Abstract

Bleaching of unbleached and oxygen delignified pulps from nineteen non-wood plants has been evaluated in elemental chlorine free bleaching. Chlorine dioxide charge (kappa factor 0.15, 0.20 and 0.25) and temperature (70 and 85 °C) in the delignification stage (D) were varied. Chlorine dioxide (ClO2) charge and temperature exhibited lower kappa number and higher brightness after alkaline extraction (EP) stage. High temperature ClO2 delignification (DHT) exhibited higher final pulp brightness. The final brightness of wheat straw pulp reached to 90 % after D0/DHT(EP)D1 bleaching, while banana pseudo stem pulp showed the worst bleachability. Residual hexeneuronic acid contents in final pulp from most of the non-wood plants were lower and exhibited 1–2 % higher pulp brightness in DHT process than D0 process. Oxygen delignified pulp and DHT process discharged lower COD load.

Introduction

Most of the forest deficient countries like Bangladesh are recommended to use non-wood fibers in pulp and paper manufacturing due to limited wood supply. Despite wood is the main raw material for paper pulp manufacturing, non-wood lignocellulosic fibers from cereal straw and other sources are widely used in many developing countries (Hart 2020). The global production of paper and cardboard stood at approximately 419.7 million metric tons in 2017. The market value of paper and pulp globally is expected to experience an increase within the five-year period comprised between 2019 and 2024, from an estimate of 63.3 billion U.S. dollars, to around 79.6 billion U.S. dollars by 2024 (Garside 2019). This increasing trend is mainly from developing countries like china. The GDP growth in Bangladesh is above 6 % since last 15 years, consequently increasing the living standard of people. The per capita paper and board consumption in Bangladesh is about 5 kg, which is much lower than the advanced countries (250 kg/capita), and the Asian average (≅45 kg/capita) (FAO 2017; https://paperonweb.com/Bangladesh.htm). The major drawback for pulp and paper production here is that it has very limited forest resources and more than half of the demand is fulfilled by import. Thus the country needs alternative fibrous raw materials. In this regard, many researches have been working on alternative raw materials for pulping (Akhtaruzzaman et al. 1991, Ferdous et al. 2020, 2020a, Jahan et al. 2007, 2007a, 2012, Matin et al. 2015).

Studies have shown that the soda anthraquinone (AQ) pulping is the widely accepted process for efficient conversion of non-woods into pulp without with faster delignification (Hart and Rudie 2014). The major part of delignification occurs during the pulping process and rest is removed further in bleaching stages. Pulp bleaching is a chemical process to brighten the pulp through the removal of lignin. It is the most expensive and polluting step in pulp industry as extensive bleaching is required by pulps produced by chemical pulping. It is accomplished with various compounds containing chlorine or oxygen and alkali extractions in several stages. During bleaching lignin is reacted with elemental chlorine and its derivatives to produce fragmented chlorolignins (Kumar et al. 2007). Alkali used in extraction stage dissolves these fragmented non-cellulosic chlorolignin compounds. The major groups of chlorolignin compounds found in pulp mill effluent are chlorophenols, chlorocatechols, chlorotannins, chlorinated resin and fatty acids etc. (Kaur et al. 2018). The reduction of chlorine compounds in pulp bleaching reduces chlorinated organics in the effluent (Kaur et al. 2018, Nie et al. 2013, 2014). Many attempts have been studied in reducing ClO2 consumption (Bajpai et al. 2006, Shin and Mera 1994, Jahan et al. 2013, 2017, Haque et al. 2019, Nie et al. 2015). The studies showed that xylanase, oxygen, peracid or acid treatment improved subsequent ClO2 bleaching. Hot acid treatment and high temperature chlorine dioxide delignification (DHT) bleaching are thoroughly investigated by Ragnar and Lindström (2004) and showed that the DHT had superior results of the investigated parameters. The delignification efficiency of ClO2 in the D0 stage depends on the reaction time and reaction temperature, while reducing the effluent load of bleaching chemicals and also improving the bleached pulp properties (Nie et al. 2015, Kumar et al. 2007).

The basic concept for the high temperature ClO2 delignification (DHT) stage is that the reaction rate of chlorine dioxide with remaining pulp lignin is faster at high temperature than that with hexeneuronic acid (HexA). Thus, at the early stage of the reaction most of the chlorine dioxide reacts with lignin, but the HexA remains in the pulp and are eliminated later through pulp acid hydrolysis stages (Eiras et al. 2003). Ventorim et al. (2005) revealed that a partial acid hydrolysis of HexA occurred in DHT treatment resulting into decrease in generation of chlorinated organic halides. Ventorim et al. (2005) also found that at a similar ClO2 dose (kappa factor 0.20 at pH 3.0) in DHT bleaching produced 46.3 % less AOX in the filtrate in relation to the D0. Brogdon (2009) stated is his review that hot A-stage removed 30 to 90 % of HexA entering into the bleach plant and some lignin as well. Most applications of hot A-stages are combined with the D0 into a single operation, (A/D0) or “hot D0-Stage.” Such processes can be very effective at reducing the total ClO2 needed for ECF bleaching of hardwood pulps (20 to 50 %).

Most of the DHT bleaching studies used 95 °C for longer time, consequently reduced viscosity and a slight drop in final pulp brightness. The lower brightness obtained after DHTE is explained by the brightness reversion reactions caused by maintaining the pulp at high temperature/time in the complete absence of chlorine dioxide (Eiras et al. 2003). The hot acid treatment also formed new lignin phenolic hydroxyl groups, which may form new chromophores (Uchida et al. 1999). Many of the research were carried out on DHT at initial stage of bleaching of hardwood pulp (Ragnar and Lindström 2004, Ventorim et al. 2005, Zhang et al. 2018, Tavast et al. 2011, Davies et al. 2009, Lachenal and Chirat 2000) but available literature on non-wood/agricultural residues pulps are scarce.

Therefore, chlorine dioxide bleaching (ClO2) of unbleached and oxygen delignified pulps of 19 non-wood plants was carried out with varying ClO2 charge (kappa factor 0.15, 0.2 and 0.25) and temperature (70 and 85 °C). The final pulp properties as well as the effluent quality were also studied.

Chemical characteristics of crops residues (Ferdous et al. 2020).

| Raw material | Lignin (%) | α-cellulose (%) | Pentosan (%) | Ash (%) |

| Wheat straw | 25.1 | 37.0 | 18.0 | 9.12 |

| Corn stalks | 19.7 | 35.1 | 17.8 | 4.48 |

| Mustard stalks | 18.1 | 33.7 | 18.9 | 5.04 |

| Eggplant stalks | 28.4 | 35.0 | 14.3 | 1.66 |

| Chia plant | 23.2 | 30.5 | 13.2 | 2.58 |

| Banana pseudo stem | 24.1 | 40.2 | 13.4 | 6.85 |

| Banana leaf | 20.7 | 41.4 | 13.3 | 6.97 |

| Banana peduncle | 20.4 | 45.2 | 14.8 | 1.77 |

| Bagasse | 20.4 | 39.3 | 16.9 | 0.67 |

| Bamboo | 26.9 | 46.9 | 18.4 | 3.27 |

| Okra plant | 18.7 | 29. 6 | 15.1 | 0.77 |

| Kaun plant | 19.3 | 35.9 | 17.6 | 7.3 |

| Kash | 19.8 | 43.3 | 22.3 | 1.07 |

| Rice straw | 22.9 | 38. 7 | 18.0 | 15.1 |

Materials and methods

Materials

Pulps from non-wood plants were prepared separately at the laboratory by soda-anthraquinone (AQ) process. These 19 non-wood plants had a lot of variation in chemical, anatomical and morphological properties (Ferdous et al. 2020). The chemical characteristics of some of these non-woods were published elsewhere and presented in Table 1 (Ferdous et al. 2020). As for example, jute fiber was characterized with high cellulose, low lignin and longer fiber length (Jahan et al. 2007a). Rice, wheat and kaun straws had high percentage of fines generated from parenchymatic cell (Ferdous et al. 2020a). Therefore, optimum conditions were varied among the raw materials. Bleaching experiment was performed only for the pulp obtained at optimum conditions. The cooking experiment was conducted in an electrically heated thermostatically controlled digester of 20 litre capacity. 1 kg non-wood was used for all experiments. All non-wood plants were cooked under the conditions given in Table 2. Based on our previous studies, the AQ charge and material to liquor ratio were kept constant at 0.1 % and 1:6, respectively (Ferdous et al. 2020a).

Pulping conditions and pulp properties of unbleached and oxygen delignified pulps from nineteen non-wood plants.

| Raw material | Cooking conditions | Kappa number | Viscosity (mPa.s) | Brightness (%) | HexA (µmol/g) | ||||||

| Alkali charge (%) | Max temperature (°C) | Time at max temp (h) | Unbleached | O2-delignified | Unbleached | O2-delignified | Unbleached | O2-delignified | Unbleached | O2-delignified | |

| Bamboo | 18 | 170 | 2 | 26.82 | 7.31 | 16.13 | 14.98 | 19.81 | 45.74 | 13.11 | 13.34 |

| Banana pseudo stem | 18 | 170 | 2 | 23.57 | 12.03 | 19.08 | 18.51 | 11.32 | 15.93 | 10.91 | 10.67 |

| Banana leaf | 20 | 170 | 2 | 33.28 | 17.41 | 20.89 | 20.79 | 16.09 | 23.66 | 28.32 | 28.65 |

| Banana peduncle | 20 | 170 | 2 | 28.8 | 22.6 | 21.39 | 19.59 | 14.32 | 27.86 | 20.34 | 20.76 |

| Cassava stalks | 20 | 170 | 3 | 31.4 | 10.32 | 12.81 | 12.56 | 16.22 | 24.78 | 24.28 | 24.76 |

| Chia stalks | 20 | 170 | 3 | 27.65 | 12.11 | 10.96 | 10.22 | 15.62 | 22.55 | 53.65 | 53.24 |

| Cotton stalks | 20 | 170 | 3 | 31.19 | 8.01 | 11.78 | 11.61 | 11.15 | 30.57 | 76.73 | 61.23 |

| Dhaincha | 18 | 170 | 2 | 14.1 | 6.9 | 14.69 | 13.26 | 29.59 | 53.42 | 53.32 | 53.14 |

| Eggplant stalks | 18 | 170 | 3 | 28.79 | 13.68 | 12.81 | 12.56 | 21.71 | 30.5 | 26.64 | 27.22 |

| Jute fiber | 18 | 170 | 2 | 11.98 | 7.62 | 13.21 | 12.48 | 28.95 | 56.99 | 79.41 | 67.34 |

| Jute stick | 20 | 170 | 2 | 18.26 | 6.26 | 14.85 | 13.13 | 27.47 | 47.69 | 77.60 | 70.36 |

| Kaun straw | 14 | 150 | 2 | 10.07 | 6.56 | 15.49 | 14.23 | 32.26 | 41.51 | 32.32 | 33.43 |

| Mulberry stalks | 20 | 170 | 3 | 21.35 | 6.86 | 12.65 | 11.09 | 22.86 | 44.92 | 60.65 | 61.04 |

| Mustard stalks | 20 | 170 | 3 | 18.6 | 10.45 | 13.51 | 12.73 | 23.12 | 41.59 | 37.03 | 38.22 |

| Okra stalks | 20 | 170 | 3 | 30.68 | 22.31 | 21.57 | 21.01 | 13.02 | 15.28 | 22.00 | 25.32 |

| Pineapple leaves | 14 | 170 | 2 | 19.3 | 6.1 | 12.65 | 11.79 | 19.44 | 32.25 | 8.87 | 8.23 |

| Red lentil stalks | 20 | 170 | 3 | 18.26 | 5.42 | 12.69 | 11.55 | 24.75 | 39.50 | 21.90 | 22.23 |

| Rice straw | 14 | 150 | 2 | 13.16 | 5.17 | 16.04 | 15.31 | 37.93 | 50.05 | 7.66 | 7.67 |

| Wheat straw | 14 | 150 | 2 | 12.32 | 5.56 | 16.75 | 16.05 | 29.37 | 35.70 | 10.66 | 10.33 |

Oxygen delignification

Oxygen delignification (OD) was carried out in thermostatically controlled digester, rotating at 1 rpm. OD conditions were 110 °C, retention time 60 min, pulp consistency 10 %, NaOH 2 %, MgSO4 0.3 % and O2-pressure 3.5 kg.cm−2.

Evaluation of pulp

The kappa number (T 236 om-99), viscosity (T 230 om-99), brightness (T 452 om-92) and HexA (T 282 pm-07) of the resulting pulps from the unbleached and oxygen delignified state were determined in accordance with Tappi Test Methods. Three replicates of all experiments were done, and average reading was taken.

D0(EP)D1 and DHT(EP)D1 bleaching

Unbleached and oxygen delignified pulps were bleached by D0(EP)D1 and DHT(EP)D1 bleaching sequences (where D represents chlorine dioxide and (EP) represents peroxide reinforced alkaline extraction). The chlorine dioxide charge in D0 and DHT stages were varied by kappa factor 0.15, 0.2 and 0.25. The temperature was 70 °C in D0 stage for 45 min. Pulp consistency was 10 %. The pH was adjusted to 2.5 by adding dilute H2SO4. In the DHT stage, bleaching temperature was 85 °C and all other parameters remained same. In the alkaline extraction stage, temperature was 70 °C for 60 min in a water solution of 2 % NaOH and 0.5 % H2O2 (on od pulp) were used. After (EP) stage, kappa number, viscosity and brightness were determined in accordance with Tappi Test Methods as above.

In the D1 stage, pH was adjusted to get end pH 4.5. The ClO2 charge in the D1 stage was fixed to 1 %. The brightness, viscosity and HexA of the bleached pulp and COD in the mixed effluent collected from D0, EP and D1 stages were determined in accordance with PAPTAC Methods H.3.

Results and discussion

Pulps from 19 non-wood plants were prebleached by oxygen delignification under identical conditions. Entering kappa number was varied from 10.1 in kaun straw pulp to 33.3 banana leaf pulp. The oxygen delignification degree varied among the raw material from 21.5 % to 72.7 %. The lowest and highest delignification degrees on oxygen delignification were observed for banana peduncle and bamboo pulps, where entering kappa number was 28.8 and 26.8, respectively. The oxygen delignification should be limited up to 50 % delignification to maintain pulp viscosity. Oxygen delignification increased pulp brightness from 6 % to 28 % depending on non-wood pulps. Unbleached brightness of jute fiber pulp was 28.95 %, which increased to 56.99 % on oxygen delignification. On the other hand, oxygen delignification of wheat straw pulp increased to 35.7 % for 29.37 % in the unbleached state.

Pulp viscosity loss during oxygen delignification is caused by cellulose chain cleavage resulting from attack by oxygen-based radicals generated through reactions with lignin. As shown in Table 2, there were no significant changes of pulp viscosities after oxygen prebleaching. The pulp viscosities decreased by 2 % to 12 %. The maximum viscosity drop was 12 % for mulberry stalks pulp, where delignification degree was 67 %. The HexA content in 19 non-wood plants pulps was varied from 7.66 to 79.41 μmol/g pulp. The lowest HexA content was in rice straw pulp and the highest in jute fiber pulp. Oxygen delignification did not change HexA content (Table 2).

In alkaline pulping process, 4-O-methyl-α-D-glucuronic acid groups react with alkali and form hexeneuronic acids through beta elimination of the methoxyl (Teleman et al. 1995). Thus, HexA is a product of alkaline cooking, and their amount in the pulp depends on the amount of 4-O-methyl-α-D-glucuronic acid originally present in the raw material and alkaline cooking condition. Oxygen delignification is a part of extended alkaline cooking. Therefore, HexA content in oxygen delignified pulp did not decrease, even in some cases increase.

DHT(EP) and D0(EP) pulp properties

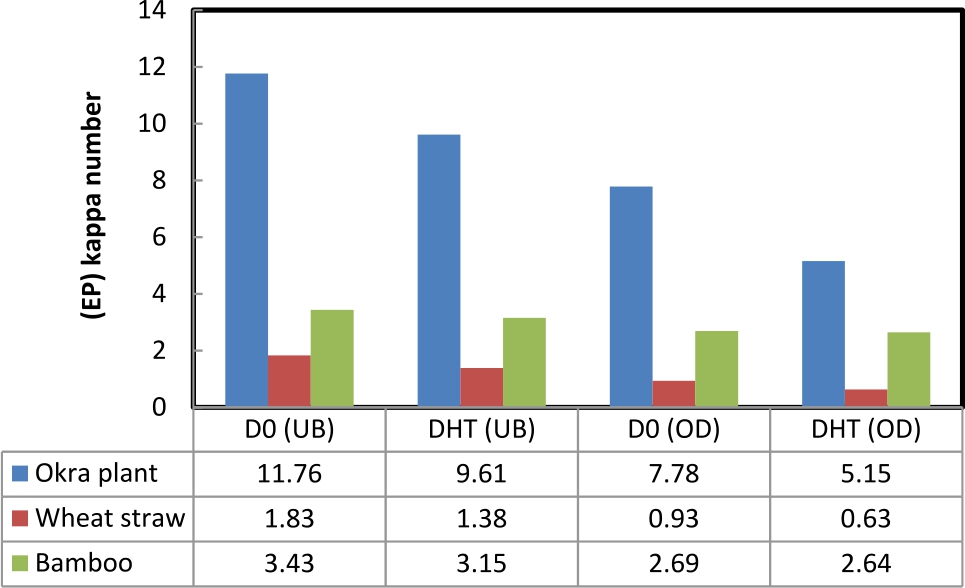

The effect of kappa factor on (EP) kappa number, brightness and viscosity of 19 non-wood pulps are shown in Table S1. First ClO2 stage is denoted as D0 and DHT at 70 °C and 85 °C, respectively. As expected, increasing kappa factor resulted in decrease kappa number and viscosity and increase brightness regardless D0 or DHT processes. DHT bleaching is more efficient than D0 and support chlorine dioxide dose reduction during bleaching (Table S1). The delignification to a lower kappa number is one of the factors to get high pulp brightness. The oxygen delignified pulp showed lower kappa number after (EP) stage. The kappa numbers after (EP) stage in DHT bleaching were always lower than the corresponding D0 bleaching. Kaur et al. (2019a) also showed that the kappa number of rice straw pulp after extraction stage was lower for DHT than D0 with the same ClO2 dose. This is related to the acid leaching of lignin as described and reported by (Ikeda et al. 1999, Ikeda et al. 1999a). The highest and lowest (EP) kappa numbers were observed for okra plant and wheat straw, respectively. From the 19 non-wood plant pulps few are shown in Figure 1. As shown in Figure 1, for the pulp bleaching with kappa factor 0.2, (EP) kappa number were 11.76 and 7.78 in D0 bleaching, which decreased to 9.61 and 5.15 in DHT for unbleached and oxygen delignified pulp, respectively. The (EP) kappa number for wheat straw pulps decreased from 1.83 and 0.98 in D0 bleaching to 1.38 and 0.63 in DHT bleaching. The higher kappa number decreased in the DHT(EP) stage as compared to the D0(EP) can be explained by the higher removal of HexA (Lachenal and Chirat 2000). This can also be explained by the degradation of hemicellulose during DHT treatment, which breaks down the bonds of the lignin-carbohydrate complex (LCC) and increases the extraction of the lignin from the surface of the fiber, which is described by Zhang and coworkers (2018). But according to Ikeda et al. (1999), the temperatures were not high enough to cleave the C-O or C-C bonds that link lignin to carbohydrates in LCC. McDonough et al. (2009) speculated that proportion of HexA contributing to the pulp’s kappa number entering the D0 stage affected bleachability of a red oak pulp that underwent a hot acid hydrolysis.

Effect of DHT delignification on kappa number after (EP) stage.

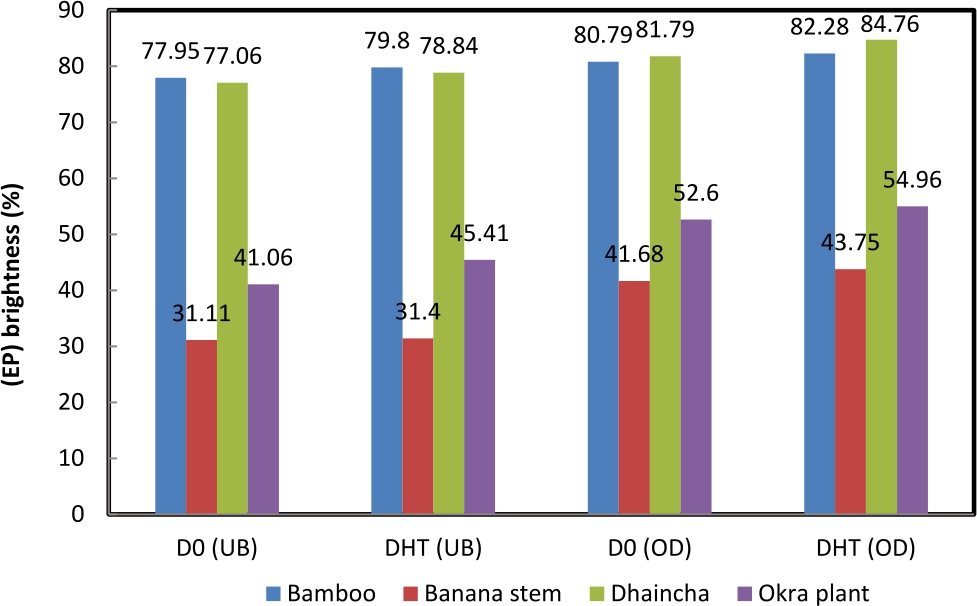

Pulp brightness after D0(EP)/DHT(EP) stage is also shown in Table S1. Oxygen delignified pulp showed better pulp brightness than the unbleached pulp regardless D0 or DHT bleaching. The (EP) brightness of DHT treated pulps was better than those treated by D0 process using an identical kappa factor. Bamboo, dhaincha, jute fiber and jute fiber pulps showed improved brightness, while banana pseudo stem pulp showed the worst brightness. Primarily, unbleached pulp brightness can predict the pulp bleachability. At the staring, banana pseudo stem pulp brightness of was 11.32 % and 15.93 % for unbleached and oxygen delignified pulps, respectively (Table S1). Only (EP) brightness data of a few non-wood plant pulps are shown in Figure 2. The highest brightness advantage in DHT stage than D0 stage after (EP) stage was 3 % for dhaincha oxygen delignified pulp. Ventorim et al. (2005) found the first chlorine dioxide stage at high temperature (DHT) decreased the brightness by 2.5 % ISO and kappa number by 46 % (1.9 units) after extraction stage as compared to the conventional D stage. Their results were also supported by others (Ragnar and Lindström 2004, Eiras et al. 2003). The target of this study was to improve brightness and kappa number reduction at 85 °C for shorter bleaching time, which was achieved in this study.

Effect of DHT delignification on brightness after (EP) stage.

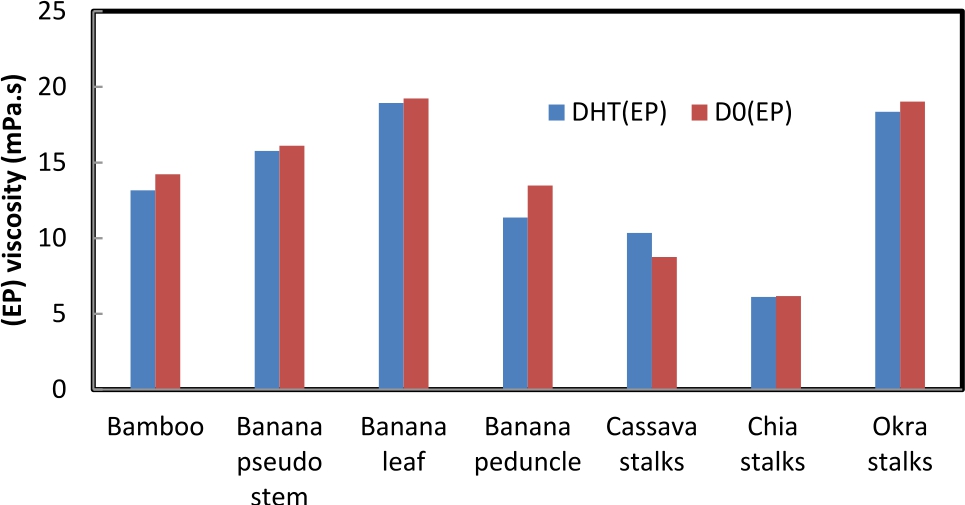

Effect of DHT delignification on viscosity after (EP) stage.

As shown in Table S1, oxygen delignification reduced pulp viscosity insignificantly. The highest and lowest (EP) pulp viscosity was for banana leaf and chia pulp, respectively. There was no significant change in post extraction pulp viscosity after DHT bleaching. As for example, Figure 3 shows that the pulp viscosity of oxygen delignified banana leaf pulp decreased from 19.23 mPa.s in D0 process to 18.93 mPa.s in DHT process only. No change of pulp viscosity was observed for chia pulp. But other studied showed that the DHTE treatment at 95 °C for resulted in significant drop in post extraction pulp viscosity as compared to the DE one (Ventorim et al. 2005, Ragnar 2003). Pulp exposed to high time/temperature reaction and acid pH may undergo slight carbohydrate hydrolysis. The significant viscosity loss is related to the hot acid hydrolysis of the carbohydrates with the 2.5 pH conditions (Ventorim et al. 2005, 2008).

DHT(EP)D1 and D0(EP)D1 pulp properties

The impact of D0 and DHT process on the final pulp brightness and viscosity of 19 non-wood plant pulps are shown in Table S2. A lot of variation of bleachability among these nineteen non-wood plant pulps was observed. Wheat straw pulp showed the highest final pulp brightness. At kappa factor 0.15, final pulp brightness of oxygen delignified was 90.17 % in D0 process, which increased to 91.30 % in DHT process. As in initial and D0/DHT(EP) low brightness, there was no improvement of final pulp brightness for banana pseudo stem pulp. The final brightness reached to 44 % only at the highest ClO2 charge. Dhaincha, eggplant plant, jute fiber and jute tick pulps also showed good bleachability. The oxygen delignified eggplant stalks pulp also showed good bleachability. At kappa factor 0.25, the final brightness of eggplant stalks oxygen delignified pulp reached to 82.24 % in D0 process, while the same brightness was obtained at kappa factor of 0.15 in DHT process and saved 40 % ClO2 in the first stage. Kumar et al. (2007) showed that the use of DHT reduced 15 % ClO2 requirement and improved the brightness and brightness stability in comparison with the reference sequences D0.

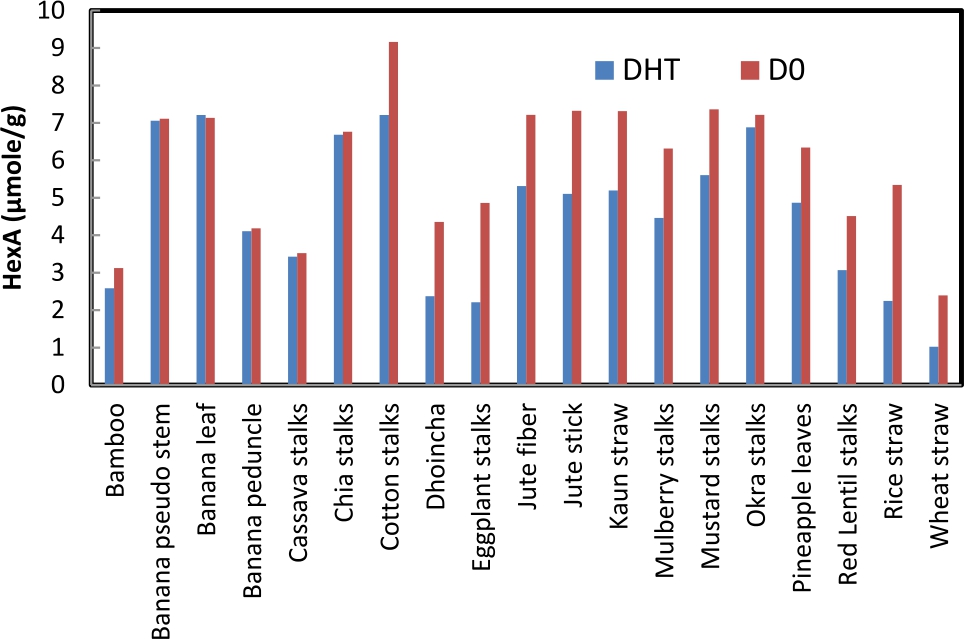

Effect of DHT delignification on HexA content in final bleached pulp.

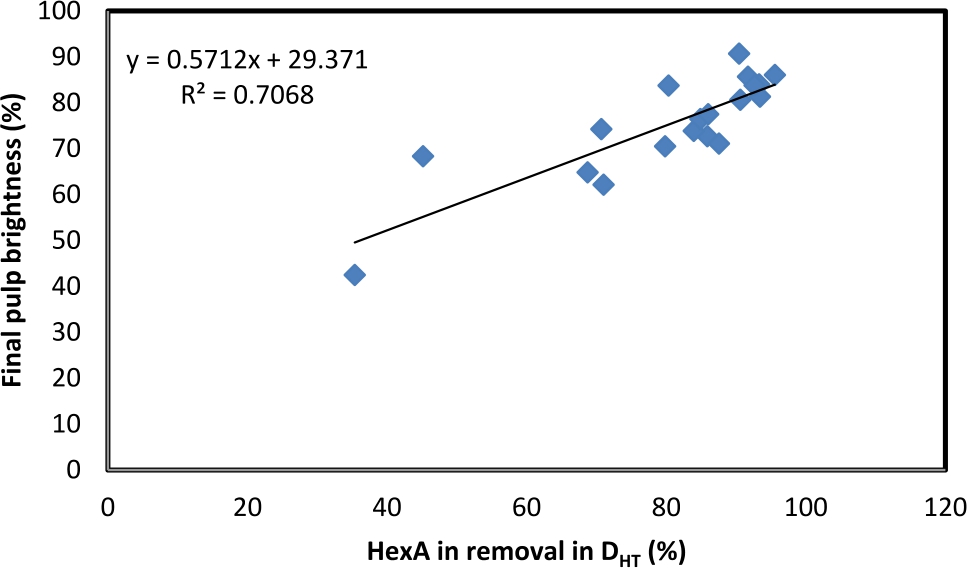

The effect of the DHT on the residual HexA of final pulps (oxygen delignified) was also studied and shown Figure 4. The residual HexA content in most of the DHT bleached pulps was much less than the D0 pulps. Banana pseudo stem, banana leaf, banana peduncle, chia plant and cassava plant pulps did not show significant differences in HexA contents between D0 and DHT in final pulps. This result reflected in final pulp brightness. At kappa factor, 0.2, the residual HexA contents were 1.02, 2.37, and 5.31 μmol/g for DHT pulps and 2.39, 4.34 and 7.21 μmol/g for D0 pulps from wheat straw, dhaincha and jute fiber pulps, respectively. This is cause of degradation of HexA in DHT process (Colodette and Henricson 2012). HexA could not react with chlorine dioxide, but react with its intermediates such as hypochlorous acid and molecular chlorine (Tarvo et al. 2010, Lehtimaa et al. 2010), thereby influencing the bleachability and enhancing the consumption of chlorine dioxide. Percentage of HexA removal in DHT process showed a linear relationship with final pulp brightness (Figure 5). The HexA removal in banana pseudo stem pulp was only 35 %, consequently showed the lowest pulp brightness (44 %) among these 19 non-wood pulps. On the other hand, the highest HexA removal was 96 % for dhaincha pulp, where final pulp brightness was 86 %.

Removal of HexA content DHT delignification and final pulp brightness.

Final pulp viscosity was also shown in Table S2. The final pulp viscosity was related to the entering viscosity of pulp of unbleached. Chia plant and lentil stalks showed the lowest final pulp viscosity of 5–7 mPa.s, where pulp viscosity entering into the bleaching system was 10–12 mPa.s. The pulp viscosity loss indicates cellulose degradation, ultimately reflected in papermaking properties.

COD values (mg/l) of bleach effluents from nineteen non-wood plant pulps.

| Pulp | Unbleached (UB) | Oxygen delignified (OD) | ||

| D0 | DHT | D0 | DHT | |

| Bamboo | 652.9 | 443.9 | 479.0 | 323.7 |

| Banana pseudo stem | 837.3 | 743.2 | 263.4 | 235.2 |

| Banana leaf | 1105.0 | 1004.0 | 832.9 | 709.2 |

| Banana peduncle | 824.6 | 808.1 | 479.3 | 404.1 |

| Cassava stalks | 1023.0 | 1007.7 | 555.1 | 376.3 |

| Chia stalks | 715.0 | 610.1 | 677.4 | 414.0 |

| Cotton stalks | 752.9 | 520.7 | 479.0 | 323.7 |

| Dhaincha | 1138.4 | 1060.7 | 845.4 | 532.8 |

| Eggplant stalks | 700.9 | 673.5 | 398.6 | 364.2 |

| Jute fiber | 525.8 | 423.4 | 297.6 | 222.3 |

| Jute stick | 728.8 | 613.4 | 652.1 | 522.6 |

| Kaun straw | 1352.4 | 1090.00 | 942.2 | 733.8 |

| Mulberry stalks | 768.7 | 668.7 | 631.6 | 563.2 |

| Mustard stalks | 1187.0 | 984.0 | 1043.0 | 822.0 |

| Okra stalks | 1132.8 | 1092.4 | 930.6 | 798.4 |

| Pineapple leaves | 723.8 | 677.4 | 639.7 | 479.8 |

| Red lentil stalks | 827.9 | 762.1 | 461.0 | 376.3 |

| Rice straw | 696.7 | 669.9 | 328.2 | 267.9 |

| Wheat straw | 713.3 | 646.7 | 200.0 | 173.3 |

COD in bleach effluent

The environmental impact of 19 non-wood plants pulps bleaching by D0 and DHT processes were investigated. As shown in Table 3, the COD value of combined effluent from D0, (EP) and D1 stage in DHT(EP)D1 bleaching was lower than D0(EP)D1. Oxygen delignified pulp had always lower COD load in effluent. The ClO2 charge in D0/DHT stage of oxygen delignified was certainly lower as kappa number was lower, thus released less organic material from the pulp to the filtrate and resulted lower COD load. Similar results were also observed in ECF bleaching by Shin and Mera (1994). As an example of bamboo pulp, the DHT process at kappa factor 0.2 decreased COD value from 652.92 mg/l to 443.9 mg/l for unbleached pulp and from 479.04 mg/l to 323.72 mg/l for oxygen delignified pulp. Similar COD value reduction in other reported data are available (Kaur et al. 2018, 2019). Kaur et al. (2019a) showed that DHT based bleaching sequence reduced chlorophenols, chlorocatechols, chloroguaiacols, chlorovanillins, chlorosyringols and bromophenols were reduced by 9 %, 50 %, 34 %, 47 %, 17 % and 31 %, respectively, at the same chemical charge. DHT based sequence also effectively reduced environmental parameters i. e. COD, BOD, TS, colour, lignin and AOX without compromising optical and strength properties Kaur et al. (2019a). Rolf et al. (2009) showed that the amount of dissolved organics, represented by COD was proportional to kappa number of unbleached pulp for wood and non-wood pulps. But at a given kappa number, the amount of COD was much higher for the non-wood pulp.

Conclusions

A lot of variation of bleachability among these nineteen non-wood plant pulps was observed. DHT delignification produced pulp of lower kappa number and higher brightness than D0 after extraction stage. HexA content in the final bleached pulp in DHT delignification was lower than those of D0, resulted higher final brightness. Percentage of HexA removal in DHT process showed a linear relationship with final pulp brightness. The oxygen delignified pulp and DHT delignification discharged lower COD.

Funding source: Bangladesh Council of Scientific and Industrial Research

Award Identifier / Grant number: 2017-2020

Funding statement: Authors received funding by the Bangladesh Council of Scientific and Industrial Research, number 2017-2020.

Conflict of interest: The authors declare no conflicts of interest.

References

Akhtaruzzaman, A.F.M., Bose, S.K., Das, P., Chowdhury, S.K. (1991) Neutral sulfite anthraquinone pulping of bagasse. Nord. Pulp Pap. Res. J. 6(1):8–11.10.3183/npprj-1991-06-01-p008-011Search in Google Scholar

Bajpai, P., Anand, A., Sharma, N., Mishra, S.P., Bajpai, P.K., Lachenal, D. (2006) Enzymes improve ECF bleaching of pulp. BioResources 1(1):34–44.10.15376/biores.1.1.34-44Search in Google Scholar

Brogdon, B.N. (2009) A fundamental review and critical analysis of hexeneuronic acids and their impact in elemental chlorine-free bleaching. In: TAPPI Engineering, Pulping & Environmental Conference Proceedings. Tappi Press, Atlanta. pp. 11–14.Search in Google Scholar

Colodette, J.L., Henricson, K.O. (2012) The hot acid stage for hexeneuronic acid removal. In: The Bleaching of Pulp, Tappi Press, GA. Eds. Hart, P.W., Rudie, A.W. pp. 103–146.Search in Google Scholar

Davies, D., Dietz, T., Suess, H.U. (2009) A comparison of options to improve brightness stability of chemical pulp. Pulp Pap. Can. 110(8):25–31.Search in Google Scholar

Eiras, K.M.M., Colodette, J.L. (2003) Eucalyptus kraft pulp bleaching with chlorine dioxide at high temperature. J. Pulp Pap. Sci. 29(2):64–69.Search in Google Scholar

FAO Yearbook of Forest Products, 2017. https://paperonweb.com/FAO2017.Paper.pdf.Search in Google Scholar

Ferdous, T., Jahan, M.S., Quaiyyum, M.A., Uddin, M.N. (2020) Formic acid pulping of crops residues available in Bangladesh. Biomass Convers. Bior. 10(2):289–297.10.1007/s13399-019-00415-3Search in Google Scholar

Ferdous, T., Quaiyyum, M.A., Bashar, S., Jahan, M.S. (2020a) Anatomical, morphological and chemical characteristics of kaun straw (Seetaria-ltalika). Nord. Pulp Pap. Res. J. 35(2):288–298.10.1515/npprj-2019-0057Search in Google Scholar

Garside, M. Global market value of paper and pulp 2019 & 2024, 2019. https://www.statista.com/statistics/1073451/global-market-value-pulp-and-paper/.Search in Google Scholar

Haque, M., Nanjiba, M., Jahan, M.S., Quaiyyum, M.A., Alam, M.Z., Nayeem, J. (2019) Pre-bleaching of kraft acacia pulp. Nord. Pulp Pap. Res. J. 34(2):165–172.10.1515/npprj-2018-0082Search in Google Scholar

Hart, P.W. (2020) Wheat straw as an alternative pulp fiber. Tappi J. 19:41–52.10.32964/TJ19.1.41Search in Google Scholar

Hart, P.W., Rudie, A.W. (2014) Anthraquinone—a review of the rise and fall of a pulping catalyst. Tappi J. 13(10):23–31.10.32964/TJ13.10.23Search in Google Scholar

Ikeda, T., Hosoya, S., Tomimura, Y., Magara, K., Ishihara, M., Takano, I. (1999a) Sulfuric Acid Bleaching of Kraft Pulp III: Reactivity of Kraft Pulping Resistant Structures under Acidic Conditions. J. Wood Sci. 45(5):417–424.10.1007/BF01177915Search in Google Scholar

Ikeda, T., Hosoya, S., Tomimura, Y., Magara, K., Takano, I. (1999) Sulfuric Acid Bleaching of Kraft Pulp I: Bleaching of Hardwood and Softwood Kraft Pulps. J. Wood Sci. 45(3):233–237.10.1007/BF01177731Search in Google Scholar

Jahan, M.S., Al-Maruf, A., Quaiyyum, M.A. (2007a) Comparative studies of pulping of jute fiber, jute cutting and jute caddis. Bangladesh J. Sci. Ind. Res. 42(4):425–434.10.3329/bjsir.v42i4.750Search in Google Scholar

Jahan, M.S., Chowdhury, D.N., Islam, M.K. (2007) Atmospheric formic acid pulping and TCF bleaching of dhaincha (Sesbania aculeata), kash (Saccharum spontaneum) and banana stem (Musa Cavendish). Ind. Crop. Prod. 26(3):324–331.10.1016/j.indcrop.2007.03.012Search in Google Scholar

Jahan, M.S., Hosen, M.M., Rahman, M.M. (2013) Comparative study on the prebleaching of bamboo and hardwood pulps produced in Kharnaphuli Paper Mills. Turk. J. Agric. For. 37(6):812–817.10.3906/tar-1211-64Search in Google Scholar

Jahan, M.S., Shamsuzzaman, M., Rahman, M.M., Moeiz, S.I., Ni, Y. (2012) Effect of pre-extraction on soda-anthraquinone (AQ) pulping of rice straw. Ind. Crop. Prod. 37(1):164–169.10.1016/j.indcrop.2011.11.035Search in Google Scholar

Jahan, M.S., Uddin, M.M., Kashem, M.A. (2017) Modification of chlorine dioxide bleaching of Gmelina arborea (gamar) pulp. Bangladesh J. Sci. Ind. Res. 52(4):247–252.10.3329/bjsir.v52i4.34812Search in Google Scholar

Kaur, D., Bhardwaj, N.K., Lohchab, R.K. (2018) A study on pulping of rice straw and impact of incorporation of chlorine dioxide during bleaching on pulp properties and effluents characteristics. J. Clean. Prod. 170:174–182.10.1016/j.jclepro.2017.09.111Search in Google Scholar

Kaur, D., Bhardwaj, N.K., Lohchab, R.K. (2019) Environmental aspect of using chlorine dioxide to improve effluent and pulp quality during wheat straw bleaching. Waste Biomass Valori 10(5):1231–1239.10.1007/s12649-017-0193-6Search in Google Scholar

Kaur, D., Bhardwaj, N.K., Lohchab, R.K. (2019a) Impact of modifying conventional chlorine dioxide stage to hot chlorine dioxide during rice straw pulp bleaching on pulp, paper and effluent characteristics. Cellulose 26(12):7469–7482.10.1007/s10570-019-02616-5Search in Google Scholar

Kumar, S., Mishra, S.P., Mishra, O.P., Bajpai, P., Tripathi, S., Bajpai, P.K., Varadhan, R. (2007) Hot chlorine dioxide versus conventional do stage in ECF. Ippta J. 19(1):87–91.Search in Google Scholar

Lachenal, D., Chirat, C. (2000) High temperature chlorine dioxide bleaching of hardwood kraft pulp. Tappi J. 83(8):96.Search in Google Scholar

Lehtimaa, T., Tarvo, V., Kuitunen, S., Jääskeläinen, A.S., Vuorinen, T. (2010) The effect of process variables in chlorine dioxide prebleaching of birch kraft pulp. Part 2. AOX and OX formation. J. Wood Chem. Technol. 30(1):19–30.10.1080/02773810903276684Search in Google Scholar

Matin, M., Rahaman, M.M., Nayeem, J., Sarkar, M., Jahan, M.S. (2015) Dissolving pulp from jute stick. Carbohydr. Polym. 115:44–48.10.1016/j.carbpol.2014.08.090Search in Google Scholar PubMed

McDonough, T.J., Uno, S., Rudie, A.W., Courchene, C.E. (2009) Optimization of ECF bleaching of kraft pulp: II, Effects of acid prehydrolysis on hardwood pulp bleachability. Tappi J. 8(8):10–18.10.32964/TJ8.8.10Search in Google Scholar

Nie, S., Wang, S., Qin, C., Yao, S., Ebonka, J.F., Song, X., Li, K. (2015) Removal of hexenuronic acid by xylanase to reduce adsorbable organic halides formation in chlorine dioxide bleaching of bagasse pulp. Bioresour. Technol. 196:413–417.10.1016/j.biortech.2015.07.115Search in Google Scholar PubMed

Nie, S., Wu, Z., Liu, J., Liu, X., Qin, C., Song, H., Wang, S. (2013) Optimization of AOX formation during the first chlorine dioxide bleaching stage (D0) of soda AQ bagasse pulp. Appita J. 66(4):306–312.Search in Google Scholar

Nie, S., Yao, S., Qin, C., Li, K., Liu, X., Wang, L., Wang, S. (2014) Kinetics of AOX formation in chlorine dioxide bleaching of bagasse pulp. BioResources 9(3):5604–5614.10.15376/biores.9.3.5604-5614Search in Google Scholar

Ragnar, M. (2003) A comparative study of hot versus conventional chlorine dioxide bleaching for different wood species. Appita J. 56(6):471–475.Search in Google Scholar

Ragnar, M., Lindström, M. (2004) A comparison of emerging technologies: hot chlorine dioxide bleaching versus hot acid treatment. Pap. Puu 86(1):39–44.Search in Google Scholar

Rolf, B., Christina, J., Lars-Ake, L., Yngve, L. (2009) Non-wood Pulping Technology-Present Status and Future. Ippta J. 21(1):115–120.Search in Google Scholar

Shin, N.H., Mera, F. (1994) The impact of RDH extended delignification on ECF and TCF bleaching. In: 1994 TAPPI Pulping Conference Proceedings. Tappi Press, Atlanta. pp. 167–175.Search in Google Scholar

Tarvo, V., Lehtimaa, T., Kuitunen, S., Alopaeus, V., Vuorinen, T., Aittamaa, J. (2010) A model for chlorine dioxide delignification of chemical pulp. J. Wood Chem. Technol. 30(3):230–268.10.1080/02773810903461476Search in Google Scholar

Tavast, D., Brännvall, E., Lindström, M.E., Henriksson, G. (2011) Selectiveness and efficiency of combined peracetic acid and chlorine dioxide bleaching stage for kraft pulp in removing hexeuronic acid. Cellul. Chem. Technol. 45(1):89–95.Search in Google Scholar

Teleman, A., Harjunpää, V., Tenkanen, M., Buchert, J., Hausalo, T., Drakenberg, T., Vuorinen, T. (1995) Characterization of 4-deoxy-β-Lthreo-hex-4-enopyranosyluronic acid attached to xylan in pine kraft pulp and pulping liquor by 1H and 13C NMR spectroscopy. Carbohydr. Res. 272(1):55–71.10.1016/0008-6215(95)96873-MSearch in Google Scholar

Uchida, Y., Miura, T., Iwasaki, M. (1999) Acid treatment under pressurized oxygen gas. In: Tappi Pulping Conference Proceedings. Tappi Press, Atlanta. pp. 317–322.Search in Google Scholar

Ventorim, G., Colodette, J.L., Eiras, K.M. (2005) The fate of chlorine species during high temperature chlorine dioxide bleaching. Nord. Pulp Pap. Res. J. 20:7–11.10.3183/npprj-2005-20-01-p007-011Search in Google Scholar

Ventorim, G., Colodette, J.L., Gomes, A.F., Mandes de Silva, L.H. (2008) Reaction Rates of Lignin and Hexenuronic Acids with Chlorine Dioxide, Ozone, and Sulfuric Acid. Wood Fiber Sci 40:190–201.Search in Google Scholar

Zhang, H., Nie, S., Qin, C., Zhang, K., Wang, S. (2018) Effect of hot chlorine dioxide delignification on AOX in bagasse pulp wastewater. Cellulose 25(3):2037–2049.10.1007/s10570-018-1670-1Search in Google Scholar

Supplemental Material

The online version of this article offers supplementary material (https://doi.org/10.1515/npprj-2020-0043).

© 2020 Ferdous et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Frontmatter

- Review

- Evolution of biobased and nanotechnology packaging – a review

- Chemical pulping

- Evaluation of sodium salt scaling in black liquor evaporators using existing process data

- Assessing the value of a diversified by-product portfolio to allow for increased production flexibility in pulp mills

- Bleaching

- Effect of introducing ozone in elemental chlorine free bleaching of pulp on generation of chlorophenolic compounds

- Chlorine dioxide bleaching of nineteen non-wood plant pulps

- A solid-phase extraction method that eliminates matrix effects of complex pulp mill effluents for the analysis of lipophilic wood extractives

- Mechanical pulping

- Development of fibre properties in mill scale high- and low consistency refining of thermomechanical pulp (Part 1)

- Measurement and interpretation of spatially registered bar-forces in LC refining

- Paper technology

- Production of a fine fraction using micro-perforated screens

- The effect of Plantago psyllium seed husk flour on the properties of cellulose sheet

- Comprehensive evaluation of the industrial processing effects on the fiber properties of the pulps from wood residues

- Paper chemistry

- Application of CS-CHO-g-PMMA emulsion in paper reinforcement and protection

- Effects of metal ions and wood pitch on retention and physical properties of TMP

- Coating

- Effect of the glass-transition temperature of latexes on drying-stress development of latex films and inkjet coating layers

- Nanotechnology

- Study of LCNF and CNF from pine and eucalyptus pulps

- Miscellaneous

- The component composition of planted pine wood cultivated in the boreal zone

Articles in the same Issue

- Frontmatter

- Review

- Evolution of biobased and nanotechnology packaging – a review

- Chemical pulping

- Evaluation of sodium salt scaling in black liquor evaporators using existing process data

- Assessing the value of a diversified by-product portfolio to allow for increased production flexibility in pulp mills

- Bleaching

- Effect of introducing ozone in elemental chlorine free bleaching of pulp on generation of chlorophenolic compounds

- Chlorine dioxide bleaching of nineteen non-wood plant pulps

- A solid-phase extraction method that eliminates matrix effects of complex pulp mill effluents for the analysis of lipophilic wood extractives

- Mechanical pulping

- Development of fibre properties in mill scale high- and low consistency refining of thermomechanical pulp (Part 1)

- Measurement and interpretation of spatially registered bar-forces in LC refining

- Paper technology

- Production of a fine fraction using micro-perforated screens

- The effect of Plantago psyllium seed husk flour on the properties of cellulose sheet

- Comprehensive evaluation of the industrial processing effects on the fiber properties of the pulps from wood residues

- Paper chemistry

- Application of CS-CHO-g-PMMA emulsion in paper reinforcement and protection

- Effects of metal ions and wood pitch on retention and physical properties of TMP

- Coating

- Effect of the glass-transition temperature of latexes on drying-stress development of latex films and inkjet coating layers

- Nanotechnology

- Study of LCNF and CNF from pine and eucalyptus pulps

- Miscellaneous

- The component composition of planted pine wood cultivated in the boreal zone