Abstract

As shared manufacturing emerges as a transformative paradigm in the industrial sector, it introduces complex resource allocation and scheduling challenges that traditional approaches struggle to address. Current platforms focus primarily on transaction management, lacking adequate mechanisms for evaluating production scenarios in multi-stakeholder environments. This research presents a novel simulation platform designed to support decision-making in shared manufacturing systems by enabling stakeholders to validate and optimize their production schedules through what-if analysis. The innovation lies in our adaptive simulation approach that dynamically reconfigures to represent diverse manufacturing scenarios without specialized modeling expertise. We demonstrate its application in the food manufacturing sector, where complex operational conditions create significant challenges for production planning and resource optimization. The results show that our platform effectively supports complex scheduling decisions while maintaining operational efficiency. This work contributes to the advancement of shared manufacturing by showing how simulation technology can facilitate the transformation of traditional manufacturing systems into flexible shared resources.

1 Introduction

The manufacturing sector is experiencing a fundamental transformation driven by increasing market volatility and the need for more flexible production models [1]. This evolution has given rise to shared manufacturing as an innovative paradigm that enables efficient resource sharing and collaborative production capabilities [2]. While cloud manufacturing established the foundation of manufacturing resources as services [3], shared manufacturing extends this approach through peer-to-peer resource sharing and distributed control mechanisms [4].

This transformation is particularly significant in industries with specialized equipment requirements, seasonal demands, and strict regulatory compliance, such as the food sector, where traditional manufacturing systems often struggle to maintain efficiency while ensuring quality standards [5]. The adoption of shared manufacturing principles is demonstrated by major platforms including Alibaba’s 1688 Tao Factory, Machinery Link, 3D Hubs, Floow2, and Foxconn’s BEACON [6], 7]. However, current implementation approaches reveal significant limitations in coordinating multiple stakeholders and optimizing resource allocation [8].

While existing platforms facilitate basic transaction management and resource matching [9], they lack sophisticated tools for simulating and evaluating complex production scenarios before implementation. This gap is particularly critical in environments with strict operational constraints, where testing new configurations in real settings could compromise product quality or disrupt operations across multiple stakeholders [10], 11].

This research addresses these challenges by introducing a novel simulation-based platform designed for shared manufacturing environments. The platform’s key innovation is its integration of web-based interfaces with automatic simulation model generation that dynamically adapts to diverse manufacturing configurations without requiring specialized modeling expertise. Unlike conventional approaches requiring expert reconfiguration [12], our platform enables stakeholders to evaluate and optimize production scenarios through intuitive interfaces that automatically translate user inputs into simulation parameters.

This research provides comprehensive tools for managing orders, products, and resources while enabling detailed what-if analyses of different production scenarios. This approach allows manufacturers to validate scheduling decisions and resource allocations while considering the broader system constraints and stakeholder requirements, ultimately supporting more efficient and reliable shared manufacturing operations.

The remainder of this paper is organized as follows: Section 2 presents a comprehensive review of shared manufacturing literature and current challenges. Section 3 outlines the methodological steps guiding our research approach. Section 4 introduces our simulation-based platform, detailing its architecture and implementation. Section 5 demonstrates the platform application through a preliminary case study in the food manufacturing sector. Section 6 discusses the results and implications of our research, including opportunities and challenges for practical implementation. Finally, Section 7 concludes the paper by summarizing our contributions and outlining future research directions for advancing shared manufacturing systems.

2 Background

The evolution of manufacturing systems towards more open and collaborative paradigms has led to significant developments in production models. While Cloud Manufacturing introduced the concept of manufacturing resources as services [3], Shared Manufacturing has emerged as a more flexible and distributed paradigm [1]. Unlike centralized architectures [4], it promotes a peer-to-peer approach to manufacturing resource sharing [2], fitting within the broader sharing economy context [13], 14].

This transformation is supported by Industry 4.0 technologies [15], 16] and cyber-physical systems [17]. The social aspects of manufacturing [18], 19] have evolved to include collaborative consumption models [20] and strategic sharing of resources [21]. This approach is particularly relevant in sectors like food manufacturing [5], where seasonal production patterns and specialized equipment requirements create opportunities for resource sharing among producers [22], 23].

Shared Manufacturing introduces significant challenges in managing and coordinating shared resources [8], especially in environments with strict hygiene and quality requirements such as food production facilities [24]. The concept of social factory [25] has emerged alongside new frameworks for credit assurance [26] and trust mechanisms [27]. Production planning in shared environments requires innovative approaches to manage multiple stakeholders [28], with various implementations demonstrating significant challenges [29].

Resource virtualization [30] and IT service integration [31] have become crucial elements, while shared warehousing systems [32] complement the production infrastructure. In particular, optimal resource allocation and activity scheduling [33] become significantly more complex compared to traditional systems, as they must account for product-specific processing conditions, perishability constraints, and cleaning requirements [34].

While literature has extensively explored technological and operational aspects of shared manufacturing, including trust and security issues [35], there remains a significant gap in simulation-based decision support tools. The servitization of manufacturing [36] has introduced new challenges [37] in system design [38]. Existing methodologies for production planning in shared environments [39] do not provide adequate mechanisms for preemptively evaluating scheduling decisions’ impact on the overall system [40].

While [41] presents a notable linear programming model for production scheduling with multiple shared-common resources in the yogurt industry – representing one of the few implementations in food manufacturing – the lack of simulation capabilities limits the model’s applicability for what-if analysis. This limitation becomes particularly critical in food manufacturing, where production constraints [42] demand accurate planning and preliminary validation of operational decisions [43].

The need for shared manufacturing-specific simulation tools is further highlighted by the evolution of cyber-physical systems and the integration of advanced digital technologies in production [9]. The fundamental framework of social manufacturing [44] is being enhanced through cloud computing and IoT integration [45]. While various manufacturing paradigms have benefited from dedicated solutions for service optimization [46], shared manufacturing still requires more robust approaches for capacity planning [47]. This gap is particularly evident in industries with complex production requirements and strict quality standards, where the ability to simulate and validate production scenarios before implementation becomes crucial for maintaining product quality and operational efficiency.

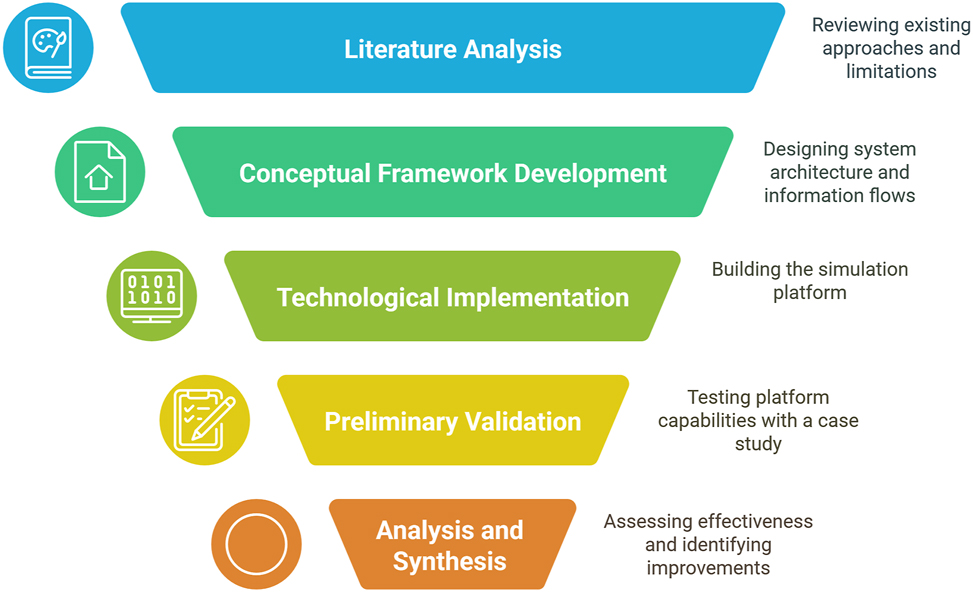

3 Methodological phases

This section outlines our systematic approach to developing and validating a simulation-based decision support platform for shared manufacturing in the food industry. Our methodology ensures research replicability through a structured sequence of phases that combine theoretical foundation with practical implementation. Figure 1 illustrates the main research phases.

Literature Analysis: the research identified a significant gap in decision support systems for production scheduling in shared manufacturing, particularly regarding the integration of simulation-based technologies. A comprehensive review of existing approaches revealed limitations in their ability to evaluate complex production scenarios involving multiple stakeholders with competing priorities and resource requirements.

Conceptual Framework Development: based on identified requirements, a system architecture was designed integrating web-based interfaces with simulation capabilities. This phase adopted a systems thinking approach to define essential information flows and interaction points, with particular attention to the integration of what-if analysis functionality for production planning and resource allocation.

Technological Implementation: object-oriented programming principles and model-driven design techniques enabled the creation of a flexible simulation environment. The implementation utilized Python Flask for the web application and Tecnomatix Plant Simulation for the adaptive simulation model. A key development focus was the comparative scenario evaluation algorithm that powers the what-if analysis, allowing stakeholders to quantitatively assess alternative production schedules through parameterized simulation runs.

Preliminary Validation: platform validation employed a conceptual case study based on Italian specialty food production, applying discrete event simulation techniques to evaluate system behavior under various production scenarios. The validation methodology assessed the effectiveness of the what-if analysis functionality by comparing baseline performance metrics against alternative scheduling configurations.

Analysis and Synthesis: results were analyzed using comparative performance evaluation, examining both technical functionality and practical applicability. This systematic assessment identified key strengths and limitations of the simulation-based approach for shared manufacturing decision support, with particular attention to the effectiveness of what-if analysis in facilitating informed scheduling decisions.

Research phases overview.

This methodological framework prioritizes reproducibility through explicit specification of techniques, tools, and evaluation criteria. The simulation-based what-if analysis approach represents a key methodological contribution, allowing stakeholders to evaluate production scenarios before implementation. The following section details the specific implementation of our simulation-based platform, demonstrating how these methodological principles were operationalized through concrete system architecture and functional components.

4 Simulation-based platform for shared manufacturing

This section presents our simulation-based platform designed to address scheduling challenges in shared manufacturing environments. We first provide a high-level overview of how the framework operates within a shared manufacturing context to support decision-making through what-if analysis. Subsequently, we detail the technical implementation of the user interface and its integration with the simulation model. Finally, we present the specific functionalities developed in our platform, showcasing its practical application in managing shared manufacturing operations.

4.1 Framework overview

The framework functions as a decision support system powered by a combination of real-time data collection and simulation capabilities. While the complete framework encompasses multiple components, this paper focuses specifically on the development and implementation of the user interface and its integration with the simulation model. Nevertheless, we first present a high-level conceptual overview of the entire framework to provide context for our implementation.

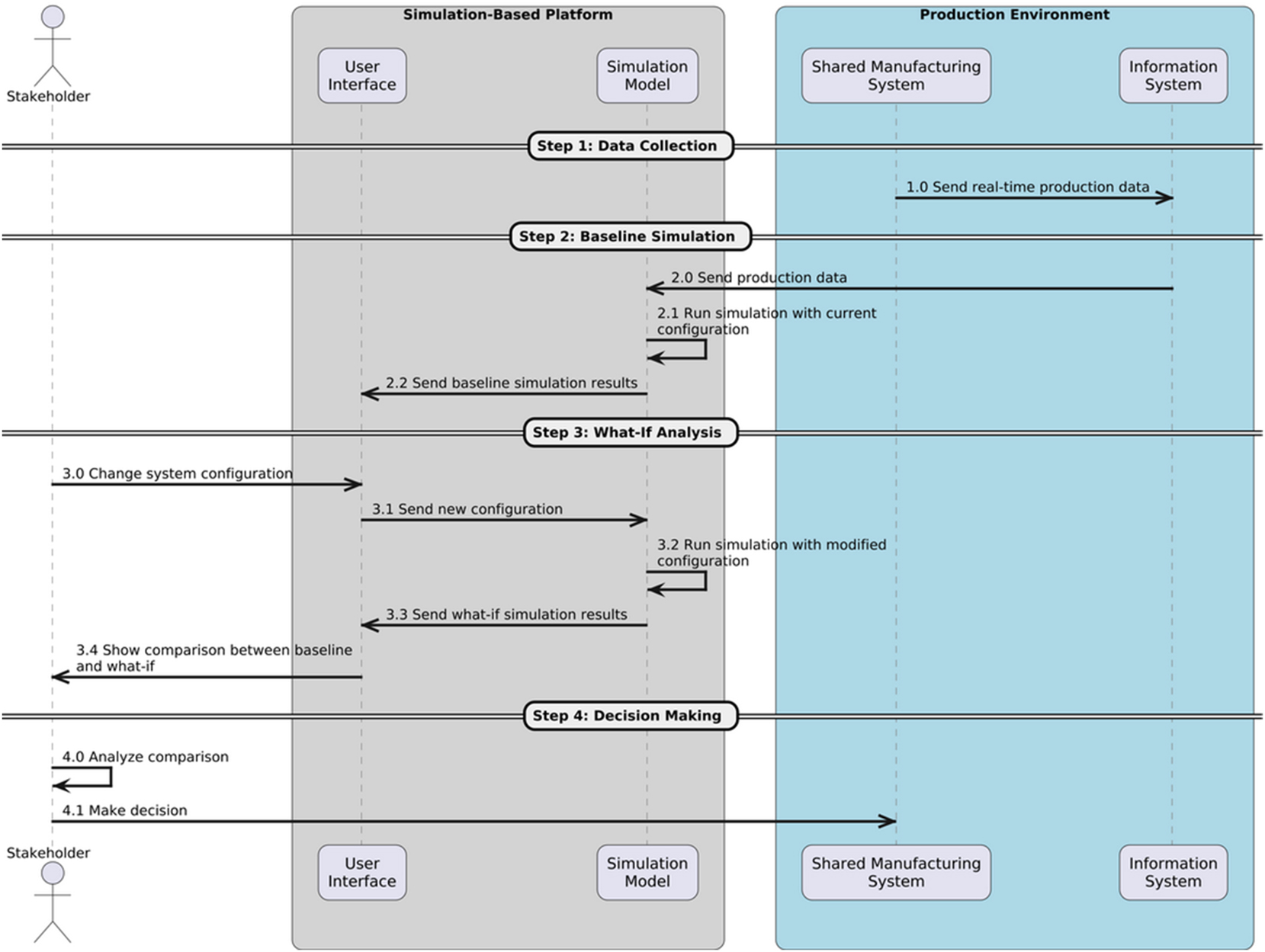

Figure 2 illustrates the conceptual system architecture and information flow between its main components: the Stakeholder Interface, Simulation Model, and the Shared Manufacturing System with its Information System. In this context, stakeholders comprise both resource providers who make their manufacturing equipment and facilities available for sharing, and resource customers (producers) who utilize these shared resources for their production needs. Specifically, resource providers include facility managers, equipment owners, and manufacturing capacity brokers who possess underutilized production assets, while resource customers encompass production managers, supply chain coordinators, manufacturing directors who require additional capacity to meet production demands or handle peak workloads, and product developers seeking to prototype and test new products without significant capital investments. This dual-stakeholder approach enables effective resource allocation and production planning within the shared manufacturing ecosystem.

Decision support system in shared manufacturing – framework architecture.

The architecture shown in Figure 2 consists of two distinct environments: the Simulation-Based Platform (gray area) and the Production Environment (blue area). The Shared Manufacturing System represents the physical production facility with shared resources, where multiple stakeholders operate manufacturing equipment. The Information System serves as the central data repository, collecting real-time operational data including resource states, production progress, and order status. Within the platform, the Simulation Model creates a digital representation of the manufacturing environment that predicts system behavior, while the User Interface connects stakeholders with the simulation model for configuration and analysis.

The framework operates through four sequential steps shown in Figure 2. While our implementation focuses primarily on the Simulation-Based Platform, understanding the complete workflow helps contextualize our contribution:

Step 1 – Data Collection: the Shared Manufacturing System transmits real-time production data to the Information System (step 1.0), ensuring simulations reflect current conditions. This data includes machine states, processing times, order status, resource availability, and other metrics needed to create an accurate simulation model of the manufacturing environment.

Step 2 – Baseline Simulation: the Information System forwards production data to the Simulation Model (step 2.0), which runs a simulation using the current system configuration (step 2.1) and sends baseline results to the User Interface (step 2.2). This establishes the reference point for comparative analysis, capturing the manufacturing system’s current state with existing resource allocation and production schedule. Key performance indicators such as resource utilization, throughput, and lead times reflect current operational performance.

Step 3 – What-If Analysis: stakeholders modify the system configuration through the interface (step 3.0), which the platform forwards to the Simulation Model (step 3.1). The model runs a simulation with these modifications (step 3.2), returns results to the user interface (step 3.3), which then presents a comparison between baseline and what-if scenarios to the Stakeholder (step 3.4). This core analytical component enables evaluation of potential changes such as adding products, adjusting resources, rescheduling orders, or modifying processes before implementing them in the actual environment.

Step 4 – Decision Making: the Stakeholder analyzes the comparison (step 4.0) and makes decisions that directly impact the Manufacturing System (step 4.1). This component combines quantitative simulation results with qualitative business considerations, helping stakeholders evaluate trade-offs between objectives like resource utilization, punctuality, and system efficiency to make data-driven decisions.

Our approach addresses the unique challenges of shared manufacturing environments where multiple stakeholders with competing interests must coordinate within the same production system. The framework supports multi-stakeholder coordination by facilitating transparent resource allocation, evaluating seasonal variations in utilization, identifying potential scheduling conflicts proactively, and enabling rapid evaluation of changes to accommodate new products or stakeholders.

This approach creates a dynamic ecosystem where potential changes can be evaluated before implementation. Through these simulation capabilities, stakeholders can assess various scenarios such as production planning, capacity utilization, and equipment investments without disrupting ongoing operations.

4.2 Simulation-based platform

This section presents the technical implementation of our decision support system (grey area of Figure 2), detailing both the web user interface and the underlying simulation model that powers it. We first describe the platform architecture that provides the user interface and data management capabilities, followed by an explanation of the simulation model that enables dynamic scenario evaluation.

4.2.1 User interface

The user interface is implemented as a web application built using the Python Flask framework. This platform serves as the interface between stakeholders and the simulation environment, providing intuitive tools for system configuration and result analysis. The implementation leverages several key technologies:

Web Application Framework: the system uses Flask for handling HTTP requests and routing, with custom handlers for resources, products, and orders. The application structure includes specialized modules for data management and simulation control, enabling efficient data processing and state management.

Frontend Interface: a JavaScript-based frontend provides interactive user controls and real-time visualization capabilities. The interface is modularly designed with separate managers for orders, products, resources, and simulation control, facilitating maintainable code organization and efficient state management.

Data Exchange Protocol: communication between components is handled through HTTP-based APIs with JSON payloads. The system implements custom JSON encoders to handle complex data types and ensure consistent data serialization across the platform.

The integration between the web platform and simulation model is managed through a dedicated SimulationHandler component that coordinates model execution and results processing. This handler manages the simulation lifecycle, including configuration translation, execution control, and results processing. When simulation results are received, the platform transforms them into interactive visualizations that allow stakeholders to analyze and compare different scenarios, supporting informed decision-making in the shared manufacturing environment.

4.2.2 Simulation model

The simulation model forms the analytical core of our system, providing the computational capabilities necessary for scenario evaluation and performance prediction. Our methodological approach employs Discrete Event Simulation (DES) as the primary analytical technique due to its proven effectiveness in modeling complex manufacturing systems with stochastic elements and resource constraints. We selected this approach specifically to address the unique challenges of shared manufacturing, where multiple stakeholders access common resources under varying production schedules.

The simulation component employs an Automatic Simulation Model Generation (ASMG) methodology implemented in Tecnomatix Plant Simulation [12], 48]. Built on object-oriented programming principles, the model combines modular and data-driven approaches to enable flexible reproduction of various manufacturing systems through input configuration changes. This methodological choice facilitates systematic analysis of different configuration scenarios while maintaining consistency in the underlying model logic, an essential requirement for reproducible research in manufacturing simulation. This architecture facilitates resource allocation, bottleneck prediction, and production scheduling from operational to strategic levels without requiring model reconstruction.

The implementation follows these replicable methodological steps:

System specification through structured JSON documents containing resource, product, and order definitions

Automatic translation of specifications into simulation objects using predefined templates

Execution of simulation with configurable run parameters (simulation duration, random seed, etc.)

Structured data collection of key performance indicators at both resource and system levels

Statistical analysis of simulation outputs to evaluate scenario performance

This structured approach ensures that the simulation process is repeatable and results are comparable across different experimental configurations.

The data-driven approach utilizes specialized libraries that serve as manufacturing resource templates. When configuration data arrives through the web interface, these templates are instantiated with specific parameters to create digital representations of workstations, material handling systems, and processing units. This approach allows the simulation to adapt dynamically to different manufacturing configurations without manual model rebuilding.

At the completion of each simulation run, the simulation environment generates comprehensive production data outputs including resource utilization metrics, order completion statistics, throughput rates, and queue dynamics. These outputs provide detailed insights into system performance under different operating conditions. The simulation model automatically collects and organizes these metrics, preparing them for transmission back to the platform where they are processed into comparative visualizations.

The simulation results serve as a powerful tool for conducting comprehensive what-if analyses, enabling stakeholders to systematically explore and evaluate alternative manufacturing scenarios. By varying input parameters such as resource configurations, production schedules, and operational constraints, decision-makers can simulate potential outcomes, identify optimal strategies, and mitigate risks before actual implementation. This analytical approach transforms the simulation from a mere predictive tool to a strategic decision-support mechanism, providing quantitative insights that guide more informed and confident manufacturing planning.

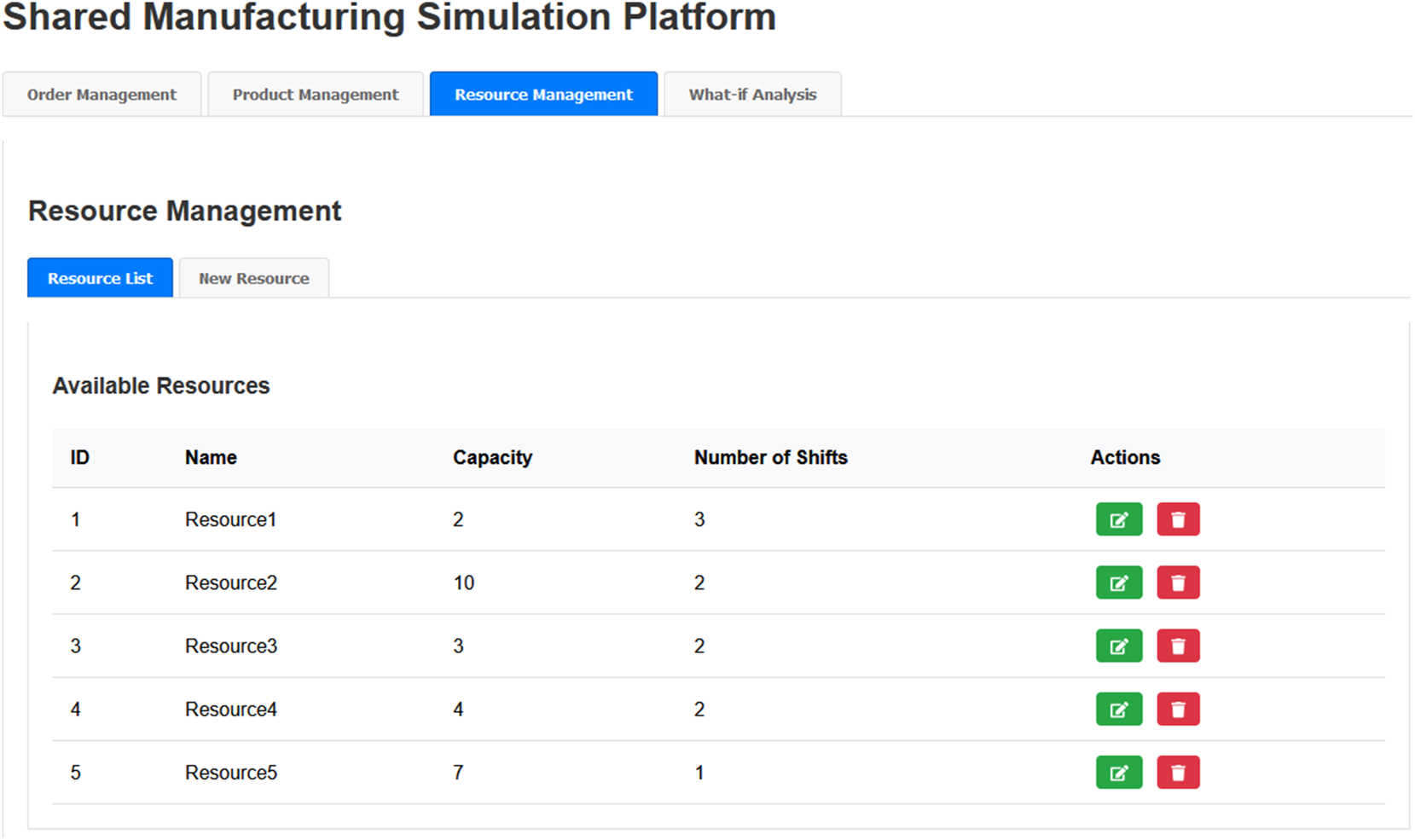

4.3 Platform description

The Shared Manufacturing Simulation Platform provides four integrated management tabs: Order Management, Product Management, Resource Management, and What-if Analysis. The first three tabs follow a consistent interface design with fundamental operations including addition, modification, visualization, and deletion of their respective elements, as illustrated by the Resource Management tab in Figure 3.

Resource Management: as shown in Figure 3, this tab provides a comprehensive view of available manufacturing resources. The interface displays key resource parameters including ID, Name, Capacity, and Number of Shifts. Users can add new resources, modify existing ones, and remove unavailable resources. The tab consists of two main sections: a resource overview that lists all current resources with modification (green button) and deletion (red button) actions, and a resource addition form where users can input basic information for new manufacturing equipment including identification details, capacity specifications, and operational parameters such as number of shifts.

Order Management: enables stakeholders to handle production orders in the shared environment. Users can add new orders with specific requirements, modify existing orders and delete orders when necessary.

Product Management: allows users to manage the product portfolio within the shared manufacturing system. Stakeholders can add new products with their processing requirements, modify existing product specifications, visualize product details, and remove products.

What-if Analysis: enables stakeholders to simulate different manufacturing scenarios before implementation. The detailed functionality and interface of this analysis tool will be demonstrated through the preliminary case study presented in the following section.

Resource management interface with key parameters and controls.

Figure 3 demonstrates how the platform maintains a clear overview of available manufacturing resources. The tabular layout provides quick access to essential resource information, while the action buttons enable efficient resource management.

These functionalities collectively enable stakeholders to effectively manage their shared manufacturing operations while maintaining strict control and visibility of all system components. The platform’s ability to track and modify resources, orders, and products supports both operational efficiency and system-wide coordination. Through these comprehensive management interfaces, the platform acquires all essential data required to execute simulation models for production planning, allowing stakeholders to make informed decisions about resource allocation and scheduling in the shared manufacturing environment.

5 Preliminary case study

This section presents an illustrative case study that demonstrates the application of our simulation platform in a shared manufacturing context. Our aim is to explore how this platform can support decision-making in complex multi-stakeholder environments and take a step forward in understanding this emerging production paradigm. The food manufacturing sector provides a compelling context for this investigation due to its unique operational challenges including seasonality, perishability, and regulatory requirements.

While the scenario and analyses are conceptual rather than reporting on a specific implementation, they are informed by realistic operational parameters derived from industry observations. This approach allows us to examine decision-making processes that would be difficult to study in traditional manufacturing systems, particularly for industries like food production where shared manufacturing applications remain limited despite their potential benefits.

5.1 Base scenario: multi-stakeholder food production

The facility operates as a collaborative production hub serving nine independent food producers. The arrangement exemplifies shared manufacturing’s core principle: enabling multiple stakeholders to utilize common production facilities while maintaining individual product specifications, quality standards, and brand identities.

The facility manages three distinct product categories: fresh products (fresh pasta, gelato, and pesto) requiring immediate processing; seasonal products (Panettone, Colomba, and Pandoro) with concentrated demand periods; and non-seasonal products (dry pasta and biscotti) providing stable year-round production.

The production infrastructure consists of 26 manufacturing resources including industrial mixers, specialized forming equipment, baking units, cooling systems, and packaging lines. The facility operates on a two-shift system (16 h/day) with capability to extend to three shifts during peak periods. Equipment capacities vary significantly, with some resources supporting parallel processing while others require complete changeover between product types, creating complex scheduling dependencies that must be carefully managed.

5.2 What-if analysis: new stakeholder integration

A recent opportunity arose when a small producer requested to process excess raw tomato material into tomato sauce, presenting an interesting case for analysis. The introduction of this new product required a two-level analysis to understand its impact on the existing production system.

In shared manufacturing environments, introducing a new stakeholder represents a complex challenge that transcends simple production scheduling. The integration process demands careful evaluation of resource compatibility, scheduling feasibility, and capacity impacts. Food manufacturing presents unique complexities due to specialized processing conditions and seasonal production patterns, requiring a comprehensive approach to assess potential system-wide impacts before actual implementation.

5.2.1 What-if analysis results

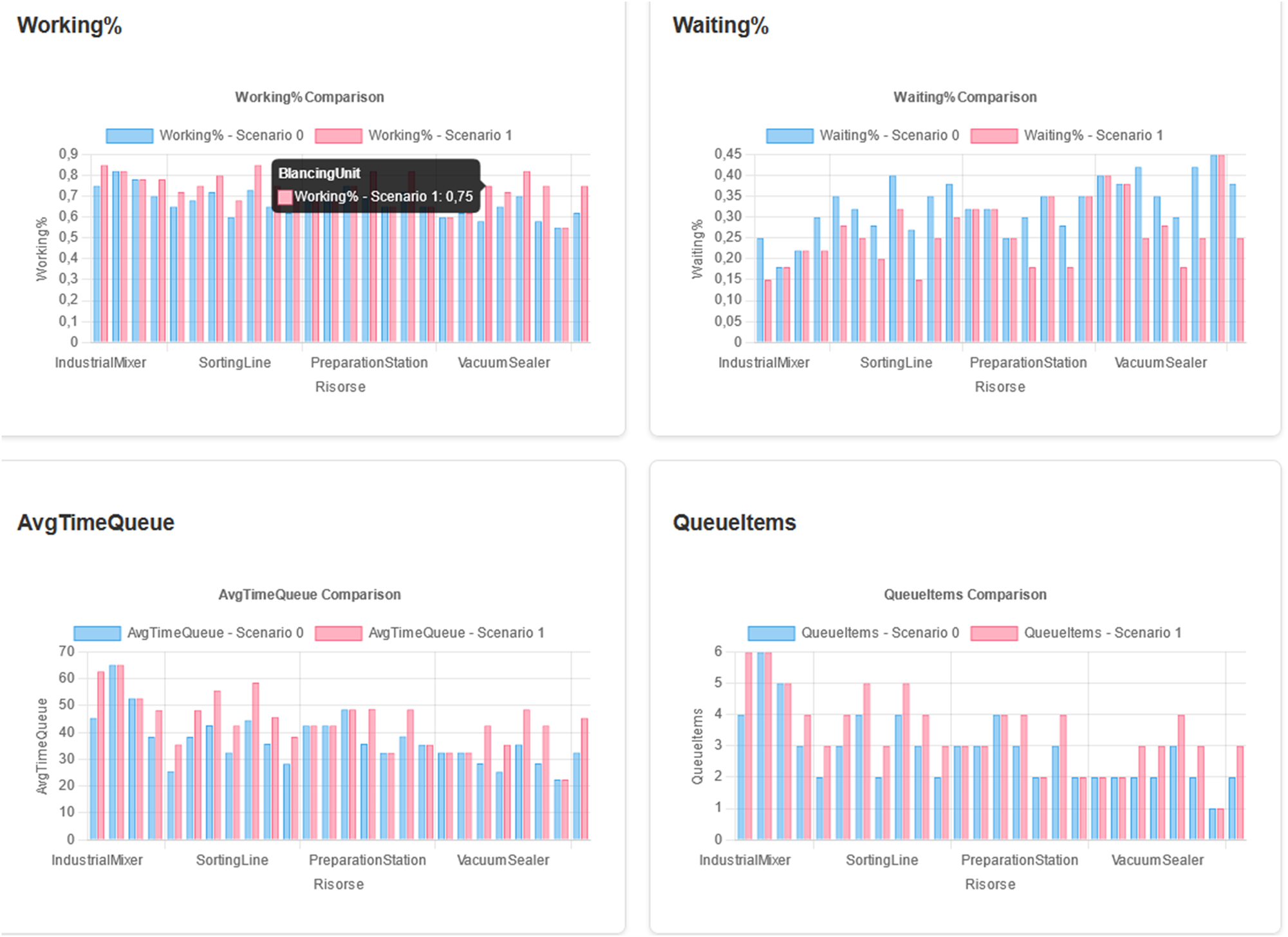

The simulation platform conducted a comprehensive what-if analysis comparing the baseline scenario (Scenario 0) with the tomato sauce integration scenario (Scenario 1), revealing critical insights into potential system modifications:

The first level of analysis, shown in Figure 4, provides a comprehensive view of how resource utilization changes when introducing new products into a shared manufacturing system. This visualization approach compares two scenarios across four fundamental performance metrics: Working Percentage (productive time), Waiting Percentage (idle time), Average Time in Queue (processing delays), and Queue Items (buffer requirements). This type of comparative analysis enables stakeholders to quickly identify potential bottlenecks and resource conflicts that might arise from modifications to the production schedule.

Resource utilization analysis comparing baseline operations (Scenario 0) with tomato sauce integration (Scenario 1).

In this specific case study, the analysis revealed significant changes in resource utilization patterns when integrating tomato sauce production. The industrial mixer showed a notable increase from 75 % to 82 % utilization in Scenario 1, while the preparation station experienced an uptick from 70 % to 78 % working time, demonstrating increased system load. Waiting times at key workstations increased moderately, with the sorting line showing an increase from 25 % to 35 %, though remaining within acceptable operational parameters. Queue metrics also indicated higher system pressure, with the industrial mixer’s average queue time increasing from 45 to 65 min and the number of items in queue rising from 4 to 6 on average.

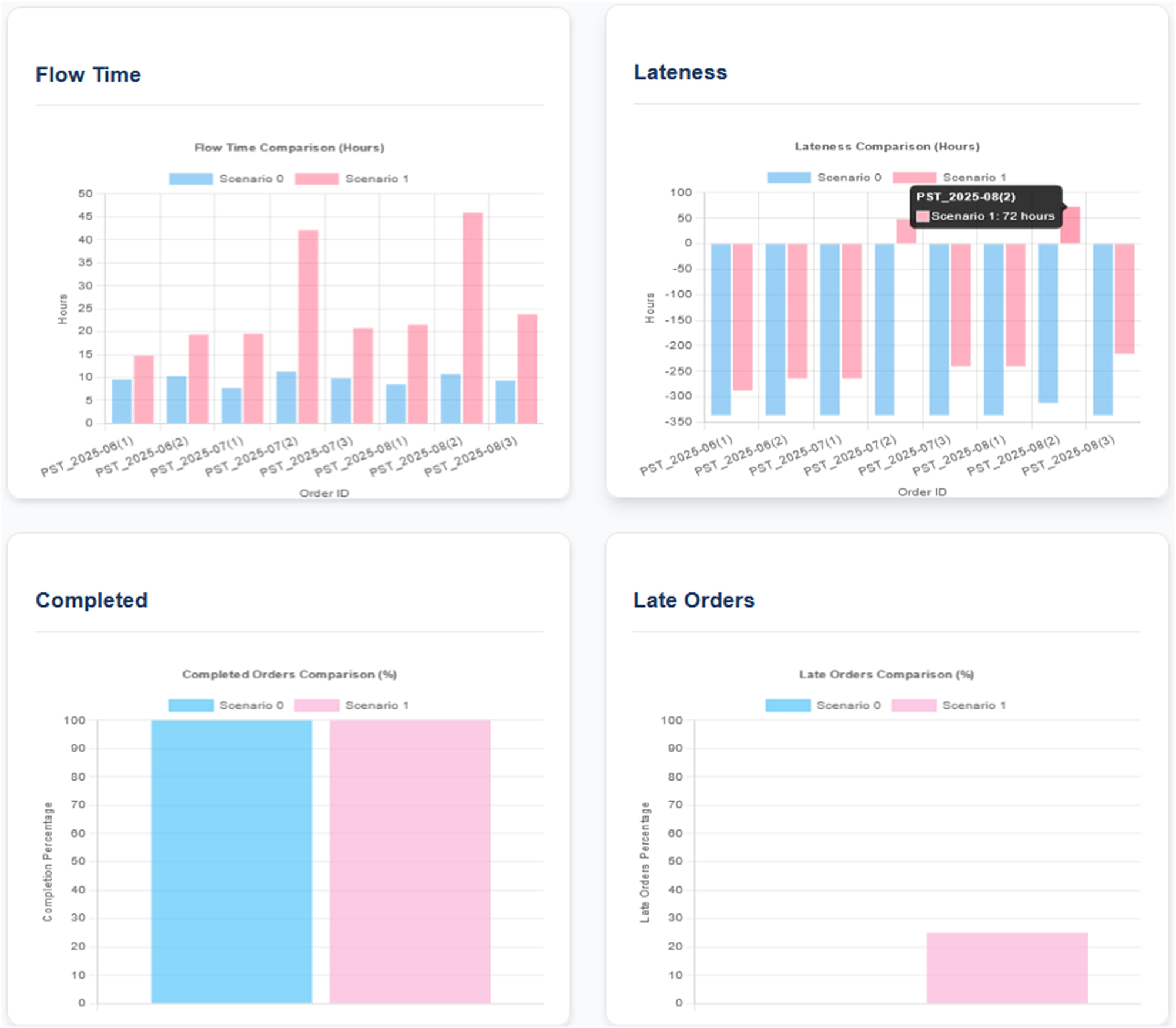

The second level of analysis, presented in Figure 5, shifts focus from resources to order fulfillment metrics. This approach is essential for evaluating how changes in resource allocation impact service levels for existing products. The visualization tracks four critical indicators: Flow Time (total processing duration), Lateness (delivery timing deviations), Completion Rate (order fulfillment success), and Late Orders (service level failures). By examining these metrics across different time periods, stakeholders can identify seasonal conflicts and evaluate the temporal distribution of production disruptions.

Detailed order analysis for pesto production across different time periods.

In the tomato sauce integration scenario, this order-level analysis revealed significant impacts on pesto production, particularly during peak seasons when both products required similar resources. Order PST_2025-07(2) showed a dramatic increase in flow time from 12 h in the baseline scenario to 42 h in Scenario 1. Lateness patterns also emerged, with order PST_2025-08(2) experiencing a 72-h delay compared to on-time delivery in the baseline. While the overall completion rate remained stable at nearly 100 % in both scenarios, the temporal distribution revealed that approximately 25 % of pesto orders became late during the July–August period in Scenario 1, indicating a seasonal conflict between the two product types.

The analysis revealed that while the system could accommodate the new tomato sauce production, its overlap with peak pesto season created resource contention for industrial mixers and packaging lines. This conflict exemplifies a common challenge in shared food manufacturing: seasonal peaks that create temporary resource shortages. In this case, both tomato sauce and pesto production exhibited seasonal patterns driven by ingredient availability, fresh tomatoes and basil reach peak quality and availability during similar summer months. When these natural production cycles align across multiple products requiring similar resources, the shared manufacturing system can experience capacity constraints even when annual average utilization remains well below maximum capacity.

Using the interactive analysis tools, the small producer identified this seasonal overlap and developed a strategic solution that considered the full production ecosystem rather than just individual product requirements. The solution involved shifting tomato sauce production to late summer (August–September) when most basil harvesting for pesto had concluded, while still maintaining access to quality tomatoes. Additionally, production volumes were adjusted to optimize resource utilization during this transition period, with larger batch sizes that reduced the total number of setups required.

This rescheduling approach successfully resolved the balancing issues while maintaining existing production efficiency for all stakeholders. By visualizing the simulated impact before implementation, the platform enabled collaborative decision-making that considered both the new stakeholder’s needs and the system’s existing commitments. This case demonstrates the platform’s effectiveness in facilitating dynamic production planning for seasonal food products in shared manufacturing environments, where proactive identification of seasonal conflicts is essential for maintaining operational harmony.

6 Results and discussion

This section presents the key findings and implications of our research on simulation-based decision support for shared manufacturing in the food industry. We first discuss the core capabilities and implementation of our simulation platform, followed by an analysis of the broader opportunities and challenges in shared manufacturing adoption. Finally, we outline critical directions for future research that could advance this field. The discussion integrates insights from both our technical implementation and the theoretical framework that supports it, providing a comprehensive view of the current state and future potential of shared manufacturing in the food sector.

6.1 Simulation platform for shared manufacturing

The research introduces an innovative web-based simulation platform designed to support decision-making in shared food manufacturing environments. The platform’s distinguishing feature is its adaptive simulation model that can be configured through an intuitive web interface, allowing stakeholders to simulate and evaluate production scenarios before implementation [40]. This approach eliminates the need for costly physical trials while providing valuable insights into potential outcomes.

The system offers comprehensive management capabilities through an integrated web interface where users can manage orders, products, and resources, as well as conduct what-if analyses [9]. Through this interface, stakeholders can evaluate various scenarios, from introducing new products to adjusting production schedules, all without disrupting ongoing operations. The simulation model automatically adapts to these changes, providing real-time feedback on system performance.

The platform’s capabilities were explored through an illustrative case study based on an Italian specialty foods scenario. While not representing a real-world implementation, this theoretical case study demonstrates how a simulation platform could support decision-making in a complex shared manufacturing environment [24]. The scenario involves multiple stakeholders sharing production facilities for various food products with different requirements and seasonal demands, showing how the platform can help optimize resource allocation while maintaining individual product specifications and quality standards.

6.2 Shared manufacturing: opportunities and challenges

Shared manufacturing represents a paradigm shift in food production systems [1], fundamentally transforming how food manufacturers operate and scale their businesses. This approach enables multiple stakeholders to utilize common production facilities while maintaining individual product specifications and quality standards.

The model presents three key opportunities for the food industry:

Resource Optimization and Cost Efficiency: small producers can access specialized equipment and temperature-controlled environments without substantial capital investments [2], reducing entry barriers and operational costs.

Production Flexibility and Scalability: manufacturers can effectively manage seasonal demand variations through coordinated facility usage [41], allowing for dynamic production scaling based on market demands.

Knowledge and Technology Sharing: producers benefit from shared expertise and access to advanced manufacturing technologies that would be cost-prohibitive for individual implementation [3].

However, implementing shared manufacturing in the food industry also presents significant challenges:

Quality and Safety Management: maintaining strict food safety standards and ensuring product traceability become more complex in shared environments [34].

Operational Coordination: managing multiple stakeholders with diverse production requirements demands sophisticated scheduling systems and efficient resource allocation mechanisms [42].

Regulatory Compliance: meeting various certification requirements and food safety standards across multiple producers demands comprehensive management systems.

Data Uncertainty Management: although the simulation model can perform analysis using different variability ranges to manage system stochasticity, it still relies on high-quality input data. Uncertainties in production times, resource availability, and demand patterns can potentially compromise the reliability of results.

6.3 Future research directions

Future research and development in shared food manufacturing simulation requires focused attention on several critical areas to enhance practical applicability. The research highlights three key directions for future development:

Advanced Food-Specific Modeling: development of more sophisticated simulation models that incorporate detailed food manufacturing requirements, including cleaning protocols and temperature-sensitive constraints [23].

System Integration and Standardization: creation of standardized interfaces for integration with existing manufacturing execution systems and quality management systems [17].

Intelligent Resource Management: implementation of advanced algorithms for dynamic resource allocation and scheduling optimization, specifically designed to handle the unique constraints of food manufacturing [33].

Robust Uncertainty Quantification: development of advanced simulation frameworks that can effectively quantify and incorporate data uncertainties through techniques would enable more reliable decision-making in stochastic food manufacturing environments and reduce dependency on perfect input data while maintaining model accuracy.

These research directions aim to bridge the gap between theoretical potential and practical implementation, focusing on creating more robust and industry-ready solutions. The continued development of these aspects will be crucial in establishing shared manufacturing as a viable and efficient model for food production systems.

7 Conclusions

This research advances decision support in shared food manufacturing through an adaptive simulation platform, demonstrating how web-based tools can facilitate complex decision-making in multi-stakeholder production environments. Through a conceptual case study in specialty food production, we explored the platform’s potential in managing diverse production requirements while highlighting the challenges of coordinating shared operations in the food industry. The implementation serves as a stepping stone for future developments, contributing to the growing field of shared manufacturing by providing insights into both technological solutions and operational challenges. As food manufacturers face increasing pressure to become more flexible and resource efficient, such simulation-based approaches will be valuable in helping stakeholders evaluate and optimize their production strategies while maintaining quality standards and meeting regulatory requirements.

Funding source: Next Generation Foundation

Award Identifier / Grant number: CUP: H23C22000360005

-

Research ethics: Not applicable.

-

Informed consent: Not applicable.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Use of Large Language Models, AI and Machine Learning Tools: None declared.

-

Conflict of interest: All other authors state no conflict of interest.

-

Research funding: This work was supported by the “National Centre for HPC, Big Data and Quantum Computing (HPC)” (Project ID: CN \00000013, CUP: H23C22000360005) – funded under the National Recovery and Resilience Plan, Mission 4, Component 2, Investment 1.4 “Strengthening research structures and creation of national R&D champions on some Key Enabling Technologies” financed by the European Union – NextGenerationEU.

-

Data availability: Not applicable.

References

1. Yu, C, Xu, X, Yu, S, Sang, Z, Yang, C, Jiang, X. Shared manufacturing in the sharing economy: concept, definition and service operations. Comput Ind Eng 2020;146:106602. https://doi.org/10.1016/j.cie.2020.106602.Suche in Google Scholar

2. Jiang, P, Li, P. Shared factory: a new production node for social manufacturing in the context of sharing economy. Proc Inst Mech Eng Part B J Eng Manufact 2020;234:285–94. https://doi.org/10.1177/0954405419863220.Suche in Google Scholar

3. Tao, F, Cheng, Y, Xu, LD, Zhang, L, Li, BH. Cciot-cmfg: cloud computing and internet of things-based cloud manufacturing service system. IEEE Trans Ind Inf 2014;10:1435–42. https://doi.org/10.1109/tii.2014.2306383.Suche in Google Scholar

4. Liu, Y, Zhang, L, Tao, F, Wang, L. Resource service sharing in cloud manufacturing based on the gale – shapley algorithm: advantages and challenge. Int J Comput Integrated Manuf 2017;30:420–32.Suche in Google Scholar

5. Zhou, Q, Zhang, H, Wang, S. Artificial intelligence, big data, and blockchain in food safety. Int J Food Eng 2022;18:1–14. https://doi.org/10.1515/ijfe-2021-0299.Suche in Google Scholar

6. Lei, W, Yang, L, Yan, P, Chu, C, Yang, J. Production coordination of local and cloud orders in shared manufacturing: a bi-objective pre-scheduling approach. Ann Oper Res 2024:1–39. https://doi.org/10.1007/s10479-024-06380-z.Suche in Google Scholar

7. He, J, Zhang, J, Gu, X. Research on sharing manufacturing in Chinese manufacturing industry. Int J Adv Manuf Technol 2019;104:463–76. https://doi.org/10.1007/s00170-019-03886-w.Suche in Google Scholar

8. Duran, E, Ozturk, C, O’Sullivan, B. Planning and scheduling shared manufacturing systems: key characteristics, current developments and future trends. Int J Prod Res 2024:1–33. https://doi.org/10.1080/00207543.2024.2442549.Suche in Google Scholar

9. Wang, G, Zhang, G, Guo, X, Zhang, Y. Digital twin-driven service model and optimal allocation of manufacturing resources in shared manufacturing. J Manuf Syst 2021;59:165–79. https://doi.org/10.1016/j.jmsy.2021.02.008.Suche in Google Scholar

10. Qu, Y, Wang, Y, Ming, X, Chu, X. Multi-stakeholder’s sustainable requirement analysis for smart manufacturing systems based on the stakeholder value network approach. Comput Ind Eng 2023;177:109043. https://doi.org/10.1016/j.cie.2023.109043.Suche in Google Scholar

11. Mourtzis, D. Simulation in the design and operation of manufacturing systems: state of the art and new trends. Int J Prod Res 2020;58:1927–49. https://doi.org/10.1080/00207543.2019.1636321.Suche in Google Scholar

12. Cimino, A, Elbasheer, M, Longo, F, Mirabelli, G, Solina, V, Veltri, P. Automatic simulation models generation in industrial systems: a systematic literature review and outlook towards simulation technology in the industry 5.0. J Manuf Syst 2025;80:859–82. https://doi.org/10.1016/j.jmsy.2025.03.027.Suche in Google Scholar

13. Hamari, J, Sjöklint, M, Ukkonen, A. The sharing economy: why people participate in collaborative consumption. J Assoc Inf Sci Technol 2016;67:2047–59. https://doi.org/10.1002/asi.23552.Suche in Google Scholar

14. Narasimhan, C, Papatla, P, Jiang, B, Kopalle, PK, Messinger, PR, Moorthy, S, et al.. Sharing economy: review of current research and future directions. Cust Needs Solut 2018;5:93–106. https://doi.org/10.1007/s40547-017-0079-6.Suche in Google Scholar

15. Hermann, M, Pentek, T, Otto, B. Design principles for industrie 4.0 scenarios. In: 2016 49th Hawaii international conference on system sciences (HICSS). IEEE; 2016:3928–37 pp.10.1109/HICSS.2016.488Suche in Google Scholar

16. Kagermann, H, Helbig, J, Hellinger, A, Wahlster, W. Recommendations for implementing the strategic initiative INDUSTRIE 4.0: securing the future of German manufacturing industry; final report of the Industrie 4.0 Working Group Forschungsunion; 2013.10.3390/sci4030026Suche in Google Scholar

17. Lee, J, Bagheri, B, Kao, HA. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf Lett 2015;3:18–23. https://doi.org/10.1016/j.mfglet.2014.12.001.Suche in Google Scholar

18. Jiang, P. Social manufacturing: fundamentals and applications. Cham, Switzerland: Springer; 2019.10.1007/978-3-319-72986-2Suche in Google Scholar

19. Tao, F, Cheng, Y, Zhang, L, Nee, AYC. Advanced manufacturing systems: socialization characteristics and trends. J Intell Manuf 2017;28:1079–94. https://doi.org/10.1007/s10845-015-1042-8.Suche in Google Scholar

20. Jiang, B, Tian, L. Collaborative consumption: strategic and economic implications of product sharing. Manag Sci 2018;64:1171–88. https://doi.org/10.1287/mnsc.2016.2647.Suche in Google Scholar

21. Tian, L, Jiang, B. Effects of consumer-to-consumer product sharing on distribution channel. Prod Oper Manag 2018;27:350–67. https://doi.org/10.1111/poms.12794.Suche in Google Scholar

22. Böckmann, M. The shared economy: it is time to start caring about sharing; value creating factors in the shared economy. Enschede, Netherlands: University of Twente, Faculty of Management and Governance; 2013, vol 350.Suche in Google Scholar

23. Piva, E, Tebaldi, L, Vignali, G, Bottani, E. Simulation of different reordering policies for optimizing the inventory of perishable food: an Italian case study. Int J Food Eng 2022;18:201–38. https://doi.org/10.1515/ijfe-2021-0047.Suche in Google Scholar

24. Silvestri, B, Facchini, F, Digiesi, S, Ranieri, L. A sustainable management model to reduce food loss and waste in agro-processing industries. Int J Food Eng 2024. https://doi.org/10.1515/ijfe-2023-0050.Suche in Google Scholar

25. Kassner, L, Hirmer, P, Wieland, M, Steimle, F, Königsberger, J, Mitschang, B. The social factory: connecting people, machines and data in manufacturing for context-aware exception escalation. Waikoloa, Hawaii: HICSS; 2017.10.24251/HICSS.2017.202Suche in Google Scholar

26. Liu, J, Jiang, P, Leng, J. A framework of credit assurance mechanism for manufacturing services under social manufacturing context. In: 2017 13th IEEE conference on automation science and engineering (CASE). IEEE; 2017:36–40 pp.10.1109/COASE.2017.8256072Suche in Google Scholar

27. Zhang, F, Wu, L, Liu, W, Ding, K, Hui, J, Leng, J, et al.. Evolutionary game-based incentive models for sustainable trust enhancement in a blockchained shared manufacturing network. Adv Eng Inform 2022;54:101791. https://doi.org/10.1016/j.aei.2022.101791.Suche in Google Scholar

28. Wu, Y, Liu, P. Pricing strategies for shared manufacturing platform considering cooperative advertising based on differential game. PLoS One 2024;19:e0303928. https://doi.org/10.1371/journal.pone.0303928.Suche in Google Scholar PubMed PubMed Central

29. Bao, S, Cai, R. Intelligent production sharing and user experience: a case study of Shenyang machine tool. Ind Eng Manag 2017;22:77–82.Suche in Google Scholar

30. Lu, Y, Xu, X. Resource virtualization: a core technology for developing cyber-physical production systems. J Manuf Syst 2018;47:128–40. https://doi.org/10.1016/j.jmsy.2018.05.003.Suche in Google Scholar

31. Goh, M, Prakash, S, Yeo, R. Resource-based approach to it shared services in a manufacturing firm. Ind Manag Data Syst 2007;107:251–70. https://doi.org/10.1108/02635570710723831.Suche in Google Scholar

32. He, J, Gu, X. Value analysis of shared warehousing system based on web. Comput Integr Manuf Syst 2018;24:2322–8.Suche in Google Scholar

33. Peng, X, Wang, S, Zhang, L. Production routing problem in shared manufacturing: robust chance-constrained formulation and multi-diversification based matheuristic. Comput Ind Eng 2024;195:110422. https://doi.org/10.1016/j.cie.2024.110422.Suche in Google Scholar

34. Longo, F, Nicoletti, L, Padovano, A. Estimating the impact of blockchain adoption in the food processing industry and supply chain. Int J Food Eng 2020;16:20190109. https://doi.org/10.1515/ijfe-2019-0109.Suche in Google Scholar

35. Yu, C, Jiang, X, Yu, S, Yang, C. Blockchain-based shared manufacturing in support of cyber physical systems: concept, framework, and operation. Robot Comput Integrated Manuf 2020;64:101931. https://doi.org/10.1016/j.rcim.2019.101931.Suche in Google Scholar

36. Baines, TS, Lightfoot, HW, Kay, JM. Servitized manufacture: practical challenges of delivering integrated products and services. Proc Inst Mech Eng Part B J Eng Manufact 2009;223:1207–15. https://doi.org/10.1243/09544054jem1552.Suche in Google Scholar

37. Nudurupati, SS, Lascelles, D, Wright, G, Yip, N. Eight challenges of servitisation for the configuration, measurement and management of organisations. J Serv Theory Pract 2016;26:745–63. https://doi.org/10.1108/jstp-02-2015-0045.Suche in Google Scholar

38. Yoon, B, Kim, S, Rhee, J. An evaluation method for designing a new product-service system. Expert Syst Appl 2012;39:3100–8. https://doi.org/10.1016/j.eswa.2011.08.173.Suche in Google Scholar

39. Yuan, H, Hu, Q, Bi, J, Gong, G, Zhang, J, Zhou, MC. Machine-level collaborative manufacturing and scheduling for heterogeneous plants. IEEE Internet Things J 2024;11:16591–603. https://doi.org/10.1109/jiot.2024.3354251.Suche in Google Scholar

40. Liu, Y, Ping, Y, Zhang, L, Wang, L, Xu, X. Scheduling of decentralized robot services in cloud manufacturing with deep reinforcement learning. Robot Comput Integrated Manuf 2023;80:102454. https://doi.org/10.1016/j.rcim.2022.102454.Suche in Google Scholar

41. Niaki, MK, Nonino, F, Komijan, AR, Dehghani, M. Food production in batch manufacturing systems with multiple shared-common resources: a scheduling model and its application in the yoghurt industry. Int J Serv Oper Manag 2017;27:345–65. https://doi.org/10.1504/ijsom.2017.084442.Suche in Google Scholar

42. Wei, G, Ye, C, Xu, J. Shared manufacturing-based distributed flexible job shop scheduling with supply-demand matching. Comput Ind Eng 2024;189:109950. https://doi.org/10.1016/j.cie.2024.109950.Suche in Google Scholar

43. Song, H, Lu, X, Zhang, X, Tang, X, Zhang, Q. Collaborative optimization for energy saving and service composition in multi-granularity heavy-duty equipment cloud manufacturing environment. J Ind Manag Optim 2023;19:2742–71. https://doi.org/10.3934/jimo.2022063.Suche in Google Scholar

44. Leng, JW, Jiang, PY, Zhang, FQ, Cao, W. Framework and key enabling technologies for social manufacturing. Appl Mech Mater 2013;312:498–501. https://doi.org/10.4028/www.scientific.net/amm.312.498.Suche in Google Scholar

45. Yu, C, Xu, X, Lu, Y. Computer-integrated manufacturing, cyber-physical systems and cloud manufacturing–concepts and relationships. Manuf Lett 2015;6:5–9. https://doi.org/10.1016/j.mfglet.2015.11.005.Suche in Google Scholar

46. Alarcon-Gerbier, E, Chokparova, Z, Ghondaghsaz, N, Zhao, W, Shahmoradi-Moghadam, H, Aßmann, U, et al.. Software-defined mobile supply chains: rebalancing resilience and efficiency in production systems. Sustainability 2022;14:2837. https://doi.org/10.3390/su14052837.Suche in Google Scholar

47. Li, J, White, CC. Capacity planning in a decentralized autologous cell therapy manufacturing network for low-cost resilience. Flex Serv Manuf J 2023;35:295–319. https://doi.org/10.1007/s10696-022-09475-6.Suche in Google Scholar PubMed PubMed Central

48. Cimino, A, Longo, F, Nicoletti, L, Veltri, P. Automated simulation modeling: ensuring resilience and flexibility in industry 4.0 manufacturing systems. Procedia Comput Sci 2024;232:1011–24. https://doi.org/10.1016/j.procs.2024.01.100.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.