Abstract

The tensile properties of the alloy 2618 and 2618-Ti were tested using a tensile testing machine. The morphologies of the fracture of tensile samples were observed using scanning electron microscopy. The strengthening and toughening mechanisms of alloy 2618-Ti at elevated temperature were systematically investigated based on the analyses of experimental results. The results showed that the tensile strength of alloy 2618-Ti is much higher than that of alloy 2618 at the temperature range of 250 and 300 °C. But the elongation of alloy 2618-Ti is much higher than that of alloy 2618 at the temperature range of 200 and 300 °C. The equal-strength temperature of intragranular and grain boundary of alloy 2618-Ti is about 235 °C. When the temperature is lower than 235 °C, the strengthening of alloy 2618-Ti is ascribed to the strengthening effect of fine grains and dispersed Al3Ti/Al18Mg3Ti2 phase. When the temperature is higher than 235 °C, the strengthening effect of alloy 2618-Ti is mainly attributed to the load transfer of Al3Ti and Al18Mg3Ti2 particles. The toughening of alloy 2618-Ti at elevated temperature is mainly ascribed to the fine grain microstructure, excellent combination between matrix and dispersed Al3Ti/Al18Mg3Ti2 particles as well as the recrystallization of the alloy at elevated temperature.

Introduction

Aluminum alloy 2618 (AA2618) is a kind of heat resistant alloy, for which equal amounts of Fe and Ni are added in Al-Cu-Mg alloy. The alloy is widely used as aerospace materials due to its higher strength at room and elevated temperature. Many researches have been carried out to improve its mechanical properties at elevated temperature [1, 2, 3]. Generally, the improvement of the strength of alloy 2618 at elevated temperature [4, 5, 6] results in the decrease of its strength and toughness at room temperature [7].

Up till now, alloy 2618 prepared by conventional ingot metallurgy method (IM) is only used below 150 °C under long-term services condition. The strength of the alloy at elevated temperature would obviously decrease because the precipitated S’ phase formed during ageing treatment becomes coarser at higher temperature. For this reason, the alloy cannot be used at higher temperature in industry.

Among the Al-rich intermetallics such as Al3Ni, Al3Fe, Al3Zr and Al3Ti, Al3Ti has attracted wide attention because of its lower density, higher melting point (1,350 °C) and high Young modulus (217 GPa) [8, 9]. Aluminum matrix composite reinforced with Al3Ti particles possesses higher tensile strength and better thermal stability at elevated temperature [10, 11]. Li et al. [12] investigated the solidification microstructure of alloy Al-Cu-Mg reinforced with a large amount of dispersed Al3Ti particles which were introduced by solid-liquid mixing and near-liquids casting method. It was found that the size of Al3Ti particles in Al-Cu-Mg alloy was in the range of 2–10 um, which was almost the same as that in Al-7wt.%Ti powders [13]. Liu et al. [14] found that the grain size of the alloy 2618-Ti was much smaller than that of alloy 2618. Because of the fine grain microstructure in alloy 2618-Ti, the optimized homogenizing time for the alloy was much shorter than that for alloy 2618. Li et al. [15] studied the flow behavior of alloy 2618-Ti during the process of hot compression. The results showed that flow stress of the alloy decreased with the increase of deformation temperature, and increased with the increase of strain rate. Wu et al. [16] investigated the evaluation of microstructure and hardness of the alloy 2618-Ti during its preparation. It was found that the hardness of the alloy 2618-Ti at T6 state was much lower than that of alloy 2618 at the same state. But tensile strength of alloy 2618-Ti at room temperature was higher than that of alloy 2618. The strengthening effect of alloy 2618-Ti at room temperature is mainly attributed to the synergistic effect of the fine grain microstructure, precipitating S’ phase, and the dispersed Al3Ti and Al18Mg3Ti2 phases. Up till now, there is no report on the strengthening and toughening mechanisms of alloy 2618-Ti at elevated temperature. In this work, based on the analyses of mechanical properties of alloy 2618-Ti at elevated temperature and their tensile fracture morphologies, the strengthening and toughening mechanisms of alloy 2618-Ti at elevated temperature were investigated. This work could provide valuable reference for the use of alloy 2618-Ti in industry.

Experimental procedures

The alloy 2618 (as a reference alloy) was prepared by ingot metallurgy method using industrial pure Al (99.7 mass%), Al-50 mass% Cu, Al-25 mass% Mg and Al-10 mass% Ni master alloys[17]. The alloy 2618-Ti (1.5 % Ti in mass fraction) was prepared by solid-liquid mixing and near-liquids casting method [12]. The nominal compositions of the studied alloys are listed in Table 1. After homogenization, hot rolling, cold rolling, solid solution and ageing treatment, the tensile specimens were prepared using wire cutting machine. The sizes of the specimens are shown in Figure 1. The tensile tests were carried out in a computer controlled electronic universal testing machine (model WDT-030). Before stretching tests, the specimens were kept at 25 °C, 150 °C, 200 °C, 250 °C and 300 °C for 10 min, respectively. In order to make the fixed temperature of the specimens more accurate, the thermocouple was placed near the tested specimens. And the temperature was controlled through the thermostat. During the tests, the stretching rate of the specimens was kept at 2 mm/min. The fracture morphologies of the specimens were observed using JSM-6510 scanning electron microscopy (SEM).

Schematic of tensile specimens.

Nominal composition of the studied alloys (mass%).

| Alloy | Cu | Mg | Fe | Ni | Ti | Al |

|---|---|---|---|---|---|---|

| 2618 | 2.3 | 1.6 | 1.1 | 1.1 | – | Bal. |

| 2618-Ti | 2.3 | 1.6 | 1.1 | 1.1 | 1.5 | Bal. |

In order to obtain the alloy 2618-Ti with different grain size, the cold rolled specimens were kept at 530 °C for different time as shown in Table 2. Then all the specimens were aged at 190 °C for 16 h. The linear fitting of the tensile strength of alloy 2618-Ti at elevated temperatures was carried out using Origin software. The approximate equal-strength temperature of alloy 2618-Ti was obtained by averaging the intersection temperatures of the fitting lines of tensile strength of the alloy 2618-Ti with different grain size as a function of temperature.

Parameters of solid solution treatment for alloy 2618-Ti.

| Alloy | Temperature/°C | Time/min |

|---|---|---|

| A | 530 | 30 |

| B | 530 | 480 |

| C | 530 | 960 |

Results and discussion

Mechanical properties of alloy 2618 and 2618-Ti at different temperatures

The mechanical properties of alloy 2618 and 2618-Ti at room temperature and elevated temperatures are listed in Table 3. The curves of the tensile strength of these two alloys as a function of temperature are drawn in Figure 2. It can be seen that the tensile strength of alloy 2618 and that of 2618-Ti decrease remarkably with the increase of temperature. The downward trend of the tensile strength of the alloy at elevated temperatures is similar to that of Al18B4O33 whiskers reinforced aluminum composite [18]. The tensile strength of alloy 2618-Ti is just 1.9 MPa higher than that of alloy 2618 at room temperature. The strengthening effect of alloy 2618 at room temperature includes ageing enhancement of S’(Al2CuMg) phase and enhancement of Al9FeNi phase. Compared with alloy 2618, the strengthening effect of alloy 2618-Ti should include fine grain strengthening, ageing enhancement of S’ phase, enhancement of Al9FeNi phase and the enhancement of dispersive Al3Ti and Al18Mg3Ti2 phase. Because of the formation of Al18Mg3Ti2 phase during homogenization, the dissolved amount of magnesium in the matrix of the alloy 2618-Ti would be decreased, resulting in the decrease of the amount of S’ phase. So the ageing enhancement effect of S’ phase decreases in alloy 2618-Ti. However, the fine grain strengthening and dispersive strengthening of Al3Ti and Al18Mg3Ti2 phase would make up for the decrease of ageing enhancement effect of S’ phase [16].

The tensile strength of alloy 2618 and 2618-Ti as a function of temperature.

Mechanical properties of alloy 2618 and 2618-Ti at different temperatures.

| Alloy | 25 °C σb δ | 150 °C σb δ | 200 °C σb δ | 250 °C σb δ | 300 °C σb δ |

|---|---|---|---|---|---|

| 2618 | 411.9 8.8 | 328.4 14.6 | 271.8 21.0 | 214.7 24.6 | 161.0 29.8 |

| 2618-Ti | 413.8 9.0 | 349.2 15.3 | 290.6 25.4 | 245.9 28.6 | 189.6 33.7 |

Compared with the tensile strength of alloy 2618 at the same temperature, it can be known that the tensile strength for 2618-Ti at 150 and 200 °C is only 6.3 % and 6.6 % higher than that of alloy 2618, respectively. However, the tensile strength of 2618-Ti is 14.5 % and 17.8 % higher than that of alloy 2618 at 250 and 300 °C, respectively. Take into account these facts, we suppose there should exist a critical temperature within the range from 200 °C to 250 °C for alloy 2618-Ti. The strengthening mechanism of alloy 2618-Ti below the critical temperature would be different from that of the alloy above this temperature. The strengthening mechanism of alloy 2618-Ti would be elaborated in 3.3.

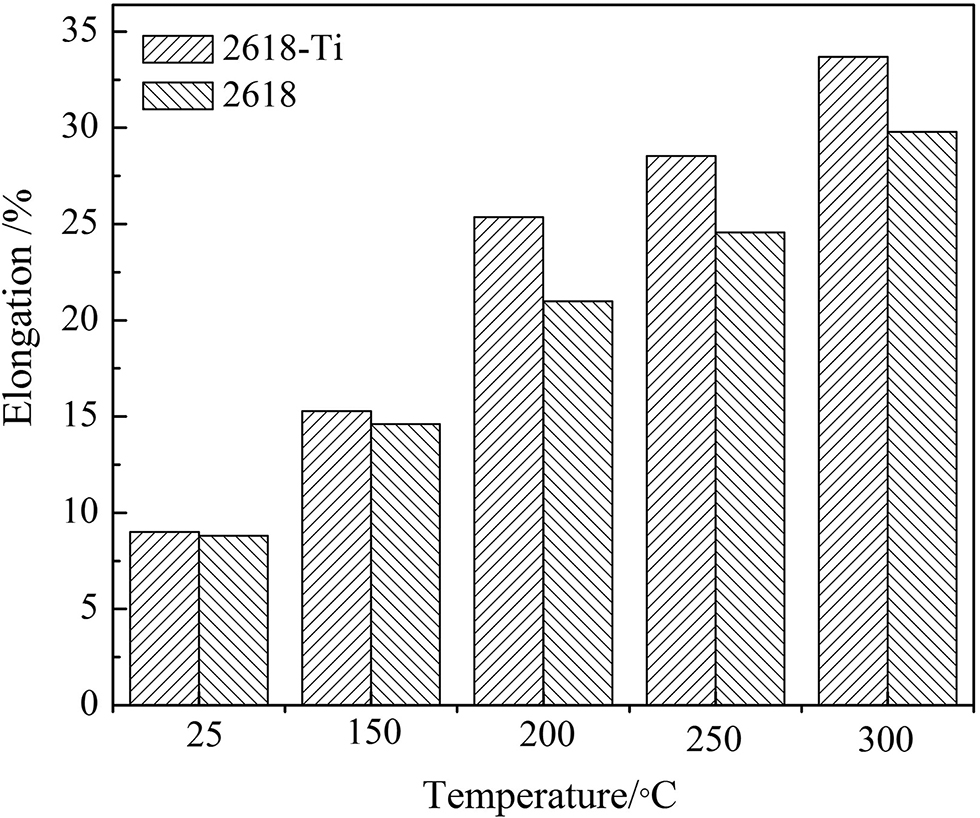

Figure 3 shows the elongation of the alloy 2618 and 2618-Ti at different temperatures. It can be seen that the elongation of the two alloys increase significantly with the increase of temperature. At room temperature and 150 °C, the elongation of the alloy 2618-Ti is only a little higher than that of alloy 2618. The elongations of alloy 2618-Ti is only 2.3 % and 4.8 % higher than that of alloy 2618 at these two temperatures, respectively. The increase of the elongation of the alloy 2618-Ti should be ascribed to the grain refinement of the alloy. When the temperature is above 200 °C, the elongation of the alloy 2618-Ti is much higher than that of alloy 2618. The elongations of alloy 2618-Ti is 21.0 %, 16.3 % and 13.1 % higher than that of alloy 2618 at 200, 250 and 300 °C, respectively. The toughening mechanism of alloy 2618-Ti at elevated temperature would be elaborated in 3.3, too.

The elongation of alloy 2168 and 2618-Ti at different temperatures.

Determination of equal-strength temperature of alloy 2618-Ti

As we know, there exists an equal-strength temperature (Te) for alloy materials, at which the grain boundary strength of alloys is equal to the intragranular strength. The schematic of the grain boundary strength and intragranular strength of alloys as a function of temperature is shown in Figure 4. When the temperature is lower than Te, the grain boundary strength is higher than the intragranular strength. The smaller the grain size of alloys is, the more the grain boundaries in alloys are. The larger grain boundaries results in the increase of glide resistance of dislocation in alloys and the tensile strength of alloys. This kind of strengthening is called fine grain strengthening. When the temperature is higher than Te, the grain boundary strength is lower than the intragranular strength. So, the grain refinement of alloys would make their strength decrease due to the existence of large amount of grain boundaries.

Schematic of the strength of grain boundary and intragranular of alloys as a function of temperature.

The curves of tensile strength of alloy 2618-Ti (A, B and C) with different grain size as a function of temperature are shown in Figure 5. The linear fitting for these curves has been carried out and the fitting lines are shown in Figure 6. Because the solid solution temperature for alloy C is the highest among three alloys (A, B and C) and its solution time is much longer than that for alloy B and A, so the grain size of alloy C is much larger than that of alloy B and A. Because of this reason, the tensile strength of alloy C could be approximately considered as the intragranular strength of alloy 2618-Ti. The tensile strength of alloy A and B with smaller grain size could be approximately considered as the boundary strength of alloy 2618-Ti. The intersections of the fitting line of tensile strength of alloy C as function of temperature with that of alloy B and A could be obtained, respectively. It can be seen from Figure 6 that the temperatures corresponding to the two intersection points are 216 and 253 °C, respectively. As an approximation, we take the average value of the two temperatures as the equal-strength temperature. So, Te is equal to 235 °C. The strengthening mechanism of alloy 2618-Ti below 235 °C would be different from that of the alloy above this temperature.

Tensile strength of alloy 2618-Ti with different grain size as a function of temperature.

The linear fitting of the tensile strength of alloy 2618-Ti with different grain size as function of temperature.

Strengthening and toughening mechanisms of alloy 2618-Ti at elevated temperature

Grain size of alloy 2618-Ti is smaller than that of the alloy 2618. Besides, there are a lot of dispersive Al3Ti and Al18Mg3Ti2 particles in alloy 2618-Ti. So the strengthening effect of alloy 2618-Ti at elevated temperatures should include the following aspects: 1) fine grain strengthening, 2) ageing enhancement of S’ phase, 3) enhancement of Al9FeNi phase and 4) the enhancement of dispersive Al3Ti and Al18Mg3Ti2 phase. Compared with alloy 2618, the increase of tensile strength of alloy 2618-Ti at elevated temperatures would be the synergy effect of the fine grain strengthening and the load transfer strengthening of Al3Ti/Al18Mg3Ti2 particles. As we all know, fine grain strengthening effect would be weakened sharply with the increase of temperature. Due to the formation of Al18Mg3Ti2 phase, the amount of ageing phase (S’) in alloy 2618-Ti is less than that in alloy 2618. Moreover, the ageing phase would grow up at the elevated temperature. Once the coarsening of S’ phase occurs, the ageing strengthening effect would significantly decrease. So the strengthening effect of ageing phase in alloy 2618-Ti is smaller than that in alloy 2618 at elevated temperature. Besides, the strengthening effect of Al9FeNi in alloy 2618-Ti is the same with that in alloy 2618. When the temperature is below the critical temperature 235 °C, the increase of tensile strength of alloy 2618-Ti compared with alloy 2618 is mainly caused by the fine grain strengthening and the strengthening of dispersive Al3Ti/Al18Mg3Ti2 particles. Due to the decrease of precipitating strengthening of S’ phase in alloy 2618-Ti, the tensile strength of alloy 2618-Ti is a little larger than that of alloy 2618. When the temperature is higher than 235 °C, the grain boundary strength is smaller than intragranular strength and the decreasing rate of grain boundary strength with the increase of temperature is larger than that of intragranular strength. Because the grain size of the alloy 2618-Ti is much smaller than that of alloy 2618, the tensile strength of alloy 2618-Ti would be lower than that of alloy 2618 if we only consider the effect of grain boundaries. In fact, tensile strength of alloy 2618-Ti is much higher than that of alloy 2618 when the temperature is above 235 °C. So the strengthening mechanism of alloy 2618-Ti at elevated temperature is mainly the load transfer strengthening of Al3Ti/Al18Mg3Ti2 particles.

Figure 7 shows the fracture morphologies of tensile samples of alloy 2618-Ti and 2618. It could be seen that two kinds of dimples exist on the tensile fracture at 150 °C as shown in Figure 7(a) and (b). One is in the form of small dimples and the other is in the form of large dimples. Their fracture mechanism was mainly micro pore coalescence fracture. There exist a lot of heterogeneous particles at the bottom of these dimples. The number of these dimples corresponds to the number of grains and the heterogeneous particles on the fracture. It could be seen that the number of dimples on the fracture of the alloy 2618-Ti is more than that of alloy 2618. When the temperature is at 200 °C, the fracture morphologies of the two alloys change a little, except that the size of the dimples increases slightly. It indicates that the grain boundary strengthening and the load transfer effect of Al3Ti/Al18Mg3Ti2 particles play important roles in alloy 2618-Ti at 150 and 200 °C. Therefore, the strengthening effect of fine grains and dispersed Al3Ti/Al18Mg3Ti2 phase is the strengthening mechanism for alloy 2618-Ti at lower temperatures.

The fracture morphologies of tensile samples of alloy 2618-Ti and 2618 at different temperatures.

When temperature exceeds 250 °C, the number of tiny dimples on the fracture of the alloy 2618-Ti and 2618 reduces drastically and the size of large dimples increases obviously. It indicates that the merge of small grains with big grains happens at 250 and 300 °C. Although the quantity of small dimples in alloy 2618 is more than that in alloy 2618-Ti, the tensile strength of alloy 2618 is much lower than that of alloy 2618-Ti. Thereby, we could conclude that fine grain strengthening would not be the strengthening mechanism for alloy 2618-Ti at 250 and 300 °C. Our research [14] confirms that there exist a large number of Al3Ti and Al18Mg3Ti2 particles in the alloy 2618-Ti. Based on the above analyses, when temperature exceeds 235 °C, the effect of fine grain strengthening and aging strengthening would be significantly weakened. Therefore, the strengthening mechanism for alloy 2618-Ti at 250 and 300 °C is mainly the load transfer of dispersive Al3Ti and Al18Mg3Ti2 particles. From Figure 7 it could be seen that the particles combine well with the substrate. When an external force is applied to alloy 2618-Ti, the load would transform from matrix to the dispersive particles through their combining interfaces. So the alloy could bear larger load before fracture, which greatly improves the tensile strength of alloy 2618-Ti at elevated temperature. So the strengthening mechanism of alloy 2618-Ti at 250 and 300 °C is mainly the load transfer mechanism of Al3Ti and Al18Mg3Ti2 particles.

When the temperature is above 200 °C, the elongation of the alloy 2618-Ti is much higher than that of the alloy 2618 as shown Table 3. There are three reasons for the higher elongation of alloy 2618-Ti at 250 and 300 °C. The first reason is the decrease in the grain size of the alloy 2618-Ti. The second reason is the uniform distribution of Al3Ti/Al18Mg3Ti2 particles in matrix and excellent combination of the matrix with dispersed Al3Ti/Al18Mg3Ti2 particles. Al3Ti particles in alloy 2618-Ti were added by solid-liquid mixing and near-liquids casting, their size is very small and they distributed uniformly in the matrix. Besides, because the lattice constant of Al3Ti is closed with the matrix and it could act as the nucleation core for the matrix, so the combination of Al3Ti phase with the matrix is very well. The formation of Al18Mg3Ti2 particles is in the form of in situ reaction between AlTi3 with Mg in matrix, so the combination between Al18Mg3Ti2 particles and matrix is also very well [14]. It was reported there was no elongation decrease for composite if the reinforced phase was generated in the form of in situ reaction [19]. The third reason is the recrystallization of the alloy 2618-Ti at 250 and 300 °C.

Generally, extraordinary plasticity of metals at elevated temperature would be attributed to the recovery, recrystallization softening and defect repairing [20, 21]. The recrystallization temperature of industrial pure aluminum which is suffered strong cold deformation is 150 °C. The addition of alloying elements in aluminum could increase its recrystallization temperature. For alloy 2618-Ti and 2618, their recrystallization temperatures are about 200 °C. When the temperature is above this temperature, the recrystallization of the alloy 2618 and 2618-Ti would occur. So, the elongation of alloy 2618-Ti increases obviously when the temperature is above 200 °C. Moreover, when the external force was applied on the alloy, the synergic deformation of the dispersive Al3Ti/Al18Mg3Ti2 particles with matrix is very easy at higher temperature. Therefore, when the temperature is higher than 200 °C, the toughening of alloy 2618-Ti would be ascribed to the fine grain structure, excellent combination of dispersive Al3Ti/Al18Mg3Ti2 particles with matrix and the recrystallization of the alloy.

Conclusions

The tensile strength of alloy 2618-Ti is only a little higher than that of alloy 2618 at the temperature range from 25 °C to 200 °C, but it is much higher than that of alloy 2618 at the temperature range from 250 °C to 300 °C. The elongation of alloy 2618-Ti is only a little higher than that of alloy 2618 at the temperature range from 25 °C to 150 °C, but it is much higher than that of alloy 2618 at the temperature range from 200 °C to 300 °C.

The equal-strength temperature of alloy 2618-Ti is about 235 °C. When the temperature is lower than 235 °C, the strengthening mechanism of alloy 2618-Ti is mainly the fine grain strengthening and the load transfer strengthening of Al3Ti/Al18Mg3Ti2 particles compared with that of alloy 2618.

When the temperature is higher than 235 °C, the strengthening mechanism of alloy 2618-Ti is mainly the load transfer effect of Al3Ti/Al18Mg3Ti2 particles compared with that of the alloy 2618.

When the temperature is higher than 200 °C, the toughening mechanism of alloy 2618-Ti is mainly attributed to fine grain microstructure, excellent combination of dispersive Al3Ti/Al18Mg3Ti2 particles with the substrate and recrystallization of the alloy at elevated temperature.

Funding statement: This investigation is supported by the national Natural Science Foundation of China (51074030), and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

References

1 F. Nový, M. Janeček and R. Král, J. Alloys Compd., 487 (2009) 146–151.10.1016/j.jallcom.2009.08.014Search in Google Scholar

2 Z.W. Du, G.J. Wang, X.L. Han et al., J. Mater. Sci., 47 (2011) 2541–2547.10.1007/s10853-011-6077-4Search in Google Scholar

3 K. Yu, S.R. Li, W.X. Li et al., J. Mater. Sci. Technol., 16 (2000) 416–420.Search in Google Scholar

4 J.H. Wang and D.Q. Yi, J. Mater. Eng. Perform, 15 (2006) 596–600.10.1361/105994906X136133Search in Google Scholar

5 L. Zeng, Z.Y. Li, R.Q. Che et al., Int. J. Fatigue, 59 (2014) 215–223.10.1016/j.ijfatigue.2013.08.016Search in Google Scholar

6 N.M. Kumar, S.S. Kumaran and L.A. Kumaraswamidhas, J. Alloys Compd., 672 (2016) 213–216.Search in Google Scholar

7 J.H. Wang, D.Q. Yi and B. Wang, T. Nonferr Met. Soc., 13 (2003) 590–594.Search in Google Scholar

8 F. Wang, D. Eskin, T. Connolley et al., J. Cryst. Growth, 435 (2015) 24–30.10.1016/j.jcrysgro.2015.11.034Search in Google Scholar

9 C. Parlikar, M.Z. Alam, R. Sarkar et al., Surf. Coat. Technol., 236 (2013) 107–117.10.1016/j.surfcoat.2013.09.036Search in Google Scholar

10 S.H. Wang and P.W. Kao, Acta Mater., 46 (1998) 2675–2682.10.1016/S1359-6454(97)00470-9Search in Google Scholar

11 J.M. Wu, S.L. Zheng and Z.Z. Li, Mater. Sci. Eng. A., 289 (2000) 246–254.10.1016/S0921-5093(00)00886-8Search in Google Scholar

12 J. Li, Y.F. Song, J.H. Wang, X.P. Su et al., T. Mater. Heat Treat., 34 (2013) 64–69. In Chinese.Search in Google Scholar

13 J. Li, M.X. Zhao, X.P. Su et al., Int. J. Metalcast., 8 (2014) 43–50.10.1007/BF03355590Search in Google Scholar

14 T.T. Liu, Y. Liu, X.P. Su et al., Mater. Proc., 33 (2014) 261–267.Search in Google Scholar

15 J. Li, J.H. Wang, Y.F. Song et al., T. Mater. Heat Treat., 34 (2013) 6–12 (in Chinese).Search in Google Scholar

16 B. Wu, X.P. Su, H. Tu et al., T. Mater. Heat Treat., 35 (2014) 43–49 (in Chinese).Search in Google Scholar

17 T.T. Liu, X.P. Su, Y. Liu et al., High Temp. Mater. Proc., 33 (2014) 85–94.10.1515/htmp-2013-0029Search in Google Scholar

18 W.D. Fei, H.Y. Yue and L.D. Wang, Mater. Chem. Phys., 119 (2010) 515–518.10.1016/j.matchemphys.2009.10.006Search in Google Scholar

19 Z.D. Wang, H.Q. Hu and C.Y. Li, Acta Metall. Sin., 31 (1995) 255–260.Search in Google Scholar

20 M.Q. Chen, S.S. Quek, Z.D. Sha, Y.W. Zhang et al., Carbon, 85 (2015) 135–146.10.1016/j.carbon.2014.12.092Search in Google Scholar

21 R. Zhao, J.Q. Han and M. Wan, Mater Design, 94 (2016) 195–206.10.1016/j.matdes.2016.01.022Search in Google Scholar

© 2018 Walter de Gruyter GmbH, Berlin/Boston

This article is distributed under the terms of the Creative Commons Attribution Non-Commercial License, which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articles in the same Issue

- Frontmatter

- Research Articles

- Effect of Reductant Type on the Metallothermic Magnesium Production Process

- Study on Strengthening and Toughening Mechanisms of Aluminum Alloy 2618-Ti at Elevated Temperature

- Concentration of Point Defects in Metal Deficient Zn1-yO

- The Effect of a Dissipative Ladle Shroud on Mixing in Tundish: Mathematical and Experimental Modelling

- The Effect of Acidity Coefficient on Crystallization Behavior of Blast Furnace Slag Fibers

- A Modified Constitutive Model for Tensile Flow Behaviors of BR1500HS Ultra-High-Strength Steel at Medium and Low Temperature Regions

- Preparation of High Surface Area Activated Carbon from Spent Phenolic Resin by Microwave Heating and KOH Activation

- Study of the Boron Distribution and Microstructure of Solidified Al-Si Alloy During the Process of Silicon Purification

- A Modified Double Multiple Nonlinear Regression Constitutive Equation for Modeling and Prediction of High Temperature Flow Behavior of BFe10-1-2 Alloy

- Structural Study on Nano-crystals of Spinel Mgx-Zn1-X-Fe2O4 Ferrite with and without Calcination

- Effect of Bi on Microstructure and Mechanical Properties of Extruded AZ80-2Sn Magnesium Alloy

- Erratum

- Corrigendum for the paper: F. Saint-Antonin, A. Mitchell, “Potential niobium base superalloys”, High Temperature Materials and Processes, vol. 13, no. 2, June 1994, pp. 159–171

Articles in the same Issue

- Frontmatter

- Research Articles

- Effect of Reductant Type on the Metallothermic Magnesium Production Process

- Study on Strengthening and Toughening Mechanisms of Aluminum Alloy 2618-Ti at Elevated Temperature

- Concentration of Point Defects in Metal Deficient Zn1-yO

- The Effect of a Dissipative Ladle Shroud on Mixing in Tundish: Mathematical and Experimental Modelling

- The Effect of Acidity Coefficient on Crystallization Behavior of Blast Furnace Slag Fibers

- A Modified Constitutive Model for Tensile Flow Behaviors of BR1500HS Ultra-High-Strength Steel at Medium and Low Temperature Regions

- Preparation of High Surface Area Activated Carbon from Spent Phenolic Resin by Microwave Heating and KOH Activation

- Study of the Boron Distribution and Microstructure of Solidified Al-Si Alloy During the Process of Silicon Purification

- A Modified Double Multiple Nonlinear Regression Constitutive Equation for Modeling and Prediction of High Temperature Flow Behavior of BFe10-1-2 Alloy

- Structural Study on Nano-crystals of Spinel Mgx-Zn1-X-Fe2O4 Ferrite with and without Calcination

- Effect of Bi on Microstructure and Mechanical Properties of Extruded AZ80-2Sn Magnesium Alloy

- Erratum

- Corrigendum for the paper: F. Saint-Antonin, A. Mitchell, “Potential niobium base superalloys”, High Temperature Materials and Processes, vol. 13, no. 2, June 1994, pp. 159–171