Abstract

This paper studied the mechanical performance of aerated concrete and its bonding performance with glass fiber grille, and explores the influence of aluminum powder and aluminum powder on mechanical performance and bonding performance. The results showed that the compressive strength of aerated concrete decreased with the increase of aluminum powder content, while it first increased and then decreased with the increase of ferrosilicon alloy powder content. The failure modes of specimens were fiber fracture failure, and the fibers were not pulled out from the aerated concrete. It can provide a theoretical basis for the application of aerated concrete and glass fiber in engineering.

1 Introduction

At present, the prefabricated building structure system has been vigorously promoted. As vertical non-load-bearing component, internal and external partition wall panels are widely used in prefabricated building structures. Aerated concrete wall panels have light weight, good thermal insulation performance, strong seismic performance, good processing performance, inevitable high temperature resistance, good sound insulation performance, and strong adaptability are widely used.

Alexanderson et al. [1], Petrov et al. [2] and Prim et al. [3] investigated the micro-structure of aerated concrete and found that the pore structure of aerated concrete was mainly divided into two levels: micro-pore structure and macro-pore structure, and analyzed the formation of pore structure. Wang et al. [4], Robler et al. [5] and Ho et al. [6] investigated the influencing factors of the compressive strength of aerated concrete. Varela et al. [7] analyzed autoclaved aerated concrete block shear wall through quasi-static test, and developed relevant applications to optimize the structural design of autoclaved aerated concrete. Tomá [8] studied the shrinkage and damage phenomena of aerated concrete through experiments and carried out numerical simulation analysis on this basis. The research showed that the experimental phenomena of numerical simulation analysis were basically consistent with the experimental values. Yu [9] investigated the mechanical properties, failure phenomena and failure principle of aerated concrete block wall by quasi-static test. Jin [10] studied the bearing capacity of connection joints of aerated concrete wallboard under different factors through experiments. Leng [11] studied the bending performance of autoclaved aerated concrete slab under load through experiments, and deduced the calculation formula of ultimate bending moment according to the failure mode of slab and test data. Wu [12] studied conducted nonlinear analysis on autoclaved aerated concrete block wall using ABAQUS finite element simulation software. Zeng et al. [13] analyzed the stress-strain curve of autoclaved aerated concrete block under uniaxial compression through experimental research and theoretical analysis. Li [14] carried out experimental and theoretical studies on several connection joints of autoclaved aerated concrete wallboard, and analyzed the failure mode and the bearing capacity. Zhang et al. [15] studied the variation of ultimate bearing capacity of autoclaved aerated concrete slabs. Li [16] studied enhancing carbonation and chloride resistance of autoclaved concrete by incorporating Nano-CaCo3.

The tensile properties of wall panels are mostly improved by setting steel bars in aerated concrete. However, as a traditional ductile material, steel bars have disadvantages such as self-weight and poor corrosion resistance. If a fiber-forming material can be used to replace traditional steel bars, it can not only reduce the weight of the wall panel, but also improve its durability. High-strength glass fiber is a good choice.

Furthermore, good bonding performance between glass fiber grille and aerated concrete is the premise of their joint work [17]. It is necessary to study the bonding performance of glass fiber grille and aerated concrete. However, there is few studies focused on the bonding performance of aerated concrete and glass fiber grille.

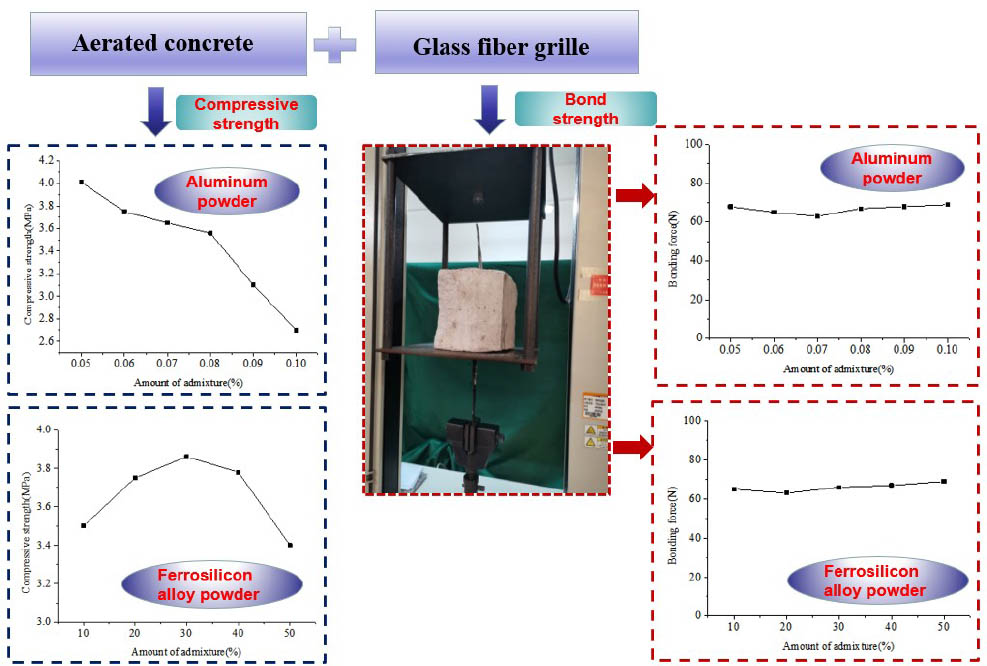

The purpose of this paper is to investigate the mechanical performance of aerated concrete and its bonding performance with glass fiber grill, obtain the influence of aluminum powder and ferrosilicon alloy powder on cubic compressive strength on cubic compressive strength of aerated concrete, and obtain the bonding force between aerated concrete and glass fiber grill. The graphical abstract is shown in Figure 1.

Graphical abstract

2 Experiment

2.1 Materials and mix proportions

In this study, the cement type used for the concrete mixtures was P.O 42.5 Portland cement, the cement properties are listed in Table 1. Desulphurized gypsum was homogenized and milled by ball mill before use. The chemical composition of desulfurized gypsum is listed in Table 2. Lime meets the requirements of JC/T621-2009 [18]. The chemical composition of lime are shown in Table 3. The chemical composition of fly ash is shown in the Table 4. The active aluminum content of aluminum paste is 83%, and the solid content is 74%. The water to material ratio of mix proportions of aerated concrete is 0.52, and the basis mix proportions are listed in Table 5. The glass fiber properties are listed in Table 6.

Cement properties

| Property | Value |

|---|---|

| Specific surface area (m2 kg−1) | 335 |

| Initial setting times (min) | 130 |

| Final setting times (min) | 215 |

| 28-day compressive strength (MPa) | 45.8 |

| 28-day flexural strength (MPa) | 7.5 |

| SO3 (%) | 2.35 |

| MgO (%) | 1.67 |

Chemical composition of desulfurized gypsum (%)

| Property | Value |

|---|---|

| CaO | 40 |

| SO2 | 2.75 |

| SO3 | 34 |

| MgO | 0.45 |

Chemical composition of lime (%)

| Property | Value |

|---|---|

| CaO | 76.57 |

| MgO | 3.62 |

| SO2 | 5.42 |

| SO3 | 0.43 |

| Al2O3 | 3.96 |

Chemical composition of fly ash (%)

| Property | Value |

|---|---|

| CaO | 8.10 |

| MgO | 1.49 |

| SO2 | 57.30 |

| SO3 | 0.18 |

| Al2O3 | 21.40 |

Basis mix proportions (%)

| Material type | Value |

|---|---|

| Cement | 70 |

| Desulfurized gypsum | 4.5 |

| Lime | 14.5 |

| Fly ash | 11 |

Glass fiber grille properties

| Property | Value |

|---|---|

| Radial fracture strength (kN/m) | 50 |

| Latitudinal fracture strength (kN/m) | 50 |

| Radial breaking elongation (%) | 4 |

| Latitudinal breaking elongation (%) | 4 |

2.2 Specimens

The specimens (150 mm×150 mm×150 mm) were used to test the cubic compressive strength of aerated concrete; The pullout specimens (150 mm×150 mm×150 mm) were used to test the bonding properties of aerated concrete and different glass fiber, and the details are listed in Figure 2.

Pullout specimens

2.3 Loading test

The cubic specimens and pullout specimens were tested in the electro-hydraulic servo machine, and the applied load was collected by the computer. Pullout test setup is shown in Figure 3.

Pullout test setup

3 Results

3.1 Cubic compressive strength

The gas generating agent will generate a large number of bubbles inside the concrete, thereby reducing the dry density and thermal conductivity of the specimen. However, it will also reduce the compressive strength of aerated concrete, so an appropriate amount of gas generating agent has an important effect on aerated concrete. Aluminum powder and ferrosilicon alloy powder are currently commonly used gas generating agents.

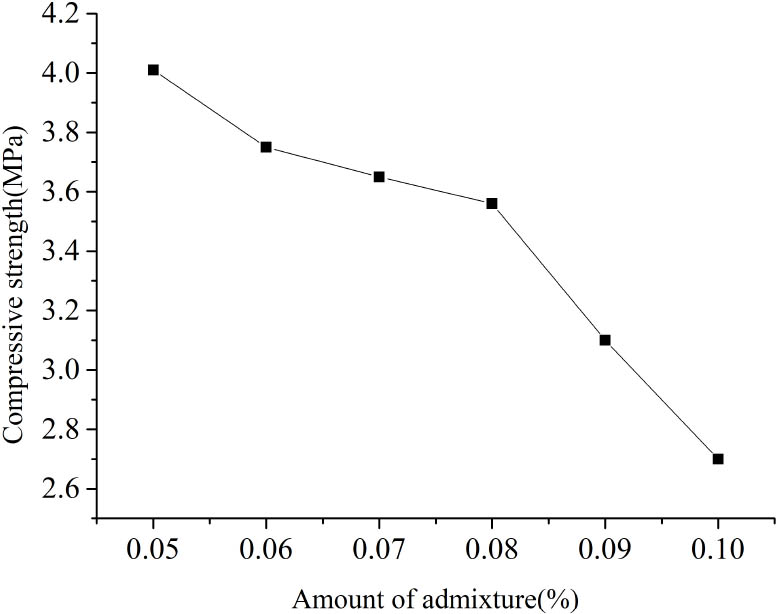

3.1.1 Influence of aluminum powder on cubic compressive strength

The change curve of the compressive strength of aerated concrete with the amount of aluminum powder is shown in the Figure 4. It can be seen that the compressive strength of aerated concrete decreased with the increase of aluminum powder content, this is consistent with Zhang [19]. The reason is that as the amount of aluminum powder increases, the amount of gas generated in the paste is greater, and more pores will be generated inside the paste, which reduces the hydration products per unit volume, and the internal skeleton structure of the concrete becomes weaker, which reduce the compressive strength of aerated concrete [19].

Compressive strength versus aluminum powder content

In addition, when the aluminum powder content was less than 0.08%, the concrete strength of aerated concrete decreased slowly; when the aluminum powder content was greater than 0.08%, the concrete strength of aerated concrete decreased rapidly. Therefore, the aluminum powder content should not be greater than 0.08%.

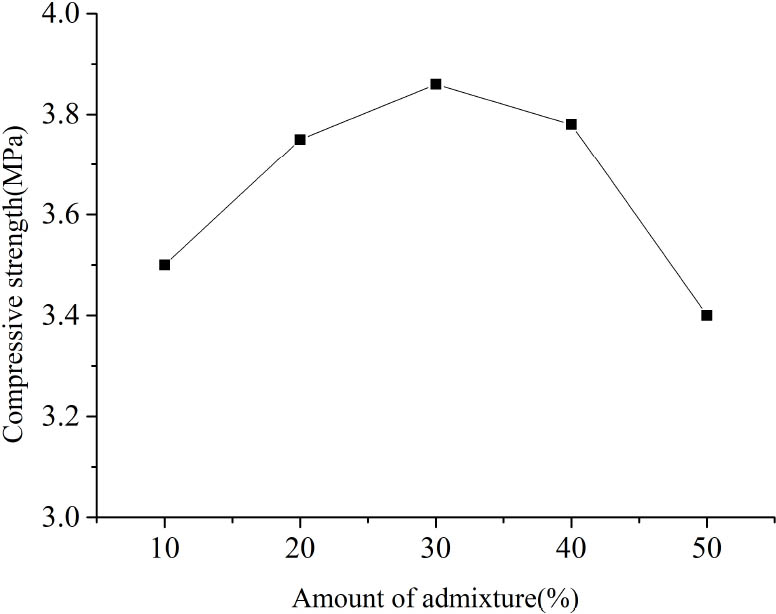

3.1.2 Ferrosilicon alloy powder on cubic compressive strength

The change curve of the compressive strength of aerated concrete with the amount of ferrosilicon alloy powder is shown in the Figure 5. It can be seen that the compressive strength of aerated concrete first increased and then decreased with the increase of ferrosilicon alloy powder content. When the ferrosilicon alloy powder content is 30%, the strength of aerated concrete is the highest.

Compressive strength versus ferrosilicon alloy powder content

3.2 Bonding performance of aerated concrete and glass fiber

The failure modes of specimens were fiber fracture failure, and the fibers were not pulled out from the aerated concrete.

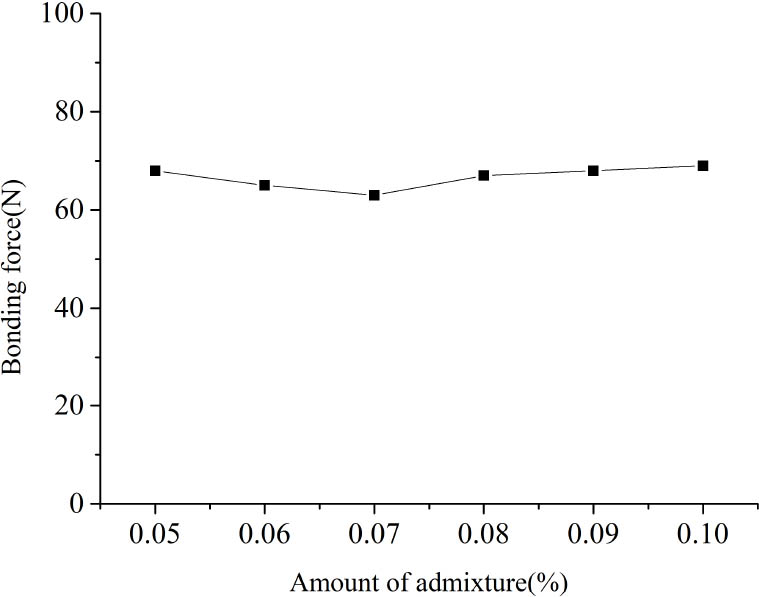

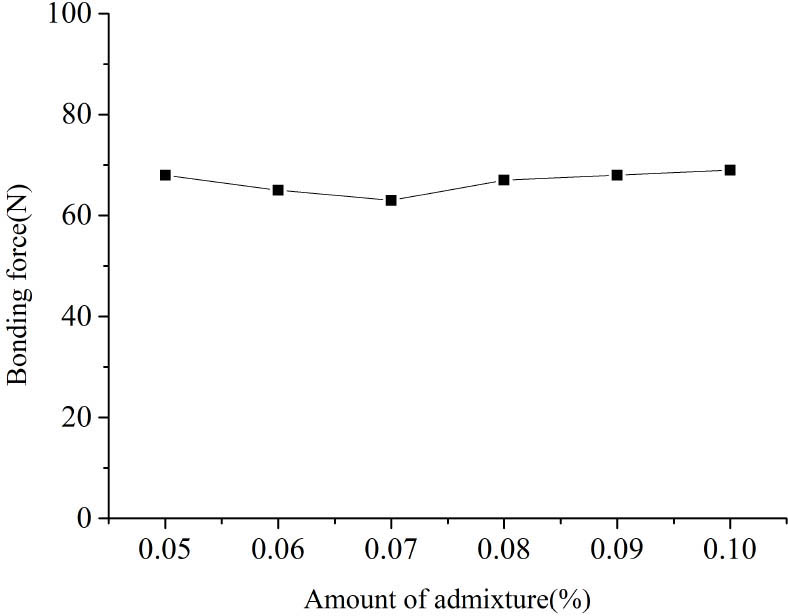

The change curve of the bonding strength of aerated concrete specimens with the amount of aluminum powder is shown in the Figure 6. The change curve of the bonding strength of aerated concrete specimens with the amount of ferrosilicon alloy powder is shown in the Figure 7.

Bonding force versus aluminum powder content

Bonding force versus ferrosilicon alloy powder content

It can be seen that the aluminum powder and ferrosilicon alloy powder did not affect the bonding strength of aerated concrete specimens. The reason is that the glass fiber was broken before the maximum bond strength was reached. This means that there is good bonding performance between the glass fiber and the aerated concrete.

In addition, with the continuous development of building materials, scholars hope to apply more technologies to building materials: Liu [20] studied the addition of graphene oxide to improve the ultra-early strength of sulphoaluminate cement-based materials. Su [21, 22] studied the possibility of using recycled concrete in engineering.

4 Conclusions

The compressive strength of aerated concrete decreased with the increase of aluminum powder content.

The compressive strength of aerated concrete first increased and then decreased with the increase of ferrosilicon alloy powder content.

The failure modes of specimens were fiber fracture failure, and the fibers were not pulled out from the aerated concrete. There is good bonding performance between the glass fiber grille and the aerated concrete.

Funding information: The authors state no funding involved.

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

Conflict of interest: The authors state no conflict of interest.

References

[1] Alexanderson J. Relations between structure and mechanical properties of autoclaved aerated concrete. Cem Concr Res. 1979;9:507–514.10.1016/0008-8846(79)90049-8Search in Google Scholar

[2] Petrov I, Schlegel E. Application of automatic image analysis for the investigation of autoclaved areated concrete structure. Cem Concr Res, 1994;24:830–840.10.1016/0008-8846(94)90003-5Search in Google Scholar

[3] Prim P, Witmann FH. Structure and water absorption of aerated concrete. Proceedings of the RILEM International Symposium on Autoclaved Aerated Concrete. 1983;6:55–69.Search in Google Scholar

[4] Wang S D. Study on preparation and properties of non-autoclaved aerated concrete. Southeast University, 2016. (in Chinese)Search in Google Scholar

[5] Robler M, Odler I. Investigations on the relationship between porosity structure and strength of hydrated portland cement pastes III. Effect of clinker composition and gypsum addition. Cem Concr Res, 1985;15:320–330.10.1016/0008-8846(85)90044-4Search in Google Scholar

[6] Ho. G C. Porosity-strength considerations for cellular concrete. Cem Concr Res, 1972;2:91–100.10.1016/0008-8846(72)90026-9Search in Google Scholar

[7] Jorge L. Varela, Jennifer E. Tanner, Richard E. Klingner. Development of seismic force reduction and displacement amplification factors for autoclaved aerated concrete structures. Earthq. Spectra, 2006;22(1):267–286.10.1193/1.2166034Search in Google Scholar

[8] Tomá. Coupled shrinkage and damage analysis of autoclaved aerated concrete. Appl. Math. and Comput, 2015;267:427–435.10.1016/j.amc.2015.02.016Search in Google Scholar

[9] Yu J H. Research on seismic performance of new lightweight aerated concrete load-bearing masonry. Tianjin University, 2008. (in Chinese)Search in Google Scholar

[10] Jin Y, Cheng C Y. Experimental study on the performance of joints of autoclaved aerated concrete wall panels. Wall material innovation and building energy saving, 2009;(2):34–37+3. (in Chinese)Search in Google Scholar

[11] Leng N, Zhao C W. Finite element analysis of autoclaved aerated concrete slab. Heilongjiang Science and Technology Information, 2010;(2):280. (in Chinese)Search in Google Scholar

[12] Wu H G, Zhao J. Seismic performance analysis of aerated concrete block masonry walls with windows. World Earthquake Engineering, 2012;28 (1):33–38. (in Chinese)Search in Google Scholar

[13] Zeng H. Experimental study on the stress-strain constitutive relationship of autoclaved fly ash-sand aerated concrete and its masonry mechanical properties. Changsha University of Science and Technology, 2013. (in Chinese)Search in Google Scholar

[14] Li X D. Design and research of lightweight autoclaved sand aerated concrete wall panel. Chang’an University, 2014. (in Chinese)Search in Google Scholar

[15] Zhang G W, Zhang P, Chen B S, Chen P. Study on displacement ductility of autoclaved aerated concrete slab. Industrial Construction, 2017;47 (12):106–110+126. (in Chinese)Search in Google Scholar

[16] Li G, Zhuang Z, Lv Y, et al. Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3. Nanotechnol. Rev. 2020;9(1):998–1008.10.1515/ntrev-2020-0078Search in Google Scholar

[17] Guo Z, Zhu Q, Wu W, et al. Research on bond-slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete. Nanotechnol. Rev. 2020;9(1):637–649.10.1515/ntrev-2020-0036Search in Google Scholar

[18] Ministry of Industry and Information Technology of the People's Republic of China. Quicklime for silicate building products JC/T621-2009, 2009. (in Chinese)Search in Google Scholar

[19] Zhang H L. Research on the performance of aerated concrete self-insulating wall in severe cold area. Harbin Institute of Technology, 2019. (in Chinese)Search in Google Scholar

[20] Liu Y, Jia M, Song C, et al. Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide. Nanotechnol. Rev., 2020;9(1):17–27.10.1515/ntrev-2020-0002Search in Google Scholar

[21] Su T, Wang C, Cao F, et al. An overview of bond behavior of recycled coarse aggregate concrete with steel bar. Rev. Adv. Mater. Sci., 2021;60(1):127–144.10.1515/rams-2021-0018Search in Google Scholar

[22] Su T, Wu J, Zou Z, et al. Bond performance of steel bar in RAC under salt-frost and repeated loading. J. Mater. Civil. Eng., 2020;32(9):04020261.10.1061/(ASCE)MT.1943-5533.0003303Search in Google Scholar

© 2021 Zhenfang Li et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Nonlinear absolute sea-level patterns in the long-term-trend tide gauges of the East Coast of North America

- Insight into the significance of Joule dissipation, thermal jump and partial slip: Dynamics of unsteady ethelene glycol conveying graphene nanoparticles through porous medium

- Numerical results for influence the flow of MHD nanofluids on heat and mass transfer past a stretched surface

- A novel approach on micropolar fluid flow in a porous channel with high mass transfer via wavelet frames

- On the exact and numerical solutions to a new (2 + 1)-dimensional Korteweg-de Vries equation with conformable derivative

- On free vibration of laminated skew sandwich plates: A finite element analysis

- Numerical simulations of stochastic conformable space–time fractional Korteweg-de Vries and Benjamin–Bona–Mahony equations

- Dynamical aspects of smoking model with cravings to smoke

- Analysis of the ROA of an anaerobic digestion process via data-driven Koopman operator

- Lie symmetry analysis, optimal system, and new exact solutions of a (3 + 1) dimensional nonlinear evolution equation

- Extraction of optical solitons in birefringent fibers for Biswas-Arshed equation via extended trial equation method

- Numerical study of radiative non-Darcy nanofluid flow over a stretching sheet with a convective Nield conditions and energy activation

- A fractional study of generalized Oldroyd-B fluid with ramped conditions via local & non-local kernels

- Analytical and numerical treatment to the (2+1)-dimensional Date-Jimbo-Kashiwara-Miwa equation

- Gyrotactic microorganism and bio-convection during flow of Prandtl-Eyring nanomaterial

- Insight into the significance of ramped wall temperature and ramped surface concentration: The case of Casson fluid flow on an inclined Riga plate with heat absorption and chemical reaction

- Dynamical behavior of fractionalized simply supported beam: An application of fractional operators to Bernoulli-Euler theory

- Mechanical performance of aerated concrete and its bonding performance with glass fiber grille

- Impact of temperature dependent viscosity and thermal conductivity on MHD blood flow through a stretching surface with ohmic effect and chemical reaction

- Computational and traveling wave analysis of Tzitzéica and Dodd-Bullough-Mikhailov equations: An exact and analytical study

- Combination of Laplace transform and residual power series techniques to solve autonomous n-dimensional fractional nonlinear systems

- Investigating the effects of sudden column removal in steel structures

- Investigation of thermo-elastic characteristics in functionally graded rotating disk using finite element method

- New Aspects of Bloch Model Associated with Fractal Fractional Derivatives

- Magnetized couple stress fluid flow past a vertical cylinder under thermal radiation and viscous dissipation effects

- New Soliton Solutions for the Higher-Dimensional Non-Local Ito Equation

- Role of shallow water waves generated by modified Camassa-Holm equation: A comparative analysis for traveling wave solutions

- Study on vibration monitoring and anti-vibration of overhead transmission line

- Vibration signal diagnosis and analysis of rotating machine by utilizing cloud computing

- Hybrid of differential quadrature and sub-gradients methods for solving the system of Eikonal equations

- Developing a model to determine the number of vehicles lane changing on freeways by Brownian motion method

- Finite element method for stress and strain analysis of FGM hollow cylinder under effect of temperature profiles and inhomogeneity parameter

- Novel solitons solutions of two different nonlinear PDEs appear in engineering and physics

- Optimum research on the temperature of the ship stern-shaft mechanical seal end faces based on finite element coupled analysis

- Numerical and experimental analysis of the cavitation and study of flow characteristics in ball valve

- Role of distinct buffers for maintaining urban-fringes and controlling urbanization: A case study through ANOVA and SPSS

- Significance of magnetic field and chemical reaction on the natural convective flow of hybrid nanofluid by a sphere with viscous dissipation: A statistical approach

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications

- Research on vibration monitoring and fault diagnosis of rotating machinery based on internet of things technology

- An improved image processing algorithm for automatic defect inspection in TFT-LCD TCON

- Research on speed sensor fusion of urban rail transit train speed ranging based on deep learning

- A Generalized ML-Hyers-Ulam Stability of Quadratic Fractional Integral Equation

- Study on vibration and noise influence for optimization of garden mower

- Relay vibration protection simulation experimental platform based on signal reconstruction of MATLAB software

- Research on online calibration of lidar and camera for intelligent connected vehicles based on depth-edge matching

- Study on fault identification of mechanical dynamic nonlinear transmission system

- Research on logistics management layout optimization and real-time application based on nonlinear programming

- Complex circuit simulation and nonlinear characteristics analysis of GaN power switching device

- Seismic nonlinear vibration control algorithm for high-rise buildings

- Parameter simulation of multidimensional urban landscape design based on nonlinear theory

- Research on frequency parameter detection of frequency shifted track circuit based on nonlinear algorithm

Articles in the same Issue

- Nonlinear absolute sea-level patterns in the long-term-trend tide gauges of the East Coast of North America

- Insight into the significance of Joule dissipation, thermal jump and partial slip: Dynamics of unsteady ethelene glycol conveying graphene nanoparticles through porous medium

- Numerical results for influence the flow of MHD nanofluids on heat and mass transfer past a stretched surface

- A novel approach on micropolar fluid flow in a porous channel with high mass transfer via wavelet frames

- On the exact and numerical solutions to a new (2 + 1)-dimensional Korteweg-de Vries equation with conformable derivative

- On free vibration of laminated skew sandwich plates: A finite element analysis

- Numerical simulations of stochastic conformable space–time fractional Korteweg-de Vries and Benjamin–Bona–Mahony equations

- Dynamical aspects of smoking model with cravings to smoke

- Analysis of the ROA of an anaerobic digestion process via data-driven Koopman operator

- Lie symmetry analysis, optimal system, and new exact solutions of a (3 + 1) dimensional nonlinear evolution equation

- Extraction of optical solitons in birefringent fibers for Biswas-Arshed equation via extended trial equation method

- Numerical study of radiative non-Darcy nanofluid flow over a stretching sheet with a convective Nield conditions and energy activation

- A fractional study of generalized Oldroyd-B fluid with ramped conditions via local & non-local kernels

- Analytical and numerical treatment to the (2+1)-dimensional Date-Jimbo-Kashiwara-Miwa equation

- Gyrotactic microorganism and bio-convection during flow of Prandtl-Eyring nanomaterial

- Insight into the significance of ramped wall temperature and ramped surface concentration: The case of Casson fluid flow on an inclined Riga plate with heat absorption and chemical reaction

- Dynamical behavior of fractionalized simply supported beam: An application of fractional operators to Bernoulli-Euler theory

- Mechanical performance of aerated concrete and its bonding performance with glass fiber grille

- Impact of temperature dependent viscosity and thermal conductivity on MHD blood flow through a stretching surface with ohmic effect and chemical reaction

- Computational and traveling wave analysis of Tzitzéica and Dodd-Bullough-Mikhailov equations: An exact and analytical study

- Combination of Laplace transform and residual power series techniques to solve autonomous n-dimensional fractional nonlinear systems

- Investigating the effects of sudden column removal in steel structures

- Investigation of thermo-elastic characteristics in functionally graded rotating disk using finite element method

- New Aspects of Bloch Model Associated with Fractal Fractional Derivatives

- Magnetized couple stress fluid flow past a vertical cylinder under thermal radiation and viscous dissipation effects

- New Soliton Solutions for the Higher-Dimensional Non-Local Ito Equation

- Role of shallow water waves generated by modified Camassa-Holm equation: A comparative analysis for traveling wave solutions

- Study on vibration monitoring and anti-vibration of overhead transmission line

- Vibration signal diagnosis and analysis of rotating machine by utilizing cloud computing

- Hybrid of differential quadrature and sub-gradients methods for solving the system of Eikonal equations

- Developing a model to determine the number of vehicles lane changing on freeways by Brownian motion method

- Finite element method for stress and strain analysis of FGM hollow cylinder under effect of temperature profiles and inhomogeneity parameter

- Novel solitons solutions of two different nonlinear PDEs appear in engineering and physics

- Optimum research on the temperature of the ship stern-shaft mechanical seal end faces based on finite element coupled analysis

- Numerical and experimental analysis of the cavitation and study of flow characteristics in ball valve

- Role of distinct buffers for maintaining urban-fringes and controlling urbanization: A case study through ANOVA and SPSS

- Significance of magnetic field and chemical reaction on the natural convective flow of hybrid nanofluid by a sphere with viscous dissipation: A statistical approach

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications

- Research on vibration monitoring and fault diagnosis of rotating machinery based on internet of things technology

- An improved image processing algorithm for automatic defect inspection in TFT-LCD TCON

- Research on speed sensor fusion of urban rail transit train speed ranging based on deep learning

- A Generalized ML-Hyers-Ulam Stability of Quadratic Fractional Integral Equation

- Study on vibration and noise influence for optimization of garden mower

- Relay vibration protection simulation experimental platform based on signal reconstruction of MATLAB software

- Research on online calibration of lidar and camera for intelligent connected vehicles based on depth-edge matching

- Study on fault identification of mechanical dynamic nonlinear transmission system

- Research on logistics management layout optimization and real-time application based on nonlinear programming

- Complex circuit simulation and nonlinear characteristics analysis of GaN power switching device

- Seismic nonlinear vibration control algorithm for high-rise buildings

- Parameter simulation of multidimensional urban landscape design based on nonlinear theory

- Research on frequency parameter detection of frequency shifted track circuit based on nonlinear algorithm