrows the oxygen delignification. The white single arrows are relative to the single oxygen stage, while the two white arrows overlapping are relative to the double oxygen stage. The samples are denominated KX_OY, where X is the kappa number of the cooked pulp and Y the kappa number after oxygen delignification.

2.2.3 Refining, paper making

The pulp samples were refined at two different levels (2000 and 4,000 rpm) in a PFI-mill according to ISO 5264–2 and handsheets were prepared according to ISO 5269–1 with deionized water, to a grammage of 60 g/m2 for the standard handsheets and a grammage of 20 g/m2 for the tissue handsheets, with no pressing.

2.3 Analysis of pulp and paper properties

Table 1 and 2 present the different pulp and paper characterization standards.

Standards used for the pulp characterization.

| Methods | Standards |

|---|---|

| Kappa number | ISO 302:2004 |

| Water retention value (WRV) | SCAN-C 62:00 |

| Total fiber charge | SCAN-CM 65:02 (Katz et al. 1984) |

Standards used for the standard and tissue handsheet characterization.

| Methods | Samples | Standards |

|---|---|---|

| Grammage | 60 and 20 g/m2 | ISO-12625-6:2017 |

| Thickness and bulk | 60 and 20 g/m2 | ISO-12625-3:2014 |

| Basket immersion test | 20 g/m2 | ISO-12625-8:2011a |

| Capillarity rise (Klemm) | 20 g/m2 | ISO-8787:2022 b |

| Dry tensile strength | 60 g/m2 | ISO 1924-3:2005 |

| Dry and wet tensile strength | 20 g/m2 | ISO 12625-5:2017 |

| Tissue Softness analyzer (TSA) | 20 g/m2 | RISE internal standard |

-

ainstead of 5 g the test was performed with 1 g of sample, binstead of 10 min the test was performed for 5 min.

Measuring tissue properties usually depends on several factors that are often poorly controlled such as the sample size, the number of plies, among others. In the present study, the papers were produced and evaluated in the same conditions: lab tissue handsheets of 20 g/m2 for the commercial fully bleached pulp and for the oxygen delignified pulps.

2.3.1 Softness evaluation

The softness of the tissue handsheets was evaluated by the Tissue Softness Analyzer (TSA). TSA collects data from several sensors in the instrument, but three parameters are considered to be of most importance: softness (TS7), surface smoothness (TS750) and sheet stiffness (D). The equipment uses a rotating lamellar fan on the paper’s surface to estimate the sample’s softness. Both TS7 and TS750 are determined from the sound spectrum captured by microphones on either side of the sample. The higher the response from the sensor the lower is the paper softness. The top microphone algorithm was used in this work.

2.3.2 Total fiber charge increase calculation

To quantify how much the increase in the fiber charge after oxygen delignification was compared to the kraft cooking, a regression fit was made for the kraft cooked pulps as a reference, given by Equation (1).

TTFCCook is the Theoretical value for the Total Fiber Charge of a kraft cooked pulp for a given kappa number. The fiber charge increase obtained by oxygen delignification is then calculated according to Equation (2):

where TFCOxygen is the total fiber charge of pulp after oxygen delignification to kappa number “x”, and TTFCCook is the theoretical total fiber charge of pulp after kraft cooking until the kappa number (x) was the same as the oxygen delignified pulps.

3 Results and discussion

3.1 Delignification

The cooking trials were aimed to obtain three different kappa numbers: a high kappa number (109), a medium-high kappa (61) and a low kappa number (29) – Table 3. The kappa numbers aimed for are based on results from previous studies (Esteves 2022; Esteves et al. 2021a; Mai 2021) where it was seen that the higher the starting kappa number is after cooking the higher will be the fiber charge increase. Having kraft-cooked pulps between kappa 109 and 29 will also allow us to evaluate the influence of the lignin content on the final absorption and strength properties in connection with the fiber charge.

Summary of the kraft cooking and oxygen delignification trials. Cooking temperature was 160 °C, sulfidity 30 %, effective alkali 21 % and liquor-to-wood ratio 4.5 l/kg. For the single oxygen trials the pressure was 0.7 MPa and the temperature was 100 °C, while for the double oxygen trials the pressure was 1 MPa and the temperature was 85 °C for the first stage and 0.5 MPa and 100 °C for the second stage.

| Samples | H factor | – | Kappa no. | Total yield (cooking stage) (%) | Residual alkali (g/l) |

|---|---|---|---|---|---|

| K29 | 1700 | – | 29 | 48.0 | 10.3 |

| K61 | 720 | – | 61 | 52.5 | 12.2 |

| K109 | 420 | – | 109 | 54.8 | 14.5 |

|

|

|||||

| Samples | Time, min | Alkali charge, % | Kappa no. | Total yield (oxygen stage) (%) | End pH |

|

|

|||||

| K29_O10 | 130 | 4.5 | 10.4 | 94.8 % | 12.4 |

| K29_OO8 | 45/150 | 5.5 | 8.0 | 92.6 % | 12.2 |

| K61_O25 | 105 | 4.2 | 24.5 | 92.9 % | 10.3 |

| K61_OO18 | 40/140 | 6.2 | 17.5 | 90.2 % | 10.2 |

| K109_O47 | 150 | 6.2 | 47.4 | 90.1 % | 10.8 |

| K109_OO35 | 60/185 | 9.2 | 35.2 | 89.9 % | 10.3 |

The pulp with the highest kappa number (K109) was defibrated in a Sprout Waldron refiner before the oxygen delignification. The oxygen trials were aimed to have extended delignification (more than 60 min) with a high alkali charge (more than 3 % NaOH) and an end pH between 10 and 11.5. The goal was to achieve the highest possible total fiber charge. However, for the lower cooked kappa number (K29) the end pH was higher than it was aimed at since the alkali charge was too high for the delignification efficiency.

3.2 Total fiber charge

It is known that the carboxylic acid groups are the main charged groups found in the chemical pulp fibers (Dang et al. 2006; Zhang et al. 2005). However, the charges suffer modifications during the different pulping processes that can eventually lead to their decline. Figure 2 illustrates the different behaviors that occur during Kraft cooking, oxygen delignification, and bleaching.

Total fiber charge for non refined pulps at different kappa numbers after kraft cooking (black line) and oxygen delignification (green, orange and blue lines) at different alkali charges, given as % NaOH in the figure. The oxygen trials presented in green were performed on kraft cooked pulp with an initial kappa (iKa) number of 29, while the oxygen trials presented in orange were performed on kraft cooked pulp with an initial kappa number (iKa) of 61 and the oxygen trials presented in blue were performed on kraft cooked pulp with an initial kappa number (iKa) of 109. The commercial fully bleached pulp is denominated as reference in the figure (black square).

The linear decrease in the charged groups as the lignin content is reduced during kraft cooking is clear (Figure 2) and it is well documented (Buchert et al. 1997; Chai et al. 2003; Dang et al. 2006; Esteves 2022). This is caused by the lignin removal during the delignification and by some xylan dissolution (Buchert et al. 1997; Chai et al. 2003; Dang et al. 2006; Esteves et al. 2021a) since they are the main components where the charged groups are present.

For oxygen delignification, the total fiber charge development is not straightforward, but the increase in total fiber charge when compared to the kraft cooked pulps for the same lignin content is evident in the higher kappa numbers. The higher values for the charge content were obtained for the pulp with the highest kappa number from the cooking, which was expected. This is mainly due to the oxidation reactions in lignin that lead to a higher content of new charged groups on the pulp due to the higher lignin content. These groups are largely from the muconic acid structures created in lignin (Dang et al. 2006; Snowman et al. 1999; Yang et al. 2003), but also from oxidized carbohydrates (Tao et al. 2011; Zhang et al. 2006; Zhao et al. 2016). For the lower kappa number (K29) the increase in fiber charges was almost insignificant after oxygen delignification. This was not a surprise since the lignin content was reduced significantly during the kraft cooking step, and the potential to maximize the charges was reduced.

Previous studies have reported that the fiber charge increase from oxygen delignification will be dependent on several factors, such as initial lignin content, alkali charge applied, delignification degree and the extension of the reaction (Esteves 2022; Esteves et al. 2021a; Zhang et al. 2006). From Figure 2 the variation in those parameters can be observed. Pulps with different starting kappa number (109, 61 and 29) will have different final charge content after extended oxygen delignification depending on the conditions in the oxygen stage (alkali charge and reaction time).

Table 4 presents the final total fiber charge obtained after oxygen delignification and the increased amount of total fiber charge if the pulp would be only cooked to the same kappa numbers, calculated by equation (1) and (2).

Fiber charge increase for the studied pulps. The samples that obtained the highest increase of fiber charges within each kraft cooking series are highlighted in bold.

| Samples | Kappa number | Total fiber charge, meq/kg | Fiber charge increase, % |

|---|---|---|---|

| K29_O13 | 13 | 66 | No increase |

| K29_O10 | 10 | 84 | 23 |

| K29_OO8 | 8 | 76 | 15 |

| K61_O38 | 38 | 143 | 55 |

| K61_O25 | 25 | 146 | 81 |

| K61_OO18 | 18 | 131 | 77 |

| K109_O62 | 62 | 185 | 63 |

| K109_O47 | 47 | 184 | 83 |

| K109_OO35 | 35 | 163 | 82 |

Previous studies (Esteves 2022; Esteves et al. 2020) have shown that a minimum increase (>60 %) in the fiber charge is vital for the change in pulp properties. From Table 4 the samples that presented the highest fiber charge increase were selected and considered for further studies (refining and paper testing). The samples from the cooked pulp with kappa number 29 didn’t have a significant increase in the fiber charge, achieving only 23 % increase, nevertheless, the sample was also considered for further trials to evaluate the influence of the lignin content on the final properties.

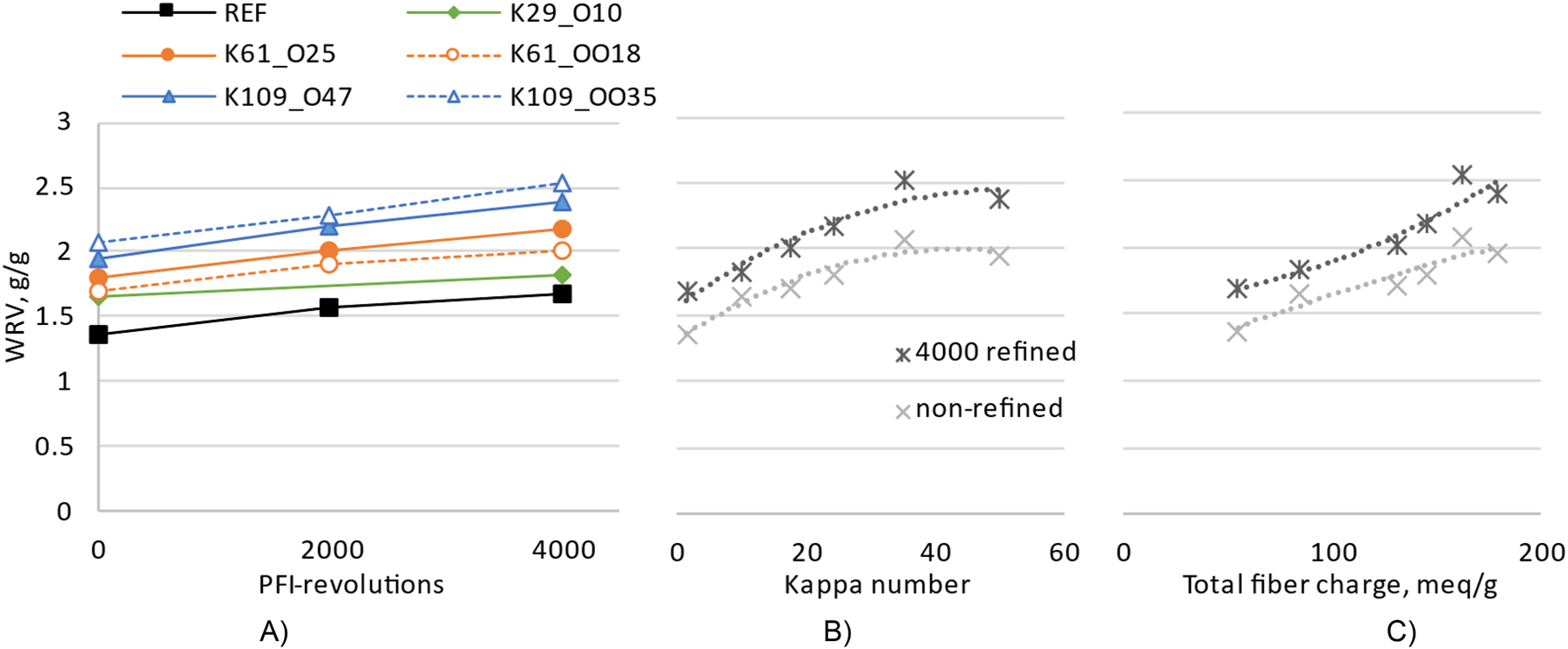

3.3 Water retention value

The water retention value (WRV) was significantly higher for the oxygen delignified pulps compared to the commercial fully bleached pulp (reference) – Figure 3A. This behavior was already expected since the oxygen delignified fibers presented a higher total fiber charge (higher content of carboxylic acid groups) which leads to an increase in fiber swelling (Esteves et al. 2020; Sjöstedt et al. 2015; Zhao et al. 2016). The pulps with the highest kappa number were the ones with the highest water retention values, while the reference fully bleached pulp presented the lowest charge and the lowest WRV – Figure 3B and C.

Water retention value for unbleached oxygen delignified pulps and fully bleached pulp as a function of A) PFI-refining, B) kappa number and C) total fiber charge.

Figure 3B shows the water retention value correlation along the kappa number when pulps are unrefined or refined with 4000 revolutions. As expected, the WRV increases with refining and decreases with kappa number. A similar relation can be seen in Figure 3C where the WRV is plotted against the total fiber charge. As previously suggested, WRV is highly dependent on the total fiber charge (Esteves et al. 2021b).

The significant increase in the water retention value is very beneficial to the absorption and strength properties of the pulps, however, it might impact the paper drying section, leading to higher energy requirements. However, the increase in the water retention value also leads to a decrease in the refining required to a certain tensile strength, which in turn will lead to lower energy consumption.

3.4 Absorption and capillarity properties

To evaluate the absorption and capillarity properties of the studied pulps, the basket method and Klemm test were used, respectively. The absorption capacity can be defined as a measurement of the fiber ability to absorb water (g water/g fiber) until it gets saturated (Schuchard and Berg 1991). The absorption quantification also considers the fiber capacity of holding water, since there is a dewatering period before measuring the wet weight. The absorption capacity for the analyzed samples is presented in Figure 4. As expected, the absorption capacity is directly related to the paper bulk despite the large span in kappa number, ranging from 0 (REF) to 47.

Absorption capacity for unbleached oxygen delignified pulps and fully bleached pulp as a function of bulk (20 g/m2 laboratory tissue handsheets were used). Decrease in bulk for each pulp sample is obtained by increased refining.

The commercial fully bleached pulp and the pulps K61_O and K61_OO presented very similar results for the absorption capacity (Figure 4) while the oxygen delignified pulps with the highest kappa number (K109_O and K109_OO) and the lowest (K29_O10) after the cooking step presented lower absorption capacity.

Absorbency can be significantly increased through the increase in the product bulk (Sedin and Vomhoff 2017). Bulk is therefore an important property of tissue paper, as it regulates the paper absorption, paper network porosity and softness sensation. The oxygen delignified pulps (K61_O25 and K61_OO18) presented similar absorption capacity as the reference pulp with slightly higher bulk. The oxygen delignified pulps K109_O47, K109_OO35 and K29_O10 presented a much lower bulk when compared to the other pulps and, consequently lower absorption capacity. For the unrefined samples, K109_O47 and K29_O10, the bulk and absorption capacity are very similar, even though the lignin content is significantly different.

Contrary to what happens with the water retention value (Figure 3A), when refining is applied the water absorption capacity of the pulps decreases – Figure 4. While the water retention value is mainly related to the water absorption in the fiber wall, the absorption capacity is related to the water absorption within the fiber network. The external and internal fibrillation created by the refining leads to a greater swelling potential by increasing the water penetration between the fibrils seen as water retention value (Hartman 1985; Kang 2007), but simultaneously, the increase in fibrillation also leads to better fiber bonding which promotes a denser paper structure, leading to a lower absorption values (Lumiainen 2000).

Figure 5 shows the capillary rise behavior of the different pulps obtained by the Klemm method. Similar to the results in Figure 4, the pulps K61_O25 and K61_OO18 presented the most similar results when compared to the reference fully bleached pulp.

Water capillarity rise distance for unbleached oxygen delignified pulps and fully bleached pulp as a function of bulk (20 g/m2 laboratory tissue handsheets were used). Decrease in bulk for each pulp sample is obtained by increased refining.

Capillary rise depends on the cohesion and adhesion forces of the water molecules that will rise along the fiber walls or within the pores (Morais and Curto 2022). The size of those pores will define the capillary pressure inside the fibers and the fiber network, determining how fast the water will rise. Micropores are present in native fibers, but during pulping the lignin–hemicellulose matrix is gradually removed creating some pores in the cell wall, called macropores (Brännvall et al. 2021). The micro and macropores will influence the water absorption capacity of the fibers, once they influence the fiber capillary pressure (Beuther et al. 2010). Bigger pores tend to decrease the capillary forces and the holding capacity (Joutsimo and Asikainen 2013), while smaller pores are capable of retaining more liquid at higher pressures than larger pores due to greater capillary force (Brodin and Theliander 2012).

When fibers undergo refining, the capillary pressure tends to decrease, probably due to internal and external fibrillation. As fiber interactions get stronger, the sheet thickness is reduced by the increase in sheet densification, and consequently, the open voids available in the sheet in which water can be held will be reduced (Kullander 2012). The decrease in the capillary pressure with the increase in fibrillation was suggested before (Morais et al. 2021). The higher the bulk, the higher the volume of pores inside the paper network.

Figure 6 shows the different speeds in the capillary rise for the studied pulps. For unrefined pulps, the oxygen delignified K29_O10 and K61_O25 had the fastest water rise (Figure 6A). The pulps with slower water rising were the oxygen delignified pulps with higher kappa numbers, K109_O47 and K109_OO35. The faster capillarity rise seen for the K61_O and K61_OO is probably due to the more open structure of the paper network since both pulp presented the highest bulk.

Rate of water capillarity rise for unbleached oxygen delignified pulps and fully bleached pulp for A) unrefined and B) 4000 PFI-refined pulps. (20 g/m2 laboratory tissue handsheets were used).

When refining is applied, the fastest water rise is for the commercial fully bleached pulp, while the oxygen delignified pulps land in lower water rising, especially for the K29_O10.

3.5 Mechanical properties

3.5.1 Dry tensile properties

The reference fully bleached pulp presented a much lower tensile index than the unbleached oxygen delignified pulps – Figure 7A. The difference in the tensile index is even more significant for unrefined pulps. This is caused by the different chemistry of the fully bleached and unbleached fibers and the harsher industrial treatment that the fully bleached pulp was subjected to. The oxygen delignified pulps obtained a higher tensile index. All the unrefined oxygen delignified pulps, obtained similar tensile index (between 74 and 83 Nm/g) and higher bulk (1.55–1.45 cm3/g) when compared to the reference fully bleached pulp refined with 2000 PFI-revolutions (72 Nm/g and 80 g/cm3). For higher refining levels, the unbleached pulps continued to present higher tensile index values than the reference pulp. The results showed that oxygen delignification pulps obtain similar absorption properties with much higher tensile strength than fully bleached pulps, with lower refining energy required.

Tensile index for the reference and oxygen delignified pulps as a function of A) bulk (60 g/m2 laboratory tissue handsheets were used) and B) absorption capacity (20 g/m2 laboratory tissue handsheets were used). The increase in tensile strength for each pulp sample is obtained by increased refining.

The increase in paper strength was surely achieved by the increase in internal and external fibrillation in the refining step. Refining breaks some inner bonds in the fibers wall, making them more flexible and swellable, leading to better fiber bonding (Gharehkhani et al. 2015; Kullander 2012; Maloney and Paulapuro 1999). However, for the fully bleached pulps, the increase in the tensile index seems to be more influenced by the increase of sheet densification due to refining, rather than the increase in the fiber bonding strength. Oxygen delignified pulps presented higher strength for similar bulk compared to the reference pulp. This suggests that a less bonded area is needed to accomplish a certain strength. Nordström (2014) and Esteves et al. (2021b) have previously reported similar results, where pulps with higher lignin content obtained a higher tensile index to a given low density.

From Figure 7B, it is interesting to highlight that the oxygen delignified pulps have a significantly higher strength for similar absorption capacity. As seen for the other properties, the samples K61_O25 and K61_OO18 presented the best strength and absorption performance, as shown in Figure 4.

3.5.2 Wet tensile properties

Cellulose-based materials such as tissue products are highly sensitive to humidity since cellulose molecules hold a large number of hydroxyl groups. Paper is, therefore, a hydrophilic material; when in contact with water or moisture, it starts to swell, breaking down the hydrogen bonds and losing its structure. Therefore, the wet strength becomes critical for tissue papers exposed to water and moisture.

Wet tensile strength is one of the important properties of tissue products since they should be resistant and maintain their structure when wetted. Figure 8 presents the wet tensile index for the oxygen delignified pulps and the reference fully bleached pulp. The wet tensile index for the reference unrefined pulp was not possible to determine due to the lack of wet strength since no wet strength additives were used in this study.

Wet tensile index for the reference and oxygen delignified pulps as a function of A) bulk, B) water retention value and C) absorption capacity. (20 g/m2 laboratory tissue handsheets were used).

The reference fully bleached pulp after 2000 and 4000 PFI revolutions did not present an increase in the wet tensile strength (Figure 8A). The unbleached pulps, on the other hand, had an almost linear increase of the wet tensile index with the refining, obtaining between 200 and 400 % higher wet tensile than the reference fully bleached pulp for similar bulk values.

When the wet tensile index is seen as a function of the water retention value, the relation is almost linear for the unbleached pulps (Figure 8B). The higher the pulp swelling the higher the wet tensile index.

Figure 8C shows similar behaviour as seen in Figure 8A, since bulk and absorption capacity have a linear relationship. For similar absorption capacity (around 7 g/g), the pulps with the higher kappa number (K109_O47 and K109_OO35) present the highest wet strength (2.5 Nm/g).

The increase in fiber fibrillation and fiber bonding, that is expected from refining, seems to vanish when the paper is wetted for the commercial fully bleached pulp. The unrefined unbleached pulps presented wet tensile strength in the same range as the commercial fully bleached pulp when it was refined with 2,000 and 4,000 revolutions, with much higher bulk. The higher wet strength seen for the unbleached pulps shows a great potential for towel papers, for example, where they can still have a high absorption capacity and higher strength.

When the strength values are plotted as a function of the kappa number the relation is clear: higher lignin content in the pulps leads to higher wet tensile strength (Figure 9). Some old laboratory studies have also shown a connection between high lignin content and increased wet strength (Gunnarsson 2012). Figure 9B shows the fairly linear relation of the pulps’ relative strength and lignin content.

Strength properties for the reference and oxygen delignified pulps at different levels of refining as a function of kappa number. A) Wet tensile index and B) relative strength. (20 g/m2 laboratory tissue handsheets were used). The numbers on the top of the symbols in graph A) are the total fiber charge of the samples. The values are in meq/kg.

These results show the potential of using pulps with high lignin content to increase the wet strength of the tissue products. The equilibrium between wet strength and absorption capacity of unbleached tissue products can be altered by the oxygen delignification conditions and by the starting kappa number of the pulps.

3.6 Softness

Softness can be described as the human perception of something that is bulky and delicate with no sharp edges. However, it is also a quite complex phenomenon to evaluate and quantify. Softness depends on several factors, such as individual sensibility, bulk, flexibility, thickness, among others. Softness is considered one of the most essential properties of tissue products (de Assis et al. 2018).

The studied samples were evaluated using the Tissue Softness Analyzer (TSA), which is claimed to give a perception of the sample’s softness (Figure 10). The softness can be estimated by the TS7 parameter, where lower TS7 values are attributed to higher softness (de Assis et al. 2020).

Softness for unbleached oxygen delignified pulps and fully bleached pulp as a function of, a) bulk, b) wet and c) dry tensile index (20 g/m2 laboratory tissue handsheets were used).

The unbleached pulps (K61_O25 and K61_OO18) presented similar TS7 values for slightly higher bulk as the reference pulp when no refining was applied. The highest and lowest kappa samples also obtained a similar TS7 value as the reference but for lower bulk values. The increase in TS7 with refining was expected since the higher strength is usually associated with lower softness (Debnath et al. 2021; Scott et al. 1995). Thus, an increased strength results in impaired softness and vice versa (Figure 10B and C).

An increase in the paper strength is generally followed by a decrease in softness (Salem et al. 2023). However, it can be seen that unbleached pulps presented similar softness levels with much higher wet and dry strength (Figure 10B and C). Figure 10B shows that oxygen delignified pulps, when not refined, present higher wet strength for lower TS7 values (higher softness). When the pulps are refined, the wet strength significantly increases without varying the TS7 factor significantly (K109_O47 and K109_OO35). Quite similar behavior was seen for the dry strength – Figure 10C. The oxygen delignified pulps even showed slightly better softness at specific tensile strength than commercially bleached pulp. Unfortunately, the softness measurements through the TSA equipment come with a significantly large standard deviation for some samples, which gives some uncertainty about the softness comparison between the samples.

4 Conclusions

This work showed the potential of using oxygen delignified pulps as a replacement for fully bleached pulps. Compared to the commercial fully bleached pulp, similar absorption and much higher tensile strength were obtained for the oxygen delignified pulps, especially for unrefined pulps. Two of the oxygen delignified pulps (K61_O25 and K61_OO18) achieved similar absorption capacity and faster water rising with higher bulk when compared to commercial pulp. Significantly higher wet strength and higher strength ratio were obtained for the oxygen delignified pulps, especially for the pulps with the highest lignin content. The oxygen pulps showed similar softness levels for higher tensile strength. Lignin content was seen to have an impact on the WRV but no effect on absorption capacity or capillary rising, which only depended on bulk. As expected, when the oxygen delignification starts with a kraft cooked pulp with a low kappa number the increase in the fiber charges is not maximized as in the higher kappa number pulps and therefore no significant benefit was seen.

The higher wet strength and similar absorption capacity seen for the oxygen unbleached fibers will be suitable for different types of tissue products, making them a more sustainable option than the fully bleached fibers, since no bleaching would be necessary. Nevertheless, other considerations must be considered and studied further, such as the possibly higher energy consumption in the drying paper section.

Award Identifier / Grant number: project 2022-297

Acknowledgments

The author gratefully acknowledges “Södra Skogsägarnas Stiftelse för Forskning, Utveckling och Utbildning” for the financial support of this project 2022–297. The author would also like to acknowledge Mikaela Kubat for the cooking, oxygen delignification and fiber charge measurements. Fredrik Adås and Ladan Fouladi are also acknowledged for their guidance and comments on the tissue testing. Elisabet Brännvall and Aron Tysén are acknowledged for reading and commenting on the manuscript.

-

Research ethics: Not applicable.

-

Author contributions: The author has accepted responsibility for the entire content of this manuscript and approved its submission.

-

Competing interests: The author states no conflict of interest

-

Research funding: Södra Skogsägarnas Stiftelse för Forskning, Utveckling och Utbildning, 2022–297.

-

Data availability: The raw data can be obtained on request from the corresponding author.

References

Beuther, P.D., Veith, M.W., and Zwick, K.J. (2010). Characterization of absorbent flow rate in towel and tissue. J. Eng. Fiber Fabr. 5, https://doi.org/10.1177/155892501000500201.Search in Google Scholar

Brännvall, E., Larsson, P.T., and Stevanic, J.S. (2021). Changes in the cellulose fiber wall supramolecular structure during the initial stages of chemical treatments of wood evaluated by NMR and X-ray scattering. Cellulose 28: 3951–3965, https://doi.org/10.1007/s10570-021-03790-1.Search in Google Scholar

Brito, A., Suarez, A., Pifano, A., Reisinger, L., Wright, J., Saloni, D., Kelley, S., Gonzalez, R., Venditti, R., and Jameel, H. (2023). Environmental life cycle assessment of premium and ultra hygiene tissue products in the United States. BioResources 18: 4006–4031, https://doi.org/10.15376/biores.18.2.4006-4031.Search in Google Scholar

Brodin, F.W. and Theliander, H. (2012). Absorbent materials based on kraft pulp: preparation and material characterization. BioResources 7, https://doi.org/10.15376/biores.7.2.1666-1683.Search in Google Scholar

Buchert, J., Bergnor, E., Lindblad, G., Viikari, L., and Ek, M. (1997). Significance of xylan and glucomannan in the brightness reversion of kraft pulps. Tappi J. 80: 165–171.Search in Google Scholar

Chai, X.-S., Hou, Q., and Zhu, J. (2003). Carboxyl groups in wood fibers. 2. The fate of carboxyl groups during alkaline delignification and its application for fiber yield prediction in alkaline pulping. Ind. Eng. Chem. Res. 42: 5445–5449, https://doi.org/10.1021/ie0209733.Search in Google Scholar

Dang, Z., Elder, T., and Ragauskas, A.J. (2006). Influence of kraft pulping on carboxylate content of softwood kraft pulps. Ind. Eng. Chem. Res. 45: 4509–4516, https://doi.org/10.1021/ie060203h.Search in Google Scholar

de Assis, T., Pawlak, J., Pal, L., Jameel, H., Reisinger, L.W., Kavalew, D., Campbell, C., Pawlowska, L., and Gonzalez, R.W. (2020). Comparison between uncreped and creped handsheets on tissue paper properties using a creping simulator unit. Cellulose 27: 5981–5999, https://doi.org/10.1007/s10570-020-03163-0.Search in Google Scholar

de Assis, T., Reisinger, L.W., Pal, L., Pawlak, J., Jameel, H., and Gonzalez, R.W. (2018). Understanding the effect of machine technology and cellulosic fibers on tissue properties–A review. BioResources 13: 4593–4629, https://doi.org/10.15376/biores.13.2.deassis.Search in Google Scholar

Debnath, M., Salem, K.S., Naithani, V., Musten, E., Hubbe, M.A., and Pal, L. (2021). Soft mechanical treatments of recycled fibers using a high-shear homogenizer for tissue and hygiene products. Cellulose 28: 7981–7994, https://doi.org/10.1007/s10570-021-04024-0.Search in Google Scholar

Esteves, C.V. (2022). Pulp strength enhancement by oxygen delignification, PhD Compilation. KTH Royal Institute of Technology, Stockholm.Search in Google Scholar

Esteves, C.V., Brännvall, E., Östlund, S., and Sevastyanova, O. (2020). Evaluating the potential to modify pulp and paper properties through oxygen delignification. ACS Omega 5: 13703–13711, https://doi.org/10.1021/acsomega.0c00869.Search in Google Scholar PubMed PubMed Central

Esteves, C.V., Sevastyanova, O., Östlund, S., and Brännvall, E. (2021a). Differences and similarities between kraft and oxygen delignification of softwood fibers: effects on chemical and physical properties. Cellulose 28: 3149–3167, https://doi.org/10.1007/s10570-021-03713-0.Search in Google Scholar

Esteves, C.V., Sevastyanova, O., Östlund, S., and Brännvall, E. (2021b). Differences and similarities between kraft and oxygen delignification of softwood fibers: effects on mechanical properties. Cellulose 28: 3775–3788, https://doi.org/10.1007/s10570-021-03781-2.Search in Google Scholar

Feber, D., Granskog, A., Lingqvist, O., and Nordigården, D. (2020). Sustainability in packaging: inside the minds of US consumers, Retrieved 08-2023, 2023, Available from: https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/sustainability-in-packaging-inside-the-minds-of-us-consumers.Search in Google Scholar

Fišerová, M., Gigac, J., Stankovska, M., and Opalena, E. (2019). Influence of bleached softwood and hardwood kraft pulps on tissue paper properties. Cell. Chem. Technol. 53: 469–477, https://doi.org/10.35812/cellulosechemtechnol.2019.53.47.Search in Google Scholar

Gharehkhani, S., Sadeghinezhad, E., Kazi, S.N., Yarmand, H., Badarudin, A., Safaei, M.R., and Zubir, M.N.M. (2015). Basic effects of pulp refining on fiber properties – a review. Carbohyd. Polym. 115: 785–803, https://doi.org/10.1016/j.carbpol.2014.08.047.Search in Google Scholar PubMed

Gigac, J. and Fišerová, M. (2008). Influence of pulp refining on tissue paper properties. Tappi J. 7: 27–32, https://doi.org/10.32964/tj7.8.27.Search in Google Scholar

Gunnarsson, M. (2012) Decreased wet strength in retorted liquid packaging board. Master, Chalmers University of Technology.Göteborg, Sweden.Search in Google Scholar

Haller, K., Lee, J., and Cheung, J. (2020). Meet the 2020 consumers driving change. IBM Institute for Business Value, Available online: https://www.ibm.com/downloads/cas/EXK4XKX8 (Accessed on 29 March 2021).Search in Google Scholar

Hartman, R.R. (1985). Mechanical treatment of pulp fibres for property development, PhD. Appleton, USA.Search in Google Scholar

Jour, P., Halldén, K., and Wackerberg, E. (2013). Environmental systems analysis of alternative bleaching sequences with focus on carbon footprint. In: Proceedings of the ABTCP, the 46th ABTCP international pulp and paper congress. © 2013 ABTCP, Sao Paulo, Brazil.Search in Google Scholar

Joutsimo, O.P. and Asikainen, S. (2013). Effect of fiber wall pore structure on pulp sheet density of softwood kraft pulp fibers. BioResources 8: 2719–2737, https://doi.org/10.15376/biores.8.2.2719-2737.Search in Google Scholar

Kang, T. (2007). Role of external fibrillation in pulp and paper properties, PhD. Helsinki University of Technology, Espoo.Search in Google Scholar

Katz, S., Beatson, R.P., and Scallon, A.M. (1984). The determination of strong and weak acidic groups in sulfite pulps. Svensk papperstidn 87: 48–53.Search in Google Scholar

Kim, J.J., Shalev, I., and Barker, R.L. (1994). Softness properties of paper towels. Tappi J. 77: 83–89.Search in Google Scholar

Kullander, J. (2012). Evaluation of furnishes for tissue manufacturing, Ph.D. Karlstad, Karlstads universitet.10.3183/npprj-2012-27-05-p947-951Search in Google Scholar

Lumiainen, J. (2000). Refining of chemical pulp. Papermaking part 1: 86–122.Search in Google Scholar

Mai, J. (2021). Development of pulp fiber charge in oxygen delignification of softwood, Master degree. KTH, Stockholm.Search in Google Scholar

Maloney, T. and Paulapuro, H. (1999). The formation of pores in the cell wall. J. Pulp Pap. Sci. 25: 430–436.Search in Google Scholar

Man, Y., Li, J., Hong, M., and Han, Y. (2020). Energy transition for the low-carbon pulp and paper industry in China. Renewable Sustainable Energy Rev. 131: 109998, https://doi.org/10.1016/j.rser.2020.109998.Search in Google Scholar

Mohlin, U.-B. and Alfredsson, C. (1990). Fibre deformation and its implications in pulp characterization. Nord. Pulp Pap. Res. J. 5: 172–179, https://doi.org/10.3183/npprj-1990-05-04-p172-179.Search in Google Scholar

Morais, F.P. and Curto, J.M. (2022). Challenges in computational materials modelling and simulation: a case-study to predict tissue paper properties. Heliyon 8: e09356, https://doi.org/10.1016/j.heliyon.2022.e09356.Search in Google Scholar PubMed PubMed Central

Morais, F.P., Carta, A., Amaral, M.E., and Curto, J.M. (2021). Cellulose fiber enzymatic modification to improve the softness, strength, and absorption properties of tissue papers. BioResources 16: 846–861, https://doi.org/10.15376/biores.16.1.846-861.Search in Google Scholar

Nordström, B. (2014). Unbleached linerboard kraft pulps with different kappa number (yield)–effects on tensile properties and compression strength with free or restrained drying. Nord. Pulp Pap. Res. J. 29: 462–467, https://doi.org/10.3183/npprj-2014-29-03-p462-467.Search in Google Scholar

Rebola, S.M., Azevedo, C.A., and Evtuguin, D.V. (2021). Effect of cooking and bleaching conditions on the properties of eucalyptus kraft fluff pulps. Cellulose 28: 4411–4426, https://doi.org/10.1007/s10570-021-03789-8.Search in Google Scholar

Salem, K., Jameel, H., Lucia, L., and Pal, L. (2023). Sustainable high-yield lignocellulosic fibers and modification technologies educing softness and strength for tissues and hygiene products for global health. Mater. Today Sustainability 22: 100342, https://doi.org/10.1016/j.mtsust.2023.100342.Search in Google Scholar

Schuchard, D.R. and Berg, J.C. (1991). Liquid transport in composite cellulose—superabsorbent fiber networks. Wood Fiber Sci.: 342–357.Search in Google Scholar

Scott, W.E., Abbott, J.C., and Trosset, S. (1995). The properties of creped tissue papers. In: Properties of paper: an introduction. TAPPI, Atlanta, GA, pp. 179–185.Search in Google Scholar

Sedin, M.F., F. and Vomhoff, H. (2017). The influence of absorption direction on the absorption capacity of kitchen towel. Innventia Research Programme: 2015–2017, Innventia Report 973.Search in Google Scholar

Sjöstedt, A., Wohlert, J., Larsson, P.T., and Wågberg, L. (2015). Structural changes during swelling of highly charged cellulose fibres. Cellulose 22: 2943–2953, https://doi.org/10.1007/s10570-015-0701-4.Search in Google Scholar

Snowman, V.R., Genco, J.M., Cole, B.J., Kwon, H.B., and Miller, W.J. (1999). Bond strength of oxygen-delignified kraft pulps. Tappi J. 82: 103–109.Search in Google Scholar

Tao, L., Genco, J.M., Cole, B.J., and Fort Jr, R.C. (2011). Selectivity of oxygen delignification for southern softwood kraft pulps with high lignin content. Tappi J. 10: 29–39, https://doi.org/10.32964/tj10.8.29.Search in Google Scholar

Yang, R., Lucia, L., Ragauskas, A.J., and Jameel, H. (2003). Oxygen delignification chemistry and its impact on pulp fibers. J. Wood Chem. Technol. 23: 13–29, https://doi.org/10.1081/wct-120018613.Search in Google Scholar

Zambrano, F., Marquez, R., Vera, R., Jameel, H., Venditti, R., and Gonzalez, R. (2022). Developing alternative, high-absorbency Brown fibers: tissue paper from upcycled corrugated packaging waste to meet new consumer trends. ACS Sustain. Chem. Eng. 10: 13343–13356, https://doi.org/10.1021/acssuschemeng.2c03280.Search in Google Scholar

Zhang, D., Chai, X.-S., Hou, Q., and Ragauskas, A. (2005). Characterization of fiber carboxylic acid development during one-stage oxygen delignification. Ind. Eng. Chem. Res. 44: 9279–9285, https://doi.org/10.1021/ie050489a.Search in Google Scholar

Zhang, D., Pu, Y., Courchene, C., Chai, X.-S., and Ragauskas, A. (2006). Total fibre charge of fully bleached SW kraft pulps: a comparative study. J. Pulp Pap. Sci. 32: 231–237.Search in Google Scholar

Zhao, C., Zhang, H., Zeng, X., Li, H., and Sun, D. (2016). Enhancing the inter-fiber bonding properties of cellulosic fibers by increasing different fiber charges. Cellulose 23: 1617–1628, https://doi.org/10.1007/s10570-016-0941-y.Search in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Evaluation of oxygen delignified fibers with high water absorbency, as a greener alternative to fully bleached fibers for tissue paper

- Effects of partial lignin extraction on rheological characteristics and combustion performance of high solids bamboo kraft black liquor

- A preliminary investigation of banana pseudo-stem (Musa cavendish) for pulp and paper production: morphology, chemical composition, FTIR, XRD and thermogravimetric analysis

- Sodium carbonate pulping of oil palm empty fruit bunches for paperboard production

- Mechanical Pulping

- Development of fibre properties in mill scale: high- and low consistency refining of thermomechanical pulp (part 2) – Importance of fibre curl

- Paper Technology

- Multi-objective optimization design of a circular core paper sandwich panel

- Paper Physics

- Effects of xylan-modified precipitated calcium carbonate filler on the properties of paper

- Influence mechanism of paper mechanical properties: numerical simulation and experimental verification based on a fiber network

- Enhancing the strength of tissue paper through pulp fractionation and stratified forming

- Paper Chemistry

- Effects of surfactants on the wettability of sodium propionate aqueous deacidification agent

- Coating

- Biobased nanocomposite coating of paper for packaging

- Printing

- Improving the lightfastness of paperboard prints with pearlescent pigments

- Packaging

- Preparation of environmentally friendly hydrophobic paper by coating method

- Recycling

- Hybrid solar drying of sludge from kraft pulp mills

- Chemical Technology/Modifications

- Effect of pre-hydrolysis on the dissolution of hardwood pulp in double salt ionic liquid

- Lignin

- Comparison of three different industrial lignin-based porous carbon electrodes for electrochemical applications

- UV–vis spectroscopy as a rapid method for evaluation of total phenolic hydroxyl structures in lignin

- Miscellaneous

- Paper fingerprint by forming fabric: analysis of periodic marks with 2D lab formation sensor and machine learning for forensic paper-identification

Articles in the same Issue

- Frontmatter

- Chemical Pulping

- Evaluation of oxygen delignified fibers with high water absorbency, as a greener alternative to fully bleached fibers for tissue paper

- Effects of partial lignin extraction on rheological characteristics and combustion performance of high solids bamboo kraft black liquor

- A preliminary investigation of banana pseudo-stem (Musa cavendish) for pulp and paper production: morphology, chemical composition, FTIR, XRD and thermogravimetric analysis

- Sodium carbonate pulping of oil palm empty fruit bunches for paperboard production

- Mechanical Pulping

- Development of fibre properties in mill scale: high- and low consistency refining of thermomechanical pulp (part 2) – Importance of fibre curl

- Paper Technology

- Multi-objective optimization design of a circular core paper sandwich panel

- Paper Physics

- Effects of xylan-modified precipitated calcium carbonate filler on the properties of paper

- Influence mechanism of paper mechanical properties: numerical simulation and experimental verification based on a fiber network

- Enhancing the strength of tissue paper through pulp fractionation and stratified forming

- Paper Chemistry

- Effects of surfactants on the wettability of sodium propionate aqueous deacidification agent

- Coating

- Biobased nanocomposite coating of paper for packaging

- Printing

- Improving the lightfastness of paperboard prints with pearlescent pigments

- Packaging

- Preparation of environmentally friendly hydrophobic paper by coating method

- Recycling

- Hybrid solar drying of sludge from kraft pulp mills

- Chemical Technology/Modifications

- Effect of pre-hydrolysis on the dissolution of hardwood pulp in double salt ionic liquid

- Lignin

- Comparison of three different industrial lignin-based porous carbon electrodes for electrochemical applications

- UV–vis spectroscopy as a rapid method for evaluation of total phenolic hydroxyl structures in lignin

- Miscellaneous

- Paper fingerprint by forming fabric: analysis of periodic marks with 2D lab formation sensor and machine learning for forensic paper-identification